电磁干扰(EMI)屏蔽膜的结构,有混合结构、多孔结构、核壳结构、夹层结构和多层结构[9]。相比之下,夹层结构和多层结构的设计灵活,能使屏蔽材料具有多种功能。Han等[10]用真空过滤和热压技术制备的Janus结构(BNNS/ANF)-(AgNWs/ANF)复合膜,其屏蔽性能优异。夹层结构的制造工艺简便和屏蔽效能较高,其特定层中的导电填料形成导电路径,外层材料不仅能保护内层导电路径,还能提供其他功能。Gong等[11]用真空辅助过滤法制备的多功能柔性PCC/MXene/PVA相变复合膜,不仅具有EMI屏蔽功能(43.13 dB),还具备多源驱动的热管理性能。同时,现代高集成化电子设备的内部空间日益紧凑,薄膜对其实际应用尤为重要。Lei等[12]用逐层真空过滤技术制备出三明治结构的AgNWs/EGP/ANF复合薄膜,具有导热和焦耳加热功能。

聚乙烯醇(PVA)具有易燃性和导电率较低,使其在高性能复合材料中的应用受到限制。为了提高PVA的导电性和阻燃性能,须掺入高导电性填料和阻燃剂,但是使其材料的密度和成本提高以及可加工性和柔韧性降低[13,14]。降低填料在聚合物基体中的分布维数,可解决这些问题。银纳米线(AgNWs)是一种一维柔性导电填料,具有较大的比表面积、优异的导电性和良好的柔韧性。低量AgNWs能形成导电网络,构建出导电通路。聚磷酸铵(APP)是一种高效阻燃剂,氮磷含量较高、无毒、防滴、高分解温度以及与高分子材料的相容性较好[15]。本文使用环境友好的PVA基材,用APP作为阻燃剂和AgNWs导电填料,制备一种PVA复合薄膜,研究其阻燃性能、电磁屏蔽性能和热稳定性。

1 实验方法

1.1 实验原料

1799型聚乙烯醇(PVA 1799,醇解度为98%~99%,聚合度约为1700)、甘油(GL,AR)、聚乙烯吡咯烷酮(PVP,Mn = 58000)和二氯甲烷(DCM,AR)、硝酸银(AgNO3,AR)、氯化钠(NaCl,AR)、聚磷酸铵(APP II,DP 1000)、康道宁184 PDMS主剂(Sylgrd 184a)、固化剂(Sylgrd 184b)、去离子水(DI水,超纯)以及无水乙醇(EtOH,AR)。

1.2 阻燃型电磁屏蔽复合薄膜的制备

在三口烧瓶中加入190 mL的甘油后缓慢加入5.86 g的PVP,将混合物升温至80 ℃后进行机械搅拌(速度约为80 r/s),PVP完全溶解后停止加热。

在容积为10 mL的烧杯中加入0.059 g的NaCl、10 mL的甘油和500 μL的去离子水,混合均匀后放入60 ℃烘箱中烘烤5 min。将三口烧瓶内的溶液冷却至55 ℃后尽快加入1.58 g的AgNO3,AgNO3溶解后将烧杯中的NaCl混合溶液倒入,然后加热至210 ℃,整个反应在缓慢的机械搅拌下进行。当溶液的颜色从亮黄色变为红色最后变为灰绿色时停止反应,将得到的溶液倒入烧杯中冷却,加入200 mL去离子水后静置一周。依次用去离子水和乙醇各离心3次(4500 r/min,5 min),得到AgNWs溶液。

在三口烧瓶中加入180 mL去离子水后加入20 g的PVA,让其在90 ℃的水浴锅中反应4 h,制备出200 mL浓度为10% (质量分数)的PVA溶液。分别在两份适量的10%PVA溶液中加入APP,使PVA与APP的固含量分别为70% (质量分数)和30%,机械搅拌2 h使其混合均匀,然后将其置入真空烘箱中消除气泡,得到FPA溶液。

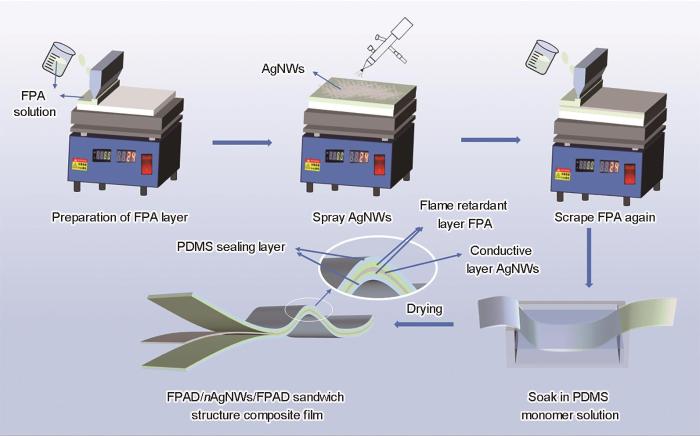

先将FPA溶液均匀刮涂到放置在40 ℃恒温加热台的玻璃板上,干燥成膜后用喷枪喷涂不同负载量(0.05、0.10、0.20、0.50 mg/cm2)的AgNWs,得到FPA/nAgNWs薄膜(n为AgNWs负载量)样品。

图1

图1

FPAD/nAgNWs/FPAD三明治结构复合薄膜的制备工艺示意图

Fig.1

Schematic diagram of the preparation process of FPAD/nAgNWs/FPAD sandwich structure composite film

表1 样品的名称和组成

Table 1

| Samples | 10%PVA | APP | AgNWs/mg·cm-2 | 20%PDMS |

|---|---|---|---|---|

| PVA | 100% | 0 | 0 | 0 |

| FPA | 70% | 30% | 0 | 0 |

| FPAD | 70% | 30% | 0 | 20% |

| FPAD/0.05AgNWs/FPAD | 70% | 30% | 0.05 | 20% |

| FPAD/0.10AgNWs/FPAD | 70% | 30% | 0.10 | 20% |

| FPAD/0.20AgNWs/FPAD | 70% | 30% | 0.20 | 20% |

| FPAD/0.50AgNWs/FPAD | 70% | 30% | 0.50 | 20% |

1.3 性能表征

用GeminiSEM500扫描电镜(SEM)观察FPAD和AgNWs的微观结构以及FPAD/AgNWs复合膜的表面形貌。将样品进行90 s的金溅射和5 min的红外光干燥,使横截面样品低温断裂得到较为光滑的断口表面。用Bruker A8 Advance X射线衍射仪(XRD)测试薄膜的XRD谱。扫描范围为10°~90°。用Bruker Tensor 27傅里叶变换红外光谱仪(FT-IR)测试薄膜的红外光谱,测试范围为500~4000 cm-1,扫描次数为32,分辨率为16 cm-1。用Thermo Scientific K-alpha X射线光电子能谱仪(XPS)分析样品的元素组成。用AV3672矢量网络分析仪测试样品的屏蔽性能,频率范围为8.2~12.4 GHz (X波段)。

样品的反射屏蔽效能(SER)、吸收屏蔽效能(SEA)、多重反射屏蔽效能(SEM)、总屏蔽效能(SET)和屏蔽效率(%)分别为

其中S11和S21为样品的散射参数。

SET 15 dB时,可将SEM忽略不计。为了满足更高的要求,须考虑材料的密度(

根据热重(TG209F3)分析(在空气气氛,以流速40 mL/min,温度30~800 ℃)结果评估样品的热稳定性和热氧化稳定性。依据UL-94标准在定制的夹具上进行垂直燃烧实验:样品的截面积为200 mm × 60 mm,距离火焰20 mm。先将样品暴露于火焰10 s后离开火焰。用VOUCH 6820微热量计(MCC)测试样品的热释放性能。样品的质量为3~5 mg,以1 ℃/s的速率升温至800 ℃,记录放热数据。使用KJ-1065B万能材料试验机测试样品的拉伸性能(薄膜样品的尺寸为80 mm × 30 mm,拉伸间距为60 mm,拉伸速度为5 mm/min)。用DSA25接触角测量仪测试样品的接触角。

2 结果和讨论

2.1 三明治结构FPAD/nAgNWs/FPAD薄膜的形态

图2

图2

PVA,FPA和FPAD/nAgNWs/FPAD薄膜可承受500.00 g的载荷、FPAD/0.50AgNWs/FPAD薄膜的柔性、可折叠性及其厚度的数码照片

Fig.2

Digital photographs of PVA (a), FPA (b), and FPAD/nAgNWs/FPAD films (c), the FPAD/nAgNWs/FPAD film which can withstand a weight of 500.00 g (d), flexibility and foldability for FPAD/0.50AgNWs/FPAD films (e), and the thickness for FPAD/0.50AgNWs/FPAD film (f)

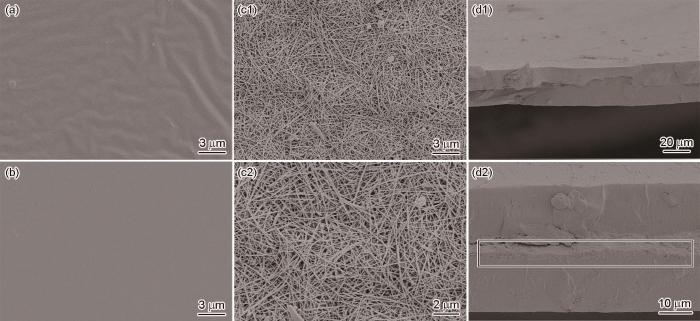

FPAD薄膜的表面形貌(图3a)较为平整。从图3b可见,FPA层的表面极为光滑平整,有利于AgNWs均匀分布构建平整连续的导电网络。图3c给出了未覆盖另一层FPA的FPA/0.50AgNWs薄膜的微观结构。可以看出,在FPA层上无规则排列的AgNWs形成了高度连接且致密的导电网络。为了观察FPA层与AgNWs网络层间的界面,对FPAD/0.50AgNWs/FPAD薄膜的截面进行了扫描。如图3d所示,薄膜呈现出夹层结构,AgNWs层(黑框内)位于两层FPAD之间。从暴露的截面可以看出,FPA层与AgNWs层界面堆叠紧密,表明异质层间存在强烈的相互作用力。这表明,这种FPAD/nAgNWs/FPAD复合薄膜的界面相互作用良好,内部的导电网络完整。

图3

图3

FPAD薄膜、FPA薄膜、FPA/0.50AgNWs薄膜银层的表面以及FPAD/0.50AgNWs/FPAD薄膜截面的SEM照片

Fig.3

SEM images of the FPAD film (a), the FPA film (b), the silver layer surface of the FPA/0.50AgNWs film (c), and the cross-section of the FPAD/0.50AgNWs/FPAD film (d)

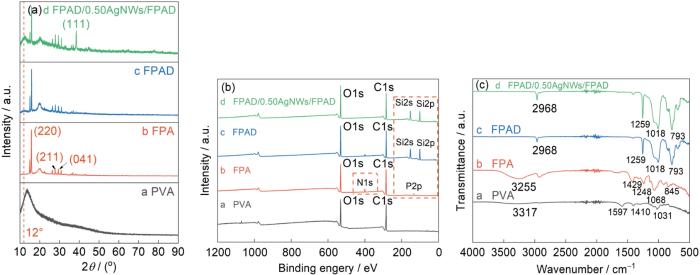

从图4a可见,在PVA的XRD谱中大约13.2°处强而锐的衍射峰,是PVA分子链有序排列结晶区的特征峰。FPA谱中位于15.6°、26.2°和29.1°处的衍射峰,分别对应APP的(220)、(211)和(041)晶面,与纯APP相比只是峰的强度有所降低[16]。这表明,PVA与APP共混没有改变APP的晶型和结构。与FPA相比,FPAD和FPAD/0.50AgNWs/FPAD的谱中12°处都出现了新的聚硅氧烷软段的弥散峰,表明聚硅氧烷具有无定形结构[17]。FPAD/0.50AgNWs/FPAD复合薄膜与另3种薄膜的谱,其最显著的特点是在38.1°处出现了明显的特征峰,与AgNWs的(111)晶面相对应。如图4b所示,在FPA的XPS谱中134.1和401.0 eV处出现的新特征峰分别对应P 2p和N 1s,表明FPA复合薄膜的确含有APP。经PDMS处理后,在FAPD和FPAD/0.50AgNWs/FPAD的XPS谱中结合能为102.3 eV(Si 2p)和152.0 eV(Si 2s)处出现了新的特征峰,但是P 2p和N 1s峰几乎消失,表明PDMS完全覆盖在FPA表面[18]。但是,在FPAD/0.50AgNWs/FPAD的XPS谱中未检测到Ag 3d,其原因可能是XPS的探测深度只有1~10 nm[8]。但是,根据对XRD谱的分析,FPAD/0.50AgNWs/FPAD复合薄膜的谱中出现了Ag的衍射峰。

图4

图4

PVA、FPA、FPAD及FPAD/0.50AgNWs/FPAD的XRD谱、XPS和FT-IR谱

Fig.4

XRD patterns (a), XPS (b), and FT-IR (c) spectra of PVA, FPA, FPAD, and FPAD/0.50AgNWs/FPAD

图4c给出了薄膜的FT-IR谱。在PVA的谱中3317 cm-1处出现了一条较宽的-O-H拉伸振动吸收峰。在1597 cm-1处的峰对应-CH2-的伸缩振动,1410 cm-1处的峰与-CH2-弯曲振动相关;而1031 cm-1处的峰则对应PVA结晶区域C-O键的伸缩振动[19]。在FPA谱中3255 cm-1处的峰明显变宽,其原因是阻燃剂APP和NH4+的引入使其与-OH基的特征峰重叠而使峰的宽度增大。同时,1429 cm-1处的吸收峰强度比PVA的谱中1410 cm-1处的峰增强,表明PVA/APP薄膜的成功制备。845 cm-1处的峰对应P-O-P弯曲振动,1248 cm-1处峰归因于P=O吸收,而1068 cm-1的峰则对应P-O对称拉伸振动,其强度相比于纯PVA中1031 cm-1处有明显变化,是APP中的P-O键与PVA中的C-O键重叠所致[20]。FPAD与FPAD/0.50AgNWs/FPAD的峰基本相同,只是在793、1259和1018 cm-1处出现了吸收峰,对应PDMS层中Si-O-Si键的对称振动和Si-O-Si键的不对称拉伸振动[21]。

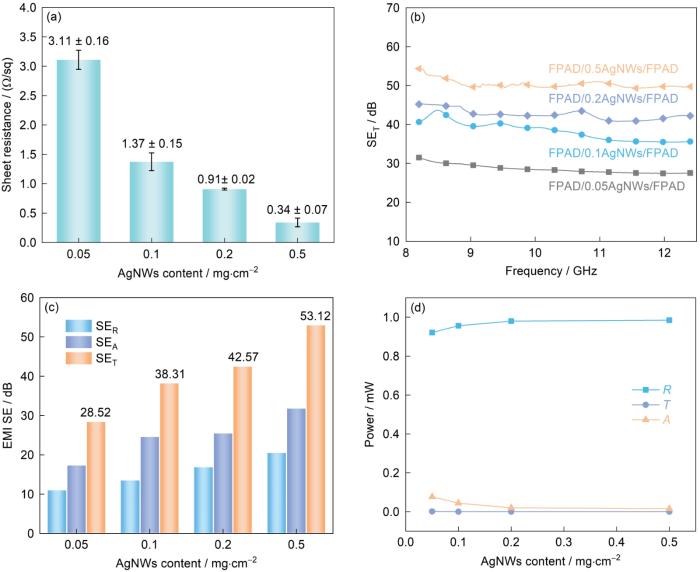

2.2 三明治结构FPAD/nAgNWs/FPAD的电磁屏蔽性能

如图5a所示,随着AgNWs负载量从0.05 mg/cm2提高到0.50 mg/cm2,薄膜的方阻从3.11 Ω/sq降低至0.34 Ω/sq。其原因是,AgNWs含量的增加使夹层中的AgNWs连接更加紧密,从而形成更为连续的导电网络而使方阻降低。

图5

图5

FPAD/nAgNWs/FPAD薄膜的方阻、在X波段的电磁屏蔽性能、平均SER、SEA和SET值以及平均功率系数

Fig.5

Sheet resistance (a), EMI shielding performance in X-band (b), average SER, SEA and SET values in X-band (c) and average power coefficient curves in X-band (d) of the FPAD/nAgNWs/FPAD films

图5b给出了样品SET的变化曲线。可以看出,在X波段SET随着AgNWs含量的提高而增大,AgNWs负载量为0.05 mg/cm2时SET为28.52 dB。由

表2 薄膜样品的SEA、SER、SET、R、T、A、t和SSE/t的数值

Table 2

| AgNWs contentmg·cm-2 | SEAdB | SERdB | SETdB | R | A | T | tmm | SSE / tdB·cm-2 |

|---|---|---|---|---|---|---|---|---|

| 0.05 | 11.07 | 17.45 | 28.52 | 0.922 | 0.077 | 0.001 | 0.06 | 49628.66 |

| 0.10 | 13.60 | 24.71 | 38.31 | 0.956 | 0.044 | 0.001 | 0.06 | 65751.53 |

| 0.20 | 16.96 | 25.59 | 42.57 | 0.980 | 0.020 | 0.001 | 0.06 | 70753.31 |

| 0.50 | 20.60 | 31.92 | 53.12 | 0.984 | 0.016 | 0.001 | 0.06 | 85226.54 |

从图5c可以看出,随着AgNWs负载量的增加SEA值显著增加,而SER值缓慢增加。虽然图5c中的SEA值都高于SER值,但是大部分EMWs进入屏蔽层前便被反射,因此需要进一步分析EMI屏蔽的吸收系数(A)、反射系数(R)和透射系数(T) (如图5d所示),以揭示电磁屏蔽的机制。EMWs入射到复合薄膜时先接触外层FPAD层,此时只有小部分EMWs被反射,大部分EMWs穿过FPAD层进入中间的AgNWs层。在AgNWs层,阻抗失配使大量EMWs被反射。同时,AgNWs网络中移动的载流子之间相互作用产生的感应电流使EMWs能量衰减[22]。从图5d可以看出,薄膜的T值接近于0,表明FPAD/nAgNWs/FPAD屏蔽了几乎全部入射EMWs。同时,R值远高于A值,表明FPAD/nAgNWs/FPAD的主要屏蔽机制是对电磁波的反射。

图6

图6

FPAD/0.50AgNWs/FPAD薄膜在不同处理条件下的平均SER、SEA和SET值

Fig.6

Average SER, SEA, and SET values of the FPAD/0.50AgNWs/FPAD film under different treatment conditions

2.3 FPAD/nAgNWs/FPAD薄膜的热稳定性

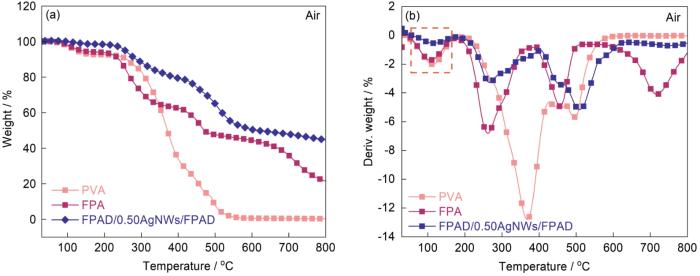

图7给出了PVA、FPA和FPAD/0.50AgNWs/FPAD薄膜在空气中的热重分析(TGA)和差分热重分析(DTG)结果,相关数据列于表3。由图7b可见,纯PVA在100~150 ℃有轻微的质量损失,主要是薄膜中DI的分解和PVA上-OH的脱去所致。PVA的热分解有两个阶段。第一阶段发生在温度低于370 ℃时,质量损失速率最高,主要原因是PVA侧链基团的降解产生了水和醛等物质;第二阶段发生在430~510 ℃,质量损失速率较低,主要是PVA中C-C主链的分解和环化反应所致。在530 ℃基本上达到平衡[23]。FPA薄膜的分解可分为3个阶段。FPA薄膜的第一次质量损失(262.70 ℃)比PVA薄膜的Tmax1提前了105.83 ℃,因为APP发生了分解。第二次质量损失,随着温度的上升APP分解生成的磷酸与PVA中的-OH发生酯化反应生成了一种阻燃保护层,延缓了PVA的降解[15]。这个保护层还能降低材料的总质量损失并在高温下产生阻燃作用,减少可燃性气体的生成。因此,发生第三次质量损失的温度更高且质量损失较小。在718.37 ℃,APP分解产生的无水磷酸进一步分解生成了焦磷酸等固体残余物。由表3可知,PVA残留物的质量分数为0.38%,因为PVA的有机部分分解成气态产物。FPA的残重为22.34% (质量分数),主要是APP分解生成了如焦磷酸盐等无机残留物。由图7a可见,FPA的残重明显高于PVA,再次证明成功引入了阻燃剂APP。FPAD/0.50AgNWs/FPAD薄膜的疏水特性减少了PVA的吸湿性,降低了薄膜在较低温度下的脱水。FPAD/0.50AgNWs/FPAD的Tmax1与FPA接近,这个阶段主要是APP的分解释放出氨气(NH3)和水(H2O)并生成无水磷酸(P2O5),但是质量损失明显减少[24]。最后一个阶段,主要是APP和PDMS分子链的硅氧键(Si-O-Si)分解,其质量损失明显高于前一阶段。其中FPAD/0.50AgNWs/FPAD的残重比FPA高100.67%,是PDMS分解后产生的无机残留物(如SiO)和内部AgNWs层中的成焦所致。这些结果表明,FPAD/nAgNWs/FPAD复合薄膜的热稳定性较高。

图7

图7

PVA、FPA和FPAD/0.50AgNWs/FPAD在空气中的TGA和DTG曲线

Fig.7

TGA (a) and DTG (b) curves of PVA, FPA and FPAD/0.50AgNWs/FPAD under air atmosphere

表3 薄膜样品的TGA和DTG曲线

Table 3

| Samples | T-5% / oC | Tmax1 / oC | Tmax2 / oC | Tmax3 / oC | Residue at 800 oC (mass fraction) |

|---|---|---|---|---|---|

| PVA | 113.59 | 368.53 | 501.32 | - | 0.38% |

| FPA | 110.93 | 262.70 | 451.89 | 718.37 | 22.34% |

| FPAD/0.50AgNWs/FPAD | 112.90 | 264.29 | 511.40 | - | 44.83% |

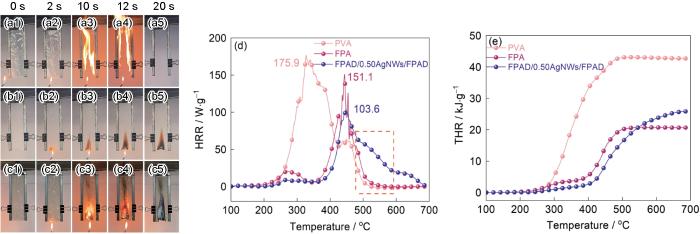

2.4 FPAD/nAgNWs/FPAD薄膜的燃烧性能

如图8a1~a5所示,PVA薄膜接触火焰后迅速点燃,在12 s内完全燃烧,表现出极强的可燃性。但是,正如图8b1~b5所示,FPA薄膜接触火焰后在10 s内燃烧,一旦火源移除立即熄灭,薄膜表面迅速形成炭化层,根据UL-94阻燃测试标准,达到V-0等级。其原因是,阻燃剂APP使FPA薄膜具有较高的阻燃性能。图8c1~c5给出了FPAD/0.50AgNWs/FPAD薄膜的燃烧行为。可以看出,薄膜在约10 s燃烧,火焰移除后部分火苗向上引燃。其原因是,PDMS单体有一定的助燃性能,但是最终仍表现出自熄性能。这个结果表明,FPAD/0.50AgNWs/FPAD薄膜的阻燃等级达到V-0级。本文根据最大热量释放速率(pHRR)和总热释放量(THR)评估了薄膜的火灾安全性能,数据列于表4。结果表明,PVA薄膜的pHRR为175.9 W/g,THR为42.7 kJ/g。APP的加入使FPA薄膜的pHRR和THR分别降低到151.1 W/g和20.7 kJ/g,且其对PVA裂解的抑制使达到pHRR的温度从约224.5 ℃提高到339.0 ℃。同样地,PDMS和AgNWs的引入进一步使薄膜的pHRR值降低到103.6 W/g,但是THR却增大到25.8 kJ/g。从图8a、d可见,FPAD/0.50AgNWs/FPAD薄膜的燃烧过程发生了显著变化,是PDMS的低闪点和燃烧时释放大量热能所致[25]。这表明,尽管PDMS的引入降低了薄膜的pHRR值,但其THR的增大使复合薄膜的阻燃性能比FPA薄膜有所降低。以上结果表明,FPAD/0.50AgNWs/FPAD薄膜的火灾安全性较高。

图8

图8

PVA、FPA和FPAD/0.5AgNWs/FPAD的垂直燃烧图像,以及HRR和THR曲线

Fig.8

Vertical combustion test results for PVA (a1-a5), FPA (b1-b5), and FPAD/0.5AgNWs/FPAD (c1-c5), respectively, and HRR (d) and THR (e) curves of PVA, FPA, FPAD/0.50AgNWs/FPAD

表4 薄膜样品的UL-94评级和MCC数据

Table 4

| Samples | UL-94 | Melt dripping | pHRR / W·g-1 | THR / kJ·g-1 | Tempreture / oC |

|---|---|---|---|---|---|

| PVA | NR | Y/Y | 175.9 | 42.7 | 224.5 |

| FPA | V-0 | N/N | 151.1 | 20.7 | 339.0 |

| FPAD/0.50AgNWs/FPAD | V-0 | N/N | 103.6 | 25.8 | 341.5 |

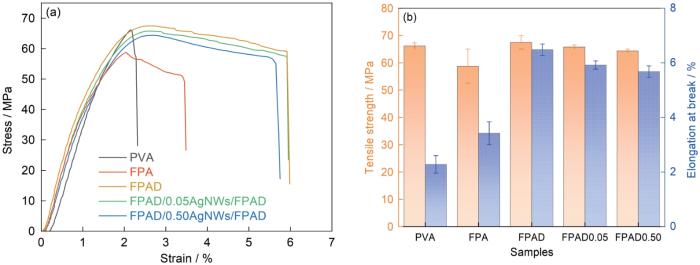

2.5 FPAD/nAgNWs/FPAD薄膜的机械性能和疏水性能

图9a、b给出了薄膜样品的拉伸应力-应变曲线和力学性能。可以看出,纯PVA的拉伸强度为(66.19 ± 1.17) MPa,断裂伸长率为2.2%。与PVA相比,FPA的拉伸强度明显降低,其主要原因是APP的引入破坏了PVA结构的完整性,使分子链间的相互作用减弱[26]。但是,FPA的断裂伸长率提高了66.7%。其原因是,PVA中的-OH与APP中的-NH4+之间形成的氢键具有增塑剂的作用,使PVA分子链更加柔韧,更易滑移和伸展。与FPA相比,FPAD薄膜的拉伸强度有所提高,因为PDMS在FPA薄膜的表面或表层区域形成了缠结或交联结构,产生了类似复合材料的特性[27]。这种缠结有助于分散材料受到的应力,从而使其拉伸强度提高。同时,FPAD薄膜的断裂伸长率也显著高于PVA和FPA。其原因是,PDMS单体的低表面能和高分子链的灵活性使其在渗透到FPA薄膜中起类似增塑剂的作用。这种类似增塑剂提高了PVA分子链的自由度,从而提高了材料的韧性和断裂伸长率。随着AgNWs含量的提高,FPAD/nAgNWs/FPAD薄膜的拉伸强度和断裂伸长率略有下降。其原因是,夹层结构中的AgNWs发生了滑移[28]。虽然AgNWs降低了材料的力学强度,但是FPAD的延展性仍然占主导地位。总之,只有厚度为0.05~0.06 mm的FPAD/nAgNWs/FPAD薄膜才具有优异的力学性能。

图9

图9

PVA、FPA、FPAD、FPAD/0.05AgNWs/FPAD和FPAD/0.50AgNWs/FPAD薄膜的拉伸应力-应变曲线以及对应的拉伸强度和断裂伸长率

Fig.9

Tensile stress-strain curves (a) and tensile strength and elongation at break (b) of PVA, FPA, FPAD, FPAD/0.05AgNWs/FPAD and FPAD/0.50AgNWs/FPAD films

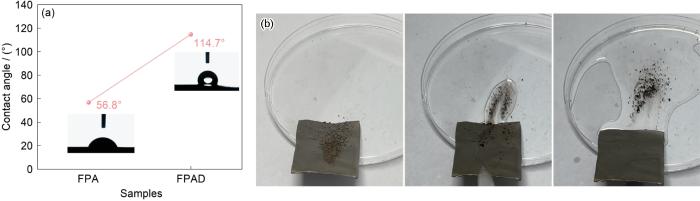

复合薄膜应用在柔性电子器件和可穿戴等设备中,对其防水防潮性的要求较高。但是,PVA较强的亲水性容易吸湿并与水分子发生作用而使外层FPA受损。一旦FPA层受到破坏,夹层中的AgNWs就会氧化进而降低其导电性以及相关性能的稳定性。对薄膜进行PDMS封装处理,可显著降低PVA的吸湿能力且使其具有自清洁性能(图10b)。图10a表明,FPA复合膜的水滴接触角约为56.8°(小于90°),表明其表面具有亲水性;而FPAD薄膜的水滴接触角约为114.7°(大于90°),表明其表面具有疏水性。薄膜的自清洁过程如图10b所示。将污染物撒在样品表面,水滴将在污染物处聚集,随着水滴的增加污染物被带走,使薄膜干净和干燥[21]。这表明,PDMS封装使FPA薄膜具有疏水性能,从而延长其使用寿命和保持其在潮湿环境中性能的稳定。

图10

图10

PDMS处理对FPA薄膜接触角的影响和FPAD/0.50AgNWs/FPAD薄膜的自洁性能

Fig.10

Effect of PDMS treatment on the contact angle of FPA film before and after treatment (a) and self-cleaning experiment of FPAD/0.50AgNWs/FPAD film (b)

3 结论

(1) 采用刮涂和喷涂技术可制备一种功能可调控的三明治结构FPAD/nAgNWs/FPAD复合薄膜。调控薄膜外层的三明治结构可使其具有优异的阻燃性能、良好的机械性能和疏水性,改变内层银纳米线(AgNWs)的负载量可调控其EMI屏蔽性能。

(2) 这种复合薄膜具有优异的柔韧性和疏水性,弯折后和暴露在乙醇和水等环境中,仍保持其优异的电磁屏蔽性能,表明其具有良好的稳定性。这种薄膜还具有自熄性能,阻燃等级为V-0级。

参考文献

Heterointerface construction for permalloy microparticles through the surface modification of bilayer metallic organic frameworks: Toward microwave absorption enhancement

[J].

Recent advances in design strategies and multifunctionality of flexible electromagnetic interference shielding materials

[J].With rapid development of 5G communication technologies, electromagnetic interference (EMI) shielding for electronic devices has become an urgent demand in recent years, where the development of corresponding EMI shielding materials against detrimental electromagnetic radiation plays an essential role. Meanwhile, the EMI shielding materials with high flexibility and functional integrity are highly demanded for emerging shielding applications. Hitherto, a variety of flexible EMI shielding materials with lightweight and multifunctionalities have been developed. In this review, we not only introduce the recent development of flexible EMI shielding materials, but also elaborate the EMI shielding mechanisms and the index for "green EMI shielding" performance. In addition, the construction strategies for sophisticated multifunctionalities of flexible shielding materials are summarized. Finally, we propose several possible research directions for flexible EMI shielding materials in near future, which could be inspirational to the fast-growing next-generation flexible electronic devices with reliable and multipurpose protections as offered by EMI shielding materials.© 2022. The Author(s).

Controlled distributed Ti3C2T x hollow microspheres on thermally conductive polyimide composite films for excellent electromagnetic interference shielding

[J].

Leather solid waste/poly (vinyl alcohol)/polyaniline aerogel with mechanical robustness, flame retardancy, and enhanced electromagnetic interference shielding

[J].

Exceptionally flame retardant and electromagnetic interference shielding aramid nanofiber-Ti3C2T x MXene twin-layered films with remarkable mechanical strength and flexibility

[J].

A biomimetic closed-loop recyclable, long-term durable, extreme-condition resistant, flame-retardant nanocoating synthesized by reversible flocculation assembly

[J].

Toward high efficiency thermally conductive and electrically insulating pathways through uniformly dispersed and highly oriented graphites close-packed with SiC

[J].

Flame-retardant poly (vinyl alcohol)/MXene multilayered films with outstanding electromagnetic interference shielding and thermal conductive performances

[J].

Research progress of electrospinning flame retardant nanofiber

[J].

静电纺丝阻燃纳米纤维的研究进展

[J].

Janus (BNNS/ANF)-(AgNWs/ANF) thermal conductivity composite films with superior electromagnetic interference shielding and Joule heating performances

[J].

A multifunctional flexible composite film with excellent multi-source driven thermal management, electromagnetic interference shielding, and fire safety performance, inspired by a “Brick-Mortar” sandwich structure

[J].

Flexible sandwich-structured silver nanowire/exfoliated graphite platelet/aramid nanofiber composite films with excellent EMI shielding, thermal conduction and Joule heating performances

[J].

Ultrastrong and hydrophobic sandwich-structured MXene-based composite films for high-efficiency electromagnetic interference shielding

[J].

Hollow engineering of sandwich NC@Co/NC@MnO2 composites toward strong wideband electromagnetic wave attenuation

[J].

Preparation and performance of PVA/APP modified lithium battery separators

[J].

聚乙烯醇/聚磷酸铵改性锂电隔膜的制备与性能

[J].

Flexible, hydrophobic, and robust composite films with sandwich structure for electromagnetic interference shielding and Joule heating

[J].

Preparation and performance of multifunctional thermoplastic polyurethane composite fiber membrane

[D].

多功能热塑性聚氨酯复合纤维膜的制备及性能研究

[D].

Preparation and performance study of leakage-proof polyurethane prosthetic shell material

[D].

防渗型聚氨酯假体外壳材料的制备及性能研究

[D].

Preparation of superhydrophobic/superoleophilic functional paper and its application in oil-water separation

[D].

超疏水/超亲油功能纸的制备及在油水分离中的应用

[D].

Synthesis and application of a pH-responsive amino acid acidizing foaming agent

[J].

一种pH响应性氨基酸酸液起泡剂的合成与应用

[J].

Preparation of flexible carbon fiber fabrics with adjustable surface wettability for high-efficiency electromagnetic interference shielding

[J].

Coaxial electrospinning synthesis of size-tunable CuO/NiO hollow heterostructured nanofibers: Towards detection of glucose level in human serum

[J].

Advances in waterborne polymer/carbon material composites for electromagnetic interference shielding

[J].

High-performance flame-retardant polycarbonate composites: Mechanisms investigation and fire-safety evaluation systems establishment

[J].

Preparation and study for flame retardant PVA packaging film

[D].

阻燃型聚乙烯醇(PVA)包装薄膜的制备与研究

[D].

Ultrathin flexible graphene film: an excellent thermal conducting material with efficient EMI shielding

[J].

Research on flame retardant and smoke suppression properties and mechanism of modified ammonium polyphosphate in epoxy resin

[D].

改性聚磷酸铵在环氧树脂中的阻燃抑烟性能及机理研究

[D].

Nacre-inspired tunable electromagnetic interference shielding sandwich films with superior mechanical and fire-resistant protective performance

[J].