亚稳β钛合金具有较高的比强度、疲劳强度以及优异的耐蚀性、生物相容性和易成型性,在航天航空、海洋工程、生物医学以及汽车工业等领域得到了广泛的应用[1~5]。固溶处理主要影响亚稳β钛合金中α相的形貌、分布与体积分数等,且α相的存在可提高其强度[6~8]。因此,控制α相的析出对于调控合金的性能极为重要。亚稳β钛合金中有足量的β稳定元素,因此当固溶温度高于β相变点(Tβ )时合金保持单一的β相组织,但是固溶温度过高则使β相长大而显著降低合金的强度[9, 10]。当固溶温度略低于Tβ 时则有α相的析出,可显著提高合金的强度[11~13]。但是,进一步降低固溶温度则使合金元素固溶不充分,反而不能提高合金的强度。亚稳β钛合金的力学性能与其显微组织密切相关,且其显微组织对固溶温度十分敏感,因此选择适当的固溶处理工艺对调控亚稳β钛合金的力学性能极为重要[14~17]。本文选取不同的固溶温度对一种新型Ti-Al-Mo-V-Cr-Zr钛合金进行热处理,研究固溶温度对其组织和性能的影响。

1 实验方法

表1 Ti-4Al-6Mo-2V-5Cr-2Zr合金的化学成分

Table 1

| Al | Mo | V | Cr | Zr | Ti |

|---|---|---|---|---|---|

| 3.74 | 5.60 | 1.85 | 4.82 | 2.09 | Bal. |

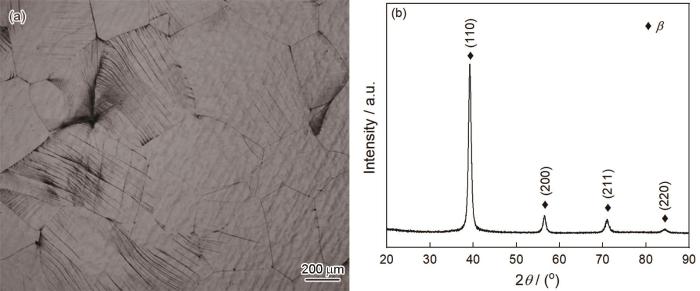

图1

图1

锻态Ti-4Al-6Mo-2V-5Cr-2Zr合金的光学显微组织和XRD谱

Fig.1

Optical microstructure (a) and XRD pattern (b) for as-forged Ti-4Al-6Mo-2V-5Cr-2Zr alloy

为了研究固溶温度对合金室温拉伸性能的影响在锻件上切取的板状拉伸试样,使用箱式电阻炉分别在(α+β)两相区和β单相区各选取两个温度进行固溶处理,固溶后水冷。固溶处理工艺参数列于表2。

表2 Ti-4Al-6Mo-2V-5Cr-2Zr合金的固溶处理工艺参数

Table 2

| Treated state | Solution temperature/℃ | Solution time/h | Cooling mode |

|---|---|---|---|

S1 S2 S3 S4 | 750 770 810 830 | 1 1 1 1 | Water cooling Water cooling Water cooling Water cooling |

使用WDW-200E型电子万能试验机进行室温拉伸试验,拉伸试样的标距长度为20 mm、标距宽度为6 mm、标距厚度为2.5 mm。在每个温度进行三组试验,取其结果的平均值。用S-3400N型扫描电子显微镜观察合金的显微组织和拉伸断口形貌,使用蔡司热场扫描电镜(配备EBSD)分析相形貌和分布,腐蚀液的体积配比为HF∶HNO3∶H2O=5∶15∶80。

2 实验结果和讨论

2.1 固溶处理后合金的显微组织

图2给出了Ti-4Al-6Mo-2V-5Cr-2Zr合金在低于相变点温度的750℃和770℃分别固溶1 h水冷后的显微组织。由图2a和2c可见,由于固溶温度处于(α+β)两相区,与锻态的单β相组织明显不同,呈现出两相组织特征。在750℃固溶处理时,α相从晶界、滑移带周围与β基体中同时析出,且大量α相聚集在滑移带周围(图2b)。其原因是,在塑性变形产生的滑移带周围出现大量的位错等缺陷,为α相的析出提供了形核位置。随着固溶温度的升高并接近相变点,α相的数量明显减少,但是形貌没有明显的变化,依然为短棒状和少量球状,同时滑移带也随着固溶温度的升高呈现逐渐消失的趋势(图2d)。究其原因,随着固溶温度的升高更多的溶质原子溶入β基体中,而且锻件在热变形过程中产生的缺陷数量因热激活而减少,故减少了α相形核的位置。

图2

图2

Ti-4Al-6Mo-2V-5Cr-2Zr合金在相变点以下固溶处理1 h后的显微组织

Fig.2

Microstructures of Ti-4Al-6Mo-2V-5Cr-2Zr alloy after solution treatment below phase transition temperature for 1 h at 750℃, low magnification (a); at 750℃, high magnification (b); at 770℃, low magnification (c) and at 770℃, high magnification (d)

图3给出了合金在高于相变点温度固溶处理的EBSD-IPF图和相分布。由于固溶温度处于β单相区且合金中有足量的β稳定元素,合金的显微组织以单一β相为主只有极少量的α相。对比图3a和图3c中的EBSD-IPF图,可见极少量的α相分布在晶界周围,且随着固溶温度的升高析出数量降低。这表明,合金在β单相区热处理后的冷却过程中极少量的α相从β相中析出。而α相析出数量减少的原因是,随着固溶温度的升高大量β相稳定元素溶入β基体使β相更加稳定,从而抑制了α相的析出 [19]。β相晶粒则随着固溶温度的升高呈现出聚集长大的趋势,平均尺寸由260 µm增大到450 µm,形貌仍为等轴状。EBSD分析给出的相分布表明,固溶温度为810℃时β相与α相所占体积分数分别为99.6%与0.4%(图3b),固溶温度升高至830℃时,β相与α相所占体积分数则为99.9%与0.1%(图3d)。

图3

图3

Ti-4Al-6Mo-2V-5Cr-2Zr合金在相变点以上固溶1 h后的EBSD-IPF图和相分布

Fig.3

EBSD-IPF images and phase distribution images of Ti-4Al-6Mo-2V-5Cr-2Zr alloy after solution treatment above phase transition temperature for 1 h at 810℃, EBSD-IPF (a); at 810℃, phase distribution (b); at 830℃, EBSD-IPF (c) and at 830℃, phase distribution (d)

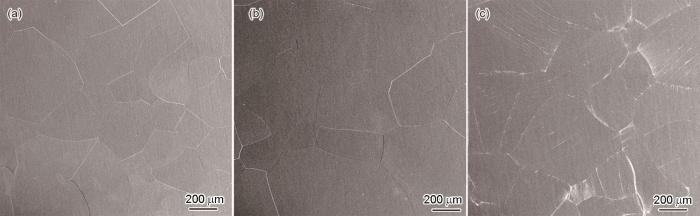

图4给出了合金在相变点以上固溶处理的显微组织。可以看出,在相变点以上固溶处理可得到近乎全β相组织,β相的晶粒粗大晶界平直,且随固溶温度升高β晶粒长大的趋势明显(图4a和图4b)。这个结果,与EBSD分析结果一致。与锻态组织作对比(图4c)可见,固溶处理温度高于β相变点时显微组织中的滑移带完全消失。这一结果表明,在相变点以上的温度固溶处理可消除合金中热变形产生的晶体缺陷,从而使锻造过程中产生的滑移带消失。在合金的塑性变形过程中,部分能量以畸变能的形式储存在空位和位错等缺陷中,使其自由能升高而在热力学上处于亚稳态,并且有向稳定态转变的趋势。因此,当固溶温度足够高时,原子热运动的加剧促进了由亚稳态向稳态的转变。在这种转变过程中空位迁移至表面、晶界或位错处消失,同时在位错的运动中异号位错互相合并而抵消,最终使空位和位错的密度降低,从而使锻造过程中产生的晶体缺陷数量减少。

图4

图4

不同处理状态Ti-4Al-6Mo-2V-5Cr-2Zr合金的显微组织

Fig.4

Microstructures of forged Ti-4Al-6Mo-2V-5Cr-2Zr alloy with different treated states (a) solution treatment for 1 h at 810℃; (b) solution treatment for 1 h at 830℃; (c) as-forged

2.2 固溶温度对合金室温拉伸性能的影响

表3列出了Ti-4Al-6Mo-2V-5Cr-2Zr合金在不同温度固溶处理后的室温拉伸性能。可以看出,固溶温度为750℃的合金其室温拉伸性能最高,抗拉强度(Rm)达到957MPa,屈服强度(RP0.2)达到887 MPa,伸长率(A)为11.7%;固溶温度提高到770℃时合金的拉伸性能显著降低,抗拉强度和屈服强度分别下降到915 MPa与875 MPa,伸长率最低仅为6.5%;当固溶温度升高到相变点以上时合金的强度和塑性小幅度提高,抗拉强度和屈服强度分别达到925 MPa与885 MPa,伸长率提高到8.5%;随着固溶温度升高到830℃合金的抗拉强度和屈服强度再次降低,分别为896 MPa与866 MPa,而伸长率继续提高到9.3%。值得注意的是,尽管不同的固溶处理条件使合金的室温拉伸性能波动,但是都锻态合金的高。

表3 不同热处理状态Ti-4Al-6Mo-2V-5Cr-2Zr合金的拉伸性能

Table 3

| Treated state | Rm/MPa | RP0.2/MPa | A/% |

|---|---|---|---|

S1 S2 S3 S4 | 957 915 925 896 | 887 875 885 866 | 11.7 6.5 8.5 9.3 |

| As-forged | 857 | 824 | 2.1 |

亚稳β钛合金的室温拉伸性能,决定于相组成。当固溶处理温度处于(α+β)两相区时,合金的显微组织主要由从β基体中析出的α相与β基体组成。固溶温度为750℃时,在合金的显微组织中出现大量的α相,部分聚集在滑移带周围其余的弥散分布在β基体中。具有密排六方结构的α相中的滑移系数目较少,可有效地阻碍位错运动,起第二相的强化作用[20]。同时,大量聚集在滑移带周围的α相可有效地降低滑移带对裂纹扩展的有利作用。因此,当固溶温度为750℃时,虽然锻造产生的滑移带依然存在而不利合金的性能,但是此时α相产生的析出强化依然起主要作用,使合金具有最高的室温拉伸强度。在相变点以下的温度进行固溶处理时,随着固溶温度的升高α相的析出数量减少,其产生的析出强化效应减弱。当固溶温度为770℃时滑移带虽有消失的趋势但是依旧存在,在此条件固溶处理的合金其抗拉强度和屈服强度均明显下降。因此,当析出的α相体积分数减少到一定程度,第二相强化的效果明显降低,在第二相强化能力减弱和锻造缺陷的双重影响下裂纹的萌生与扩展更加容易,从而使合金的强度和塑性同时降低。当在相变点以上温度固溶处理时,合金的显微组织几乎全为β相。其原因是:β相为体心立方结构滑移系较多,因此塑性较好;另一方面,足够高的固溶温度使合金的成分更均匀并消除了热变形产生的滑移带,有利于提升合金的强度。因此,与在770℃固溶处理相比,在810℃固溶处理的合金其伸长率和抗拉强度均呈提高趋势。但是,随着固溶温度的继续升高β相晶粒粗化和晶界强化效应减弱,使合金的室温拉伸强度降低。

2.3 合金的拉伸断裂行为

图5给出了锻态Ti-4Al-6Mo-2V-5Cr-2Zr合金在不同温度固溶处理后的室温拉伸断口的典型形貌。由图5a可见,在750℃固溶处理的合金其拉伸断口呈现出典型的韧性断裂特征,大量的等轴韧窝均匀地分布在断口,因此合金具有较高的塑性。图5b给出了合金在770℃固溶处理后拉伸断口的形貌。可以看出,与固溶温度为750℃的合金断口相比,韧窝的数量大大减少且分布不均匀。同时,还能观察到大量的解理面和解理台阶。因此,在此条件下固溶处理的合金其拉伸断口呈现出韧脆混合断裂特征且以脆性断裂为主,与固溶温度为770℃的合金具有最低伸长率的拉伸结果一致。图5c表明,在相变点以上的810℃固溶处理的合金,其断口上密集分布着大量等轴韧窝和少量解理面。这表明,合金在拉伸变形时发生韧脆混合断裂但是以韧性断裂为主,与770℃固溶处理后的合金相比其塑性明显改善。在固溶温度升高到830℃的断口上解理面消失,断口形貌以韧窝为主,但仍可观察到河流状花样(图5d)。与此相对应,在830℃固溶处理的合金其塑性进一步提高,但是与图5a相比其韧窝较浅,因此伸长率依然不如在750℃固溶温度处理的合金。综上所述,在不同温度固溶处理的Ti-4Al-6Mo-2V-5Cr-2Zr合金其拉伸断裂方式的变化,与其室温断裂伸长率随固溶处理温度呈先降低后提高的趋势一致。

图5

图5

Ti-4Al-6Mo-2V-5Cr-2Zr合金在不同温度固溶处理后的拉伸断口形貌

Fig.5

Morphology of tensile fracture surfaces for Ti-4Al-6Mo-2V-5Cr-2Zr alloy after solution treatment at different temperatures (a) 750℃; (b) 770℃; (c) 810℃; (d) 830℃

3 结论

(1) Ti-4Al-6Mo-2V-5Cr-2Zr合金的锻态显微组织为单一β相,在部分晶粒中有大量的滑移带。在相变点以下的温度进行固溶处理时,β基体中析出大量α相;随着固溶温度的提高α相体积分数明显减少,部分滑移带消失。当固溶温度高于相变点时,显微组织为全β相且滑移带完全消失,随着固溶温度的进一步升高β晶粒聚集并长大。

(2) 与锻态相比,固溶处理使Ti-4Al-6Mo-2V-5Cr-2Zr合金的室温拉伸性能显著提升。在相变点以下或以上进行固溶处理时,随着固溶温度的提高合金的室温抗拉强度和屈服强度均呈下降趋势。同时,随着固溶温度的提高这种合金的伸长率呈现先下降后提高的趋势。

(3) 锻态Ti-4Al-6Mo-2V-5Cr-2Zr合金经750℃×1 h双相区固溶处理后,其室温拉伸性能最高,相应的抗拉强度、屈服强度和伸长率分别为957 MPa、887 MPa和11.7%,具有良好的强塑性匹配。

参考文献

Research development of titanium alloy in aerospace industry

[J].

航空用钛合金研究进展

[J].

Development of ultra-high strength titanium alloy

[J].

超高强度钛合金研究进展

[J].

Progress of metastable β titanium alloy with transformation-induced plasticity and twinning-induced plasticity

[J].

亚稳β型TRIP/TWIP钛合金研究进展

[J].

Recent development in titanium alloys with high strength and high elasticity

[J].

高强度高弹性钛合金的研究进展

[J].

Review on 3D printing of biomedical titanium alloy

[J].Titanium and its alloys have been used as one of the most important biomaterials due to their high strength, good corrosion resistance and excellent biocompatibility. Casting is the most important way to produce implantable products such as spinal cage and knee implants before. However, this method is outdated to fit new biomaterials requirement such as personalized implants and precision medicine cure. The advantages of 3D printing technology in medical titanium alloys are gradually highlighted due to its abundant processing methods. This paper mainly discussed the development of 3D printing technology on bio-used titanium and its alloys, and especially focused on porous titanium implants printing. The technical barrier of current 3D printing for bio-used titanium alloys was analyzed. Suggestions for further development on biomaterials 3D printing industry were also given at the end of the paper.

3D打印医用钛合金研究进展

[J].

Effect of aging heat treatment on microstructure and tensile properties of a new β high strength titanium alloy

[J].

Effect of heat treatment on microstructure and mechanical properties of a new β high strength titanium alloy

[J].

Influence of solution treatment on microstructure and mechanical properties of a near β titanium alloy Ti-7333

[J].

Deformation behavior and microstructure evolution during hot working of a coarse-grained Ti-5Al-5Mo-5V-3Cr-1Zr titanium alloy in beta phase field

[J].

Effect of α precipitation on β texture evolution during β-processed forging in a near-β titanium alloy

[J].

Effect of solution temperature on microstructure and properties of new type metastable β titanium alloy

[J].

固溶温度对新型亚稳β钛合金组织与性能的影响

[J].

Effects of solution temperature on microstructure and property of Ti55531 alloy

[J].

固溶温度对Ti55531钛合金的组织与性能的影响

[J].

Phase transformation in a β-Ti alloy with good balance between high strength and high fracture toughness

[J].

Effect of solution temperature on microstructure and tensile properties of metastable beta titanium alloy Ti-4Mo-6Cr-3Al-2Sn

[J].

固溶温度对亚稳β钛合金Ti-4Mo-6Cr-3Al-2Sn的组织和拉伸性能的影响

[J].

Effect of heat treatment on mechanical properties of Ti-3Al-8V-6Cr-4Mo-4Zr alloy

[J].The effects of solution treatment and aging treatment on microstructures and mechanical properties of Ti-3Al-8V-6Cr-4Mo-4Zr alloy bars have been investigated. The results show that the highest hardness and the highest tensile strength can be achieved by the solution and aging treatment (800℃×30 min/AC+510℃×16 h/AC), and an insignificant decline on elongation rate and necking rate is also acquired. The quantity and size of the ω-phases and α-phases result in the increase of hardness and strength of Ti-3Al-8V-6Cr-4Mo-4Zr alloy bars. A lot of dimples exist in the tensile fractures of the hot rolling alloys and heat treatment alloysdemonstrating a typical ductile fracture.

时效处理对Ti-3Al-8V-6Cr-4Mo-4Zr合金力学性能的影响

[J].研究了固溶时效处理对Ti-3Al-8V-6Cr-4Mo-4Zr合金拉伸性能的影响。结果表明:在800℃/30 min+500℃/12 h处理后,合金的硬度和抗拉强度达到极大值,其延伸率和断面收缩率没有明显的降低。合金的硬度和强度的提高是ω和α析出相共同作用的结果。在合金的热轧态和热处理态的断口都出现了大量的韧窝,表明其为典型的韧性断裂。

Effect of heat treatment process on microstructure and mechanical properties of titanium alloy Ti6246

[J].The influence of heat treatment temperature and cooling rate on the microstructure, phase and tensile deformation behavior of Ti-alloy Ti6246 alloy was investigated. The results show that the α′′ martensite was observed in prior β phase after solution heat treatment followed by water quenching. While a fine transformed β microstructure produced as a result of air cooling. For the air cooling alloy, both the size and volume fraction of the secondary α grain increased with the increasing solution heat temperature in air cooling samples. A “double yield” phenomenon appeared in the engineering stress-strain curves of the water quenching alloy samples. After aging treatment, the strength of water- and air-cooled alloys samples increased but the plasticity decreased. An optimal property in strength and ductility was achieved for the alloysamples after soluted solution treated at 900-920°C and then aged at 595°C.

热处理工艺对Ti6246钛合金组织与力学性能的影响

[J].研究了热处理温度和冷却方式对Ti6246合金显微组织、相组成以及室温拉伸性能的影响。结果表明:固溶热处理后合金的相组成主要与冷却方式有关。在β单相区及(α+β)两相区固溶后水冷,β相均转化为α′′马氏体和少量亚稳β相。空冷组织中的β相转变为含有少量次生α相的β转变组织,随着热处理温度的提高次生α相的含量逐渐增加,尺寸也逐渐增大。时效后组织中的亚稳相发生分解,析出细小的次生α相。固溶后水冷试样的拉伸曲线上出现“双屈服”现象,且随着固溶温度的提高合金第一屈服点逐渐升高。水淬和空冷合金试样在595℃/8 h时效后其室温拉伸强度提高,延伸率及断面收缩率降低,水淬试样室温拉伸性能的变化更大。固溶后空冷且在595℃时效处理的合金,其室温拉伸性能可达到较好的强塑性匹配。

Effect of Pre-aging on Superplasticity of TB8 Ti-Alloy

[J].The effect of pre-aging processes on superplasticity and microstructure of TB8 Ti-alloy was investigated. Results show that after pre-aging at 520oC for 1 h, the superplasticity of the alloy can be the best, and the elongation is up to 362%, increased by 1.65 fold of that for the counterpart alloy; A certain amount of fine α phase precipitated at grain boundaries and in grains of the metastable β-phase after pre-aging; During the deformation process, the precipitated α phase can restrain the growth of recrystallization grains and break the dissolution phase structure, so that induce grain refinement and increase the superplasticity of TB8 alloy. In case of pre-aging at a desired pre-aging temperature, the grain size of the fractured surface decreases first and then increases with the increasing aging time, while the grain size is the smallest and the elongation is the highest by pre-aging for 1 h. In case of pre-aging for a desired period of time, the alloy aged at 520oC presents the highest elongation at break with the most uniform fracture microstructure.

预时效对TB8钛合金超塑性的影响

[J].研究了预时效对TB8钛合金的显微组织和超塑性的影响。结果表明,当预时效温度为520℃预时效时间为1 h时TB8钛合金的超塑性能最佳,伸长率达到362%,比未经时效的伸长率提高了165%。时效处理后在亚稳态β相晶界和晶内析出一定量的细小α相,变形时α相既能抑制基体组织的晶粒过分长大,又能在一定程度上使脱溶组织发生应变集中而破碎,使晶粒细化从而提高TB8钛合金的超塑性。在预时效温度一定的条件下,随着时效时间的延长断口组织的晶粒度先减小后增大,在时效时间约为1 h的晶粒最细小,伸长率最高。时效时间一定时,时效温度约为520℃的断口组织最为均匀,伸长率最高。

Composition design of beta-titanium alloys: theoretical, methodological and practical advances

[J].

β钛合金成分设计: 理论、方法、实践

[J].

Microstructural dependence of strength and ductility in a novel high strength β titanium alloy with Bi-modal structure

[J].