晶界或其他界面在热力学上是稳定的,并具有类似于“相”的特征,因此可将晶界视为一种“准二维相”。Tang等[7]引入“界面相”(Complexions) 这一术语表示这种界面状态。界面层与邻接相处于热力学平衡状态,使界面相具有稳定且有限的厚度。界面相由溶质原子的界面偏析诱导产生,因此不能独立存在而是依附于基体晶粒。很难预测界面相的形成,样品制备和观测也具有一定难度。这些因素,限制了对界面相的深入研究。形成界面相需要的晶界偏析是纳米级现象,因此原子尺度的模拟是研究界面相的理想方法。可将Monte Carlo(MC)方法与分子动力学(MD)结合,研究合金晶界处界面相的形成及其对材料力学性能的影响。

本文总结晶界偏析对纳米晶材料的力学性能和晶界能的影响并指出传统偏析理论的不足,结合“界面相”的相关研究成果综述界面偏析和界面相对纳米晶材料综合性能的影响。

1 晶界偏析理论

晶界的Gibbs自由能,高于相同原子组分单晶的Gibbs自由能。为了使系统的总Gibbs自由能最小化,溶质原子倾向于在晶界区域积累。这种现象,称为晶界偏析。晶界偏析,对金属结构材料力学性能有极大的影响。针对晶界偏析的研究,主要集中在:(1)平衡偏析理论和非平衡偏析理论;(2)晶界偏析工程;(3)由晶界偏析而引出“界面相”的发展。

1.1 晶界偏析模型

在多组元材料中发生晶界偏析,基体中溶质元素的含量降低,晶界处溶质元素的含量高,即晶界的溶质浓度与基体平衡时的整体溶解度不同。

在界面足够大且保持外界恒定压力的情况下,可使用Gibbs等温吸附模型确定界面处溶质的密度[62]

而在包括基体晶粒和周围晶界的封闭系统内,晶界有一定的厚度。文献[8]在不考虑溶质原子之间相互作用的情况下提出的Langmuir-McLean模型,在保留经典热力学分析方法的同时用统计热力学方法计算了溶质原子附近的晶格畸变能。Langmuir-McLean模型假设:(1)晶界由畸变的位点组成。这些位点数量有限,溶质原子在畸变位点的自由能与晶体位点中的自由能不同,其差异即为晶界偏析能。(2)晶界单位面积内有数量一定且均匀分布的偏析位点,并假定偏析限制在晶界处的单原子层内。(3)晶界可看作一个独立的热力学实体,与基体处于平衡状态。满足以上条件时可用等式

描述晶界偏析[8]。其中R为普适气体常数,

针对这些局限性,Seah和Hondros提出溶质在偏析位点饱和时溶质的原子分数为[62]

但是,溶质原子不一定能填满所有偏析位点,因此其偏析覆盖率

将偏析覆盖率代入初始模型得到Seah & Hondros模型[62]

1.2 晶界偏析工程

(1) 溶质原子的区别和晶界偏析位点的不同状态影响材料的宏观性能,降低或提高晶界结合强度;

(2) 界面的溶质偏析改变晶界原子的键合特性、电荷密度,降低或提高晶界结合强度[18];

(3) 晶界的内应力、晶界能以及偏析原子的共同作用改变了晶界的热力学状态,形成界面相[19]。

对晶界偏析的设计也要遵循热力学原则,因此应该从以下几方面确定合适的合金体系和界面的溶质-基体组合。(1) 溶质元素的偏析系数;(2) 溶质元素的扩散系数;(3) 偏析产物和基体相的自由能。

充分考虑上述条件后,可根据上文提出的四点方案调控材料的综合性能。从工程应用的角度,热处理应用于材料制备的各个阶段,而且晶界偏析大多可通过热处理实现,因此以上调控手段可以应用于生产。

2 界面相

随着高分辨率像差校正透射电镜(TEM)表征技术的发展和第一性原理计算在材料领域的进一步应用,新的偏析理论不断突破旧理论的局限性[20~24]。2006年Tang M等[7]首次提出“界面相”概念。界面相最早在未掺杂的Al2O3和分别掺杂了CaO、MgO、SiO2、Nd2O3的Al2O3晶界发现。在氧化铝中观察到一系列偏析行为,结合合金中的晶界偏析,界面相理论初步形成并作为偏析理论的重要发展广泛探究。界面相理论认为,晶界或其他界面在热力学上是稳定的并表现出类似于“相”的特征,其结构和化学性质可能随着外界温度和压力等热力学参数的变化而变化。Turlo V等[25]研究体心立方铁镍合金中位错处线性界面相的形成时发现,亚稳的B2-FeNi相和稳定的L10-FeNi相在Ni原子偏析的驱动下沿刃位错产生,证明偏析是诱导界面相形成的关键因素。

需要说明的是,界面相可以在纯金属中存在,但是大多数关于界面相的研究都集中于多元合金中,其中晶界偏析起着关键性的作用。本文主要讨论多元合金系统中的界面相。

2.1 界面相的分类

界面相具有相对稳定的厚度,可根据原子层数或厚度分类。对界面相最有说服力的分类方式,是Dillon-Hammer分类法。这种分类方法,根据界面相的原子层数、厚度把界面相可分为六种。如图1所示,使用高角环形暗场扫描透射电子显微镜(HAADF-STEM)表征各种不同的界面相[17,21,26,27]。界面相简化模型将代表溶质原子的小球夹在界面之间模拟晶界处溶质原子的富集,包括没有溶质原子富集的晶界(Ⅰ型界面相),如图1a~c;单原子层界面相(Ⅱ型界面相),如图1d~f;双原子层界面相(Ⅲ型界面相),如图1g~i;三原子层界面相(Ⅳ型界面相),如图1j~l;纳米层界面相(Ⅴ型界面相),如图1m~o;润湿层界面相(Ⅵ型界面相),如图1p~r。润湿层界面相的产生源于晶界的预熔融和预润湿,其厚度大于其他五种界面相。纳米层界面相的厚度虽大于三个原子层,但是还不足以突破热力学限制,因此大多数界面相厚度取决于晶界热力学状态。再次建立晶界模型,将代表溶质原子的小球夹在两界面之间。根据胶体理论,振荡结构相互作用将产生最小自由能,而产生最小自由能的层厚恰好与相应界面相的厚度

图1

Kuzmina M等[31]将界面相的概念从三维缺陷引入二维缺陷。Kuzmina M等在Fe-Mn合金位错处发现了异常的成分和结构状态:Mn原子在位错处偏析随后在位错核心附近形成面心立方区域,但该区域没有进一步生长。这些线性界面相区域与基体处于平衡状态且含量极高,一立方米合金内线性界面相长达一光年。这表明,线性界面相可通过改变位错处的成分和结构调控金属结构材料的性能。

2.2 界面相的转变

随着晶界热力学状态的改变界面相将发生转变,这种转变使材料力学性能的发生变化。透射电子显微镜和其他表征手段保障了晶界相变和界面相转变的观测和研究。

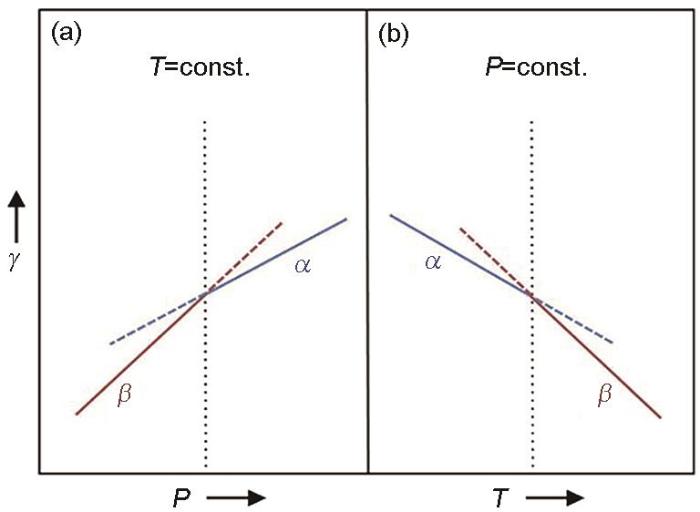

Gibbs认为,晶界的结构和化学成分决定热力学状态。Gibbs提出界面热力学的相关理论,并量化了热力学特性。Gibbs分析认为,界面可以α和β两种不同的状态存在,即不同界面状态的自由能不同,当界面处于平衡状态时[28]

图2

3 晶界偏析和界面相对纳米晶材料性能的影响

通过转变界面相调控材料宏观性能,值得关注和研究。虽然对界面相的转变已经研究多年,但是引入界面相后材料性能的变化,还是难以预测的。纳米晶金属材料的晶界密度高,强度和硬度也比较高,但是其有限的热稳定性和塑性使其应用受到一定的限制。晶界偏析和在晶界处引入界面相,可显著提高纳米晶金属材料的综合性能。

3.1 晶界偏析和界面相对材料塑性的影响

多数强化机制虽然能提高材料的强度,但是通常使其塑性降低。纳米晶金属材料的高强度源于高晶界密度,而晶界密度的提高不可避免地使其材料塑性降低。研究表明[32, 33],晶界偏析和界面相影响纳米晶金属材料的机械性能。如图3所示,Turlo V等[34]根据分子动力学模拟研究了Cu-Zr合金体系中界面相对位错形核和位错滑移的影响,并进一步研究了其对材料力学性能的影响。结果表明:Cu-Zr合金中有序和无序界面相的自由体积都比较大,降低位错临界发射应力可促进位错的发射,而具有无序界面相的晶界低应力区中的钉扎位错,增大了位错传播所需的流变应力并提高了材料强度。2015年Kuzmina M等[31]观测到Mn原子在位错处偏析,并在位错处形成面心立方结构区域。这些区域与基体处于平衡态,将界面相从平面维度引申到线性维度。Rupert T J等[33]通过大规模原子模拟研究Fe-Ni合金中线性界面相对位错运动的影响。当施加机械剪切应力驱动位错运动时,位错运动受到线性界面相的限制并观察到强烈的钉扎效应。这与晶体中位错应力场的改变有关,这种钉扎效应使位错运动所需的应力显着增大。

图3

图3

Cu-Zr合金中不同的晶界结构对位错发射和滑移的影响[34]

Fig.3

Effect of different grain boundary structures on dislocation emission and slip of Cu-Zr alloys[34] (a) quilibrium grain boundary structures obtained using the hybrid MD/MC method, (b) atomic shear stress distribution during dislocation propagation simulations at 3% applied shear strain,black arrows denote local regions of low stress, (c) relative changes of the critical stress required for dislocation emission and propagation, as measured by the MD simulation

目前针对纳米晶金属材料的研究,主要集中于在保证强度不明显降低的条件下提高其塑性变形能力。Khalajhedayati A等[35]的结果表明,具有VI型界面相的Cu-Zr合金的延展性比纯纳米晶Cu高一个数量级。Raabe D等[19]将Fe-9Mn在1050℃进行30 min的重结晶和固溶热处理后水淬,使Mn原子在晶界处偏析。在一般情况下,Mn原子在晶界处的偏析容易使钢材脆性断裂,但是Raabe D在450℃对Fe-9Mn钢进一步热处理48 h后偏析的Mn原子促进了晶界处奥氏体的形成。奥氏体充当机械缓冲层,使材料的塑性提高。随着晶粒尺寸减小到纳米级位错滑移主导的变形机制逐渐受到抑制,晶界滑移和晶粒旋转逐渐主导纳米晶金属材料的变形[36]。提高纳米晶材料塑性的关键,在于产生抑制晶界主导的变形机制。而晶界偏析和界面相的引入,为设计纳米晶金属材料提供了新思路。

根据Hall-Petch关系,在一定的尺寸范围内随着晶粒尺寸的减小材料的强度和韧性同时提高。但是,当晶粒尺寸小于临界尺寸时会出现反Hall-Petch关系,即强度不随晶粒尺寸的减小提高,反而出现反常的降低[37]。出现反Hall-Petch关系的原因,是纳米晶金属材料变形机制的改变。晶粒尺寸不断减小时晶粒内位错滑移主导的变形机制受到抑制,主导变形的是晶界剪切滑动和晶粒旋转。为了缓解这种情况,可用晶界偏析增强纳米晶合金[38, 39]。图4a~c显示,Hu J等[39]用电沉积制备纳米晶Ni-Mo合金,用Mo原子在晶界的偏析稳定晶界以抑制晶界主导的变形机制,使晶粒尺寸极小的纳米晶金属材料依然保持高硬度和高强度。提高晶界的抗剪切能力以抑制晶界主导的变形,是进一步提高纳米晶金属材料塑性的主要方向。Zheng S J等[40]用磁控溅射法制备纳米层状材料,作为界面模型材料加以研究。如图4d~f所示,将非晶层引入Cu/Nb界面,可制备出具有非晶界面层(VI型界面相)的多层Cu/Nb复合材料。力学性能测试的结果表明,非晶界面相的引入吸收了大量位错,使位错难以穿过界面而产生了超高的硬度。同时,MD模拟结果表明,非晶界面相可提高界面剪切所需的流变应力进而提高界面的抗剪切能力。在晶界引入VI型界面相如硬质的非晶界面相使晶界的抗剪切能力提高,抑制了晶界剪切滑动和晶粒旋转并延缓了反Hall-Petch关系的发生,使材料的强度进一步提高。

图4

图4

引入不同界面相以提高纳米结构材料的界面稳定性 [39, 40]

Fig.4

Improving the interfacial stability of nanostructured materials by introducing different complexions[39, 40] (a, b) three-dimensional atom probe tomography (APT) reconstruction of the nanograined Ni-Mo alloy, (c) softening and hardening in the nanograined Ni-Mo alloys, Cu/Nb composites with amorphous complexions, (d) TEM image of Cu/Nb composite, (e) TEM image of amorphous complexions, (f) schematic diagram of interaction between amorphous complexions and dislocations

3.2 晶界偏析和界面相对材料断裂韧性的影响

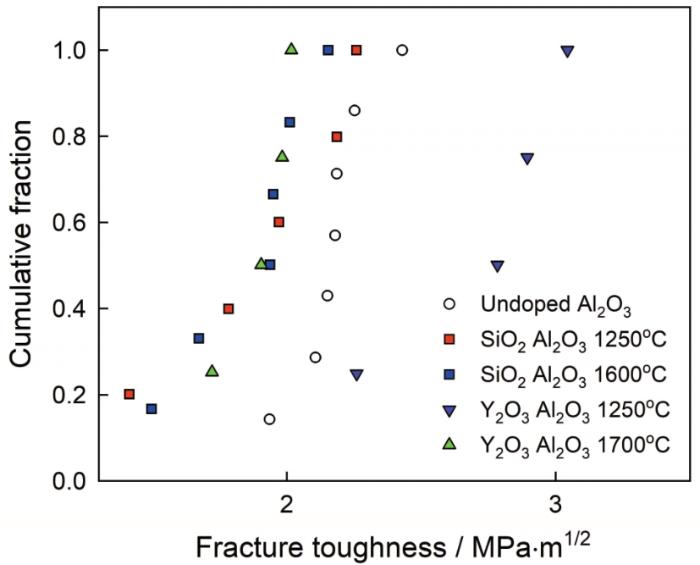

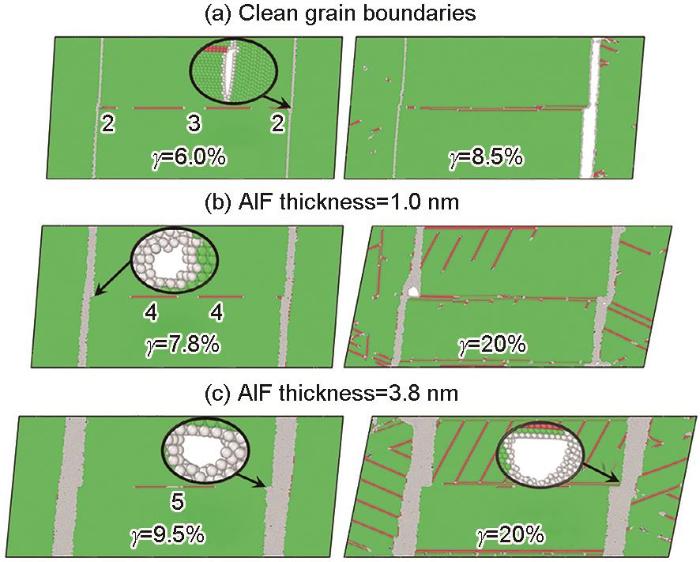

与同成分的粗晶材料相比,纳米晶材料的断裂韧性较低。位错在晶粒内成核并滑移至晶界使晶界局部发生应力集中,裂纹在应力集中部位形成并沿晶界扩展。退火和晶界偏析可降低纳米晶材料的晶界能而使抗裂纹扩展能力提高。Feng L等 [41]对Al2O3微悬臂试样进行原位弯曲实验,使用聚焦离子束(FIB)制备样品,用纳米机械加载的测试方法评估Al2O3的晶界断裂抗力。结果如图5所示,Al2O3样品界面相的类型决定断裂行为,界面相的引入提高了Al2O3的断裂韧性。Y2O3掺杂的Al2O3具有最大的抗断裂性,而SiO2掺杂的Al2O3比未掺杂的Al2O3具有更小的抗断裂性。Farkas D等[42]发现,裂纹沿着纳米级晶粒的晶界扩展。在晶界裂纹前缘的位置产生纳米级空洞,然后纳米级空洞聚集生长与裂纹连接,造成裂纹的扩展。由此可见,晶界状态对纳米晶金属材料的韧性有极大的影响,而界面相的引入则可调整晶界的结构和成分。Schuler J D等[43]对经过热处理的Cu-1% Zr(原子分数)样品进行原位疲劳实验,两种样品分别为有非晶晶间膜的样品和有序界面相。加载后有序界面相样品具有高度局部塑性,裂纹扩展不稳定。相反,具有非晶晶间膜的样品表现出优异的延展性,裂纹扩展稳定,塑性变形均匀。这表明,非晶晶间膜分散了晶界应变并抑制了沿晶断裂。Rupert T J等[44]使用分子动力学模拟VI型非晶界面相对位错的吸收,研究了界面相减轻产生晶界损伤的能力。如图6所示,在铜晶粒内添加了一个人工位错源,引入三种不同的晶界结构吸收位错。结果表明,VI型非晶界面相吸收位错延缓了裂纹形核和降低了裂纹扩展速率,其吸收位错的效果随着界面相厚度的增加而增加。这充分说明,非晶晶间膜可充当晶粒间的增韧结构,有希望设计不同非晶晶间膜的厚度和成分制备出高强韧性的材料。

图5

图6

图7

3.3 晶界偏析和界面相对材料变形行为的影响

纳米晶金属材料具有高硬度和高强度,但是其塑性严重不稳定(例如剪切局部化)。一直以来,公认的变形机制是晶界主导变形,例如晶粒旋转和滑动[36],而晶界偏析和界面相的引入可改变和调控纳米晶材料的变形行为。如图8所示,Rupert T J等[35]在Cu-Zr合金晶界处引入有序和无序的界面相,用不同结构的界面相调控纳米晶材料的变形行为,其中无晶界偏析的样品在压缩过程中产生宏观剪切断裂,具有无序界面相的样品压缩后均匀变形,在产生无剪切带的同时强度大幅度提高。Balbus G H等[45]也研究了晶粒尺寸小于10 nm的三元铝合金在各种热处理后的变形特征。结果表明,在70%熔点温度的退火降低了剪切局部化的倾向并提高了强度。变形行为从明显的应变局部化转变到更均匀变形,均匀变形行为与退火过程中非晶晶间膜的形成相吻合。而为了分析界面相对纳米晶金属材料力学性能的影响,Wang Y M等[46]制备Cu/CuZr(晶体/非晶)多层材料,将厚度为5 nm的CuZr非晶层引入Cu层之间以模拟非晶界面相在晶界的分布,并测试其进行力学性能,发现这种多层材料的拉伸变形能力极高。非晶层可作为良好的位错形核点和位错吸收体,位错被非晶层吸收后在非晶层内形成剪切转变区,而非晶层的厚度极薄,剪切转变区不足以相互连结形成剪切带,剪切转变区释放吸收位错产生的应力集中,保证了材料的均匀变形能力。这些研究结果表明,引入晶界偏析和不同种类界面相可调控超细结构金属材料的变形行为。调控晶界处界面相和偏析,拓展了纳米晶金属材料的设计思路。

图8

3.4 晶界偏析和界面相对晶界稳定性的影响

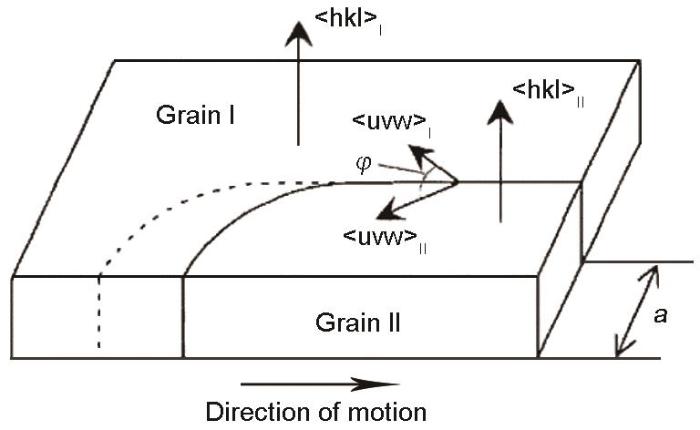

金属材料中的溶质影响晶界运动,溶质原子对晶界的钉扎会降低晶界运动速率,溶质阻碍的程度取决于溶质类型和晶界结构。但是,溶质原子在晶界的偏析不一定都阻碍晶界运动,某些特定溶质原子在晶界的偏析产生新的晶界迁移机制,使晶界的迁移率提高。

其中m为晶界迁移率,驱动力保持恒定,即

其中H为晶界迁移激活焓,A0为预指数因子。Ga掺杂影响晶界迁移激活焓和预指数因子,使晶界迁移率的取向依赖性大大降低。Molodov D等[16]将晶界迁移率的急剧上升解释为晶界结构和晶界迁移机制改变为相变主导,即晶界迁移机制由原子扩散机制改变为预润湿相变和在晶界上形成液态(或准液态)富Ga层主导晶界迁移。

图9

图10

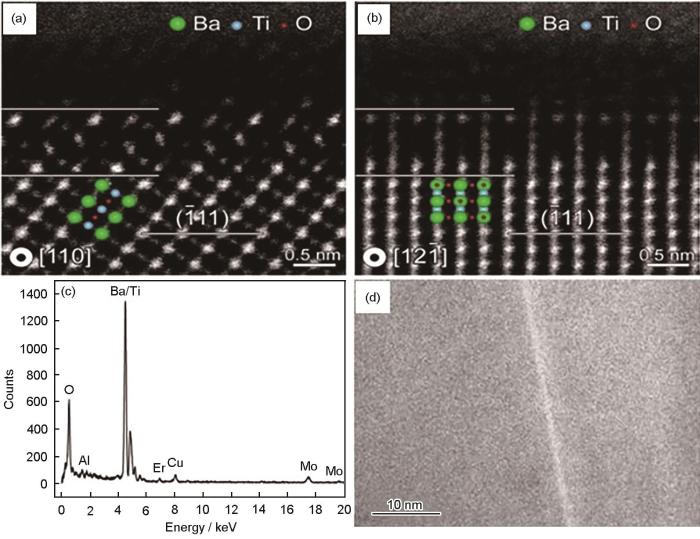

作为描述晶界偏析的工具,界面相理论提供了晶界结构和化学成分的信息。晶界结构不同,显著影响偏析效果。Pan Z等[52]通过分子动力学模拟研究Cu-Zr系统中六种不同界面的界面相形成和转变,研究了不同界面的偏析及其对界面的影响。在溶质浓度和温度较低的情况下,晶界处趋向于形成有序的单层界面相。当溶质浓度达到临界值且温度足够高时(95%固相线温度),晶界处趋向于形成润湿层界面相。润湿层界面相在高温下形成并保持稳定,其降低晶界能和钉扎晶界的效果明显优于相同成分溶质原子的晶界偏析。Grigorian C M等[53] 对比研究了二元Cu-Zr合金和三元Cu-Zr-Hf合金。结果表明,与二元Cu-Zr合金体系相比,三元Cu-Zr-Hf合金具有更好的热稳定性,因为三元合金笔二元合金具有更复杂的晶界偏析并产生更厚的非晶晶间膜。如图11所示,Schuler J D等[54]发现,Ni-W合金在1000℃或更高温度下退火后迅速淬火可在晶界处生成厚度大约为1 nm的非晶膜。这种非晶膜能在1000℃将晶粒尺寸稳定在60 nm左右。Balbus G H等[55]对含有非晶晶间膜的纳米晶Al-Ni-Ce合金进行了详细的原位和非原位热分析、X射线衍射以及高温压痕研究。结果表明,非晶晶间膜的存在使合金具有优异的显微结构稳定性,在低温退火过程中非晶晶间膜的短程有序性降低了金属间化合物形成的倾向,抑制高温下的晶粒生长,使纳米晶体的微观结构稳定。高温压痕实验结果表明,具有非晶晶间膜的Al-Ni-Ce合金在300℃表现出超高的高温强度。

图11

图11

Ni-W合金界面相的表征和在不同温度的晶粒尺寸分布[54]

Fig.11

Characterisation of the Ni-W alloy interfacial phase and grain size distribution at different temperatures[54] (a, b) high resolution TEM images of 1 nm thick amorphous intergranular films, (c) grain size analysis of the Ni-6%W (atomic fraction) electrodeposited alloys after annealing for 1 h at different temperatures

4 总结和展望

(1) 对于实际工程应用,目前针对界面相工程最主要的不足是尚未系统地归纳和总结各种常用合金体系的界面相相图。这方面工作已经在二元体系中进行,在理论和实验上证明了界面相转变的存在。

(2) 界面相转变是通过新相的形核和生长发生的,但是其机制和驱动力尚不明确。研究界面相形核和生长的机制可解决界面相制备困难和空间分布不均匀的问题,也可为抑制或促进界面相转变提供新的思路。

(3) 目前针对界面相的实验研究,只局限于纳米晶金属材料热稳定性和强塑性。对此应该通过控制变量法排除干扰因素并设计简化模型,分析不同界面相对材料宏观性能的影响。例如,把多层材料作为模型和在基体层界面处引入不同界面相,通过原位拉伸、压缩、弯曲实验研究层状界面相如何影响材料性能,并分析其原子尺度的机理。

总之,未来的研究应该侧重于为工程实际应用建立常用二元及三元合金体系的界面相相图。建立模型以研究每种界面相怎样影响晶界特性和宏观性能,引入不同界面相以调控材料的某种性能。例如,用VI型非晶界面相吸收位错以缓解应力集中提高材料延展性但是不降低强度,制备出高强高韧的金属结构材料。

参考文献

Solute segregation and classification of [100] tilt grain boundaries in α-iron: Consequences for grain boundary engineering

[J].

Stabilizing nanocrystalline materials with dopants

[J].

The influence of phosphorus in dilute solid solution on the absolute surface and grain boundary energies of iron

[J].

Anisotropy of segregation at grain boundaries and surfaces

[J].

Grain coarsening inhibited by solute segregation

[J].

Reducing grain boundary, dislocation line and vacancy formation energies by solute segregation. I. Theoretical background

[J].

Diffuse interface model for structural transitions of grain boundaries

[J].

Solute segregation at ordered grain boundaries

[J].

Grain boundaries with impurities in a two-dimensional lattice-gas model

[J].

Thermodynamics of grain boundary premelting in alloys. I. Phase-field modeling

[J].

The control of brittleness and development of desirable mechanical properties in polycrystalline systems by grain boundary engineering

[J].

Grain boundary segregation engineering in metallic alloys: A pathway to the design of interfaces

[J].

The adsorption of gases on plane surfaces of glass, mica and platinum

[J].

Thermodynamics and structural aspects of grain boundary segregation

[J].

Acceleration of grain boundary motion in Al by small additions of Ga

[J].

The role of a bilayer interfacial phase on liquid metal embrittlement

[J].Intrinsically ductile metals are prone to catastrophic failure when exposed to certain liquid metals, but the atomic-level mechanism for this effect is not fully understood. We characterized a model system, a nickel sample infused with bismuth atoms, by using aberration-corrected scanning transmission electron microscopy and observed a bilayer interfacial phase that is the underlying cause of embrittlement. This finding provides a new perspective for understanding the atomic-scale embrittlement mechanism and for developing strategies to control the practically important liquid metal embrittlement and the more general grain boundary embrittlement phenomena in alloys. This study further demonstrates that adsorption can induce a coupled grain boundary structural and chemical phase transition that causes drastic changes in properties.

First-principles determination of grain boundary strengthening in tungsten: Dependence on grain boundary structure and metallic radius of solute

[J].

Segregation engineering enables nanoscale martensite to austenite phase transformation at grain boundaries: A pathway to ductile martensite

[J].

First principles determination of the effects of phosphorus and boron on iron grain boundary cohesion

[J].Toward an electronic level understanding of intergranular embrittlement and its control in steels, the effects of phosphorus and boron impurities on the energy and electronic properties of both an iron grain boundary and its corresponding intergranular fracture surface are investigated by the local density full potential augmented plane wave method. When structural relaxations are taken into account, the calculated energy difference of phosphorus in the two environments is consistent with its measured embrittlement potency. In contrast to the nonhybridized interaction of iron and phosphorus, iron-boron hybridization permits covalent bonding normal to the boundary contributing to cohesion enhancement. Insights into bonding behavior offer the potential for new directions in alloy composition for improvement of grain boundary-sensitive properties.

Bismuth-induced embrittlement of copper grain boundaries

[J].Catastrophic brittle fracture of crystalline materials is one of the best documented but most poorly understood fundamental phenomena in materials science. Embrittlement of copper by bismuth is a classic example of this phenomenon. Because brittle fracture in any structural material can involve human tragedy, a better understanding of the mechanisms behind it is of the highest interest. In this study, we use a combination of two state-of-the-art atomic characterization techniques and ab initio theoretical materials simulations to investigate the geometric and electronic structure of a copper grain boundary with and without bismuth. Only with this unique combination of methods are we able to observe the actual distribution of bismuth in the boundary and detect changes in the electronic structure caused by the bismuth impurity. We find that the copper atoms that surround the segregated bismuth in the grain boundary become embrittled by taking on a more zinc-like electronic structure.

Zr segregation and associated Al vacancies in alumina grain boundaries

[J].

Oxygen segregation at coherent grain boundaries of cubic boron nitride

[J].

Atom-resolved imaging of ordered defect superstructures at individual grain boundaries

[J].

Dislocation-assisted linear complexion formation driven by segregation

[J].

Insight into the atomic-scale mechanism of liquid metal embrittlement

[J].A method has been developed to investigate material embrittlement on the atomistic level. By ion implantation the embrittling agent is introduced into a small volume enclosing a segment of a grain boundary of a thin specimen prepared for transmission electron microscopy (TEM). After allowing the implanted ions to segregate at the grain boundary, the position of the ions is determined by atomic-resolution TEM. In the present study this was applied to the Al(Ga) system. Close correspondence with previous ab initio calculations is found and a model for the initial stages of embrittlement is proposed.

Grain boundary wetting and prewetting in Ni-doped Mo

[J].Grain boundary (GB) wetting and prewetting in Ni-doped Mo are systematically evaluated via characterizing well-quenched specimens and thermodynamic modeling. In contrast to prior reports, the δ-NiMo phase does not wet Mo GBs in the solid state. In the solid-liquid two-phase region, the Ni-rich liquid apparently wets Mo GBs completely. Furthermore, high-resolution transmission electron microscopy demonstrates that nanometer-thick quasiliquid films persist at GBs into the single-phase region where the bulk liquid phase is no longer stable. This is interpreted as a case of GB prewetting. An analytical thermodynamic model is developed and validated; this model can be applied to other alloys.

Grain boundary complexion transitions

[J].

Grain boundary disordering in binary alloys

[J].This letter reports a grain boundary (GB) premelting/prewetting model based on the Miedema model and computational thermodynamics, predicting that GB disordering can start at as low as 60%–85% of the bulk solidus temperatures in selected systems. This model quantitatively explains the long-standing mystery of subsolidus activated sintering in W–Pd, W–Ni, W–Co, W–Fe and W–Cu, and it has broad applications for understanding GB-controlled transport kinetics and physical properties. Furthermore, this study demonstrates the necessity of developing GB “phase” diagrams as a tool for material design.

Linear complexions: Confined chemical and structural states at dislocations

[J].For 5000 years, metals have been mankind's most essential materials owing to their ductility and strength. Linear defects called dislocations carry atomic shear steps, enabling their formability. We report chemical and structural states confined at dislocations. In a body-centered cubic Fe-9 atomic percent Mn alloy, we found Mn segregation at dislocation cores during heating, followed by formation of face-centered cubic regions but no further growth. The regions are in equilibrium with the matrix and remain confined to the dislocation cores with coherent interfaces. The phenomenon resembles interface-stabilized structural states called complexions. A cubic meter of strained alloy contains up to a light year of dislocation length, suggesting that linear complexions could provide opportunities to nanostructure alloys via segregation and confined structural states. Copyright © 2015, American Association for the Advancement of Science.

Bulk nanocrystalline Al alloys with hierarchical reinforcement structures Via grain boundary segregation and complexion formation

[J].

Interdependent linear complexion structure and dislocation mechanics in Fe-Ni

[J].Using large-scale atomistic simulations, dislocation mechanics in the presence of linear complexions are investigated in an Fe-Ni alloy, where the complexions appear as nanoparticle arrays along edge dislocation lines. When mechanical shear stress is applied to drive dislocation motion, a strong pinning effect is observed where the defects are restricted by their own linear complexion structures. This pinning effect becomes weaker after the first dislocation break-away event, leading to a stress-strain curve with a profound initial yield point, similar to the static strain aging behavior observed experimentally for Fe-Mn alloys with the same type of linear complexions. The existence of such a response can be explained by local diffusion-less and lattice distortive transformations corresponding to L10-to-B2 phase transitions within the linear complexion nanoparticles. As such, an interdependence between a linear complexion structure and dislocation mechanics is found.

Grain boundary complexions and the strength of nanocrystalline metals: Dislocation emission and propagation

[J].

Manipulating the interfacial structure of nanomaterials to achieve a unique combination of strength and ductility

[J].The control of interfaces in engineered nanostructured materials has met limited success compared with that which has evolved in natural materials, where hierarchical structures with distinct interfacial states are often found. Such interface control could mitigate common limitations of engineering nanomaterials. For example, nanostructured metals exhibit extremely high strength, but this benefit comes at the expense of other important properties like ductility. Here, we report a technique for combining nanostructuring with recent advances capable of tuning interface structure, a complementary materials design strategy that allows for unprecedented property combinations. Copper-based alloys with both grain sizes in the nanometre range and distinct grain boundary structural features are created, using segregating dopants and a processing route that favours the formation of amorphous intergranular films. The mechanical behaviour of these alloys shows that the trade-off between strength and ductility typically observed for metallic materials is successfully avoided here.

Grain rotation in plastic deformation

[J].The plastic deformation behaviors of crystalline materials are usually determined by lattice dislocations. However, below a certain particle or grain size, focus is placed on the grain-boundary-mediated mechanisms (e.g., grain rotation, grain boundary sliding, and diffusion), which has been observed during recrystallization, grain growth, and plastic deformation. However, the underlying mechanisms of grain rotation remain to be studied. In this article, we review the theoretical models, molecular dynamics simulations, and experimental investigations on grain rotation. Especially, the development of in situ transmission electron microscopy (TEM) and X-ray characterization methods for probing grain boundary processes during plastic deformation provides a better understanding of the mechanisms of grain rotation. Moreover, the ability to acquire high-quality X-ray diffraction patterns from individual nanograins is expected to find broad applications in various fields such as physics, chemistry, materials science, physics, and nanoscience.

The hall–petch and inverse hall-petch relations and the hardness of nanocrystalline metals

[J].We review some of the factors that influence the hardness of polycrystalline materials with grain sizes less than 1 µm. The fundamental physical mechanisms that govern the hardness of nanocrystalline materials are discussed. The recently proposed dislocation curvature model for grain size-dependent strengthening and the 60-year-old Hall–Petch relationship are compared. For grains less than 30 nm in size, there is evidence for a transition from dislocation-based plasticity to grain boundary sliding, rotation, or diffusion as the main mechanism responsible for hardness. The evidence surrounding the inverse Hall–Petch phenomenon is found to be inconclusive due to processing artefacts, grain growth effects, and errors associated with the conversion of hardness to yield strength in nanocrystalline materials.

Observations of grain boundary impurities in nanocrystalline Al and their influence on microstructural stability and mechanical behaviour

[J].

Grain boundary stability governs hardening and softening in extremely fine nanograined metals

[J].Conventional metals become harder with decreasing grain sizes, following the classical Hall-Petch relationship. However, this relationship fails and softening occurs at some grain sizes in the nanometer regime for some alloys. In this study, we discovered that plastic deformation mechanism of extremely fine nanograined metals and their hardness are adjustable through tailoring grain boundary (GB) stability. The electrodeposited nanograined nickel-molybdenum (Ni-Mo) samples become softened for grain sizes below 10 nanometers because of GB-mediated processes. With GB stabilization through relaxation and Mo segregation, ultrahigh hardness is achieved in the nanograined samples with a plastic deformation mechanism dominated by generation of extended partial dislocations. Grain boundary stability provides an alternative dimension, in addition to grain size, for producing novel nanograined metals with extraordinary properties.Copyright © 2017, American Association for the Advancement of Science.

Hardening induced by dislocation core spreading at disordered interface in Cu/Nb multilayers

[J].

The influence of dopants and complexion transitions on grain boundary fracture in alumina

[J].

Dislocation activity and nano-void formation near crack tips in nanocrystalline Ni

[J].

In situ high-cycle fatigue reveals importance of grain boundary structure in nanocrystalline Cu-Zr

[J].

Amorphous intergranular films as toughening structural features

[J].

Suppression of shear localization in nanocrystalline Al-Ni-Ce Via segregation engineering

[J].

Ductile crystalline-amorphous nanolaminates

[J].It is known that the room-temperature plastic deformation of bulk metallic glasses is compromised by strain softening and shear localization, resulting in near-zero tensile ductility. The incorporation of metallic glasses into engineering materials, therefore, is often accompanied by complete brittleness or an apparent loss of useful tensile ductility. Here we report the observation of an exceptional tensile ductility in crystalline copper/copper-zirconium glass nanolaminates. These nanocrystalline-amorphous nanolaminates exhibit a high flow stress of 1.09 +/- 0.02 GPa, a nearly elastic-perfectly plastic behavior without necking, and a tensile elongation to failure of 13.8 +/- 1.7%, which is six to eight times higher than that typically observed in conventional crystalline-crystalline nanolaminates (<2%) and most other nanocrystalline materials. Transmission electron microscopy and atomistic simulations demonstrate that shear banding instability no longer afflicts the 5- to 10-nm-thick nanolaminate glassy layers during tensile deformation, which also act as high-capacity sinks for dislocations, enabling absorption of free volume and free energy transported by the dislocations; the amorphous-crystal interfaces exhibit unique inelastic shear (slip) transfer characteristics, fundamentally different from those of grain boundaries. Nanoscale metallic glass layers therefore may offer great benefits in engineering the plasticity of crystalline materials and opening new avenues for improving their strength and ductility.

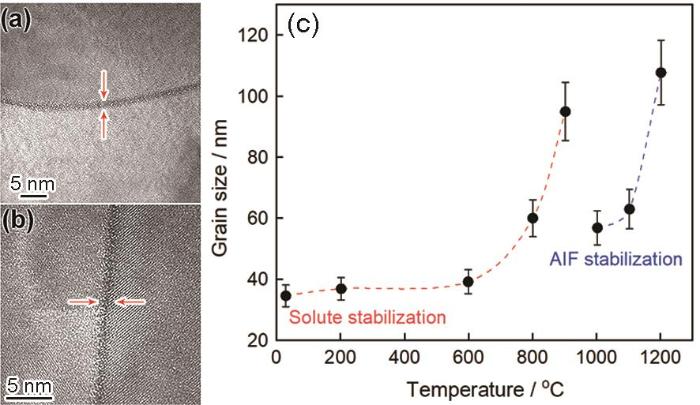

Atomistic study of abnormal grain growth structure in BaTiO3 by transmission electron microscopy and scanning transmission electron microscopy

[J].

Alloy effects in nanostructures

[J].

High-temperature stability and grain boundary complexion formation in a nanocrystalline Cu-Zr alloy

[J].

The role of W on the thermal stability of nanocrystalline nitiwx thin films

[J].

Tailoring the thermal stability of nanocrystalline Ni alloy by thick grain boundaries

[J].

Effect of grain boundary character on segregation-induced structural transitions

[J].

Thick amorphous complexion formation and extreme thermal stability in ternary nanocrystalline Cu-Zr-Hf alloys

[J].

Amorphous complexions enable a new region of high temperature stability in nanocrystalline Ni-W

[J].

Disordered interfaces enable high temperature thermal stability and strength in a nanocrystalline aluminum alloy

[J].