材料的流动软化,能显著降低变形抗力、细化晶粒以及提高力学性能,对其机制的研究已成为热点。Xu等[3]研究了具有片层组织的Ti-17合金在热变形过程中的流动软化,发现片状α相的分离和球化影响流动软化。Wan等[4]根据流动应力曲线和微观组织研究了Fe-8.5Mn-1.5Al中锰钢的流动软化和再结晶机理,认为DRV和DRX是主要的软化机制。Zhang等[5]研究发现,高应变速率的变形热效应和流动失稳导致流动软化。与流动软化的机制相比,应变硬化的机制更加复杂。Won等[6]研究发现,随着变形温度从298 K降至100K纯Ti的拉伸应变硬化显著增大,延展性大大提高,棱柱状<a>滑移的激活和在100 K下显著增大的临界分切应力是其主要的硬化机制。Chen等[7]定量描述了析出物与位错的交互作用以及位错密度在变形过程中的演化,发现影响其应变硬化的机制是析出物。Madivala等[8]研究了高锰奥氏体孪生诱发塑性(TWIP)钢在123~773 K温度范围内的应变硬化,发现孪生和应变诱发的ε-马氏体相变是其应变硬化机制。目前对9310钢的研究主要集中在渗碳工艺和表面处理[9,10]。虽然有学者研究了这种钢的热变形,但是多数研究都是关于热变形过程中的本构方程[11,12]。本文进行9310钢的等温热压缩实验,根据其应力-应变曲线定量计算流动软化和应变硬化,根据应变硬化率θ和应变速率敏感性指数m分析流动软化和应变硬化,根据微观组织演变揭示其流动软化和应变硬化的机制。

1 实验方法

表1 9310钢的成分

Table 1

| C | Si | Mn | P | S | Ni | Cr | Mo | O | N | B | Cu |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.11 | 0.22 | 0.61 | 0.001 | 0.000 4 | 3.19 | 1.30 | 0.11 | 0.000 6 | 0.000 9 | 0.001 | 0.02 |

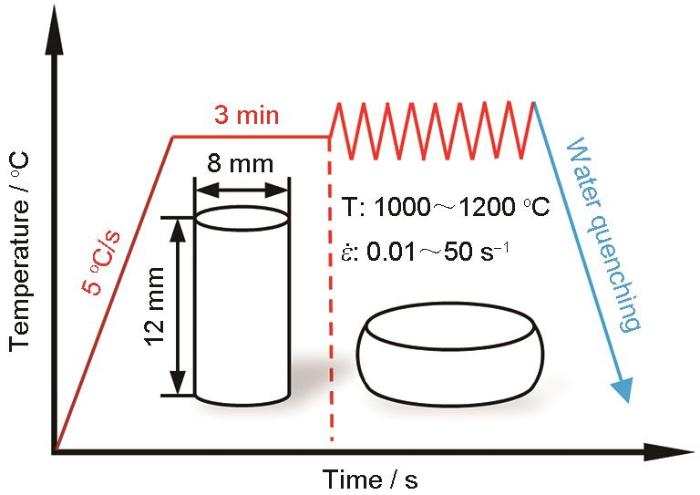

图1

图1

9310钢的热压缩实验参数

Fig.1

Schematic diagram of the parameters of 9310 steel hot compression experiment

将压缩后的9310钢试样沿压缩方向的轴线将其线切割对半剖开。将一半镶嵌后打磨抛光制成金相试样,用体积分数为4%的硝酸酒精溶液将抛光后的试样腐蚀,以得到水冷后的组织。将另一半试样水浴加热至60~70 ℃,再用饱和苦味酸+少量海鸥洗剂灵溶液腐蚀,以显示高温下的奥氏体晶界,然后用XJP-6A型光学显微镜观察其微观组织。

用D8ADVANCE型X射线衍射仪测试试样的XRD谱,扫描速率为10(°)/min,扫描范围(2θ)为20°~80°,Cu靶Kα射线,波长(λ)为0.15406 nm。将试样电解抛光后用装有Oxford Nordlys Max3 EBSD探头的ZEISS Sigma 500场发射扫描电子显微镜进行EBSD观察,步长为0.2 μm,加速电压为20 kV。

2 实验结果

2.1 原始试样的组织和物相

图2

图2

9310钢原始组织和XRD谱

Fig.2

Original microstructure and XRD pattern of 9310 steel (a) the original organization, (b) XRD patterns

2.2 9310钢的应力-应变曲线

应力-应变曲线是热变形过程中流动软化与应变硬化协同竞争的体现。图3给出了在不同变形条件下9310钢的应力-应变曲线,从图3a,b可见,在温度不变的条件下,随着应变速率的提高应力峰变宽,表明在低应变速率下更容易发生流动软化。从图3c可见,在低应变速率0.01 s-1下变形时,在变形初期流动应力迅速增大至峰值,是形变产生的位错的扩散和堆积引起的应变硬化所致[14]。随着应变的增大,DRV (动态回复)和DRX (动态再结晶)引起的流动软化降低了位错密度,使流动应力显著降低。流动软化与应变硬化达到动态平衡时,曲线出现稳态。应变量增大到大约0.4,流动应力又增大。由图3d可见,高应变速率(10 s-1)变形时流动应力先迅速增大然后缓慢增大,因为DRV和DRX抵消了部分应变硬化。随着应变增至大约0.7,流动应力又缓慢减小。

图3

图3

9310钢的应力-应变曲线

Fig.3

Stress-strain curve of 9310 steel (a) 1000 oC, (b) 1100 oC, (c) 0.01 s-1, (d) 10 s-1

从图3还可以看出,9310钢在一定的温度变形,随着应变速率的提高流动应力增大。其原因是,应变速率的提高使位错增殖速率提高、变形时间缩短使DRV和DRX没有足够的时间,位错的湮灭速率远低于位错增殖速率,从而提高了位错密度和增大了流动应力[15]。在应变速率一定的条件下,随着变形温度的提高流动应力降低。其原因是:随着变形温度的提高原子的动能增大,使依赖原子间相互作用的临界剪切应力减小和点缺陷的扩散加快,使依赖于扩散的位错容易启动,从而减小了变形过程中产生的应变硬化[16,17]。另一方面,金属材料的变形是金属原子之间金属键的断裂和结合。变形温度越高则原子的能量越高,越容易挣脱金属键的束缚而使材料处于软化状态,从而使流动应力减小[18]。

2.3 流动软化和应变硬化

2.3.1 软化和硬化程度 可用

量化流动软化和应变硬化的程度。式中

使用

图4

图4

在不同变形条件下9310钢的软化和硬化

Fig.4

Softening and hardening of 9310 steel under different deformation conditions

2.3.2 应变硬化率 应变硬化率

是在一定应变速率和变形温度条件下钢应力-应变曲线的斜率[19],可用于分析应变硬化与流动软化之间的关系。

图5a给出了应变速率为0.01 s-1时应变硬化率(θ)与应变的关系。由图5a可见,随着应变的增大θ先迅速减小而后缓慢减小到0点以下,到达最低点后又增大到0点以上。这表明,变形开始发生弹塑性转变[20];在DRV的作用下位错发生滑动和攀移,使θ变缓减小;然后由亚结构排列形成的小角度晶界逐渐转变为大角度晶界,生成了DRX晶粒,使θ减小到0点以下(应变为0.1~0.2);随着变形的进行应变硬化逐渐增大,抵消了流动软化而使θ增大到0点以上(应变为0.2~0.4),应变硬化又占主导(应变大于0.4)。而产生应变硬化的机制,与位错、应变场以及晶体结构中障碍物的相互作用有关。例如,应变诱导相或孪晶界,这些障碍通过变形引入结构中并降低了位错迁移率[21]。图5b给出了应变速率为10 s-1时应变硬化率(θ)与应变的关系。如图5b所示,θ随着应变量的增大迅速减小后缓慢减小,在应变大于0.7后减小到负值。其原因是,在变形的初始阶段(应变小于0.1)螺型位错通过交叉滑移绕过障碍,位错的抵消使其密度降低而θ随之迅速减小。然后,在0.1~0.7应变范围内位错胞壁变长形成具有软化作用的亚晶界,应变硬化越来越弱使θ的减小变缓[22]。与低应变速率的微观机制不同,高应变率的DRV时间太短,不能限制边界迁移的时间而延迟了通过亚晶粒聚集和应变诱导边界迁移的DRX成核[23]。应变达到0.7后DRX晶粒开始长大,流动软化逐渐占据主导而使θ减小为负值。应变增大到0.7,流动软化才开始占据主导。应变硬化与应变软化之间持续的动态竞争,使应变为0.9~1.2时出现显著的波动。

图5

图5

不同应变速率的应变硬化率(θ)与应变的关系

Fig.5

Relationship curves between strain hardening rate (θ) and strain at different strain rates (a)

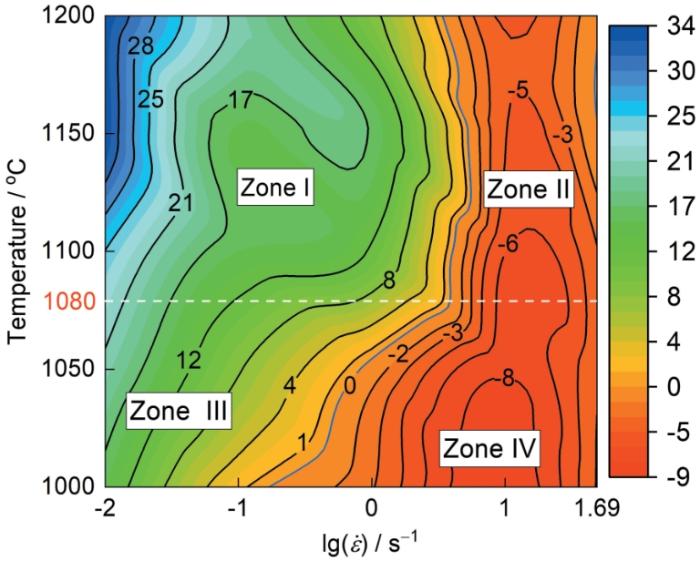

图6

图6

应变硬化率(θ)与温度和应变速率关系的等值线图

Fig.6

Contour plot of strain hardening rate (θ) as a function of temperature and strain rate (a)

2.3.3 应变速率敏感性指数

在不同条件下变形,其应变速率敏感性指数为[18]

式中

图7给出了应变速率敏感性指数m与应变和应变速率的关系。由图7a可以看出,变形温度为1150 ℃、应变速率分别为0.01、0.1、1 s-1时,随着应变的增大m值减小。其原因是,位错的增殖、累积和相互作用使应变硬化占主导。随着应变速率提高到10 s-1,变形热效应的增强抵消了部分应变硬化,使应变小于0.9时的m值保持稳定。应变大于0.9后,热软化引起的位错湮灭速率比位错增殖速率更低,位错密度的提高产生应力集中,材料的塑性流动能力降低而使m值显著降低[24]。随着应变速率的提高变形热效应进一步增强,应变速率达到50 s-1时流动软化超过了应变硬化而使m值缓慢增大。同时,变形热引起的晶粒长大使应变达到1.1时m值减小。总之,控制m值随应变变化的机制有:微观组织演变、与位错湮灭有关的流动软化以及位错积累和位错相互作用引起的应变硬化[25]。图7b给出了应变速率敏感性指数m与应变速率的关系。可以看出,随着应变速率的提高,m先增大后减小然后再增大。应变速率为0.01、0.1 s-1时变形时间较长,使材料的DRX时间足够长,在此变形条件下m值较大。应变速率达到1、10 s-1时变形时间缩短,位错不能及时消耗而使储能较高,位错的扩散不能充分进行而阻碍了再结晶晶粒的形核,从而使m值减小。随着应变速率提高到50 s-1,变形热效应使m值再次增大。同时,m随着变形温度的提高而增大,因为变形温度的提高使材料中原子的平均动能增加,晶体产生滑移的临界切向应力的降低促进了位错滑移和晶界扩散,从而使m值增大[26]。

图7

图7

应变速率敏感性指数m与应变和应变速率的关系

Fig.7

Relationship between strain rate sensitivity index m and strain and strain rate (a) T = 1150 oC, (b)

3 讨论

3.1 变形热效应的影响

上述分析结果表明,流动软化与应变硬化的协同竞争变形机制不同。

在材料的热变形过程中,随着变形量的增大其微观组织随之发生变化。变形过程中的大部分塑性变形功转化为热能,小部分储存在材料中。同时,变形速率过高使热变形产生的变形热在短时间内难以散出,因此对流动软化的影响较大。可用温升

定量表征变形热效应。式中

为热转化率[28]。

图8

图8

应变为1.2时不同变形条件下9310钢的温升和1200 ℃/50 s-1条件下的微观组织

Fig.8

Microstructure diagram of temperature rise value of 9310 steel under different deformation conditions and 1200 oC/50 s-1 parameters under strain 1.2 (a) temperature rise under different deformation conditions, (b) microstructure at 1200 oC/50 s-1 parameters

3.2 微观组织的演变

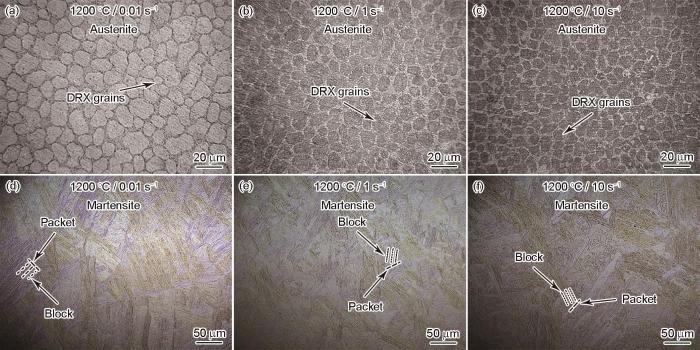

图9a~c给出了变形温度为1200 ℃时应变速率不同9310钢的奥氏体组织。可以看出,应变速率为0.01 s-1时(图9a),在高温下DRX晶粒长大。其原因是,DRX是一种热激活的扩散控制过程,在很大程度上取决于原子扩散速率、晶界或亚晶界迁移以及位错运动[29]。变形温度的提高有利于晶界迁移,从而促进晶粒长大。同时,变形温度为1200 ℃时Cr与C原子发生反应生成CrC相。但是,在1200 ℃的高温下只有较少的CrC相,其粗化和球化产生的软化效应可以忽略。第二相的产生降低了位错迁移率,使晶粒之间的晶界逐渐“分离”而阻碍了再结晶形核。这导致大应变下的流动软化减弱,而使应变硬化占主导。与应变速率为0.01 s-1时的变形相比,应变速率为1 s-1时DRX晶粒更加细小(图9b),平均尺寸约为10 μm,此时变形热效应的增强使应变硬化程度降低了25%。随着应变速率提高到10 s-1 (图9c),与低温段不同的是,高温段的DRX晶粒取代了原始奥氏体晶粒。其原因是,应变速率较高时较大的形核驱动力为DRX的形核提供了足够的动力[30],较高的变形温度也促进了晶界迁移。DRX的发生消耗储存能和产生无位错晶粒,产生了显著的流动软化,而变形热的贡献小得多。因此,在高温、高应变速率下变形的流动软化,主要是DRX所致。

图9

图9

在1200 ℃不同应变速率条件下9310钢中的奥氏体组织和变形后的水冷马氏体组织

Fig.9

Austenite microstructure and water-cooled martensitic microstructure of 9310 steel at different strain rates at 1200 oC (a, d) 1200 oC/0.01 s-1, (b, e) 1200 oC/1 s-1, (c, f) 1200 oC/10 s-1

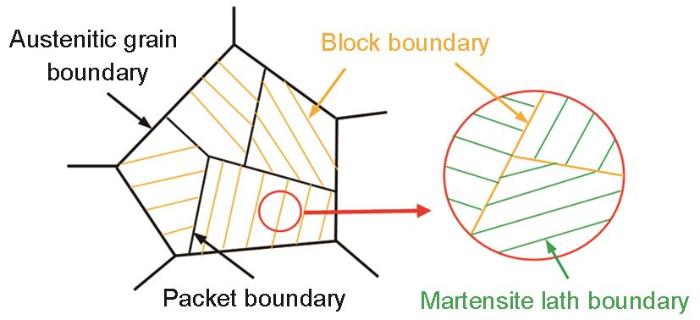

图10

图10

马氏体组织多级结构示意图

Fig.10

Schematic diagram of the multi-level structure of martensitic structure

图11

图11

在1150 ℃/0.1 s-1变形条件下9310钢的EBSD处理图

Fig.11

EBSD treatment of 9310 steel under 1150 oC/0.1 s-1 deformation (a) GB+BC figure, (b) IPF diagrams

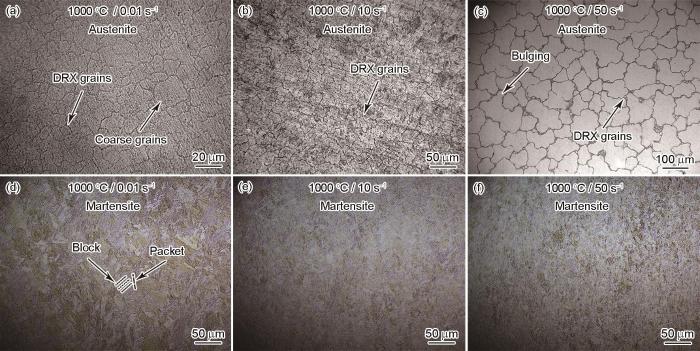

图12a~c给出了变形温度为1000 ℃应变速率不同的9310钢的奥氏体组织。可以看出,在低应变速率0.01 s-1下变形时(图12a),较长的变形时间使DRX晶粒逐渐粗化,使晶界处位错聚集的可能性降低和再结晶形核位置减少,流动软化的竞争力不足使应变硬化占据主导。应变速率为10 s-1时(图12b),局部的高储能使原始奥氏体晶界附近的位错密度提高和DRX晶粒形核,在应变大于0.7后长大。但是,较短的变形时间限制了DRX行为。应变速率达到50 s-1使变形时间进一步缩短,使微观组织的大部分是原始奥氏体晶粒且存在晶界弓出现象,许多细小的DRX晶粒沿着原始奥氏体晶界成核生长,尺寸约为2~4 μm (图12c)。这表明,在此温度区间内高应变速率变形后的微观组织演变以DRV为主,对流动软化有一定的影响。同时,在低温、高应变速率条件下ΔT最高可达49.6 ℃。因此,在低温、高应变速率条件下变形的流动软化是变形热和DRV共同作用的结果。

图12

图12

在1000 ℃不同应变速率条件下9310钢中的奥氏体组织和变形后的水冷马氏体组织

Fig.12

Austenite microstructure and water-cooled martensitic microstructure of 9310 steel at different strain rates at 1000 oC (a, d) 1000 oC/0.01 s-1, (b, e) 1000 oC/10 s-1, (c, f) 1000 oC/50 s-1

3.3 流动软化与应变硬化协同竞争机制

的计算结果进行线性拟合,由拟合直线的斜率和截距计算出平均晶粒尺寸D和有效微应变ε。式中的θ为衍射峰对应的入射角;λ为Cu靶Kα衍射目标的波长(0.15406 nm);β为衍射峰半高宽;

将D和ε代入

可计算出位错密度。式中 b 为伯氏矢量,低合金钢一般取0.248 nm。

位错密度ρ的计算结果在图13中给出。未变形的原始试样中的位错密度为0.328 × 1014 m-2。变形条件为1000 ℃/0.01 s-1时,随着应变的增大位错不能及时被DRX消耗,加剧了位错之间的交错、缠结,位错密度的提高使其运动困难。同时,变形热效应和微观组织演变产生的流动软化较弱,从而使应变硬化占主导。随着变形温度提高到1200 ℃,碳化物(CrC)的析出产生的钉扎严重阻碍晶界迁移并提高了晶界附近的位错密度,使其由0.480 × 1014 m-2提高到0.671 × 1014 m-2,应变硬化程度也由14%提高到34%。

图13

图13

在不同变形条件下9310钢的位错密度曲线

Fig.13

Corresponding dislocation density curves of 9310 steel under different deformation conditions

同时,在塑性变形的过程中位错的形变储能为Es。Es值受位错密度的影响,还与位错边界的间距和晶粒取向差密切相关。Es间接反映奥氏体相的状态。变形后微观结构中单位体积的存储能可表示为[34]

式中ρ为变形奥氏体的总位错密度,G为剪切模量(高温下G为4 × 104 MPa), b 为伯氏矢量。流动应力与位错密度之间的经验关系为[35]

其中

图14

图14

应变为1.2不同变形温度下的平均Es值

Fig.14

Average Es values at different deformation temperatures under strain 1.2

4 结论

(1) 9310钢高温(1080~1200 ℃)变形后的微观组织演变以动态再结晶(DRX)为主,流动软化和应变硬化主要受应变速率的影响。高应变速率(5~50 s-1)变形的流动软化机制为DRX;低应变速率(0.01~5 s-1)变形的应变硬化机制是碳化物(CrC)的钉扎。

(2) 9310钢在低温(1000~1080 ℃)变形时的流动软化和应变硬化受应变速率和变形温度的影响较为显著。随着应变速率的增大和变形温度的降低应变硬化程度随之降低,变形热效应的影响逐渐增大。低温、低应变速率条件下的应变硬化与DRX晶粒的粗化有关;在低温、高应变速率条件下变形后存在大量原始形变奥氏体晶粒,其组织演变主要是动态回复(DRV),流动软化是变形热效应和DRV共同作用的结果。

(3) DRX的发生消耗形变储能Es,水冷相变促进马氏体多级结构的形成。原始形变奥氏体组织容易产生局部Es强化,水冷相变破坏马氏体的形态。

参考文献

Fracture analysis of the components made of high strength and carburizing steel

[J].

高强度渗碳钢制构件的断裂分析

[J].

High temperature compression deformation behavior of 9Mn27Al10Ni3Si low density steel

[J].The deformation characteristics of 9Mn27Al10Ni3Si low density steel at 850~1050℃ with strain rate within the range of 0.01~5 s-1 were investigated by using Gleeble thermal simulator, XRD, OM, SEM and TEM. The results show that when the steel is hot compressed at 850~950℃ with low strain rate (0.01~1 s-1), the flow stress of the steel increases obviously as the strain reaches a certain critical value, which may be due to the precipitation and coarsening of κ-carbides, and the increase of friction coefficient of the steel during hot compression. With the increase of strain rate, the number of twins increases significantly, which can speed up the process of dynamic recrystallization of austenite, however, during thermal compression by high strain rate, the dynamic recrystallization process is more significant rather than by low strain rate. Due to the softening effect of recrystallization, the abnormal rise of flow stress gradually weakens or even disappears.

9Mn27Al10Ni3Si低密度钢的高温压缩变形行为及其机制

[J].使用Gleeble热模拟试验机、XRD、OM、SEM和TEM等手段研究了9Mn27Al10Ni3Si低密度钢在850~1050℃和0.01~5 s<sup>-1</sup>条件下的热压缩变形特征及其机制。结果表明,对这种钢在850~950℃进行低应变速率(0.01~1 s<sup>-1</sup>)热压缩时,κ-碳化物的析出和粗化以及在热压缩过程中摩擦系数的增大使其应变达到临界值后流变应力明显增大;随着应变速率的提高,实验钢的孪生显著增强,显著加快了奥氏体的动态再结晶过程,使其在高应变速率热压缩时动态再结晶的程度比低应变速率压缩时更为显著。再结晶的软化作用,使上述流变应力异常增大的现象逐渐减弱甚至消失。

Analysis of flow softening during hot deformation of Ti-17 alloy with the lamellar structure

[J].

Dynamic recrystallization behavior and microstructure evolution of low-density high-strength Fe-Mn-Al-C steel

[J].

Flow softening of 253 MA austenitic stainless steel during hot compression at higher strain rates

[J].

Tensile strain-hardening behavior and related deformation mechanisms of pure titanium at cryogenic temperature

[J].

Insights into flow stress and work hardening behaviors of a precipitation hardening AlMgScZr alloy: experiments and modeling

[J].

Temperature dependent strain hardening and fracture behavior of TWIP steel

[J].

Effects of laser shock peening on low temperature carburizing of AISI9310 gear steel

[J].AISI 9310 steel is a kind of high-strength carburized steel with good toughness. Owing to its material properties, this steel is usually used to fabricate gear parts. Gear tooth surface is prone to wear and contact fatigue damage during service processing. Therefore, to effectively resolve the resistance properties and for the synergistic strengthening of the wear and contact fatigue properties, the AISI 9310 steel sample was processed by laser shock peening (LSP) and then treated by low temperature gaseous carburization (LC). The carburized layer and cross-sectional crystallographic characteristics were imaged using optical microscopy (OM), scanning electron microscopy (SEM), and electron backscatter diffraction (EBSD); subsequently, the cross-sectional hardness was measured. The following results were obtained. After LC treatment, a white carburized layer, which was approximately 14-μm thick and uneven, was induced on the 9310 steel matrix surface. The maximum hardness achieved for the carburized layer of 9310 steel was about 305.67 HV with the depth of work hardening being 300 μm. The maximum hardness of the LCed sample was enhanced by 27.56% compared to the as-received sample. However, with pre-LSP treatment, the thickness of the carburized layer of 9310 steel was improved to approximately 23 μm and the maximum hardness to approximately 328.87 HV with the depth of work hardening being 700 μm. The maximum hardness of the LSP-LCed sample was enhanced by 5.46 % compared to the LCed sample. However, in comparison, the pre-LSP treatment improves the thickness of the carburized layer by 64.3%, the maximum hardness by 23.17 HV, and the depth of work hardening by 133%. The underlying reasons for these enhancements are as follows. Generally, LSP treatment induces plastic deformation and improves the proportion of low angle grain boundary (LGB); this enhances the diffusion behavior of the carbon atoms, and consequently improves the hardness of the LCed layer and the depth of work hardening. After pre-LSP treatment, the carbon diffusion behavior and hardness of LC were enhanced. Specifically, combining pre-LSP and LC processing results in cross-sectional work hardening because LC alone can hardly influence the Kernel average misorientation (KAM) and proportion of LGB of as-received 9310 steel. In other words, pre-LSP improves the KAM of the LCed sample by 15.38% (from 0.52° to 0.60°), and the depth from 0-100 μm. Moreover, pre-LSP enhances the KAM of the LCed sample by 15.79 % (to 0.66°) and the depth from 100-200 μm. Finally, the low angle grain boundary was measured. Notably, LC does not affect the proportion of the low angle grain boundary and the cross-sectional distribution for 9310 steel. On the contrary, pre-LSP processing evidently enhances the proportion of the low angle grain boundary. At the depth of 0-100 μm, pre-LSP enhances the total proportion of the LGB of the LCed sample by 13.04% (from 36.8% to 41.6%). Moreover, the total proportions of the LGB of the LCed sample were enhanced from 36.8% to 55.8% and from 38% to 46.2% for the depth ranging from 100-200 μm and 200-300 μm, respectively. Based on the above results, the main conclusions to enhance the carbon atoms diffusion behavior are as follows. Pre-LSP enhances the carbon diffusion behavior of LC by inducing plastic deformation via increased KAM and increasing the proportion of low-angle grain boundary. Consequently, the easier carbon diffusion behavior of LC could induce the thicker carburized layer, the harder work hardening level, and even improves the thickness of work hardening layer. The problem of carbon diffusion enhanced by microstructure defects induced by LSP pretreatment is preliminarily solved. This resolution would provide technical support for LSP compound strengthening to extend the service life of key components of aviation gear.

激光冲击强化前处理对AISI9310齿轮钢低温渗碳的影响

[J].AISI 9310 钢是一种高强度渗碳齿轮钢,具有较好的韧性。服役过程中,齿面极易发生磨损和接触疲劳失效损伤。为有效改善 9310 齿轮钢的耐磨损和抗接触疲劳性能,实现磨损和接触疲劳性能协同强化,提出采用激光冲击(LSP)+渗碳(LC) 复合强化的技术思路,采用激光冲击强化技术对 AISI 9310 钢基体进行前处理,再对其开展低温渗碳热处理。为进一步研究 LSP 和 LC 对 9310 齿轮钢微观组织形貌的影响规律,利用光学显微镜、扫描电子显微镜和电子背散射衍射表征渗碳层微观组织形貌和截面方向的晶体学特征,并对试件截面方向的硬度进行考核。研究结果表明,AISI 9310 钢的渗碳层厚度约为 14 μm, 最大硬度约为 305.67 HV,硬化层厚度约 300 μm;LSP 前处理后,渗碳层厚度提升到 23 μm,最大硬度提升到 328.87HV,硬化层厚度提升到约 700 μm。对比发现,LSP 前处理分别可将 9310 钢低温渗碳层厚度提升 64.3%,渗碳层硬度提升 23.17 HV, 硬化层深度提升 133%。这主要是低温渗碳对 9310 钢的 Kernel 平均取向差(KAM)和小角度晶界影响较小,但是 LSP 前处理可引入塑性变形并提升小角度晶界比例,有助于碳元素扩散,促进 9310 钢低温渗碳行为,提升渗碳层厚度、硬化层硬度和厚度。初步解决了 LSP 前处理诱导微观组织缺陷促进碳元素扩散的问题,可为 LSP 复合强化提升航空齿轮关键部件服役寿命提供技术支撑。

Further enhancement of surface mechanical properties of carburized 9310 steel by electropulsing-assisted ultrasonic surface rolling process

[J].

Constitutive equations of a high-strength carburizing steel during high temperature thermal deformation

[J].

高强渗碳钢高温热变形的本构方程

[J].

Research on constitutive model of 9310 steel based on physical parameters and BP neural network

[J].

基于物理参数和BP神经网络的9310钢本构模型研究

[J].

Determination and analysis of CCT curve of 9310 steel

[J].

9310钢的CCT曲线测定与分析

[J].

Dynamic recrystallization behavior of a typical nickel-based superalloy during hot deformation

[J].

Continuous dynamic recrystallization in an Al-Li-Mg-Sc alloy during equal-channel angular extrusion

[J].

Effect of heat treatment on the microstructure and properties of deformation-processed Cu-7Cr in situ composites

[J].

Flow stress characteristics and microstructure evolution during hot compression of Nb-47Ti alloy

[J].

Research on the relationship between the strain rate sensitivity exponent, strain hardening exponent and deformation parameters, grain size of Ti2AlNb titanium alloy

[J].

Ti2AlNb合金应变速率敏感指数和应变硬化指数与变形参数和晶粒尺寸关系研究

[J].

High-temperature deformation behavior and microstructural characterization of Ti-35421 titanium alloy

[J].

Strain rate effects of dynamic compressive deformation on mechanical properties and microstructure of CoCrFeMnNi high-entropy alloy

[J].

Strain hardening behavior and microstructural evolution during plastic deformation of dual phase, non-grain oriented electrical and AISI 304 steels

[J].

Study on the critical condition and deformation mechanism of dynamic recrystallization of novel lightweight steel based on the work hardening rate

[J].

基于加工硬化率的新型轻质钢动态再结晶临界条件及变形机制研究

[J].

The effect of cooling rates on the microstructure and mechanical properties of thermo-mechanically processed Ti-Al-Mo-V-Cr-Fe alloys

[J].

Strain rate sensitivity of flow stress at large strains

[J].

Strain rate sensitivity and strain hardening exponent during the isothermal compression of Ti60 alloy

[J].

Study of strain rate sensitivity exponent and strain hardening exponent of typical titanium alloys

[J].

Effect of strain rate on softening mechanism of TB15 titanium alloy

[J].

应变速率对TB15钛合金软化机制的影响

[J].

Flow softening and microstructural evolution of near β titanium alloy Ti-55531 during hot compression deformation in the α+β region

[J].

Hot deformation behaviour and fracture of 10CrMoWNb ferritic-martensitic steel

[J].

Influence of hot compressive parameters on flow behaviour and microstructure evolution in a commercial medium carbon micro-alloyed spring steel

[J].

Transformation behavior and microstructural characteristics of acicular ferrite in linepipe steels

[J].

Softening mechanisms and microstructure evolution of 42CrMo steel during hot compressive deformation

[J].

Precipitation behavior and mechanical properties of 7A62 aluminum alloy after thermal-magnetic aging

[J].

7A62铝合金在热磁时效后的析出行为与力学性能

[J].

Stored energy, microstructure, and flow stress of deformed metals

[J].

Influences of silicon on the work hardening behavior and hot deformation behavior of Fe-25wt%Mn-(Si, Al) TWIP steel

[J].