TiAl基合金具有高比强度、高比弹性模量、较高的高温抗氧化性和优异的高温性能[1,2,3],有望取代镍基高温合金成为新一代高温材料[4,5,6,7]。但是,TiAl基合金的室温脆性较大[8,9,10]、断裂韧性较低[11,12]。用定向凝固[13,14,15,16,17,18,19]可使TiAl合金的片层方向平行于加载方向,提高其室温力学性能。使用电磁冷坩埚定向凝固设备可制备大尺寸和组织可控的定向凝固铸锭。为了避免过多的B2相和改善TiAl合金的塑性,可添加适当含量的Cr和Nb等β稳定元素[20,21]。本文用定向凝固工艺制备Ti-(43-48)Al-2Cr-2Nb合金,研究Al含量对其凝固组织和性能的影响。

1 实验方法

实验用原材料:高纯海绵钛(纯度:99.98%,质量分数)、纯铝(99.99%)、铌粉(99.98%)、铬粉(99.89%)。

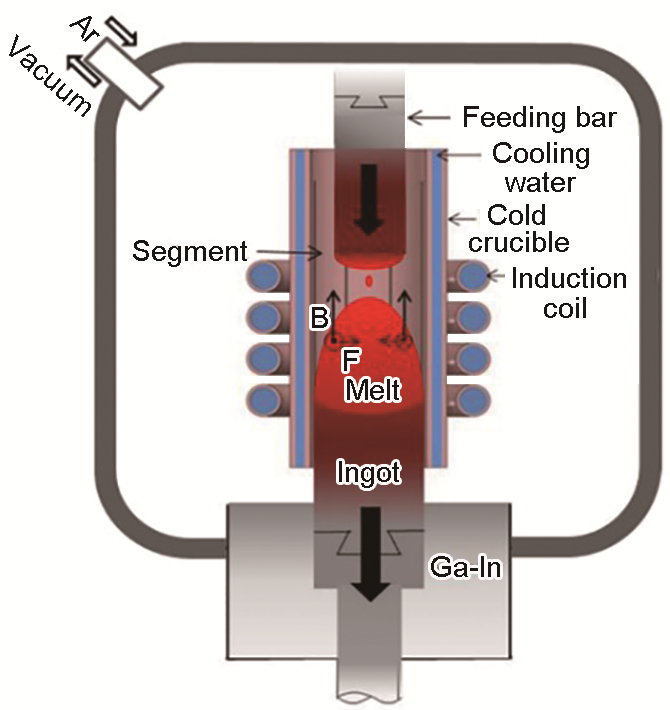

图1

在冷坩埚定向凝固设备的上送料杆和下抽拉杆底托上安装棒料,将设备抽真空至1 Pa以下,重复充氩气至300 Pa两次后将炉内充氩气保持在300 Pa。开启电源,感应圈产生的高频磁场将送料棒和底托熔化。进行定向凝固实验时,开启上送料和下抽拉系统将试棒抽拉至液态的镓铟合金液中强制冷却,当试样抽拉到100 mm长时停止抽拉并断开加热电源。

将定向凝固试样线切割制成金相试样,将其打磨、抛光并化学腐蚀(腐蚀剂为10% HNO3+10% HF+80% H2O)。用OlympusTG-3金相显微镜观察定向凝固试样的形貌,用HITACHIS-4700扫描电子显微镜(SEM)观察微观组织。

用线切割加工直径为3 mm厚度为4.5 mm的压缩试样,按国标GB/T 7314-2017在Instron-5569型万能电子试验机上进行室温压缩试验,压缩速度为0.5 mm/min。

2 实验结果和分析

2.1 Al含量对相组成的影响

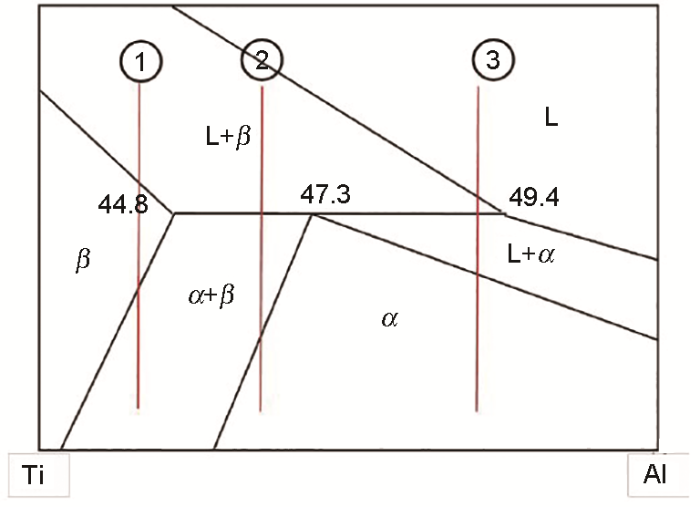

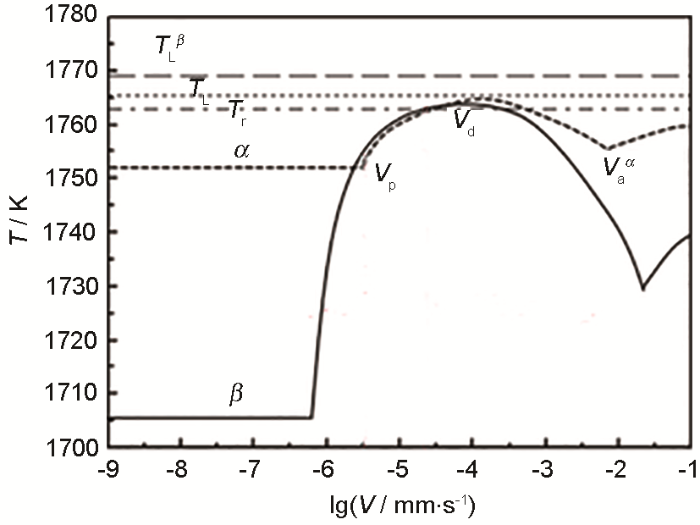

图2

图2

二元TiAl合金相图的高温部分

Fig.2

Binary phase diagram of TiAl alloy at high temperature

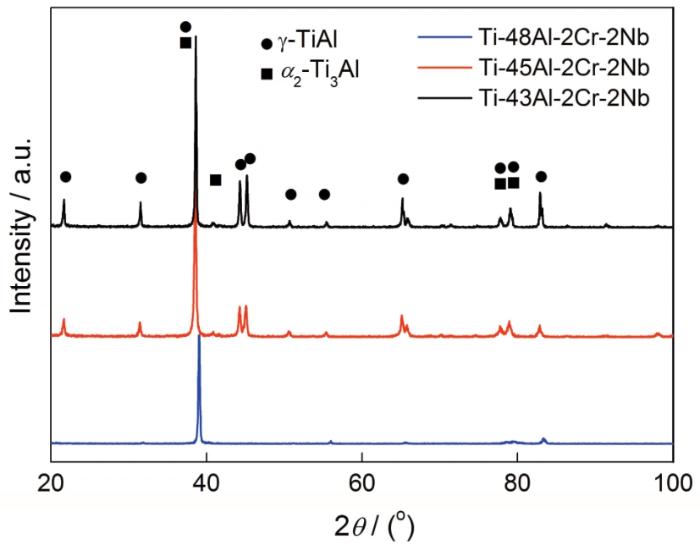

图3给出了功率为50 kW抽拉速度为0.6 mm/min时Ti-43Al-2Cr-2Nb、Ti-45Al-2Cr-2Nb和Ti-48Al-2Cr-2Nb的XRD衍射图谱。可以看出,Ti-43Al-2Cr-2Nb和Ti-45Al-2Cr-2Nb合金定向凝固组织主要是由α2相和γ相两相组成,而Ti-48Al-2Cr-2Nb只在39°左右时有明显的衍射峰,其主要由γ相构成,而其他的衍射峰都不太明显,衍射图谱中α2相的峰值很少且不明显,说明Ti-48Al-2Cr-2Nb中α2相的含量较低。

图3

图3

定向凝固Ti-(43-48)Al-2Cr-2Nb合金的X射线衍射谱

Fig.3

XRD pattern of DS Ti-(43-48)Al-2Cr-2Nb alloy

2.2 Al含量对凝固组织的影响

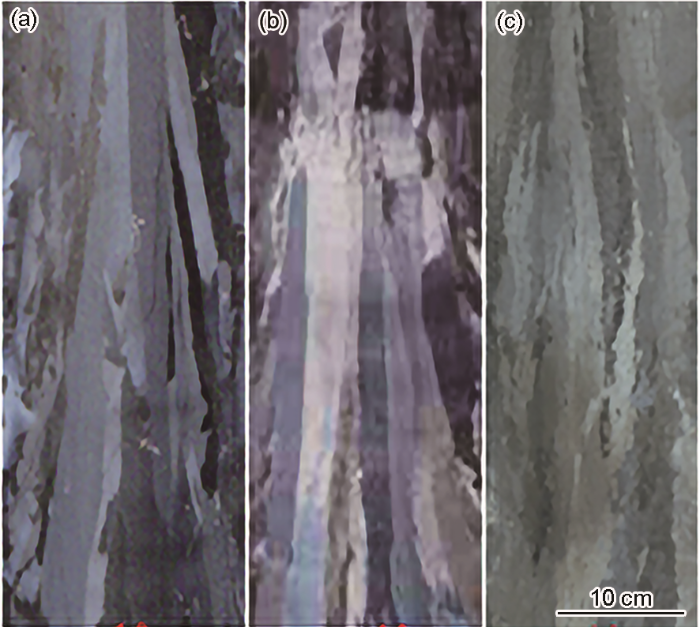

图4

图4

抽拉速度为0.6 mm/min的Ti-(43-48)Al-2Cr-2Nb合金定向凝固区的宏观形貌

Fig.4

Macro-profile of directional solidification region of CCDS Ti-(43-48)Al-2Cr-2Nb ingots with draw-ing rate of 0.6 mm/min (a) Ti-43Al-2Cr-2Nb; (b) Ti-45Al-2Cr-2Nb; (c) Ti-48Al-2Cr-2Nb

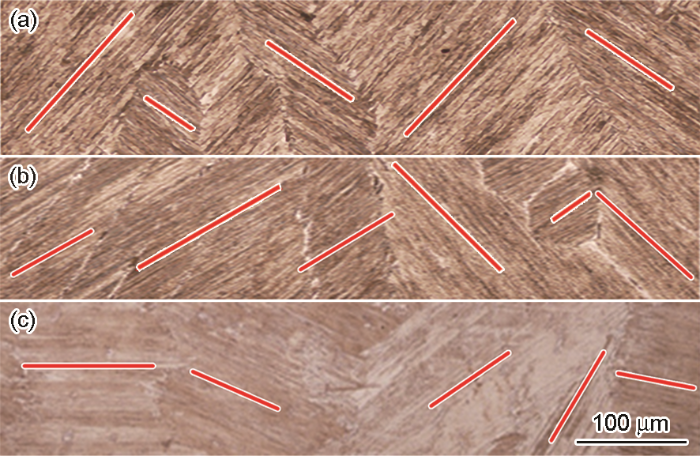

图5给出了抽拉速度为0.6 mm/min时Ti-(43-48)Al-2Cr-2Nb定向凝固纵剖面的金相显微组织,图5a和b分别给出了Ti-43Al-2Cr-2Nb和Ti-45Al-2Cr-2Nb金相照片,图中的红线为α2/γ片层。从图5a和b可见,在纵向剖面上的片层取向与下拉方向的角度大都在45°-0°-45°,没有出现垂直于下拉方向的片层。从Ti-Al合金相图上,Ti-43Al-2Cr-2Nb和Ti-45Al-2Cr-2Nb合金都以β相为初生相生长。Al含量(原子分数)提高到48%,对应Ti-Al二元合金Al的当量成分为49.31%。根据Ti-49Al合金界面响应函数的研究结果[23]可估算出Ti-48Al-2Cr-2Nb合金过冷度为20 K/mm时的界面响应函数曲线,如图6所示。由于实际的凝固条件很复杂,如熔池的温度和浓度梯度及液相流动等因素的影响,而且随着铝含量的提高枝晶间Al偏析程度增加,凝固速率在Vp和Vd的范围内时T α和T β的温度差很小,因此同时出现了初生相β和α相。如图5c所示,Ti-48Al-2Cr-2Nb合金的初生相由β相和少量α相组成,片层组织大多由与下拉方向成45°的片层组成,而且还出现少量垂直于生长方向的片层;图7给出了抽拉速度为0.6 mm/minAl含量影响片层取向的统计结果。可以看出,只有当Al含量提高到48%才出现60°~90°的片层结构,且随着Al含量的提高0°~30°的片层含量逐渐减少,而30°~60°片层在Al含量适中为45%(原子分数)时含量最高。从图8也可见,在三种成分TiAl基合金定向凝固试样的典型微观组织中,基体组织都由α2相和γ相组成全片层组织,片层组织中都镶嵌着B2相和单相块状γ相。

图5

图5

抽拉速度为0.6 mm/min的Ti-(43-48)Al-2Cr-2Nb合金定向凝固纵剖面的显微组织

Fig.5

Lognitudinal macrostructures of directionally solidified Ti-45Al-2Cr-2Nb alloys under drawing rate of 0.6 mm/min (a) Ti-43Al-2Cr-2Nb; (b) Ti-45Al-2Cr-2Nb; (c) Ti-48Al-2Cr-2Nb

图6

图6

Ti-48Al-2Cr-2Nb 合金的界面响应函数示意图

Fig.6

Interface response function of directional solidification of Ti-48Al-2Cr-2Nb alloy

图7

图7

Al含量对抽拉速度为0.6 mm/min的合金片层取向的影响

Fig.7

Effect of different Al content on the orientation of lamellae of alloy with drawing rate of 0.6 mm/min

图8

图8

定向凝固TiAl合金的背散射电子图像

Fig.8

Back-scattered images of DS TiAl alloys (a) Ti-43Al-2Cr-2Nb; (b) Ti-45Al-2Cr-2Nb; (c) Ti-48Al-2Cr-2Nb

图7给出了片层取向的统计结果。可以看出,定向凝固Ti-43Al-2Cr-2Nb和Ti-45Al-2Cr-2Nb合金片层组织取向与生长方向的夹角大多在0~55°。其原因是,抽拉速度较小(0.6 mm/min)且Al含量较低,初生β相的择优取向是

2.3 Al含量对定向凝固压缩性能的影响

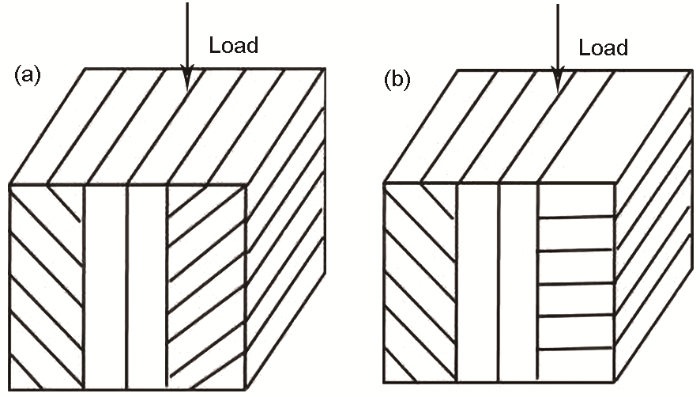

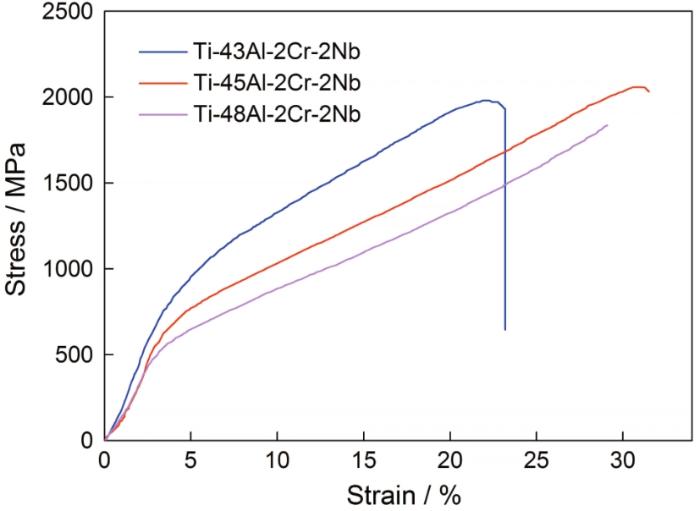

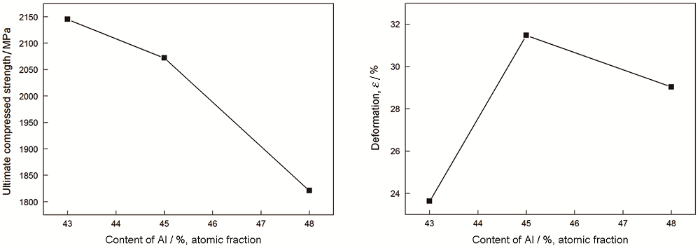

对于定向凝固Ti-(43-48)Al-2Cr-2Nb合金,抽拉速度相同时Al含量不同其凝固组织的片层方向也有所不同,尤其是当Al含量提高到48%时其凝固组织中出现了垂直的片层结构。其片层结构示意图如图9所示,总体上可以分为两类,即45°-0°-45°与0°-45°-90°,其主要区别在于出现90°片层。片层的取向不同也是影响其性能的重要因素之一。图10给出了不同Al含量定向凝固Ti-(43-48)Al-2Cr-2Nb合金的压缩性能,其数据列于表1。可以看出,随着Al含量的提高屈服强度和极限抗压强度都逐渐降低,从Al含量为43%时屈服强度由768MPa降低到45%Al的709 MPa,而当Al含量提高到48%时屈服强度降低至528 MPa,降幅幅度较大。极限抗压强度与屈服强度的降幅规律类似,降幅程度都是先小后大。压缩变形率由43%Al的23.6%先增加至31.5%(Al含量为45%),而随Al含量进一步提高到48%时反而降低到29%。

图9

图9

定向凝固Ti-(43-48)Al-2Cr-2Nb合金的压缩试样片层与加载方向的关系示意图

Fig.9

The schematic diagram of compression samples from DS Ti-(43-48)Al-2Cr-2Nb ingots:(a) 45°-0°-45° samples; (b) 0°-45°-90° samples

图10

图10

不同Al含量定向凝固Ti-(43-48)Al-2Cr-2Nb合金的压缩应力-应变曲线

Fig.10

Stress-strain curves corresponding to the compression tests of Ti-(43-48)Al-2Cr-2Nb alloy with different Al contents

表1 抽拉速度为0.6 mm/min的定向凝固Ti-(43-48)Al-2Cr-2Nb合金的压缩性能

Table 1

| Samples | Growth rate /mm·min-1 | Yield strength σ0.2/MPa | Ultimate compressed strength/MPa | Deformation ε/% |

|---|---|---|---|---|

| 1-43 | 0.6 | 768 | 2145 | 23.63 |

| 2-45 | 0.6 | 709 | 2072 | 31.48 |

| 3-48 | 0.6 | 528 | 1821 | 29.04 |

图11

图11

Al含量对Ti-(43-48)Al-2Cr-2Nb合金压缩性能的影响

Fig.11

Effect of Al content in Ti-(43-48)Al-2Cr-2Nb alloy on the compressive properties

当片层与应力方向平行时其抗压强度和塑性等综合性能较好,即强度较高室温塑性也较高。其原因是,压缩应力的加载方向平行于片层方向,应力平行于γ相

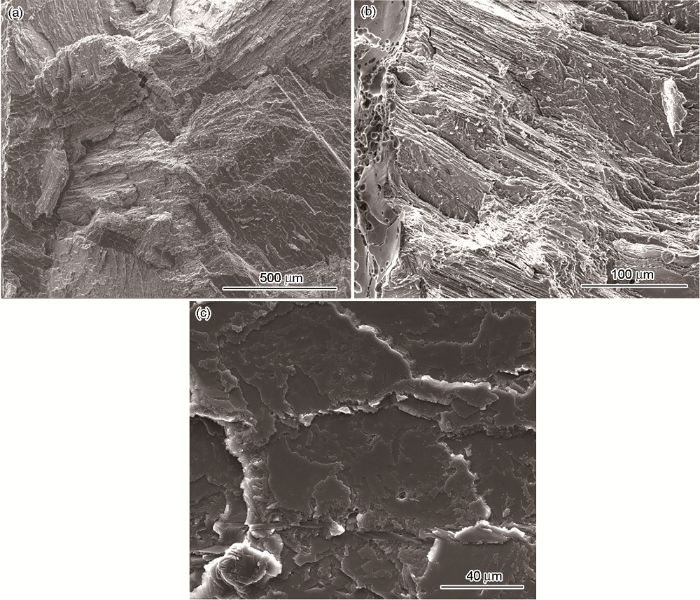

图12给出了抽拉速度为0.6 mm/min时定向凝固Ti-45Al-2Cr-2Nb试样压缩的断口形貌。可以看出,断裂方式的断口与其片层结构的取向相对应,呈现出2种典型模式,分别为沿片层断裂与穿片层断裂。图12b为图12a的局部放大照片,可见为穿片层断裂模式,片层结构主要以α2相和γ相两相为主,虽然γ相有一定程度的塑性变形,但从断口的片层结构可以看到,片层的位错并不在同一平面,微裂纹在裂纹延伸过程中贯穿片层,使断裂的片层呈高低不同形貌;另外一种如图12c所示,为沿片层断裂,其断口表面较为平滑,但是在片层出现“台阶”结构。形成这样结构的原因,主要是各个片层间的结合力不同,较弱片层裂纹在扩展过程中类似于层层剥落,进而形成了这种类似台阶的片层结构。

图12

图12

抽拉速度为0.6 mm/min的定向凝固Ti-45Al-2Cr-2Nb合金的压缩试样断口形貌

Fig.12

Fracture surface of DS Ti-45Al-2Cr-2Nb alloy at drawing rate of 0.6 mm/min

3 结论

(1) 冷坩埚定向凝固的Ti-(43-48)Al-2Cr-2Nb合金,Al含量较低时其定向凝固组织主要由α2相和γ相组成。随着Al含量的提高α2相减少而γ相增多,片层由平行片层和45°片层为主的混合片层向垂直混合片层转变。

(2) 当片层取向与应力方向垂直时Ti-(43-48)Al-2Cr-2Nb晶体具有较高的抗压强度但是塑性低,而片层取向与应力方向平行时在保持较高强度的同时室温延伸率也较高。

(3) Al含量为43%和45%的Ti-(43-48)Al-2Cr-2Nb合金,其组织由以平行片层和45°片层为主的混合片层组成,铝含量提高到48%开始出现垂直片层时其抗压强度和塑性降低。

参考文献

Microstructures and mechanical properties of directionally solidified C-containing γ-TiAl alloys via electromagnetic cold crucible

[J].

Modeling concepts for intermetallic titaniumaluminides

[J].

Evolution of B2 (ω) region in high-Nb containing TiAl alloy in intermediate temperature range

[J].

The effect of hydrogen on phase transformation and mechanical properties of a β containing γ-TiAl based alloy

[J].

In-situ study of the time-temperature-transformation behaviour of a multi-phase intermetallic β-stabilised TiAl alloy

[J].

Deformation mechanisms in micron-sized PST TiAl compression samples: experiment and model

[J].Titanium aluminides are the most promising intermetallics for use in aerospace and automotive applications. Consequently, it is of fundamental interest to explore the deformation mechanisms occurring in this class of materials. One model material which is extensively used for such studies are polysynthetically twinned (PST) TiAl crystals, which consist predominantly of parallel gamma-TiAl and, fewer, alpha(2)-Ti(3)Al lamellae. In the present study, PST TiAl crystals with a nominal composition of Ti-50 at.% Al were machined by means of the focused ion beam (FIB) technique into miniaturized compression samples with a square cross-section of approximately 9 mu m x 9 mu m. Compression tests on the miniaturized samples were performed in situ inside a scanning electron microscope using a microindenter equipped with a diamond flat punch. After deformation, thin foils were cut from the micro-compression samples and thinned to electron transparency using a FIB machine in order to study the deformation structure by transmission electron microscopy (TEM). The TEM studies reveal mechanical twinning as the main deformation mechanism at strains of 5.4%, while at strains of 8.3% dislocation glide becomes increasingly important. The experimentally observed twins scale in size with the width of the gamma-TiAl lamella. A kinematic and thermodynamic model is developed to describe the twin-related length change of the micro-compression sample at small strains as well as the relationship of an increase of twin width with increasing gamma-TiAl lamella thickness. The developed twin model predicts a width of the twins in the range of a few nanometers, which is in agreement with experimental findings. (C) 2011 Acta Materialia Inc. Published by Elsevier Ltd.

Microstructure and deformation of two-phase γ-titanium aluminides

[J].

The effect of Ruthenium addition on the microstructure and mechanical properties of TiAl alloys

[J].The high temperature compression behavior of TiAl-Ru alloys was studied at different temperatures and strain rates. Ru was found to have a strong strengthening effect on TiAl alloys. However the Ru addition amount was limited by its low solubility in gamma-TiAl and alpha 2-Ti3Al, and the detrimental effect of excessive ternary phase precipitation. Furthermore, the melting temperature decreases when Ru >= 0.6 at.% as the alloy composition approaches a ternary eutectic point. The strengthening mechanism is discussed and two separate mechanisms are proposed, viz, solid solution strengthening and refined colony strengthening. Intergranular cracks were found in the alloys with low Ru or no Ru addition, but were barely detected as Ru content increased to above 0.6 at.%. It was suggested that Ru showed a beneficial effect on both strength and ductility of TiAl alloys due to the refined colony size. Three-point bend test results showed that the Ru addition can also improve the room temperature ductility of TiAl alloys. Hot workability was increased according to the compression tests. Thermal-mechanically treated TiAl-Ru had much smaller grain size than the heat-treated samples due to dynamic recrystallization. But it did not show superior strength in the compression test compared to the heat-treated samples. The Zener-Hollomon parameter was calculated from the compression strength of heat-treated TiAl-Ru alloys. Its relationship with dynamic recrystallization and hot work is discussed. The mechanical properties of TiAl-Ru alloys are compared with TiAl-Nb samples and demonstrate a promising combination of strength and ductility. (C) 2011 Elsevier Ltd.

Effects of extrusion deformation on microstructure, mechanical properties and hot workability of β containing TiAl alloy

[J].

Effect of internal stresses on the fracture toughness of a TiAl-based alloy with duplex microstructures

[J].AbstractA series of fine duplex microstructures with different volume ratios of equiaxed γ and lath colonies (α2+γ) were achieved from an isothermally forged Ti–46.5Al–2Cr–2Nb alloy. The internal stress determination using X-ray diffraction techniques and plane-strain fracture toughness tests were carried out at room temperature, and the effects of the internal stresses on the fracture toughness were investigated. It was found that the internal stresses play an important role in determining the fracture toughness of the TiAl-based alloy. The compressive internal stresses in γ phase and the tensile internal stresses in α2 phase may be responsible for the delamination along the γ/α2 boundaries. For the microstructures with different volume fraction of lamellar grains, the fracture toughness increases with the internal stresses, which facilitate the formation of shear ligaments; and the effects of the α2 phase and equiaxed gamma grains on the internal stresses and the fracture toughness were discussed.]]>

Microstructure and toughness of nitrogen-doped TiAl alloys

[J].

Solidification behaviour of TiAl-based alloys studied by directional solidification technique

[J].Solidification behaviour of TiAl-based alloys with the nominal chemical composition Ti-46Al-8Ta and Ti-46Al-8Nb (at.%) was studied at steady- and unsteady-state conditions in Y(2)O(3) moulds using Bridgman solidification technique. The effect of growth parameters (growth rate V and temperature gradient G(L)) on primary solidification phase, solidification path and microstructure parameters were determined. Directional solidification at unsteady-state conditions was applied to determine columnar to equiaxed transition (CET) in the studied systems. (C) 2010 Elsevier Ltd.

Tailored microstructure creation of TiAl-based refractory alloys within VGF solidification

[J].

Microstructure engineering of TiAl-based refractory intermetallics within power-down directional solidification process

[J].

Directional solidification of TiAl-W-Si alloy by electromagnetic confinement of melt in cold crucible

[J].The directional solidified Ti-46Al-0.5W-0.5Si alloy with lower oxygen content has been performed successfully by electromagnetic confinement of melt within a water-cooling inductive cold crucible device. By varying the growth rate from 0.5 to 1.5 mm/min, the effects of growth rate on primary phase selection and solidification path as well as structure characteristics either in macro- or micro- scale were determined. The results reveal that the alloys will display 13 phase primarily when the peritectic reaction completed at a growth rate of less than 1.0 mm/min, which implies that the brittle lamellae with orientation that is perpendicular to the crystal growth direction might be disappeared accordingly. It is also found that the average columnar grain size decreased from 312 to 126 gm with increasing of the growth rate, which is in balance with the similarity of primary dendrite arm spacing (PDAS) lambda, decreased according to a relationship of lambda proportional to V-0.41. Due to the oxygen content is reduced to a lower degree for individual DS sample, the oxygen stabilizing effect on yielding a phase to participate primarily seems to be retarded to some extent. Thus, by controlling the directional solidification processing with cold crucible, the gamma based fully lamellar dual-phase DS Ti-46Al-0.5W-0.5Si alloy exhibits good combination of tensile properties at ambient temperature, in which it yields more than 479 MPa of yield strength and as much 3.6% in maximum of fracture elongation. (C) 2012 Elsevier Ltd.

Microstructure and mechanical properties of directionally solidified high-Nb containing Ti-Al alloys

[J].

Deformation and fracture of PST crystals and directionally solidified ingots of TiAl-based alloys

[J].

TiAl alloys in commercial aircraft engines

[J].

Microstructure and mechanical properties control of γ-TiAl(Nb, Cr, Zr) intermetallic alloy by induction float zone processing

[J].

Effect of growth rate on microstructure and tensile properties of Ti-45Al-2Cr-2Nb prepared by electromagnetic cold crucible directional solidification

[J].

Room-temperature tensile deformation of polysynthetically twinned (PST) crystals of TiAl

[J].

Microstructure evolution of Ti-(44-50)Al alloys during directional peritectic solidification

[J].Using the thermodynamic model of TiAl binary system, part ofphase diagram of Ti-(44-50)Al around the peritectic reactionwas calculated and the solidus and liquidus of primary phase βand peritectic phase α were determined and the parametersused for interface response function were obtained. Theinterface temperatures of primary phase βand peritectic phase α were calculated for different growthconditions. According to the criterion of the maximumgrowth temperature, the phase selection andmicrostructure evolution of Ti-(44-50)Al weretheoretically studied and a microstructure-selection map ofTiAl stable state solidification as a function of the meltcomposition and the G/v ratio was constructed.

Ti-(44-50)Al合金定向包晶凝固过程中的组织演化

[J].利用TiAl二元系的热力学模型,计算了Ti-(44—50)Al(原子分数,%)合金包晶反应附近的相图,确定了初生相β和包晶相α的固、液相线,得到了界面响应函数所需的部分参数. 利用这些参数及单相合金凝固界面响应函数模型,计算了初生相β和包晶相α的界面温度与生长条件变化的关系;结合最高界面生长温度判据,分析了Ti-(44—50)Al合金凝固过程中的相选择和组织演化,并确定了Ti-Al合金稳态凝固时以成分和G/v为框架的相选择图.

Fracture behavior and toughness of PST crystals of TiAl

[J].

Flow behavior of PST and fully lamellar polycrystals of Ti-48Al in the microstrain regime

[J].