钛合金的比强度高、密度低、耐高温和耐腐蚀性能优异,在航空航天、汽车制造和生物医疗等领域得到了广泛的应用[1~3]。但是,传统钛合金的制造工艺成本高昂且流程复杂,使其应用受到了限制。增材制造(Additive manufacturing, AM)技术的自由度高和材料的浪费较少,可替代传统工艺制造钛合金[4~6]。AM技术中的激光选区熔化(Selective laser melting, SLM)技术基于粉末床的熔化和固化特性,应用较广[7]。但是,金属AM工艺仍有一定的局限性。用AM工艺制造的部件内部往往出现大量的缺陷,常见的有未熔合和气孔[8,9]。航空航天和工程机械等领域设备的部件承受复杂的动态载荷,这些缺陷成为应力集中源和疲劳裂纹的萌生点,从而使其疲劳性能降低[10]。除了内部的固有缺陷,工程机械零部件中还常有几何形状突变的区域,如凹槽、轴肩和切口等,这些部位统称为缺口。在缺口的根部,局部应力集中产生极大的应力梯度,是疲劳损伤高发区域[11]。这种应力集中显著降低材料缺口区域的抗疲劳性能,尤其是较小的缺口曲率半径使其尖锐度提高,从而使缺口的应力集中系数增大和材料疲劳失效的风险提高[12~14]。

1 实验方法

表1 Ti-6Al-4V合金的成分

Table 1

| Material | Al | V | O | C | N | Fe | Ti |

|---|---|---|---|---|---|---|---|

| Wrought | 6.00 | 4.07 | 0.152 | 0.016 | 0.004 | 0.050 | Bal. |

| SLM+HIP | 6.11 | 4.05 | 0.08 | 0.01 | 0.01 | 0.11 | Bal. |

用EOS-M280增材制造试件,采用双向平行扫描,在预热至约200 ℃的基板上沿Z方向逐层构建Ti-6Al-4V毛坯零件。为了提高质量,SLM工艺的优化参数为:激光功率为280 W,扫描速度为1400 mm/s,单层厚度为30 μm,舱口间距为90 μm。在打印过程用氩气保护。

打印完成后,将试件退火:(1) 在800 ℃真空炉中保温2 h,以释放残余应力;(2) 依据ASTM F2924标准在氩气环境中进行HIP处理:在920 ℃施加150 MPa的压力,保温保压3 h,加热速率为9 ℃/min,冷却过程是自然对流。依据ASTM标准E466和E647将热处理后的试件加工成标准几何形状的拉伸试样和含缺口(Kt = 3)的高周疲劳试样。图1a、b分别给出了拉伸试样和高周疲劳试样的尺寸。

图1

图1

试样的尺寸形状和实验方法

Fig.1

Dimensions of tensile (a) and fatigue (b) specimens, and experimental method (c)

用MTS-370伺服液压疲劳实验机进行拉伸测试和高周疲劳寿命测试。使用位移加载模式进行拉伸测试,设定加载速率为0.5 mm/min,将预校准的引伸计安装在试样的工作段,实时记录力载荷变化,以分析试样的拉伸变形行为和力学性能。用力控制模式进行高周疲劳测试,用夹具固定试样并施加正弦波载荷。疲劳测试的频率为30 Hz,应力比为0.06,试样循环加载直至失效,失效时的循环次数由试验机传感器自动记录,测试场景在图1c中给出。

表征和分析失效试样断口的微观组织。用扫描电子显微镜(SEM,COXEM EM-30AX)观察断口的形貌,以识别疲劳裂纹的萌生和扩展路径,揭示材料失效机制。将硬度测试样品用400#、800#、1500#砂纸逐级打磨至表面光洁,用无水乙醇清洗后干燥。用维氏硬度计(TMVS-S1-ALC)进行压痕实验测试硬度,载荷为1 kg,保载时间为15 s;沿样品均匀区域选取12个测试点,剔除结果的最大和最小值后取剩余10个点硬度的均值。用电子背散射衍射(EBSD,eFlash FS-Bruker)技术表征试样的微观组织。从钛合金棒材上截取试样并用砂纸(180至1200目)逐级打磨后进行电解抛光。抛光电压为14 V,阳极为试样,阴极为铁极,抛光液为甲醇(90 mL)与高氯酸(10 mL)的混合液,抛光温度为-30 ℃,抛光时间100 s。将抛光后的试样用清水和乙醇清洗后吹干,进行EBSD扫描,步长为0.15 µm,放大倍数为2000,扫描区域的分辨率高于90%。将试样电解抛光后,用Kroll试剂HF∶HNO3∶H2O = 1∶3∶6 (体积比)腐蚀10 s,用酒精冲洗并气吹干燥后用光学显微镜(Leica,DMI 3000M)观察其金相组织。

2 实验结果

2.1 金相组织和显微硬度

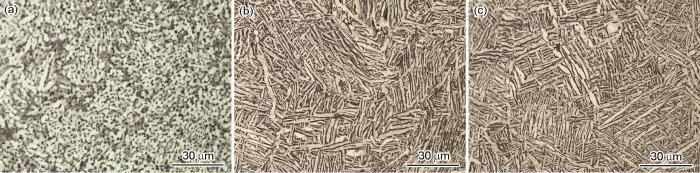

图2

图2

Ti-6Al-4V合金的金相组织

Fig.2

Metallographic microstructure of Ti-6Al-4V alloy (a) wrought Ti-6Al-4V alloy, (b) HIP-X Ti-6Al-4V alloy, (c) HIP-Z Ti-6Al-4V alloy

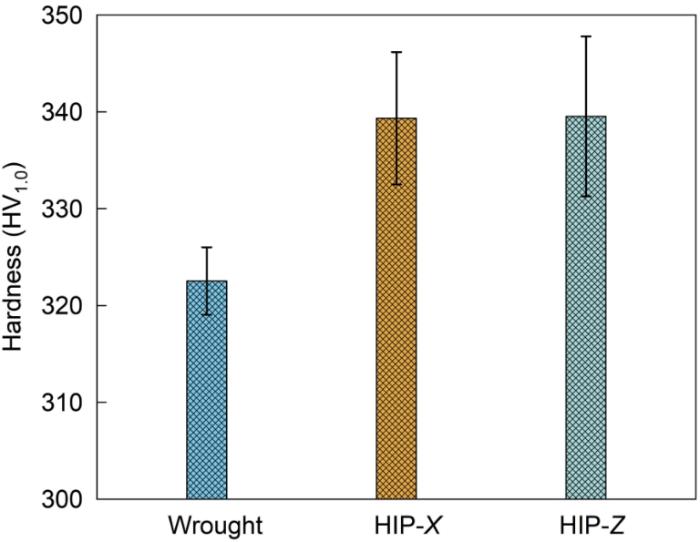

图3给出了Ti-6Al-4V合金的显微硬度。经SLM+HIP处理的Ti-6Al-4V合金在X向和Z向的显微硬度均约为339HV1.0。传统锻造Ti-6Al-4V合金的硬度约为322HV1.0,比SLM+HIP处理合金的硬度略低。

图3

图3

Ti-6Al-4V合金在不同条件下的显微硬度

Fig.3

Hardness of Ti-6Al-4V under different conditions

2.2 力学性能

表2列出了静力拉伸力学测试的结果。可以看出,锻造态Ti-6Al-4V合金与SLM+HIP Ti-6Al-4V合金的弹性模量没有显著的不同,SLM+HIP处理的合金拉伸强度显著高于锻造态。两种合金的断后伸长率都高于15%,表明其塑性和延展性良好。

表2 不同状态Ti-6Al-4V合金的静力拉伸力学性能

Table 2

| Material | Modulus / GPa | Strength / MPa | Elongation / % |

|---|---|---|---|

| Wrought | 115 ± 3.6 | 886 ± 17 | 19 ± 2.4 |

| HIP-X | 121 ± 6.3 | 1015 ± 8.7 | 18 ± 1.7 |

| HIP-Z | 117 ± 8.5 | 1022 ± 5.7 | 16 ± 2.5 |

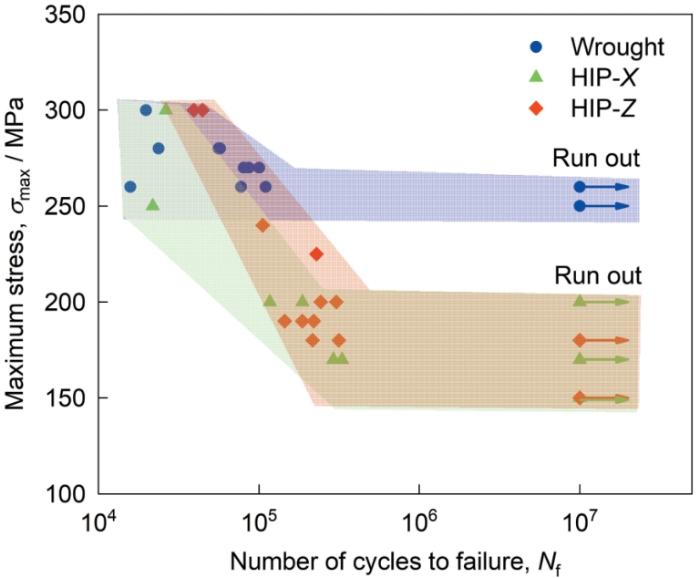

图4

2.3 断口形貌

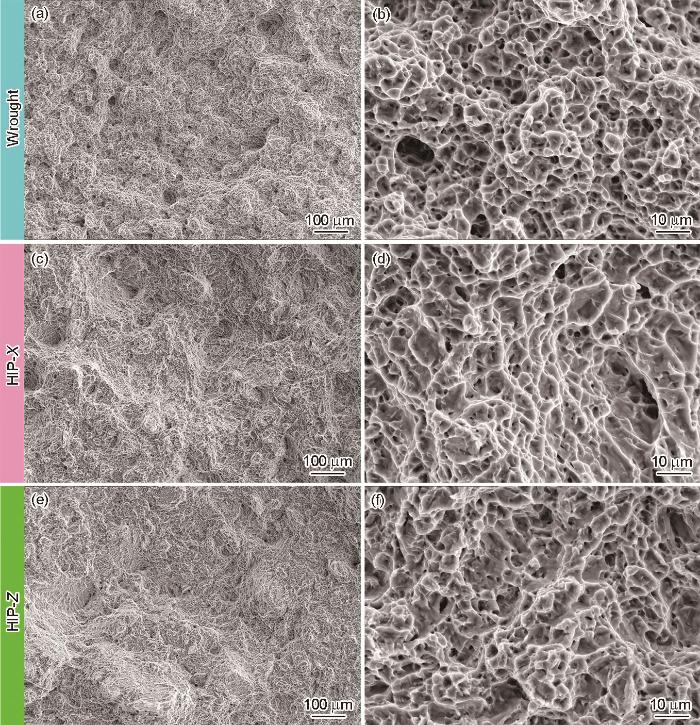

图5

图5

Ti-6Al-4V合金的拉伸断口形貌

Fig.5

Tensile fracture morphology of Ti-6Al-4V alloy (a, b) wrought Ti-6Al-4V alloy, (c, d) HIP-X Ti-6Al-4V alloy, (e, f) HIP-Z Ti-6Al-4V alloy

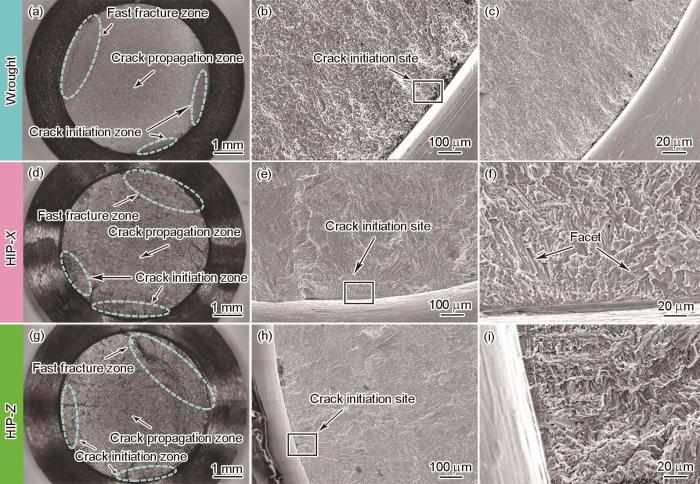

图6给出了在不同条件下处理的Ti-6Al-4V合金疲劳断口和裂纹源区域的宏观形貌。对比图6a、d和g可见,含缺口的SLM+HIP工艺Ti-6Al-4V合金试件的断裂面比锻造态试件更为粗糙。这表明,SLM+HIP工艺对Ti-6Al-4V合金的疲劳裂纹扩展路径的影响更为复杂,使其断口更曲折。值得注意的是,与光滑试件的高周疲劳中常见的单一裂纹源萌生不同,含缺口的Ti-6Al-4V合金的高周疲劳具有多裂纹源萌生的特点。对裂纹源区域的进一步观察表明,锻造态Ti-6Al-4V合金的裂纹起源于表面,具有典型的韧性断裂形貌,没有出现明显的缺陷(图6b和c)。SLM+HIP处理的Ti-6Al-4V合金虽然也表现出多裂纹源萌生特征,但是在裂纹萌生处有光滑刻面,呈现出准解理断裂特征(图6e、f、h、i)。

图6

图6

疲劳试件断口的宏观形貌和裂纹萌生位置的微观形貌

Fig.6

Macro fracture morphology and microstructure at crack initiation site in fatigue specimens (a-c) wrought Ti-6Al-4V alloy, (d-f) HIP-X Ti-6Al-4V alloy, (g-i) HIP-Z Ti-6Al-4V alloy

图7

图7

不同位置的疲劳裂纹扩展的微观形貌

Fig.7

Microstructure of fatigue crack propagation zone (a-c) wrought Ti-6Al-4V alloy, (d-f) HIP-X Ti-6Al-4V alloy, (g-i) HIP-Z Ti-6Al-4V alloy

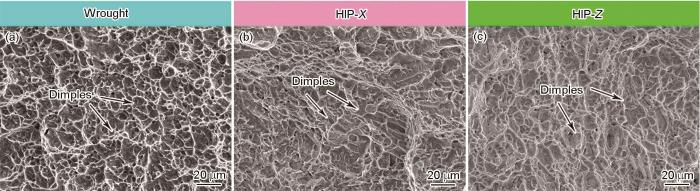

图8

图8

不同状态下Ti-6Al-4V合金疲劳瞬断区的微观形貌

Fig.8

Microstructure of fatigue instantaneous fracture zone (a) wrought Ti-6Al-4V alloy, (b) HIP-X Ti-6Al-4V alloy, (c) HIP-Z Ti-6Al-4V alloy

3 讨论

3.1 微观组织的不同

HIP处理消除了SLM Ti-6Al-4V合金内部的缺陷,使试件的致密程度与锻造件相同,图6中断口的照片可以佐证。裂纹源处未见划痕或硬质颗粒,表明裂纹的萌生与表面加工质量无关。同时,对所有试件的热处理消除了残余应力,因此在缺口应力集中条件下SLM+HIP Ti-6Al-4V合金的疲劳性能低于锻造件与微观组织的不同有关。

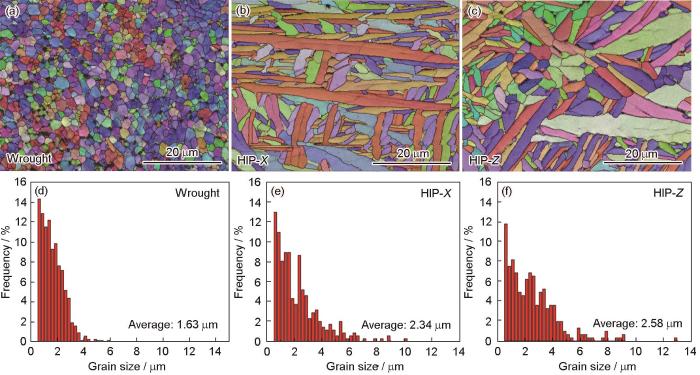

图9a、b、c中的EBSD图给出了不同条件下Ti-6Al-4V合金的典型微观结构。锻造态Ti-6Al-4V合金具有等轴晶和随机取向晶粒的形貌,而SLM+HIP Ti-6Al-4V合金具有复杂的板条状形貌。使用Azteccrystal软件统计了晶粒尺寸:用等效圆直径表征等轴晶,用等效椭圆短轴长度表征板条状组织。图9d、e、f表明,SLM+HIP态Ti-6Al-4V合金的大尺寸晶粒比例显著高于锻造件。统计结果表明,X向(2.34 μm)与Z向(2.58 μm)的平均晶粒尺寸都显著比锻造件的(1.63 μm)高。根据Hall-Petch关系[27, 28],粗大晶粒的晶界处塞积的位错较多和应力集中严重,易于启动相邻晶粒的位错源使塑性变形容易;晶粒细小则晶界增多,晶界对位错运动的阻力使变形困难。

图9

图9

不同状态下Ti-6Al-4V合金样品的晶粒尺寸和微观结构

Fig.9

Grain structure (a-c) and size distribution (d-f) of Ti-6Al-4V under different processing conditions (a, d) wrought Ti-6Al-4V alloy, (b, e) HIP-X Ti-6Al-4V alloy, (c, f) HIP-Z Ti-6Al-4V alloy

3.2 缺口应力集中条件下Ti-6Al-4V的断裂模式

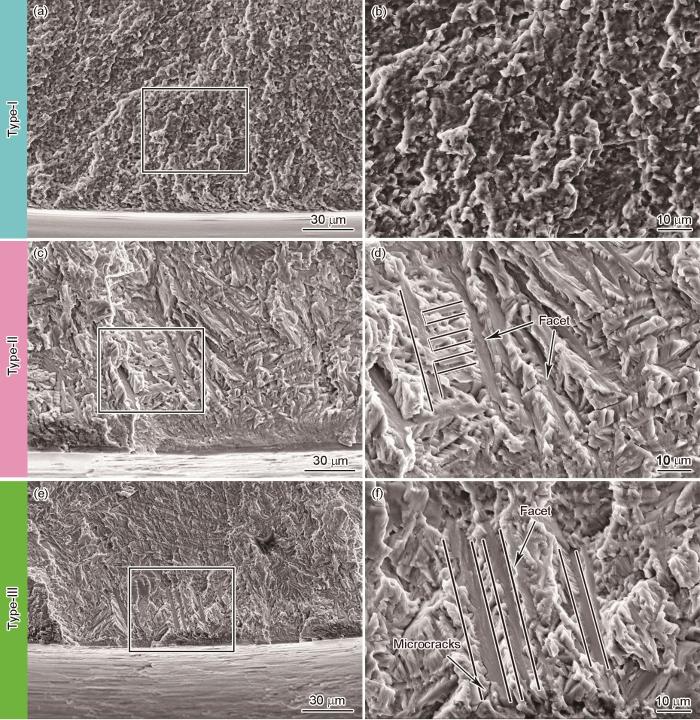

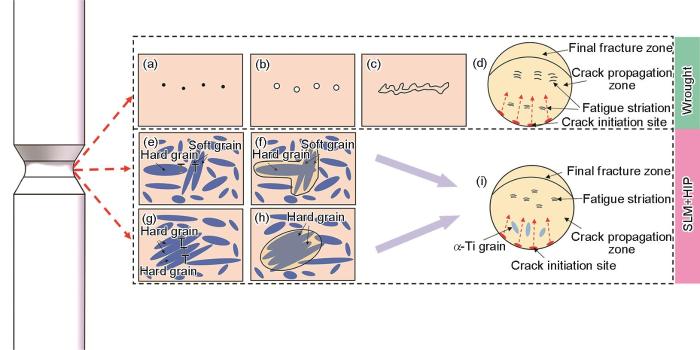

在本文的实验中观察到3种类型的疲劳裂纹萌生机制,分别命名为I型、II型和III型。I型为锻造态Ti-6Al-4V合金的疲劳裂纹萌生机制,裂纹萌生区域具有凹凸不平的“小峰”形貌(图10a和b),因为在塑性变形过程中微裂纹扩展并连接。SLM+HIP Ti-6Al-4V合金的疲劳裂纹萌生机制为II型和III型,两者都与微观结构中的刻面相关,与HIP导致的α板条粗化和变形有关[31](图10c~f)。其中II型刻面的分布较为复杂,由多个“T”形构成,而III型则由多条平行刻面构成,且附近出现了细小的次级裂纹(图10d和f)。刻面的形成机制遵循Bache[32]和Neal[33]提出的钛合金软/硬晶粒裂纹形核模型,涉及穿晶断裂和沿晶断裂两种模式。

图10

图10

缺口条件下Ti-6Al-4V合金的裂纹萌生机制

Fig.10

Different crack initiation mechanisms of Ti-6Al-4V alloy (a, b) ductile fracture, (c, d) transgranular fracture, (e, f) intergranular fracture

图11

图11

缺口应力集中条件下Ti-6Al-4V合金的断裂模式

Fig.11

Fracture modes of Ti-6Al-4V subjected to notch stress concentration (a-d) wrought, (e-i) SLM+HIP

结果还表明,缺口应力集中的锻造Ti-6Al-4V合金与SLM+HIP Ti-6Al-4V合金疲劳性能的不同,其原因是微观组织和裂纹萌生机制的不同。

4 结论

(1) 与传统的锻造件的拉伸强度相比,SLM+HIP技术制备的Ti-6Al-4V合金在X向和Z向的拉伸强度更高。两者的延伸率都比较高(超过15%),表明其延展特性优异。

(2) 与传统锻造件相比,SLM+HIP Ti-6Al-4V合金的缺口敏感性更高。SLM+HIP Ti-6Al-4V合金的疲劳缺口敏感性,主要源于其裂纹萌生机制及晶粒尺寸效应。SLM+HIP合金表现出准解理断裂特征,其危害性更高。其较大的晶粒尺寸,进一步使其疲劳性能降低。

参考文献

Damage tolerant design of additively manufactured metallic components subjected to cyclic loading: State of the art and challenges

[J].

Defects in additive manufactured metals and their effect on fatigue performance: A state-of-the-art review

[J].

A holistic review on fatigue properties of additively manufactured metals

[J].

Development of the additive manufacturing (3D Printing) technology

[J].

增材制造(3D打印)技术发展

[J].

Microstructural characterization and comparison of Ti-6Al-4V manufactured with different additive manufacturing processes

[J].

Research progress of microstructure and fatigue behavior in additive manufacturing Ti-6Al-4V alloy

[J].

增材制造Ti-6Al-4V合金组织及疲劳性能研究进展

[J].

Additive manufacturing in the context of structural integrity

[J].

Defect induced fatigue behaviors of selective laser melted Ti-6Al-4V via synchrotron radiation X-Ray tomography

[J].

基于同步辐射X射线成像的选区激光熔化Ti-6Al-4V合金缺陷致疲劳行为

[J].

Influences of surface integrity on fatigue property of Ti6Al4V alloy

[J].

表面完整性对Ti6Al4V钛合金疲劳性能的影响

[J].

Fracture and fatigue in additively manufactured metals

[J].

Influence of Notch Stress-concentration on the ultra-high-cycle fatigue behaviors of 40Cr steel

[J].

缺口应力集中对40Cr钢高周疲劳性能的影响

[J].

Notch deformation and stress gradient effects in multiaxial fatigue

[J].

Stress gradients around notches

[J].

Multiaxial fatigue analysis of notched components using combined critical plane and critical distance approach

[J].

Fatigue behaviour of notched additive manufactured Ti6Al4V with as-built surfaces

[J].

Fatigue strength of blunt V-notched specimens produced by selective laser melting of Ti-6Al-4V

[J].

Numerical modelling of surface roughness effect on the fatigue behavior of Ti-6Al-4V obtained by additive manufacturing

[J].

Notch fatigue and crack growth resistance of Ti-6Al-4V ELI additively manufactured via selective laser melting: A critical distance approach to defect sensitivity

[J].

Length scale parameters to estimate fatigue lifetime of 3D-printed titanium alloy Ti6Al4V containing notches in the as-manufactured condition

[J].

Investigation of the mechanisms by which hot isostatic pressing improves the fatigue performance of powder bed fused Ti-6Al-4V

[J].

Impact of hot isostatic pressing treatments on the mechanical performance of EBMed Ti-6Al-4V alloy

[J].

Comparison of the microstructures and mechanical properties of Ti-6Al-4V fabricated by selective laser melting and electron beam melting

[J].

Features of heat treatment the Ti-6Al-4V GTD blades manufactured by DLD additive technology

[J].

Fatigue life of additively manufactured Ti-6Al-4V in the very high cycle fatigue regime

[J].

On the mechanical behaviour of titanium alloy TiAl6V4 manufactured by selective laser melting: Fatigue resistance and crack growth performance

[J].

A comparative study of laser metal deposited and forged Ti-6Al-4V alloy: Uniaxial mechanical response and vibration fatigue properties

[J].

The deformation and ageing of mild steel: III discussion of results

[J].

Interior initiation and early growth of very high cycle fatigue crack in an additively manufactured Ti-alloy

[J].

Propensities of crack interior initiation and early growth for very-high-cycle fatigue of high strength steels

[J].

Effects of post-processing and loading orientation on high-cycle fatigue of selective laser melted Ti-6Al-4V

[J].

Processing titanium alloys for optimum fatigue performance

[J].

Internal fatigue origins in α-β titanium alloys

[J].