在电力、矿山和水泥等领域,用于制造高效、长寿命粉磨设备的高铬铸铁和高锰钢等不仅依赖Cr、Mo、Ni等稀有元素,其耐磨性能也不高[3]。陶瓷/金属复合材料综合了陶瓷的高硬度和金属强韧性。制造陶瓷颗粒增强金属复合材料需要Al2O3、ZTA[4]、SiC、WC、TiC等陶瓷颗粒,其基体主要有高铬铸铁[5,6]、耐磨钢等金属材料;制备工艺有粉末冶金法、真空浸渗法和挤压铸造法。用粉末冶金法制备的WC、TiC金属陶瓷因成本的限制主要应用在刀具和钻具等领域;用真空浸渗法制备的ZTA陶瓷颗粒增强高铬铸铁磨辊磨盘在各电厂的粉磨设备上获得了应用,并取得了良好的经济效益。但是,在陶瓷颗粒增强金属复合材料中金属陶瓷界面的结合较弱,使陶瓷颗粒容易剥落;过高的工作温度使金属软化,导致陶瓷颗粒增强效果减弱直至消失。

SiC泡沫陶瓷/球墨铸铁三维双连续相复合材料是一种SiC泡沫陶瓷整体增强球墨铸铁的复合材料。其中的陶瓷相与金属相之间形成了相互贯穿和相互支撑的三维联通网络。三维空间中的每一个相都是连通的,这种结构有助于最大限度的保留和利用两相的优势。通过陶瓷相和金属相的人工设计可以使复合材料兼具低膨胀系数、高强度、良好的耐磨性[7,8,9,10]和优异的强韧性[11,12],比传统的耐磨材料有明显的优势[13,14]。杜奇等[15]研究了Si3N4/1Cr18Ni9Ti双连续相复合材料的泥浆冲蚀性能,发现Si3N4/1Cr18Ni9Ti双连续相复合材料因Si3N4泡沫陶瓷的保护作用比1Cr18Ni9Ti不锈钢具有更好的耐冲蚀性。陈亮[16]研究了用常压浇注法制备的SiC/Fe基双连续相复合材料并研究其摩擦性能。结果表明:SiC/Fe基双连续相复合材料的耐磨性能是铸铁的2.1~7.9倍。本文以球墨铸铁作为基体相以SiC泡沫陶瓷为约束骨架,利用挤压铸造工艺制备出SiC泡沫陶瓷/球墨铸铁双连续复合材料,同时制备了SiC陶瓷颗粒/球墨铸铁复合材料。对比研究了DI、SiCfoam/DI、SiCp/DI等复合材料的耐冲蚀性能,以期为SiCfoam/DI复合材料在工程中的应用提供实验基础。

1 实验材料、设备及方法

1.1 实验材料选择与制备

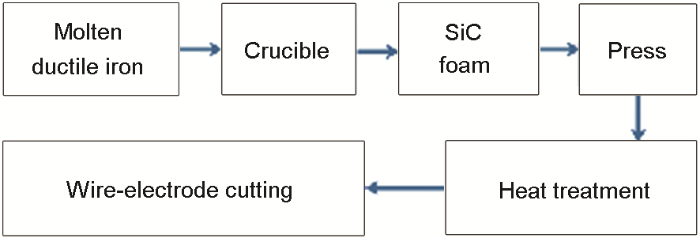

图1

图1

复合材料SiCfoam/DI的制备工艺

Fig.1

SiCfoam/DI composite material preparation process

1.2 实验设备

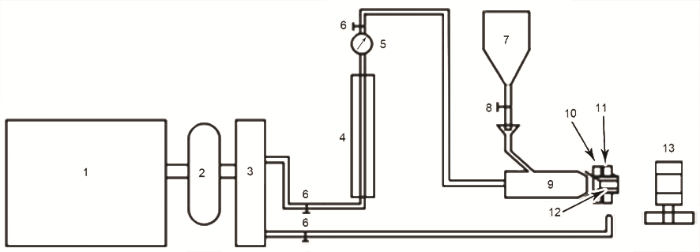

图2

图2

实验装置示意图

Fig.2

Experimental device schematic 1-air compressor, 2-pressure vessel, 3-dryer, 4-flowmeter, 5-pressure gauge, 6-ball valve, 7-silo, 8-butterfly valve, 9-spray gan, 10-bearing, 11-fan, 12-nozzle, 13-sample stage

图3

图3

靶台示意图

Fig.3

Target table schematic 1-base, 2-rotary table, 3-sample table, 4-sample slot, 5-bolt, 6-scale line

1.3 实验方法

实验使用的冲蚀粒子是60目的SiO2颗粒,质量为25 kg。为了研究冲蚀粒子的冲蚀角度和速度对材料冲蚀速率的影响,选取的冲蚀角度为15°、30°、45°、60°、90°等,选取的粒子速度为50 m/s、62.5 m/s、75 m/s、87.5 m/s、100 m/s。实验机料仓中的粒子出口流量为10.4 g/s。样品尺寸为31.5 mm×31.5 mm×14 mm,冲蚀面积为31.5 mm×31.5 mm。实验前用砂纸打磨样品表面,磨好后的样品放入无水乙醇中,超声清洗20 min,后放入120℃烘箱中烘干后取出室温后,每个样品用感量为0.001 mg的电子天平称量三次取平均值。每次冲蚀实验后,清洗样品、烘干,室温后称量三次取平均值。对于每种参数的实验进行三次,实验结果取平均值。

冲蚀速率Er=Δm/M,式中Δm为样品的失重量;M为每次实验所用冲蚀粒子的质量(25 kg)。

2 结果与讨论

2.1 冲蚀时间对材料冲蚀速率的影响

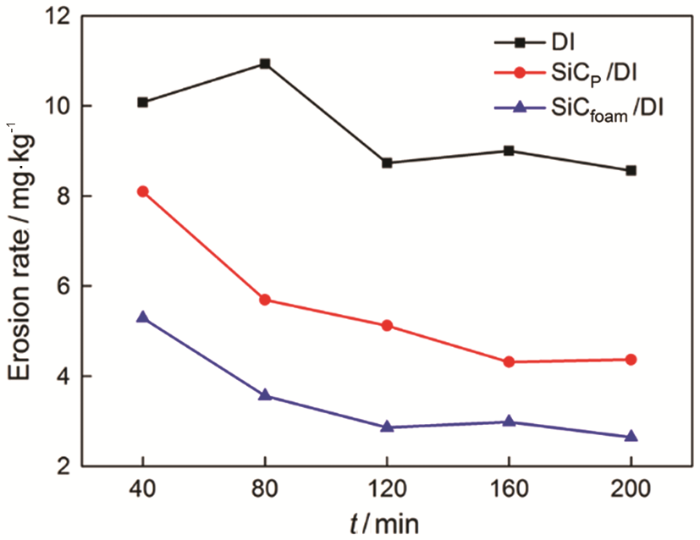

图4是三种材料在冲击速率ν=75 m/s、α=30°条件下冲蚀速率随时间的变化。从图中可以看出,随着冲蚀时间的增加,三种材料的冲蚀速率逐渐下降并趋于稳定,且DI的冲蚀速率最高,SiCfoam/DI复合材料的冲蚀速率最低,三种材料的稳定冲蚀速率分别为8.562 mg/kg、4.368 mg/kg、2.64 mg/kg。

图4

图4

三种材料α=30°、ν=75 m/s时的冲蚀速率随冲蚀时间的变化

Fig.4

Variation of erosion rate of three materials with the erosion time at α=30° and ν=75 m/s

2.2 冲蚀角度对材料冲蚀速率的影响

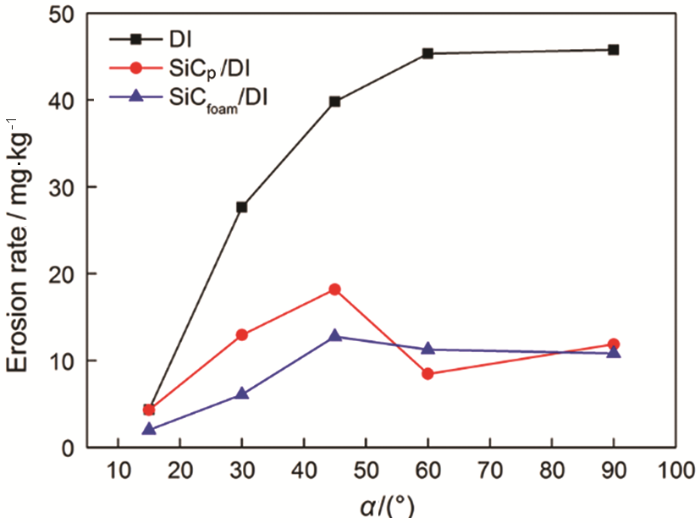

图5

图5

三种材料ν=100 m/s时的冲蚀速率随冲蚀角度的变化

Fig.5

Variation of erosion of three materials rate with erosion angle at ν=100 m/s

2.3 粒子冲击速度对冲蚀速率的影响

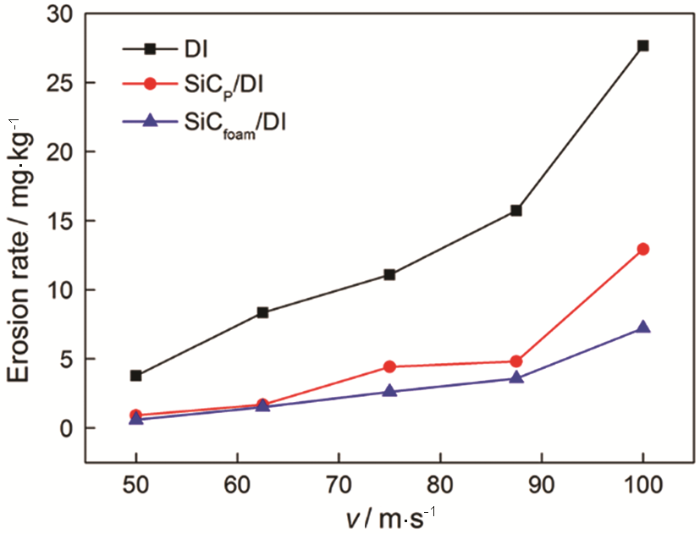

冲蚀粒子的动能随着冲蚀粒子速度的增加逐渐增大,与材料表面作用的力也就越大,对材料产生的冲蚀磨损也越严重。图6是三种材料的冲蚀速率随粒子冲击速度的变化规律。可以看出,随着粒子速度的增加,DI的冲蚀速率均较SiCP/DI、SiCfoam/DI的冲蚀速率大。当粒子速度低于87.5 m/s时,DI的冲蚀速率是复合材料的3~6倍,通过拟合,DI的冲蚀速率与ν之间的关系大致满足Er(DI)=3.36×10-5×ν2.95;SiCP、SiCfoam/DI等复合材料的冲蚀速率差别不大,通过拟合,发现SiCP/DI复合材料和SiCfoam/DI复合材料的冲蚀速率与粒子速度之间的关系分别符合Er(SiCP/DI)=3.69×10-9×ν4.76和Er(SiCfoam/DI)=3.70×10-8×ν4.14。

图6

图6

三种材料α=30°时的冲蚀速率随粒子冲击速度的变化

Fig.6

Variation of erosion rate of three materials with particle impact velocity at α=30°

当粒子速度为100 m/s时,三种材料的冲蚀速率都显著增加,其中DI的冲蚀速率大约分别是SiCp/DI、SiCfoam/DI的2倍和3.2倍。在高速冲刷工况下复合材料的耐冲蚀性能明显优于球墨铸铁基体,且SiCfoam/DI复合材料的耐冲蚀性能最高。

3 冲蚀机理

图7

图7

α=30°、ν=75 m/s和α=90°、ν=75 m/s时DI的冲蚀形貌

Fig.7

Erosion appearance of DI erosion at α=30° and ν=75 m/s (a) (b), at α=90° and ν=75 m/s (c)

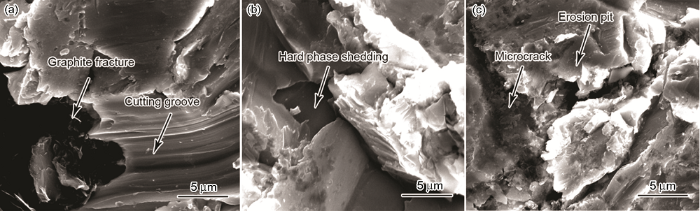

DI的冲刷磨损过程分为以下几个过程:(1)表层石墨逐渐变形[23];(2)粒子冲击产生的边缘凸起沿冲刷方向生长;(3)石墨和凸起脱落。粒子作用在材料表面的力可以分解成水平方向和垂直方向的分力。低角度时水平方向的分力与材料表面的作用占主要地位,粒子对材料表面的作用主要表现为微切削。随着冲蚀角逐渐增大垂直方向的力逐渐增大,尖角粒子对材料表面的作用表现为产生微观裂纹,钝角粒子对材料表面的作用表现为产生冲蚀坑。

颗粒增强复合材料的基体材料和DI的冲蚀磨损机理相同,但切削和犁削的沟槽较浅。图8是SiCP/DI复合材料在α=30°、ν=100 m/s条件下的冲蚀形貌。由于SiC颗粒的保护作用,减弱了球墨铸铁基体相的冲蚀磨损,因此磨损量相比于DI较低。随着冲击速度的增加,粒子的动能增大,增强颗粒在冲蚀粒子的连续冲击下出现破碎和脱落。

图8

图8

SiCP/DI复合材料α=30°、ν=100 m/s时的冲蚀形貌

Fig.8

Erosion morphology of SiCP/DI composites with α=30° and ν=100 m/s

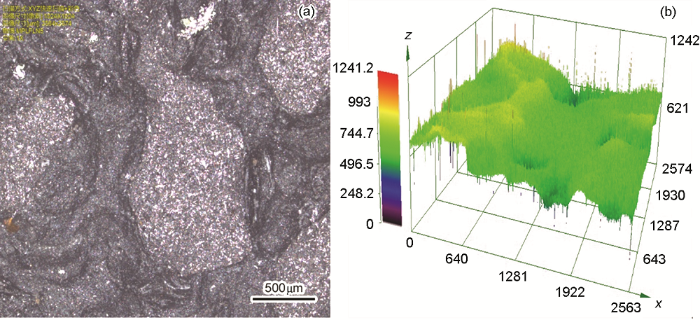

对于SiCfoam/DI复合材料,其独特的双连续相空间结构,对金属基体的保护作用更强。图9是SiCfoam/DI复合材料在α=30°、ν=100 m/s条件下的冲蚀形貌。陶瓷相质硬,磨损量较小,同时极大地减小了粒子的运动速度。DI相对SiC泡沫陶瓷属于软质相,当冲击粒子与陶瓷作用时,产生的冲击力一方面通过SiC泡沫陶瓷-界面传递到DI上,通过软质相的“缓冲”以及对能量的吸收,另一方面三维连续的泡沫陶瓷使冲蚀粒子的冲击应力分散,使得粒子对陶瓷相的伤害减轻。SiC泡沫陶瓷在空间中的连续性,以及DI对陶瓷相的支撑,在冲蚀过程中没有出现类似于SiCP/DI复合材料中陶瓷颗粒的脱落,因此,与颗粒增强复合材料相比,双连续相复合材料表现出优异的耐冲蚀性能。

图9

图9

SiCfoam/DI复合材料α=30°、ν=100 m/s时的冲蚀形貌

Fig.9

Erosion morphology of SiCfoam/DI composites at α=30° and ν=100 m/s

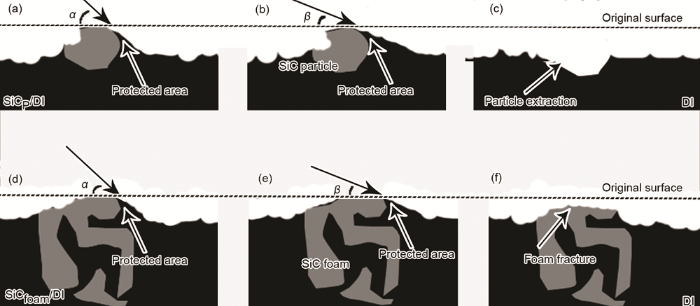

在冲蚀磨损过程中,当金属基体被冲掉以后,陶瓷相高于金属基体,对金属基体起到很好的保护效应。图10是SiCP/DI复合材料和SiCfoam/DI复合材料的冲蚀磨损陶瓷增强相阴影保护效应的示意图。可以看出随着冲蚀角度的降低,SiC陶瓷对基体的阴影保护作用逐渐增大(图10a~b和d~e),但SiC泡沫陶瓷具有整体增强机制,断裂之后,仍然对基体有较强的增强作用和阴影保护效应,SiC颗粒在冲蚀磨损过程中一旦出现剥落,SiC颗粒对周围基体的增强作用消失,同时阴影保护效应也会消失(图10c)。由于SiC泡沫和DI两相在空间中连续,这种结构使得DI对SiC泡沫陶瓷具有更好的支撑效果,在SiC泡沫陶瓷被部分冲蚀时依然对DI基体提供阴影保护效应(图10f),可以看出SiC泡沫陶瓷与DI这种相互增强方式使得SiCfoam/DI具有更好的耐冲蚀性能。

图10

图10

复合材料SiCP/DI和SiCfoam/DI的冲蚀磨损示意图

Fig.10

Schematic diagrams of erosion wear of SiCP/DI and SiCfoam/DI Composites

4 结论

采用自制的气固两相流冲蚀磨损实验机,对比测试了SiCP/DI复合材料、SiCfoam/DI复合材料和DI基体三种材料的冲蚀性能。三种材料在冲蚀的过程中都经过一段时间后,冲蚀速率保持稳定。保持稳定后,SiCfoam/DI的耐磨性分别是SiCP/DI复合材料和DI的2倍和3.2倍。随着冲蚀角度的增大,DI呈现出脆性材料的冲蚀特征,SiCfoam/DI、SiCP/DI等复合材料均在冲蚀角为45°时冲蚀速率达到最大值,其表观冲蚀特征与均质塑性材料相似。随着粒子速度的增加,三种材料的冲蚀速率随之增大,其中DI的冲蚀速率与ν2.95成正比,当粒子速度小于87.5 m/s时,SiCfoam/DI复合材料和SiCP/DI复合材料的冲蚀速率与ν之间的关系分别符合Er(SiCP/DI)=3.69×10-9×ν4.76和Er(SiCfoam/DI)=3.70×10-8×ν4.14;当粒子速度高于87.5 m/s时SiCP/DI复合材料的冲蚀速率急剧增大,SiCfoam/DI复合材料的冲蚀速率远小于SiCP/DI复合材料的冲蚀速率。三种材料中DI的磨损方式均为低角度时为塑性变形和微切削,高角度时为冲蚀坑、微观裂纹。由于复合材料中陶瓷相的保护作用和阴影效应,基体的磨损较轻。由于SiC颗粒在基体中的非连续、弥散分布,粒子高速冲击时易于碎裂脱落,使复合材料的磨损量增大;SiCfoam/DI复合材料具有独特的三维双连续相空间结构,泡沫陶瓷能通过整体增强作用和阴影保护效应减小了粒子对基体的磨损,从而提高了SiCfoam/DI复合材料的耐冲蚀性能。

参考文献

Optimization and erosion wear response of NiCrSiB/WC-Co HVOF coating using Taguchi method

[J].

Erosion wear studies on high concentration fly ash slurries

[J].

Recent progress of research on wear resistant metal materials

[J].

耐磨金属材料的最新研究进展

[J].

Numerical simulation of mold filling process for high chromium cast iron matrix composite reinforced by ZTA ceramic particles

[J].

Characterization of interfacial layer of ZTA ceramic particles reinforced iron matrix composites

[J].

Wear resistance mechanism of ZTAP/HCCI composites with a honeycomb structure

[J].

Fabrication and tribological properties of Ti3AlC2/Cu co-continuous composites

[D].

双连续相Ti3AlC2/Cu复合材料的制备及摩擦学性能研究

[D].

Dry wear and friction properties of an A356/SiC foam interpenetrating phase composite

[J].

Thermal analysis for brake disks of SiC/6061 Al alloy co-continuous composite for CRH3 during emergency braking considering airflow cooling

[J].

Experimental study and numerical analysis on dry friction and wear performance of co-continuous SiC/Fe-40Cr against SiC/2618 Al alloy composites

[J].

Effect of porous Si3N4 preform on the mechanical properties of Si3N4/Al composites with interpenetrating network structure

[J].

The mechanical properties of co-continuous Si3N4/Al composites manufactured by squeeze casting

[J].

Co-Continuous Composite Materials for Stiffness, Strength, and Energy Dissipation

[J].

Fabrication of a new SiC/2024Al co-continuous composite with lamellar microstructure and high mechanical properties

[J].

Preparation and Erosion Performance for Co-continuous Phase Composites of Si3N4/1Cr18Ni9Ti

[J].

双连续Si3N4/1Cr18Ni9Ti复合材料的制备和冲蚀性能

[J].

Study on the preparation technology and performance of 3D-reticulated porous SiC/Fe composite material

[D].

三维网络结构SiC/Fe基复合材料的制备工艺和性能研究

[D].

Microstructure and mechanical properties of diffusion bonded SiC/steel joint using W/Ni interlayer

[J].

Effect of SiC volume fraction and size on dry sliding wear of Fe/SiC/graphite hybrid composites for high sliding speed applications

[J].

Control of the interface reaction between silicon carbide and iron

[J].

Preparation and performance of SiC foam ceramic/Fe matrix co-continuous phase composites

[J].

SiC泡沫陶瓷/Fe基双连续相复合材料的制备和性能

[J].

Developments of research on the solid particle erosion of materials

[J].

固体粒子冲蚀磨损研究进展

[J].

The optimal selection of wear resistant materials for powder pipe transportation by investigating their blasting erosion behaviors

[D].

粉料输送管道用材的冲蚀行为及优选研究

[D].