含有铀、钚以及裂变产物的乏燃料,是在核电站运行过程中产生的有害物质。乏燃料污染环境,因此必须处理。转轮是后处理设备中溶解乏燃料的关键焊接结构件。转轮长期服役在高温、浓硝酸和乏燃料溶解后释放的氧化性离子环境中,因此对转轮材料及其焊缝金属的耐蚀性能要求极高 [1]。

奥氏体不锈钢是建设核电站使用的主要耐蚀材料,提高奥氏体不锈钢中的Si含量,可解决其晶间腐蚀问题[2~6]。耐腐蚀性能优异的高SiN奥氏体不锈钢,是处理乏燃料设备使用的结构材料[7~10]。焊接奥氏体不锈钢时易出现热裂纹,因此须调整焊材的成分使焊缝组织中有适量的δ-铁素体。P、S、Si、Nb等元素在δ-铁素体中的溶解度较大,能防止其在焊缝凝固过程中生成低熔点共晶相和阻止裂纹的产生。但是,含量过高的δ-铁素体又会降低焊缝的耐蚀性能。柳剑等[11]根据第一性原理计算出铁素体的晶胞总能量比奥氏体的低且能带宽度较大,使铁素体的稳定性和抗腐蚀性能降低。Guo等[12]用原位AFM测量了盐酸溶液中双相不锈钢2507中铁素体的腐蚀速率,发现其比奥氏体的高。Antony等[13]认为,双相不锈钢中奥氏体和铁素体的分布以及合金元素的分配对其耐蚀性的影响很大。以上研究表明,δ-铁素体是高SiN奥氏体不锈钢焊材焊缝金属中的关键相,不仅影响奥氏体钢焊缝金属的抗裂性能,还影响其耐硝酸腐蚀性能。本文设计并制备不同δ-铁素体含量的焊缝金属,研究δ-铁素体含量对其抗热裂纹敏感性的影响以确定δ-铁素体含量范围,在此基础上研究δ-铁素体含量和腐蚀时间对焊缝金属耐蚀性能的影响。

1 实验方法

1.1 制备焊缝熔敷金属材料

表1 焊丝的化学成分

Table 1

| No. | C | Cr | Ni | Mo | Mn | Si | N | Nb | Fe |

|---|---|---|---|---|---|---|---|---|---|

| 1δ | 0.01 | 19.4 | 15.8 | 0.02 | 1 | 4.2 | 0.1 | 0.02 | Bal. |

| 2δ | 19.4 | 15.8 | 0.02 | 0.5 | 4.2 | 0.1 | 0.02 | ||

| 7δ | 20.0 | 16.0 | 0.7 | 1.5 | 4.0 | 0.08 | 0.1 | ||

| 8δ | 20.0 | 16.0 | 0.3 | 1.5 | 4.0 | 0.035 | 0.1 | ||

| 10δ | 20.0 | 16.0 | 0.3 | 1.5 | 4.5 | 0.06 | 0.02 |

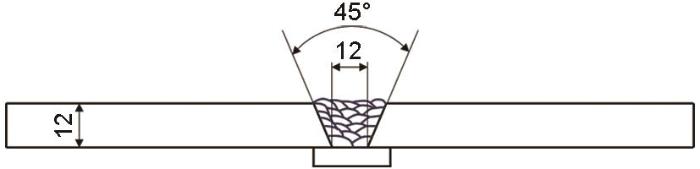

实验用母材是高SiN奥氏体不锈钢板,尺寸为350 mm × 80 mm × 12 mm。沿母材较长的一边加工出角度为22.5°的单V型坡口。为了防止钢板焊接变形,在坡口底部装配垫板并进行反变形处理。焊接工艺参数为:电流:180 A;电压:14~15 V;焊接速度为0.1 m/min;送丝速度为1 m/min;保护气体为99.999%氩气,气体流速为20 L/min。为了保证焊接质量,焊前清理待焊坡口及周边50 mm范围的母材表面以去除锈迹、油污等杂质。为了降低焊缝金属的热裂倾向,使焊缝的层间温度低于50 ℃。每完成一道焊接即用钢刷清理焊缝表面的氧化层,再进行下一道的焊接。图1给出了熔敷金属焊接时坡口的形式和尺寸示意图。

图1

图1

焊缝熔敷金属试样坡口的形式及其尺寸示意图(单位:mm)

Fig.1

Schematic diagram of groove form and size of weld deposit metal (units: mm)

焊缝熔敷金属材料的化学成分及其δ-铁素体含量列于表2,用铁素体仪(型号:SP10a)测量其δ-铁素体含量。

表2 δ-铁素体含量不同的焊缝熔敷金属的化学成分

Table 2

| No. | C | Cr | Ni | Mo | Mn | Si | N | Nb | Fe | δ content |

|---|---|---|---|---|---|---|---|---|---|---|

| 1δ | 0.0033 | 19.34 | 15.6 | 0.031 | 1.01 | 4.12 | 0.100 | 0.007 | Bal. | 1.3 |

| 2δ | 0.0023 | 19.33 | 15.6 | 0.026 | 0.56 | 4.12 | 0.100 | 0.007 | 1.7 | |

| 7δ | 0.0082 | 19.95 | 16.0 | 0.67 | 1.41 | 4.02 | 0.074 | 0.10 | 7.1 | |

| 8δ | 0.0044 | 19.80 | 16.1 | 0.30 | 1.50 | 3.95 | 0.036 | 0.084 | 8.2 | |

| 10δ | 0.0078 | 19.68 | 15.5 | 0.31 | 1.46 | 4.27 | 0.051 | 0.005 | 9.7 |

1.2 评价热裂纹的敏感性

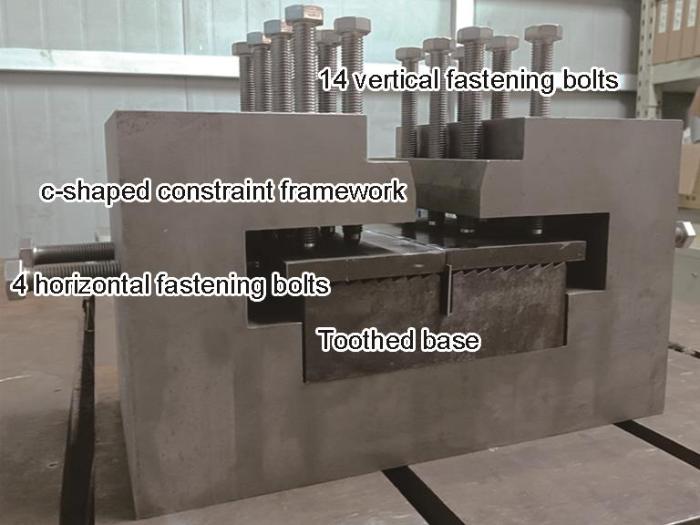

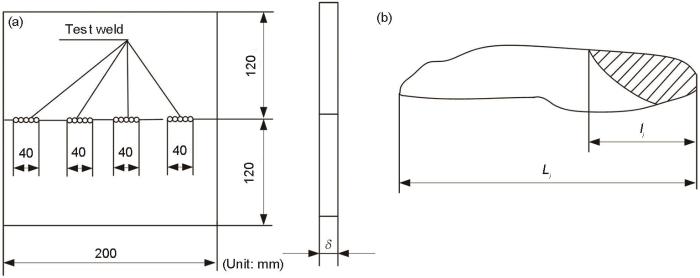

使用表1中编号为1δ、2δ和7δ的3种焊材,研究δ-铁素体含量对焊缝热裂纹敏感性的影响。依据GB/T 4675.4[15],进行压板对接焊接裂纹实验(FISCO实验),以评价3种焊材的热裂纹敏感性。母材为高SiN奥氏体不锈钢板,尺寸为200 mm × 120 mm × 12 mm。采用对接焊接,坡口的形状为I形。焊接前对钢板的待焊部位进行机械打磨以清理表面的铁锈和氧化层,再用丙酮和酒精清洗去除油污。FISCO实验装置如图2所示。将两块钢板放在齿形底座上,在坡口处插入特定尺寸的定位塞片以保证坡口间隙为1.5 mm。先将水平方向的螺栓紧固(共4个)顶住钢板,使坡口间隙不变以固定钢板的位置。然后用测力扳手将垂直方向的螺栓(共14个)紧固,给钢板施加垂直向下的作用力以防止焊接时钢板翘曲,测力扳手的扭矩为120 N·m。将钢板固定后进行焊接,焊接工艺参数为:电流:180 A;焊接速度:0.1 m/min;保护气体:99.999%氩气,气体流速:20 L/min。沿坡口依次进行四道次焊接,单道焊缝的长度约为40 mm,焊缝间距为10 mm,焊缝尾部的弧坑不填满,钢板的尺寸和焊接示意图如图3a所示。待焊件冷却至室温后将其取出,肉眼检查焊缝表面的裂纹情况。最后,使用折弯机将焊件沿焊缝方向弯断,观察断面裂纹并测量裂纹的长度,裂纹的示意图如图3b所示。裂纹率为

式中∑li 为4条焊缝裂纹的总长度(mm);∑Li 为4条焊缝的总长度(mm)。

图2

图3

1.3 浸泡腐蚀实验

使用电火花线切割机从熔敷金属试样横截面的中心取样,取样方向与焊接方向平行。将试样研磨抛光后用稀释王水溶液(盐酸∶硝酸∶水的体积比为3∶1∶4)腐蚀试样的表面,腐蚀时间为10~30 s。用金相显微镜(OM, Zeiss AXIO LabA1)观察δ-铁素体含量不同的焊缝熔敷金属试样的微观组织,用电子探针显微镜(EPMA, JXA-IHP200F)测量其组织的成分。

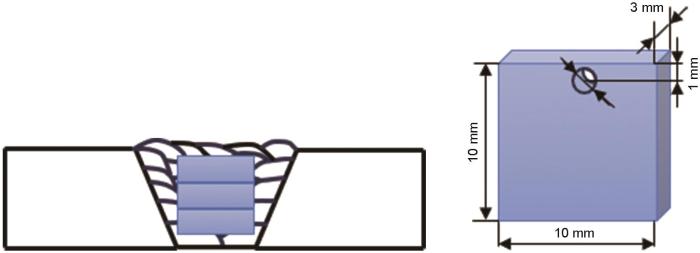

依据JB/T 7901-1999《金属材料实验室均匀腐蚀全浸试验方法》进行焊缝熔敷金属的浸泡腐蚀实验。用电火花切割机沿焊缝的纵向取样,每种焊缝金属取3个尺寸为10 mm × 10 mm × 3 mm的平行试样(图4)。用2000#砂纸将试样表面磨光后放入(球形瓶中)温度为95 ℃的6 mol/L硝酸溶液中分别连续浸泡240、480和720 h,在硝酸溶液中额外加入一定浓度的氧化性阳离子(1.70 g/L V5+、0.125 g/L Cr6+、2.06 g/L Ce4+),以模拟乏燃料的腐蚀环境。为了保证腐蚀实验的可靠性,硝酸溶液的体积与试样表面积之比大于20 mL/cm2。用SARTORIUS AG电子分析天平(精度0.1 mg)测量实验前后试样的质量,用质量损失法评估焊缝熔敷金属的平均腐蚀速率。用SUPRA 35扫描电子显微镜(SEM)观察腐蚀后试样表面的形貌。

图4

图4

腐蚀试样的取样位置及其尺寸示意图

Fig.4

Schematic diagram of sampling location and size of corrosion samples

2 结果和讨论

2.1 δ-铁素体含量对焊缝抗热裂纹敏感性的影响

图5

图5

FISCO实验后焊板表面的宏观形貌

Fig.5

Photos of the welded plate surface after FISCO test (a) 1δ, (b) 7δ

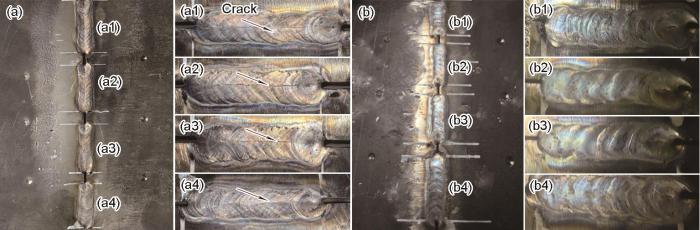

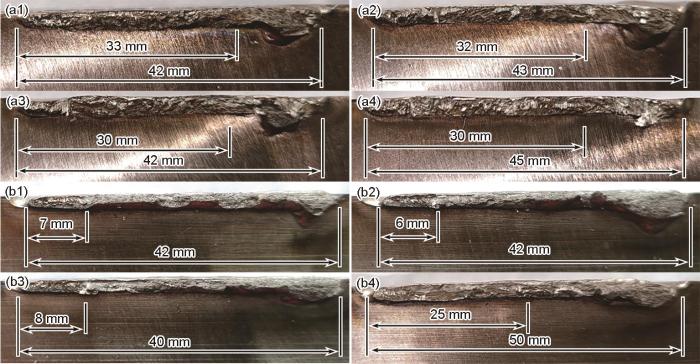

将焊板沿着焊缝的焊接方向弯断,以观察焊缝内的热裂纹。图6给出了焊缝的纵截面照片。焊接热裂纹在凝固末期产生,折弯时产生热裂纹的部位是起裂处。同时,在凝固末期热裂纹区域表面氧化成黄褐色,而未产生裂纹因折弯而断裂的部位其颜色则为金属的亮白色。用肉眼分辨两者后,即可测量出焊缝的热裂纹长度。结果表明,随着δ-铁素体含量的提高热裂纹的长度减小。可用

图6

图6

1δ和7δ试样焊缝纵截面的宏观形貌

Fig.6

Macroscopic appearance of weld seam cross-section (a1-a4) 1δ, (b1-b4) 7δ

表3 FISCO实验后焊缝金属的裂纹长度、焊缝长度和裂纹率

Table 3

| No. | Crack length / mm | Weld seam length / mm | Crack rate / % |

|---|---|---|---|

| 1δ | 125 | 172 | 72.7 |

| 2δ | 68 | 178 | 38.2 |

| 7δ | 46 | 174 | 26.4 |

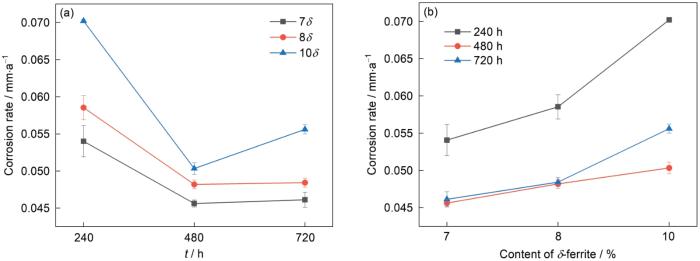

2.2 δ-铁素体含量对焊缝熔敷金属耐蚀性的影响

图7

图7

不同δ-铁素体含量的熔敷金属的微观组织

Fig.7

Microstructure of deposited metals with varying δ- ferrite contents (a) 7δ, (b) 8δ, (c) 10δ

图8

图8

不同熔敷金属的腐蚀速率及其与时间的关系

Fig.8

Corrosion rate of different deposited metals (a) and variation of corrosion rate with time (b)

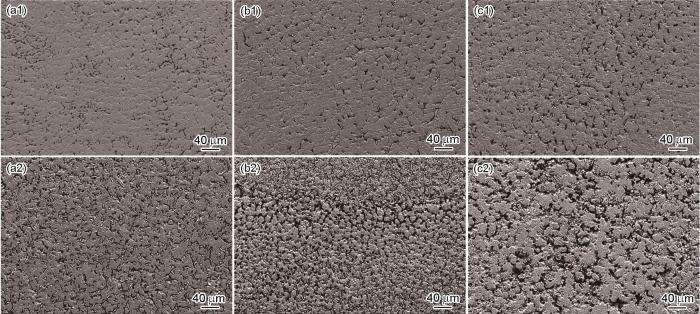

图9给出了3种δ-铁素体含量的焊缝金属腐蚀10 d和30 d后的表面形貌。可以看出,在腐蚀时间相同的条件下,随着δ-铁素体含量的提高表面的腐蚀程度随之严重。随着腐蚀时间的增加,3种δ-铁素体含量的焊缝金属其表面的腐蚀都较为严重,其中10δ焊缝金属表面的坑洞明显比另外两种焊缝金属的大。

图9

图9

不同δ-铁素体含量的焊缝金属腐蚀10 d和30 d后的表面形貌

Fig.9

Surface corrosion morphology of weld metal with different δ-ferrite contents after 10 d (a1-c1) and 30 d (a2-c2) (a1, a2) 7δ, (b1, b2) 8δ, (c1, c2) 10δ

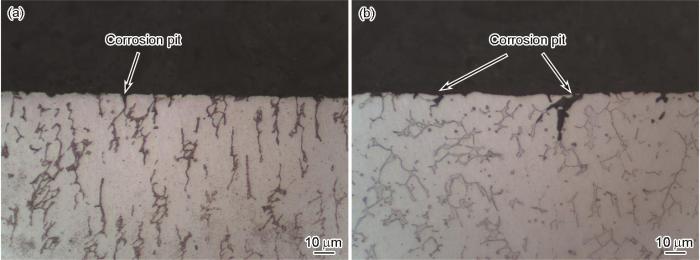

腐蚀10 d试样的表面形貌,如图10所示。可以看出,所有试样表面的腐蚀坑均发生在δ-铁素体上,可见焊缝金属的耐蚀性与δ-铁素体有较大的关系。

图10

图10

腐蚀坑处的高倍微观形貌

Fig.10

Microscopic morphology of corroded pits at high magnification (a) 7δ, (b) 8δ, (c) 10δ

图11

图11

腐蚀试样的纵截面形貌

Fig.11

Transverse section morphology of corroded sample (a) 8δ, (b) 10δ

从图10和11可见,奥氏体表面只发生了速率较低的均匀腐蚀,而δ-铁素体发生的溶解和深入腐蚀则使熔敷金属的整体腐蚀速率提高。用EPMA测量了不同熔敷金属中不同相的元素含量,结果列于表4。在腐蚀初期,在金属表面生成一层钝化膜避免了腐蚀的加剧。在奥氏体不锈钢表面生成的氧化铬钝化膜,只在钝化区有保护作用。当硝酸浓度和温度提高且腐蚀溶液中含有氧化性离子时,不锈钢的腐蚀电位随之提高极易使金属过钝化[17]。在不锈钢的过钝化区三价铬氧化成溶于硝酸的四价铬[18,19],使钝化膜失效。从表4可以看出,δ-铁素体与奥氏体的相组成有较大的不同。δ-铁素体富含Cr、Mo、Si元素而贫Ni,奥氏体则恰好相反。正是这种差异使材料中的δ-铁素体优先腐蚀。Cr、Mo元素在含有氧化性离子的高温浓硝酸中易发生过钝化而使元素高价放电[20],使δ-铁素体与奥氏体的电位产生较大的差异而形成了原电池。在熔敷金属中δ-铁素体属于含量较低的少数相。因此,原电池构成了更为严重的“小阳极大阴极”腐蚀回路,使腐蚀更容易在δ-铁素体处向材料内部深入,产生危害更大的局部腐蚀。另外,奥氏体中Ni元素的含量比δ-铁素体中的高,而Ni元素能降低钝化膜的溶解速率[21],因此奥氏体的腐蚀速率低于δ-铁素体。上述两个因素的共同作用,使δ-铁素体的腐蚀优先发生。这表明,δ-铁素体使焊缝金属在强氧化性环境中的耐腐蚀性能降低。

表4 不同δ-铁素体含量的熔敷金属中铁素体和奥氏体的占比以及元素成分

Table 4

| No. | Phase | Composition / % | ||||||

|---|---|---|---|---|---|---|---|---|

| Cr | Ni | Fe | Si | Mn | Mo | N | ||

| 7δ | FCC | 19.12 | 16.90 | 57.72 | 3.91 | 1.52 | 0.69 | 0.07 |

| BCC | 23.62 | 11.13 | 58.45 | 4.54 | 1.04 | 0.99 | 0.04 | |

| 8δ | FCC | 19.55 | 16.62 | 58.46 | 3.48 | 1.57 | 0.20 | 0.04 |

| BCC | 24.74 | 10.61 | 58.50 | 4.39 | 1.06 | 0.44 | 0.02 | |

| 10δ | FCC | 19.24 | 16.63 | 58.07 | 4.24 | 1.50 | 0.26 | 0.05 |

| BCC | 24.15 | 10.54 | 58.92 | 4.93 | 0.99 | 0.44 | 0.03 | |

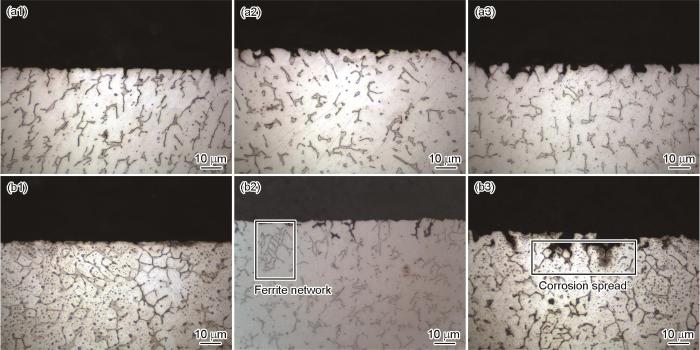

如图8b所示,3种焊缝金属腐蚀10 d的腐蚀速率远高于后期的腐蚀速率。其原因是,在腐蚀的初期金属表面的钝化膜尚未生成,焊缝金属的质量损失过大。随着腐蚀的进行,在7δ和8δ试样表面逐渐生成钝化膜,使腐蚀速率逐渐降低并趋于稳定,如图8b所示。但是10δ试样的情况异常,与腐蚀20 d相比,腐蚀30 d后其腐蚀速率提高。图12给出了8δ和10δ试样腐蚀不同时间后纵截面的金相照片。可以看出,随着腐蚀时间的延长试样表面的腐蚀严重,沿着δ-铁素体方向的腐蚀更深,但是奥氏体组织的腐蚀仍然较轻。8δ试样的腐蚀情况表明,熔敷金属内的δ-铁素体均匀分布,随着腐蚀时间的延长腐蚀表面始终有残存的δ-铁素体,表明熔敷金属整体的腐蚀速率在30 d后达到了平衡。对于δ-铁素体含量过高(如10δ试样)的试样,大量的δ-铁素体在熔敷金属内形成铁素体网,如图12b2所示。可以看出,一方面铁素体分割了奥氏体组织和细化了晶粒,使焊缝不易开裂,但是腐蚀极易在熔敷金属内部沿着铁素体网蔓延而增大了铁素体的暴露面积,也使腐蚀30 d后的腐蚀速率稍有提高。

图12

图12

8δ和10δ试样腐蚀不同时间后纵截面的金相照片

Fig.12

Metallographic photographs of longitudinal sections of 8δ (a1-a3) and 10δ (b1-b3) specimens after corrosion for 10 d (a1, b1), 20 d (a2, b2), and 30 d (a3, b3)

3 结论

(1) δ-铁素体含量的提高使高SiN奥氏体不锈钢焊缝金属的热裂纹敏感性降低,含量为7%的δ-铁素体使热裂纹敏感性显著降低。

(2) 在含有氧化性阳离子的高温浓硝酸环境中,由于δ-铁素体富含Cr元素,会与奥氏体形成“小阳极大阴极”腐蚀回路,再加之贫Ni,导致δ-铁素体比奥氏体基体更易腐蚀。

(3) 随着腐蚀时间的延长,δ-铁素体含量不同的焊缝金属的腐蚀速率都降低并趋于稳定,含量达到10%的δ-铁素体其腐蚀极易沿着铁素体网蔓延并使腐蚀速率稍有提高。

参考文献

19 - Corrosion issues in nuclear fuel reprocessing plants

[A].

Materials development and corrosion problems in nuclear fuel reprocessing plants

[J].

Corrosion resistance of silicon-containing austenitic stainless steel in boiling nitric acid containing Ru n +

[J].

硅对含强氧化性离子沸腾硝酸中奥氏体不锈钢耐蚀性的影响

[J].

Corrosion behavior of Fe-Mn-Si-Cr-Ni-Co shape memory stainless steel in highly oxidizing medium

[J].

Dissolution and passivation of a silicon-rich austenitic stainless steel during active-passive cycles in sulfuric and nitric acid

[J].

Correlation between composition of passive layer and corrosion behavior of high Si-containing austenitic stainless steels in nitric acid

[J].

2 - Overview of nuclear materials and nuclear corrosion science and engineering

[A].

8 - Corrosion behavior of stainless steels in nitric acid in the context of nuclear fuel reprocessing plants

[A].

Dependence of corrosion resistance on grain boundary characteristics in a high nitrogen CrMn austenitic stainless steel

[J].Processing schedules for grain boundary engineering involving different types of cold deformation (tension, compression, and rolling) and annealing were designed and carried out for 18Mn18Cr0.6N high nitrogen austenitic stainless steel. The grain boundary characteristic distribution was obtained and characterized by electron backscatter diffraction (EBSD) analysis. The corrosion resistance of the specimens with different grain boundary characteristic distribution was examined by using potentiodynamic polarization test. The corrosion behavior of different types of boundaries after sensitization was also studied. The fraction of low-Σ boundaries decreased with increasing strain, and it was insensitive to the type of cold deformation when the engineering strain was lower than 20%. At the strain of 30%, the largest and smallest fractions of low-Σ boundaries were achieved in cold-tensioned and rolled specimens, respectively. The fraction of low-Σ boundaries increased exponentially with the increase of grain size. The proportion of low-angle grain boundaries increased with decreasing grain size. Increasing the fraction of low-Σ boundaries could improve the pitting corrosion resistance for the steels with the same grain size. After sensitization, the relative corrosion resistances of low-angle grain boundaries, Σ3 boundaries, and Σ9 boundaries were 100%, 95%, and 25%, respectively, while Σ27 boundaries, other low-Σ boundaries and random high-angle grain boundaries had no resistance to corrosion.

Corrosion assessment of nitric acid grade austenitic stainless steels

[J].

Influence of crystall structure on corrosion resistance of 316 stainless steel by first-principles calculation

[J].

晶体结构对316不锈钢腐蚀影响的第一性原理研究

[J].

Effect of annealing temperature on the corrosion behavior of duplex stainless steel studied by in situ techniques

[J].

Influence of thermal aging on sulfate-reducing bacteria (SRB)-influenced corrosion behaviour of 2205 duplex stainless steel

[J].

Corrosion mechanisms of austenitic stainless steels in nitric media used in reprocessing plants

[J].

Microstructural development and solidification cracking susceptibility of austenitic stainless steel welds

[J].

Corrosion control in nuclear fuel reprocessing

[J].

Electrochemical behavior of Cr2O3/Fe2O3 artificial passive films studied by in situ XANES

[J].

Effect of chemical species in spent nuclear fuel reprocessing solution on corrosion of austenitic stainless steel

[J].

Study on preferential dissolution of duplex weldments of stainless steels

[J].

不锈钢双相焊缝选择性腐蚀研究

[J].采用动电位扫描,恒电位浸蚀以及金相检测等方法,研究了不锈钢双相组织在酸性介质中发生选择性腐蚀的机理。研究发现,选择性腐蚀与体系所处的氧化-还原电位有关。在活化区的低电位段发生铁素体相的选择性腐蚀,较高电位段则发生奥氏体相的选择性腐蚀,两者之间存在一个两相腐蚀区;在过钝化区和近过钝化区,腐蚀优先发生在铁素体相上,然后向奥氏体相扩展。

X‐Ray photoelectron spectroscopy and scanning tunneling microscopy study of passive films formed on (100) Fe‐18Cr‐13Ni single‐crystal surfaces

[J].