只进行6H-SiC的超精密磨削实验,难以在原子尺度上实时分析其微观结构和缺陷的演变。基于分子动力学(MD)的原子模拟,可深入研究6H-SiC微观结构的演化,从而揭示超精密磨削时其变形机制的演变以及纳米级磨粒尺寸的变化对磨削力、磨削后工件表面质量等关键指标的影响[7,8]。Tian[9]进行分子动力学模拟研究了6H-SiC加工的纳米力学性能和材料去除机理,发现磨粒形状等因素对纳米材料工件表面的去除行为有显著的影响。Zhao等[10]研究了不同尺寸的磨粒对3C-SiC纳米磨削损伤的影响,发现选择合适的磨粒尺寸可获得更好的加工表面和亚表面质量。同时,采用较小尺寸的磨粒会挤压和刮擦工件,从而降低材料去除率。Yin等[11]对6H-SiC进行了金刚石砂轮磨料加工,发现进给速率不如磨粒尺寸对表面生成的影响显著,且金刚石磨粒尺寸从20

本文进行分子动力学模拟研究磨削速度和磨粒尺寸对6H-SiC表面形貌、亚表面损伤深度、工件的温度和力学性能的影响,并揭示其在纳米磨削中的变形机理。

1 模拟方法

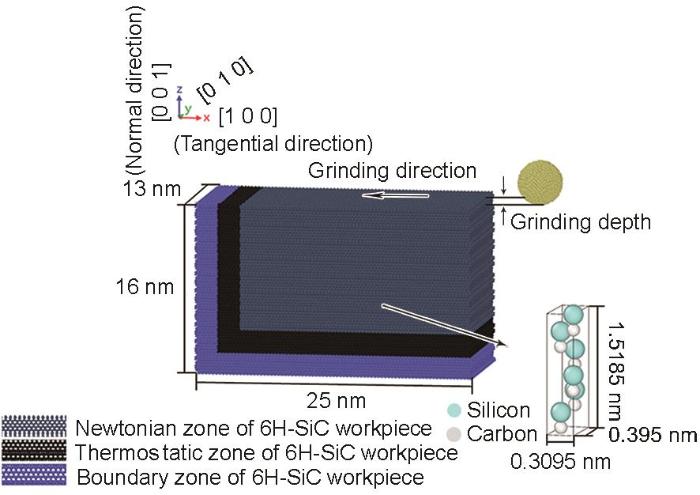

使用开源分子动力学模拟软件LAMMPS (Large-scale Atomic/Molecular Massively Parallel Simulator)进行分子动力学模拟[14~17]。图1给出了本文建立的纳米磨削的分子动力学模拟模型。此模型由6H-SiC工件和金刚石磨粒组成,其中工件分为边界层、恒温层、牛顿层[18]。设置固定的边界层以确保工件在磨削过程中保持静止[19]。其中的恒温层原子采用NVT系综以传导纳米磨削时产生的热量,从而维持系统的平衡温度。牛顿层的原子采用NVE系综,使其运动遵循牛顿第二定律[20]。模型在y方向上设置周期性边界条件以消除边界效应,在x和z方向上设置固定边界条件。

图1

使用Tersoff势函数模拟6H-SiC的纳米磨削过程。用Tersoff势函数模拟化学键的形成和断裂,解释磨削过程中材料的去除行为。Tersoff势函数用于模拟Si-Si、C-C、Si-C原子之间的相互作用,Morse势描述金刚石磨粒与工件的Si原子和C原子之间的相互作用。视金刚石磨粒为刚体,忽略金刚石磨粒内部C-C原子之间的相互作用[21]。

表1 纳米磨削模拟参数

Table 1

| Parameter | Value |

|---|---|

Workpiece dimension Grinding direction | 25 nm × 13 nm × 16 nm |

| Grinding speed / m·s-1 | 50、100、200 |

| Grinding depth / nm | 0.15 |

| Tool radius / nm | 4.9、5.4、5.9 |

| Timestep / ps | 0.001 |

| Initial temperature / K | 300 |

| Ensemble | NVT, NVE |

2 模拟结果

2.1 表面形貌分析

图2给出了工件原子在z方向上的位移。可以看出,磨粒尺寸为5.4 nm时绝大部分工件原子在z方向的位移相近,表明此刻工件的加工表面质量较高。如图3a所示,随着磨削速度的提高磨屑原子数量先增加后减小。其原因是,尺寸适当的磨粒前方的磨屑原子会被移动的磨粒挤压至工件表面,从而得到了较小的磨屑原子数量和较高的表面加工质量。图3a还表明,磨削速度恒定时,随着磨粒尺寸的增大磨屑原子的数量先增加后减少。磨屑原子是磨削中遭到破坏的晶体结构的原子,因此使用直径为5.4 nm的磨粒可减小6H-SiC工件表面的破坏程度和磨屑的堆积。图3b给出了使用不同磨削参数的工件中非晶原子的数量。磨削速度恒定时,随着磨粒尺寸的增大非晶原子的数量先减少后增加,表明使用5.4 nm的磨粒可减少工件的非晶化。

图2

图3

图3

6H-SiC工件不同磨削速度和磨粒尺寸研究下的切屑原子数量和非晶原子数量

Fig.3

Number of chip atoms (a), the number (b) of amorphous atoms under different grinding speeds and abrasive grain sizes

2.2 亚表面的损伤

图4

图4

不同磨削速度和磨粒尺寸条件下6H-SiC工件的亚表面损伤深度

Fig.4

Subsurface damage depth of workpiece under different grinding speeds and abrasive grain sizes

图5给出了工件亚表面中的相变。在纳米磨削过程中,磨粒下方的立方金刚石结构中的原子受到磨粒的挤压而转变为非晶原子。这表明,工件亚表面发生了相变,工件表面发生了弹性变形。同时,在工件亚表面的损伤深度区域,少量原子从立方金刚石结构转变为六方金刚石结构。在纳米磨削过程中,少量原子从六方金刚石结构转变为立方金刚石结构。这表明,在已磨削区域部分原子间的共价键可能被磨粒破坏或削弱,成为无定形结构的黏附状态。

图5

图5

不同磨削速度和磨粒尺寸条件下6H-SiC工件亚表面中的相变

Fig.5

Phase transition in the subsurface of the workpiece under different grinding speeds and abrasive grain sizes

图6

图6

径向分布函数:(a)不同纳米磨削阶段、(b)不同磨削速度、(c)不同磨粒尺寸

Fig.6

Radial distribution function: (a) different grinding cutting stage, (b) different grinding speeds, (c) different abrasive grain sizes

2.3 温度和Von Mises应力

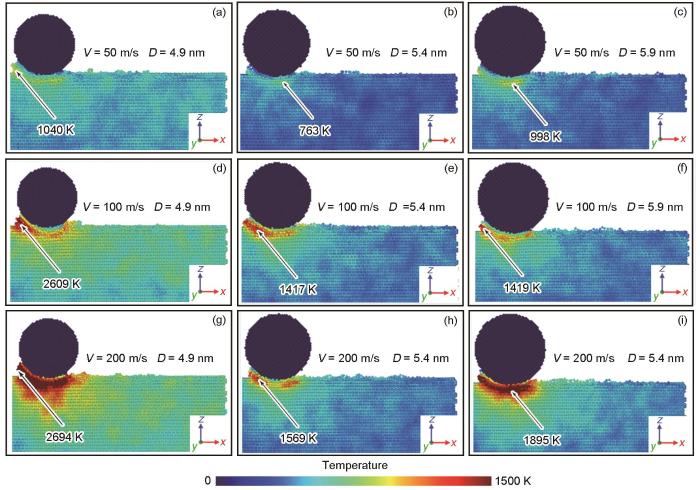

图7

图7

不同磨削速度和磨粒尺寸研究下6H-SiC工件的温度分布

Fig.7

Temperature distribution of the workpiece under different grinding speeds and abrasive grain sizes

Von Mises应力

可用于评估材料在复杂应力状态下变形和安全性[29,30]。其中

图8

图8

不同磨削速度和磨粒尺寸条件下的最大Von Mises应力

Fig.8

Maximum Von Mises stress under different grinding speeds and abrasive grain sizes

图9

图9

不同磨削速度和磨粒尺寸条件下6H-SiC工件的Von Mises应力分布

Fig.9

Von Mises stress distribution of the workpiece under different grinding speeds and abrasive grain sizes

2.4 磨削力和摩擦系数

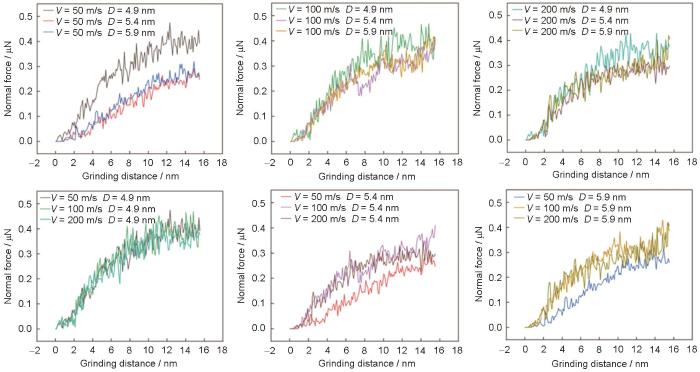

图10

图10

不同磨削速度和磨粒尺寸条件下的切向磨削力

Fig.10

Tangential grinding force under different grinding speeds and abrasive grain sizes

图11

图11

不同磨削速度和磨粒尺寸条件下的法向磨削力

Fig.11

Normal grinding force under different grinding speeds and abrasive grain sizes

摩擦系数为切向力与法向力的商。如图12所示,在磨削速度恒定的条件下,随着磨粒尺寸的增大摩擦系数先减小后增大。这表明,直径为5.4 nm的磨粒对工件表面的破坏程度最低,从而使表面质量更好。在磨粒尺寸恒定的条件下,摩擦系数随着磨削速度的提高而减小,特别是磨粒尺寸为5.4 nm时。

图12

图12

不同磨削速度和磨粒尺寸条件下6H-SiC工件的摩擦系数

Fig.12

Friction coefficient under different grinding speeds and abrasive grain sizes

3 结论

(1) 磨粒的尺寸大于4.9 nm时,随着磨削速度的提高6H-SiC工件的去除率先提高后降低。在磨削速度较高的条件下使用5.4 nm的磨粒时6H-SiC工件的加工表面质量和亚表面质量较高。

(2) 在黏附状态下,6H-SiC的塑性变形机理主要是表面非晶化。在恒定的磨削速度条件下,随着磨粒尺寸的增大工件亚表面的损伤深度和晶格缺陷程度先减小后增大。

(3) 与磨削速度相比,磨粒尺寸对工件温度、Von Mises应力的影响更为显著。在磨削速度恒定的条件下,随着磨粒尺寸的增大工件的最大温度先降低后提高,切向力和法向力先减小后增大。使用尺寸为5.4 nm磨粒,随着磨削速度的提高摩擦系数显著减小。

参考文献

Mechanical properties and deformation mechanisms of surface-modified 6H-silicon carbide

[J].The effect of amorphous film on the deformation mechanism and mechanical properties of 6H-SiC were systematically explored by a combination of both experiments and molecular dynamic (MD) simulations in nanoindentation. The experimental results showed that the plastic deformation of surface-modified 6H-SiC is mainly accommodated by dislocation activities in the subsurface and an amorphous layer with uniform thickness. The MD results indicated that the amorphous layer on the surface of the residual indentation mark consists of both amorphous SiO2 and SiC due to direct amorphization. In addition, the amorphous SiO2 film undergoes densification and then ruptures with the indentation depth increases. The modulus and hardness increase with increasing the indentation depth at the initial stage but will reach their stable values equivalent to monocrystalline 6H-SiC.

Indentation in single-crystal 6H silicon carbide: experimental investigations and finite element analysis

[J].

Numerical investigation on the influence of cutting-edge radius and grinding wheel speed on chip formation in SiC grinding

[J].

Revealing the deformation mechanisms of 6H-silicon carbide under nano-cutting

[J].

Molecular dynamics simulation of removal behavior and subsurface damage mechanism in high-speed nano-grinding of 6H-SiC

[J].

6H-SiC高速纳米磨削的去除行为及亚表面损伤机制的分子动力学仿真研究

[J].

Chemical mechanical polishing (CMP) of on-axis Si-face 6H-SiC wafer for obtaining atomically flat defect-free surface

[J].

Nanogrinding of SiC wafers with high flatness and low subsurface damage

[J].

Effect of grinding depths on SiC nanogrinding behavior based on molecular dynamics

[J].

Investigation of material removal mechanism of SiC in nano-scale machining using molecular dynamics simulation

[D].

Effects of different sizes and cutting-edge heights of randomly distributed tetrahedral abrasive grains on 3C–SiC nano grinding

[J].

Surface characterization of 6H-SiC (0001) substrates in indentation and abrasive machining

[J].

Effect of abrasives on the lapping performance of 6H-SiC single crystal wafer

[J].

Effect of different abrasive grain sizes of the diamond grinding wheel on the surface characteristics of GaN

[J]. J.

Atomic Understanding of the plastic deformation mechanism of 4H-SiC under different grain depth-of-cut during nano-grinding

[J].

Subsurface damage in high-speed grinding process of monocrystalline silicon based on molecular dynamics

[J].

单晶硅高速磨削亚表层损伤机制的分子动力学仿真研究

[J].

Molecular dynamics of the grinding and polishing collaborative-processing on monocrystalline silicon

[J].

单晶硅磨抛协同加工的分子动力学

[J].

A molecular dynamics simulation on the subsurface damage mechanism in the nano-polishing process of silicon carbide

[J].

碳化硅纳米抛光亚表面损伤机理的分子动力学模拟

[J].

Advances in molecular dynamics simulation of nano-manufacturing of monocrystalline materials

[J].

单晶材料纳米加工的分子动力学模拟研究进展

[J].

Molecular simulation of the plastic deformation and crack formation in single grit grinding of 4H-SiC single crystal

[J].

Analysis of crystal structure transition of polycrystalline 3C-SiC in nanocrystalline grinding based on molecular dynamics simulation

[J].

Structural anisotropy effect on the nanoscratching of monocrystalline 6H-silicon carbide

[J].

Molecular dynamics analysis of friction damage on nano-twin 6 H-SiC surface

[J].

Molecular dynamics study on grinding mechanism of polycrystalline silicon carbide

[J].

Impact of multiple abrasive particles on surface properties of SiC: a molecular dynamics simulation study

[J].

Molecular simulation of ultrasonic assisted diamond grit scratching 4H-SiC single-crystal

[J].

Experimental investigations on cylindrical grinding temperature of silicon carbide

[J].

Subsurface damage and material removal of Al–Si bilayers under high-speed grinding using molecular dynamics (MD) simulation

[J].

Understanding of the effect of wear particles removal from the surface on grinding silicon carbide by molecular dynamics simulations

[J].

Molecular dynamics study of the removal mechanism of SiC in a fixed abrasive polishing in water lubrication

[J].

Diamond machining of silicon: a review of advances in molecular dynamics simulation

[J].

Atomic analysis of contact-induced subsurface damage behavior of single crystal SiC based on molecular simulation

[J].It is helpful to understand the microstructure evolution characteristics and mechanical properties of monocrystalline SiC semiconductor devices during contact from the perspective of atomic scale to understand the microscopic mechanism of subsurface damage behavior and phase transformation. Based on the Vashishta potential function of molecular dynamics, the microscopic evolution characteristics of the nano-indentation induced dislocation rings, the amount of phase transformation and the contact mechanical properties of the corresponding monocrystalline SiC surface were studied, and the effect of extreme service temperature on the subsurface damage behavior and the contact mechanical properties were analyzed. The results show that the plastic deformation of SiC subsurface damage is mainly caused by dislocation nucleation, dislocation accumulation and dislocation slip, whilst the dislocation ring goes through four evolution stages during contact, i.e., dislocation nucleation, dislocation ring growth, dislocation ring reproduction and dislocation ring brittle break. Besides, with the increasing temperature, the maximum bearing capacity, hardness, Young's modulus and contact stiffness curves of silicon carbide materials show a parabolic trend of decline. The main reason is that the higher the temperature is, the SiC lattice is easy to get rid of the bondage of atomic bond energy, resulting in lattice defects, and easy to breed dislocation, which result in the enrichment of stress concentration on subsurface of materials at lastly. As a result, the mechanical properties of SiC materials are greatly reduced while being contacted. In addition, the subsurface stress concentration is also the fundamental reason for the phase transformation from cubic to sphalerite for SiC materials. With the increase of temperature, the amount of phase transformation increases. The dynamic contact plastic deformation and micro-structure evolution of SiC in semiconductor devices under loading, and the phase transformation are significantly dependent on the operating temperature. The rising temperature related change of crystal lattice and the generation of random rough spots on the surface are the main causes of contact adhesion. This study may provide a deeper understand on contact mechanical properties and sub-surface damage behavior at extreme service temperatures, and will also enrich the understanding of the contact failure mechanism of nano silicon carbide.

单晶碳化硅接触中亚表层损伤与破坏机理的原子尺度分析

[J].

Effects of grinding speeds on the subsurface damage of single crystal silicon based on molecular dynamics simulations

[J].