1 实验方法

1.1 实验用材料和试剂

NaOH(98%,质量分数)、泊洛沙姆(F127,Mw=12600)、苯酚以及聚乙烯亚胺(PEI,Mw=10000)、环氧树脂(EP,AB-EP-20)、环氧树脂固化剂(AB-HGF)、氧化石墨烯(GO,1%,质量分数)、甲醛(37%,质量分数)、纤维素板(TF1002)、钢板(Q235)。

1.2 自组装碳/环氧树脂复合吸波涂料的制备

将1 g苯酚加到25 mL的NaOH溶液(0.1 mol·mL-1)中,搅拌溶解后加入3 mL甲醛,在70 ℃搅拌30 min后形成酚醛树脂预聚体溶液。将2 g预先溶解在25 mL去离子水中的F127加到预聚体溶液中,搅拌8 h后将混合溶液转移至水热反应釜中升温至130℃,反应24 h后离心分离,将产物干燥后得到酚醛树脂(PF)微球。

将150 mg的PF微球溶解于100 mL去离子水中,超声分散后依次加入12 mL 的PEI(3.0 mg·mL-1)和15 mL的 GO(0.5 mg·mL-1),分别搅拌1 h和2 h后离心分离,用去离子水和乙醇交替洗涤至pH值为7,干燥后得到氧化石墨烯包覆酚醛树脂微球,记为PF@GO。重复上述操作三次,在N2气氛中在800℃热处理4 h得到多界面还原氧化石墨烯包覆酚醛树脂微球,记为CS@rGO,将PF微球碳化后的产物命名为CS。

将5 g环氧树脂、1.25 g固化剂和6.25 g去离子水依次加入烧杯内配置成环氧树脂涂料基体,然后按照一定比例将CS@rGO加到上述基体溶液中,超声搅拌分散30 min后得到自组装碳/环氧树脂复合吸波涂料,记为CS@rGO/EP。

将CS@rGO/EP均匀地涂覆于纤维板和钢板(50℃固化2 h,重复3次)上,得到不同涂覆板材的测试样。将纯纤维板和纯环氧树脂涂料涂覆钢板试样分别记为S-0和SF-0;将加入吸波剂的试样记为S-X或SF-X,其中X表示CS@rGO加入量分别为质量分数为5%,10%、15%、20%和25%。

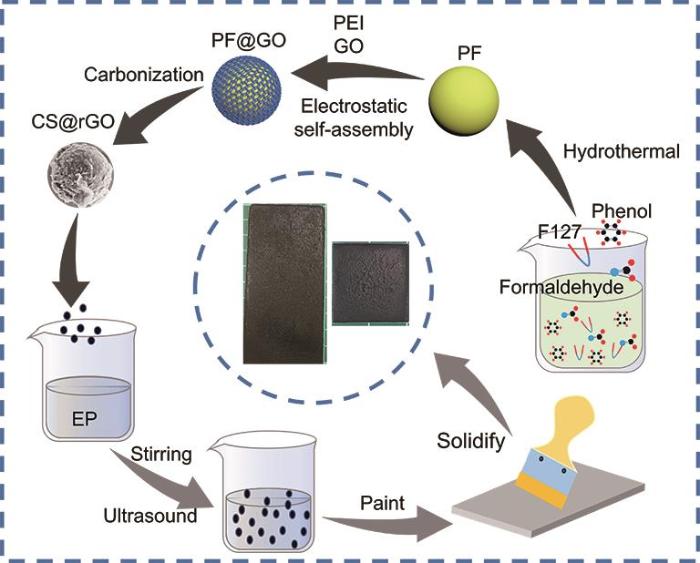

制备流程的示意图在图1中给出。

图1

图1

自组装碳/环氧树脂(CS@rGO/EP)复合功能涂料的制备流程

Fig.1

Preparation procedures of self-assembled carbon/epoxy resin (CS@rGO/EP) functional coating

1.3 性能表征

用场发射扫描电子显微镜(FESEM,Hitachi S-4800)观察CS@rGO和CS@rGO/EP的微观形貌。用傅里叶红外光谱仪(FT-IR,Thermo Electron Corp)分别检测CS@rGO (KBr压片法)和CS@rGO/EP(ATR法)的表面官能团结构 (测试范围:500~4000 cm-1)。用X射线衍射仪(XRD,D8 discover,Bruker)表征分析多界面CS@rGO复合吸波剂的晶体结构(测试范围:50°~70°,步进速度:2(°)/min)。用矢量网络分析仪(N5224A,Keysight)测试试样电磁参数(测试频率:8.2~18.0 GHz;测试方法:波导法)。根据国家标准GB/T9286-1998[14],用附着力测定仪测试涂层的附着力。样品的制备方法:将涂料涂覆于120 mm×50 mm×0.28 mm钢板上(涂层厚度小于60 μm),固化后使用百格刀(11道,2 mm间距)操作。根据ASTM D714-87的涂层表面脱落等级评价标准[15](如表1所示),将试样分别浸泡在5%NaCl、5%NaOH、5%HCl介质溶液中,浸泡30 d后观察并分析不同试样涂层的耐介质性。

表1 涂层表面脱落的等级评价标准

Table 1

| Grade | Shedding situation |

|---|---|

| 1 | The shedding area of the coating surface accounts for more than 30% of the entire coating surface |

| 2 | The shedding area of the coating surface accounts for less than 30% of the entire coating surface |

| 3 | The shedding area of the coating surface accounts for less than 10% of the entire coating surface |

| 4 | The shedding area of the coating surface accounts for less than 5% of the entire coating surface |

| 5 | No shedding phenomenon on the coating surface |

2 结果和讨论

2.1 形貌和结构

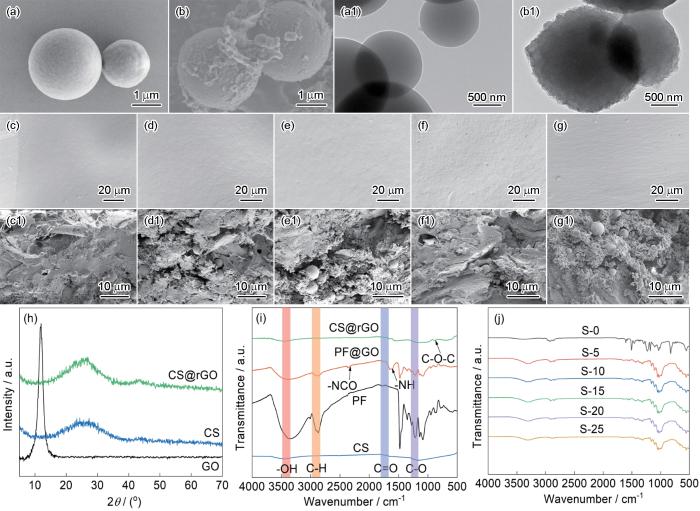

图2a、b给出了CS微球和CS@rGO复合吸波剂的FESEM图。可以看出,CS微球表面光滑,直径为2~3 μm;CS@rGO复合吸波剂由PF微球和GO纳米片经自组装、碳化处理而得,因此呈现多界面结构。图2a1、b1给出了CS微球和CS@rGO复合吸波剂的TEM照片。可以看出,褶皱的rGO纳米片包覆在CS微球表面,易产生界面极化作用,而rGO纳米片相互连接形成导电通路,有利于提高材料的吸波性能。图2c~g1给出了试样S-5、S-10、S-15、S-20和S-25的扫描电镜照片,其中图2c~g给出了试样表面的FESEM图。可以看出,随着CS@rGO含量的提高平整光滑的表面逐渐变得粗糙。图2c1~g1给出了试样截面的FESEM图,可见S-5试样中的吸波剂粒子比较稀疏;随着吸波剂添加量的增加,S-10、S-15、S-20和S-25试样中的吸波剂粒子数明显增多。除了S-25试样出现少量团聚,其它试样中的吸波剂分散良好。

图2

图2

CS和CS@rGO的FESEM图、TEM照片、各试样表面的FESEM图、各试样截面的FESEM图以及试样的XRD谱和FT-IR谱

Fig.2

FESEM images of CS (a) andCS@rGO (b); TEM images of CS (a1) andCS@rGO (b); FESEM images of surfaces (c-g) and cross sections (c1-g1) of samples with different mass fractions of CS@rGO; XRD pattern (h) and FT-IR spectra(i-j) of samples

图2i分别给出了PF、CS微球、PF@GO和CS@ rGO复合吸波剂的红外光谱。在PF微球的光谱中3433 cm-1、2890 cm-1、1730 cm-1和1221 cm-1处的吸收峰分别对应于—OH、C—H、C═O和C—O基团的伸缩振动[20,21]。在PF@GO微球的谱中1608 cm-1和2269 cm-1处出现了新的吸收峰,是PEI中-NH和-NCO的伸缩振动特征峰,进一步说明PEI修饰了PF微球;此外,在PF@GO复合材料的谱中3433 cm-1和2890 cm-1处的两个吸收峰变弱,可归因于GO的羧基与PF微球表面PEI的氨基之间产生了静电作用。在CS微球和CS@rGO复合材料的谱中1730 cm-1、1221 cm-1处的吸收峰几乎消失,其原因是聚合物微球高温热解碳化后化学基团基本消失。在870 cm-1处出现的对应C—O—C的拉伸振动[22]的新吸收峰,进一步证明GO被还原为rGO。

2.2 吸波性能

根据用波导法测试的电磁参数和传输线理论[25,26],计算了试样的反射损耗值。图3a给出了试样在8.2~18.0 GHz内的反射损耗图。可以看出,S-0试样的反射损耗值接近0,表明其没有吸波特性。随着涂料中吸波剂含量的提高,S-5、S-10、S-15、S-20和S-25试样的吸波性能均有所提高,S-20试样的吸波性能最佳。涂层厚度为1.1 mm时这个试样在频率为18.00 GHz时的最小反射损耗值(RLmin)为-25.03 dB,有效吸波频宽(反射损耗值<-10 dB对应的频带[27])为1.82 GHz(16.18 GHz~18.00 GHz)。介电损耗型材料的介电常数(εr =ε′-jε″)是影响电磁吸波性能的重要参数。图3b、c分别给出了各试样在8.2~18.0 GHz频率范围内的介电常数实部和虚部曲线图。由图3b、c可见,随着频率的提高试样的ε′和ε″值略有降低,是电磁场变化引起介质极化滞后所致[28]。S-0试样的介电常数实部与虚部接近于0,表明纯纤维板没有损耗性能;随着涂料中吸波剂含量的提高试样的介电常数实部和虚部均呈增加趋势,表明吸波剂含量的增加有利于提高试样的ε′和ε″值。S-5、S-10、S-15、S-20和S-25试样的介电损耗值均比S-0试样的高,S-20试样的介电损耗值最高(图3d),表现出优异的介电损耗性能。

图3

图3

CS@rGO/EP的吸波性能

Fig.3

The absorption properties of CS@rGO/EP (a) reflection loss, (b)the real part of the dielectric constant, (c) the imaginary part of the dielectric constant, (d) dielectric loss, (e) impedance matching, (f) attenuation constant (g) Schematic diagram of microwave absorption mechanism; (h) Comparison of electromagnetic wave absorption performance of functional coatings

S-5、S-10、S-15、S-20和S-25试样在1.1 mm下的阻抗匹配Z(|Zin/Z0|)和衰减常数(α),在图3e、f中给出。由图3e可见,S-20试样的阻抗匹配系数接近1,表明其阻抗匹配特性最佳,有利于电磁波进入材料内部。衰减常数越大,表明材料对电磁波的衰减能力越强[29]。图3f给出了各试样在8.2~18.0 GHz内的衰减常数曲线。由图3f可见,S-20和S-25试样的衰减常数比S-5、S-10和S-15试样的高,表明吸波剂含量的增加有助于提高试样对电磁波的损耗能力。由此可见,S-20试样的综合阻抗匹配程度和衰减特性最优。同时,如图3h所示,与近年文献中复合涂料的吸波性能相比,较薄的S-20试样其反射损耗最小,是理想的电磁波吸收材料。S-20试样优异的吸波性能得益于良好的阻抗匹配特性和介电损耗特性,其吸波机制在图3g中给出。首先,S-20试样的阻抗匹配特性良好,有利于电磁波进入材料内部而使其吸波性能提高。其次,吸波剂的组分、吸波剂之间以及吸波剂与环氧树脂基体之间的多界面结构,有利于界面极化和增加入射电磁波的多重反射路径。同时,吸波剂形成的导电网络也使电导损耗提高。

2.3 涂层的附着力

图4

图4

试样涂层附着力和耐介质性的测试效果

Fig.4

Coating adhesion test effect of samples(a), solvent resistant test effect of samples after soak in 5%NaCl medium for 30 days (b) and Soak in 5%NaOH medium for 30 days (c)

2.4 涂层的耐介质性能

表2 不同涂层的耐介质性能

Table 2

| Sample | 5%NaCl | 5%NaOH | 5%HCl |

|---|---|---|---|

| SF-5 | 2 | 1 | Entirely shedding |

| SF-10 | 2 | 1 | Entirely shedding |

| SF-15 | 3 | 1 | Entirely shedding |

| SF-20 | 4 | 2 | Entirely shedding |

| SF-25 | 4 | 2 | Entirely shedding |

2.5 涂层的防腐性能

2.5.1 阻抗谱

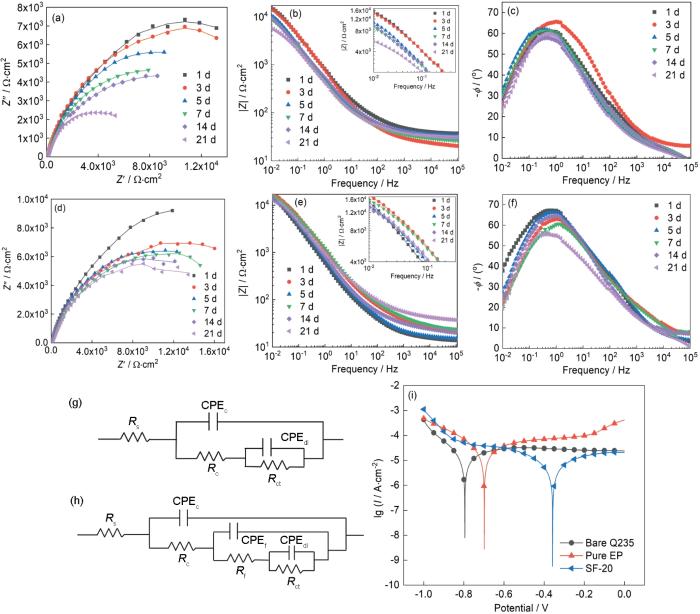

阻抗谱包括Nyquist图和Bode图,其中Nyquist图描述材料阻抗虚部与实部之间的关系。阻抗谱为半圆曲线,圆弧的半径越大表明试样中电荷转移难度越大,即防腐性能越好;Bode图反映阻抗的绝对值随频率的变化,|Z|0.01Hz阻抗的绝对值可用来表征试样的防腐性能。试样的|Z|0.01Hz值越大,表明其防腐性能越好[40~42]。图5a和d分别给出了SF-0和SF-20试样的Nyquist图。可以看出,SF-0和SF-20试样的阻抗圆弧均随着浸泡时间的延长逐渐减小,表明防腐性能随着浸泡时间的延长而降低。浸泡天数相同的SF-20试样其阻抗圆弧仍然比SF-0试样大,表明CS@rGO的添加使试样的防腐性能提高。图5b和e分别给出了SF-0和SF-20试样的阻抗-频率Bode图。可以看出,浸泡21 d后SF-0试样的|Z|0.01 Hz值从最初的15090 Ω减小为5763 Ω,表明其防腐性能大幅度下降;而SF-20试样的|Z|0.01 Hz值仍能保持14260 Ω,接近SF-0试样的初始|Z|0.01 Hz值。此外,Bode图中反映相位随频率变化,高频处的相位(ϕ105 Hz)是评价试样防腐性能的另一个参数。试样的ϕ105 Hz值越大,表明其防腐性能越好[43,44]。图5c和f分别给出了SF-0和SF-20试样的相位-频率Bode。可以看出,SF-0试样的ϕ105 Hz值明显低于SF-20试样。上述结果均表明,SF-20试样的防腐性能优于SF-0试样,其原因可能是CS@rGO、环氧树脂与基板之间形成了钝化膜阻止电解液渗透。

图5

图5

涂层的防腐性能

Fig.5

Coating corrosion resistance (a) Nyquist plot, (b) impedance-frequency Bode plot, (c) phase-frequency Bode plot of SF-0; (d) Nyquist plot, (e) impedance-frequency Bode plot, (f) phase-frequency Bode plot of SF-20; Equivalent circuit diagrams of (g) SF-0 and (h)SF-20; (i) The Tafel curve of samples immersed in 3.5%NaCl solution for 21 days

为进一步分析涂层在浸泡过程中的腐蚀行为,基于试样的阻抗谱模拟其等效电路。浸泡1 d后的SF-0试样阻抗圆弧半径较大,表明纯环氧树脂涂层阻隔了腐蚀介质与基板,此时纯环氧树脂涂层可等效为一个纯电阻,模拟等效电路如图5g所示[45]。此外,SF-20试样的防腐性能优于SF-0试样,除了环氧树脂的阻隔作用,CS@rGO的快速导电能力使电子快速传递到涂层表面,抑制了试样内部的腐蚀反应。此时SF-20试样的防腐性能可视为SF-0试样与新增电阻的叠加,模拟等效电路如图5h所示[46]。模拟电路中的Rs 代表溶液电阻,Rc代表环氧涂层电阻,CPEc、CPEdl和CPEf代表恒相电容,Rct代表转移电荷的电阻,Rf代表填料涂层电阻。

2.5.2 塔菲尔极化曲线

式中M为55.85 g·mol-1,密度ρ为7.85 g·cm-3,铁的化合价n为2,F为法拉第常数(F=96485 C·mol-1=26.8 A h),Icorr, 0(A·cm-2)为基板的腐蚀电流密度,Icorr, i (A·cm-2)为涂层的腐蚀电流密度。

基板浸泡21 d后的腐蚀电位为-0.795 V,而SF-0和SF-20试样的腐蚀电位依次上升到-0.698 V和-0.358 V;SF-20试样的腐蚀速率最小,保护效率最高,达到92.86%,进一步证实SF-20试样优异的防腐特性,具体数据列于表3。

表3 试样在溶液中浸泡21 d后的Tafel曲线拟合值

Table 3

| Sample | Ecorr / V | Icorr / A·cm-2 | V / mm·a-1 | EPE / % |

|---|---|---|---|---|

| Steel plate | -0.795 | 7.87×10-9 | 9.17×10-5 | - |

| Pure epoxy resin coating | -0.698 | 3.16×10-9 | 3.67×10-5 | 59.85 |

| CS@rGO/EP coating | -0.358 | 5.62×10-10 | 6.53×10-6 | 92.86 |

3 结论

(1) 自组装碳/环氧树脂(CS@rGO/EP)复合功能涂料覆盖在钢板表面,分散特性良好。

(2) CS@rGO/EP复合功能涂料中吸波剂的含量能优化阻抗匹配,提高吸波性能。吸波剂含量为20%、涂层厚度1.1 mm的试样在18.00 GHz处的最小反射损耗为-25.03 dB,有效吸收频宽为1.82 GHz(16.18~18.00 GHz)。

(3) 吸波剂含量为20%的试样,其腐蚀速率较低(6.53×10-6 mm·a-1)和高保护效率(92.86%)。复合涂料附着力和耐碱性良好。

参考文献

Enhanced anti-corrosion and microwave absorption performance with carbonyl iron modified by organic fluorinated chemicals

[J].

Multi-dimensional C@NiCo-LDHs@Ni aerogel: Structural and componential engineering towards efficient microwave absorption, anti-corrosion and thermal-insulation

[J].

Balancing interface polarization strategy for enhancing electromagnetic wave absorption of carbon materials

[J].

Hybrid silica-carbon bilayers anchoring on FeSiAl surface with bifunctions of enhanced anti-corrosion and microwave absorption

[J].

Bifunctional carbon-encapsulated FeSiAl hybrid flakes for enhanced microwave absorption properties and analysis of corrosion resistance

[J].

Advances in core—shell engineering of carbon-based composites for electromagnetic wave absorption

[J].

Toward the Application of High Frequency Electromagnetic Wave Absorption by Carbon Nanostructures

[J].

The latest research progress of graphene-based composite absorbing materials

[J].

石墨烯基复合吸波材料的最新研究进展

[J].

Preparation and study of Al2O3@PPy@rGOcomposites with microwave absorption properties

[J].

A comprehensive review on graphene-based anti-corrosive coatings

[J].Graphene has attracted significant attention for applications in many industrial fields due to its excellent anti-corrosion properties, and a series of satisfactory results have been achieved. In recent years, the scope of research into graphene-based anti-corrosive applications has been extremely diversified and encompasses two aspects: pure graphene coatings and graphene composite coatings. In this study, the application of graphene coatings to metal anti-corrosion is comprehensively reviewed. First, the preparation methods for graphene and pure graphene coatings are described in detail. Second, the corrosion resistance, existing problems, and optimizations of pure graphene coating are presented. Third, methods for improving the dispersibility of graphene, such as chemical modification and surface decoration nanoparticles, are introduced. Next, the corrosion resistance, anti-corrosion mechanism, existing problems, and optimization measures of graphene composite coatings are summarized. Finally, future development directions for graphene anti-corrosive coatings are proposed, and their viability in near-future applications is discussed.

Investigation of the anticorrosion properties of graphene oxide-modified waterborne epoxy coatings for AA6061

[J].

Dispersion and parallel assembly of sulfonated graphene in waterborne epoxy anticorrosion coatings

[J].

Growth of NiAl‐layered double hydroxide on graphene toward excellent anticorrosive microwave absorption application

[J].

Preparation and application of conductive polyaniline modified carbon composite absorbers

[D].

导电聚苯胺修饰碳复合吸波材料的制备及应用探索

[D].

Preparation and research of reduced graphene oxide/ferric oxide/polyaniline microwave absorbing anticorrosion nanocomposite

[D].

还原氧化石墨烯/四氧化三铁/聚苯胺吸波防腐纳米复合材料的制备及研究

[D].

Polyaniline/carbon nanotube hybrids modified with ionic liquids as anticorrosive additive in epoxy coatings

[J].

Epoxy coating with in-situ synthesis of polypyrrole functionalized graphene oxide for enhanced anticorrosive performance

[J].

Core-shell, wire-in-tube and nanotube structures: Carbon-based materials by molecular layer deposition for efficient microwave absorption

[J].

Design of dual-frequency electromagnetic wave absorption by interface modulation strategy

[J].

Facile synthesis of FeCo layered double oxide/raspberry-like carbon microspheres with hierarchical structure for electromagnetic wave absorption

[J].

Carbon hollow microspheres with a designable mesoporous shell for high-performance electromagnetic wave absorption

[J].

Hierarchical Fe3O4/Fe@C@MoS2 core-shell nanofibers for efficient microwave absorption

[J].

Preparation of polyaniline/graphene composites with excellent anti-corrosion properties and their application in waterborne polyurethane anticorrosive coatings

[J].

Enhanced electromagnetic and microwave absorption properties of carbonyl iron/Ti3SiC2/epoxy resin coating

[J].

Temperature dependence of the microwave absorption performance of carbonyl iron powder/boron-modified phenolic resin composite coating

[J].

Y2Mo3O12 modified carbonyl iron powder-boron-phenolic resin coatings for microwave absorption

[J].

Sandwich-like Fe3O4/Fe3S4 composites for electromagnetic wave absorption

[J].

Electromagnetic and microwave absorption properties of Ti3SiC2/NiFe2O4/epoxy resin coatings

[J].

Influence of particle size on the microwave absorption properties of FeSiAl/ZnO-filled resin composite coatings

[J].

Microwave absorption properties of carbonyl iron-based paint coatings for military applications

[J].

Wave-transmitting material to optimize impedance matching and enhance microwave absorption properties of flaky carbonyl iron coating

[J].

Dielectric and microwave absorption properties of resin-matrix composite coating filled with multi-wall carbon nanotubes and Ti3SiC2 particles

[J].

Nanocomposite based on epoxy and MWCNTs modified with NiFe2O4 nanoparticles as efficient microwave absorbing material

[J].

Synergistically assembled nitrogen-doped reduced graphene oxide/multi-walled carbon nanotubes composite aerogels with superior electromagnetic wave absorption performance

[J].

CoNi nanoparticles encapsulated by nitrogen-doped carbon nanotube arrays on reduced graphene oxide sheets for electromagnetic wave absorption

[J].

A hybrid comprised of porous carbon nanofibers and rGO for efficient electromagnetic wave absorption

[J].

Synergistic polarization loss of MoS2‐based multiphase solid solution for electromagnetic wave absorption

[J].

Dispersion and parallel assembly of sulfonated graphene in waterborne epoxy anticorrosion coatings

[J].

Fe3O4/PANI nanocomposite core-shell structure in epoxy resin matrix for the application as electromagnetic waves absorber

[J].

Dispersion and parallel assembly of sulfonated graphene in waterborne epoxy anticorrosion coatings

[J].

Graphene to tune microwave absorption frequencies and enhance absorption properties of carbonyl iron/polyurethane coating

[J].

Fabrication of novel ionic liquids-doped polyaniline as lubricant additive for anti-corrosion and tribological properties

[J].

The green synthesis rGO/Fe3O4/PANI nanocomposites for enhanced electromagnetic waves absorption

[J].

Synthesis of hydrophobic fluoro-substituted polyaniline filler for the long-term anti-corrosion performance enhancement of epoxy coatings

[J].

Growth of NiAl-Layered double hydroxide on graphene toward excellent anticorrosive microwave absorption application

[J].

Preparation of MgAl layered double hydroxides intercalated with nitrite ions and corrosion protection of steel bars in simulated carbonated concrete pore solution

[J].