激光功率和扫描速度对SLM 制备Ti5553 合金性能的影响

王铭宇 1 , 3 , 李述军 , 2 , 和正华 , 1 , 3 , 唐明德 1 , 3 , 张思倩 1 , 3 , 张浩宇 1 , 3 , 周舸 1 , 3 , 陈立佳 1 , 3

1.沈阳工业大学材料科学与工程学院 沈阳 110870

2.中国科学院金属研究所 沈阳 110016

3.沈阳工业大学 沈阳市先进结构材料与应用重点实验室 沈阳 110870

Effect of Process Parameters on Density and Compressive Properties of Ti5553 Alloy Block Prepared by SLM

WANG Mingyu 1 , 3 , LI Shujun , 2 , HE Zhenghua , 1 , 3 , TANG Mingde 1 , 3 , ZHANG Siqian 1 , 3 , ZHANG Haoyu 1 , 3 , ZHOU Ge 1 , 3 , CHEN Lijia 1 , 3

1.School of Materials Science and Engineering, Shenyang University of Technology, Shenyang 110870, China

2.Institute of Metal Research, Chinese Academy of Sciences, Shenyang 110016, China

3.Shenyang Key Laboratory of Advanced Structural Materials and Applications, Shenyang University of Technology, Shenyang 110870, China

通讯作者: 李述军,研究员,shjli@imr.ac.cn ,研究方向为医用钛合金及其增材制造研究;和正华,副教授,hezhh@sut.edu.cn ,研究方向为新型磁致伸缩合金与先进钛合金的组织与织构控制

责任编辑: 黄青

收稿日期: 2024-09-27

修回日期: 2025-02-14

基金资助:

国家自然科学基金 (U2241245 )国家自然科学基金 (52321001 )航空科学基金 (2022Z053092001 )

Corresponding authors: LI Shujun, Tel:(024)83978841 , E-mail:shjli@imr.ac.cn ;HE Zhenghua, Tel:(024)25496301 , E-mail:hezhh@sut.edu.cn

Received: 2024-09-27

Revised: 2025-02-14

Fund supported:

National Natural Science Foundation of China (U2241245 )National Natural Science Foundation of China (52321001 )Aeronautical Science Foundation of China (2022Z053092001 )

摘要

用选区激光熔化(SLM)工艺制备Ti-5Al-5Mo-5V-3Cr (Ti5553)合金构件,研究了激光功率和扫描速度对其致密度、微观缺陷和力学性能的影响。结果表明,随着激光能量密度的提高构件样品中的缺陷减少,致密度提高,激光功率为110~120 W、扫描速度为300~500 mm/s的样品其致密度高于99.99%。样品中的缺陷有形状不规则的未熔合缺陷和规则匙孔。在能量密度较低(~111 J/mm3 )的条件下制备的样品中的未熔合缺陷,随着能量密度的提高而减少;在能量密度过高(~167 J/mm3 )的条件下制备的样品其缺陷是体积分数较小、形状规则、球形度较好的匙孔。在致密度高于99%的条件下制备样品其屈服强度较高,最高达到864 MPa。

关键词:

金属材料 Ti5553 SLM 致密度 压缩性能

Abstract

Bulk Ti-5Al-5Mo-5V-3Cr (Ti5553) alloy was prepared by selective laser melting (SLM) technique, then the effect of laser power and scanning speed on the relative density, microstructural defects, and mechanical properties of the prepared alloy was assessed. The results indicate that as laser energy density increases, defects in the Ti5553 alloy decrease and relative density is improved. By laser power within the range 110-120 W and scanning speed 300-500 mm/s, the relative density of the alloy exceeded 99.99%. The main defects in the alloy include irregularly shaped lack-of-fusion defects and regular keyholes. Lack-of-fusion defects mainly existed in the alloys prepared by laser of lower energy densities (~111 J/mm³) however which decrease with the increasing laser energy density. Excessive energy density (~167 J/mm³) results in the formation of keyholes of a small volume fraction with regular shape, and good sphericity. Compression test results show that alloys of relative density above 99% exhibit high yield strength, reaching up to 864 MPa. These findings may provide a reference for the research and development in the application selective laser melting for manufacturing workpieces of Ti5553 alloy.

Keywords:

metallic materials Ti5553 SLM density compression performance

本文引用格式

王铭宇, 李述军, 和正华, 唐明德, 张思倩, 张浩宇, 周舸, 陈立佳. 激光功率和扫描速度对SLM 制备Ti5553 合金性能的影响 [J]. 材料研究学报 , 2025, 39(8): 583-591 DOI:10.11901/1005.3093.2024.398

WANG Mingyu, LI Shujun, HE Zhenghua, TANG Mingde, ZHANG Siqian, ZHANG Haoyu, ZHOU Ge, CHEN Lijia. Effect of Process Parameters on Density and Compressive Properties of Ti5553 Alloy Block Prepared by SLM [J]. Chinese Journal of Materials Research 10.11901/1005.3093.2024.398

Ti5553(Ti-5Al-5Mo-5V-3Cr)合金是一种商用亚稳态β 钛合金,其比强度较高、质量轻、断裂韧性、淬透性和耐蚀性较好[1 ~5 ] 。用高性能Ti5553钛合金可制造发动机舱、机壳、机翼以及机翼连接构件等关键部件[6 ~10 ] 。

选区激光熔化(Selective Laser Melting,SLM)是一种先进的增材制造技术,可用于制造复杂形状的金属零件[11 ~13 ] 。SLM使用的原材料是小粒径金属粉末,在激光熔化过程中能均匀熔化和固化。激光束聚焦到特定位置的金属粉末,使其瞬间熔化形成一个极小的熔池。一层金属粉末熔化和固化后,建造台下降一个微小的距离为下一层金属粉末提供空间。这个过程不断重复,直到制备出整个零件。SLM技术的优势有:可制造复杂几何形状的零件、材料利用率高、制造效率高[14 ] 。调节激光功率和扫描速度等SLM工艺参数,可改变零件的致密度等性能[15 ,16 ] 。Zhou等[17 ] 使用CT分析了用不同工艺参数制造的样品中缺陷的尺寸、形态和空间分布。他们建立了一个将缺陷体积分数与工艺参数相关联的数学模型,证明使用无损X射线CT技术可表征SLM零件中的缺陷并优化制造工艺。Gong等[18 ] 研究了激光和电子束选区熔化制备的Ti-6Al-4V零件中的缺陷对其力学性能的影响,发现缺陷使材料的强度和延伸率显著降低。Fousová等[19 ] 采用不同参数的SLM工艺制备了Ti-6Al-4V样品,发现激光功率和扫描速度是影响其致密度和压缩性能的关键参数。Choy等[20 ] 优化激光功率和扫描速度,用SLM技术制备出致密度高达99.9%的Ti-6Al-4V零件。

本文用SLM技术制备Ti5553合金构件,研究激光功率和扫描速度等工艺参数对其致密度等性能的影响,分析缺陷的特征和形成规律,以及力学性能与致密度的关系。

1 实验方法

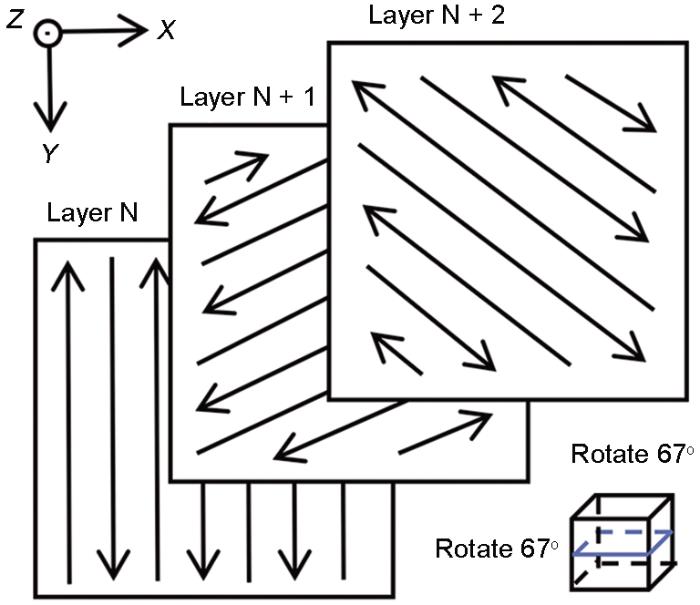

SLM成型用Ti5553粉末的粒径为15~53 μm。用AmPro SP101型金属铺粉3D打印机制备实验用Ti5553样品,粉层厚度为0.03 mm,扫描间距为0.06 mm,层间旋转角度为67°,条宽为10 mm,激光光斑直径为0.06 mm (图1 )。以功率和扫描速度为变量设计了36组参数制备样品。激光功率为70~120 W,功率跨度为10 W,扫描速度为300~800 mm/s,跨度为100 mm/s。样品的长、宽、高均为10 mm。

图1

图1

SLM扫描策略,层间旋转角度67°

Fig.1

SLM scanning strategies. The layer rotation angle is 67°

使用线切割从基板上截取样品,基板的材质为TC4。在36个样品中选取9个试样,其命名(A1-C3)列于表1 。

用GeminiSEM-300场发射扫描电子显微镜(SEM)观察用于打印的粉末的形貌。沿打印样品生长方向的截面截取金相试样,依次用80#、200#、800#、1500#、2000#、3000#砂纸打磨样品的表面,然后用二氧化硅抛光液抛光。用Archimedes法、金相法和CT (Computed Tomography,计算机断层扫描)法测量致密度。用SHUJU SJ-300固体密度计和Archimedes 法测试样品的密度计算样品的致密度。用HAL-100 ZEISS型光学显微镜(OM)观察样品中缺陷的分布。将9个打印样品分别加工成长4 mm、宽4 mm和高6 mm的立方体,用Xradia 515 Versa型X射线断层扫描仪统计样品的致密度,得到直观可见的缺陷形貌、数量、体积分数图像。用MTS Landmark型伺服液压控制测试系统按照GB/T 7314—2017标准测试样品的压缩性能,压缩速率为0.5 mm/min,每个工艺参数测试2个样品,取其结果的平均值。用密度计测量样品的密度,将其除以Ti5553的理论密度4.65 g/cm3 得到样品的致密度,孔隙率=1-致密度。

2 实验结果

2.1 Ti5553 合金粉末的形貌和粒度分布

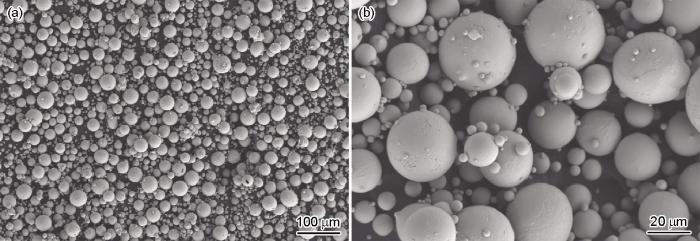

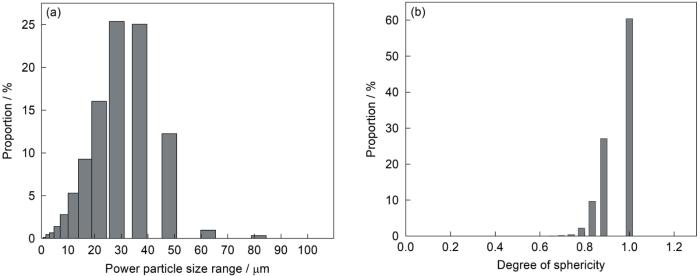

图2 和图3 给出了Ti5553合金粉末的形貌和粒度分布。可以看出,粉末的粒度为12.77~48.04 μm,D03 = 10.25 μm、D50 = 32.90 μm、D90 = 50.45 μm。粉末的平均圆形度为0.945,C03 = 0.837、C50 = 0.951、C90 = 0.990。粉末的松散密度为2.65 g/cm3 ,振实密度为2.88 g/cm3 。

图2

图2

Ti5553合金粉末的SEM形貌

Fig.2

SEM images of Ti5553 alloy powder morphology (a) 100×, (b) 500×

图3

图3

Ti5553合金粉末的粒径和球形度统计

Fig.3

Particle size (a) and sphericity distribution chart (b) of Ti5553 alloy powder

2.2 样品的致密度和孔隙率

如图4a 所示,激光功率为110 W,扫描速度为300 mm/s的样品,其最大致密度可达99.99%。在相同功率下扫描速度降低使密度提高,扫描速度为500~600 mm/s的样品其致密度最高。能量密度与致密度的关系散点图,如图4b 所示。可以看出,随着能量密度的提高致密度随之提高。功率高于200 J/mm3 时,致密度达到最大值后降低,因为过高的能量密度导致匙孔的形成。

图4

图4

用Archimedes法测出的孔隙率和致密度与能量密度的关系

Fig.4

Measurement of porosity using the archimedes method (a) and the relationship between relative density and energy density (b)

2.3 样品中微观缺陷的分布

图5 给出了不同工艺参数样品的微观缺陷分布。可以看出,在能量密度较低的A区域出现了较多的未熔合缺陷;B区域中的缺陷较少。在功率不变的情况下,扫描速度的提高使致密度降低,在金相照片中可见明显的未熔合缺陷。功率为70~90 W时,这种情况尤为显著。

图5

图5

不同激光功率和扫描速度制备的样品的缺陷的OM图

Fig.5

Optical microscopy (OM) images of defect morphologies by different laser powers and scanning speeds

使用Image J软件计算A1~C3这9个样品的微观缺陷图中非缺陷区域与图片区域的比值即孔隙率,再根据孔隙率计算出致密度。

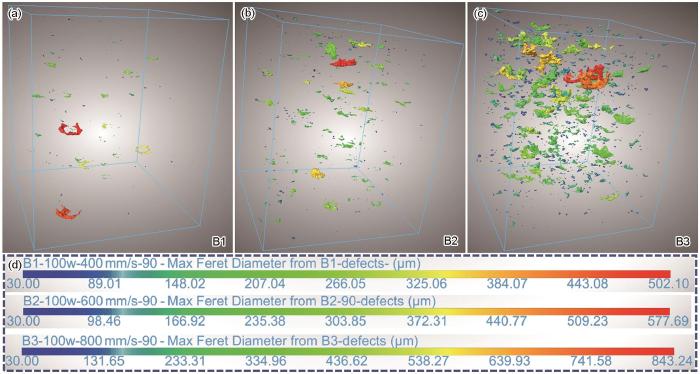

2.4 样品中的CT 缺陷

样品中缺陷的形貌可分为两类:一类是能量密度较低时形成的形状不规则、尺寸较大的未熔合缺陷;另一类是能量密度过高时形成的球形度较大、尺寸较小的匙孔,是粉末中的杂质气化形成的气孔。

图6 给出了样品A1、A2、A3的CT图,图中不同的颜色表示缺陷的大小不同。在功率低于70 W的样品中缺陷无规则且体积分数较大,不同大小的缺陷均匀弥散分布。较大的未熔合缺陷呈不规则的椭圆状或片状,沿打印方向上的弗雷特直径较小,在打印方向的法平面方向弗雷特直径较大。随着扫描速度的提高缺陷的体积分数提高(数量增多),缺陷的最大弗雷特直径随之增大(表2 )。A3样品中缺陷的最大弗雷特直径达到了4.237 mm。在能量密度较低的样品中未熔合缺陷极多,将较小的缺陷连成较大且连续的未熔合缺陷群。随着扫描速度的降低这些缺陷群逐渐断开和变小,在A1样品中只见一个标红的较大缺陷。

图6

图6

激光功率为70 W制备的样品的缺陷形貌和尺寸的CT图

Fig.6

CT image of defects in sample A1 with 70 W laser power and 400 mm/s scanning speed, with a relative density of 98.71% (a), CT image of defects in sample A2 with 70 W laser power and 600 mm/s scanning speed, with a relative density of 96.32% (b), CT image of defects in sample A3 with 70 W laser power and 800 mm/s scanning speed, with a relative density of 91.79% (c) and the scale of defect sizes in the CT images (d)

图7 给出了B1、B2和B3的CT图。与激光功率为70 W的样品相比,随着激光功率的提高可观测到未熔合缺陷的体积分数降低、数量减少。与功率为70 W的样品相同的是,随着激光扫描速度的提高功率为100 W的样品中不规则的未熔合缺陷数量增多和体积分数提高。在B1样品中可观察到较大的环状未熔合缺陷。

图7

图7

激光功率为100 W制备的样品内部缺陷的形貌和尺寸的CT图

Fig.7

CT image of defects in sample B1 with 100 W laser power and 400 mm/s scanning speed, with a relative density of 99.93% (a), CT image of defects in sample B2 with 100 W laser power and 600 mm/s scanning speed, with a relative density of 99.62% (b), CT image of defects in sample B3 with 100 W laser power and 800 mm/s scanning speed, with a relative density of 98.83% (c) and the scale of defect sizes in the CT images (d)

图8 给出了C1、C2和C3的CT图。与功率为70 W和100 W的6个样品相比,激光功率为120 W的样品中未熔合缺陷的体积分数大幅度降低,数量也大幅度减少。扫描速度的提高也使功率为120 W样品的致密度降低,在C2和C3样品中也观察到一个弗雷特直径较大的未熔合缺陷。在C1样品中形状规则、球形度较高且体积分数较小的匙孔,是过高的能量密度使金属蒸发产生的气孔。

图8

图8

激光功率为120 W制备的样品内部缺陷的形貌和尺寸的CT图

Fig.8

CT image of defects in sample C1 with 120 W laser power and 400 mm/s scanning speed, with a relative density of 99.99% (a), CT image of defects in sample C2 with 120 W laser power and 600 mm/s scanning speed, with a relative density of 99.92% (b), CT image of defects in sample C3 with 120 W laser power and 800 mm/s scanning speed, with a relative density of 99.62% (c) and the scale of defect sizes in the CT images (d)

在功率不变的情况下,提高扫描速度使样品中的缺陷增多、体积分数提高和分布密集;在扫描速度不变的情况下,激光功率的提高使样品中的缺陷数量减少、体积分数降低。这表明,一味地提高激光功率和降低扫描速度并不能使致密度持续提高。过高能量密度使金属粉末熔化后进一步气化,熔融的金属凝固使样品中产生形状规则的气孔。

用Archimedes法和金相法测得的致密度与用CT法测得的致密度比较,其差别如表3 所示。可以看出,样品的致密度越低差别越大。样品的致密度越高,差别越小。

2.5 样品的压缩性能

图9 给出了样品的工程应力-应变曲线。致密度高于99%的样品其屈服强度为805.5~864 MPa,其中致密度为99.99%的C1样品其打印态屈服强度为862.5 MPa。A1、A2、A3、B3样品在压缩过程中发生了断裂失效,其他样品均未失效。由此可以推测,致密度低于98.71%的样品在压缩时失效。根据图9 计算出各参数样品的屈服强度和对应的能量密度,如表4 所示。

图9

图9

不同工艺参数的样品压缩后的工程应力-应变曲线

Fig.9

Engineering stress-strain curve of A1 (a), engineering stress-strain curve of A2 (b), engineering stress-strain curve of A3 (c), engineering stress-strain curve of B1 (d), engineering stress-strain curve of B2 (e), engineering stress-strain curve of B3 (f), engineering stress-strain curve of C1 (g), engineering stress-strain curve of C2 (h) and engineering stress-strain curve of C3 (i)

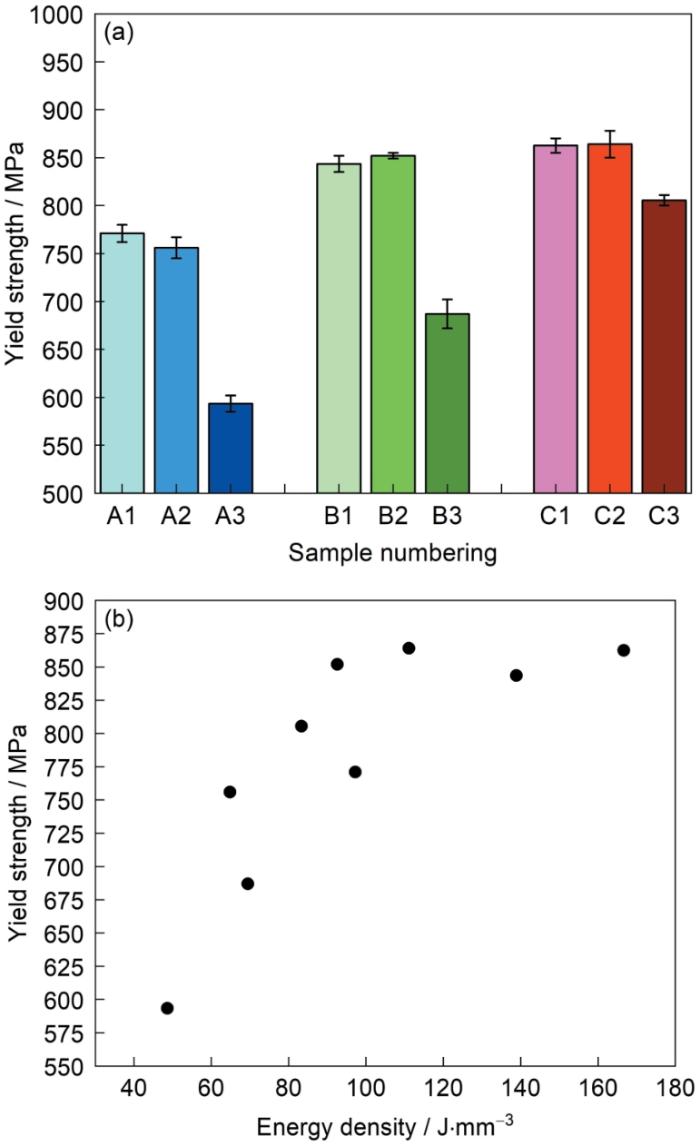

图10 给出了不同激光打印参数Ti5553的屈服强度及其与能量密度的关系。可以看出,在功率相同的条件下,随着扫描速度的提高屈服强度随之降低。其原因是,样品中的缺陷对力学性能产生了较大的影响。样品中的缺陷越多、缺陷的尺寸越大,则样品的屈服强度越低[21 ] 。激光功率同为100 W,B2样品的屈服强度最高(852 MPa),比致密度较高的样品B1高。同样地,功率同为120 W的样品C2和C1也出现了相同的情况。随着能量密度的提高Ti5553样品的屈服强度随之提高,这种趋势在能量密度较低时尤为显著。能量密度高于约166.67 J/mm3 的样品,屈服强度趋于平稳。

图10

图10

不同工艺参数Ti5553样品的屈服强度和屈服强度-能量密度图

Fig.10

Yield strength of Ti5553 under different process parameters (a) and relationship between yield strength and energy density (b)

3 讨论

3.1 工艺参数对缺陷形成的影响

E = P / V = P / v h d

式中E 为能量密度(J/mm3 );P 为激光功率(W);V 为单位时间内扫过的粉体体积(mm3 );v 为扫描速度(mm/s);h 为粉层厚度(mm);d 为扫描间距(mm)。用金相法测试致密度的结果表明,激光功率为110 W、扫描速度为300 mm/s的样品致密度最高。能量密度为203.7 J/mm3 制备的样品,其致密度为99.99%。能量密度的提高使样品的致密度提高,但是过高的能量密度使金属发生气化,产生的匙孔使致密度降低。实验结果表明,在能量密度相同的条件下,其它工艺参数不同也使致密度不同。其原因是,在能量密度足够高的条件下,提高激光功率和扫描速度也可能使轨迹从连续状态转变为不规则和球化状态,从而影响构件的致密度[22 ] 。因此,只依据能量密度确定的最优参数,是不准确的。从图7a 和图8c 可以看出,扫描速度和激光功率都较高的样品,其中缺陷的体积较大。激光功率和扫描速度较低的样品,其中的缺陷体积较小。这表明,即使能量密度接近,降低激光功率和扫描速度也能减小缺陷的体积。需要指出的是,本文关注激光功率和扫描速度对样品的组织和力学性能的影响,因此使用了一种层厚。层厚不同也显著影响构件的缺陷和组织[23 ] 。这表明,调节层厚也是优化SLM制备的Ti5553构件的致密度和力学性能的有效手段。

3.2 用不同方法测量的致密度的误差和工艺参数影响压缩性能的机制

用金相法和Archimedes法测出的致密度有一定的误差。用Archimedes法测量致密度,样品的体积越小误差越大。样品中缺陷的体积分数和数量也影响其压缩性能。样品的缺陷越少、体积越小,其压缩性能越高,尤其是致密度不高于99%时。致密度高于99%的样品(图5 ),B1的致密度为99.93%,屈服强度为843.5 MPa,B2的致密度为99.62%,屈服强度为852 MPa。B2的致密度低于B1,但是其屈服强度却高于B1。致密度高于99%的样品,缺陷对力学性能的影响较小。在功率相同的条件下,扫描速度越高熔池的冷却越快,只能生成较小的晶粒,其屈服强度就比较高[24 ] 。同时,能量密度较低的样品具有混合的柱状和细晶粒结构,因为熔池的重叠不足以打破柱状晶粒结构。能量密度更高的样品呈现出等轴晶粒形貌,因为其熔池足够大且重叠,整个区域熔融生成了等轴晶粒[25 ] 。与柱状晶样品相比,这些等轴晶样品具有各向同性并具有更好的塑性变形能力,因此其压缩性能更优。

4 结论

(1) 随着激光能量密度的提高,用选区激光熔化技术(SLM)制备的Ti5553合金样品缺陷减少,致密度提高。能量密度相同但是工艺参数不同的样品其致密度不同。

(2) 在工艺窗口外,降低激光功率、提高扫描速度使未熔合缺陷的增多,提高激光功率、降低扫描速度使形状规则、体积较小的匙孔增多。

参考文献

View Option

[1]

Leyens C Peters M Titanium and Titanium Alloys: Fundamentals and Applications [M]. Weinheim : Wiley-VCH Verlag GmbH & Co. KGaA , 2003 : 1

[本文引用: 1]

[2]

Fanning J C Boyer R R Ti-2003 Science and Technology [M]. Weinheim : Wiley VCH , 2004 : 1

[3]

Jones N G Dashwood R J Jackson M et al β phase decomposition in Ti-5Al-5Mo-5V-3Cr

[J]. Acta Mater. , 2009 , 57 : 3830

[4]

Boyer R R Briggs R D The use of β titanium alloys in the aerospace industry

[J]. J. Mater. Eng. Perform. , 2005 , 14 : 681

[5]

Zhang H Effects of heat treatment on microstructures and properties ofa new type high strength beta titanium alloy

[D]. Xi'an : Xi'an University of Architecture and Technology , 2013

[本文引用: 1]

张 虎 热处理工艺对新型高强β钛合金组织和性能的影响

[D]. 西安 : 西安建筑科技大学 , 2013

[本文引用: 1]

[6]

Panza-Giosa R The effect of heat treatment on the microstructure evolution and mechanical properties of Ti-5Al-5V-5Mo-3Cr, and its potential application in landing gears

[D]. Hamilton : McMaster University , 2010

[本文引用: 1]

[7]

Warchomicka F Poletti C Stockinger M Study of the hot deformation behaviour in Ti-5Al-5Mo-5V-3Cr-1Zr

[J]. Mater. Sci. Eng. , 2011 , 528A : 8277

[8]

Jérôme P Advanced materials and technology for A380 structure

[J]. Aeronaut. Maint. Eng. , 2003 , (6 ): 50

杰罗姆P A380结构的先进材料和技术-未来发展的技术平台

[J]. 航空维修与工程 , 2003 , (6 ): 50

[9]

Parida A K Maity K Analysis of some critical aspects in hot machining of Ti-5553 superalloy: experimental and FE analysis

[J]. Def. Technol. , 2019 , 15 : 344 -352

DOI

In this study, a newly developed titanium superalloy, i.e., the Ti-5553 alloy has used for hot machining. This material replaced Ti-grade-5 alloy in the application of aerospace, automobile, and biomedical sector. However, similar to Ti-grade-5 alloy, the Ti-5553 alloy has a low thermal conductivity which makes it difficult-to-cut material categories hence, high tool wear, cutting force and bad surface finish. Hot machining of Ti-5553 has been studied at different machining condition (room and hot) using Deform-2D finite element analysis. The result from the simulation test was compared with the experimental value and reduction of cutting and thrust forces was observed. The experiment was carried out with the same input parameters as simulation, and good coherence between them observed. Additionally, cutting zone temperature, effective stress, etc. for both room and elevated the temperature are also discussed. © 2018 The Authors

[10]

Zopp C Blümer S Schubert F et al Processing of a metastable titanium alloy (Ti-5553) by selective laser melting

[J]. Ain Shams Eng. J. , 2017 , 8 : 475

[本文引用: 1]

[11]

Kurzynowski T Pawlak A Smolina I The potential of SLM technology for processing magnesium alloys in aerospace industry

[J]. Arch. Civ. Mech. Eng. , 2020 , 20 : 23

[本文引用: 1]

[12]

Zhang W N Wang L Z Feng Z X et al Research progress on selective laser melting (SLM) of magnesium alloys: a review

[J]. Optik , 2020 , 207 : 163842

[13]

Huang J Yan X C Chang C et al Pure copper components fabricated by cold spray (CS) and selective laser melting (SLM) technology

[J]. Surf. Coat. Technol. , 2020 , 395 : 125936

[本文引用: 1]

[14]

Vekilov S S Lipovskyi V I Marchan R A et al Distinctive features of SLM technology application for manufacturing of LPRE components

[J]. J. Rocket-Space Technol. , 2021 , 29 (4 ): 112

[本文引用: 1]

[15]

Jia H L Sun H Wang H Z et al Scanning strategy in selective laser melting (SLM): a review

[J]. Int. J. Adv. Manuf. Technol. , 2021 , 113 : 2413

[本文引用: 1]

[16]

Razavykia A Brusa E Delprete C et al An overview of additive manufacturing technologies—a review to technical synthesis in numerical study of selective laser melting

[J]. Materials (Basel) , 2020 , 13 (17 ): 3895

[本文引用: 1]

[17]

Zhou X Dai N Chu M Q et al X-ray CT analysis of the influence of process on defect in Ti-6Al-4V parts produced with Selective Laser Melting technology

[J]. Int. J. Adv. Manuf. Technol. , 2020 , 106 : 3

[本文引用: 1]

[18]

Gong H J Rafi K Gu H F et al Influence of defects on mechanical properties of Ti-6Al-4V components produced by selective laser melting and electron beam melting

[J]. Mater. Des. , 2015 , 86 : 545

[本文引用: 1]

[19]

Fousová M Vojtěch D Kubásek J et al Promising characteristics of gradient porosity Ti-6Al-4V alloy prepared by SLM process

[J]. J. Mech. Behav. Biomed. Mater. , 2017 , 69 : 368

DOI

PMID

[本文引用: 1]

Porous structures, manufactured of a biocompatible metal, mimicking human bone structure are the future of orthopedic implantology. Fully porous materials, however, suffer from certain drawbacks. To overcome these, gradient in structure can be prepared. With gradient in porosity mechanical properties can be optimized to an appropriate value, implant can be attributed a similar gradient macrostructure as bone, tissue adhesion may be promoted and also various modification with organic or inorganic substances are possible. In this study, additive technology selective laser melting (SLM) was used to produce three types of gradient porosity model specimens of titanium alloy Ti-6Al-4V. As this technology has the potential to prepare complex structures in the near-net form, to control porosity, pore size and shape, it represents a promising option. The first part of the research work was focused on the characterization of the material itself in the as-produced state, only with heat treatment applied. The second part dealt with the influence of porosity on mechanical properties. The study has shown SLM brings significant changes in the surface chemistry. Despite this finding, titanium alloy retained its cytocompatibility, as it was outlined by in vitro tests with U-2 OS cells. With introduced porosity yield strength, ultimate strength and stiffness showed linear decrease, both in tension and compression. With respect to the future use in the form of orthopedic implant, especially reduction in Young's modulus down to the human bone value (30.5±2GPa) is very appreciated as the stress-shielding effect followed by possible implant loosening is limited.Copyright © 2017 Elsevier Ltd. All rights reserved.

[20]

Choy S Y Sun C N Leong K F et al Compressive properties of Ti-6Al-4V lattice structures fabricated by selective laser melting: Design, orientation and density

[J]. Addit. Manuf. , 2017 , 16 : 213

[本文引用: 1]

[21]

Liu W Chen C Y Shuai S S et al Study of pore defect and mechanical properties in selective laser melted Ti6Al4V alloy based on X-ray computed tomography

[J]. Mater. Sci. Eng. , 2020 , 797A : 139981

[本文引用: 1]

[22]

Bertoli U S Wolfer A J Matthews M J et al On the limitations of volumetric energy density as a design parameter for selective laser melting

[J]. Mater. Des. , 2017 , 113 : 331

[本文引用: 1]

[23]

Shi X Z Yan C Feng W W et al Effect of high layer thickness on surface quality and defect behavior of Ti-6Al-4V fabricated by selective laser melting

[J]. Opt. Lasers Technol. , 2020 , 132 : 106471

[本文引用: 1]

[24]

Wang F Z Zhang C H Cui X et al Effect of energy density on the defects, microstructure, and mechanical properties of selective-laser-melted 24CrNiMo low-alloy steel

[J]. J. Mater. Eng. Perform. , 2022 , 31 : 3520

[本文引用: 1]

[25]

Kirka M M Lee Y Greeley D A et al Strategy for texture management in metals additive manufacturing

[J]. JOM , 2017 , 69 (3 ): 523

[本文引用: 1]

1

2003

... Ti5553(Ti-5Al-5Mo-5V-3Cr)合金是一种商用亚稳态β 钛合金,其比强度较高、质量轻、断裂韧性、淬透性和耐蚀性较好[1 ~5 ] .用高性能Ti5553钛合金可制造发动机舱、机壳、机翼以及机翼连接构件等关键部件[6 ~10 ] . ...

β phase decomposition in Ti-5Al-5Mo-5V-3Cr

0

2009

The use of β titanium alloys in the aerospace industry

0

2005

Effects of heat treatment on microstructures and properties ofa new type high strength beta titanium alloy

1

2013

... Ti5553(Ti-5Al-5Mo-5V-3Cr)合金是一种商用亚稳态β 钛合金,其比强度较高、质量轻、断裂韧性、淬透性和耐蚀性较好[1 ~5 ] .用高性能Ti5553钛合金可制造发动机舱、机壳、机翼以及机翼连接构件等关键部件[6 ~10 ] . ...

热处理工艺对新型高强β钛合金组织和性能的影响

1

2013

... Ti5553(Ti-5Al-5Mo-5V-3Cr)合金是一种商用亚稳态β 钛合金,其比强度较高、质量轻、断裂韧性、淬透性和耐蚀性较好[1 ~5 ] .用高性能Ti5553钛合金可制造发动机舱、机壳、机翼以及机翼连接构件等关键部件[6 ~10 ] . ...

The effect of heat treatment on the microstructure evolution and mechanical properties of Ti-5Al-5V-5Mo-3Cr, and its potential application in landing gears

1

2010

... Ti5553(Ti-5Al-5Mo-5V-3Cr)合金是一种商用亚稳态β 钛合金,其比强度较高、质量轻、断裂韧性、淬透性和耐蚀性较好[1 ~5 ] .用高性能Ti5553钛合金可制造发动机舱、机壳、机翼以及机翼连接构件等关键部件[6 ~10 ] . ...

Study of the hot deformation behaviour in Ti-5Al-5Mo-5V-3Cr-1Zr

0

2011

Advanced materials and technology for A380 structure

0

2003

A380结构的先进材料和技术-未来发展的技术平台

0

2003

Analysis of some critical aspects in hot machining of Ti-5553 superalloy: experimental and FE analysis

0

2019

Processing of a metastable titanium alloy (Ti-5553) by selective laser melting

1

2017

... Ti5553(Ti-5Al-5Mo-5V-3Cr)合金是一种商用亚稳态β 钛合金,其比强度较高、质量轻、断裂韧性、淬透性和耐蚀性较好[1 ~5 ] .用高性能Ti5553钛合金可制造发动机舱、机壳、机翼以及机翼连接构件等关键部件[6 ~10 ] . ...

The potential of SLM technology for processing magnesium alloys in aerospace industry

1

2020

... 选区激光熔化(Selective Laser Melting,SLM)是一种先进的增材制造技术,可用于制造复杂形状的金属零件[11 ~13 ] .SLM使用的原材料是小粒径金属粉末,在激光熔化过程中能均匀熔化和固化.激光束聚焦到特定位置的金属粉末,使其瞬间熔化形成一个极小的熔池.一层金属粉末熔化和固化后,建造台下降一个微小的距离为下一层金属粉末提供空间.这个过程不断重复,直到制备出整个零件.SLM技术的优势有:可制造复杂几何形状的零件、材料利用率高、制造效率高[14 ] .调节激光功率和扫描速度等SLM工艺参数,可改变零件的致密度等性能[15 ,16 ] .Zhou等[17 ] 使用CT分析了用不同工艺参数制造的样品中缺陷的尺寸、形态和空间分布.他们建立了一个将缺陷体积分数与工艺参数相关联的数学模型,证明使用无损X射线CT技术可表征SLM零件中的缺陷并优化制造工艺.Gong等[18 ] 研究了激光和电子束选区熔化制备的Ti-6Al-4V零件中的缺陷对其力学性能的影响,发现缺陷使材料的强度和延伸率显著降低.Fousová等[19 ] 采用不同参数的SLM工艺制备了Ti-6Al-4V样品,发现激光功率和扫描速度是影响其致密度和压缩性能的关键参数.Choy等[20 ] 优化激光功率和扫描速度,用SLM技术制备出致密度高达99.9%的Ti-6Al-4V零件. ...

Research progress on selective laser melting (SLM) of magnesium alloys: a review

0

2020

Pure copper components fabricated by cold spray (CS) and selective laser melting (SLM) technology

1

2020

... 选区激光熔化(Selective Laser Melting,SLM)是一种先进的增材制造技术,可用于制造复杂形状的金属零件[11 ~13 ] .SLM使用的原材料是小粒径金属粉末,在激光熔化过程中能均匀熔化和固化.激光束聚焦到特定位置的金属粉末,使其瞬间熔化形成一个极小的熔池.一层金属粉末熔化和固化后,建造台下降一个微小的距离为下一层金属粉末提供空间.这个过程不断重复,直到制备出整个零件.SLM技术的优势有:可制造复杂几何形状的零件、材料利用率高、制造效率高[14 ] .调节激光功率和扫描速度等SLM工艺参数,可改变零件的致密度等性能[15 ,16 ] .Zhou等[17 ] 使用CT分析了用不同工艺参数制造的样品中缺陷的尺寸、形态和空间分布.他们建立了一个将缺陷体积分数与工艺参数相关联的数学模型,证明使用无损X射线CT技术可表征SLM零件中的缺陷并优化制造工艺.Gong等[18 ] 研究了激光和电子束选区熔化制备的Ti-6Al-4V零件中的缺陷对其力学性能的影响,发现缺陷使材料的强度和延伸率显著降低.Fousová等[19 ] 采用不同参数的SLM工艺制备了Ti-6Al-4V样品,发现激光功率和扫描速度是影响其致密度和压缩性能的关键参数.Choy等[20 ] 优化激光功率和扫描速度,用SLM技术制备出致密度高达99.9%的Ti-6Al-4V零件. ...

Distinctive features of SLM technology application for manufacturing of LPRE components

1

2021

... 选区激光熔化(Selective Laser Melting,SLM)是一种先进的增材制造技术,可用于制造复杂形状的金属零件[11 ~13 ] .SLM使用的原材料是小粒径金属粉末,在激光熔化过程中能均匀熔化和固化.激光束聚焦到特定位置的金属粉末,使其瞬间熔化形成一个极小的熔池.一层金属粉末熔化和固化后,建造台下降一个微小的距离为下一层金属粉末提供空间.这个过程不断重复,直到制备出整个零件.SLM技术的优势有:可制造复杂几何形状的零件、材料利用率高、制造效率高[14 ] .调节激光功率和扫描速度等SLM工艺参数,可改变零件的致密度等性能[15 ,16 ] .Zhou等[17 ] 使用CT分析了用不同工艺参数制造的样品中缺陷的尺寸、形态和空间分布.他们建立了一个将缺陷体积分数与工艺参数相关联的数学模型,证明使用无损X射线CT技术可表征SLM零件中的缺陷并优化制造工艺.Gong等[18 ] 研究了激光和电子束选区熔化制备的Ti-6Al-4V零件中的缺陷对其力学性能的影响,发现缺陷使材料的强度和延伸率显著降低.Fousová等[19 ] 采用不同参数的SLM工艺制备了Ti-6Al-4V样品,发现激光功率和扫描速度是影响其致密度和压缩性能的关键参数.Choy等[20 ] 优化激光功率和扫描速度,用SLM技术制备出致密度高达99.9%的Ti-6Al-4V零件. ...

Scanning strategy in selective laser melting (SLM): a review

1

2021

... 选区激光熔化(Selective Laser Melting,SLM)是一种先进的增材制造技术,可用于制造复杂形状的金属零件[11 ~13 ] .SLM使用的原材料是小粒径金属粉末,在激光熔化过程中能均匀熔化和固化.激光束聚焦到特定位置的金属粉末,使其瞬间熔化形成一个极小的熔池.一层金属粉末熔化和固化后,建造台下降一个微小的距离为下一层金属粉末提供空间.这个过程不断重复,直到制备出整个零件.SLM技术的优势有:可制造复杂几何形状的零件、材料利用率高、制造效率高[14 ] .调节激光功率和扫描速度等SLM工艺参数,可改变零件的致密度等性能[15 ,16 ] .Zhou等[17 ] 使用CT分析了用不同工艺参数制造的样品中缺陷的尺寸、形态和空间分布.他们建立了一个将缺陷体积分数与工艺参数相关联的数学模型,证明使用无损X射线CT技术可表征SLM零件中的缺陷并优化制造工艺.Gong等[18 ] 研究了激光和电子束选区熔化制备的Ti-6Al-4V零件中的缺陷对其力学性能的影响,发现缺陷使材料的强度和延伸率显著降低.Fousová等[19 ] 采用不同参数的SLM工艺制备了Ti-6Al-4V样品,发现激光功率和扫描速度是影响其致密度和压缩性能的关键参数.Choy等[20 ] 优化激光功率和扫描速度,用SLM技术制备出致密度高达99.9%的Ti-6Al-4V零件. ...

An overview of additive manufacturing technologies—a review to technical synthesis in numerical study of selective laser melting

1

2020

... 选区激光熔化(Selective Laser Melting,SLM)是一种先进的增材制造技术,可用于制造复杂形状的金属零件[11 ~13 ] .SLM使用的原材料是小粒径金属粉末,在激光熔化过程中能均匀熔化和固化.激光束聚焦到特定位置的金属粉末,使其瞬间熔化形成一个极小的熔池.一层金属粉末熔化和固化后,建造台下降一个微小的距离为下一层金属粉末提供空间.这个过程不断重复,直到制备出整个零件.SLM技术的优势有:可制造复杂几何形状的零件、材料利用率高、制造效率高[14 ] .调节激光功率和扫描速度等SLM工艺参数,可改变零件的致密度等性能[15 ,16 ] .Zhou等[17 ] 使用CT分析了用不同工艺参数制造的样品中缺陷的尺寸、形态和空间分布.他们建立了一个将缺陷体积分数与工艺参数相关联的数学模型,证明使用无损X射线CT技术可表征SLM零件中的缺陷并优化制造工艺.Gong等[18 ] 研究了激光和电子束选区熔化制备的Ti-6Al-4V零件中的缺陷对其力学性能的影响,发现缺陷使材料的强度和延伸率显著降低.Fousová等[19 ] 采用不同参数的SLM工艺制备了Ti-6Al-4V样品,发现激光功率和扫描速度是影响其致密度和压缩性能的关键参数.Choy等[20 ] 优化激光功率和扫描速度,用SLM技术制备出致密度高达99.9%的Ti-6Al-4V零件. ...

X-ray CT analysis of the influence of process on defect in Ti-6Al-4V parts produced with Selective Laser Melting technology

1

2020

... 选区激光熔化(Selective Laser Melting,SLM)是一种先进的增材制造技术,可用于制造复杂形状的金属零件[11 ~13 ] .SLM使用的原材料是小粒径金属粉末,在激光熔化过程中能均匀熔化和固化.激光束聚焦到特定位置的金属粉末,使其瞬间熔化形成一个极小的熔池.一层金属粉末熔化和固化后,建造台下降一个微小的距离为下一层金属粉末提供空间.这个过程不断重复,直到制备出整个零件.SLM技术的优势有:可制造复杂几何形状的零件、材料利用率高、制造效率高[14 ] .调节激光功率和扫描速度等SLM工艺参数,可改变零件的致密度等性能[15 ,16 ] .Zhou等[17 ] 使用CT分析了用不同工艺参数制造的样品中缺陷的尺寸、形态和空间分布.他们建立了一个将缺陷体积分数与工艺参数相关联的数学模型,证明使用无损X射线CT技术可表征SLM零件中的缺陷并优化制造工艺.Gong等[18 ] 研究了激光和电子束选区熔化制备的Ti-6Al-4V零件中的缺陷对其力学性能的影响,发现缺陷使材料的强度和延伸率显著降低.Fousová等[19 ] 采用不同参数的SLM工艺制备了Ti-6Al-4V样品,发现激光功率和扫描速度是影响其致密度和压缩性能的关键参数.Choy等[20 ] 优化激光功率和扫描速度,用SLM技术制备出致密度高达99.9%的Ti-6Al-4V零件. ...

Influence of defects on mechanical properties of Ti-6Al-4V components produced by selective laser melting and electron beam melting

1

2015

... 选区激光熔化(Selective Laser Melting,SLM)是一种先进的增材制造技术,可用于制造复杂形状的金属零件[11 ~13 ] .SLM使用的原材料是小粒径金属粉末,在激光熔化过程中能均匀熔化和固化.激光束聚焦到特定位置的金属粉末,使其瞬间熔化形成一个极小的熔池.一层金属粉末熔化和固化后,建造台下降一个微小的距离为下一层金属粉末提供空间.这个过程不断重复,直到制备出整个零件.SLM技术的优势有:可制造复杂几何形状的零件、材料利用率高、制造效率高[14 ] .调节激光功率和扫描速度等SLM工艺参数,可改变零件的致密度等性能[15 ,16 ] .Zhou等[17 ] 使用CT分析了用不同工艺参数制造的样品中缺陷的尺寸、形态和空间分布.他们建立了一个将缺陷体积分数与工艺参数相关联的数学模型,证明使用无损X射线CT技术可表征SLM零件中的缺陷并优化制造工艺.Gong等[18 ] 研究了激光和电子束选区熔化制备的Ti-6Al-4V零件中的缺陷对其力学性能的影响,发现缺陷使材料的强度和延伸率显著降低.Fousová等[19 ] 采用不同参数的SLM工艺制备了Ti-6Al-4V样品,发现激光功率和扫描速度是影响其致密度和压缩性能的关键参数.Choy等[20 ] 优化激光功率和扫描速度,用SLM技术制备出致密度高达99.9%的Ti-6Al-4V零件. ...

Promising characteristics of gradient porosity Ti-6Al-4V alloy prepared by SLM process

1

2017

... 选区激光熔化(Selective Laser Melting,SLM)是一种先进的增材制造技术,可用于制造复杂形状的金属零件[11 ~13 ] .SLM使用的原材料是小粒径金属粉末,在激光熔化过程中能均匀熔化和固化.激光束聚焦到特定位置的金属粉末,使其瞬间熔化形成一个极小的熔池.一层金属粉末熔化和固化后,建造台下降一个微小的距离为下一层金属粉末提供空间.这个过程不断重复,直到制备出整个零件.SLM技术的优势有:可制造复杂几何形状的零件、材料利用率高、制造效率高[14 ] .调节激光功率和扫描速度等SLM工艺参数,可改变零件的致密度等性能[15 ,16 ] .Zhou等[17 ] 使用CT分析了用不同工艺参数制造的样品中缺陷的尺寸、形态和空间分布.他们建立了一个将缺陷体积分数与工艺参数相关联的数学模型,证明使用无损X射线CT技术可表征SLM零件中的缺陷并优化制造工艺.Gong等[18 ] 研究了激光和电子束选区熔化制备的Ti-6Al-4V零件中的缺陷对其力学性能的影响,发现缺陷使材料的强度和延伸率显著降低.Fousová等[19 ] 采用不同参数的SLM工艺制备了Ti-6Al-4V样品,发现激光功率和扫描速度是影响其致密度和压缩性能的关键参数.Choy等[20 ] 优化激光功率和扫描速度,用SLM技术制备出致密度高达99.9%的Ti-6Al-4V零件. ...

Compressive properties of Ti-6Al-4V lattice structures fabricated by selective laser melting: Design, orientation and density

1

2017

... 选区激光熔化(Selective Laser Melting,SLM)是一种先进的增材制造技术,可用于制造复杂形状的金属零件[11 ~13 ] .SLM使用的原材料是小粒径金属粉末,在激光熔化过程中能均匀熔化和固化.激光束聚焦到特定位置的金属粉末,使其瞬间熔化形成一个极小的熔池.一层金属粉末熔化和固化后,建造台下降一个微小的距离为下一层金属粉末提供空间.这个过程不断重复,直到制备出整个零件.SLM技术的优势有:可制造复杂几何形状的零件、材料利用率高、制造效率高[14 ] .调节激光功率和扫描速度等SLM工艺参数,可改变零件的致密度等性能[15 ,16 ] .Zhou等[17 ] 使用CT分析了用不同工艺参数制造的样品中缺陷的尺寸、形态和空间分布.他们建立了一个将缺陷体积分数与工艺参数相关联的数学模型,证明使用无损X射线CT技术可表征SLM零件中的缺陷并优化制造工艺.Gong等[18 ] 研究了激光和电子束选区熔化制备的Ti-6Al-4V零件中的缺陷对其力学性能的影响,发现缺陷使材料的强度和延伸率显著降低.Fousová等[19 ] 采用不同参数的SLM工艺制备了Ti-6Al-4V样品,发现激光功率和扫描速度是影响其致密度和压缩性能的关键参数.Choy等[20 ] 优化激光功率和扫描速度,用SLM技术制备出致密度高达99.9%的Ti-6Al-4V零件. ...

Study of pore defect and mechanical properties in selective laser melted Ti6Al4V alloy based on X-ray computed tomography

1

2020

... 图10 给出了不同激光打印参数Ti5553的屈服强度及其与能量密度的关系.可以看出,在功率相同的条件下,随着扫描速度的提高屈服强度随之降低.其原因是,样品中的缺陷对力学性能产生了较大的影响.样品中的缺陷越多、缺陷的尺寸越大,则样品的屈服强度越低[21 ] .激光功率同为100 W,B2样品的屈服强度最高(852 MPa),比致密度较高的样品B1高.同样地,功率同为120 W的样品C2和C1也出现了相同的情况.随着能量密度的提高Ti5553样品的屈服强度随之提高,这种趋势在能量密度较低时尤为显著.能量密度高于约166.67 J/mm3 的样品,屈服强度趋于平稳. ...

On the limitations of volumetric energy density as a design parameter for selective laser melting

1

2017

... 式中E 为能量密度(J/mm3 );P 为激光功率(W);V 为单位时间内扫过的粉体体积(mm3 );v 为扫描速度(mm/s);h 为粉层厚度(mm);d 为扫描间距(mm).用金相法测试致密度的结果表明,激光功率为110 W、扫描速度为300 mm/s的样品致密度最高.能量密度为203.7 J/mm3 制备的样品,其致密度为99.99%.能量密度的提高使样品的致密度提高,但是过高的能量密度使金属发生气化,产生的匙孔使致密度降低.实验结果表明,在能量密度相同的条件下,其它工艺参数不同也使致密度不同.其原因是,在能量密度足够高的条件下,提高激光功率和扫描速度也可能使轨迹从连续状态转变为不规则和球化状态,从而影响构件的致密度[22 ] .因此,只依据能量密度确定的最优参数,是不准确的.从图7a 和图8c 可以看出,扫描速度和激光功率都较高的样品,其中缺陷的体积较大.激光功率和扫描速度较低的样品,其中的缺陷体积较小.这表明,即使能量密度接近,降低激光功率和扫描速度也能减小缺陷的体积.需要指出的是,本文关注激光功率和扫描速度对样品的组织和力学性能的影响,因此使用了一种层厚.层厚不同也显著影响构件的缺陷和组织[23 ] .这表明,调节层厚也是优化SLM制备的Ti5553构件的致密度和力学性能的有效手段. ...

Effect of high layer thickness on surface quality and defect behavior of Ti-6Al-4V fabricated by selective laser melting

1

2020

... 式中E 为能量密度(J/mm3 );P 为激光功率(W);V 为单位时间内扫过的粉体体积(mm3 );v 为扫描速度(mm/s);h 为粉层厚度(mm);d 为扫描间距(mm).用金相法测试致密度的结果表明,激光功率为110 W、扫描速度为300 mm/s的样品致密度最高.能量密度为203.7 J/mm3 制备的样品,其致密度为99.99%.能量密度的提高使样品的致密度提高,但是过高的能量密度使金属发生气化,产生的匙孔使致密度降低.实验结果表明,在能量密度相同的条件下,其它工艺参数不同也使致密度不同.其原因是,在能量密度足够高的条件下,提高激光功率和扫描速度也可能使轨迹从连续状态转变为不规则和球化状态,从而影响构件的致密度[22 ] .因此,只依据能量密度确定的最优参数,是不准确的.从图7a 和图8c 可以看出,扫描速度和激光功率都较高的样品,其中缺陷的体积较大.激光功率和扫描速度较低的样品,其中的缺陷体积较小.这表明,即使能量密度接近,降低激光功率和扫描速度也能减小缺陷的体积.需要指出的是,本文关注激光功率和扫描速度对样品的组织和力学性能的影响,因此使用了一种层厚.层厚不同也显著影响构件的缺陷和组织[23 ] .这表明,调节层厚也是优化SLM制备的Ti5553构件的致密度和力学性能的有效手段. ...

Effect of energy density on the defects, microstructure, and mechanical properties of selective-laser-melted 24CrNiMo low-alloy steel

1

2022

... 用金相法和Archimedes法测出的致密度有一定的误差.用Archimedes法测量致密度,样品的体积越小误差越大.样品中缺陷的体积分数和数量也影响其压缩性能.样品的缺陷越少、体积越小,其压缩性能越高,尤其是致密度不高于99%时.致密度高于99%的样品(图5 ),B1的致密度为99.93%,屈服强度为843.5 MPa,B2的致密度为99.62%,屈服强度为852 MPa.B2的致密度低于B1,但是其屈服强度却高于B1.致密度高于99%的样品,缺陷对力学性能的影响较小.在功率相同的条件下,扫描速度越高熔池的冷却越快,只能生成较小的晶粒,其屈服强度就比较高[24 ] .同时,能量密度较低的样品具有混合的柱状和细晶粒结构,因为熔池的重叠不足以打破柱状晶粒结构.能量密度更高的样品呈现出等轴晶粒形貌,因为其熔池足够大且重叠,整个区域熔融生成了等轴晶粒[25 ] .与柱状晶样品相比,这些等轴晶样品具有各向同性并具有更好的塑性变形能力,因此其压缩性能更优. ...

Strategy for texture management in metals additive manufacturing

1

2017

... 用金相法和Archimedes法测出的致密度有一定的误差.用Archimedes法测量致密度,样品的体积越小误差越大.样品中缺陷的体积分数和数量也影响其压缩性能.样品的缺陷越少、体积越小,其压缩性能越高,尤其是致密度不高于99%时.致密度高于99%的样品(图5 ),B1的致密度为99.93%,屈服强度为843.5 MPa,B2的致密度为99.62%,屈服强度为852 MPa.B2的致密度低于B1,但是其屈服强度却高于B1.致密度高于99%的样品,缺陷对力学性能的影响较小.在功率相同的条件下,扫描速度越高熔池的冷却越快,只能生成较小的晶粒,其屈服强度就比较高[24 ] .同时,能量密度较低的样品具有混合的柱状和细晶粒结构,因为熔池的重叠不足以打破柱状晶粒结构.能量密度更高的样品呈现出等轴晶粒形貌,因为其熔池足够大且重叠,整个区域熔融生成了等轴晶粒[25 ] .与柱状晶样品相比,这些等轴晶样品具有各向同性并具有更好的塑性变形能力,因此其压缩性能更优. ...