制备冷喷涂复合涂层使用的基底,有Al基、Cu基、Ti基和Ni基,增强相有Al2O3和SiC陶瓷粉末。在Al基中添加Al2O3陶瓷粉末能消除喷嘴堵塞,去除表面杂质、氧化层和提高表面的粗糙度,起“原位夯实”作用[15~17]。陈金雄[18]研究了AZ31镁合金冷喷涂纯Al和Al基复合涂层的摩擦学性能,发现AZ31镁合金和纯Al涂层的体积磨损率比Al-50% Al2O3复合涂层分别提高了约5倍和6倍。Qiu等[19]用冷喷涂法制备了Al2O3粉末增强A380铝合金复合涂层,随着Al2O3含量的提高涂层的孔隙率降低到约1%,且其摩擦系数和磨损率远低于纯A380涂层。Shockley等[20]用冷喷涂技术制备了Al-Al2O3复合涂层,Al2O3含量为50%的复合涂层其磨损率是纯Al涂层的18.69%。这表明,Al2O3粉末的加入可提高Al基复合涂层的耐磨性。

有限元模拟分析有材料配比及参数可调,节约成本等优势,并能为实验研究提供理论支撑。本文用冷喷涂技术在AZ91镁合金基体上制备不同Al2O3含量(0%、15%、30%、45%)的Al基复合涂层,测量涂层的孔隙率和Al2O3沉积效率并进行往复干摩擦磨损实验,研究Al2O3含量、载荷、频率对Al基复合涂层摩擦磨损行为的影响。基于ABAQUS有限元软件和PYTHON脚本建立不同Al2O3含量的Al基复合涂层有限元模型,在载荷为2 N、频率为1 Hz条件下进行Al基复合涂层往复摩擦磨损过程的仿真以与实验结果比较。

1 实验方法

1.1 实验用材料

冷喷涂实验用基体是用熔铸法制备的AZ91镁合金,其化学成分列于表1。冷喷涂材料是球形纯Al粉末(纯度为99.98%)和椭球形Al2O3粉末(纯度为99.5%)。

表1 AZ91镁合金的化学成分

Table 1

| Element | Al | Zn | Mg |

|---|---|---|---|

| Content | 9 | 1 | Bal. |

1.2 Al基复合涂层的制备

用冷喷涂(采用中国科学院金属研究所自主研发的IMR1000系统)制备不同Al2O3含量(质量分数分别为0%、15%、30%、45%)的Al基复合涂层,载气为压缩空气。冷喷涂工艺参数列于表2。用砂纸将冷喷涂复合涂层打磨到Ra0.2。用金相显微镜拍摄涂层截面图像,使用Image J软件测试涂层的孔隙率和Al2O3粉末的沉积效率。

表2 冷喷涂工艺参数

Table 2

Spray pressure / MPa | Gas temperature / oC | Powder feeding voltage / mV | Powder feeding rate / g·min-1 | Nozzle distance / mm |

|---|---|---|---|---|

| 1.6 | 230 | 28 | 30 | 30 |

1.3 摩擦磨损性能的测试

使用布鲁克TriboLab摩擦磨损试验机进行往复干摩擦试验,对磨副是直径为4 mm的氮化硅陶瓷球。载荷分别为2、4、8、10 N,频率分别为0.5、1、2 Hz,实验的总行程为1200 mm。使用2300A-R表面粗糙度测量仪测量磨损沟壑横截面轮廓,使用MATLAB计算沟壑的平均横截面积,将其与磨痕长度相乘即为磨损沟壑体积[21]。由于复合涂层中有孔隙,将其从沟壑体积中扣除即可得Al基复合涂层磨损量。与AZ91镁合金基体相比Al基复合涂层的耐磨性提高率ε为

式中n为数据组数,V1, i 为第i组AZ91镁合金基体磨损量(mm3),V2, i 为第i组Al基复合涂层磨损量(mm3)。

2 有限元磨损计算方程及实现方法

2.1 有限元磨损方程的建立

使用Archard模型,Al基复合涂层的磨损量V(mm3)为

式中K为无量纲磨损系数,F为法向载荷(N),s为滑动距离(mm),H为材料硬度(N/mm2)。

有限元中节点接触面积的有量纲磨损系数k(mm2/N)可表示为

于是

由此可得

式中h为磨损深度(mm),p为接触压力(MPa)。

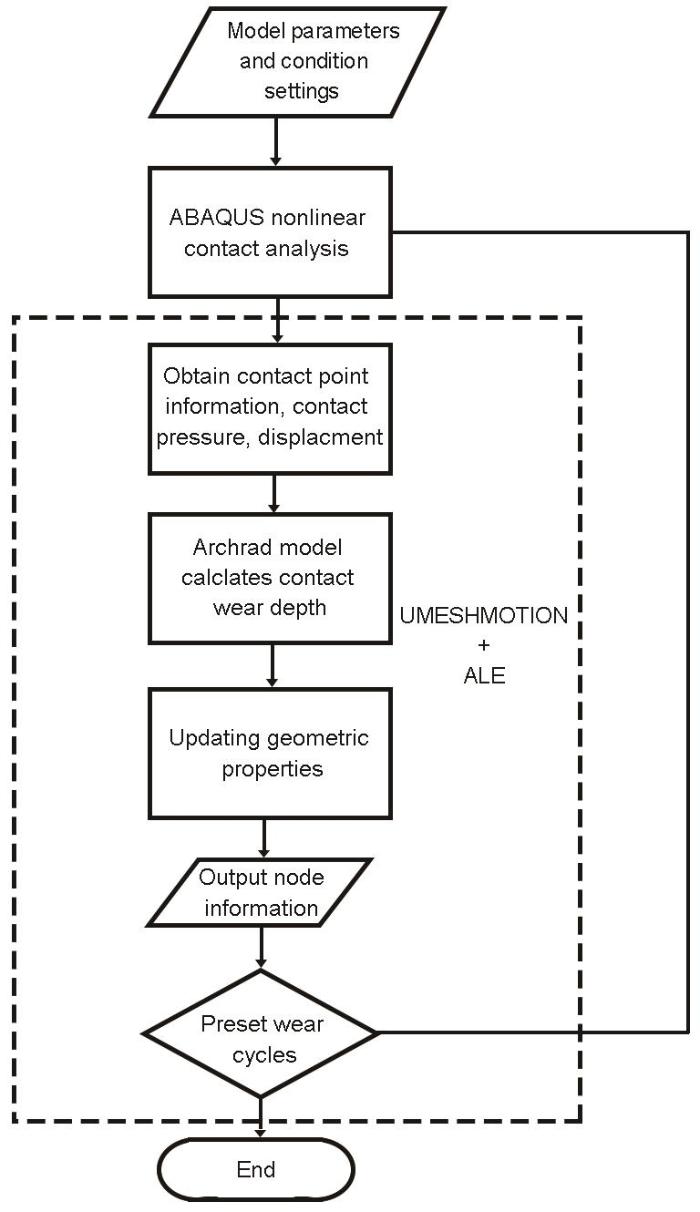

2.2 磨损深度的计算

使用通用静力学模块求解磨损过程中每个增量步的深度,以确保每个增量步为准静态过程。在摩擦磨损子程序UMESHMOTION中输入磨损系数,通过子程序读取求解过程的节点数据,代入Archard公式计算出节点偏移量增量,使用ALE自适应网格更新几何模型,完成增量步内的循环过程。磨损仿真流程,在图1中给出。经多次循环后得到磨损深度,在增量步内接触压力、滑移距离和磨损系数是常量。根据

图1

经多次往复循环,磨损深度为

式中N为循环次数。

3 磨损三维仿真模型的建立

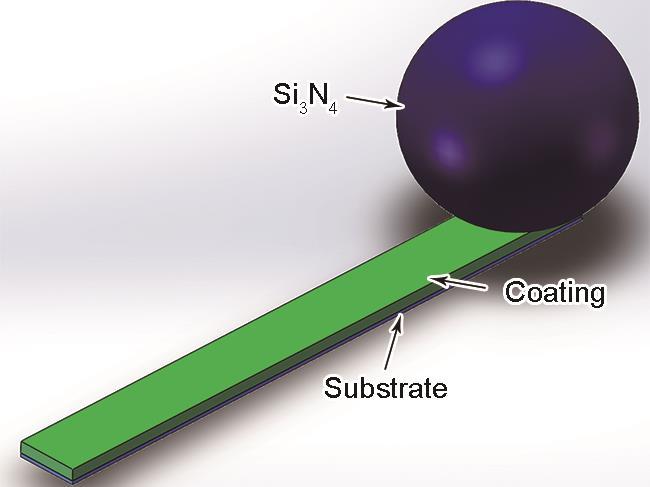

与涂层和基体相比,直径为4 mm的Si3N4对磨副弹性模量比较高,故可将其建模为解析刚体。为了便于施加载荷,在ABAQUS部件模块中将参考点设置在Si3N4球中心位置。为了减少运算时间,将涂层和基体的长宽高分别设置为12 mm × 1.2 mm × 0.24 mm和12 mm × 1.2 mm × 0.08 mm。图2给出了SOLIDWORKS往复摩擦磨损的三维实体模型,Si3N4小球沿着涂层做正弦往复运动。在建模过程中,假定复合涂层是各向同性弹性的且其摩擦系数为常量。

图2

图2

SOLIDWORKS往复摩擦磨损的三维实体模型

Fig.2

SOLIDWORKS 3D solid model of reciprocating dry friction wear

3.1 Al基复合涂层模型的使用

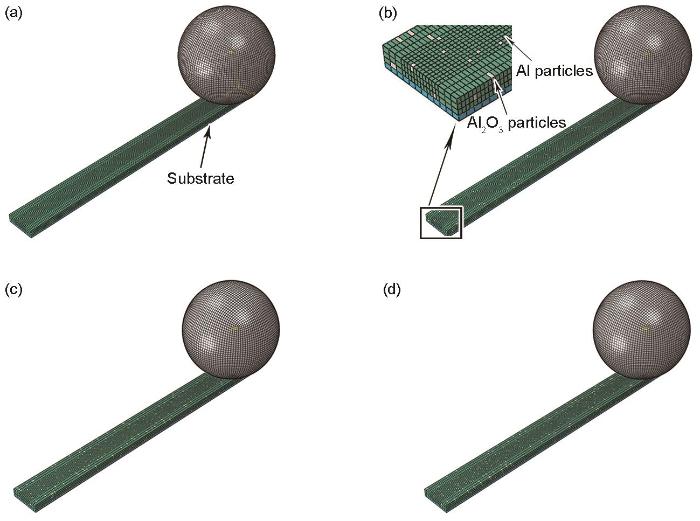

图3

图3

Al基复合涂层的模型

Fig.3

Al-based composite coating model (a) 0% Al2O3; (b) 15% Al2O3; (c) 30% Al2O3; (d) 45% Al2O3

表3 模型材料的属性

Table 3

| Sample | Material | Elastic modulus / MPa | Μ | ρ / t·mm-3 |

|---|---|---|---|---|

| Coating | Al | 70000 | 0.33 | 2.7 × 10-9 |

| Al2O3 | 375000 | 0.23 | 3.5 × 10-9 | |

| Grinding pair | Si3N4 | 320000 | 0.26 | 3.15 × 10-9 |

| Subtrate | AZ91 | 45000 | 0.35 | 1.78 × 10-9 |

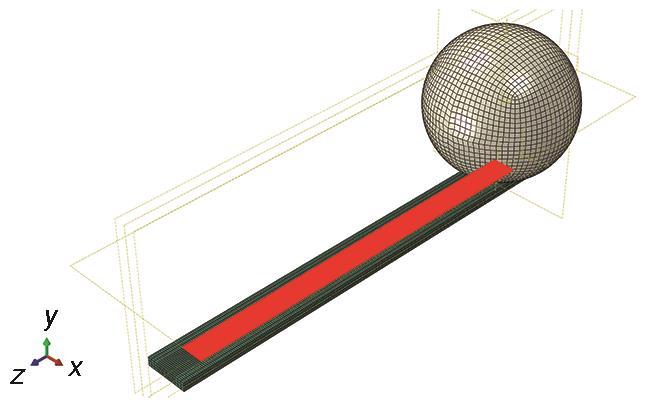

3.2 往复摩擦磨损模型的设置

网格模块中,镁合金基体和复合涂层的网格,采用沙漏控制增强的八节点线性六面体单元(C3D8R)满足磨损分析中的Lagrange-Euler自适应网格(Arbitrary lagrangian eulerian adaptive meshing,简写为ALE)节点的需求,同时降低求解过程复杂性与随机性。经网格无关性验证并考虑模型接触区域的网格数量,接触区域网格长宽高确定为0.05 mm × 0.05 mm × 0.08 mm。

在相互作用模块中,采用面-面接触控制,将Si3N4表面设为主表面,将涂层表面设为从表面。设置两个接触属性,切向行为选择罚函数,其摩擦系数由实验测得;选择法向行为为硬接触,约束执行为默认。

图4

在载荷模块中,约束磨损部件下底面,Si3N4小球在y轴方向上移动实现2 N的线性法向载荷的施加。载荷施加稳定后施加循环位移约束,开启Si3N4小球的往复运动。

设置上述参数后,调用写入Archard模型的UMESHMOTION子程序输入磨损系数K值,读取ABAQUS有限元软件节点数据和获取磨损深度和方向,最终更新ALE网格。经过多次循环后,在后处理模块中可得Al基复合涂层有限元磨损量的仿真值。

有限元磨损量仿真与磨损量的实验实测值的差e可表示为

式中

由于在大载荷条件下ALE网格方法网格易出现畸变和不收敛,选择2 N、1 Hz的工况作为有限元摩擦磨损仿真条件。载荷超过2 N时,需调整网格的尺寸,并验证网格无关化。本文的有限元磨损仿真次数与往复试验次数相同,因此不必考虑有限元加速系数对模拟仿真结果的影响。

4 结果和讨论

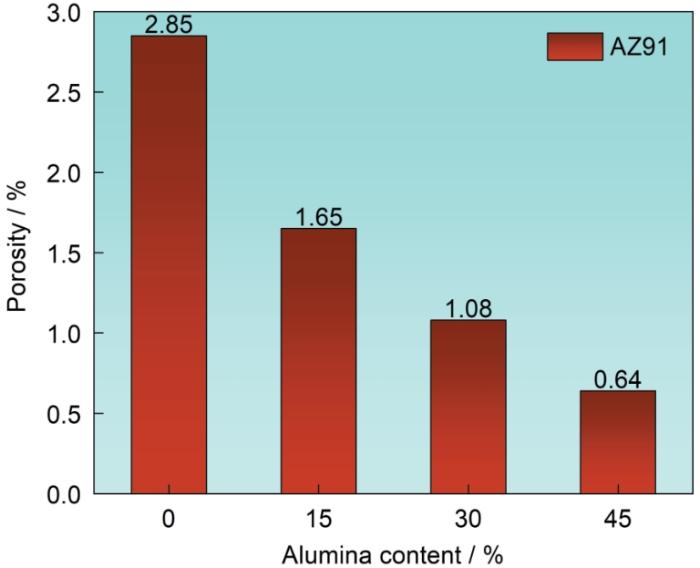

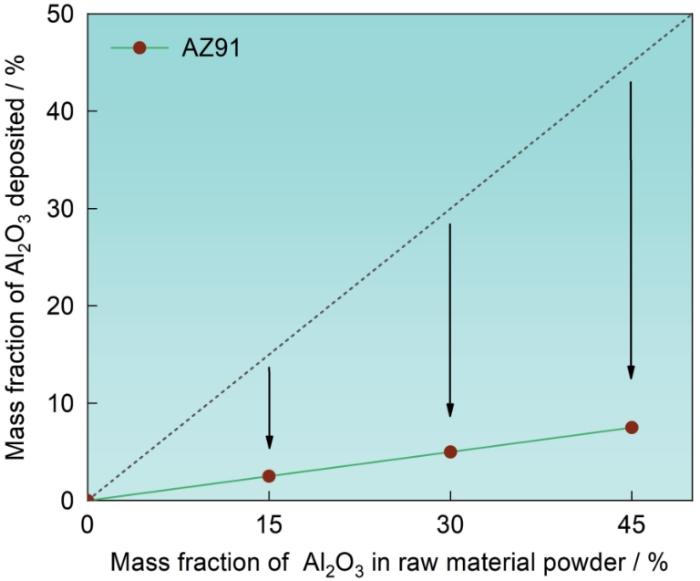

4.1 涂层的孔隙率和Al2O3 沉积效率

图5

图6

4.2 复合涂层的摩擦系数

表4 AZ91镁合金基体和冷喷涂涂层的摩擦系数随载荷和频率的变化

Table 4

| Load / N | Frequency / Hz | Friction coefficient | ||||||

|---|---|---|---|---|---|---|---|---|

| AZ91 | Al | 15% Al2O3 | 30% Al2O3 | 45% Al2O3 | ||||

| 2 | 1 | 0.28 | 0.95 | 0.82 | 0.69 | 0.52 | ||

| 4 | 0.25 | 0.92 | 0.79 | 0.66 | 0.49 | |||

| 8 | 0.26 | 0.91 | 0.77 | 0.54 | 0.49 | |||

| 10 | 0.23 | 0.88 | 0.65 | 0.60 | 0.46 | |||

| 4 | 0.5 | 0.29 | 0.97 | 0.94 | 0.70 | 0.55 | ||

| 2 | 0.22 | 0.86 | 0.78 | 0.58 | 0.40 | |||

AZ91镁合金和Al基复合涂层的磨损量随载荷和频率的变化,列于表5。当频率(速度)不变时,随着载荷的增大AZ91镁合金和Al基复合涂层的磨损量增大。载荷的增大使表面承受更大的剪切应力,容易产生摩擦磨损[32]。载荷不变时,频率的提高使磨损量降低。在相同的时间内频率越高摩擦产生的热量越多,更容易生成光滑薄膜而使磨损降低。表5中2 N、1 Hz工况下Al基复合涂层的磨损量与往复总行程和载荷的比值为该工况下复合涂层的磨损系数K,Al2O3含量为0%、30%、45%时K的数值列于表6。Al基复合涂层的磨损量与涂层中Al2O3的含量成线性关系[33],15% Al2O3的Al基复合涂层的磨损系数可由30%和45%得到。根据表6中的数据,可得15% Al2O3的Al基复合涂层的磨损系数为8.8751 × 10-6。冷喷涂Al基复合涂层与AZ91镁合金基体之间的机械咬合和冶金结合,使结合强度极高[23]。本文实验中施加的载荷较小,磨损沟壑深度远小于涂层厚度,因此可忽略磨损过程中Al基复合涂层和AZ91镁合金基体之间的结合强度对磨损系数的影响。

表5 AZ91镁合金及其Al基复合涂层的磨损量与载荷和频率的关系

Table 5

| Load / N | Frequency / Hz | AZ91 | Al | 15% Al2O3 | 30% Al2O3 | 45% Al2O3 | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Wear | Gully volume | Wear | Gully volume | Wear | Gully volume | Wear | Gully volume | Wear | ||

| 2 | 1 | 0.0325 | 0.0699 | 0.0679 | 0.0239 | 0.0235 | 0.0192 | 0.0190 | 0.0168 | 0.0167 |

| 4 | 0.0500 | 0.1074 | 0.1043 | 0.0428 | 0.0421 | 0.0375 | 0.0371 | 0.0324 | 0.0322 | |

| 8 | 0.1066 | 0.2073 | 0.2014 | 0.0938 | 0.0923 | 0.0802 | 0.0793 | 0.0697 | 0.0693 | |

| 10 | 0.1218 | 0.2379 | 0.2311 | 0.1161 | 0.1142 | 0.0944 | 0.0934 | 0.0846 | 0.0841 | |

| 4 | 0.5 | 0.0675 | 0.1461 | 0.1419 | 0.0533 | 0.0525 | 0.0477 | 0.0472 | 0.0432 | 0.0429 |

| 2 | 0.0420 | 0.0903 | 0.0878 | 0.0345 | 0.0340 | 0.0299 | 0.0290 | 0.0229 | 0.0228 | |

表6 2 N、1 Hz工况下的磨损系数

Table 6

| Coating | Al | 30% Al2O3 | 45% Al2O3 |

|---|---|---|---|

| K / mm2·N-1 | 2.8292 × 10-5 | 7.9167 × 10-6 | 6.9583 × 10-6 |

图7

图7

与AZ91基体相比Al基复合涂层耐磨性提升率ε

Fig.7

Increased wear resistance of Al-based composite coatings compared to AZ91 matrix

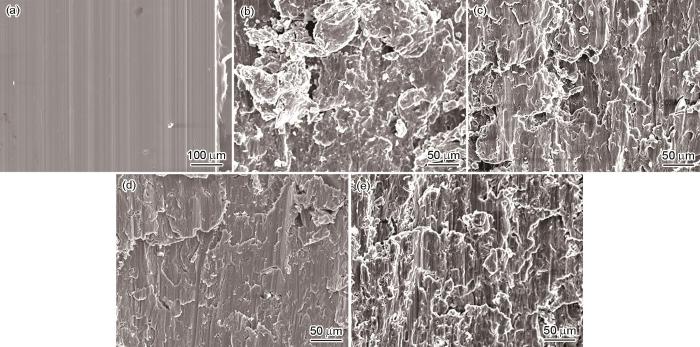

4.3 涂层的干摩擦机理

图8

图8

AZ91镁合金和Al基复合涂层在磨痕的照片

(a) AZ91; (b) 0% Al2O3; (c) 15% Al2O3; (d) 30% Al2O3; (e) 45% Al2O3

Fig.8

Photos of wear scars of AZ91 magnesium alloy and Al-based composite coating at 10N and 1 Hz

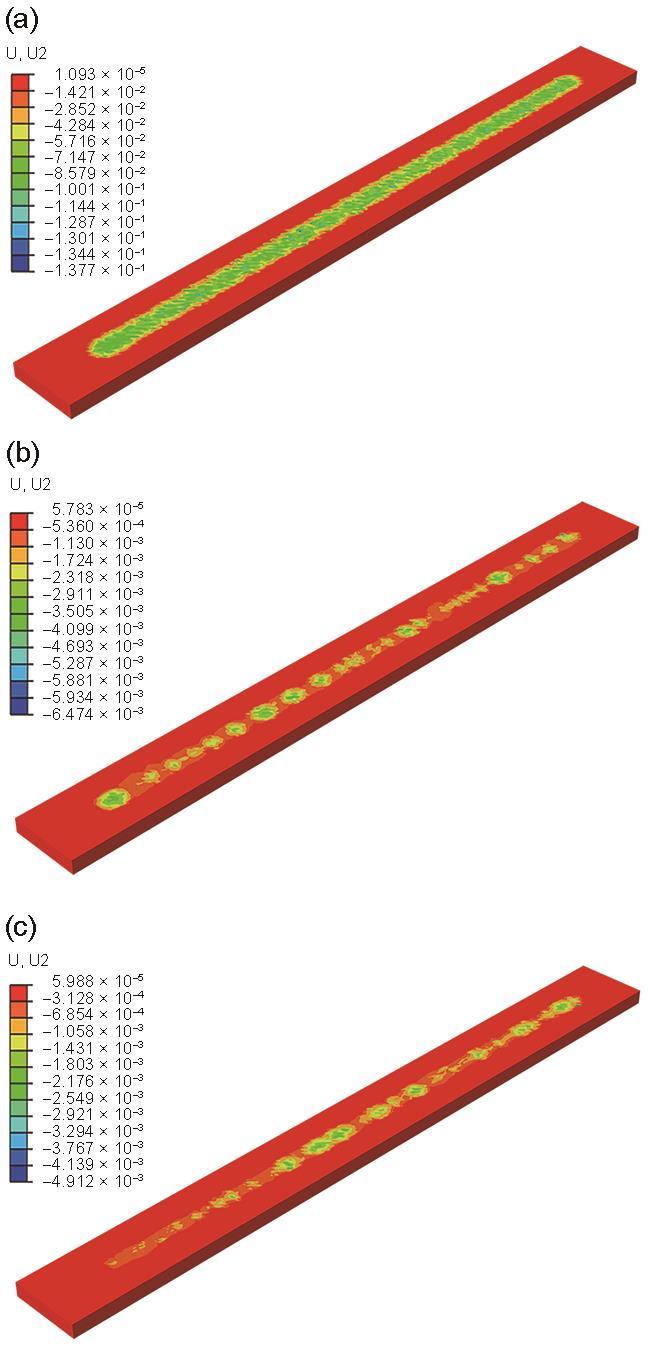

4.4 磨损量的有限元分析

网格无关化验证,是创建不同尺寸的网格、比较有限元分析运行结果和运行时间进而得到网格的最佳尺寸。本文对载荷为2N、Al2O3含量为30%时的Al基复合涂层进行网格无关化验证,采用4种不同大小的网格,单元边长从0.2 mm开始以50%逐级递减,网格无关化验证的结果列于表7。可以看出,随着单元边长从0.2 mm变为0.025 mm磨损量的模拟值降低了26.72%,但是运行时间却增加了5.2倍。综合考虑计算精度和模拟计算成本,选择网格尺寸为0.05mm。

表7 网格无关化的验证

Table 7

| Category | Thick | Normal | Thin | Very thin |

|---|---|---|---|---|

| Grid side length / mm | 0.2 | 0.1 | 0.05 | 0.025 |

| Time / h | 10 | 16 | 25 | 62 |

| Wear / mm3 | 0.0262 | 0.0225 | 0.0195 | 0.0192 |

图9

图9

Al2O3粉末含量不同的Al基复合涂层的磨损深度有限元仿真云图

Fig.9

Finite element simulation cloud of wear depth of Al-based composite coatings with different Al2O3 powder contents(a) 0% Al2O3; (b) 30% Al2O3; (c) 45% Al2O3

表8 Al2O3含量为0%、30%、45%的Al基复合涂层的磨损量仿真值和实验数据及其差

Table 8

| Coating | Al | 30% Al2O3 | 45% Al2O3 |

|---|---|---|---|

| Simulated / mm3 | 0.0702 | 0.0195 | 0.0170 |

| Experimental / mm3 | 0.0679 | 0.0190 | 0.0167 |

| e / % | 3.3873 | 2.6316 | 1.7964 |

表8给出了Al2O3含量分别为0%、30%、45%的Al基复合涂层磨损量仿真值、实验值及其差。可以看出,三种不同Al2O3含量的Al基复合涂层其磨损量仿真值与实验值之间的差均小于4%,证实了Al基复合涂层有限元模型和嵌入Archard模型的UMESHMOTION子程序的准确性。

图10

图10

Al2O3含量为15%的Al基复合涂层的磨损深度仿真云图

Fig.10

Wear depth simulation cloud chart of 15% Al2O3 Al-based composite coating

4.5 讨论

本文得到的Al基复合涂层磨损量仿真值与实验值的一致性较好,但是仍存在一定的差。首先,Al基复合涂层的摩擦磨损受表面形貌、温度和湿度等因素的影响,并且这些因素有高度的非线性和随机性[36]。有限元仿真虽然考虑了Al2O3的沉积效率、摩擦系数、磨损系数等参数,但是无法模拟磨损过程中Al2O3粉末的脱落、表面的氧化、磨屑在磨痕表面的运动等因素,因此磨损量的有限元仿真只能近似地反映磨损过程。其次,冷喷涂Al基复合涂层中有孔隙,虽然在计算实验磨损量时扣除了孔隙率的影响,但是在往复磨损过程中在孔隙处易产生裂纹而加大磨损。ABAQUS摩擦磨损静力学分析无法研究裂纹扩展,使模拟仿真值与实验值不同。最后,Al基复合涂层磨损有限元仿真模型虽然使用了实体单元,但是使用了ALE自适应网格实现全局节点移动进而获得磨损深度的变化[37]。在每一个增量步后重新对ALE自适应网格进行平滑调整,使有限元磨损量的仿真值大于实验值。

5 结论

(1) 随着冷喷涂粉末中Al2O3含量的提高,Al基复合涂层的孔隙率降低,Al2O3粉末沉积效率线性提高,复合涂层的耐磨性提高。冷喷涂纯Al涂层的磨损机制为粘着磨损,随着Al2O3含量的提高Al基复合涂层的磨损机制由粘着磨损向磨粒磨损转变。

(2) 在载荷为2 N、频率为1 Hz条件下,不同Al2O3含量(0%、30%、45%)的Al基复合涂层其有限元磨损量仿真值与实验值的差小于4%,验证了有限元模型的正确性;15% Al2O3涂层的有限元磨损量仿真值为0.0249 mm3,与实验磨损量的差为5.9574%,表明模型具有普适性。

参考文献

Friction stir processing of magnesium alloys: a review

[J].

Recent developments in high-pressure die-cast magnesium alloys for automotive and future applications

[J].

Stress corrosion cracking behavior of micro-arc oxidized AZ31 alloy

[J].

Synthesis of Ni-WC/Al-Ni functionally graded coating with advanced corrosion and wear resistance on AZ91D Mg alloy by laser cladding

[J].

Tungsten carbide coating prepared by ultrasonic shot peening to improve the wear properties of magnesium alloys

[J].

Improved deposition quality of calcium-phosphate coating on the surface of WE43 magnesium alloy via FCVA sputtering pretreatment

[J].

Effect of plasma treatment on performance of polybutylene adipate coating on biomedical AZ31 Mg-alloy

[J].Polybutylene adipate (PBA) protective coating was prepared on fluorinated AZ31 Mg-alloy by uniform speed lifting method and then the coated Mg-alloys were subjected to plasma treatment with different power and time. The effect of plasma treatment on the surface morphology, phase composition and surface wettability of PBA protective coating were characterized by means of scanning electron microscope (SEM), X-ray photoelectron spectroscope (XPS), Fourier transform infrared spectroscope (FT-IR) and contact angle measuring instrument. The corrosion resistance of the coated Mg-alloy was characterized by potentiodynamic polarization curve measurement and electrochemical impedance spectroscope (EIS). The biological activity of the protective coatings was verified by comparing the cells adhesion on the coating surface before and after plasma treatment. Results show that plasma treatment could increase the surface roughness of PBA protective coating, increase the oxygen atom proportion, and thereby enhance the wettability of the coating surface obviously. However, plasma treatment reduced the corrosion resistance of the PBA coated Mg-alloy to a certain extent, but its corrosion current density was 2~3 orders of magnitude lower than that of the AZ31 Mg-alloy without protective coating and the fluorinated ones. In sum, the PBA protective coating can provide effective protection for Mg-alloy substrate, and the EIS curve also showed the same results. Besides, Cell adhesion on the surface of plasma treated samples increased significantly.

等离子处理对医用镁合金表面聚合物防护涂层的影响

[J].用匀速提拉法在氟化处理的AZ31镁合金表面制备PBA防护涂层,然后再进行等离子处理。使用扫描电子显微镜(SEM)、X射线光电子能谱(XPS)、傅里叶红外测试(FT-IR)和接触角测量仪等手段对其表征,研究了等离子处理对PBA防护涂层表面的微观形貌、物相组成以及表面润湿性的影响;用动电位极化曲线(PD)和电化学阻抗谱(EIS)表征防护涂层处理镁合金的耐蚀性;对在等离子处理前后样品表面细胞的铺展进行比较,以验证防护涂层的生物活性。结果表明,等离子处理使PBA防护涂层表面粗糙化提高了氧原子的占比,从而显著提高了防护涂层表面的浸润性;等离子处理在一定程度上降低了防护涂层处理镁合金的耐蚀性,但是与未经防护处理的AZ31镁合金和氟化处理的镁合金相比其电流密度仍高2~3个数量级,表明防护涂层能有效防护镁合金基体;等离子处理,使样品表面黏附的细胞显著增多。

Effect of hot isostatic pressing (HIP) on microstructure and mechanical properties of Ti6Al4V alloy fabricated by cold spray additive manufacturing

[J].

Cold-sprayed Cu-Zn-Al2O3 coating on magnesium alloy: enhanced microhardness and corrosion behavior

[J].

Comparison of cold-sprayed coatings of copper-based composite deposited on AZ31B magnesium alloy and 6061 T6 aluminum alloy substrates

[J].

New insights into the in-process densification mechanism of cold spray Al coatings: Low deposition efficiency induced densification

[J].This work details new insights into the in-process densification mechanism of cold spray Al coatings. The results show a trend counter to common observations: coating plastic deformation levels and coating density decreases with an increase in particle impact velocity. A lower particle impact velocity and the consequent lower deposition efficiency (DE) results in greater tamping energy per unit volume of deposit, which is the primary reason for the observed trend. This is the first time that DE has been shown to have a non-linear impact on the density of a cold spray coating, with particle in-process tamping being the primary mechanism for coating densification.

Cold spraying of Al-aerospace alloys: Ease of coating deposition at high stagnation temperatures

[J].

Solid-state additive manufacturing and repairing by cold spraying: A review

[J].High-performance metal additive manufacturing (AM) has been extensively investigated in recent years because of its unique advantages over traditional manufacturing processes. AM has been applied to form complex components of Ti, Fe or Ni alloys. However, for other nonferrous alloys such as Al alloys, Mg alloys and Cu alloys, AM may not be appropriate because of its melting nature during processing by laser, electron beam, and/or arc. Cold spraying (CS) has been widely accepted as a promising solid-state coating technique in last decade for its mass production of high-quality metals and alloys, and/or metal matrix composites coatings. It is now recognized as a useful and powerful tool for AM, but the related research work has just started. This review summarized the literature on the state-of-the-art and problems for CS as an AM and repairing technique.

Interfacial microstructure characterization and solderability of the low pressure cold sprayed Cu-Al2O3 coating on Al substrate

[J].

Effect of powder type and composition on structure and mechanical properties of Cu + Al2O3 coatings prepared by using low-pressure cold spray process

[J].

A review of advances in cold spray additive manufacturing

[J].

Effect of ball-milled feedstock powder on microstructure and mechanical properties of Cu-Ni-Al-Al2O3 composite coatings by cold spraying

[J].

Research on structure and properties of cold sprayed aluminum and micro-arc oxidation film on AZ31 magnesium alloy

[D].

AZ31镁合金冷喷涂铝及微弧氧化膜结构与性能研究

[D].

Microstructure, microhardness and tribological behavior of Al2O3 reinforced A380 aluminum alloy composite coatings prepared by cold spray technique

[J].

In situ tribometry of cold-sprayed Al-Al2O3 composite coatings

[J].

Microstructure, mechanical property and wear performance of cold sprayed Al5056/SiCp composite coatings: effect of reinforcement content

[J].

Influence of irregular Al2O3 content on electrical conductivity, adhesion strength, and tribological properties of cold sprayed Al-Al2O3 coatings on polyether ether ketone substrate

[J].

The impact of AA7075 cold spray coating on the fatigue life of AZ31B cast alloy

[J].

An arbitrary Lagrangian-Eulerian discontinuous Galerkin method for two-dimensional compressible flows on adaptive quadrilateral meshes

[J].

An arbitrary Lagrangian-Eulerian method for fluid-structure interactions due to underwater explosions

[J].

Effect of Al2O3 particle content on microstructure and mechanical properties of 1060Al/Al-Al2O3 composites fabricated by cold spraying and accumulative roll bonding

[J].

Numerical analysis of deformation behavior and interface bonding of Ti6Al4V particle after subsequent impact during cold spraying

[J].

Cold spray aluminum-alumina cermet coatings: effect of alumina content

[J].

Study on dry sliding friction and wear properties of ZM6 and ZK60 magnesium alloys

[D].

ZM6和ZK60镁合金干式滑动摩擦磨损性能研究

[D].

Effects of frequency on the fretting wear behavior of aluminum bronze coatings

[J].

Influence of Al2O3 mass fractions on microstructure, oxidation resistance and friction-wear behaviors of CoCrAlYTaSi coatings

[J].

Effect of loading on microstructure and friction and wear behavior of an austenite lightweight steel

[J].

Material characterization of SiC and Al2O3-reinforced hybrid aluminum metal matrix composites on wear behavior

[J].

Tribo- and tribocorrosion properties of magnesium AZ31 alloy

[J].

Mechanical and tribological properties of 5A06 aluminum alloy at low temperature

[J].

Understanding the complexities of dry sliding wear behaviour of steels

[J].

Simulation of wire bonding process using explicit FEM with ALE remeshing technology

[J].Thermosonic wire bonding is a common fabrication process for connecting devices in electronic packaging. However, when the free air ball (FAB) is compressed onto the I/O pad of the chip during bonding procedure, chip cracking may occur if the contact pressure is too large. This study proposes an effective simulation technique that can predict the wire ball geometry after bonding in an accurate range. The contact force obtained in the simulation can be used for possible die cracking behavior evaluation. The simulation in this study used the explicit time integration scheme to deal with the time marching problem, and the second-order precision arbitrary Lagrangian-Eulerian (ALE) algorithm was used to deal with the large deformation of the wire ball during the bonding process. In addition, the equilibrium smoothing algorithm in LS-DYNA can make the contact behavior and geometry of the bonding wire almost the same as the experiment, which can also significantly reduce the distortion of the mesh geometry after remeshing.