制造桥梁结构件、高性能汽车车身以及航空航天设备的结构件,须用超高强度、轻量化的钢铁材料[1,2]。中锰钢是一种第三代先进高强度钢,具有优异的综合性能。近年来,热机械处理或大塑性变形技术使中锰钢的强度提高并保持了良好的塑性和韧性[3~5]。Liu等[3,4]对中锰钢进行热轧、温轧、冷轧和退火及配分等处理,在其中引入了片层状马氏体/奥氏体双相组织和高密度的位错,使其强度提高到约2 GPa,且界面分层开裂机制使裂纹萌生韧度值高达46.9 kJ·m-2。Li等[5]用锻造、深冷和回火等手段构筑一种全新的拓扑学双重有序排列的马氏体和多尺度亚稳奥氏体的纳米级多层次组织结构,将中锰钢的强度提高到约2.2 GPa,且其均匀延伸率高达20%。

超高强钢中夹杂物的硬度、弹性模量与基体材料不同,在其疲劳过程中外部循环载荷容易使夹杂物与基体界面成为应力集中区域进而萌生疲劳裂纹[10,11]。在高周疲劳条件下,马氏体时效钢、轴承钢等高强钢绝大多数疲劳失效都是非金属夹杂物引起的,且随着夹杂物尺寸的增大其疲劳寿命显著缩短[8,12,13]。特别是,随着材料强度的提高其组织敏感性随之提高,而疲劳极限并不提高甚至下降。例如,当40CrNiMoA钢的抗拉强度高于2000 MPa时,其疲劳强度从最高值下降,因为夹杂物的临界尺寸和疲劳裂纹萌生位置发生了变化[12]。Murakami和Endo[14]建立了钢铁材料的疲劳极限与其中非金属夹杂物尺寸关系的模型,指出随着硬度的提高和夹杂物尺寸的增大疲劳极限下降。夹杂物的尺寸小于临界尺寸时,疲劳裂纹不在夹杂物处萌生。Yang等[15]发现,随着材料强度的提高,夹杂物的临界尺寸减小。本文对Li等[5]研发的2 GPa超高强中锰钢进行高周疲劳实验,测试其疲劳性能并系统观察疲劳断口和分析疲劳裂纹萌生行为,研究夹杂物对其疲劳性能的影响。

1 实验方法

实验用2 GPa级中锰钢的化学成分,列于表1。

表1 实验用2 GPa级中锰钢的化学成分

Table 1

| C | Mn | Si | V | Fe |

|---|---|---|---|---|

| 0.39 | 7.8 | 1 | 0.5 | Bal. |

将铸造的2 GPa级中锰钢坯在650~800 ℃进行多道次横向锻造,得到横截面为18 mm × 18 mm的长棒,然后空冷至室温。将长棒切割成长度为95 mm的样品,将其在液氮中低温处理40 min以使不稳定的残余奥氏体转化为高强度的马氏体组织。待其恢复室温后进行300 ℃回火配分30 min,空冷后得到实验用钢。

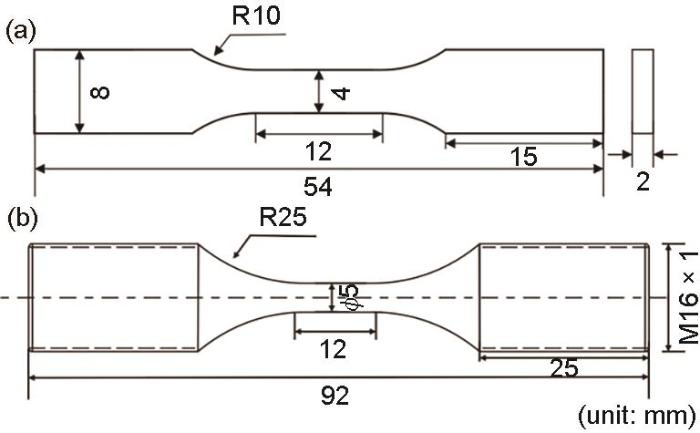

用AI-7000-LAU10 100 kN电子万能实验机进行室温拉伸实验,板状狗骨状样品标距段的长、宽、厚分别为12 mm × 4 mm × 2 mm (图1a)。用10 mm标距的接触式引伸计测量应变直至断裂,拉伸应变速率为1 mm/min。用RUMUL-TESTRONIC 100 kN高频疲劳试验机进行高周疲劳实验。用应力控制的单轴加载方式,应力比为-1,加载频率约为85 Hz。高周疲劳实验用圆棒状试样的横截面直径为5 mm,形状和尺寸在图1b中给出。用FM-810显微维氏硬度计测量基体的硬度,样品的尺寸为6 mm × 6 mm × 3 mm,载荷为1000 gf,载荷保持时间为15 s,测量6个不同区域60个点的硬度,以保证实验数据的可靠性。测试硬度、拉伸和疲劳的样品其长轴方向与锻造方向垂直。进行拉伸和疲劳实验前,将试样的工作段表面和侧面磨削和抛光。

图1

图1

实验用2 GPa级中锰钢样品的形状和尺寸示意图

Fig.1

Schematic diagram of the shape and size for tensile samples (a) and high-cycle fatigue samples (b)

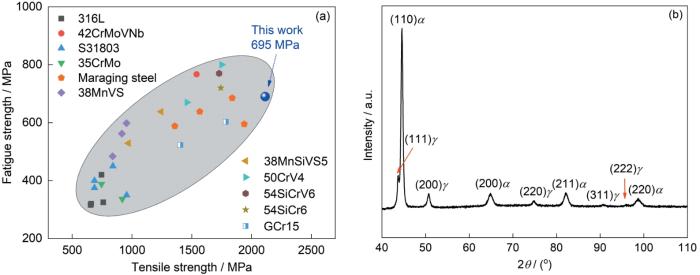

将尺寸为8 mm × 8 mm × 3 mm的块状样品在垂直锻造方向研磨和电解抛光,电解液为高氯酸和酒精的混合液,体积比为1∶7,抛光电压为22 V,抛光时间为23 s。用X射线衍射仪(XRD)测试实验用钢的XRD谱。扫描速度为2(°)/min。根据谱中{110}α、{200}α、{211}α、{220}α、{111}γ、{200}γ、{220}γ、{311}γ、{222}γ等9个衍射峰计算钢中残余奥氏体的体积分数[16]

式中V、I和R分别为残余奥氏体的体积分数、布拉格反射积分强度和衍射系数。残余奥氏体γ为面心立方(FCC)结构,马氏体α为体心立方(BCC)结构,p和q为XRD谱中BCC和FCC衍射峰的总数,i和j为BCC和FCC衍射峰之一。基于参考文献[17]确定R值。

用硝酸和酒精体积比为1∶24的混合液将样品腐蚀,用ZEISS ULTRA 55场发射扫描电镜(SEM)观察初始2 GPa级中锰钢变形前的微观组织。高周疲劳实验完成后,用配有能谱仪(EDS)的Quanta 600钨灯丝SEM观察疲劳试样的断口形貌,使用Image-Pro Plus(IPP)软件统计夹杂物面积,将面积的平方根记为疲劳断口裂纹源处夹杂物的尺寸。

2 实验结果

2.1 2 GPa级中锰钢的初始显微组织

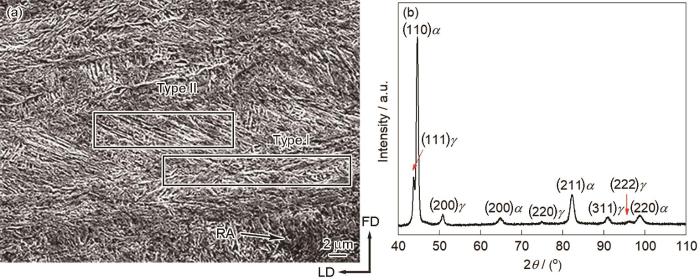

将试样回火空冷后,其腐蚀形貌的SEM照片如图2a所示。在热锻过程中样品的总横截面减小而形成棱柱状母体奥氏体微观结构,奥氏体晶粒沿垂直于锻造方向(FD)的纵向(LD)拉长呈棒状,在空冷过程中大部分奥氏体转变为马氏体[5]。深冷处理使残余奥氏体转化为马氏体,通过回火配分使奥氏体的稳定性提高,最终得到马氏体和残余奥氏体构成的多层次组织结构。从SEM照片可见,马氏体的分布呈Type I型和Type II型两种形态。Type I型马氏体与纵向平行,Type II型马氏体大部分与纵向约呈40°~50°倾斜。这种马氏体微观结构的构型称为组织良好的马氏体,其形成可归因于细小的棒状母体奥氏体中的有限变体选择。残余奥氏体呈薄膜状和块状结构,薄膜状奥氏体均匀分布在马氏体板条之间[5]。这种中锰钢初始组织的XRD谱,如图2b所示。根据

图2

图2

实验用2 GPa级中锰钢的微观组织和XRD谱

Fig.2

Microstructure (a) and XRD pattern (b) of experimental steel

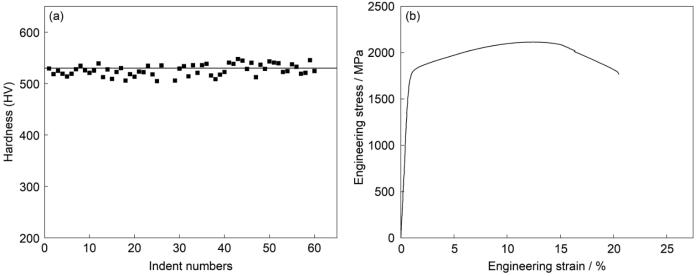

2.2 实验用钢的硬度和拉伸性能

图3

图3

实验钢的静态力学性能

Fig.3

Vickers hardness diagram (a) and tensile engineering stress-strain curve (b) of experimental steel

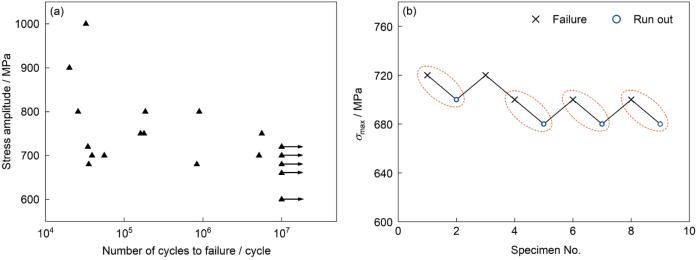

2.3 2 GPa级中锰钢的高周疲劳应力-寿命曲线和疲劳强度

图4给出了这种中锰钢的高周疲劳相关性能。从图4a中的应力-寿命曲线可见,疲劳寿命的分散性较大。四对试样的疲劳强度阶梯图,如图4b所示。计算结果表明,这种中锰钢的疲劳强度σ-1 = 695 MPa,抗拉强度为2137 MPa,故疲劳比为σ-1/σb ≈0.33。中低强度钢中的疲劳裂纹从基体表面萌生,疲劳极限约为抗拉强度的一半。疲劳对缺陷的敏感性随着强度的提高而提高,即疲劳裂纹更容易从应力集中处萌生,而不是从基体萌生,这导致疲劳极限小于拉伸强度的一半[19]。从疲劳开裂断口可见,所有的样品均由夹杂物导致开裂[20,21]。这表明,超高强度钢疲劳性能对夹杂物更为敏感,正是夹杂物导致其疲劳寿命的分散性。

图4

图4

实验钢的S-N曲线和疲劳强度

Fig.4

S-N curve (a)and fatigue strength test staircase method diagram (b) of experimental steel

2.4 疲劳断口的形貌

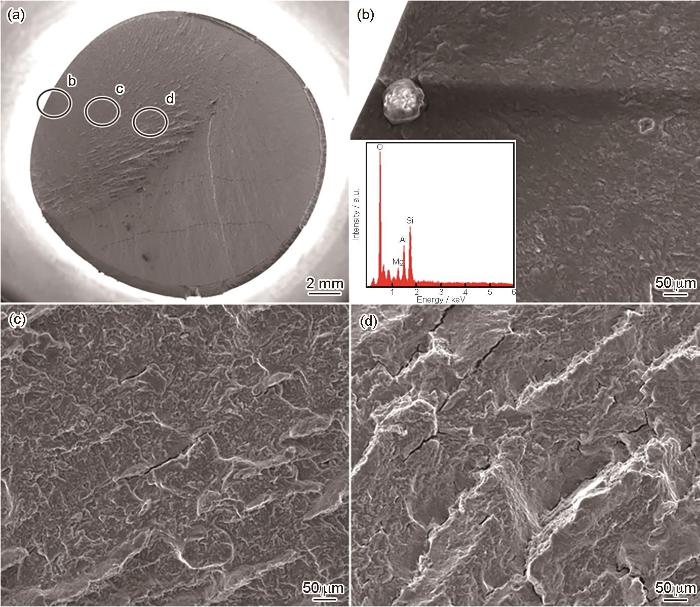

对疲劳断口形貌的观察表明,超高强中锰钢的高周疲劳断口都起源于夹杂物。对断口夹杂物成分的EDS分析结果表明,本文所用中锰钢中的夹杂物主要为Mg、Al、Si的混合非金属复合氧化物。而根据断口处夹杂物相对于表面的位置,可将其分为三种形式:表面夹杂物疲劳起裂、亚表面夹杂物疲劳起裂和内部夹杂物疲劳起裂。图5给出了典型的表面夹杂物开裂断口形貌,可见明显的解理断裂特征。图5a给出了疲劳断口的宏观形貌,包括裂纹萌生、裂纹扩展和最终断裂。在裂纹萌生前,试样先发生局部塑性变形并达到极限,从而形成微裂纹。图5b给出了裂纹源的微观形貌,可见一近似圆形的夹杂物,EDS结果表明其成分主要为Al2O3、MgO。疲劳裂纹从夹杂物处萌生,并以放射状的方式向四周扩展。图5c给出了裂纹稳态扩展阶段,可见少量开裂程度较小的二次裂纹。图5d给出了高速扩展阶段的裂纹,可见二次裂纹的开裂程度较高且尺寸较大,随着裂纹的继续扩展试样断裂失效。

图5

图5

表面夹杂物疲劳开裂断口的形貌

Fig.5

Fatigue fracture morphology of surface inclusion-induced cracking at different propagation stages (a) macroscopic fracture morphology, (b) microstructural characteristics of crack origin and associated inclusion chemistry, (c) morphology of the crack steady-state propagation zone, (d) morphology of the crack rapid propagation zone

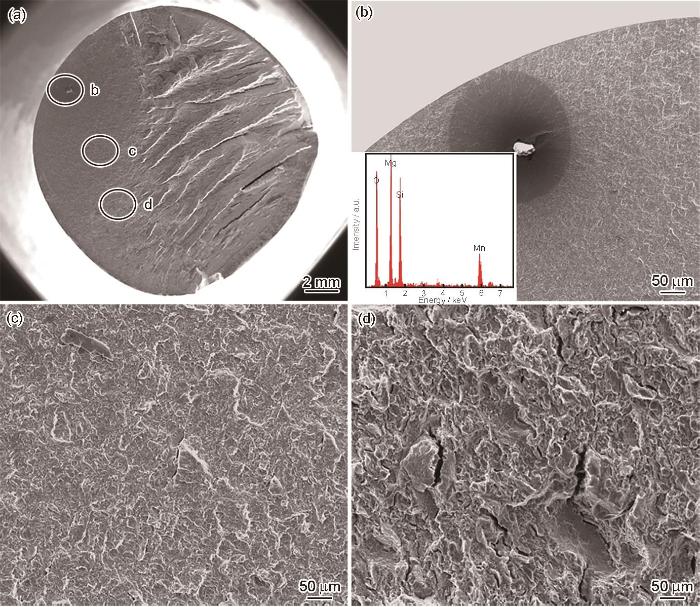

图6

图6

亚表面夹杂物疲劳开裂断口形貌

Fig.6

Fatigue fracture morphology of subsurface inclusion-induced cracking at different propagation stages (a) macroscopic fracture morphology, (b) microstructural characteristics of crack origin and associated inclusion chemistry, (c) morphology of the crack steady-state propagation zone, (d) morphology of the crack rapid propagation zone

图7给出了典型的内部夹杂物开裂断口形貌。从图7b清晰可见裂纹源周围一个近似圆形的深色区域,形成类似“鱼眼”状的断裂面,故称该区域为鱼眼特征区[24~26]。在本文的样品中未观察到典型的“颗粒小亮片区”(GBF)。鱼眼区中心部分较为平坦,裂纹沿着一定的方向向外扩展,在靠近夹杂物的中心区域裂纹扩展受局部应力场控制,扩展速率较低。而在外缘区域裂纹扩展逐渐转变为由宏观应力场主导,扩展加快而使裂纹呈放射状扩展。图7c、d分别给出了裂纹稳态扩展区形貌和裂纹快速扩展区形貌,其扩展规律与上述表面和亚表面夹杂物开裂类型相似,二次裂纹的数量增加以及开裂愈发显著。夹杂物的主要成分为MgO、SiO2,裂纹的扩展规律与上述两种开裂类型相近。

图7

图7

内部夹杂物疲劳开裂断口的形貌

Fig.7

Fatigue fracture morphology of internal inclusion-induced cracking at different propagation stages (a) macroscopic fracture morphology, (b) microstructural characteristics of crack origin and associated inclusion chemistry, (c) morphology of the crack steady-state propagation zone, (d) morphology of the crack rapid propagation zone

3 讨论

3.1 实验用钢的疲劳性能与夹杂物的尺寸和分布的关系

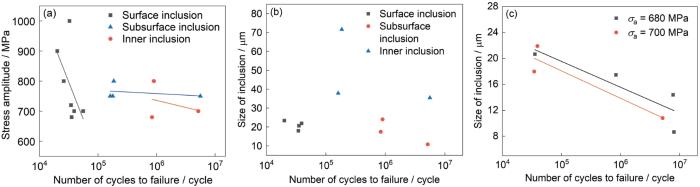

图8a给出了疲劳断口处夹杂物的分布和对应的疲劳寿命的汇总。可以看出,夹杂物的分布对疲劳寿命的影响很大。随着夹杂物由内部向亚表面和表面过渡,相同应力水平的疲劳寿命显著降低。图8b给出了疲劳寿命与疲劳断口裂纹源处夹杂物尺寸的关系。可以看出,相同位置夹杂物的尺寸越小则疲劳寿命越高。对比三种位置的夹杂物可见,表面夹杂物和亚表面夹杂物尺寸很小即引起疲劳断裂的发生。内部夹杂物的尺寸与应力水平有关:夹杂物的尺寸越小则疲劳寿命越长。图8c表明,在等应力幅条件下(σa = 680 MPa、σa = 700 MPa),超高强中锰钢的疲劳寿命随着夹杂物尺寸的减小而延长。而且随着循环应力幅的增大,断口夹杂物的尺寸减小。

图8

图8

夹杂物位于不同位置的S-N曲线和夹杂物尺寸对疲劳性能的影响

Fig.8

Effect of inclusion location and size on fatigue performance (a) S-N curves for inclusions at different locations, (b) statistical distribution of inclusion sizes, (c) relationship between inclusion size and fatigue life at constant stress amplitude

本文实验用超高强钢的疲劳寿命和疲劳强度对夹杂物的尺寸和位置极为敏感。其原因是,暴露在外部环境中的表面夹杂物容易受到外部应力影响,更显著的应力集中导致裂纹萌生和高速扩展。而亚表面夹杂物疲劳开裂,是指夹杂物位于材料的亚表面区域,这种夹杂物不直接受到外部载荷的作用。内部应力可传递到基体材料内部的夹杂物,但是不会像表面夹杂物和亚表面夹杂物那样受到过度集中的应力。即使存在裂纹萌生的条件,裂纹扩展到表面也需要更长的时间和经历载荷循环。

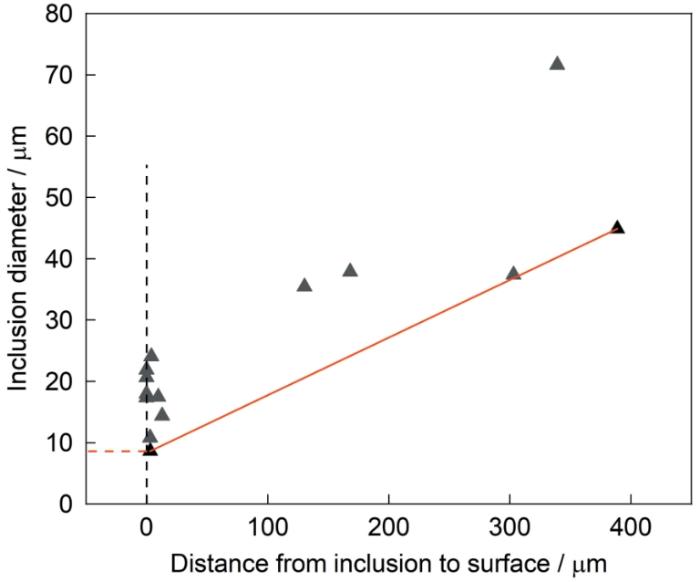

3.2 实验钢中夹杂物的临界尺寸

本文的实验用钢倾向于从大尺寸夹杂物开裂,比小尺寸夹杂物更有害[25]。夹杂物的尺寸存在一个临界值,称为“临界夹杂物尺寸”。疲劳裂纹不会从小于临界尺寸的夹杂物处萌生。Murakami等[34]和Atkinson等[35,36]分别提出两种统计学方法即统计极值法和广义帕累托分布法,估算一定体积的钢中夹杂物的最大尺寸。结果表明,疲劳开裂临界夹杂物尺寸随着夹杂物到试样表面深度的增大而增大[37]。外推法[31]是一种估算疲劳开裂临界夹杂物尺寸的方法,图9给出了用外推法估算的这种中锰钢裂纹源夹杂物尺寸与夹杂物距表面深度的关系。结果表明,夹杂物到试样表面的深度越小则夹杂物的尺寸越小。用外推法测得这种中锰钢的临界夹杂物尺寸为8.6 μm,高于超高强度钢42CrMoVNb的7.3 μm临界夹杂物尺寸[31]。

图9

图9

用外推法测得的实验钢中夹杂物的临界尺寸

Fig.9

Size of the critical inclusion was measured by extrapolation

表2 用Murakami公式反推疲劳强度和夹杂物临界尺寸

Table 2

| No. of samples | σ-1 / MPa | Nf / cycles | Murakami formula | ||

|---|---|---|---|---|---|

| σ-1 / MPa | |||||

| 6 | 600 | 1 × 107 | 37.4 | 523 | 16.4 |

| 8 | 660 | 1 × 107 | 8.6 | 604 | 5.0 |

| 10 | 660 | 1 × 107 | 44.9 | 507 | 9.2 |

| 11 | 680 | 1 × 107 | 8.7 | 603 | 4.2 |

| 13 | 680 | 1 × 107 | 14.4 | 554 | 4.1 |

3.3 实验用钢的断口TRIP效应对疲劳性能的影响

对比多种中高强度钢应力比R = -1时的σ-1与σb关系,绘制出图10a。可以看出,这种中锰钢的疲劳比明显低于中高强度钢。这个结果,与夹杂物的尺寸和分布密切相关。但是高于同级别强度的钢,其趋势是强度越高则疲劳强度越高。其原因是,这种实验钢的疲劳强度较高和临界夹杂物尺寸较大,以及其独特的微观组织产生的良好强塑性匹配。材料的屈服强度是位错滑移的阻力,且屈服强度越高位错滑移的阻力越大。当外加循环应力相同时,高屈服强度材料在循环变形过程中产生的滑动位错数量少于低屈服强度材料。同时,位错的不可逆滑移是引起疲劳损伤的一个主要原因。因此,对于相同的位错滑移模式,滑动位错数量的减少可在一定程度上减少不可逆滑动位错的数量,从而抑制疲劳损伤的累积而有利于抑制实验钢的裂纹萌生和提高高周疲劳性能。这种中锰钢多相组织中的马氏体硬度和强度极高,使夹杂物附近的材料在循环载荷下能承受更高的应力而不发生塑性变形。

图10

同时,根据疲劳断口的形貌,测试了内部夹杂物起裂样品的断口起裂源鱼眼区的XRD谱,如图10b所示。用

4 结论

(1) 2 GPa超高强中锰钢的高周疲劳主要有三种疲劳断口形貌,分别是表面、亚表面和内部夹杂物起裂。三种不同位置夹杂物疲劳开裂的比例接近,但是随着疲劳裂纹萌生位置逐渐由表面向内部过渡,疲劳寿命延长。

(2) 这种超高强钢的疲劳寿命和疲劳强度对夹杂物的尺寸极为敏感。在高周疲劳实验中,随着夹杂物从表面向内部迁移其临界尺寸逐渐增大。在应力幅相同的条件下,超高强中锰钢的疲劳寿命随着夹杂物尺寸的减小而延长。

(3) 这种高强钢疲劳断口处裂纹萌生区域和附近发生的残余奥氏体向马氏体的转变以及相变效应减缓了裂纹萌生和降低了扩展速率,使其疲劳强度与疲劳之比较高和夹杂物的临界尺寸较大。

参考文献

Technological progresses of research activities on steel products

[J].

钢铁材料研发的技术进展

[J].

High dislocation density-induced large ductility in deformed and partitioned steels

[J].A wide variety of industrial applications require materials with high strength and ductility. Unfortunately, the strategies for increasing material strength, such as processing to create line defects (dislocations), tend to decrease ductility. We developed a strategy to circumvent this in inexpensive, medium manganese steel. Cold rolling followed by low-temperature tempering developed steel with metastable austenite grains embedded in a highly dislocated martensite matrix. This deformed and partitioned (D and P) process produced dislocation hardening but retained high ductility, both through the glide of intensive mobile dislocations and by allowing us to control martensitic transformation. The D and P strategy should apply to any other alloy with deformation-induced martensitic transformation and provides a pathway for the development of high-strength, high-ductility materials.Copyright © 2017 The Authors, some rights reserved; exclusive licensee American Association for the Advancement of Science. No claim to original U.S. Government Works.

Making ultrastrong steel tough by grain-boundary delamination

[J].Developing ultrahigh-strength steels that are ductile, fracture resistant, and cost effective would be attractive for a variety of structural applications. We show that improved fracture resistance in a steel with an ultrahigh yield strength of nearly 2 gigapascals can be achieved by activating delamination toughening coupled with transformation-induced plasticity. Delamination toughening associated with intensive but controlled cracking at manganese-enriched prior-austenite grain boundaries normal to the primary fracture surface dramatically improves the overall fracture resistance. As a result, fracture under plane-strain conditions is automatically transformed into a series of fracture processes in "parallel" plane-stress conditions through the thickness. The present "high-strength induced multidelamination" strategy offers a different pathway to develop engineering materials with ultrahigh strength and superior toughness at economical materials cost.Copyright © 2020 The Authors, some rights reserved; exclusive licensee American Association for the Advancement of Science. No claim to original U.S. Government Works.

Ductile 2-GPa steels with hierarchical substructure

[J].Mechanically strong and ductile load-carrying materials are needed in all sectors, from transportation to lightweight design to safe infrastructure. Yet, a grand challenge is to unify both features in one material. We show that a plain medium-manganese steel can be processed to have a tensile strength >2.2 gigapascals at a uniform elongation >20%. This requires a combination of multiple transversal forging, cryogenic treatment, and tempering steps. A hierarchical microstructure that consists of laminated and twofold topologically aligned martensite with finely dispersed retained austenite simultaneously activates multiple micromechanisms to strengthen and ductilize the material. The dislocation slip in the well-organized martensite and the gradual deformation-stimulated phase transformation synergistically produce the high ductility. Our nanostructure design strategy produces 2 gigapascal-strength and yet ductile steels that have attractive composition and the potential to be produced at large industrial scales.

Improving the high-cycle fatigue lives of Fe-30Mn-0.9C twinning-induced plasticity steel through pre-straining

[J].

Fatigue behavior of 18% Ni maraging steels: A review

[J].

Effects of inclusion types on the high-cycle fatigue properties of high-strength steel

[J].

Influence of non-metallic inclusions on the high cycle fatigue strength of steels

[J].

Recent advances in very high cycle fatigue behavior of metals and alloys-a review

[J].We reviewed the research and developments in the field of fatigue failure, focusing on very-high cycle fatigue (VHCF) of metals, alloys, and steels. We also discussed ultrasonic fatigue testing, historical relevance, major testing principles, and equipment. The VHCF behavior of Al, Mg, Ni, Ti, and various types of steels were analyzed. Furthermore, we highlighted the major defects, crack initiation sites, fatigue models, and simulation studies to understand the crack development in VHCF regimes. Finally, we reviewed the details regarding various issues and challenges in the field of VHCF for engineering metals and identified future directions in this area.

Microscopic and nanoscopic observations of metallurgical structures around inclusions at interior crack initiation site for a bearing steel in very high-cycle fatigue

[J].

Investigation on fatigue and fracture of high-strength metallic materials

[D].

高强度金属材料的疲劳与断裂研究

[D].

Optimizing the fatigue strength of 18Ni maraging steel through ageing treatment

[J].

Effects of defects, inclusions and inhomogeneities on fatigue strength

[J].

On the critical inclusion size of high strength steels under ultra-high cycle fatigue

[J].

On the improvement of measurement accuracy of retained austenite in steel with X-ray diffraction

[J].

Phase transformation of austenitic stainless steels as a result of cathodic hydrogen charging

[J].

General relation between tensile strength and fatigue strength of metallic materials

[J].

Ultra-high cycle fatigue behavior of a novel 1.9 GPa grade super-high strength maraging stainless steel

[J].

A study of the effects of cyclic thermal stresses on a ductile metal

[J].

Effects of inclusions on very high cycle fatigue properties of high strength steels

[J].

Gigacycle fatigue properties for high-strength low-alloy steel at 100 Hz, 600 Hz, and 20 kHz

[J].

Very high cycle fatigue properties of bearing steel with different aluminum and sulfur content

[J].

Mechanism of fatigue failure in ultralong life regime

[J].The fatigue fracture surfaces of specimens of heat treated hard steels which failed in the regime of N = 105 to 5 × 108 cycles, were investigated by optical microscopy and SEM. Specimens having a longer fatigue life had a particular morphology beside the inclusion at the fracture origin. The particular morphology looked optically dark and in the previous paper it was named the Optically Dark Area, ODA. The roughness inside ODA is larger than outside ODA. The relative size of the ODA to the size of the inclusion at the fracture origin increases with increase in fatigue life. Thus, the ODA is considered to have a crucial role in the mechanism of ultra long life fatigue failure. Direct evidences of existence of hydrogen at the inclusion at fracture origin are presented. It is presumed that the ODA is made by the cyclic stress coupled with the hydrogen which is trapped by the inclusion at the fracture origin. To verify the influence of hydrogen, specimens containing different levels of hydrogen were prepared by different heat treatments. The results obtained by fatigue tests of these specimens suggest that the hydrogen trapped by inclusions is a crucial factor which causes the ultra long fatigue failure of high strength steels. Aspects of the double S–N curve are also discussed in terms of experimental methods, specimen size and statistical distribution of inclusions sizes.

Small scale yielding analysis for a disclination-nucleated Zener-Stroh crack interacting with a circular inclusion

[J].The elastic-plastic fracture behavior of a Zener-Stroh crack nucleated by a wedge disclination dipole interacting with a nearby circular inclusion is investigated. It is known that a disclination is a strong source of internal stresses and energy, one possible way for the relaxation of the stresses can be in the form of an initiated crack. In the current work, the nucleated Zener-Stroh crack is simulated by a series of edge dislocations with distributed dislocation method. The influence of the disclination is accounted through crack surface traction free condition. To improve the analysis accuracy, the Irwin plastic zone correction is employed to evaluate the elastic-plastic fracture behavior at the sharp crack tip. Von Mises yielding criterion is applied in the plastic zone area to judge the yielding occurrence. Numerical results are given to study the influence of the disclination strength, disclination dipole arm as well as material properties on the stress intensity factor (SIF), plastic zone size (PZS), and crack tip opening displacement (CTOD). It is found that the property of the wedge disclination dipole has great effect on the stress field and the elastic-plastic fracture behavior of the Zener-Stroh crack. Either disclination strength or dipole arm increases, the SIF, PZS, and CTOD will increase significantly. For the same disclination, if the nucleated Zener-Stroh crack has a longer crack length, the SIF, PZS, and CTOD could be smaller. For a Zener-Stroh crack nucleated between the inclusion and the disclination dipole, the interaction between the disclination and inclusion greatly influences the elastic-plastic fracture behavior. However, this influence highly depends on material combinations of the two phases.

Abnormal relation between tensile and fatigue strengths for a high-strength low-alloy steel

[J].

Correlation of microstructure and fatigue properties of two high-strength spring steels

[J].

Influence of inclusion size on fatigue behavior of high strength steels in the gigacycle fatigue regime

[J].

High cycle fatigue behaviour of a multiphase microalloyed medium carbon steel: a comparison between ferrite-pearlite and tempered martensite microstructures

[J].

The effect of inclusions on the fatigue behavior of fine-grained high strength 42CrMoVNb steel

[J].

Fatigue behaviors of AISI 316L stainless steel with a gradient nanostructured surface layer

[J].

Enhanced fatigue resistance in 316L austenitic stainless steel due to low-temperature paraequilibrium carburization

[J].

Application of the generalized Pareto distribution to the estimation of the size of the maximum inclusion in clean steels

[J].

Statistical prediction of inclusion sizes in clean steels

[J].

The fatigue behaviors of zero-inclusion and commercial 42CrMo steels in the super-long fatigue life regime

[J].

Fatigue cracking criterion of high-strength steels induced by inclusions under high-cycle fatigue

[J].Fatigue properties of high-strength steels become more and more sensitive to inclusions with enhancing the ultimate tensile strength (UTS) because the inclusions often cause a relatively low fatigue strength and a large scatter of fatigue lives. In this work, four S-N curves and more than 200 fatigue fracture morphologies were comprehensively investigated with a special focus on the size and type of inclusions at the fatigue cracking origin in GCr15 steel with a wide strength range by different heat treatments after high-cycle fatigue (HCF). It is found that the percentage of fatigue failure induced by the inclusion including Al<sub>2</sub>O<sub>3</sub> and TiN gradually increases with increasing the UTS, while the percentage of failure at sample surfaces decreases conversely and the fatigue strength first increases and then decreases. Besides, it is interestingly noted that the inclusion sizes at the cracking origin for TiN are smaller than that for Al<sub>2</sub>O<sub>3</sub> because the stress concentration factor for TiN is larger than that for Al<sub>2</sub>O<sub>3</sub> based on the finite element simulation. For the first time, a new fatigue cracking criterion including the isometric inclusion size line in the strength-toughness coordinate system with specific physical meaning was established to reveal the relationship among the UTS, fracture toughness, and the critical inclusion size considering different types of inclusions based on the fracture mechanics. And the critical inclusion size of Al<sub>2</sub>O<sub>3</sub> is about 1.33 times of TiN. The fatigue cracking criterion could be used to judge whether fatigue fracture occurred at inclusions or not and provides a theoretical basis for controlling the scale of different inclusion types for high-strength steels. Our work may offer a new perspective on the critical inclusion size in terms of the inclusion types, which is of scientific interest and has great merit to industrial metallurgical control for anti-fatigue design.