在原油的开采和运输过程中使用的各种助剂使原油变稠、变重,含水、盐增加,硫含量和酸值提高[1]。注水开发油田时必须使用油井管,而腐蚀导致的管道破裂和原油泄漏是油田注水出现油水混合。原油泄漏引起腐蚀,危害人类安全和造成环境污染[2]。因此,油井管的防腐极为重要[3]。油井管的腐蚀,包括CO2腐蚀、H2S腐蚀以及微生物腐蚀等。工业中超过20%的严重腐蚀失效是微生物腐蚀(Microbiologically influenced corrosion,MIC)造成的[4~8]。微生物腐蚀,是指微生物活动引起的材料腐蚀,微生物还能促进和加速材料的腐蚀[9~11]。油田中的MIC以厌氧的硫酸盐还原菌(Sulfate-reducing bacteria,SRB)和好氧的铁细菌(Iron-oxidizing bacteria,IOB)为主,对金属材料最具破坏性。MIC产生的生物膜是发生生物腐蚀的核心因素。因此,为了减缓MIC处理生物膜极为重要。

在MIC的防护方法中,杀菌剂是最高效的[12]。传统杀菌剂的长期使用使微生物产生抗药性,且大多数杀菌剂对生物膜内的细菌无效,大量使用还污染环境[13]。D-络氨酸(D-tyrosine)能抑制生物膜的形成且促进成熟生物膜解体,是一种对环境无害的杀菌剂 [14~16]。毫摩尔浓度的D-氨基酸能抑制空肠梭菌生物膜的形成并触发其分解[17]。1 × 10-6 (质量分数) D-络氨酸和1 × 10-4 (质量分数) D-蛋氨酸能增强低浓度四羟甲基硫酸磷(THPS)杀菌剂对碳钢上硫酸盐还原菌生物膜的抑制性能[18]。D-络氨酸作为2,2-二溴-3-次氮基丙酰胺(DBNPA)杀菌剂的杀菌增强剂,能减缓SRB对纯锌的MIC[19]。由此可见,D-tyrosine作为杀菌增强剂对杀菌剂THPS有增强作用。同时,D-tyrosine是自然产生的化学物质,对环境无污染[18,20]。本文研究P110钢在不同油水比的混合菌SRB和IOB中D-络氨酸增强型复配杀菌剂对P110钢混合菌腐蚀行为的影响。

1 实验方法

1.1 实验用材料和菌种

实验用P110钢的化学成分(质量分数,%)为C 0.26,Mn 0.65,Si 0.25,S 0.003,P 0.006,Cu 0.036,余量为Fe。先用金相砂纸(240~1000目)将尺寸为50 mm × 25 mm × 2 mm的片状试样横纵交替打磨,然后用95%的无水乙醇和丙酮分别进行脱水和脱脂,用冷风吹干后在无菌操作台上灭菌30 min。实验用来自国内某油田的SRB和IOB菌种,通过富集、分离和提纯。实验用的杀菌剂是THPS和二甲基亚砜(DMSO);杀菌增强剂是D-络氨酸。

1.2 细菌的培养和腐蚀介质的配制

按照国家标准(GB/T14643.5-2009,GB/T14643.6-2009)[20]进行实验。用分析纯药品和去离子水配制SRB和IOB的培养基溶液,为了防止杂菌污染,将其放在121 ℃的高压灭菌锅中灭菌20 min,用无菌操作台接种SRB和IOB。实验前用离子色谱仪检测国内某油田采出水离子的含量(mg/L),其中,Cl- 854.35, $\mathrm{CO}_3^{2-}$ 212.28, $\mathrm{SO}_4^{2-}$ 94, Ca2+ 200, Mg2+ 100.02。

在120 mL的消毒密封瓶中各倒入38 mL的SRB、IOB的培养基、国内某油田采出水模拟溶液与原油的混合液(油水比例分别为0.5∶9.5、1∶9、2∶8,质量比)模拟油水混合环境,再各取3 mL的SRB和IOB菌种放入溶液中并注入复配杀菌剂,其中各组分的含量(质量分数)分别为:8 × 10-5~1.2 × 10-4的杀菌剂THPS、1 mL的0.3‰~0.8‰ DMSO与1 × 10-6~3 × 10-6的D-络氨酸。为了对比,3组实验各有3个平行试样,并将其放入(37 ± 1) ℃的培养箱中培养。

1.3 性能表征

除去试样表面的腐蚀产物将其浸入装有除锈液(500 mL盐酸 + 500 mL去离子水 + 3.5 g六次甲基四胺)的烧杯中,将烧杯置于超声波清洗机中进一步除锈,用无水乙醇逐级脱水后放置干燥皿中,1 d后用天平称量,其腐蚀速率(V)为

为了研究三元复配杀菌剂对P110钢腐蚀行为的影响,根据相关腐蚀速率计算三元复配杀菌剂对P110钢的缓蚀率

式中W0为腐蚀实验前试片的原始质量(g);W1为试样去除腐蚀产物后重量(g);ρ为试样密度(g/cm3);A为试样暴露表面积(cm2);t为腐蚀实验时间(h);V为腐蚀速率(mm/a);V1为无复配杀菌剂的腐蚀速率(mm/a);V2为有复配杀菌剂的腐蚀速率(mm/a);X为缓蚀率(%)。

将在有/无三元复配杀菌剂中腐蚀0、3、7、14 d的P110钢试样从培养箱中取出后,放入4%的戊二醛溶液中浸泡30 min以固定生物膜,干燥后用扫描电镜观察腐蚀产物形貌并用配套的电子能谱仪(EDS)分析腐蚀产物;用X射线衍射仪(XRD)测试腐蚀产物的物相组成。

在面积为10 mm × 10 mm的试样背面用焊锡连接铜导线,然后用环氧树脂密封。用金相砂纸(240~1000目)将试样工作面打磨由后依次用去离子水、丙酮和无水乙醇清洗,用冷风吹干后放在干燥皿中。用美国EG&G公司生产的M2273电化学测试系统测量极化曲线,以全浸泡试样作为工作电极,饱和甘汞电极(SCE)作为参比电极,铂电极作为辅助电极。电位范围(相对于开路电位(OCP))为-250~300 mV,扫描速率为0.5 mV/s。

2 结果和分析

2.1 P110钢的质量损失

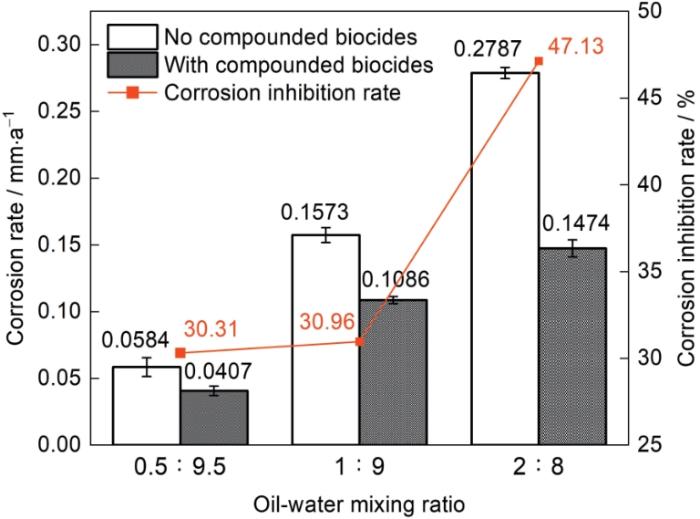

将P110钢分别在油水比为0.5∶9.5、1∶9和2∶8的SRB+IOB混合菌溶液中进行挂片腐蚀实验,每组有3个平行试样,其中一组不加复配杀菌剂,另一组第0 d加入复配杀菌剂,在溶液中腐蚀14 d得到图1给出的质量损失和缓蚀率。

图1

图1

P110钢在不同油水比的混合菌环境中腐蚀14 d后的质量损失和缓蚀率

Fig.1

Mass loss and corrosion inhibition rate of P110 steel after 14 d of corrosion in mixed bacterial environments with different oil-water ratios

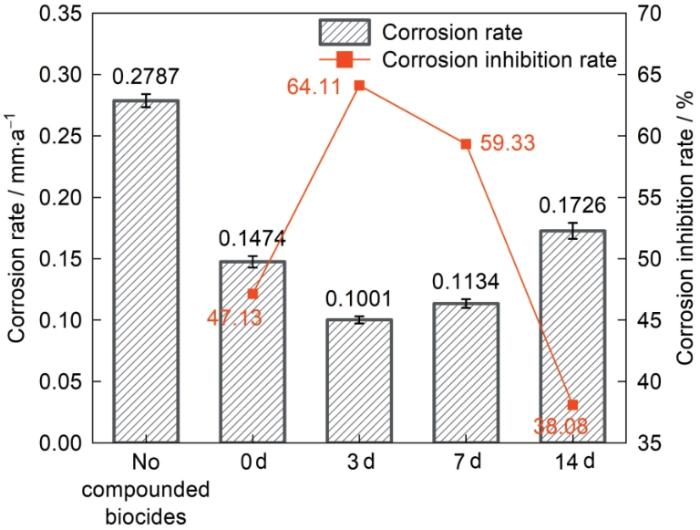

图2

图2

P110钢在油水比为2∶8的混合菌环境中腐蚀14 d的腐蚀速率和缓蚀率

Fig.2

Corrosion rate and corrosion inhibition of P110 steel corroded for 14 d in a mixed bacterial environment with an oil-water ratio of 2∶8

从表1可见,加入复配杀菌剂的杀菌效果显著,SRB的杀菌率均高于90%以上,对IOB的杀菌率高于80%。这表明,本文针对SRB+IOB混合菌腐蚀使用的复配杀菌剂有显著的杀菌缓蚀效果。

表1 P110钢在油水比为2∶8的混合菌环境中腐蚀14 d后杀菌率和缓蚀率

Table 1

| Time of biocides addition / d | SRB sterilization rate / % | IOB sterilization rate / % | Corrosion inhibition rate / % |

|---|---|---|---|

| 0 | 99.73 | 85.00 | 38.08 |

| 3 | 93.67 | 85.00 | 64.11 |

| 7 | 97.00 | 100.00 | 59.33 |

| 14 | 100.00 | 100.00 | 47.13 |

2.2 P110钢腐蚀后的形貌

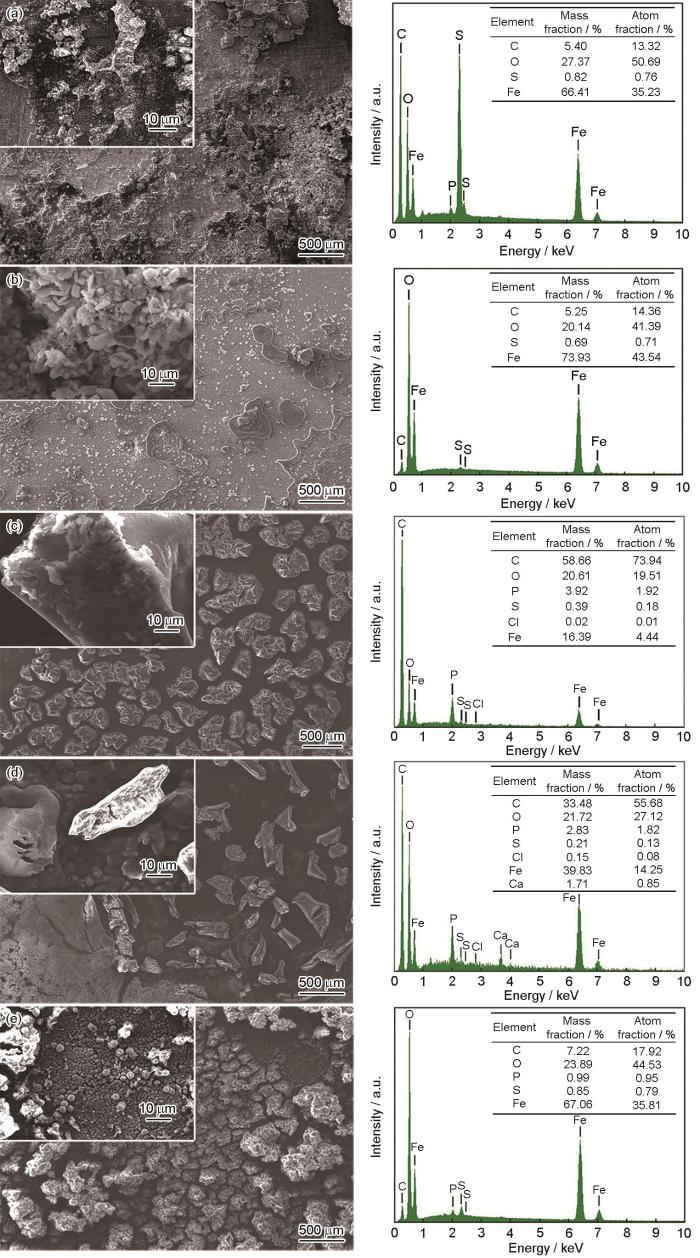

图3

图3

P110钢在不同时间添加复配杀菌剂腐蚀14 d后的SEM照片和EDS谱

Fig.3

SEM images and EDS of P110 steel after corrosion for 14 d after addition of compounded biocides at different time (a) no compounded biocides, addition of compounded biocides after (b) 0 d, (c) 3 d, (d) 7 d, (e) 14 d

EDS分析结果表明,腐蚀产物主要由P、S化物和部分铁的氧化物组成。加入复配杀菌剂使P、S两种元素的含量大幅度降低,表明复配杀菌剂抑制了微生物的代谢活动。其原因是,D-络氨酸抑制生物膜中胞外蛋白的合成,使细菌胞外的基质结构变薄和松散,分解了细菌附着的场所使之成为游离态的细菌,从而易被杀菌剂消灭[24]。Fe含量显著降低发原因,是复配杀菌剂的加入抑制了IOB的代谢活动,使其不能通过铁的氧化得到能量。

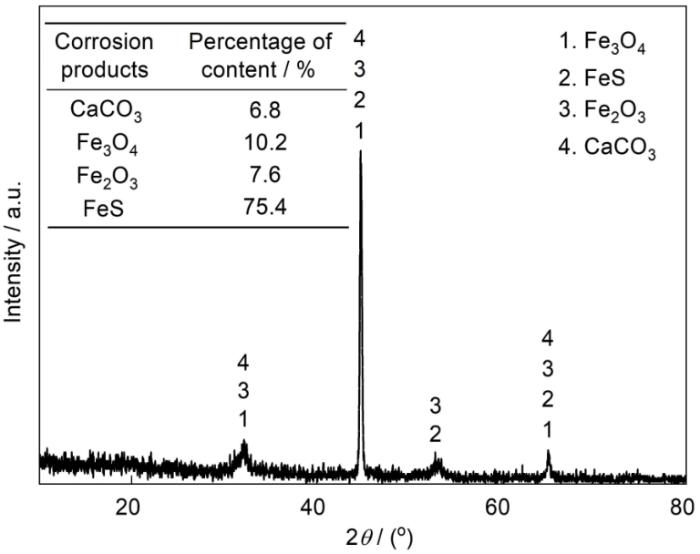

图4给出了P110钢在油水比为2∶8的混合菌环境中腐蚀14 d后腐蚀产物的XRD谱。结果表明,P110钢在混合菌环境下的腐蚀产物为FeS(75.4%)、Fe3O4(10.2%)、Fe2O3(7.6%)和CaCO3(6.8%),其中SRB产生的H2S与基体Fe反应生成的FeS占比最大。

图4

图4

P110钢在油水比为2∶8的混合菌环境中腐蚀14 d后的XRD谱

Fig.4

XRD pattern of P110 steel after corrosion for 14 d in a mixed bacterial environment with an oil-water ratio of 2∶8

2.3 电化学分析

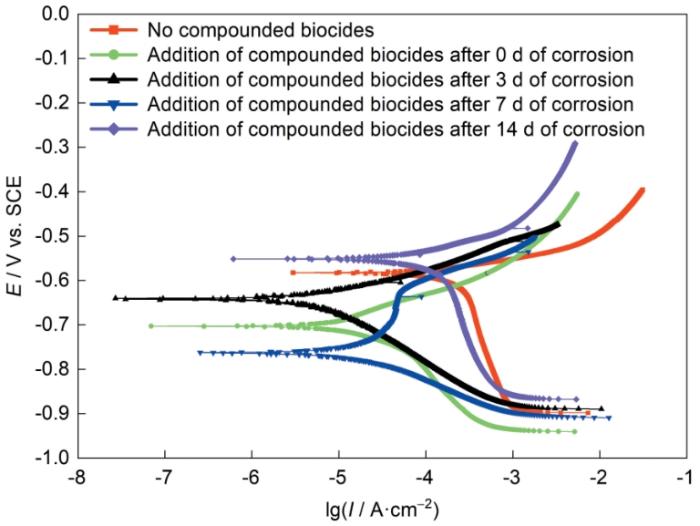

图5和表2给出了P110钢在油水比为2∶8的混合菌环境中腐蚀0、3、7、14 d加入复配杀菌剂,再腐蚀14 d的极化曲线图和Tafel拟合结果。可以看出,极化曲线的Icorr越大表明材料的腐蚀越严重[25]。由图5和表2可见,不添加复配杀菌剂的的试样其极化曲线的阳极区以活化溶解为主,且自腐蚀电流密度(Icorr)达到了26.4 × 10-5 A/cm2。与不添加复配杀菌剂组相比,添加复配杀菌剂组的极化曲线都呈左移趋势,即Icorr降低。这也证实了,加入复配杀菌剂可减缓腐蚀。由表1可见,P110钢在油水比为2∶8的混合菌环境中的Icorr排序为Icorr,without > Icorr(14 d,with) > Icorr(0 d,with) > Icorr(7 d,with) > Icorr(3 d,with)。在不同时间加入复配杀菌剂,P110钢的自腐蚀电流密度变化趋势是先减小后增大。腐蚀3 d添加复配杀菌剂的自腐蚀电流密度最小,Icorr由26.4×10-5 A/cm2下降到0.52 × 10-5 A/cm2(降幅高达98%);同时也验证了质量损失分析给出的结果,即腐蚀3 d加入复配杀菌剂的效果最好。

图5

图5

P110钢在不同时间添加复配杀菌剂腐蚀14 d后的极化曲线

Fig.5

Polarization curves of P110 steel after 14 d of corrosion with addition of compounded biocides at different time

表2 P110钢在不同时间添加复配杀菌剂后腐蚀14 d后的Tafel曲线拟合结果

Table 2

| With/without compounded biocides | ba / mV | bc / mV | Ecorr / mV | Icorr / A·cm-2 |

|---|---|---|---|---|

| No compounded biocides | 50.45 | 694.1 | -586 | 26.4 × 10-5 |

| Addition of compounded biocides after 0 d | 102.2 | 226.9 | -701 | 3.58 × 10-5 |

| Addition of compounded biocides after 3 d | 57.27 | 109.7 | -642 | 0.52 × 10-5 |

| Addition of compounded biocides after 7 d | 329.4 | 80.80 | -763 | 2.51 × 10-5 |

| Addition of compounded biocides after 14 d | 83.95 | 449.7 | -550 | 14.0 × 10-5 |

3 讨论

在油水比不同的环境,油含量的提高使溶液中的腐蚀性物质和细菌所需的碳源随之增加,为微生物的生长提供了充足的碳源,从而加剧了微生物腐蚀。同时,对SEM与极化曲线的分析结果表明,SRB与IOB之间的协同作用使其在适宜的环境中大量繁衍,生成的硫化物和铁的氧化物等腐蚀产物在试样表面形成结瘤。结瘤下方构成的贫氧阳极区为SRB提供良好的生长环境,而结瘤上方成为富氧的阴极区,两者形成氧浓差电池。同时,IOB将Fe2+氧化成Fe3+而使基体加速溶解。

在不同时间内加入复配杀菌剂使P110钢的极化曲线比未加入复配杀菌剂的极化曲线呈现左移,即Icorr降低。这表明,复配杀菌剂的加入破环了破环氧浓差腐蚀环境而使生物膜分解和脱落,从而减缓了混合菌对P110钢的腐蚀。在第3 d加入复配杀菌剂使细菌细胞壁上的D-丙氨酸被其他的D-氨基酸所取代,而其他D-氨基酸是生物膜分散的群体感应(Quorum sensing,QS)信号分子,于是使生物膜分散[26, 27]。此时复配杀菌剂产生了最好的杀菌缓蚀效果,使腐蚀复配杀菌剂的Icorr最小,与质量损失对应。但是,腐蚀7、14 d加入复配杀菌剂的试样已经腐蚀了一段时间,细菌与生物膜已经处于成熟阶段,生物膜是碳源扩散的传质屏障,生物膜顶层的细菌消耗一定数量的碳源为生物膜底层的固着细菌留下的有机碳更少,使靠近或直接在生物膜底层的细菌饥饿。靠近生物膜底部的细菌通过细胞外电子转移(EET)被迫从元素Fe中收集阴极电子以产生SRB生长代谢所需的能量,从而使腐蚀加速[18,28,29]。这表明,腐蚀7、14 d加入复配杀菌剂的自腐蚀电流密度比腐蚀3 d加入复配杀菌剂的高。其原因是,复配杀菌剂不仅能调节生物膜的结构,还能抑制胞外蛋白的合成和使微生物膜分散,从而使混合菌难以生存,减缓了P110钢的腐蚀。

其次,SRB产生的S2-与Fe2+相互作用生成Fe的硫化物附着在Fe的表面。这种硫化物形成阴极与Fe阳极组成浓差电池,从而加剧了金属的腐蚀:

IOB把水中的Fe2+氧化成Fe3+,Fe2+与OH-结合形成Fe(OH)2。但是Fe(OH)2并不稳定,Fe2+转变为Fe3+生成的Fe2O3沉积在细菌周围形成结瘤。结瘤下部的缺氧区(作为阳极)与结瘤周围(作为阴极)形成氧浓差电池,促进了P110钢的腐蚀:

另一方面,溶液中含有大量Ca2+、Cl-等离子。$\mathrm{CO}_3^{2-}$与Ca2+生成CaCO3沉淀并吸附在产物膜上形成不均匀诱发膜,诱发膜覆盖区与裸漏区形成微电偶效应,使腐蚀加剧[30]。

4 结论

(1) P110钢在不同油水混合比环境下腐蚀速率的排序为V(2∶8) (重度腐蚀,0.2787 mm/a) > V(1∶9) (中度腐蚀,0.1573 mm/a) > V(0.5∶9.5) (中度腐蚀,0.0584 mm/a)。油水比为2∶8时腐蚀最严重,因为油含量的提高使溶液中的腐蚀性物质和细菌生长所需的碳源增加,为细菌的繁殖提供了更适宜的环境而加剧了P110钢的微生物腐蚀。

(2) P110钢在油水比为2∶8的混合菌腐蚀环境中腐蚀不同时间再加入复配杀菌剂后的缓蚀率高低的排序为X3 d(64.11%) > X7 d(59.33%) > X0 d(47.13%) > X14 d(38.08%)。腐蚀第3 d加入复配杀菌剂时杀菌缓蚀效果最佳(缓蚀率可达64.11%)。三元复配杀菌剂中各组分的协同作用加速了混合菌的杀灭进程,而抑制了P110钢的腐蚀。

(3) 加入复配杀菌剂后,D-络氨酸改变细菌壁上肽聚糖的结构抑制了细菌的细胞壁合成和繁衍,致使生物膜脱落,使生物膜下的细菌由固着状态转变为易被杀菌剂杀死的游离状态,破坏了氧浓差环境。杀菌剂THPS的加入使SRB、IOB失去活性;DMSO作为增效渗透剂使THPS加速进入生物膜内,使细菌更易被杀菌剂杀灭,显著地减缓了P110钢的腐蚀。

参考文献

Current status of corrosion studies on oil well pipe materials

[J].

油井管材料腐蚀研究现状

[J].

Advances in corrosion growth modeling for oil and gas pipelines: a review

[J].

Internal corrosion in oil and gas wells during casings and tubing: challenges and opportunities of corrosion inhibitors

[J].

Failure analysis of an offshore drilling casing under harsh working conditions

[J].

Research progress on sulfate reducing bacteria induced corrosion of pipeline steel in soil environment

[J].

油气管线钢土壤环境硫酸盐还原菌腐蚀研究进展

[J].

Formation, function and evolution of biofilm in microbiologically influenced corrosion

[J].

微生物腐蚀中生物膜的生成、作用与演变

[J].

Microbially influenced corrosion and its control measures: a critical review

[J]. J.

Failure analysis of casing dropping in shale oil well during large scale volume fracturing

[J].

Microbially induced corrosion issues in the underground buried crude oil and natural gas bearing pipelines: a review

[J].

Microbiologically influenced corrosion-more than just microorganisms

[J].

Research progress on microbial corrosion of aluminum alloys

[J].

铝合金微生物腐蚀研究进展

[J].

Progress of biocides for corrosive microorganisms in industrial systems

[J].

用于工业系统腐蚀微生物的杀菌剂研究进展

[J].

Biosurfactants: eco-friendly and innovative biocides against biocorrosion

[J].

Laboratory testing of enhanced biocide mitigation of an oilfield biofilm and its microbiologically influenced corrosion of carbon steel in the presence of oilfield chemicals

[J].

Preparation, characterization, and Staphylococcus aureus biofilm elimination effect of baicalein-loaded tyrosine/hyaluronic acid/β-cyclodextrin-grafted chitosan nano-delivery system

[J].

Charge adaptive phytochemical-based nanoparticles for eradication of methicillin-resistant staphylococcus aureus biofilms

[J].

Inhibition of Campylobacter jejuni biofilm formation by D-amino acids

[J].

Enhanced biocide mitigation of field biofilm consortia by a mixture of D-amino acids

[J].Microbiologically influenced corrosion (MIC) is a major problem in the oil and gas industry as well as in many other industries. Current treatment methods rely mostly on pigging and biocide dosing. Biocide resistance is a growing concern. Thus, it is desirable to use biocide enhancers to improve the efficacy of existing biocides. D-Amino acids are naturally occurring. Our previous work demonstrated that some D-amino acids are biocide enhancers. Under a biocide stress of 50 ppm (w/w) hydroxymethyl phosphonium sulfate (THPS) biocide, 1 ppm D-tyrosine and 100 ppm D-methionine used separately successfully mitigated the Desulfovibrio vulgaris biofilm on carbon steel coupons. The data reported in this work revealed that 50 ppm of an equimolar mixture of D-methionine, D-tyrosine, D-leucine, and D-tryptophan greatly enhanced 50 ppm THPS biocide treatment of two recalcitrant biofilm consortia containing sulfate reducing bacteria (SRB), nitrate reducing bacteria (NRB), and fermentative bacteria, etc., from oilfield operations. The data also indicated that individual D-amino acids were inadequate for the biofilm consortia.

Assessment of 2, 2-dibromo-3-nitrilopropionamide biocide enhanced by D-tyrosine against zinc corrosion by a sulfate reducing bacterium

[J].

Effect of D-amino acids on corrosion behavior of different steels due to mixed bacteria

[J].The effect of biocide and D-amino acid on the corrosion behavior of 20# carbon steel, N80 steel and P110 steel in the media of SRB+IOB mixed bacteria, was comparatively assessed by using weight loss method, electrochemical measurements and SEM. In the tests without biocide, P110 suffered from severe corrosion with weight loss of 0.278 mm/a, while weight loss of 20# and N80 were 0.149 and 0.148 mm/a respectively, while uniform and dense biofilms with deposited corrosion products formed on the surface of all the steels; in the tests with biocide, the corrosion of the three steels slowed down, it is found that the formed rust scales on the surface of steels with significantly lower content of Ca Mg, P, and S, but with cracks and spallation steels. The electrochemical measurement results also revealed that the corrosion rate of three steels was significantly reduced when they were immersed for 14 d in the corrosive media with addition of biocides. The corrosion mechanism of SRB and IOB mixed bacteria is probably due to that SRB oxidizes Fe to Fe2+ through its own metabolism, and Fe2+ is further oxidized by IOB to Fe3+, and IOB provides environmental conditions for SRB so as to form a synergistic effect. It is proposed that D-amino acids and biocide effectively inhibit MIC behavior by regulating the bacterial gene expression and destroys the cell structure, as well as the oxygen concentration difference environment. Due to the different content of C, Cu and others, the corrosion rate of the three steels may be different under the sterile conditions.

D-氨基酸对不同钢材混合菌腐蚀行为的影响

[J].研究了杀菌剂与D-氨基酸对20#碳钢、N80钢以及P110钢在硫酸盐还原菌(SRB)+铁氧化菌(IOB)混合菌腐蚀过程中的影响作用,利用失重与电化学测量以及扫描电镜(SEM)对腐蚀形貌分析等初步探索了D-氨基酸的杀菌缓蚀增强机理。无杀菌剂组中P110发生严重腐蚀(0.278 mm/a),20#与N80腐蚀速率较低(为0.149、0.148 mm/a),所有试样表面有均匀且致密的生物膜以及腐蚀产物堆积;有杀菌剂组中三种钢材腐蚀程度减缓,腐蚀产物膜发生龟裂、剥离,其中Ca、Mg、P以及S含量明显减少。在添加杀菌剂溶液中浸泡14 d后,三种钢材的腐蚀速率明显降低。有无杀菌剂下,三种钢材耐蚀性由优到差排序均为N80>20#>P110。SRB和IOB混合菌的腐蚀机制可能是由于SRB通过自身代谢将基体Fe氧化为Fe<sup>2+</sup>,Fe<sup>2+</sup>又被IOB进一步氧化为Fe<sup>3+</sup>且IOB为SRB提供环境条件形成了协同作用。D-氨基酸和杀菌剂通过调控细菌基因表达、破坏细胞结构、氧浓差环境等方式有效的抑制微生物腐蚀(MIC)行为。三种钢材由于C、Cu等元素含量不同,使得三种钢材在无菌条件下腐蚀速率有所差异。

Effect of compound bactericidal corrosion inhibitor on corrosion behavior of N80 steel at different temperatures

[J].

复配杀菌缓蚀剂对N80钢在SRB环境中微生物腐蚀行为的影响

[J].

SRB corrosion behavior of L245 pipeline steel with different cathode polarization potential

[J].

不同阴极极化条件对L245的SRB腐蚀行为影响

[J].

Microbiologically influenced corrosion of pipeline steels

[J].

管线钢的微生物腐蚀

[J].介绍了管线钢的微生物腐蚀及其危害,分析了近年来管线钢微生物腐蚀的失效案例,总结了管线钢微生物腐蚀的研究现状及管线的微生物腐蚀防治措施。从材料自身角度阐述了耐微生物腐蚀管线钢的研究进展,在此基础上提出了耐微生物腐蚀管线钢的发展方向。

Study on the behavior and mechanism of D-amino acid dispersing biofilm

[J].

D-氨基酸驱散生物膜的行为与作用机理研究

[J].

Effect of temperature on corrosion behavior of copper-nickel alloys by sulphate-reducing bacteria in anaerobic environment

[J].

温度对厌氧环境中硫酸盐还原菌所致铜镍合金腐蚀行为的影响

[J].

D-amino acids for the enhancement of a binary biocide cocktail consisting of THPS and EDDS against an SRB biofilm

[J].

Advances in quorum sensing regulating formation of biofilm

[J].

群体感应系统介导细菌生物膜形成的研究进展

[J].

Toward a better understanding of microbiologically influenced corrosion caused by sulfate reducing bacteria

[J].Sulfate reducing bacteria (SRB) are often the culprits of microbiologically influenced corrosion (MIC) in anoxic environments because sulfate is a ubiquitous oxidant. MIC of carbon steel caused by SRB is the most intensively investigated topic in MIC because of its practical importance. It is also because biogenic sulfides complicate mechanistic SRB MIC studies, making SRB MIC of carbon steel is a long-lasting topic that has generated considerable confusions. It is expedient to think that biogenic H2S secreted by SRB acidifies the broth because it is an acid gas. However, this is not true because endogenous H2S gets its H+ from organic carbon oxidation and the fluid itself in the first place rather than an external source. Many people believe that biogenic H2S is responsible for SRB MIC of carbon steel. However, in recent years, well designed mechanistic studies provided evidence that contradicts this misconception. Experimental data have shown that cathodic electron harvest by an SRB biofilm from elemental iron via extracellular electron transfer (EET) for energy production by SRB is the primary cause. It has been demonstrated that when a mature SRB biofilm is subjected to carbon source starvation, it switches to elemental iron as an electron source and becomes more corrosive. It is anticipated that manipulations of EET related genes will provide genetic-level evidence to support the biocathode theory in the future. This kind of new advances will likely lead to new gene probes or transcriptomics tools for detecting corrosive SRB strains that possess high EET capabilities.

Extracellular electron transfer in microbial biocorrosion

[J].