根据多主元合金(MPEAs,multi-principal element alloys)体系的混合熵,可将其分为高熵合金和中熵合金。2004年叶均蔚等提出的高熵合金(HEAs,high entropy alloys)[1,2],高熵效应、晶格畸变效应、缓慢扩散效应和鸡尾酒效应[3]使其具有许多优于传统合金的性能,例如优异的强度和延展性[4,5],高温强度[6, 7],耐磨性能[8],良好的耐辐照性[9,10]和耐腐蚀性[11]等。难熔高熵合金的主相是Cr、Ta、Mo、V、Hf、W等难熔元素组成的相,在室温和高温具有优异的机械性能,是航空航天工业理想的高温结构候选材料之一[12,13]。Senkov等开发的NbMoTaW和VNbMoTaW具有优异的高温屈服强度(1600℃时高于400 MPa)和良好的高温稳定性[7,14],甚至优于Inconel 718和Haynes 230等典型高温合金。但是,这类高熵合金的室温脆性高、塑性低(往往不足2%),难以进行塑性加工。同时,难熔多主元合金作为高温结构材料服役时难熔元素难以生成致密连续的氧化膜,使其高温抗氧化性能极差[15]。例如,HfNbTaTiZr在700℃氧化100 h后增重高达55 mg/cm2[16]。

早期研制的多主元合金过于追求单相固溶结构,认为金属间化合物相的析出使合金脆化而难以加工成型。但是,许多性能优异的固溶体结构合金,包括高温合金,析出的金属间化合物能产生析出强化效应,使其具有优异的强度和一定的延展性和损伤容限[20, 21]。为了提高这种难熔合金的抗氧化性能,可在其中加入Cr、Al、Si等能在合金表面生成致密氧化层的元素。同时,复杂氧化物CrTaO4也能提高合金的抗氧化性能力[22],而且与Cr2O3和Al2O3相比,CrTaO4形成的体积与所消耗的基体体积(PBR,pilling bed-worth ratio)相比更低,不易开裂。鉴于此,本文对Cr、Ta以及也具有一定抗氧化性能的Ti进行合理成分设计制备一种包含金属间化合物的CrTaTi难熔中熵合金,研究其室温力学性能和高温氧化行为及其抗氧化机理。

1 实验方法

使用Thermo-Calc软件和TTNI8、TCHEA1等数据库,计算出CrTaTi合金的热力学平衡相图。使用纯度为(质量分数)99.9%的Cr、Ta、Ti单质金属块为原料,用真空电弧炉制备中熵合金纽扣锭,反复重熔7次以保证其成分均匀。用直径为3 mm的水冷铜模制备力学性能测试用棒材样品。室温压缩实验用圆柱试样的直径为3 mm,长度约为6 mm。用CMT5504万能力学试验机测试力学性能,应变速率为1×10-3 s-1。为了保证数据的可靠性,至少重复5次。用HVS 1000A型显微硬度仪测量合金的维氏硬度,压力为1.96 N,保压时间为15 s,每个样品测量9个点取其结果的平均值。用超声波回波法(UMS-100 超声回波材料表征系统)测量杨氏模量,柱状样品的直径为3 mm厚度为1.5 mm,用Archimedes排水法测量合金的密度。用SHIMADZU XRD-6100型X射线衍射仪(XRD)分析样品的结构,扫描速率为4 (°)/min,衍射角2θ从20°到90°。对用于观察微观组织和氧化实验的样品,分别用320#、800#、1200#、2000#以及3000#的砂纸逐级打磨,随后用金刚石研磨膏抛光。使用JSM-6610型扫描电子显微镜(SEM)和二次电子和背散射电子探头观察样品的微观形貌,用配备的能谱仪(EDS)分析样品的成分和元素分布。

高温氧化实验用试样是尺寸为3 mm×3 mm×2 mm的长方体。分别在温度为600、700、800、900℃和1000℃的马弗炉中进行等温氧化实验,以20℃/min的速率升温至目标温度,分别连续氧化不同时间后随炉冷却至室温,测量氧化样品的质量。为了研究样品的早期氧化行为,分别将其在1000℃的马弗炉中氧化5、10、30 min空冷。用同步热分析仪(PerkinElmer STA8000)测定从室温到1000℃和在1000℃氧化3 h的质量增益曲线,加热速率为20℃/min,实验气氛为空气。

用TFESCALAB 250Xi 型 X射线光电子能谱仪(Al-Kα)分析合金氧化0、5、10和30 min后样品表面元素Cr、Ta、Ti的价态。

2 实验结果

2.1 微观组织和室温力学性能

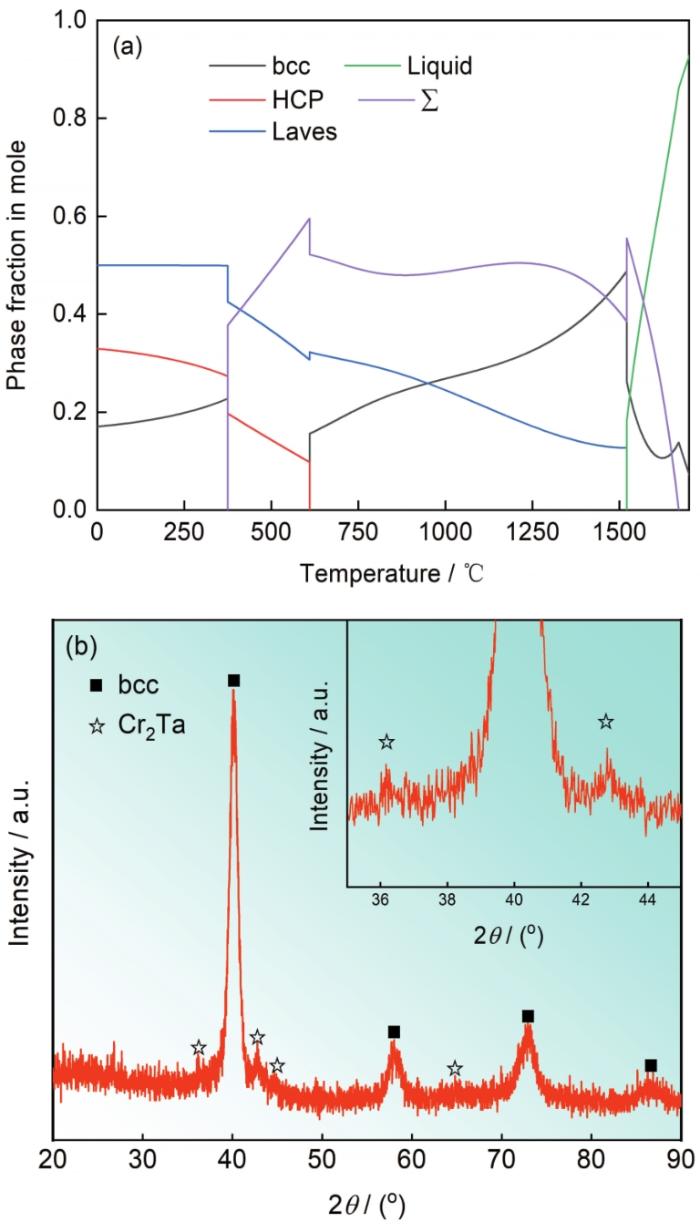

图1a给出了CrTaTi中熵合金的相成分随温度的变化。可以看出,随着温度的降低从液相中先析出bcc相和∑相,温度下降到约1520℃后bcc相逐渐转化为∑相和Laves相。温度下降到约610℃时bcc相全部分解并出现HCP相。继续降温至约370℃则∑相全部消失,重新出现bcc相。

图1

图1

CrTaTi在不同温度下平衡相的计算摩尔分数和铸态CrTaTi难熔中熵合金的XRD谱

Fig.1

Calculated mole fraction of equilibrium phases at various temperatures for the CrTaTi (a) and XRD pattern of as-cast CrTaTi refractory medium-entropy alloy (b)

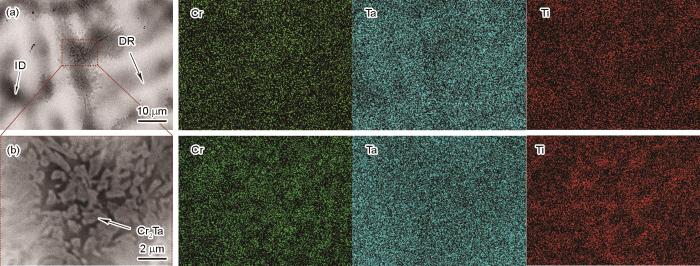

图1b给出了铸态CrTaTi中熵合金的XRD谱。可以看出,CrTaTi合金的基体是bcc固溶体相,只有少量的析出相Cr2Ta Laves相。结合图1a中的计算相图分析可见,∑相在冷却过程中分解成bcc相和Laves相,而水冷铜模的冷却较快和HCP相的析出温度较低使其来不及析出,因此合金最终的相组成是bcc相和少量Laves相。为了进一步探究相分布,用扫描电子显微镜观察了合金的显微组织,如图2所示。可以看出,CrTaTi铸态合金具有明显的枝晶组织。能谱分析结果表明,明亮的枝晶区域(Dendrites, DR)主要含熔点较高的Ta,而较暗的枝晶间区域(Interdendritic, ID)则富集低熔点的Cr和Ti。不同区域EDS点的成分扫描结果,列于表1。图2b给出了枝晶间的高倍背散射图,可见枝晶间有析出的第二相,结合XRD和能谱分析可知此其为Cr2Ta。由于Cr元素与Ta和Ti的形成焓较负,Cr的存在降低了合金体系的焓值和bcc相的稳定性,出现了Laves相。同时,在合金的凝固过程中熔点最高的Ta先凝固形成枝晶。因Cr和Ta的混合焓最小(-7 kJ/mol),在凝固过程中Cr和Ta更容易生成Cr2Ta相。而Cr和Ti的熔点较低,Cr和Ti构成了枝晶间区域。

图2

图2

铸态CrTaTi难熔中熵合金的SEM背散射图

Fig.2

Backscattered SEM images of the as-cast CrTaTi refractory medium-entropy alloy (a) the overall microstructure of the alloy, (b) the interdendritic microstructure, with the presence of the Cr2Ta second phase in the interdendritic

表1 CrTaTi难熔中熵合金枝晶与枝晶间区域化学组成

Table 1

| Alloy | Region | Cr | Ta | Ti |

|---|---|---|---|---|

| CrTaTi | DR | 29.6 | 42.4 | 28 |

| ID | 40.1 | 22.6 | 37.3 |

图3

图3

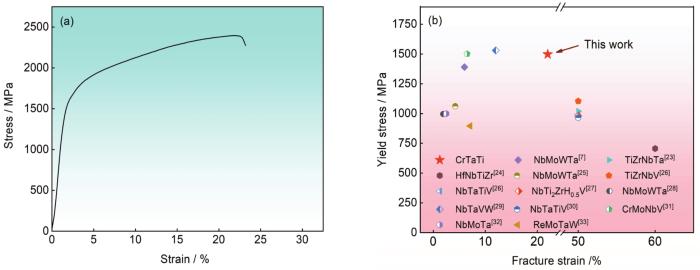

铸态CrTaTi难熔中熵合金的室温压缩工程应力应变曲线和典型铸态难熔多主元合金力学性能的统计图[7,23~33]

Fig.3

Room-temperature compressive stress-strain curve of the as-cast CrTaTi refractory entropy alloy (a), the mechanical properties of the as-cast CrTaTi alloy and some typical refractory multi-principal element alloys previously reported[7,23~33] (b)

2.2 高温氧化行为

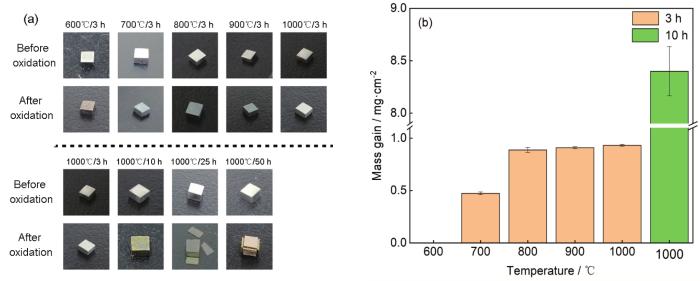

图4给出了CrTaTi难熔中熵合金在600~1000℃氧化3 h和在1000℃氧化不同时间后外观和质量的变化。图4a表明,随着氧化温度的提高CrTaTi难熔中熵合金氧化3 h后形貌规则光滑,表明其具有良好的短期抗氧化性能。为了进一步研究其高温长期抗氧化性能,观察了合金在1000℃氧化不同时间后形貌的变化。可以看出,随着氧化时间的延长合金的形貌发生变化,氧化10 h后样品表面的部分区域变黄且凹凸不平。氧化时间延长到25 h样品因夹持受力氧化皮出现剥落,表明样品发生了较为严重的氧化。氧化50 h后样品变得不规则,棱角处严重开裂,表明其氧化较为严重。图4b给出了这种合金在不同温度氧化3 h和在1000℃氧化10 h后的氧化增重柱状图。可以看出,CrTaTi合金在中高温短时间内具有良好的抗氧化性能;而延长在1000℃的氧化时间其氧化增重明显增加,表明氧化膜没有减缓氧化过程。从表2可见,本文制备的合金具备优异的早期抗氧化性能,氧化3 h后其增重不到1 mg/cm2,远比一些常见的难熔高熵合金的增重低[6,34~40]。

图4

图4

在不同温度等温氧化不同时间后样品的形貌和等温氧化不同时间后样品的质量变化

Fig.4

Appearance changes (a) and the changes of mass gain (b) of samples after isothermal oxidation at different temperatures with different times, respectively

表2 一些典型难熔多主元合金在1000℃氧化3 h后的增重

Table 2

| Alloy composition | Weight gain /mg·cm-2 | Ref. | Alloy composition | Weight gain /mg·cm-2 | Ref. |

|---|---|---|---|---|---|

| CrTaTi | 0.932 | This work | AlNb1.5Ta0.5Ti1.5Zr0.5 | 10 | [37] |

| CrTaVW | 30 | [34] | AlCrMoTiW | 3.8 | [38] |

| CrMo0.5NbTa0.5TiZr | 110 | [36] | AlCr0.5Mo0.5NbTiZr | 21 | [39] |

| CrNbTiZr | 25 | [35] | Al0.5Mo1.5NbTiZr | 20 | [39] |

| NbTiVZr | 100 | [35] | AlCrNbTiZr | 39 | [39] |

| AlCrMoNbTi | 0.8 | [36] | CrMoNbTaV | 13 | [40] |

3 讨论

3.1 合金相的生成规律

在多主元合金中,多种元素的混合而使固溶体具有较高的混合熵,Gibbs自由能的降低促进了合金中固溶体相的生成。根据Hume-Rothery规则,除了混合熵,影响固溶体相生成的因素还有原子尺寸、电负性、元素化合价、电子浓度和晶体结构等。

式中Ci 为第i中组分的百分比含量,R为气体常数。

式中Ci 为第i种组分的百分比含量,Ωij =4Δ

式中Ci 为第i种组分的百分比含量,ri 为第i种组分元素的原子半径,

式中Tm为加权熔点,其值根据混合规则计算。

表3 CrTaTi难熔中熵合金的混合熵(ΔSmix)、混合焓(ΔHmix)、原子尺寸差(δ)、参数Ω、价电子浓度(VEC)以及电负性差(ΔX)

Table 3

| Alloy | ΔSmix | ΔHmix | δ | Ω | ΔX | VEC |

|---|---|---|---|---|---|---|

| CrTaTi | 9.13 | -5.8 | 6.72 | 3.85 | 6.80 | 5 |

也有利于固溶体相的生成,式中xi 为元素的电负性。根据价电子浓度(VEC)

可判断固溶体相的类型[43],式中Ci 为第i种组分的百分比含量,VEC i 为元素价电子数。

研究表明,fcc固溶体相偏向于在VEC>8时存在,VEC<6.87时bcc固溶体相更稳定。CrTaTi中熵合金的VEC值为5,表明更容易生成bcc固溶体相。而实际铸态CrTaTi难熔中熵合金的相组成以bcc固溶体相为主,只有少量的Cr2Ta Laves相,与预测结果基本相符。

3.2 室温力学性能

CrTaTi中熵合金具有良好的室温综合力学性能,其强度主要源于固溶强化和析出强化。等比浓度的三种原子具有不同的原子半径和性质,其中Cr(125 pm)的原子半径远小于其他两种元素Ta(143 pm)和Ti(146 pm)。较大的原子半径差使合金的晶格严重扭曲,在合金内产生的局部弹性应力场阻碍位错运动而使合金的强度提高。用Labush方法的改进模型,可计算出中熵合金的固溶强化对其屈服强度的贡献[44]。计算表达式为

其中

为溶质i的硬化参数,Xi 为其含量。

其中

为合金的失配参数,Z为拟合常数,μ为元素的剪切模量,α的值取决于合金中位错类型。合金为bcc相时ξ=4。ηi 为剪切模量失配参数,δi 为原子尺寸失配参数,其表达式分别为

其中ri 为原子半径,

表4 Cr、Ta和Ti的剪切模量和原子半径[45]

Table 4

| Alloy | Cr | Ta | Ti |

|---|---|---|---|

| μ/GPa | 64.7 | 71.6 | 37.3 |

| r/pm | 125 | 143 | 146 |

3.3 氧化行为及其机制

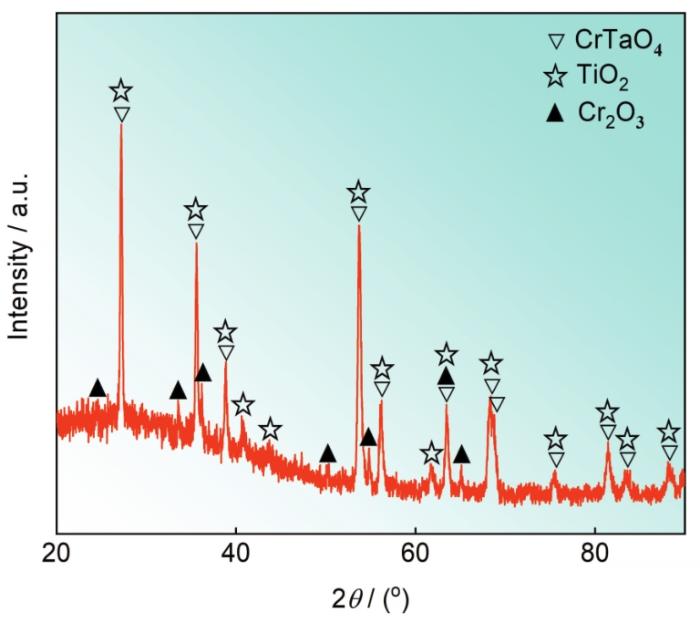

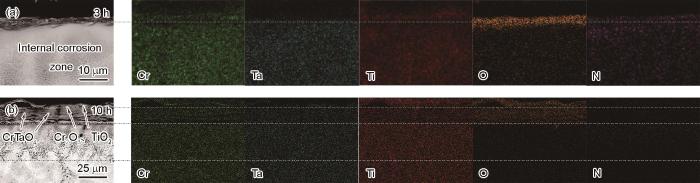

为了揭示CrTaTi 合金的氧化机理,分析了其在1000℃氧化10 h后氧化产物的XRD谱。结果表明,氧化层主要由CrTaO4、TiO2以及Cr2O3构成(图5)。为了分析氧化层的生长规律,图6给出了合金在1000℃氧化3 h和10 h后的截面背散射图和元素分布。从图6a可见,氧化3 h后CrTaTi合金表面只生成一层很薄的氧化层,厚度只有3.2±0.2 μm。在氧化层下可观察到较深的内氧化区。样品截面的元素分布结果表明,氧化层主要由Cr2O3和TiO2构成。复合氧化层中的Cr2O3使合金在短期内具有较高的抗氧化能力。但是,随着氧化时间的延长,氧化10 h后氧化层的厚度明显增大,约为23.4±2 μm,如图6b所示。同时,氧化层分为表层、中间层和下层内氧化区,且不致密,其表层部分凸起,表层与中间层有明显的空隙。进一步观察发现,合金的内氧化很严重,氮化区的厚度明显增加,氮化物主要分布在枝晶间。CrTaTi合金发生内氧化时,枝晶间区域是氮、氧等阴离子向内扩散的主要途径。元素分析结果表明,合金氧化10 h后的氧化表层富集Cr和Ti元素,中间层主要是Cr和Ta元素。氧化产物的XRD谱表明,表层的氧化产物主要是Cr2O3和TiO2,中间层主要是CrTaO4。

图5

图5

在1000℃氧化10 h后样品表面氧化物的XRD谱

Fig.5

XRD pattern of the oxidation products on the sample surface after 10 h oxidation at 1000℃

图6

图6

CrTaTi合金在1000℃等温氧化3 h和10 h后的截面SEM图像和EDS元素分布

Fig.6

Cross-sectional SEM images and element distribution of oxide layer for CrTaTi alloys isothermally exposed to the air at 1000℃ for 3 h (a) and 10 h (b), respectively

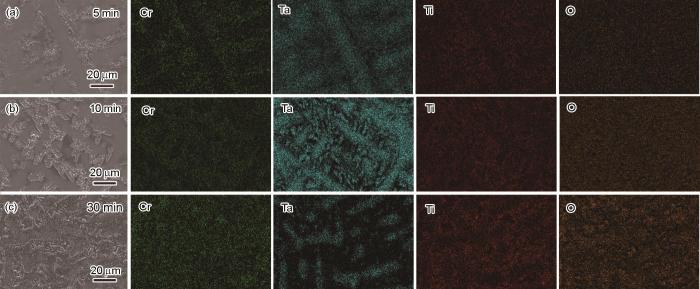

为了揭示CrTaTi合金氧化层的生长机理,对其进行了5、10、30 min的早期氧化实验。合金氧化后的形貌和元素分布特征,如图7所示。可以看出,氧化5 min后CrTaTi合金表面枝晶间区域生成了少量氧化物,而枝晶处仍较为光滑平整,没有出现明显的氧化产物。能谱分析结果表明,O均匀分布在样品的表面,而Cr和Ti富集在枝晶间区域,与其形貌中氧化物的主要生长位置吻合。虽然Ta富集在枝晶处,但是整体上与基体中Ta的分布类似。这表明,基体中主要有Ta和极少量的氧化物。随着氧化时间的延长,氧化10 min后枝晶间区域的氧化产物明显增多,且枝晶间和枝晶交界处也生成了少量的氧化物。与氧化5 min的能谱分析结果相比,Cr和Ti的分布没有明显的不同。但是Ta的分布图表明,在Cr、Ti 富集的枝晶间区域Ta含量相当低。这表明,随着氧化时间的延长,氧化产物的增加使电子难以穿透变厚的氧化层。因此,Ta的含量在氧化物较多的枝晶间区域较低,在其它区域与基体中的相似。随着氧化时间进一步延长到30 min,整个样品表面布满了均匀分布的氧化产物,意味着枝晶处也发生了氧化。EDS结果表明,Ti、Cr主要富集在枝晶间区域,而Ta的分布情况则与氧化5、10 min有较大的不同。整个表面Ta含量较低,枝晶间区域几乎没有 Ta,表明样品表层的氧化产物主要是Cr2O3和TiO2。

图7

图7

CrTaTi合金氧化5 min、10 min、30 min后的SEM图以及EDS元素的分布特征

Fig.7

SEM and EDS results of CrTaTi alloys after 5 min (a), 10 min (b) and 30 min (c) oxidation

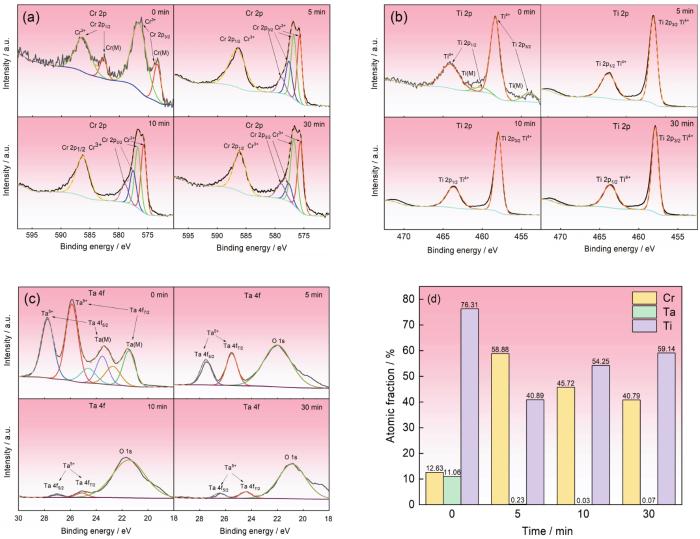

为了揭示CrTaTi合金氧化层的初始生长过程,根据XPS谱分析了合金未氧化(0 min)、氧化5、10和30 min后样品表面Cr、Ta、Ti 三种元素的价态。图8a给出了样品表面Cr的精细谱。分峰拟合结果表明,未氧化时Cr元素的峰由金属态峰和氧化态峰组成,Cr2p可分解为结合能分别为575.9、576.15 eV的两个双峰,依次是CrO、Cr2O3。在高温氧化5、10和30 min后的Cr精细谱分峰拟合结果基本一致,只有Cr2O3的峰,表明氧化时样品表面迅速生成Cr2O3。Ti的精细谱分峰拟合结果与Cr相似(图8b),未氧化时由金属态峰和氧化态峰组成,Ti2p可分解为结合能分别为458.35、464.06 eV两个双峰,依次是TiO和TiO2。高温氧化后其精细谱都只有TiO2的峰,表明在氧化过程中在样品表面迅速生成了TiO2。虽然未氧化时Ta的分峰拟合结果与Cr、Ti一致,也是由金属态峰和氧化态峰组成,但是氧化后可检测到的Ta含量很低。图8d进一步给出了氧化不同时间三种元素氧化物归一化后的占比。结果表明,氧化后样品表面基本上没有生成Ta的氧化物。而Ti含量则随着氧化时间的延长而增多,也表明TiO2的生长速率更高。Cr2O3的生长速率较低,随着氧化时间的延长样品表面的Cr含量反而降低。以上结果表明,CrTaTi难熔中熵合金早期氧化时样品表面优先生成Cr2O3和TiO2,几乎没有生成Ta的氧化物。

图8

图8

CrTaTi合金在1000℃氧化0、5、10和30 min后样品表面Cr2p精细谱分峰的拟合、Ti2p精细谱分峰拟合、Ta4f精细谱分峰拟合结果以及氧化不同时间后Cr、Ta和Ti三种元素的氧化物占比

Fig.8

XPS results of oxidized CrTaTi alloy at 1000℃ for 0, 5, 10 and 30 min: the peak fitting of Cr2p fine spectrum on the sample surface (a), Ti2p fine spectrum peak fitting (b), Ta4f fine spectrum peak fitting (c), and the proportion of oxides of Cr, Ta and Ti after oxidation with different times (d)

表5列出了Cr、Ta、Ti三种元素的氧化物在1000℃的标准摩尔生成Gibbs自由能[48]。TiO2优先生成的原因,是Ti在1000℃生成氧化物的Gibbs自由能较低。虽然Ta2O5的生成Gibbs自由能也较低,但是与Ti、Cr相比Ta的扩散速率更低,且Ta的原子质量(181)远大于Ti(48)和Cr(52)。同时,高熵合金严重的晶格畸变使其扩散必须克服多个组元协同扩散和晶格畸变引起的阻力,因此其有效扩散效率极低。这种缓慢扩散效应使扩散速率较低的 Ta难以生成氧化物,以致整个合金表面几乎没有生成Ta2O5。而Cr2O3的标准摩尔生成Gibbs自由能虽然略高于Ta2O5,但是其扩散速率较高且枝晶区域的Cr含量也较高,有利于生成Cr2O3,因此可在枝晶间区域明显观察到Cr2O3。

表5 Cr、Ta和Ti的氧化物在1000℃的标准Gibbs自由能

Table 5

| Oxide | Cr2O3 | TiO2(rutile) | Ta2O5 |

|---|---|---|---|

| ΔG/kJ·mol-1 | -538 | -713 | -598 |

以上结果表明,在CrTaTi难熔中熵合金早期的氧化层生长过程中先生成了主要含 Cr2O3和TiO2的复合氧化层,随着氧化时间的延长在复合氧化层的下面又生成了以CrTaO4为主的氧化层。表层的Cr2O3和TiO2的氧化层在短期有较高的抗氧化性能,但是随着氧化时间的延长复合氧化层开裂使氧和氮持续进入。其原因是,TiO2的热力学驱动力较大且与氧的亲和力较强,随着氧化时间的延长TiO2比Cr2O3更快地生长,因此生成的TiO2较多。TiO2和CrO2生长速率的差异使表层氧化层因体积比失衡引起应力集中而开裂,最终使其抗氧化性能降低。在1000℃由Cr2O3与Ta2O5反应生成CrTaO4需要一个潜伏期[49],且Ta的扩散速率较低,延缓了Ta2O5的生成,所以CrTaO4 滞后生长在下层[50]。在1000℃的温度下CrTaO4的生长速率很低,其氧化生长常数仅为 3.83×10-17[51],甚至低于保护性Cr2O3的生长常数(8.08×10-17[52]),抑制阳离子向外扩散可阻止难熔高熵合金的氧化,因此CrTaO4具有高抗氧化性。但是,随着氧化时间的延长CrTaTi合金的内氮化区变厚,表明CrTaTi合金的整个氧化过程以氧、氮的内扩散为主。同时,难熔高熵合金中Laves相的晶界作为空气中氮和氧的扩散通道使合金进一步氧化[53]。因此氮化区中的氮化物主要存在于枝晶间,与基体中Cr2Ta相的分布一致。这表明,CrTaO4虽然是一种抗氧化性很高的氧化产物,但是CrTaTi合金的氧化方式以氧向内扩散为主,CrTaO4不能阻止阴离子向内扩散[49]。虽然Cr的氧化物能提高含Cr合金的抗氧化性能,但是含Cr的难熔多主元合金中常常出现Cr2Ta Laves相[54]。虽然Laves相强化了合金的室温综合力学性能,但是在一定程度上影响其抗氧化性能。因此,只有适当调控Laves相的含量和分布,才能制备出综合力学性能和抗氧化性能优异的新型难熔中熵合金。

4 结论

(1) CrTaTi难熔中熵合金由基体bcc固溶体相和少量的Cr2Ta Laves相组成。这种合金的铸态具有明显的树枝晶微观组织,Cr2Ta相分布在枝晶间区域。CrTaTi难熔中熵合金具有优异的室温力学性能,其高屈服强度主要源于固溶强化和沉淀强化。

(2) CrTaTi难熔中熵合金在高温具有良好的短期抗氧化性能,因为生成了含TiO2和Cr2O3的复合氧化层。但是,随着高温氧化时间的延长TiO2和CrO2生长速率的差异使表层复合氧化层开裂从而降低了长期抗氧化性能,尤其是中间层的CrTaO4不能阻止氮氧向内扩散。Laves相虽然提高了合金的室温综合力学性能,但是在一定程度上影响其抗氧化性能。

参考文献

Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes

[J].

Microstructural development in equiatomic multicomponent alloys

[J].

A critical review of high entropy alloys and related concepts

[J].

Strengthening CrFeCoNi-Mn0.75Cu0.25 high entropy alloy via laser shock peening

[J].

A fracture-resistant high-entropy alloy for cryogenic applications

[J].High-entropy alloys are equiatomic, multi-element systems that can crystallize as a single phase, despite containing multiple elements with different crystal structures. A rationale for this is that the configurational entropy contribution to the total free energy in alloys with five or more major elements may stabilize the solid-solution state relative to multiphase microstructures. We examined a five-element high-entropy alloy, CrMnFeCoNi, which forms a single-phase face-centered cubic solid solution, and found it to have exceptional damage tolerance with tensile strengths above 1 GPa and fracture toughness values exceeding 200 MPa·m(1/2). Furthermore, its mechanical properties actually improve at cryogenic temperatures; we attribute this to a transition from planar-slip dislocation activity at room temperature to deformation by mechanical nanotwinning with decreasing temperature, which results in continuous steady strain hardening. Copyright © 2014, American Association for the Advancement of Science.

Oxidation behavior of a refractory NbCrMo0.5Ta0.5TiZr alloy

[J].

Mechanical properties of Nb25Mo25Ta25W25 and V20Nb20Mo20Ta20W20 refractory high entropy alloys

[J].

Microstructure, mechanical and tribological properties of CoCrFeNiMn high entropy alloy matrix composites with addition of Cr3C2

[J].

Microstructural stability and mechanical behavior of FeNiMnCr high entropy alloy under ion irradiation

[J].

Interface stability, mechanical and corrosion properties of AlCrMoNbZr/(AlCrMoNbZr)N high-entropy alloy multilayer coatings under helium ion irradiation

[J].High entropy alloy (HEA) coatings are promising for use as accident-tolerant fuel cladding due to their outstanding high-temperature corrosion resistance. In this work, we investigated the interface stability, mechanical properties and corrosion resistance of AlCrMoNbZr/(AlCrMoNbZr)N multilayer coatings with individual layer thickness of 5 nm, 10 nm and 50 nm, subjected to helium (He) ion irradiations: 400 keV He+ ions with fluences of 8 x 10(15) ion/cm(2 )and 8 x 10(16) ion/cm(2). We determined that He bubbles are not observed in any of the multilayer coatings after a helium ion irradiation process with 400 keV He ions and a fluence as high as 8 x 10(16) ion/cm(2). Although intermixing and chemical reaction in the peak damage region of the AlCrMoNbZr/(AlCrMoNbZr)N multilayer coating with 5 nm monolayer thickness are induced by the high fluence He ion irradiation, the FCC structure remained, and no intermetallic compounds are detected. Moreover, we found that the AlCrMoNbZr/(AlCrMoNbZr)N multilayer coating with the monolayer thickness of 50 nm has better interface stability during the irradiation process. Nanoindentation tests reveal that the hardness of all multilayer coatings decreased for low and high fluences, which is mainly due to the thermal effect caused by irradiation. In addition, the electrochemical corrosion WA show that AlCrMoNbZr/(AlCrMoNbZr)N multilayer coating 50 nm coatings has better corrosion resistance than AlCrMoNbZr/(AlCrMoNbZr)N multilayer coating 5 nm coatings under high fluence He irradiation. The corrosion resistance of the multilayer coating depends on the stability of the multilayer interface. Our results show that the AlCrMoNbZr/(AlCrMoNbZr)N multilayer coating with a monolayer thickness of 50 nm had better interface stability, mechanical properties and corrosion resistance than the AlCrMoNbZr/(AlCrMoNbZr)N multilayer coating with a per layer thickness of 5 nm under high fluence He irradiation. This work reveals that high-entropy alloy multilayer coatings could have potential applications as an accident-tolerant fuel cladding coating in light water reactors.

Corrosion behavior and surface film characterization of TaNbHfZrTi high entropy alloy in aggressive nitric acid medium

[J].

Development and property tuning of refractory high-entropy alloys: a review

[J].

Deformation behavior and toughening of high-entropy alloys

[J].A new alloy design concept, high-entropy alloys (HEAs), has attracted increasing attentions and becomes a new research highlight recently. Different from traditional alloy design strategy which usually blends with one or two elements as the principal constituent and other minor elements for the further optimization of properties, HEAs are multicomponent alloys containing several principle elements (usually ≥5) in equiatomic or near equiatomic ratio. Due to their unique atomic structure, HEAs possess a lot of distinguished properties. Since the discovery of HEAs, a variety of HEA systems have been developed and shown unique physical, chemical and thermodynamic properties, especially the promising mechanical properties such as high strength and hardness, abrasion resistance, corrosion resistance and softening resistance. Here in this short review manuscript, starting from the research challenges for understanding the deformation mechanism of HEAs, this work briefly summarized the mechanical properties and deformation behavior of HEAs, reviewed the proposed strengthening-toughening strategies and their corresponding deformation mechanism in HEAs. A brief perspective on the research directions of mechanical behavior of HEAs was also proposed.

高熵合金的变形行为及强韧化

[J].高熵合金是近年来涌现出的一种新型金属材料。不同于传统合金设计以1种或2种元素为主添加其它合金元素为辅的方案,高熵合金由多种元素以等原子比或近等原子比的成分组成,具有独特的原子结构特征,因而呈现出诸多不同于传统合金的独特性能。自高熵合金被首次报道以来,目前已经研发出了一系列的高熵合金体系,在物理、化学、热力学性能方面显示出独有的优势,尤其在力学行为方面显示出高强、高硬、耐磨、耐蚀、抗高温软化等优异的性能,在国际学术界引起了广泛的关注和研究兴趣,已经成为新的研究热点。本文从高熵合金变形机理研究存在的挑战出发,主要综述了高熵合金的力学性能和变形行为特点,已经提出的强韧化方案及相关机理,并对未来高熵合金变形行为的研究进行了简单展望。

Refractory high-entropy alloys

[J].

The progress of high-entropy alloys with the functional properties

[J].

高熵合金功能特性研究进展

[J].

Oxidation behavior between 700 and 1300 C of refractory TiZrNbHfTa high-entropy alloys containing aluminum

[J].

A body-centered cubic Zr50Ti35Nb15 medium-entropy alloy with unique properties

[J].

Heterogeneous precipitation behavior and stacking-fault-mediated deformation in a CoCrNi-based medium-entropy alloy

[J].

High-rate superplasticity in an equiatomic medium-entropy VCoNi alloy enabled through dynamic recrystallization of a duplex microstructure of ordered phases

[J].

High-entropy intermetallics: from alloy design to structural and functional properties

[J].

Second phase strengthening in advanced metal materials

[J].

先进金属材料的第二相强化

[J].

Current status of research on the oxidation behavior of refractory high entropy alloys

[J].

(TiZrNbTa)-Mo high-entropy alloys: dependence of microstructure and mechanical properties on Mo concentration and modeling of solid solution strengthening

[J].

Effect of Al addition on structural evolution and mechanical properties of the Al x HfNbTiZr high-entropy alloys

[J].

Microstructure and mechanical properties of RexNbMoTaW high-entropy alloys prepared by arc melting using metal powders

[J].

Microstructure and compressive properties of NbTiVTaAlx high entropy alloys

[J].

A novel series of refractory high‑entropy alloys Ti2ZrHf0.5VNb x with high specific yield strength and good ductility

[J].

Alloys for application at ultra-high temperatures: Nb-silicide in situ composites: challenges, breakthroughs and opportunities

[J].

NbTaV-(Ti,W) refractory high-entropy alloys: experiments and modeling

[J].

Lattice distortion in a strong and ductile refractory high-entropy alloy

[J].

Superior high-temperature strength in a supersaturated refractory high-entropy alloy

[J].

Comparative study of the microstructures and mechanical properties of laser metal deposited and vacuum arc melted refractory NbMoTa medium-entropy alloy

[J].

Microstructure and mechanical property of a novel ReMoTaW high-entropy alloy with high density

[J].

The effect of Ti on the sintering and mechanical properties of refractory high-entropy alloy TixWTaVCr fabricated via spark plasma sintering for fusion plasma-facing materials

[J].

High temperature oxidation behaviors of equimolar NbTiZrV and NbTiZrCr refractory complex concentrated alloys (RCCAs)

[J].

High temperature oxidation behavior of an equimolar refractory metal-based alloy 20Nb-20Mo-20Cr-20Ti-20Al with and without Si addition

[J].

Native oxidation resistance of Al20Nb30Ta10Ti30Zr10 refractory complex concentrated alloy (RCCA)

[J].

Phase equilibria, microstructure, and high temperature oxidation resistance of novel refractory high-entropy alloys

[J].

A combinatorial approach for the synthesis and analysis of Al x Cr y Mo z NbTiZr high-entropy alloys: oxidation behavior

[J].

Microstructure and oxidation behavior of the CrMoNbTaV high-entropy alloy

[J].

Solid-solution phase formation rules for multi-component alloys

[J].

Prediction of high-entropy stabilized solid-solution in multi-component alloys

[J].

Effect of valence electron concentration on stability of fcc or bcc phase in high entropy alloys

[J].

Modelling solid solution hardening in high entropy alloys

[J].

Strengthening mechanisms in CrMoNbTiW refractory high entropy alloy

[J].

On the oxidation mechanism of refractory high entropy alloys

[J].

The influence of CrTaO4 layer on the oxidation behavior of a directionally-solidified nickel-based superalloy at 850~900℃

[J].

An oxidation resistant refractory high entropy alloy protected by CrTaO4-based oxide

[J].Although refractory high entropy alloys (RHEAs) have shown potentials to be developed as structural materials for elevated temperature applications, most of the reported oxidation behaviours of RHEA were associated with short term exposures for only up to 48 hours, and there is a lack of understanding on the oxidation mechanism of any RHEA to-date. In this work, by using thermogravimetric analysis, isothermal oxidation was conducted on a novel RHEA at 1000 °C and 1100 °C for up to 200 hours, which is an unprecedented testing duration. The external oxide layer strongly influenced the weight gain behaviours, and it consisted of CrTaO4-based oxide with some dispersion of Al2O3 and Cr2O3. At 1000 °C, the inability to form dense CrTaO4-based oxide layer resulted an exponential dependence of weight gain throughout 200 hours. At 1100 °C, mass gain curve showed two parabolic dependences associated with the formation of protective CrTaO4-based oxide layer and the weight gain after 200 hours was 4.03 mg/cm2, which indicates that it is one of the most oxidation resistant RHEAs comparing to literature data to-date. This work can also provide insights on how to further develop RHEA to withstand long term oxidation at elevated temperatures.

A new strategy to intrinsically protect refractory metal based alloys at ultra high temperatures

[J].

The role of Nb on the high temperature oxidation behavior of CoCrFeMnNb x Ni high-entropy alloys

[J].

Toughening pathways and regulatory mechanisms of refractory high-entropy alloys

[J].Alloying has long been used to improve the properties of metals. Typically, the design concept starts with two metal elements as the foundation and small quantities of other elements are added to change or optimize the alloy properties. Recently, a new alloy has emerged, which combines several main elements to form new alloys, known as high-entropy alloys. Among them, refractory high-entropy alloys (RHEAs) made by mixing five or more refractory metal elements that have similar atomic ratios have wide application prospects in the field of high-temperature materials because of their stable phase structures and excellent high-temperature properties. This paper reviews the mechanical properties and microstructure of typical RHEAs, mechanism of toughening and mechanical property regulation of RHEAs, and prospects for the future development of RHEAs, starting with the current research status of RHEAs. The first section delves into the classification of RHEAs based on their constituent phases, and the microstructure and phase composition of the RHEAs are investigated. The second section summarizes the mechanical properties, strengthening, and toughening mechanisms of RHEAs at room and high temperatures. The third section illustrates and discusses three different strengthening and toughening schemes that have been used to modulate the mechanical properties of RHEAs, namely, chemical composition, process, and phase structure modulations. Finally, the future development of RHEAs have been forecasted and the following recommendations are made for key RHEA research trends in the future: simulating and calculating the materials properties and formation phases using computers and other technologies, development of a research platform and database for RHEAs, accelerating the screening of new RHEAs using combinatorial experimental methods, and acquiring top-down and bottom-up experimental methods to explore RHEAs systems with excellent properties.

难熔高熵合金的强韧化途径与调控机理

[J].在众多高熵合金中,由5种或5种以上的难熔金属元素,按照等原子比或者近等原子比混合形成的难熔高熵合金,凭借稳定的相结构和优异的高温性能,在高温材料领域具有广阔的应用前景。本文从难熔高熵合金的研究现状出发,综述典型难熔高熵合金的微观组织和相组成、室温和高温力学性能、强韧化机理与力学性能调控,并对未来难熔高熵合金的研究开发进行展望。首先,将难熔高熵合金按照组成相进行分类,分析了难熔高熵合金的微观组织和相组成,然后总结了难熔高熵合金的室温和高温力学性能与强韧化机理,并讨论了3种不同的强韧化方案,即化学成分调控、工艺调控和相结构调控。最后对未来难熔高熵合金的发展进行了展望,并对其未来重点研究方向提出了如下建议:借助计算机等技术,模拟与计算材料的性能与形成相,构建难熔高熵合金的研究平台与数据库;借助组合实验方法,加快筛选新的难熔高熵合金;掌握自上而下和自下而上的实验方法,探究性能优异的新型难熔高熵合金体系。