钛合金的比强度高、耐腐蚀和高温性能优异,广泛用于航空航天、生物医学和石油化工等领域[1]。钛合金是典型的难加工材料,其高化学反应活性使切削时易粘结,低导热系数使切削时升温过高[2]。在切削钛合金刀具表面镀耐磨涂层,是目前提高切削刀具寿命的常用方法。三元TiAlN涂层中的Al在切削时生成热稳定性较好的Al2O3层,使涂层的抗氧化温度达到800℃,具有较高的硬度和高温抗氧化性能,是目前应用较为广泛的涂层[3]。目前,采用多弧离子镀制备的商用TiAlN涂层摩擦系数较高,达到0.8以上[4]。高摩擦系数使涂层与被加工件产生较高的摩擦热,且随着切削速度的提高而增加。切削速度为50 m/min时刀刃处的温度为700℃,切削速度提高到100 m/min升至900℃[5]。切削温度过高,使硬质合金刀具材料与涂层和被加工材料之间发生原子互扩散,刀具组织结构的变化使其力学性能降低[6]。切削温度较高时极容易生成硬度高于被加工材料的切屑瘤,在加工件表面产生刮擦而降低加工质量[7]。同时,切削温度过高使刀具发生热软化使其硬度降低,在加工过程中涂层容易剥落而产生沟槽磨损[8]。因此,降低涂层摩擦系数是解决切削热使涂层失效的关键。

磁控溅射制备的TiN-WS X /TiN多层涂层,其摩擦系数和磨损率约为纯TiN涂层的30%[13],但是其硬度较低(5 GPa)。同时,涂层与基体之间结构和硬度的不匹配使其结合力较低。因此制备兼具低摩擦系数和高结合力的硬质涂层,是一个亟待解决的问题。鉴于此,本文以TiAlTaN作为耐磨层、TaO层作为低粘结层以降低被加工件与涂层间的粘结作用,WS层作为低摩擦系数层,用磁控溅射方法制备TiAlTaN/TaO/WS低粘结与自润滑功能复合涂层,研究这种功能复合对涂层形貌、摩擦系数、力学性能和钛合金切削性能的影响。

1 实验方法

1.1 复合涂层的制备

用磁控溅射方法在硬质合金基体表面制备复合涂层。使用的靶材,有TiAl合金靶、Ti靶、Ta靶和WS2靶。Ti和Ta靶材用真空熔炼方法制备,纯度分别为99.99%和99.95%。TiAl靶用热等静压成型制备,Ti∶Al原子比为50∶50,纯度为99.9%。WS靶材用粉末压制而成,纯度为99.95%。

镀膜前将抛光后的基片用丙酮和酒精分别超声清洗15和10 min,用Ar气吹干后备用。镀膜时先在基体上沉积一层Ti过渡层,然后分别沉积TiAlTaN层、TaO层和WS层,工艺参数列于表1。

表1 TiAlTaN/TaO/WS低粘结与自润滑功能复合涂层的沉积参数

Table 1

| Layer | Function | Target | Power / W | Temperature / oC | Thickness / nm | Pressure / Pa | O2 pressure / Pa |

|---|---|---|---|---|---|---|---|

| Ti | Buffer layer | Ti | 700 | 50 | 0 | ||

| Gradient TiAlTaN | Hard layer | TiAl | 700 | 350 | 0 | ||

| Ta | 450 | 350 | 350 | 3×10-3 | 0 | ||

| TaO | Low adhesive wear layer | Ta | 100 | 160 | 0.15 | ||

| WS | Low friction coefficient layer | WS | 125 | 120 | 0 |

在NHC4000卧式铣床加工中心进行钛合金切削加工,采用辅助液降温的湿切加工方式。切削参数为:转速为1300 r/min,进给速度为950 mm/min,切削深度为0.3 mm,切削速度为41 m/min。

1.2 涂层的表征

用SmatLab型X射线衍射仪(XRD)分析涂层的相组成,工作电压为40 kV,电流为40 mA,掠入射角度为1°,角度范围为10°~70°。用扫描电镜(SEM; SUPRA 35, Carl Zeiss Inc)观察涂层的表面形貌和磨痕形貌。用能谱仪(EDS; OXFORD INCA)检测涂层的成分。用纳米压痕仪(Agilent G200)测量涂层的硬度:下压深度为200 nm,Poisson比为0.23,测量10个不同位置的硬度取其平均值。用多功能材料表面性能试验仪(MFT-4000)测量涂层的摩擦系数和结合力,摩擦副是直径为6 mm的TC4钛球,加载力为2 N,速度为100 mm/min,摩擦时间为60 min,摩擦长度为5 mm。检测涂层结合力时,加载力范围为0~140 N,加载力速率为100 N/min。用光学显微镜(Olympus DSX 500)和SEM观察划痕和刀具后刀面磨损形貌。

2 结果和讨论

图1

图1

TiAlTaN复合涂层表面的SEM照片

Fig.1

SEM morphologies of the TiAlTaN composite coatings (a) TiAlTaN coatings; (b) TiAlTaN/TaO composite coatings; (c) TiAlTaN/TaO/WS composite coatings

图2

图2

TiAlTaN复合涂层表面的EDS结果

Fig.2

EDS results of the TiAlTaN composite coatings (a) TiAlTaN coatings; (b) TiAlTaN/TaO composite coatings; (c) TiAlTaN/TaO/WS composite coatings

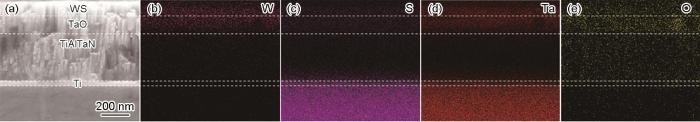

图3给出了TiAlTaN/TaO/WS复合涂层的截面形貌和EDS元素分布,可见涂层由四部分组成,分别是Ti过渡层、TiAlTaN层、TaO层和WS层。基体表面的Ti过渡层比较明显,厚度约为50 nm。然后是TiAlTaN层,其厚度约为450 nm,可见其结构与其他磁控溅射的结果一致,是典型的柱状晶结构。TiAlTaN层的上方是TaO层,厚度约为160 nm。由于TiAlTaN层柱状晶结构的影响,TaO层也具有典型的柱状结构。顶层是厚度约为120 nm的WS层。可以看出,WS下部也具有柱状结构,但表面柱状结构消失,类似于无序结构[16],与图1中表面形貌一致。图2的EDS结果也表明,WS和TaO元素分布的界面并不是十分明显。这表明,WS与TaO发生了互扩散,导致WS受柱状晶的影响较小,使一定厚度的WS也具有柱状晶结构,超过一定厚度后形成WS无序结构。

图3

图3

TiAlTaN/TaO/WS复合涂层截面的SEM照片和相应的EDS面扫描图

Fig.3

SEM morphology and EDS mapping of the TiAlTaN/TaO/WS composite coatings (a) cross section morphology; (b) W element; (c) S element; (d) Ta element; (e) O element

图4

图4

TiAlTaN涂层、TiAlTaN/TaO复合涂层以及TiAlTaN/TaO/WS复合涂层的XRD谱和局部放大

Fig.4

XRD patterns (a) and enlarged patterns (b) of the TiAlTaN coatings, the TiAlTaN/TaO composite coatings, and the TiAlTaN/TaO/WS composite coatings

图5给出了用划痕仪的划痕声信号、SEM形貌和划痕区域的成分分析三种方法确定的涂层结合力。涂层完全剥落露出基体则认为涂层失效,并据此定义涂层的结合力。图5a给出了TiAlTaN/TaO/WS复合涂层的划痕形貌,加载力为130 N。可以看出,涂层没有大面积剥落露出基体。对划痕末端不同区域成分分析的结果表明,划痕末端黑色部分(A点)主要是膜的成分,这部分是剥落的TaO和WS碎屑随着划头的移动堆积至划痕的边缘区域。划痕末端边缘白色部分涂层有少量剥落,C点的成分分析中出现了硬质合金基体中W、C和Co元素,证明涂层出现了剥落。这表明,涂层达到临界载荷时会剥落。这个结果,与划痕声信号的结果一致。划痕上B点的成分中未出现硬质合金基体中W、C和Co等元素,且TiAlTaN/TaO/WS复合涂层的声信号在130 N加载力情况下未突然增加,SEM形貌结果中也未出现C区域露出硬质合金基体的白色区域。据此可以判断,涂层未完全脱落。图5d表明,加载力70 N时TiAlTaN涂层的声信号剧烈变化,划痕末端已经露出基体,复合TaO和TaO/WS后的涂层的加载力可达到120和125 N,可见复合功能涂层具有较高的结合力。这些结果表明,TaO的低粘结和WS的低摩擦系数可降低磨损和延长涂层的寿命。

图5

图5

TiAlTaN/TaO/WS复合涂层划痕的SEM形貌和局部放大、划痕声信号和划痕区域的成分分析

Fig.5

Overall scratch SEM morphology (a) and enlarged morphologies (b, c), scratch acoustic signal curves (d) and EDS results (e) of the TiAlTaN/TaO/WS composite coatings

图6给出了三种涂层的摩擦系数、硬度和弹性模量。可见TiAlTaN/TaO/WS复合涂层的硬度为5.5 GPa,低于TiAlTaN涂层的8.2 GPa和TiAlTaN/TaO复合涂层的13.3 GPa。用多弧方法制备的TiAlTaN涂层其硬度达到了30 GPa,但是在涂层表面生成了大颗粒。而用磁控溅射方法制备涂层其表面粗糙度低于20 nm,但是磁控溅射涂层的硬度有一定程度的降低[18]。使TiAlTaN涂层硬度低的原因,一方面是涂层的Ta含量较低(仅有0.96%)[19];另一方面是TiAlTaN/TaO/WS复合涂层的硬度在复合WS后明显降低,WS的硬度较低(低于5 GPa[20])使复合后涂层的硬度下降。另外,WS是软相和多层结构,也在一定程度上使韧性提高[21]。纳米晶或非晶结构的软相以及多层结构抑制了裂纹沿柱状晶晶界的扩展,使裂纹沿多层界面扩展,其结果是裂纹从垂直膜面的穿晶断裂变成沿膜面方向的沿晶断裂,从而提高了涂层的韧性。TiAlTaN涂层的摩擦系数为0.648,复合TaO涂层后降低了涂层和钛合金之间的粘结,使摩擦系数降至0.28。复合TaO/WS涂层后,摩擦系数大幅降低至0.102。其原因是,摩擦时WS生成具有自润滑性能的转移膜,使摩擦系数较低。这些结果表明,复合涂层虽然在一定程度上降低了的涂层的硬度,但是大幅度降低了涂层的摩擦系数、提高了涂层的韧性。

图6

图6

TiAlTaN涂层、TiAlTaN/TaO复合涂层、TiAlTaN/TaO/WS复合涂层的摩擦系数、硬度和弹性模量

Fig.6

Coefficient of friction, hardness and elasticity modulus of the TiAlTaN coatings, the TiAlTaN/TaO composite coatings, and the TiAlTaN/TaO/WS composite coatings

图7给出了TiAlTaN/TaO复合涂层和TiAlTaN/TaO/WS复合涂层在不同加载力下的断裂及裂纹扩展和压痕形貌。用菱形压头分别对涂层施加了25、50和100 g的加载力。对于TiAlTaN/TaO复合涂层,压痕白色区域外没有出现明显的裂纹和破损,表明这种涂层能较好地抑制裂纹的产生和扩展。对于TiAlTaN/TaO/WS复合涂层,其表层的WS层破损露出了底部颜色较深的TiAlTaN层。根据本文测试的划痕形貌,TaO层和WS层的硬度都比较低,在载荷作用下容易破损。因此TiAlTaN/TaO/WS脱落时是TaO、WS软层先脱落,然后是TiAlTaN硬质层脱落。复合的WS软层在载荷作用下容易破损,破损后在摩擦过程中形成转移膜,实现自润滑和低粘结,从而使涂层的摩擦磨损降低和耐磨性提高。

图7

图7

TiAlTaN/TaO复合涂层和TiAlTaN/TaO/WS复合涂层在25、50和100 g加载力下纳米压痕的SEM照片

Fig.7

Nano indentation SEM morphologies of the TiAlTaN/TaO composite coatings and the TiAlTaN/TaO/WS composite coatings under different loading forces (a, d) 25 g; (b, e) 50 g; (c, f) 100 g

为了考察TiAlTaN/TaO/WS复合涂层在钛合金切削时的效果,测试了TiAlTaN/TaO/WS复合涂层硬质合金棒铣刀的切削时间和后刀面磨损量,并与相同的无涂层棒刀和商用的涂层棒刀进行了对比(图8)。切削速度为41 m/min的湿式切削,当刀具后刀面磨损量超过0.3 mm时,即认为失效[22]。可以看出,无涂层刀具在切削时间为20 min时后刀面磨损达到0.26 mm;切削时间25 min时后刀面磨损达到0.38 mm,此时刀具已经失效。用金相显微镜对后刀面磨损的观察结果表明,刀具表面出现了沟槽磨损。其原因是,刀具粗糙的表面和被加工件间有更高的摩擦力,加剧了刀具的磨损。涂层的保护,使商用涂层刀具和复合涂层刀具的寿命更长。切削时间为25 min时,商用涂层刀具的后刀面磨损量为0.22 mm,这是无涂层刀具磨损量的58%。但是,此后随着切削时间的延长磨损量快速增加,切削时间为30 min时涂层的磨损量达到了0.307 mm。对涂层刀具后刀面的观察发现,涂层剥落严重,刀具表面只有少量的涂层,表明切削加工后期涂层已经失去了对刀具的保护。而对于TiAlTaN/TaO/WS复合涂层刀具,切削时间为40 min时后刀面磨损量仅为0.267 mm,切削性能远高于无涂层刀具和商用涂层刀具。本文的复合涂层刀具其磨损面和涂层之间有明显的分界线,涂层仍完整存在于刀具表面。其原因是,复合涂层的高结合力避免了切削过程中涂层的剥落。此外,低粘结的TaO层降低了钛合金在高温环境中与空气中的氮、氧发生反应,减少了切屑瘤的产生,降低了粘结磨损和沟槽磨损。表面WS层的摩擦系数低,在摩擦接触过程中形成了转移膜,减少了切削热的产生和刀具的磨损,因此复合涂层刀具的后刀面并未出现沟槽磨损。复合涂层很好的结合力和自润滑效果,使加工时间比无涂层和商用涂层分别提高了84%和33%。

图8

图8

铣削钛合金速度为41 m/min时无涂层、商业化涂层和TiAlTaN/TaO/WS复合涂层刀具的切削距离和后刀面磨损的金相照片

Fig.8

Cutting length and flank metallurgical morphologies of uncoated, commercialized and the TiAlTaN/TaO/WS composite coated tools when milling titanium alloy at a speed of 41 m/min

3 结论

用磁控溅射方法可制备低粘结TaO与低摩擦系数WS复合的TiAlTaN/TaO/WS复合涂层。这种涂层由Ti过渡层、TiAlTaN耐磨层、TaO低粘结层和WS低摩擦系数层组成。涂层复合后表面形貌从多边形变为球形,但是不影响相组成以及柱状晶组织。涂层的摩擦系数从无复合涂层的0.648降到0.102,结合力从无复合涂层的70 N提高到125 N。复合涂层很好的结合力和自润滑效果,降低了粘结磨损和沟槽磨损,提高了刀具的切削性能,切削时间比无涂层刀具提高84%,比商用涂层刀具提高33%。

参考文献

Developments in cutting tool technology in improving machinability of Ti6Al4V alloy: A review

[J].

Advancements in material removal mechanism and surface integrity of high speed metal cutting: A review

[J].

Performance evaluation of PVD TiAlN coated carbide tools vis-à-vis uncoated carbide tool in turning of titanium alloy (Ti-6Al-4V) by simultaneous minimization of cutting energy, dimensional deviation and tool wear

[J].Titanium alloys are difficult-to-machine materials because of their poor machinability characteristics. Machining and machining performance evaluation for such materials is still a challenge. Individual machining performance indices like cutting forces, cutting energy and tool wear lead to ambiguous understanding. In this work, a Cumulative Performance Index (CPI) is defined which amalgamates non-dimensional forms of specific cutting energy, back force and average principal flank wear in turning. The CPI focuses upon simultaneous minimization of specific cutting energy, dimensional deviation and average principal flank wear. The defined index is then used to evaluate performance of five commercially available physical vapor deposited (PVD) TiAlN coated tungsten carbide/cobalt inserts vis-a-vis uncoated tungsten carbide/cobalt insert in turning of Ti-6Al-4V. Cutting forces were monitored during turning and tool wear was measured after turning experiments. The results showed that the performance of coated inserts was either comparable or poor than uncoated insert; and in no case, coated inserts performed better than uncoated insert. Although commercial recommendations are in place to use PVD coated inserts for enhanced machinability of titanium alloys, the use of coated inserts is not justified keeping in view the energy spent in coating and insignificant improvement in performance.

Comparison on the structural, mechanical and tribological properties of TiAlN coatings deposited by HiPIMS and Cathodic Arc Evaporation

[J].

Analytical thermal model of orthogonal cutting process for predicting the temperature of the cutting tool with temperature-dependent thermal conductivity

[J].

A critical review on self-lubricating ceramic-composite cutting tools

[J].

Wear performance of (nc-AlTiN)/(a-Si3N4) coating and (nc-AlCrN)/(a-Si3N4) coating in high-speed machining of titanium alloys under dry and minimum quantity lubrication (MQL) conditions

[J].

Progressive tool failure in high-speed dry milling of Ti-6Al-4V alloy with coated carbide tools

[J].

A novel ceramic with low friction and wear toward tribological applications: Boron carbide-silicon carbide

[J].

Superior wear resistance of diamond and DLC coatings

[J].

Intelligent lubricating materials: a review

[J].

Tribological behavior of ZrO2/WS2 coating surfaces with biomimetic shark-skin structure

[J].

Influence of WS2 content on high temperature wear performance of magnetron sputtered TiN-WS x thin films

[J].TiN-WSx thin films with varying WSx content were co-deposited by reactive magnetron sputtering. GAXRD analyses showed that the addition of 4 at.% WSx led to loss of crystallinity of TiN phase and a complete amorphous characteristic was manifested upon incorporation of 19 at.% WSx. Nanohardness results indicated that TiN-WSx containing 4 and 19 at.% WSx presented 19.7 GPa and 18.4 GPa, respectively, following the rule of mixtures. Friction coefficient and wear rates measured in reciprocated tribological tests revealed that TiN-WSx coatings present an improved tribological performance when compared to pure TiN thin film at room temperature, registering friction coefficient of 0.42 +/- 0.05 and 0.19 +/- 0.03 for samples with 4 and 19 at.% WSx, respectively. Wear tests at high temperatures evidenced that sample with 4 at.% WS did not provide advanced protection to substrate at 343 K and above due to deterioration. On the other hand, coating with 19 at.% WSx maintained low friction coefficient up to 343 K, registering an optimum wear rate of 0.86 x 10(-17) m(2)/N with no cracking occurrence.

Multilayer-growth of TiAlN/WS self-lubricating composite coatings with high adhesion and their cutting performance on titanium alloy

[J].

Mechanical properties, deformation behaviors and interface adhesion of (AlCrTaTiZr)N x multi-component coatings

[J].

Nanocrystalline/amorphous biphase enhanced mechanical properties in multilayer carbon films

[J].

Effect of Ta content on microstructure, hardness and oxidation resistance of TiAlTaN coatings

[J].

Complex study of protective Cr3C2-NiAl coatings deposited by vacuum electro-spark alloying, pulsed cathodic arc evaporation, magnetron sputtering, and hybrid technology

[J].

Effect of high hardness and adhesion of gradient TiAlSiN coating on cutting performance of titanium alloy

[J].

Fluorine-carbon doping of WS-based coatings deposited by reactive magnetron sputtering for low friction purposes

[J].

Improved toughness of layered architecture TiAlN/CrN coatings for titanium high speed cutting

[J].