天然气中的页岩气是有机储集岩系中的非常规天然气,开采条件极为苛刻[1-3]。开采环境的复杂和恶劣使管线钢发生严重的腐蚀,如发生缝隙腐蚀、应力腐蚀开裂、微生物腐蚀(MIC)、以及多因素耦合腐蚀[4,5]。在页岩气的开采过程中,产出的水中有大量的微生物,包括硫酸盐还原菌(SRB)、乙酸菌和甲烷菌等。SRB是产生微生物腐蚀的主要细菌。Liu等[6]和Liao等[7]分别指出,SRB极易在X70管线钢和X65管线钢的管壁表面繁殖,生成的生物膜使管线钢发生严重的局部腐蚀。温度是影响MIC的重要因素,在不同温度下细菌的生物活性和代谢机制不同。页岩气田的温度甚至高于100 ℃,且随着油气田开采过程中工况深度的变化而变化[8]。Salgar-Chaparro等[9]发现,在不同温度发生MIC的程度不同,是生物代谢活性的不同所致。

1 实验方法

1.1 试样的制备及菌种来源

实验用N80钢的化学成分为C 0.47,Mn 1.55,Si 0.25,S 0.008,P 0.015,Fe余量。将尺寸为50 mm × 25 mm × 2 mm的N80钢挂片试样用系列砂纸依次横纵打磨至1000#,用无水乙醇和丙酮冲洗后用吹风机冷风吹干,然后称其质量。将尺寸为10 mm × 10 mm × 2 mm的N80钢试样用环氧树脂和固化剂密封后风干,表面用砂纸横纵打磨至1000#后用无水乙醇冲洗并吹干。

实验用复配杀菌缓蚀剂的主要成分:THPS、D-络氨酸、二甲基亚砜和壳聚糖。将取自国内某油田的实验菌种富集培养、分离和提纯,鉴定表明其为SRB脱硫弧菌属(Desulfovibrio sp)。

1.2 细菌数的测定

用绝迹稀释法(MPN)测定溶液中的SRB菌数。将待测溶液接种并逐级稀释至10-7,在温度为37 ℃的生化培养箱中培养14 d后进行阳性反应读数,根据国家标准(GB/T14643.5-2009)[13]得到溶液中SRB的细菌浓度,复配杀菌缓蚀剂对SRB的杀菌率为

式中nWithout为不添加杀菌剂时培养14 d测得的细菌浓度(cell/mL);nWith为添加杀菌剂后培养14 d测得的细菌浓度(cell/mL)。根据SY/T5523-2016[14]测定SRB溶液中的S2-,得到SRB产生的S2-含量。

1.3 测定腐蚀速率和缓蚀率

实验中用美国石油协会(API)的标准培养基(GB/T14643.6-2009)[13]培养SRB。将配置好的培养基和广口瓶在121 ℃灭菌20 min,然后置于无菌操作台上冷却。在2个灭菌后容积为125 mL的无菌密封瓶中加入114 mL的SRB培养基和6 mL的SRB,放入3组平行试样。其中一组加入复配杀菌缓蚀剂;另一组作为对照实验放入20 ℃的培养箱中,在37和50 ℃处理,方式同上。浸泡14 d后取出,其腐蚀速率v (mm/a)为

式中:m0为腐蚀试验前试片的原始质量(g);m为腐蚀实验后去除腐蚀产物的试片质量(g);A为试片的表面积(cm2);

为了研究复配杀菌缓蚀剂对N80钢腐蚀行为的影响,根据相关腐蚀速率和计算出复配杀菌缓蚀剂对N80钢的缓蚀率(η)为

式中vWithout为不添加杀菌剂时的腐蚀速率,vWith为添加杀菌剂时的腐蚀速率。

1.4 电化学阻抗谱(EIS)的测定

在2个灭菌后容积为500 mL的无菌密封瓶瓶中加入475 mL的SRB培养基和25 mL的SRB,再分别放入2个平行试样,后续实验的分组和实验环境与细菌数的测定实验相同。使用三电极体系进行电化学实验:在不同温度下腐蚀14 d尺寸为10 mm × 10 mm × 2 mm的N80试样为工作电极,饱和甘汞电极为参比电极,铂电极为辅助电极。使用M2273电化学测试系统进行实验,EIS的测试频率范围为10-2~105 Hz,正弦波幅值为10 mV。

1.5 试样腐蚀产物的表面形貌观察

将腐蚀14 d的N80钢试样(表面附着生物膜)先在5%的戊二醛溶液中固定30 min,然后用无水乙醇逐级脱水和干燥;用扫描电子显微镜(SEM,TESCAN MAIA3LMH)观察试样腐蚀产物的表面形貌,用配套的电子能谱(EDS)仪分析腐蚀产物的成分,用X射线衍射仪分析腐蚀产物的物相。

2 结果和讨论

2.1 SRB的细菌浓度

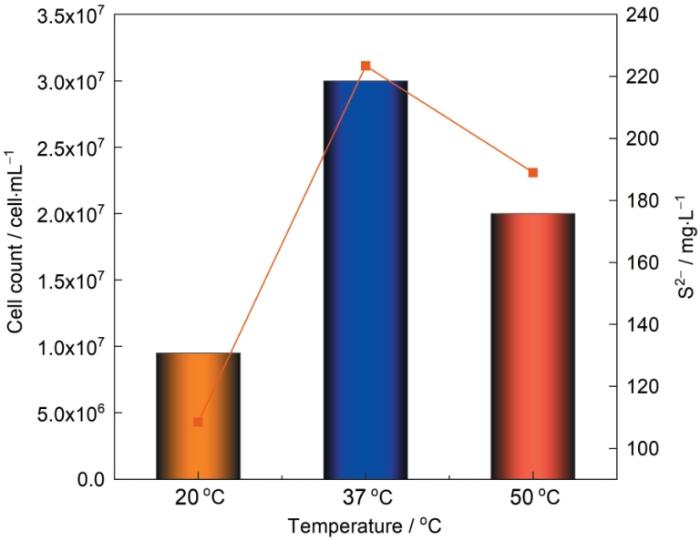

图1给出了SRB分别为在25、37和50 ℃培养14 d的SRB细菌浓度和硫化物含量。表1列出了复配杀菌缓蚀剂在25、37和50 ℃对SRB的杀菌率。由图1可见,在不同温度培养14 d后SRB的细菌浓度高低的排序为37 ℃ > 50 ℃ > 20 ℃。这表明,在37 ℃ SRB的生长繁殖最好,活性最高,细菌浓度约为20 ℃时的3倍,50 ℃时的1.5倍;而20 ℃时SRB数量最少,活性最低。SRB以SO

图1

图1

SRB在不同温度生长14 d的细菌浓度和硫化物含量

Fig.1

Bacterial concentration and sulfide content of SRB grown at different temperatures for 14 d

表1 复配杀菌缓蚀剂在不同温度下对SRB的杀菌率

Table 1

| Temperature | 20 oC | 37 oC | 50 oC |

|---|---|---|---|

| SRB bactericidal rate | 92.05% | 99.00% | 49.05% |

这表明,温度决定了SRB的生长速度和代谢活动,温度过高和过低都抑制SRB的生长。因此,本文实验中使用中温SRB,37 ℃是最适宜的生长温度,生长代谢速度最高。由表1可见,在20和37 ℃复配杀菌缓蚀剂对SRB杀菌率均达到90%以上,表明杀菌效果显著;而50 ℃时的杀菌率仅为49.05%。其原因是,在过高的温度下溶液中的分子运动加快,使缓蚀剂分子的解吸率提高和壳聚糖中的N、O、S元素与Fe2+生成的保护性吸附膜解离。

2.2 失重分析

图2

图2

N80钢在不同温度的SRB溶液中腐蚀14 d后的质量损失

Fig.2

Mass loss and corrosion inhibition rate of N80 steel corroded in SRB solution at different temperatures for 14 d

表2 复配杀菌缓蚀剂对N80钢在不同温度下的缓蚀率

Table 2

| Temperature | 20 oC | 37 oC | 50 oC |

|---|---|---|---|

| Corrosion inhibition rate (η) | 65.45% | 64.79% | 0.26% |

由图2和表2可见,N80钢在不同温度的SRB溶液中腐蚀14 d腐蚀速率高低的排序为:37 ℃(0.03553 mm/a,中度腐蚀) > 50 ℃ (0.03062 mm/a,中度腐蚀) > 20 ℃ (0.02316 mm/a,轻度腐蚀)。由此可见:在37 ℃腐蚀最严重,在50 ℃次之,在20 ℃腐蚀最轻。其原因是:SRB在37 ℃活性最高,适合其生长繁殖;SRB在20 ℃活性最低,生长繁殖受到抑制。这些结果,与图1给出的结果一致。加入复配杀菌缓蚀剂后,N80钢在37 ℃的腐蚀速率由0.03553 mm/a(中度腐蚀)降低到0.01251 mm/a(轻度腐蚀),η为64.79%,在20 ℃降低到了65.45%。而添加复配杀菌缓蚀剂后N80钢在50 ℃时的年腐蚀深度几乎不变,η仅为0.26%。其原因是,在过高的温度下激烈的热运动打破了杀菌缓蚀剂中分子的平衡,杀菌缓蚀性能的降低影响了杀菌缓蚀效果。

2.3 电化学阻抗谱

图3给出了N80钢在不同温度的SRB溶液中腐蚀14 d的Nyquist、Bode以及拟合曲线。无复配杀菌缓蚀剂时,不同温度下容弧抗半径大小的排序为37 ℃ < 50 ℃ < 20 ℃。容抗弧半径越小表明N80钢的腐蚀越严重,与质量损失和SRB计数结果吻合。加入复配杀菌缓蚀剂后N80钢在37和20 ℃的容抗弧半径显著变大,最大相位角向高频移动。这表明,此时N80钢基体表面的生物膜疏松,复配杀菌缓蚀剂的效果好。但是,50 ℃的容抗弧半径反而变小,最大相位角几乎不变。其原因是,过高的温度在复配杀菌缓蚀剂中引入了其他离子,促进了N80钢的溶解。这表明,温度对SRB引起的腐蚀有重要的影响。

图3

图3

N80钢在不同温度SRB溶液中腐蚀14 d后的Nyquist、Bode以及拟合曲线

Fig.3

N80 corrodes 14 d EIS of (a) Nyquist plots, (b, c) Bode plots in SRB solutions at different tem-peratures

表3 N80在不同温度SRB溶液中腐蚀14 d的EIS拟合结果

Table 3

| Temperature | Rs | Yf | nf | Rf | Ydl | ndl | Rct | W | Equivalent circuit |

|---|---|---|---|---|---|---|---|---|---|

| Without adding compound bactericidal corrosion inhibitor | |||||||||

| 20 oC | 16.24 | 6.14 × 10-3 | 1.00 | 42.19 | 7.716 × 10-2 | 0.977 | 756.3 | - | |

| 37 oC | 16.36 | 9.30 × 10-2 | 0.95 | 361.9 | 1.054 × 10-2 | 0.69 | 9.43 | - | |

| 50 oC | 10.08 | 5.16 × 10-4 | 1.00 | 447.9 | 4.689 × 10-4 | 1.00 | 307.4 | - | |

| Adding compound bactericidal corrosion inhibitor | |||||||||

| 20 oC | 19.81 | 2.98 × 10-3 | 1.00 | 192.3 | 1.256 × 10-3 | 0.87 | 2960 | - | |

| 37 oC | 19.76 | 1.69 × 10-3 | 1.00 | 9937 | 2.50 × 10-3 | 0.86 | 10.11 | - | |

| 50 oC | 19.13 | 6.42 × 10-4 | 0.91 | 482.2 | 1.747 × 10-3 | 0.88 | 50.36 | 3.75 × 10-3 | |

图4

由表3可见,在20和37 ℃加入复配杀菌缓蚀剂后,Yf都有不同程度的减小。Yf减小说明电极表面膜减小和Rct增大,表明电荷转移受到阻碍。其原因是,杀菌剂THPS使SRB代谢产物减少和杀菌增强剂D-络氨酸促进了生物膜解体,使N80钢的表面腐蚀程度降低。但是在50 ℃加入复配杀菌缓蚀剂后Yf没有变小的趋势,Rct和电荷转移阻碍减小且nf值偏离1。这表明,此时N80钢表面腐蚀产物膜堆积、表面粗糙,腐蚀电流不均匀的程度提高和腐蚀严重。

图5给出了N80钢在不同温度的SRB溶液中腐蚀14 d后的R

图5

图5

N80钢在不同温度的SRB溶液中腐蚀14 d后的R

Fig.5

N80 steel corroded R

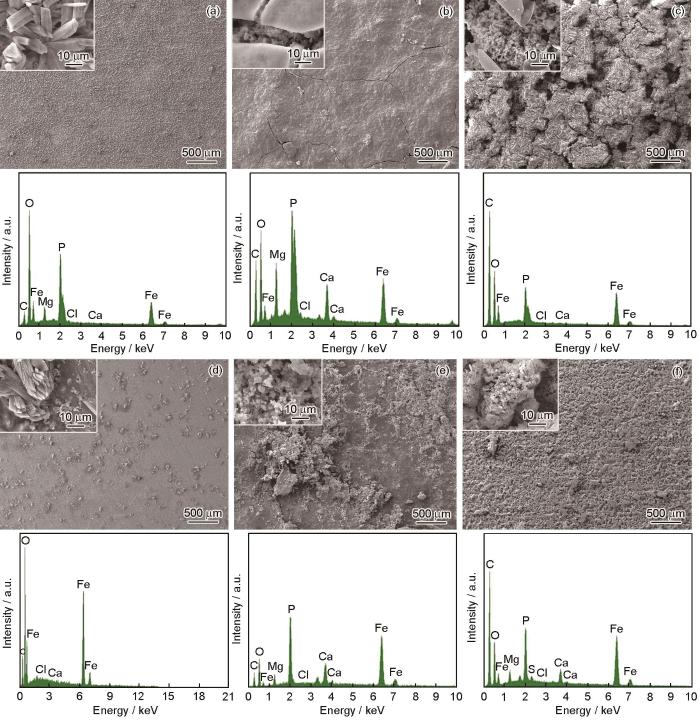

2.4 N80钢腐蚀后的表面形貌

图6给出了N80钢在不同温度的SRB溶液中腐蚀14 d的SEM照片和EDS图。根据代谢腐蚀产物理论[17],在厌氧条件下SRB代谢生成活性较高且挥发性强的磷化物,与基体反应促进基体溶解,提高了腐蚀速率。由图6可以看出,没有复配杀菌缓蚀剂时N80钢在37 ℃的腐蚀产物膜最厚,完全覆盖了基体表面。这表明,此时的SRB生长活性最好。但是在高倍下可见其上有大量裂缝,使溶液中的P2-和Cl-从裂缝处进入膜内引起基体表面的电子发生转移,进一步促进N80钢发生点蚀。同时,37 ℃时P2-、Cl-和Ca2+的含量最高。这个结果与该温度下N80钢腐蚀最严重的结果吻合,而在另外两个温度下腐蚀性的产物含量都有所降低。加入复配杀菌缓蚀剂后,N80钢表面腐蚀产物膜的厚度显著减小且分布不均匀,部分基体表面裸露,在高倍镜下可见腐蚀产物膜疏松(在37 ℃尤为明显),且介质中的腐蚀性离子Cl-与SRB代谢生成的P2-和S2-的含量显著降低。这表明,复配杀菌缓蚀剂对SRB有很好的生长抑制和杀菌作用,能杀灭微生物膜下的SRB,对N80钢有很好的缓蚀作用。

图6

图6

N80钢在不同温度SRB溶液中腐蚀14 d后的SEM照片和EDS图

Fig.6

SEM and EDS images of N80 steel corroded in SRB solution at different temperatures for 14 d (a) no bactericidal at 20 oC; (b) no bactericidal at 37 oC; (c) no bactericidal at 50 oC; (d) with bactericidal at 20 oC; (e) with bactericidal at 37 oC; (f) with bactericidal at 50 oC

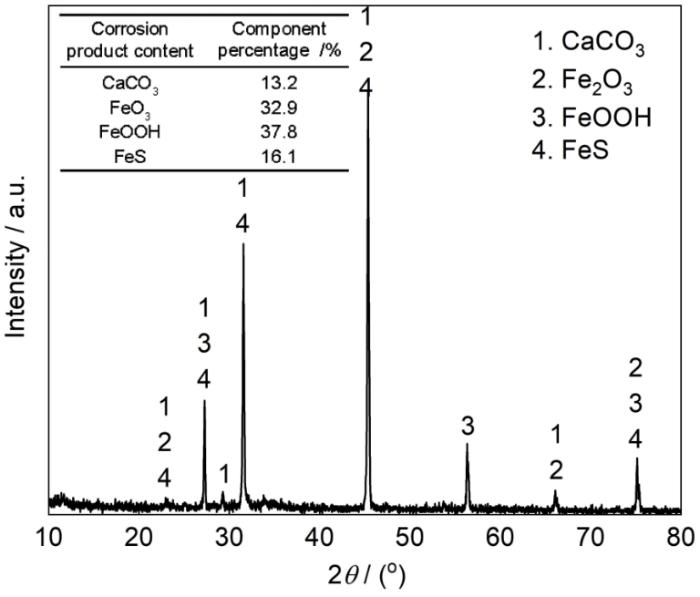

图7给出了N80钢在SRB溶液中腐蚀14 d后腐蚀产物的XRD谱。可以看出,N80钢在SRB中的腐蚀产物主要有FeOOH、Fe2O3、FeS和CaCO3,其含量分别为37.8%、32.9%、16.1%和13.2%。其中Ca2+与CO

图7

图7

N80钢在SRB溶液中腐蚀14 d后的XRD谱和腐蚀产物的含量

Fig.7

XRD pattern and corrosion product content of N80 steel after 14 d corrosion in SRB solution

3 讨论

从SEM照片和EDS可见,SRB生长代谢产生了大量的硫化物和磷化物。根据代谢腐蚀产物理论[17],SRB产生的H2S与溶液介质中的磷酸盐等发生反应生成磷化物。硫化物和磷化物与基体发生进一步反应,促进了基体的溶解。根据质量损失和细菌计数,温度是影响SRB生长代谢的重要因素。对于中温SRB,适宜的生长温度为30~37 ℃,其活性越高则腐蚀性越强。

加入复配杀菌缓蚀剂后,杀菌剂THPS中的羟甲基破坏浮游态细菌的细胞膜和蛋白质而抑制酶活性,使金属表面的细菌死亡;杀菌增强剂D-络氨酸作为信号分子与SRB蛋白质结合使生物膜分解脱落和氧浓差降低,减缓了基体腐蚀;增效渗透剂二甲基亚砜对亲水性和亲脂性基团有促渗作用且使其起效迅速,因此能促进THPS的亲油基团羟甲基渗透进入SRB细胞膜内,有利于杀菌剂发挥作用;缓蚀剂壳聚糖中的N、O、S元素继续与基体表面的Fe2+结合生成一层新的保护膜[18],减轻了N80钢的腐蚀。这表明,在37和20 ℃腐蚀速率降低,硫化物和磷化物大量减少。但是在50 ℃腐蚀速率仍然较高,因为温度超过了最佳温度,此时分子运动加快使吸附在N80钢表面的分子解吸效率提高[19,20]。同时,温度的提高也加速了N80钢的溶解,降低了缓蚀效果。结合XRD谱的产物分析可知,在SRB环境中溶液中的碳源和脂肪源为SRB提供能量,使SRB生长繁殖。同时,SRB以SO

代谢产生的S2-与Fe2+发生反应生成FeS且附着在基体表面形成锈瘤,锈瘤下的基体缺氧从而成为阳极,加剧了点蚀的发生,不稳定的Fe2+又氧化成Fe3+而生成Fe2O3:

4 结论

(1) 在不同温度下SRB生物活性的不同使N80钢的MIC行为不同,腐蚀速率与SRB的生长活性成正比。37 ℃时SRB生长繁殖的状态最佳,S2-含量最高,使腐蚀速率最高、腐蚀最严重。

(2) 复配杀菌缓蚀剂在37和20 ℃时的η分别达到了64.79%和65.45%,杀菌效果显著;过高的温度使缓蚀剂分子的解吸率提高、壳聚糖中的N、O、S元素与Fe2+生成的吸附膜解离,使缓蚀率和对SRB的杀菌率降低。

(3) 复配杀菌缓蚀中的杀菌增强剂D-酪氨酸使固着态生物膜发生脱落和氧浓差梯度减小,使腐蚀速率显著降低和杀菌剂THPS使SRB失去活性。增效渗透剂二甲基亚砜使THPS加速进入细菌细胞膜内提高杀菌作用。缓蚀剂壳聚糖与Fe2+生成的新保护膜使材料不易发生腐蚀。

(4) SRB代谢产生的硫化物、磷化物与N80钢基体发生腐蚀反应,以及腐蚀产物附着在基体表面形成的阴极与钢基体阳极形成氧浓差电池,促进点蚀的发生。

参考文献

Microbiologically influenced corrosion of carbon steel pipeline in shale gas field produced water containing CO2 and polyacrylamide inhibitor

[J].

Bio-natural gas industry in China: current status and development

[J].

Microbiological corrosion acceleration of N80 steel in shale gas field produced water containing Citrobacter amalonaticus at 60 oC

[J].

Failure analysis of an offshore drilling casing under harsh working conditions

[J].

Failure analysis of casing dropping in shale oil well during large scale volume fracturing

[J].

Effect of fluid flow on biofilm formation and microbiologically influenced corrosion of pipelines in oilfield produced water

[J].

Under-deposit microbial corrosion of X65 pipeline steel in the simulated shale gas production environment

[J].

The effect of temperature on flowback data analysis in shale gas reservoirs: a simulation-based study

[J].

Microbiologically influenced corrosion as a function of environmental conditions: a laboratory study using oilfield multispecies biofilms

[J].

Effect of D-amino acids on corrosion behavior of different steels due to mixed bacteria

[J].The effect of biocide and D-amino acid on the corrosion behavior of 20# carbon steel, N80 steel and P110 steel in the media of SRB+IOB mixed bacteria, was comparatively assessed by using weight loss method, electrochemical measurements and SEM. In the tests without biocide, P110 suffered from severe corrosion with weight loss of 0.278 mm/a, while weight loss of 20# and N80 were 0.149 and 0.148 mm/a respectively, while uniform and dense biofilms with deposited corrosion products formed on the surface of all the steels; in the tests with biocide, the corrosion of the three steels slowed down, it is found that the formed rust scales on the surface of steels with significantly lower content of Ca Mg, P, and S, but with cracks and spallation steels. The electrochemical measurement results also revealed that the corrosion rate of three steels was significantly reduced when they were immersed for 14 d in the corrosive media with addition of biocides. The corrosion mechanism of SRB and IOB mixed bacteria is probably due to that SRB oxidizes Fe to Fe2+ through its own metabolism, and Fe2+ is further oxidized by IOB to Fe3+, and IOB provides environmental conditions for SRB so as to form a synergistic effect. It is proposed that D-amino acids and biocide effectively inhibit MIC behavior by regulating the bacterial gene expression and destroys the cell structure, as well as the oxygen concentration difference environment. Due to the different content of C, Cu and others, the corrosion rate of the three steels may be different under the sterile conditions.

D-氨基酸对不同钢材混合菌腐蚀行为的影响

[J].研究了杀菌剂与D-氨基酸对20#碳钢、N80钢以及P110钢在硫酸盐还原菌(SRB)+铁氧化菌(IOB)混合菌腐蚀过程中的影响作用,利用失重与电化学测量以及扫描电镜(SEM)对腐蚀形貌分析等初步探索了D-氨基酸的杀菌缓蚀增强机理。无杀菌剂组中P110发生严重腐蚀(0.278 mm/a),20#与N80腐蚀速率较低(为0.149、0.148 mm/a),所有试样表面有均匀且致密的生物膜以及腐蚀产物堆积;有杀菌剂组中三种钢材腐蚀程度减缓,腐蚀产物膜发生龟裂、剥离,其中Ca、Mg、P以及S含量明显减少。在添加杀菌剂溶液中浸泡14 d后,三种钢材的腐蚀速率明显降低。有无杀菌剂下,三种钢材耐蚀性由优到差排序均为N80>20#>P110。SRB和IOB混合菌的腐蚀机制可能是由于SRB通过自身代谢将基体Fe氧化为Fe<sup>2+</sup>,Fe<sup>2+</sup>又被IOB进一步氧化为Fe<sup>3+</sup>且IOB为SRB提供环境条件形成了协同作用。D-氨基酸和杀菌剂通过调控细菌基因表达、破坏细胞结构、氧浓差环境等方式有效的抑制微生物腐蚀(MIC)行为。三种钢材由于C、Cu等元素含量不同,使得三种钢材在无菌条件下腐蚀速率有所差异。

Mitigation of the Desulfovibrio vulgaris biofilm using alkyldimethylbenzylammonium chloride enhanced by D-amino acids

[J].

D-Tyrosine enhancement of microbiocide mitigation of carbon steel corrosion by a sulfate reducing bacterium biofilm

[J].

Corrosion behavior of carbon steel in the presence of sulfate reducing bacteria and iron oxidizing bacteria cultured in oilfield produced water

[J].

Genesis analysis of the petroleum associated H2S: a case study of Pengyang oilfield in Ordos Basin

[J].

石油伴生H2S的成因分析——以鄂尔多斯盆地彭阳油田为例

[J].

On the use of a constant phase element (CPE) in electrochemistry

[J].

The inhibition effect of D-amino acid on the microbial corrosion of mixed bacteria

[J].

D-氨基酸对混合菌生物腐蚀的缓蚀行为影响分析

[J].

Effects of sulfate reducing bacteria on anaerobic corrosion of mild steel

[J].

硫酸盐还原菌对碳钢腐蚀的影响

[J].采用失重法,极化曲线法和 SEM 研究了硫酸盐还原菌(SRB)诱导碳钢腐蚀的主要因素。实验结果表明,在 SRB 的代谢过程中,会产生一种挥发性的含磷化合物,它具有一定的腐蚀性,但导致碳钢腐蚀的主要因素是代谢产物中的硫化物,特别是硫化氢,以及在介质中可能大量存在的 Fe~(2+),它们对腐蚀电化学过程有明显的去极化作用。

Chitosan kills bacteria through cell membrane damage

[J].The bactericidal activity of chitosan (CS) acetate solution against Escherichia coli and Staphylococcus aureus was evaluated by the enumeration of viable organisms at different incubation times. Morphologies of bacteria treated with CS were observed by transmission electron microscopy (TEM). The integrity of the cell membranes of both species and the permeabilities of the outer membrane (OM) and inner membrane (IM) of E. coli were investigated by determining the release from cells of materials that absorb at 260 nm, changes in the fluorescence of cells treated with the fluorescent probe 1-N-phenylnaphthylamine (NPN) and release of cytoplasmic beta-galactosidase activity. In addition, the interaction of CS with synthetic phospholipid membranes was studied using gel permeation chromatography (GPC), UV-VIS spectrophotometery, Fourier-transform infrared spectroscopy (FT-IR) and thermal analysis. Results showed that CS increased the permeability of the OM and IM and ultimately disrupted bacterial cell membranes, with the release of cellular contents. This damage was likely caused by the electrostatic interaction between NH(3)(+) groups of CS acetate and phosphoryl groups of phospholipid components of cell membranes.

Scale and corrosion inhibition performance of carboxymethyl chitosan

[J].

羧甲基壳聚糖阻垢缓蚀性能研究

[J].

The mechanism and inhibition effect on chitosan for mild steel in 1 mol/L HCl

[J].

壳聚糖在1 mol/L HCl中对Q235碳钢的缓蚀性能及机理研究

[J].