Improved ferroelectric, piezoelectric, and dielectric properties in pure KNN translucent ceramics by optimizing the normal sintering method

1

2022

... 各种高科技产品的研制,需要性能优异的无铅压电陶瓷材料.铌酸钾钠(KNN)基陶瓷材料,具有优异的综合性能[1].在A/B位引入Li/Ta或将第二组元引入(Bi0.5Na0.5)ZrO3和铪酸盐等钙钛矿结构,可提高KNN基陶瓷的电性能[2,3].2020年Zhao等[2]构建体系0.96(K0.48Na0.52-x Li x )NbO3-0.04Bi0.5Na0.5ZrO3得到O-T多晶相界,陶瓷的性能分别提高到d33 = 252 pC/N,TC = 382 ℃.2020年Batra等[4]制备的0.95(K0.6Na0.4)NbO3-0.05(Bi0.5Na0.5)ZrO3压电陶瓷得到R-T相界,其d33 = 340 pC/N,Pr = 19.58 μC/cm2.2022年He等[5]引入第二组元(Bi0.5-x Fe x Ag0.03Na0.47)ZrO3,使用传统固相法构建了高性能陶瓷材料体系,实现了R-O-T三相共存,其值为kp = 0.56,d33 = 464 pC/N,TC = 240 ℃.这些研究中的高性能KNN基陶瓷有一个共同特征,即构建了R-T、O-T、R-O-T多晶型共存相界,材料系统中较低的自由能垒使其电性能提高.这表明,构建多晶型共存相界可提高KNN基陶瓷的综合电性能.有研究表明,Li+能降低O-T相变温度实现室温附近的多相共存状态[6,7].鉴于此,本文制备(1-x)K0.5Na0.5(Nb0.95Ta0.05)O3-x(Bi0.5Yb0.5)0.95Li0.05ZrO3陶瓷(x分别为0.0,0.02,0.03,0.04和0.05),研究其结构和性能并揭示其机制. ...

Phase structure regulation and enhanced piezoelectric properties of Li-doped KNN-based ceramics

3

2020

... 各种高科技产品的研制,需要性能优异的无铅压电陶瓷材料.铌酸钾钠(KNN)基陶瓷材料,具有优异的综合性能[1].在A/B位引入Li/Ta或将第二组元引入(Bi0.5Na0.5)ZrO3和铪酸盐等钙钛矿结构,可提高KNN基陶瓷的电性能[2,3].2020年Zhao等[2]构建体系0.96(K0.48Na0.52-x Li x )NbO3-0.04Bi0.5Na0.5ZrO3得到O-T多晶相界,陶瓷的性能分别提高到d33 = 252 pC/N,TC = 382 ℃.2020年Batra等[4]制备的0.95(K0.6Na0.4)NbO3-0.05(Bi0.5Na0.5)ZrO3压电陶瓷得到R-T相界,其d33 = 340 pC/N,Pr = 19.58 μC/cm2.2022年He等[5]引入第二组元(Bi0.5-x Fe x Ag0.03Na0.47)ZrO3,使用传统固相法构建了高性能陶瓷材料体系,实现了R-O-T三相共存,其值为kp = 0.56,d33 = 464 pC/N,TC = 240 ℃.这些研究中的高性能KNN基陶瓷有一个共同特征,即构建了R-T、O-T、R-O-T多晶型共存相界,材料系统中较低的自由能垒使其电性能提高.这表明,构建多晶型共存相界可提高KNN基陶瓷的综合电性能.有研究表明,Li+能降低O-T相变温度实现室温附近的多相共存状态[6,7].鉴于此,本文制备(1-x)K0.5Na0.5(Nb0.95Ta0.05)O3-x(Bi0.5Yb0.5)0.95Li0.05ZrO3陶瓷(x分别为0.0,0.02,0.03,0.04和0.05),研究其结构和性能并揭示其机制. ...

... [2]构建体系0.96(K0.48Na0.52-x Li x )NbO3-0.04Bi0.5Na0.5ZrO3得到O-T多晶相界,陶瓷的性能分别提高到d33 = 252 pC/N,TC = 382 ℃.2020年Batra等[4]制备的0.95(K0.6Na0.4)NbO3-0.05(Bi0.5Na0.5)ZrO3压电陶瓷得到R-T相界,其d33 = 340 pC/N,Pr = 19.58 μC/cm2.2022年He等[5]引入第二组元(Bi0.5-x Fe x Ag0.03Na0.47)ZrO3,使用传统固相法构建了高性能陶瓷材料体系,实现了R-O-T三相共存,其值为kp = 0.56,d33 = 464 pC/N,TC = 240 ℃.这些研究中的高性能KNN基陶瓷有一个共同特征,即构建了R-T、O-T、R-O-T多晶型共存相界,材料系统中较低的自由能垒使其电性能提高.这表明,构建多晶型共存相界可提高KNN基陶瓷的综合电性能.有研究表明,Li+能降低O-T相变温度实现室温附近的多相共存状态[6,7].鉴于此,本文制备(1-x)K0.5Na0.5(Nb0.95Ta0.05)O3-x(Bi0.5Yb0.5)0.95Li0.05ZrO3陶瓷(x分别为0.0,0.02,0.03,0.04和0.05),研究其结构和性能并揭示其机制. ...

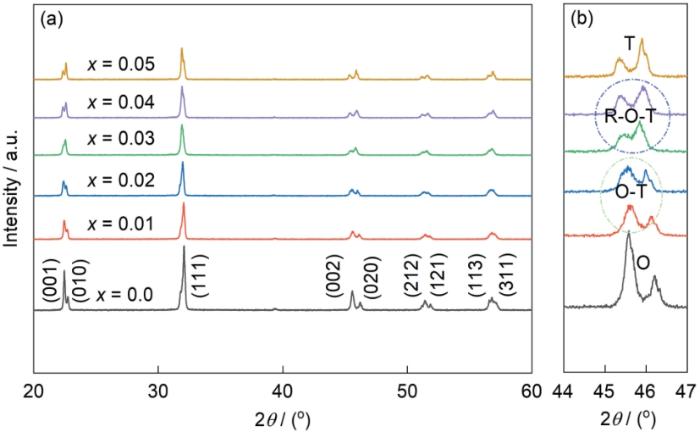

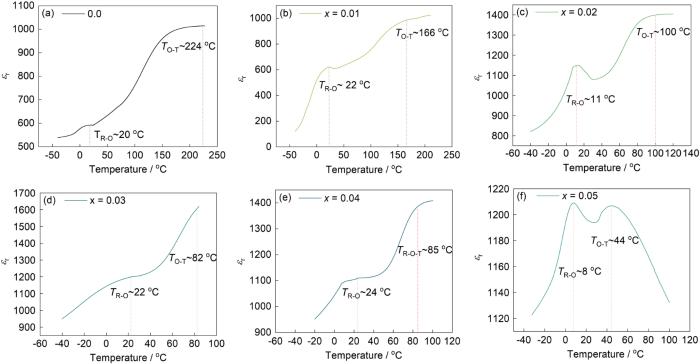

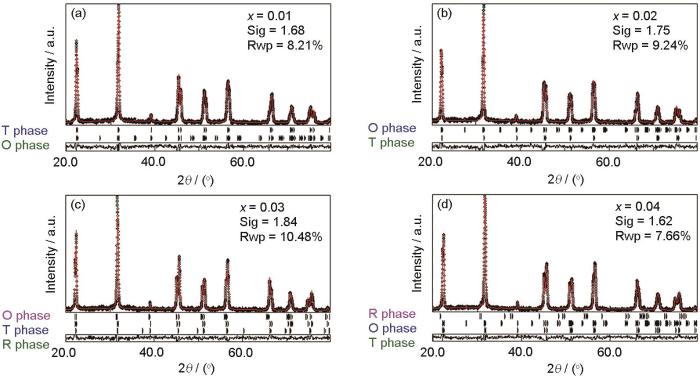

... 图1给出了(1-x)KNNT-xBYLZ陶瓷的室温XRD谱.从图1a可见,所有陶瓷样品均为单一的钙钛矿结构,表明BYLZ已经完全进入KNNT陶瓷晶格中.其原因是,Bi3+(R = 0.145 nm)、Yb3+(R = 0.0868 nm)、Li+(R = 0.125 nm)、Zr4+(R = 0.072 nm)与KNNT中离子的离子半径相似,易在常温常压下生成单一相的固溶体[8].图1b给出了(1-x)KNNT-xBYLZ陶瓷的XRD谱中44°~47°部分的放大图.可以看出,随着掺杂量的增加,44°~47°的峰型发生了变化.在x = 0.0陶瓷的谱中I(002)/I(020)处的衍射峰比值为2∶1,表明陶瓷为正交相(O)[7].在0.0 < x ≤ 0.02陶瓷的谱中I(002)/I(020)峰比值接近1∶1,表明由于掺入了BYLZ,陶瓷已经不是单一的O相.图2给出了陶瓷的低温介电常数(εr),在图2b和c中标出了R-O相变峰和O-T相变峰的温度区间.由此可以判断,陶瓷中正交-四方(O-T)两相共存.根据第一性原理,Li掺杂可能大幅度提高了A位离子p轨道与O 2p轨道的杂化.与PbTiO3的生成原因类似,Pb与O的轨道杂化诱导了四方相的生成[9~11].在0.2 < x ≤ 0.04陶瓷的谱中,I(002)/I(020)峰比值进一步减小,说明此时陶瓷中存在R相.由图2d和e可见,O-T相变峰和R-O相变峰同时向室温靠近.由此可以判断0.2 < x ≤ 0.04陶瓷是R-O-T相,因为R相完全由B位驱动.B位阳离子的无序、简单的原子间作用以及较大的Zr4+倾向于产生负的压力,有利于生成低温相结构[12].同时,Li+间较弱的耦合使NbO6的振动较为剧烈,降低了O-T相变温度而使之更容易发生[13].在0.04 < x ≤ 0.05陶瓷的谱中,I(002)/I(020)峰比值约为1∶2,表明陶瓷为T相(图2f).图2f中R-O相变峰远离室温,O-T相变峰温度向室温附近移动.其原因是,随着掺杂量的进一步增加A位离子Bi3+、Yb3+、Li+的参与使八面体倾斜,而Zr4+与O2-较强的杂化则只使T相生成;另一方面,Li等元素的掺杂将O-T相的相变峰调控至室温.但是,随着温度的升高,多晶型相界(PPB)的温度敏感性使陶瓷从R-O-T相向T相转变[2,14].图3给出的x = 0.01、0.02、0.03和0.04陶瓷的室温Rietveld拟合谱,进一步佐证了介电温谱的结果.表1列出了多相共存陶瓷的晶体结构参数.可以看出,随着掺杂量的增加T相的占比随之提高和c/a值逐渐增大,使晶格发生畸变. ...

Comparison of contribution to phase boundary from A-site aliovalent dopants in high-performance KNN-based ceramics

1

2022

... 各种高科技产品的研制,需要性能优异的无铅压电陶瓷材料.铌酸钾钠(KNN)基陶瓷材料,具有优异的综合性能[1].在A/B位引入Li/Ta或将第二组元引入(Bi0.5Na0.5)ZrO3和铪酸盐等钙钛矿结构,可提高KNN基陶瓷的电性能[2,3].2020年Zhao等[2]构建体系0.96(K0.48Na0.52-x Li x )NbO3-0.04Bi0.5Na0.5ZrO3得到O-T多晶相界,陶瓷的性能分别提高到d33 = 252 pC/N,TC = 382 ℃.2020年Batra等[4]制备的0.95(K0.6Na0.4)NbO3-0.05(Bi0.5Na0.5)ZrO3压电陶瓷得到R-T相界,其d33 = 340 pC/N,Pr = 19.58 μC/cm2.2022年He等[5]引入第二组元(Bi0.5-x Fe x Ag0.03Na0.47)ZrO3,使用传统固相法构建了高性能陶瓷材料体系,实现了R-O-T三相共存,其值为kp = 0.56,d33 = 464 pC/N,TC = 240 ℃.这些研究中的高性能KNN基陶瓷有一个共同特征,即构建了R-T、O-T、R-O-T多晶型共存相界,材料系统中较低的自由能垒使其电性能提高.这表明,构建多晶型共存相界可提高KNN基陶瓷的综合电性能.有研究表明,Li+能降低O-T相变温度实现室温附近的多相共存状态[6,7].鉴于此,本文制备(1-x)K0.5Na0.5(Nb0.95Ta0.05)O3-x(Bi0.5Yb0.5)0.95Li0.05ZrO3陶瓷(x分别为0.0,0.02,0.03,0.04和0.05),研究其结构和性能并揭示其机制. ...

Lead-free 0.95(K0.6Na0.4)NbO3-0.05(Bi0.5-Na0.5)ZrO3 ceramic for high temperature dielectric, ferroelectric and piezoelectric applications

2

2020

... 各种高科技产品的研制,需要性能优异的无铅压电陶瓷材料.铌酸钾钠(KNN)基陶瓷材料,具有优异的综合性能[1].在A/B位引入Li/Ta或将第二组元引入(Bi0.5Na0.5)ZrO3和铪酸盐等钙钛矿结构,可提高KNN基陶瓷的电性能[2,3].2020年Zhao等[2]构建体系0.96(K0.48Na0.52-x Li x )NbO3-0.04Bi0.5Na0.5ZrO3得到O-T多晶相界,陶瓷的性能分别提高到d33 = 252 pC/N,TC = 382 ℃.2020年Batra等[4]制备的0.95(K0.6Na0.4)NbO3-0.05(Bi0.5Na0.5)ZrO3压电陶瓷得到R-T相界,其d33 = 340 pC/N,Pr = 19.58 μC/cm2.2022年He等[5]引入第二组元(Bi0.5-x Fe x Ag0.03Na0.47)ZrO3,使用传统固相法构建了高性能陶瓷材料体系,实现了R-O-T三相共存,其值为kp = 0.56,d33 = 464 pC/N,TC = 240 ℃.这些研究中的高性能KNN基陶瓷有一个共同特征,即构建了R-T、O-T、R-O-T多晶型共存相界,材料系统中较低的自由能垒使其电性能提高.这表明,构建多晶型共存相界可提高KNN基陶瓷的综合电性能.有研究表明,Li+能降低O-T相变温度实现室温附近的多相共存状态[6,7].鉴于此,本文制备(1-x)K0.5Na0.5(Nb0.95Ta0.05)O3-x(Bi0.5Yb0.5)0.95Li0.05ZrO3陶瓷(x分别为0.0,0.02,0.03,0.04和0.05),研究其结构和性能并揭示其机制. ...

... Comparison of the experimental data with the electrical properties of other KNN-based piezoelectric ceramics

Table 2| Material | d33pC/N | ECkV·cm-1 | PrμC·cm-2 | εr | TCoC | Reference |

|---|

| 0.95(Na0.5K0.5)NbO3-0.05SrTiO3 | 130 | 14.2 | 13.8 | 1352 | 308 | [25] |

| 0.95(K0.6Na0.4)NbO3-0.05(Bi0.5Na0.5)ZrO3 | 340 | | 19.58 | | | [4] |

| 0.97(K0.5Na0.5)0.98-Ag0.02(Nb0.96Sb0.04)O3-0.03(Bi0.5Na0.5)ZrO3 | 550 | | | | 250 | [41] |

| 0.96K0.5Na0.5NbO3-0.04CaSnO3 | 430 | | | 32168 | 297 | [42] |

| 0.865(K0.5Na0.5)0.98Ag0.02Nb0.96Ta0.04O3-0.035CuO-0.01Na2O | 343 | 19.2 | 24.9 | 1382 | 306 | [43] |

| 0.96(K0.5Na0.5)NbO3-0.04[NaSbO3 +Bi0.5(Na0.8K0.2)0.5(Zr0.5Hf0.5)O3] | 452 | | | 4414 | | [44] |

| 0.96K0.5Na0.5(Nb0.95Ta0.05)O3-0.04(Bi0.5Yb0.5)0.95Li0.05 ZrO3 | 305 | 20.67 | 34.63 | 1710 | 340 | This work |

<strong>3</strong> 结论(1) 用传统固相法可制备具有R-O-T多相共存的(1-x)K0.5Na0.5(Nb0.95Ta0.05)O3-x(Bi0.5Yb0.5)0.95Li0.05ZrO3陶瓷.随着BYLZ含量的提高A、B位的离子半径和电荷的不同使晶格显著失配,空位(缺陷)上的局域化电子和空穴对铁电畴壁的钉扎降低了畴壁的可动性,使其铁电性提高. ...

Softening effect of trace Fe-substituted potassium-sodium niobate-based lead-free piezoceramics

1

2022

... 各种高科技产品的研制,需要性能优异的无铅压电陶瓷材料.铌酸钾钠(KNN)基陶瓷材料,具有优异的综合性能[1].在A/B位引入Li/Ta或将第二组元引入(Bi0.5Na0.5)ZrO3和铪酸盐等钙钛矿结构,可提高KNN基陶瓷的电性能[2,3].2020年Zhao等[2]构建体系0.96(K0.48Na0.52-x Li x )NbO3-0.04Bi0.5Na0.5ZrO3得到O-T多晶相界,陶瓷的性能分别提高到d33 = 252 pC/N,TC = 382 ℃.2020年Batra等[4]制备的0.95(K0.6Na0.4)NbO3-0.05(Bi0.5Na0.5)ZrO3压电陶瓷得到R-T相界,其d33 = 340 pC/N,Pr = 19.58 μC/cm2.2022年He等[5]引入第二组元(Bi0.5-x Fe x Ag0.03Na0.47)ZrO3,使用传统固相法构建了高性能陶瓷材料体系,实现了R-O-T三相共存,其值为kp = 0.56,d33 = 464 pC/N,TC = 240 ℃.这些研究中的高性能KNN基陶瓷有一个共同特征,即构建了R-T、O-T、R-O-T多晶型共存相界,材料系统中较低的自由能垒使其电性能提高.这表明,构建多晶型共存相界可提高KNN基陶瓷的综合电性能.有研究表明,Li+能降低O-T相变温度实现室温附近的多相共存状态[6,7].鉴于此,本文制备(1-x)K0.5Na0.5(Nb0.95Ta0.05)O3-x(Bi0.5Yb0.5)0.95Li0.05ZrO3陶瓷(x分别为0.0,0.02,0.03,0.04和0.05),研究其结构和性能并揭示其机制. ...

Deciphering the role of A-site ions of AZrO3-type dopants in (K, Na)NbO3 ceramics

2

2023

... 各种高科技产品的研制,需要性能优异的无铅压电陶瓷材料.铌酸钾钠(KNN)基陶瓷材料,具有优异的综合性能[1].在A/B位引入Li/Ta或将第二组元引入(Bi0.5Na0.5)ZrO3和铪酸盐等钙钛矿结构,可提高KNN基陶瓷的电性能[2,3].2020年Zhao等[2]构建体系0.96(K0.48Na0.52-x Li x )NbO3-0.04Bi0.5Na0.5ZrO3得到O-T多晶相界,陶瓷的性能分别提高到d33 = 252 pC/N,TC = 382 ℃.2020年Batra等[4]制备的0.95(K0.6Na0.4)NbO3-0.05(Bi0.5Na0.5)ZrO3压电陶瓷得到R-T相界,其d33 = 340 pC/N,Pr = 19.58 μC/cm2.2022年He等[5]引入第二组元(Bi0.5-x Fe x Ag0.03Na0.47)ZrO3,使用传统固相法构建了高性能陶瓷材料体系,实现了R-O-T三相共存,其值为kp = 0.56,d33 = 464 pC/N,TC = 240 ℃.这些研究中的高性能KNN基陶瓷有一个共同特征,即构建了R-T、O-T、R-O-T多晶型共存相界,材料系统中较低的自由能垒使其电性能提高.这表明,构建多晶型共存相界可提高KNN基陶瓷的综合电性能.有研究表明,Li+能降低O-T相变温度实现室温附近的多相共存状态[6,7].鉴于此,本文制备(1-x)K0.5Na0.5(Nb0.95Ta0.05)O3-x(Bi0.5Yb0.5)0.95Li0.05ZrO3陶瓷(x分别为0.0,0.02,0.03,0.04和0.05),研究其结构和性能并揭示其机制. ...

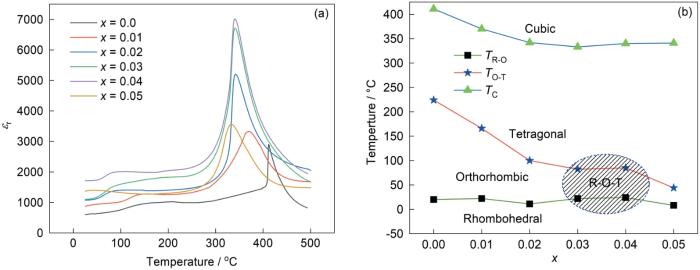

... 图8给出了陶瓷的介电温谱曲线和相图.由图8a可见,随着掺杂量的增加陶瓷的居里峰逐渐变宽,表明发生了弥散行为[24, 25].从图8b可见,随着掺杂量的增加居里温度TC稍有降低,是Ta5+和Li+共同作用的结果[26].Ta5+取代使局域结构发生了比Nb5+更小的离子位移,尽管键长比Ta更小但是Nb比Ta小的力常数使Ta掺杂后的KNNT陶瓷的TC降低.但是,Li+的A位取代使TC提高,两种作用的结果使陶瓷的TC值略有降低[9].同时,从图8b可见,0.0 ≤ x ≤ 0.05陶瓷的TO-T值随着掺杂量的增加逐渐降低.其主要原因是,在KNNT基陶瓷中添加适量的Bi0.5(Na/K/Li)0.5等钙钛矿结构化合物或Ta5+/Li+,使陶瓷中T相比例提高,把TO-T调节到室温附近[27, 28].而TR-O在室温附近的小幅度提高,可归因于Bi3+添加剂的引入,Bi3+ 6s和O2- 2p轨道的杂化产生的离子性促进了KNNT基陶瓷出现R态 [29,30].Yb3+和Li+的电负性比Bi3+低,Bi3+被取代后Yb3+和Li+与O之间的相互作用提高了A-O的离子性,有利于增强陶瓷中的R相的稳定.因此,随着掺杂量的增加,TR-O呈现出如图所示的变化趋势[6,31]. ...

The effect of (Bi0.5Li0.5)0.9-Sr0.1ZrO3 substitution on the construction of polymorphic phase boundary and high curie temperature of K0.45Na0.55NbO3 piezoelectric ceramics

2

2023

... 各种高科技产品的研制,需要性能优异的无铅压电陶瓷材料.铌酸钾钠(KNN)基陶瓷材料,具有优异的综合性能[1].在A/B位引入Li/Ta或将第二组元引入(Bi0.5Na0.5)ZrO3和铪酸盐等钙钛矿结构,可提高KNN基陶瓷的电性能[2,3].2020年Zhao等[2]构建体系0.96(K0.48Na0.52-x Li x )NbO3-0.04Bi0.5Na0.5ZrO3得到O-T多晶相界,陶瓷的性能分别提高到d33 = 252 pC/N,TC = 382 ℃.2020年Batra等[4]制备的0.95(K0.6Na0.4)NbO3-0.05(Bi0.5Na0.5)ZrO3压电陶瓷得到R-T相界,其d33 = 340 pC/N,Pr = 19.58 μC/cm2.2022年He等[5]引入第二组元(Bi0.5-x Fe x Ag0.03Na0.47)ZrO3,使用传统固相法构建了高性能陶瓷材料体系,实现了R-O-T三相共存,其值为kp = 0.56,d33 = 464 pC/N,TC = 240 ℃.这些研究中的高性能KNN基陶瓷有一个共同特征,即构建了R-T、O-T、R-O-T多晶型共存相界,材料系统中较低的自由能垒使其电性能提高.这表明,构建多晶型共存相界可提高KNN基陶瓷的综合电性能.有研究表明,Li+能降低O-T相变温度实现室温附近的多相共存状态[6,7].鉴于此,本文制备(1-x)K0.5Na0.5(Nb0.95Ta0.05)O3-x(Bi0.5Yb0.5)0.95Li0.05ZrO3陶瓷(x分别为0.0,0.02,0.03,0.04和0.05),研究其结构和性能并揭示其机制. ...

... 图1给出了(1-x)KNNT-xBYLZ陶瓷的室温XRD谱.从图1a可见,所有陶瓷样品均为单一的钙钛矿结构,表明BYLZ已经完全进入KNNT陶瓷晶格中.其原因是,Bi3+(R = 0.145 nm)、Yb3+(R = 0.0868 nm)、Li+(R = 0.125 nm)、Zr4+(R = 0.072 nm)与KNNT中离子的离子半径相似,易在常温常压下生成单一相的固溶体[8].图1b给出了(1-x)KNNT-xBYLZ陶瓷的XRD谱中44°~47°部分的放大图.可以看出,随着掺杂量的增加,44°~47°的峰型发生了变化.在x = 0.0陶瓷的谱中I(002)/I(020)处的衍射峰比值为2∶1,表明陶瓷为正交相(O)[7].在0.0 < x ≤ 0.02陶瓷的谱中I(002)/I(020)峰比值接近1∶1,表明由于掺入了BYLZ,陶瓷已经不是单一的O相.图2给出了陶瓷的低温介电常数(εr),在图2b和c中标出了R-O相变峰和O-T相变峰的温度区间.由此可以判断,陶瓷中正交-四方(O-T)两相共存.根据第一性原理,Li掺杂可能大幅度提高了A位离子p轨道与O 2p轨道的杂化.与PbTiO3的生成原因类似,Pb与O的轨道杂化诱导了四方相的生成[9~11].在0.2 < x ≤ 0.04陶瓷的谱中,I(002)/I(020)峰比值进一步减小,说明此时陶瓷中存在R相.由图2d和e可见,O-T相变峰和R-O相变峰同时向室温靠近.由此可以判断0.2 < x ≤ 0.04陶瓷是R-O-T相,因为R相完全由B位驱动.B位阳离子的无序、简单的原子间作用以及较大的Zr4+倾向于产生负的压力,有利于生成低温相结构[12].同时,Li+间较弱的耦合使NbO6的振动较为剧烈,降低了O-T相变温度而使之更容易发生[13].在0.04 < x ≤ 0.05陶瓷的谱中,I(002)/I(020)峰比值约为1∶2,表明陶瓷为T相(图2f).图2f中R-O相变峰远离室温,O-T相变峰温度向室温附近移动.其原因是,随着掺杂量的进一步增加A位离子Bi3+、Yb3+、Li+的参与使八面体倾斜,而Zr4+与O2-较强的杂化则只使T相生成;另一方面,Li等元素的掺杂将O-T相的相变峰调控至室温.但是,随着温度的升高,多晶型相界(PPB)的温度敏感性使陶瓷从R-O-T相向T相转变[2,14].图3给出的x = 0.01、0.02、0.03和0.04陶瓷的室温Rietveld拟合谱,进一步佐证了介电温谱的结果.表1列出了多相共存陶瓷的晶体结构参数.可以看出,随着掺杂量的增加T相的占比随之提高和c/a值逐渐增大,使晶格发生畸变. ...

Tolerance factor effect on the structure and properties of KNN based ceramics at orthorhombic–tetragonal phase boundary

1

2017

... 图1给出了(1-x)KNNT-xBYLZ陶瓷的室温XRD谱.从图1a可见,所有陶瓷样品均为单一的钙钛矿结构,表明BYLZ已经完全进入KNNT陶瓷晶格中.其原因是,Bi3+(R = 0.145 nm)、Yb3+(R = 0.0868 nm)、Li+(R = 0.125 nm)、Zr4+(R = 0.072 nm)与KNNT中离子的离子半径相似,易在常温常压下生成单一相的固溶体[8].图1b给出了(1-x)KNNT-xBYLZ陶瓷的XRD谱中44°~47°部分的放大图.可以看出,随着掺杂量的增加,44°~47°的峰型发生了变化.在x = 0.0陶瓷的谱中I(002)/I(020)处的衍射峰比值为2∶1,表明陶瓷为正交相(O)[7].在0.0 < x ≤ 0.02陶瓷的谱中I(002)/I(020)峰比值接近1∶1,表明由于掺入了BYLZ,陶瓷已经不是单一的O相.图2给出了陶瓷的低温介电常数(εr),在图2b和c中标出了R-O相变峰和O-T相变峰的温度区间.由此可以判断,陶瓷中正交-四方(O-T)两相共存.根据第一性原理,Li掺杂可能大幅度提高了A位离子p轨道与O 2p轨道的杂化.与PbTiO3的生成原因类似,Pb与O的轨道杂化诱导了四方相的生成[9~11].在0.2 < x ≤ 0.04陶瓷的谱中,I(002)/I(020)峰比值进一步减小,说明此时陶瓷中存在R相.由图2d和e可见,O-T相变峰和R-O相变峰同时向室温靠近.由此可以判断0.2 < x ≤ 0.04陶瓷是R-O-T相,因为R相完全由B位驱动.B位阳离子的无序、简单的原子间作用以及较大的Zr4+倾向于产生负的压力,有利于生成低温相结构[12].同时,Li+间较弱的耦合使NbO6的振动较为剧烈,降低了O-T相变温度而使之更容易发生[13].在0.04 < x ≤ 0.05陶瓷的谱中,I(002)/I(020)峰比值约为1∶2,表明陶瓷为T相(图2f).图2f中R-O相变峰远离室温,O-T相变峰温度向室温附近移动.其原因是,随着掺杂量的进一步增加A位离子Bi3+、Yb3+、Li+的参与使八面体倾斜,而Zr4+与O2-较强的杂化则只使T相生成;另一方面,Li等元素的掺杂将O-T相的相变峰调控至室温.但是,随着温度的升高,多晶型相界(PPB)的温度敏感性使陶瓷从R-O-T相向T相转变[2,14].图3给出的x = 0.01、0.02、0.03和0.04陶瓷的室温Rietveld拟合谱,进一步佐证了介电温谱的结果.表1列出了多相共存陶瓷的晶体结构参数.可以看出,随着掺杂量的增加T相的占比随之提高和c/a值逐渐增大,使晶格发生畸变. ...

Local dynamics and structure of pure and Ta substituted (K1- x Na x ) NbO3 from first principles calculations

2

2010

... 图1给出了(1-x)KNNT-xBYLZ陶瓷的室温XRD谱.从图1a可见,所有陶瓷样品均为单一的钙钛矿结构,表明BYLZ已经完全进入KNNT陶瓷晶格中.其原因是,Bi3+(R = 0.145 nm)、Yb3+(R = 0.0868 nm)、Li+(R = 0.125 nm)、Zr4+(R = 0.072 nm)与KNNT中离子的离子半径相似,易在常温常压下生成单一相的固溶体[8].图1b给出了(1-x)KNNT-xBYLZ陶瓷的XRD谱中44°~47°部分的放大图.可以看出,随着掺杂量的增加,44°~47°的峰型发生了变化.在x = 0.0陶瓷的谱中I(002)/I(020)处的衍射峰比值为2∶1,表明陶瓷为正交相(O)[7].在0.0 < x ≤ 0.02陶瓷的谱中I(002)/I(020)峰比值接近1∶1,表明由于掺入了BYLZ,陶瓷已经不是单一的O相.图2给出了陶瓷的低温介电常数(εr),在图2b和c中标出了R-O相变峰和O-T相变峰的温度区间.由此可以判断,陶瓷中正交-四方(O-T)两相共存.根据第一性原理,Li掺杂可能大幅度提高了A位离子p轨道与O 2p轨道的杂化.与PbTiO3的生成原因类似,Pb与O的轨道杂化诱导了四方相的生成[9~11].在0.2 < x ≤ 0.04陶瓷的谱中,I(002)/I(020)峰比值进一步减小,说明此时陶瓷中存在R相.由图2d和e可见,O-T相变峰和R-O相变峰同时向室温靠近.由此可以判断0.2 < x ≤ 0.04陶瓷是R-O-T相,因为R相完全由B位驱动.B位阳离子的无序、简单的原子间作用以及较大的Zr4+倾向于产生负的压力,有利于生成低温相结构[12].同时,Li+间较弱的耦合使NbO6的振动较为剧烈,降低了O-T相变温度而使之更容易发生[13].在0.04 < x ≤ 0.05陶瓷的谱中,I(002)/I(020)峰比值约为1∶2,表明陶瓷为T相(图2f).图2f中R-O相变峰远离室温,O-T相变峰温度向室温附近移动.其原因是,随着掺杂量的进一步增加A位离子Bi3+、Yb3+、Li+的参与使八面体倾斜,而Zr4+与O2-较强的杂化则只使T相生成;另一方面,Li等元素的掺杂将O-T相的相变峰调控至室温.但是,随着温度的升高,多晶型相界(PPB)的温度敏感性使陶瓷从R-O-T相向T相转变[2,14].图3给出的x = 0.01、0.02、0.03和0.04陶瓷的室温Rietveld拟合谱,进一步佐证了介电温谱的结果.表1列出了多相共存陶瓷的晶体结构参数.可以看出,随着掺杂量的增加T相的占比随之提高和c/a值逐渐增大,使晶格发生畸变. ...

... 图8给出了陶瓷的介电温谱曲线和相图.由图8a可见,随着掺杂量的增加陶瓷的居里峰逐渐变宽,表明发生了弥散行为[24, 25].从图8b可见,随着掺杂量的增加居里温度TC稍有降低,是Ta5+和Li+共同作用的结果[26].Ta5+取代使局域结构发生了比Nb5+更小的离子位移,尽管键长比Ta更小但是Nb比Ta小的力常数使Ta掺杂后的KNNT陶瓷的TC降低.但是,Li+的A位取代使TC提高,两种作用的结果使陶瓷的TC值略有降低[9].同时,从图8b可见,0.0 ≤ x ≤ 0.05陶瓷的TO-T值随着掺杂量的增加逐渐降低.其主要原因是,在KNNT基陶瓷中添加适量的Bi0.5(Na/K/Li)0.5等钙钛矿结构化合物或Ta5+/Li+,使陶瓷中T相比例提高,把TO-T调节到室温附近[27, 28].而TR-O在室温附近的小幅度提高,可归因于Bi3+添加剂的引入,Bi3+ 6s和O2- 2p轨道的杂化产生的离子性促进了KNNT基陶瓷出现R态 [29,30].Yb3+和Li+的电负性比Bi3+低,Bi3+被取代后Yb3+和Li+与O之间的相互作用提高了A-O的离子性,有利于增强陶瓷中的R相的稳定.因此,随着掺杂量的增加,TR-O呈现出如图所示的变化趋势[6,31]. ...

Diffused and successive phase transitions of (K, Na)NbO based ceramics with high strain and temperature insensitivity

0

2018

Research progress of high piezoelectric activity of potassium sodium niobate based lead-free ceramics

1

2020

... 图1给出了(1-x)KNNT-xBYLZ陶瓷的室温XRD谱.从图1a可见,所有陶瓷样品均为单一的钙钛矿结构,表明BYLZ已经完全进入KNNT陶瓷晶格中.其原因是,Bi3+(R = 0.145 nm)、Yb3+(R = 0.0868 nm)、Li+(R = 0.125 nm)、Zr4+(R = 0.072 nm)与KNNT中离子的离子半径相似,易在常温常压下生成单一相的固溶体[8].图1b给出了(1-x)KNNT-xBYLZ陶瓷的XRD谱中44°~47°部分的放大图.可以看出,随着掺杂量的增加,44°~47°的峰型发生了变化.在x = 0.0陶瓷的谱中I(002)/I(020)处的衍射峰比值为2∶1,表明陶瓷为正交相(O)[7].在0.0 < x ≤ 0.02陶瓷的谱中I(002)/I(020)峰比值接近1∶1,表明由于掺入了BYLZ,陶瓷已经不是单一的O相.图2给出了陶瓷的低温介电常数(εr),在图2b和c中标出了R-O相变峰和O-T相变峰的温度区间.由此可以判断,陶瓷中正交-四方(O-T)两相共存.根据第一性原理,Li掺杂可能大幅度提高了A位离子p轨道与O 2p轨道的杂化.与PbTiO3的生成原因类似,Pb与O的轨道杂化诱导了四方相的生成[9~11].在0.2 < x ≤ 0.04陶瓷的谱中,I(002)/I(020)峰比值进一步减小,说明此时陶瓷中存在R相.由图2d和e可见,O-T相变峰和R-O相变峰同时向室温靠近.由此可以判断0.2 < x ≤ 0.04陶瓷是R-O-T相,因为R相完全由B位驱动.B位阳离子的无序、简单的原子间作用以及较大的Zr4+倾向于产生负的压力,有利于生成低温相结构[12].同时,Li+间较弱的耦合使NbO6的振动较为剧烈,降低了O-T相变温度而使之更容易发生[13].在0.04 < x ≤ 0.05陶瓷的谱中,I(002)/I(020)峰比值约为1∶2,表明陶瓷为T相(图2f).图2f中R-O相变峰远离室温,O-T相变峰温度向室温附近移动.其原因是,随着掺杂量的进一步增加A位离子Bi3+、Yb3+、Li+的参与使八面体倾斜,而Zr4+与O2-较强的杂化则只使T相生成;另一方面,Li等元素的掺杂将O-T相的相变峰调控至室温.但是,随着温度的升高,多晶型相界(PPB)的温度敏感性使陶瓷从R-O-T相向T相转变[2,14].图3给出的x = 0.01、0.02、0.03和0.04陶瓷的室温Rietveld拟合谱,进一步佐证了介电温谱的结果.表1列出了多相共存陶瓷的晶体结构参数.可以看出,随着掺杂量的增加T相的占比随之提高和c/a值逐渐增大,使晶格发生畸变. ...

铌酸钾钠基无铅压电陶瓷的高压电活性研究进展

1

2020

... 图1给出了(1-x)KNNT-xBYLZ陶瓷的室温XRD谱.从图1a可见,所有陶瓷样品均为单一的钙钛矿结构,表明BYLZ已经完全进入KNNT陶瓷晶格中.其原因是,Bi3+(R = 0.145 nm)、Yb3+(R = 0.0868 nm)、Li+(R = 0.125 nm)、Zr4+(R = 0.072 nm)与KNNT中离子的离子半径相似,易在常温常压下生成单一相的固溶体[8].图1b给出了(1-x)KNNT-xBYLZ陶瓷的XRD谱中44°~47°部分的放大图.可以看出,随着掺杂量的增加,44°~47°的峰型发生了变化.在x = 0.0陶瓷的谱中I(002)/I(020)处的衍射峰比值为2∶1,表明陶瓷为正交相(O)[7].在0.0 < x ≤ 0.02陶瓷的谱中I(002)/I(020)峰比值接近1∶1,表明由于掺入了BYLZ,陶瓷已经不是单一的O相.图2给出了陶瓷的低温介电常数(εr),在图2b和c中标出了R-O相变峰和O-T相变峰的温度区间.由此可以判断,陶瓷中正交-四方(O-T)两相共存.根据第一性原理,Li掺杂可能大幅度提高了A位离子p轨道与O 2p轨道的杂化.与PbTiO3的生成原因类似,Pb与O的轨道杂化诱导了四方相的生成[9~11].在0.2 < x ≤ 0.04陶瓷的谱中,I(002)/I(020)峰比值进一步减小,说明此时陶瓷中存在R相.由图2d和e可见,O-T相变峰和R-O相变峰同时向室温靠近.由此可以判断0.2 < x ≤ 0.04陶瓷是R-O-T相,因为R相完全由B位驱动.B位阳离子的无序、简单的原子间作用以及较大的Zr4+倾向于产生负的压力,有利于生成低温相结构[12].同时,Li+间较弱的耦合使NbO6的振动较为剧烈,降低了O-T相变温度而使之更容易发生[13].在0.04 < x ≤ 0.05陶瓷的谱中,I(002)/I(020)峰比值约为1∶2,表明陶瓷为T相(图2f).图2f中R-O相变峰远离室温,O-T相变峰温度向室温附近移动.其原因是,随着掺杂量的进一步增加A位离子Bi3+、Yb3+、Li+的参与使八面体倾斜,而Zr4+与O2-较强的杂化则只使T相生成;另一方面,Li等元素的掺杂将O-T相的相变峰调控至室温.但是,随着温度的升高,多晶型相界(PPB)的温度敏感性使陶瓷从R-O-T相向T相转变[2,14].图3给出的x = 0.01、0.02、0.03和0.04陶瓷的室温Rietveld拟合谱,进一步佐证了介电温谱的结果.表1列出了多相共存陶瓷的晶体结构参数.可以看出,随着掺杂量的增加T相的占比随之提高和c/a值逐渐增大,使晶格发生畸变. ...

Rhombohedral-tetragonal phase coexistence and piezoelectric properties of (NaK)(NbSb)O3-LiTaO3-BaZrO3 lead-free ceramics

1

2011

... 图1给出了(1-x)KNNT-xBYLZ陶瓷的室温XRD谱.从图1a可见,所有陶瓷样品均为单一的钙钛矿结构,表明BYLZ已经完全进入KNNT陶瓷晶格中.其原因是,Bi3+(R = 0.145 nm)、Yb3+(R = 0.0868 nm)、Li+(R = 0.125 nm)、Zr4+(R = 0.072 nm)与KNNT中离子的离子半径相似,易在常温常压下生成单一相的固溶体[8].图1b给出了(1-x)KNNT-xBYLZ陶瓷的XRD谱中44°~47°部分的放大图.可以看出,随着掺杂量的增加,44°~47°的峰型发生了变化.在x = 0.0陶瓷的谱中I(002)/I(020)处的衍射峰比值为2∶1,表明陶瓷为正交相(O)[7].在0.0 < x ≤ 0.02陶瓷的谱中I(002)/I(020)峰比值接近1∶1,表明由于掺入了BYLZ,陶瓷已经不是单一的O相.图2给出了陶瓷的低温介电常数(εr),在图2b和c中标出了R-O相变峰和O-T相变峰的温度区间.由此可以判断,陶瓷中正交-四方(O-T)两相共存.根据第一性原理,Li掺杂可能大幅度提高了A位离子p轨道与O 2p轨道的杂化.与PbTiO3的生成原因类似,Pb与O的轨道杂化诱导了四方相的生成[9~11].在0.2 < x ≤ 0.04陶瓷的谱中,I(002)/I(020)峰比值进一步减小,说明此时陶瓷中存在R相.由图2d和e可见,O-T相变峰和R-O相变峰同时向室温靠近.由此可以判断0.2 < x ≤ 0.04陶瓷是R-O-T相,因为R相完全由B位驱动.B位阳离子的无序、简单的原子间作用以及较大的Zr4+倾向于产生负的压力,有利于生成低温相结构[12].同时,Li+间较弱的耦合使NbO6的振动较为剧烈,降低了O-T相变温度而使之更容易发生[13].在0.04 < x ≤ 0.05陶瓷的谱中,I(002)/I(020)峰比值约为1∶2,表明陶瓷为T相(图2f).图2f中R-O相变峰远离室温,O-T相变峰温度向室温附近移动.其原因是,随着掺杂量的进一步增加A位离子Bi3+、Yb3+、Li+的参与使八面体倾斜,而Zr4+与O2-较强的杂化则只使T相生成;另一方面,Li等元素的掺杂将O-T相的相变峰调控至室温.但是,随着温度的升高,多晶型相界(PPB)的温度敏感性使陶瓷从R-O-T相向T相转变[2,14].图3给出的x = 0.01、0.02、0.03和0.04陶瓷的室温Rietveld拟合谱,进一步佐证了介电温谱的结果.表1列出了多相共存陶瓷的晶体结构参数.可以看出,随着掺杂量的增加T相的占比随之提高和c/a值逐渐增大,使晶格发生畸变. ...

Enhanced electrical properties, phase structure, and temperature-stable dielectric of (K0.48Na0.52)NbO3-Bi0.5Li0.5ZrO3 ceramics

2

2018

... 图1给出了(1-x)KNNT-xBYLZ陶瓷的室温XRD谱.从图1a可见,所有陶瓷样品均为单一的钙钛矿结构,表明BYLZ已经完全进入KNNT陶瓷晶格中.其原因是,Bi3+(R = 0.145 nm)、Yb3+(R = 0.0868 nm)、Li+(R = 0.125 nm)、Zr4+(R = 0.072 nm)与KNNT中离子的离子半径相似,易在常温常压下生成单一相的固溶体[8].图1b给出了(1-x)KNNT-xBYLZ陶瓷的XRD谱中44°~47°部分的放大图.可以看出,随着掺杂量的增加,44°~47°的峰型发生了变化.在x = 0.0陶瓷的谱中I(002)/I(020)处的衍射峰比值为2∶1,表明陶瓷为正交相(O)[7].在0.0 < x ≤ 0.02陶瓷的谱中I(002)/I(020)峰比值接近1∶1,表明由于掺入了BYLZ,陶瓷已经不是单一的O相.图2给出了陶瓷的低温介电常数(εr),在图2b和c中标出了R-O相变峰和O-T相变峰的温度区间.由此可以判断,陶瓷中正交-四方(O-T)两相共存.根据第一性原理,Li掺杂可能大幅度提高了A位离子p轨道与O 2p轨道的杂化.与PbTiO3的生成原因类似,Pb与O的轨道杂化诱导了四方相的生成[9~11].在0.2 < x ≤ 0.04陶瓷的谱中,I(002)/I(020)峰比值进一步减小,说明此时陶瓷中存在R相.由图2d和e可见,O-T相变峰和R-O相变峰同时向室温靠近.由此可以判断0.2 < x ≤ 0.04陶瓷是R-O-T相,因为R相完全由B位驱动.B位阳离子的无序、简单的原子间作用以及较大的Zr4+倾向于产生负的压力,有利于生成低温相结构[12].同时,Li+间较弱的耦合使NbO6的振动较为剧烈,降低了O-T相变温度而使之更容易发生[13].在0.04 < x ≤ 0.05陶瓷的谱中,I(002)/I(020)峰比值约为1∶2,表明陶瓷为T相(图2f).图2f中R-O相变峰远离室温,O-T相变峰温度向室温附近移动.其原因是,随着掺杂量的进一步增加A位离子Bi3+、Yb3+、Li+的参与使八面体倾斜,而Zr4+与O2-较强的杂化则只使T相生成;另一方面,Li等元素的掺杂将O-T相的相变峰调控至室温.但是,随着温度的升高,多晶型相界(PPB)的温度敏感性使陶瓷从R-O-T相向T相转变[2,14].图3给出的x = 0.01、0.02、0.03和0.04陶瓷的室温Rietveld拟合谱,进一步佐证了介电温谱的结果.表1列出了多相共存陶瓷的晶体结构参数.可以看出,随着掺杂量的增加T相的占比随之提高和c/a值逐渐增大,使晶格发生畸变. ...

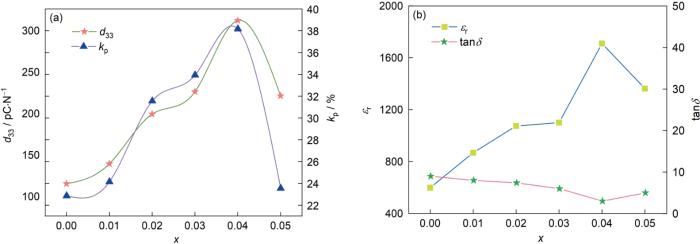

... 图7给出了(1-x)KNNT-xBYLZ陶瓷的压电性能.图7a中的d33和kp其变化趋势相同.0.0 ≤ x ≤ 0.04陶瓷的d33和kp逐渐增大,在x = 0.04时达到最大值分别为305 pC/N和38.2%.O-T相界的畴结构在室温不稳定,促进了偶极矩极化旋转,使陶瓷的d33值增大[18,19].KNNT多相共存时,多相边界的能量势垒较低,促进了畴结构的极化翻转而使其压电效应提高[20].同时,Li掺杂增强了O 2p轨道与Nb 4d轨道杂化,减小了Nb-O键距离并使其畸变程度提高.这些因素,是Li掺杂使压电性能提高的原因[13].0.04 < x ≤ 0.05陶瓷是单相的,使其d33和kp降低.图7b给出了陶瓷的介电常数εr和介电损耗tanδ的变化趋势.0.0 ≤ x ≤ 0.04陶瓷的εr增大,因为元素取代后发生的晶格畸变使晶格排列松散和系统的能垒提高.0.04 < x ≤ 0.05陶瓷的εr降低,因为过量的掺杂使晶格畸变减弱和提高了晶体的对称性[21].0.0 ≤ x ≤ 0.04陶瓷的tanδ值逐渐降低,x = 0.04的陶瓷其tanδ值最小.高密度陶瓷的漏电流较低,表明tanδ值的降低主要是密度的提高所致[22, 23]. ...

A state of the art review of the tribology of graphene/MoS2 nanocomposites

1

2023

... 图1给出了(1-x)KNNT-xBYLZ陶瓷的室温XRD谱.从图1a可见,所有陶瓷样品均为单一的钙钛矿结构,表明BYLZ已经完全进入KNNT陶瓷晶格中.其原因是,Bi3+(R = 0.145 nm)、Yb3+(R = 0.0868 nm)、Li+(R = 0.125 nm)、Zr4+(R = 0.072 nm)与KNNT中离子的离子半径相似,易在常温常压下生成单一相的固溶体[8].图1b给出了(1-x)KNNT-xBYLZ陶瓷的XRD谱中44°~47°部分的放大图.可以看出,随着掺杂量的增加,44°~47°的峰型发生了变化.在x = 0.0陶瓷的谱中I(002)/I(020)处的衍射峰比值为2∶1,表明陶瓷为正交相(O)[7].在0.0 < x ≤ 0.02陶瓷的谱中I(002)/I(020)峰比值接近1∶1,表明由于掺入了BYLZ,陶瓷已经不是单一的O相.图2给出了陶瓷的低温介电常数(εr),在图2b和c中标出了R-O相变峰和O-T相变峰的温度区间.由此可以判断,陶瓷中正交-四方(O-T)两相共存.根据第一性原理,Li掺杂可能大幅度提高了A位离子p轨道与O 2p轨道的杂化.与PbTiO3的生成原因类似,Pb与O的轨道杂化诱导了四方相的生成[9~11].在0.2 < x ≤ 0.04陶瓷的谱中,I(002)/I(020)峰比值进一步减小,说明此时陶瓷中存在R相.由图2d和e可见,O-T相变峰和R-O相变峰同时向室温靠近.由此可以判断0.2 < x ≤ 0.04陶瓷是R-O-T相,因为R相完全由B位驱动.B位阳离子的无序、简单的原子间作用以及较大的Zr4+倾向于产生负的压力,有利于生成低温相结构[12].同时,Li+间较弱的耦合使NbO6的振动较为剧烈,降低了O-T相变温度而使之更容易发生[13].在0.04 < x ≤ 0.05陶瓷的谱中,I(002)/I(020)峰比值约为1∶2,表明陶瓷为T相(图2f).图2f中R-O相变峰远离室温,O-T相变峰温度向室温附近移动.其原因是,随着掺杂量的进一步增加A位离子Bi3+、Yb3+、Li+的参与使八面体倾斜,而Zr4+与O2-较强的杂化则只使T相生成;另一方面,Li等元素的掺杂将O-T相的相变峰调控至室温.但是,随着温度的升高,多晶型相界(PPB)的温度敏感性使陶瓷从R-O-T相向T相转变[2,14].图3给出的x = 0.01、0.02、0.03和0.04陶瓷的室温Rietveld拟合谱,进一步佐证了介电温谱的结果.表1列出了多相共存陶瓷的晶体结构参数.可以看出,随着掺杂量的增加T相的占比随之提高和c/a值逐渐增大,使晶格发生畸变. ...

Nanoscale domains in K0.48Na0.52Nb0.96Sb0.04O3-Bi0.5Na0.5ZrO3 ceramics enhance piezoelectric properties

1

2022

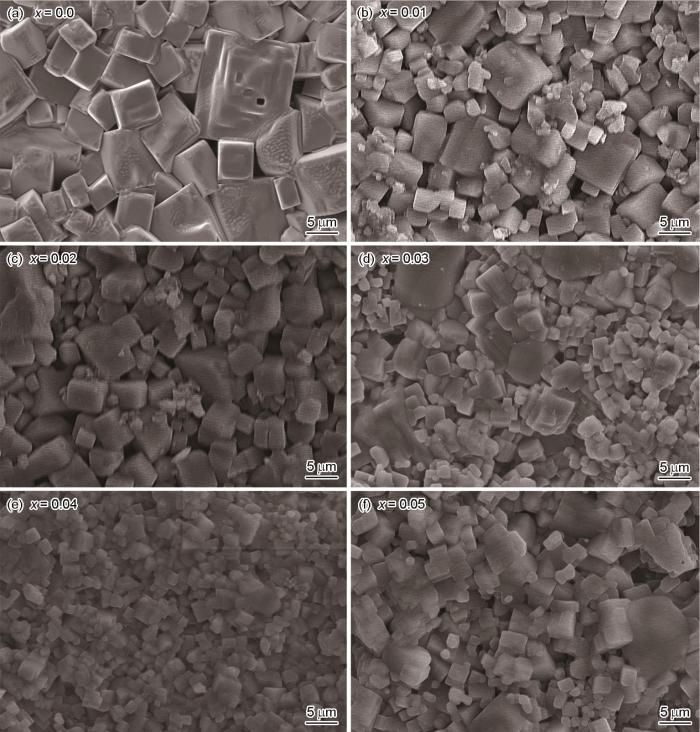

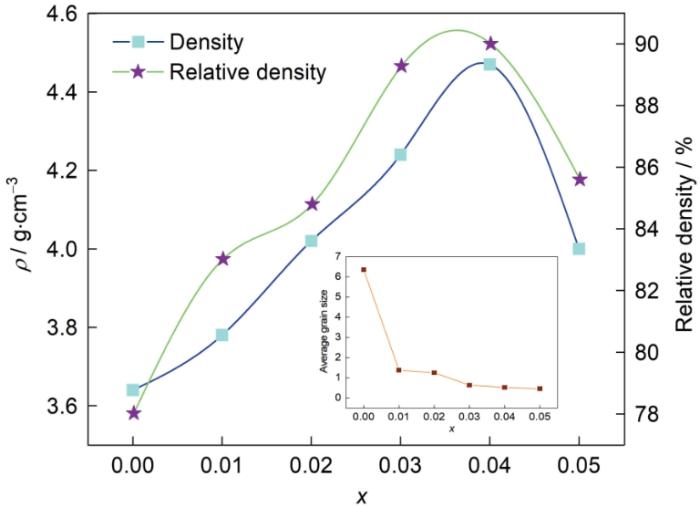

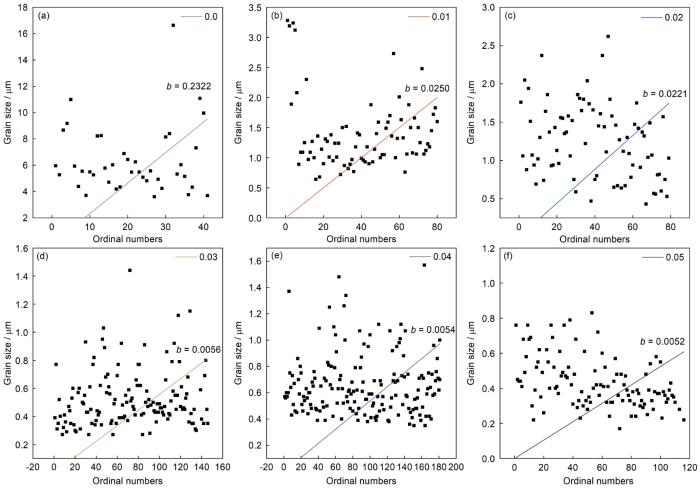

... 图4给出了(1-x)KNNT-xBYLZ陶瓷表面的形貌.可以看出,随着掺杂量的增加,大晶粒与小晶粒相伴分布.在0.0 ≤ x ≤ 0.04 (图4a~e)陶瓷中,晶粒内可见明显且分布均匀的晶界.在0.04 < x ≤ 0.05陶瓷中的晶粒极小(≤ 0.5 μm),表明其组织结构恶化(图4f).图5中的陶瓷,其密度和相对密度的变化趋势相似.x = 0.04的陶瓷其密度和相对密度最大,表明适量的BYLZ掺杂可提高密度.陶瓷的密度,也是影响其电性能的关键因素.随着x的增大孔隙减少,表明其更加致密.在高温下添加的少量BYLZ与其他组元共熔,使颗粒间更加致密[15].图5中的插图给出了晶粒平均尺寸的变化.可以看出,随着x的增大陶瓷晶粒的平均尺寸不断减小,因为Zr4+和Bi3+抑制了晶粒的生长[16].图6中直线的斜率b表征了晶粒尺寸随x的变化趋势.可以看出,随着x的增大晶粒逐渐减小.陶瓷的晶粒尺寸越小,则非铁电晶界相的含量越高,在其表面出现的去极化场使极化效果降低.因此,晶粒较小的多晶陶瓷其铁电性能较差[17]. ...

Influence of zirconia addition on the microstructure of K-0.5Na0.5NbO3 ceramics

1

2008

... 图4给出了(1-x)KNNT-xBYLZ陶瓷表面的形貌.可以看出,随着掺杂量的增加,大晶粒与小晶粒相伴分布.在0.0 ≤ x ≤ 0.04 (图4a~e)陶瓷中,晶粒内可见明显且分布均匀的晶界.在0.04 < x ≤ 0.05陶瓷中的晶粒极小(≤ 0.5 μm),表明其组织结构恶化(图4f).图5中的陶瓷,其密度和相对密度的变化趋势相似.x = 0.04的陶瓷其密度和相对密度最大,表明适量的BYLZ掺杂可提高密度.陶瓷的密度,也是影响其电性能的关键因素.随着x的增大孔隙减少,表明其更加致密.在高温下添加的少量BYLZ与其他组元共熔,使颗粒间更加致密[15].图5中的插图给出了晶粒平均尺寸的变化.可以看出,随着x的增大陶瓷晶粒的平均尺寸不断减小,因为Zr4+和Bi3+抑制了晶粒的生长[16].图6中直线的斜率b表征了晶粒尺寸随x的变化趋势.可以看出,随着x的增大晶粒逐渐减小.陶瓷的晶粒尺寸越小,则非铁电晶界相的含量越高,在其表面出现的去极化场使极化效果降低.因此,晶粒较小的多晶陶瓷其铁电性能较差[17]. ...

Balanced development of piezoelectricity, Curie temperature, and temperature stability in potassium-sodium niobhrate lead-free ceramics

1

2016

... 图4给出了(1-x)KNNT-xBYLZ陶瓷表面的形貌.可以看出,随着掺杂量的增加,大晶粒与小晶粒相伴分布.在0.0 ≤ x ≤ 0.04 (图4a~e)陶瓷中,晶粒内可见明显且分布均匀的晶界.在0.04 < x ≤ 0.05陶瓷中的晶粒极小(≤ 0.5 μm),表明其组织结构恶化(图4f).图5中的陶瓷,其密度和相对密度的变化趋势相似.x = 0.04的陶瓷其密度和相对密度最大,表明适量的BYLZ掺杂可提高密度.陶瓷的密度,也是影响其电性能的关键因素.随着x的增大孔隙减少,表明其更加致密.在高温下添加的少量BYLZ与其他组元共熔,使颗粒间更加致密[15].图5中的插图给出了晶粒平均尺寸的变化.可以看出,随着x的增大陶瓷晶粒的平均尺寸不断减小,因为Zr4+和Bi3+抑制了晶粒的生长[16].图6中直线的斜率b表征了晶粒尺寸随x的变化趋势.可以看出,随着x的增大晶粒逐渐减小.陶瓷的晶粒尺寸越小,则非铁电晶界相的含量越高,在其表面出现的去极化场使极化效果降低.因此,晶粒较小的多晶陶瓷其铁电性能较差[17]. ...

Transformation of hardening to softening behaviors induced by Sb substitution in CuO-doped KNN-based piezoceramics

1

2019

... 图7给出了(1-x)KNNT-xBYLZ陶瓷的压电性能.图7a中的d33和kp其变化趋势相同.0.0 ≤ x ≤ 0.04陶瓷的d33和kp逐渐增大,在x = 0.04时达到最大值分别为305 pC/N和38.2%.O-T相界的畴结构在室温不稳定,促进了偶极矩极化旋转,使陶瓷的d33值增大[18,19].KNNT多相共存时,多相边界的能量势垒较低,促进了畴结构的极化翻转而使其压电效应提高[20].同时,Li掺杂增强了O 2p轨道与Nb 4d轨道杂化,减小了Nb-O键距离并使其畸变程度提高.这些因素,是Li掺杂使压电性能提高的原因[13].0.04 < x ≤ 0.05陶瓷是单相的,使其d33和kp降低.图7b给出了陶瓷的介电常数εr和介电损耗tanδ的变化趋势.0.0 ≤ x ≤ 0.04陶瓷的εr增大,因为元素取代后发生的晶格畸变使晶格排列松散和系统的能垒提高.0.04 < x ≤ 0.05陶瓷的εr降低,因为过量的掺杂使晶格畸变减弱和提高了晶体的对称性[21].0.0 ≤ x ≤ 0.04陶瓷的tanδ值逐渐降低,x = 0.04的陶瓷其tanδ值最小.高密度陶瓷的漏电流较低,表明tanδ值的降低主要是密度的提高所致[22, 23]. ...

Effect of Sb-induced oxygen octahedral distortion on piezoelectric performance and thermal stability of Pb(In,Nb)O3-Pb(Hf,Ti)O3 ceramics

1

2023

... 图7给出了(1-x)KNNT-xBYLZ陶瓷的压电性能.图7a中的d33和kp其变化趋势相同.0.0 ≤ x ≤ 0.04陶瓷的d33和kp逐渐增大,在x = 0.04时达到最大值分别为305 pC/N和38.2%.O-T相界的畴结构在室温不稳定,促进了偶极矩极化旋转,使陶瓷的d33值增大[18,19].KNNT多相共存时,多相边界的能量势垒较低,促进了畴结构的极化翻转而使其压电效应提高[20].同时,Li掺杂增强了O 2p轨道与Nb 4d轨道杂化,减小了Nb-O键距离并使其畸变程度提高.这些因素,是Li掺杂使压电性能提高的原因[13].0.04 < x ≤ 0.05陶瓷是单相的,使其d33和kp降低.图7b给出了陶瓷的介电常数εr和介电损耗tanδ的变化趋势.0.0 ≤ x ≤ 0.04陶瓷的εr增大,因为元素取代后发生的晶格畸变使晶格排列松散和系统的能垒提高.0.04 < x ≤ 0.05陶瓷的εr降低,因为过量的掺杂使晶格畸变减弱和提高了晶体的对称性[21].0.0 ≤ x ≤ 0.04陶瓷的tanδ值逐渐降低,x = 0.04的陶瓷其tanδ值最小.高密度陶瓷的漏电流较低,表明tanδ值的降低主要是密度的提高所致[22, 23]. ...

Dopant tuned multi-functionality in barium titanate based lead-free piezoceramics

1

2023

... 图7给出了(1-x)KNNT-xBYLZ陶瓷的压电性能.图7a中的d33和kp其变化趋势相同.0.0 ≤ x ≤ 0.04陶瓷的d33和kp逐渐增大,在x = 0.04时达到最大值分别为305 pC/N和38.2%.O-T相界的畴结构在室温不稳定,促进了偶极矩极化旋转,使陶瓷的d33值增大[18,19].KNNT多相共存时,多相边界的能量势垒较低,促进了畴结构的极化翻转而使其压电效应提高[20].同时,Li掺杂增强了O 2p轨道与Nb 4d轨道杂化,减小了Nb-O键距离并使其畸变程度提高.这些因素,是Li掺杂使压电性能提高的原因[13].0.04 < x ≤ 0.05陶瓷是单相的,使其d33和kp降低.图7b给出了陶瓷的介电常数εr和介电损耗tanδ的变化趋势.0.0 ≤ x ≤ 0.04陶瓷的εr增大,因为元素取代后发生的晶格畸变使晶格排列松散和系统的能垒提高.0.04 < x ≤ 0.05陶瓷的εr降低,因为过量的掺杂使晶格畸变减弱和提高了晶体的对称性[21].0.0 ≤ x ≤ 0.04陶瓷的tanδ值逐渐降低,x = 0.04的陶瓷其tanδ值最小.高密度陶瓷的漏电流较低,表明tanδ值的降低主要是密度的提高所致[22, 23]. ...

Sharpening polycrystalline phase boundary for potassium sodium niobate ceramics with MnF2 modification

1

2022

... 图7给出了(1-x)KNNT-xBYLZ陶瓷的压电性能.图7a中的d33和kp其变化趋势相同.0.0 ≤ x ≤ 0.04陶瓷的d33和kp逐渐增大,在x = 0.04时达到最大值分别为305 pC/N和38.2%.O-T相界的畴结构在室温不稳定,促进了偶极矩极化旋转,使陶瓷的d33值增大[18,19].KNNT多相共存时,多相边界的能量势垒较低,促进了畴结构的极化翻转而使其压电效应提高[20].同时,Li掺杂增强了O 2p轨道与Nb 4d轨道杂化,减小了Nb-O键距离并使其畸变程度提高.这些因素,是Li掺杂使压电性能提高的原因[13].0.04 < x ≤ 0.05陶瓷是单相的,使其d33和kp降低.图7b给出了陶瓷的介电常数εr和介电损耗tanδ的变化趋势.0.0 ≤ x ≤ 0.04陶瓷的εr增大,因为元素取代后发生的晶格畸变使晶格排列松散和系统的能垒提高.0.04 < x ≤ 0.05陶瓷的εr降低,因为过量的掺杂使晶格畸变减弱和提高了晶体的对称性[21].0.0 ≤ x ≤ 0.04陶瓷的tanδ值逐渐降低,x = 0.04的陶瓷其tanδ值最小.高密度陶瓷的漏电流较低,表明tanδ值的降低主要是密度的提高所致[22, 23]. ...

Effect of a lattice distortion strategy on the phase transition and properties in KNN‐based ceramics

1

2023

... 图7给出了(1-x)KNNT-xBYLZ陶瓷的压电性能.图7a中的d33和kp其变化趋势相同.0.0 ≤ x ≤ 0.04陶瓷的d33和kp逐渐增大,在x = 0.04时达到最大值分别为305 pC/N和38.2%.O-T相界的畴结构在室温不稳定,促进了偶极矩极化旋转,使陶瓷的d33值增大[18,19].KNNT多相共存时,多相边界的能量势垒较低,促进了畴结构的极化翻转而使其压电效应提高[20].同时,Li掺杂增强了O 2p轨道与Nb 4d轨道杂化,减小了Nb-O键距离并使其畸变程度提高.这些因素,是Li掺杂使压电性能提高的原因[13].0.04 < x ≤ 0.05陶瓷是单相的,使其d33和kp降低.图7b给出了陶瓷的介电常数εr和介电损耗tanδ的变化趋势.0.0 ≤ x ≤ 0.04陶瓷的εr增大,因为元素取代后发生的晶格畸变使晶格排列松散和系统的能垒提高.0.04 < x ≤ 0.05陶瓷的εr降低,因为过量的掺杂使晶格畸变减弱和提高了晶体的对称性[21].0.0 ≤ x ≤ 0.04陶瓷的tanδ值逐渐降低,x = 0.04的陶瓷其tanδ值最小.高密度陶瓷的漏电流较低,表明tanδ值的降低主要是密度的提高所致[22, 23]. ...

The roles of Sn4+ in affecting performance of Potassium Sodium Niobate ceramics

1

2022

... 图7给出了(1-x)KNNT-xBYLZ陶瓷的压电性能.图7a中的d33和kp其变化趋势相同.0.0 ≤ x ≤ 0.04陶瓷的d33和kp逐渐增大,在x = 0.04时达到最大值分别为305 pC/N和38.2%.O-T相界的畴结构在室温不稳定,促进了偶极矩极化旋转,使陶瓷的d33值增大[18,19].KNNT多相共存时,多相边界的能量势垒较低,促进了畴结构的极化翻转而使其压电效应提高[20].同时,Li掺杂增强了O 2p轨道与Nb 4d轨道杂化,减小了Nb-O键距离并使其畸变程度提高.这些因素,是Li掺杂使压电性能提高的原因[13].0.04 < x ≤ 0.05陶瓷是单相的,使其d33和kp降低.图7b给出了陶瓷的介电常数εr和介电损耗tanδ的变化趋势.0.0 ≤ x ≤ 0.04陶瓷的εr增大,因为元素取代后发生的晶格畸变使晶格排列松散和系统的能垒提高.0.04 < x ≤ 0.05陶瓷的εr降低,因为过量的掺杂使晶格畸变减弱和提高了晶体的对称性[21].0.0 ≤ x ≤ 0.04陶瓷的tanδ值逐渐降低,x = 0.04的陶瓷其tanδ值最小.高密度陶瓷的漏电流较低,表明tanδ值的降低主要是密度的提高所致[22, 23]. ...

Stabilized piezoelectricity upon ferro-ferro phase transition achieved by aging induced domain memory effect in acceptor doped lead-free ceramics

1

2022

... 图8给出了陶瓷的介电温谱曲线和相图.由图8a可见,随着掺杂量的增加陶瓷的居里峰逐渐变宽,表明发生了弥散行为[24, 25].从图8b可见,随着掺杂量的增加居里温度TC稍有降低,是Ta5+和Li+共同作用的结果[26].Ta5+取代使局域结构发生了比Nb5+更小的离子位移,尽管键长比Ta更小但是Nb比Ta小的力常数使Ta掺杂后的KNNT陶瓷的TC降低.但是,Li+的A位取代使TC提高,两种作用的结果使陶瓷的TC值略有降低[9].同时,从图8b可见,0.0 ≤ x ≤ 0.05陶瓷的TO-T值随着掺杂量的增加逐渐降低.其主要原因是,在KNNT基陶瓷中添加适量的Bi0.5(Na/K/Li)0.5等钙钛矿结构化合物或Ta5+/Li+,使陶瓷中T相比例提高,把TO-T调节到室温附近[27, 28].而TR-O在室温附近的小幅度提高,可归因于Bi3+添加剂的引入,Bi3+ 6s和O2- 2p轨道的杂化产生的离子性促进了KNNT基陶瓷出现R态 [29,30].Yb3+和Li+的电负性比Bi3+低,Bi3+被取代后Yb3+和Li+与O之间的相互作用提高了A-O的离子性,有利于增强陶瓷中的R相的稳定.因此,随着掺杂量的增加,TR-O呈现出如图所示的变化趋势[6,31]. ...

Effects of SrTiO3 modification on the piezoelectric and strain properties of lead-free K0.5-Na0.5NbO3-based ceramics

2

2022

... 图8给出了陶瓷的介电温谱曲线和相图.由图8a可见,随着掺杂量的增加陶瓷的居里峰逐渐变宽,表明发生了弥散行为[24, 25].从图8b可见,随着掺杂量的增加居里温度TC稍有降低,是Ta5+和Li+共同作用的结果[26].Ta5+取代使局域结构发生了比Nb5+更小的离子位移,尽管键长比Ta更小但是Nb比Ta小的力常数使Ta掺杂后的KNNT陶瓷的TC降低.但是,Li+的A位取代使TC提高,两种作用的结果使陶瓷的TC值略有降低[9].同时,从图8b可见,0.0 ≤ x ≤ 0.05陶瓷的TO-T值随着掺杂量的增加逐渐降低.其主要原因是,在KNNT基陶瓷中添加适量的Bi0.5(Na/K/Li)0.5等钙钛矿结构化合物或Ta5+/Li+,使陶瓷中T相比例提高,把TO-T调节到室温附近[27, 28].而TR-O在室温附近的小幅度提高,可归因于Bi3+添加剂的引入,Bi3+ 6s和O2- 2p轨道的杂化产生的离子性促进了KNNT基陶瓷出现R态 [29,30].Yb3+和Li+的电负性比Bi3+低,Bi3+被取代后Yb3+和Li+与O之间的相互作用提高了A-O的离子性,有利于增强陶瓷中的R相的稳定.因此,随着掺杂量的增加,TR-O呈现出如图所示的变化趋势[6,31]. ...

... Comparison of the experimental data with the electrical properties of other KNN-based piezoelectric ceramics

Table 2| Material | d33pC/N | ECkV·cm-1 | PrμC·cm-2 | εr | TCoC | Reference |

|---|

| 0.95(Na0.5K0.5)NbO3-0.05SrTiO3 | 130 | 14.2 | 13.8 | 1352 | 308 | [25] |

| 0.95(K0.6Na0.4)NbO3-0.05(Bi0.5Na0.5)ZrO3 | 340 | | 19.58 | | | [4] |

| 0.97(K0.5Na0.5)0.98-Ag0.02(Nb0.96Sb0.04)O3-0.03(Bi0.5Na0.5)ZrO3 | 550 | | | | 250 | [41] |

| 0.96K0.5Na0.5NbO3-0.04CaSnO3 | 430 | | | 32168 | 297 | [42] |

| 0.865(K0.5Na0.5)0.98Ag0.02Nb0.96Ta0.04O3-0.035CuO-0.01Na2O | 343 | 19.2 | 24.9 | 1382 | 306 | [43] |

| 0.96(K0.5Na0.5)NbO3-0.04[NaSbO3 +Bi0.5(Na0.8K0.2)0.5(Zr0.5Hf0.5)O3] | 452 | | | 4414 | | [44] |

| 0.96K0.5Na0.5(Nb0.95Ta0.05)O3-0.04(Bi0.5Yb0.5)0.95Li0.05 ZrO3 | 305 | 20.67 | 34.63 | 1710 | 340 | This work |

<strong>3</strong> 结论(1) 用传统固相法可制备具有R-O-T多相共存的(1-x)K0.5Na0.5(Nb0.95Ta0.05)O3-x(Bi0.5Yb0.5)0.95Li0.05ZrO3陶瓷.随着BYLZ含量的提高A、B位的离子半径和电荷的不同使晶格显著失配,空位(缺陷)上的局域化电子和空穴对铁电畴壁的钉扎降低了畴壁的可动性,使其铁电性提高. ...

Enhancement of Qm in CuO-doped compositionally optimized Li/Ta-modified (Na,K)NbO3 lead-free piezoceramics

1

2012

... 图8给出了陶瓷的介电温谱曲线和相图.由图8a可见,随着掺杂量的增加陶瓷的居里峰逐渐变宽,表明发生了弥散行为[24, 25].从图8b可见,随着掺杂量的增加居里温度TC稍有降低,是Ta5+和Li+共同作用的结果[26].Ta5+取代使局域结构发生了比Nb5+更小的离子位移,尽管键长比Ta更小但是Nb比Ta小的力常数使Ta掺杂后的KNNT陶瓷的TC降低.但是,Li+的A位取代使TC提高,两种作用的结果使陶瓷的TC值略有降低[9].同时,从图8b可见,0.0 ≤ x ≤ 0.05陶瓷的TO-T值随着掺杂量的增加逐渐降低.其主要原因是,在KNNT基陶瓷中添加适量的Bi0.5(Na/K/Li)0.5等钙钛矿结构化合物或Ta5+/Li+,使陶瓷中T相比例提高,把TO-T调节到室温附近[27, 28].而TR-O在室温附近的小幅度提高,可归因于Bi3+添加剂的引入,Bi3+ 6s和O2- 2p轨道的杂化产生的离子性促进了KNNT基陶瓷出现R态 [29,30].Yb3+和Li+的电负性比Bi3+低,Bi3+被取代后Yb3+和Li+与O之间的相互作用提高了A-O的离子性,有利于增强陶瓷中的R相的稳定.因此,随着掺杂量的增加,TR-O呈现出如图所示的变化趋势[6,31]. ...

Giant piezoelectric response and structure evolution of Bi0.5(Na0.3K0.3Li(0.4- x )Ba x )0.5ZrO3 modified (K0.48Na0.52)(Nb0.95Sb0.05)O3 lead-free piezoelectric ceramics

1

2024

... 图8给出了陶瓷的介电温谱曲线和相图.由图8a可见,随着掺杂量的增加陶瓷的居里峰逐渐变宽,表明发生了弥散行为[24, 25].从图8b可见,随着掺杂量的增加居里温度TC稍有降低,是Ta5+和Li+共同作用的结果[26].Ta5+取代使局域结构发生了比Nb5+更小的离子位移,尽管键长比Ta更小但是Nb比Ta小的力常数使Ta掺杂后的KNNT陶瓷的TC降低.但是,Li+的A位取代使TC提高,两种作用的结果使陶瓷的TC值略有降低[9].同时,从图8b可见,0.0 ≤ x ≤ 0.05陶瓷的TO-T值随着掺杂量的增加逐渐降低.其主要原因是,在KNNT基陶瓷中添加适量的Bi0.5(Na/K/Li)0.5等钙钛矿结构化合物或Ta5+/Li+,使陶瓷中T相比例提高,把TO-T调节到室温附近[27, 28].而TR-O在室温附近的小幅度提高,可归因于Bi3+添加剂的引入,Bi3+ 6s和O2- 2p轨道的杂化产生的离子性促进了KNNT基陶瓷出现R态 [29,30].Yb3+和Li+的电负性比Bi3+低,Bi3+被取代后Yb3+和Li+与O之间的相互作用提高了A-O的离子性,有利于增强陶瓷中的R相的稳定.因此,随着掺杂量的增加,TR-O呈现出如图所示的变化趋势[6,31]. ...

Synergism optimization of ferroelectric phase-transition temperature and piezoelectric properties of KNN-based ceramics by chemical composition regulation

1

2024

... 图8给出了陶瓷的介电温谱曲线和相图.由图8a可见,随着掺杂量的增加陶瓷的居里峰逐渐变宽,表明发生了弥散行为[24, 25].从图8b可见,随着掺杂量的增加居里温度TC稍有降低,是Ta5+和Li+共同作用的结果[26].Ta5+取代使局域结构发生了比Nb5+更小的离子位移,尽管键长比Ta更小但是Nb比Ta小的力常数使Ta掺杂后的KNNT陶瓷的TC降低.但是,Li+的A位取代使TC提高,两种作用的结果使陶瓷的TC值略有降低[9].同时,从图8b可见,0.0 ≤ x ≤ 0.05陶瓷的TO-T值随着掺杂量的增加逐渐降低.其主要原因是,在KNNT基陶瓷中添加适量的Bi0.5(Na/K/Li)0.5等钙钛矿结构化合物或Ta5+/Li+,使陶瓷中T相比例提高,把TO-T调节到室温附近[27, 28].而TR-O在室温附近的小幅度提高,可归因于Bi3+添加剂的引入,Bi3+ 6s和O2- 2p轨道的杂化产生的离子性促进了KNNT基陶瓷出现R态 [29,30].Yb3+和Li+的电负性比Bi3+低,Bi3+被取代后Yb3+和Li+与O之间的相互作用提高了A-O的离子性,有利于增强陶瓷中的R相的稳定.因此,随着掺杂量的增加,TR-O呈现出如图所示的变化趋势[6,31]. ...

Bismuth-rich Bi12O17Cl2 nanorods engineered with oxygen vacancy defects for enhanced photocatalytic nitrogen fixation

1

2023

... 图8给出了陶瓷的介电温谱曲线和相图.由图8a可见,随着掺杂量的增加陶瓷的居里峰逐渐变宽,表明发生了弥散行为[24, 25].从图8b可见,随着掺杂量的增加居里温度TC稍有降低,是Ta5+和Li+共同作用的结果[26].Ta5+取代使局域结构发生了比Nb5+更小的离子位移,尽管键长比Ta更小但是Nb比Ta小的力常数使Ta掺杂后的KNNT陶瓷的TC降低.但是,Li+的A位取代使TC提高,两种作用的结果使陶瓷的TC值略有降低[9].同时,从图8b可见,0.0 ≤ x ≤ 0.05陶瓷的TO-T值随着掺杂量的增加逐渐降低.其主要原因是,在KNNT基陶瓷中添加适量的Bi0.5(Na/K/Li)0.5等钙钛矿结构化合物或Ta5+/Li+,使陶瓷中T相比例提高,把TO-T调节到室温附近[27, 28].而TR-O在室温附近的小幅度提高,可归因于Bi3+添加剂的引入,Bi3+ 6s和O2- 2p轨道的杂化产生的离子性促进了KNNT基陶瓷出现R态 [29,30].Yb3+和Li+的电负性比Bi3+低,Bi3+被取代后Yb3+和Li+与O之间的相互作用提高了A-O的离子性,有利于增强陶瓷中的R相的稳定.因此,随着掺杂量的增加,TR-O呈现出如图所示的变化趋势[6,31]. ...

First principles insight on enhanced photocatalytic performance of sulfur-doped bismuth oxide iodate

1

2023

... 图8给出了陶瓷的介电温谱曲线和相图.由图8a可见,随着掺杂量的增加陶瓷的居里峰逐渐变宽,表明发生了弥散行为[24, 25].从图8b可见,随着掺杂量的增加居里温度TC稍有降低,是Ta5+和Li+共同作用的结果[26].Ta5+取代使局域结构发生了比Nb5+更小的离子位移,尽管键长比Ta更小但是Nb比Ta小的力常数使Ta掺杂后的KNNT陶瓷的TC降低.但是,Li+的A位取代使TC提高,两种作用的结果使陶瓷的TC值略有降低[9].同时,从图8b可见,0.0 ≤ x ≤ 0.05陶瓷的TO-T值随着掺杂量的增加逐渐降低.其主要原因是,在KNNT基陶瓷中添加适量的Bi0.5(Na/K/Li)0.5等钙钛矿结构化合物或Ta5+/Li+,使陶瓷中T相比例提高,把TO-T调节到室温附近[27, 28].而TR-O在室温附近的小幅度提高,可归因于Bi3+添加剂的引入,Bi3+ 6s和O2- 2p轨道的杂化产生的离子性促进了KNNT基陶瓷出现R态 [29,30].Yb3+和Li+的电负性比Bi3+低,Bi3+被取代后Yb3+和Li+与O之间的相互作用提高了A-O的离子性,有利于增强陶瓷中的R相的稳定.因此,随着掺杂量的增加,TR-O呈现出如图所示的变化趋势[6,31]. ...

Tuning the covalency of A-O bonds to improve the performance of KNN-based ceramics with multiphase coexistence

1

2020

... 图8给出了陶瓷的介电温谱曲线和相图.由图8a可见,随着掺杂量的增加陶瓷的居里峰逐渐变宽,表明发生了弥散行为[24, 25].从图8b可见,随着掺杂量的增加居里温度TC稍有降低,是Ta5+和Li+共同作用的结果[26].Ta5+取代使局域结构发生了比Nb5+更小的离子位移,尽管键长比Ta更小但是Nb比Ta小的力常数使Ta掺杂后的KNNT陶瓷的TC降低.但是,Li+的A位取代使TC提高,两种作用的结果使陶瓷的TC值略有降低[9].同时,从图8b可见,0.0 ≤ x ≤ 0.05陶瓷的TO-T值随着掺杂量的增加逐渐降低.其主要原因是,在KNNT基陶瓷中添加适量的Bi0.5(Na/K/Li)0.5等钙钛矿结构化合物或Ta5+/Li+,使陶瓷中T相比例提高,把TO-T调节到室温附近[27, 28].而TR-O在室温附近的小幅度提高,可归因于Bi3+添加剂的引入,Bi3+ 6s和O2- 2p轨道的杂化产生的离子性促进了KNNT基陶瓷出现R态 [29,30].Yb3+和Li+的电负性比Bi3+低,Bi3+被取代后Yb3+和Li+与O之间的相互作用提高了A-O的离子性,有利于增强陶瓷中的R相的稳定.因此,随着掺杂量的增加,TR-O呈现出如图所示的变化趋势[6,31]. ...

Study on doping modification and properties of potassium-sodium niobate based piezoelectric ceramics

2

2022

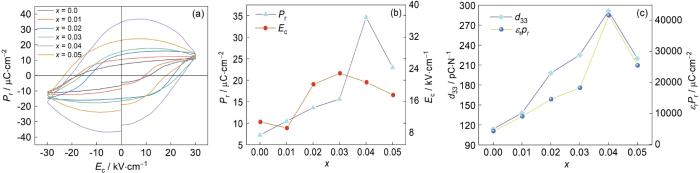

... 图9给出了(1-x)KNNT-xBYLZ陶瓷的铁电性能.从图9a中陶瓷的电滞回线可以看出,0.0 ≤ x ≤ 0.04的陶瓷,其电滞回线逐渐饱和,表明随着掺杂量的增加陶瓷的铁电性逐渐增强;0.04 < x ≤ 0.05的陶瓷,其电滞回线出现细化.从图9b可见,0.0 ≤ x ≤ 0.04的陶瓷,其剩余极化Pr逐渐增大.其原因是,Zr4+与Nb5+离子半径接近,Nb5+被Zr4+取代形成缺陷(),产生的氧空位缺陷()钉扎畴壁使Pr值增大[32~34].的作用是烧结过程中的电荷补偿: ...

... 0.04 < x ≤ 0.05的陶瓷其Pr值减小,因为和阳离子空位缺陷()产生了不可移动的中性缺陷复合物[32],如 式(3)所示,这些缺陷复合物在晶界处偏析产生了钉扎效应[35,36];同时,畴壁与空位缺陷之间较弱的相互作用使空位缺陷保持良好的流动性而使晶粒减小.这两种因素,使Pr值减小[37,38].EC的变化规律与Pr类似,即随着x的增加先增大后减小,并在x = 0.04时达到最大值.这表明,R-O-T三相共存使陶瓷具有良好的铁电性[39, 40].从图9c可见,d33和εrPr的变化趋势相同,x = 0.04陶瓷的d33和εrPr最优,符合唯像理论Pr ∝ d33εr.这表明,压电、介电与铁电相互依赖,掺杂一定量的BYLZ有助于提高陶瓷的电性能.表2列出了一些KNN基压电陶瓷的电性能.可以看出,本文制备的陶瓷其各项电性能更好的满足实际应用的要求. ...

铌酸钾钠基压电陶瓷的掺杂改性及性能研究

2

2022

... 图9给出了(1-x)KNNT-xBYLZ陶瓷的铁电性能.从图9a中陶瓷的电滞回线可以看出,0.0 ≤ x ≤ 0.04的陶瓷,其电滞回线逐渐饱和,表明随着掺杂量的增加陶瓷的铁电性逐渐增强;0.04 < x ≤ 0.05的陶瓷,其电滞回线出现细化.从图9b可见,0.0 ≤ x ≤ 0.04的陶瓷,其剩余极化Pr逐渐增大.其原因是,Zr4+与Nb5+离子半径接近,Nb5+被Zr4+取代形成缺陷(),产生的氧空位缺陷()钉扎畴壁使Pr值增大[32~34].的作用是烧结过程中的电荷补偿: ...

... 0.04 < x ≤ 0.05的陶瓷其Pr值减小,因为和阳离子空位缺陷()产生了不可移动的中性缺陷复合物[32],如 式(3)所示,这些缺陷复合物在晶界处偏析产生了钉扎效应[35,36];同时,畴壁与空位缺陷之间较弱的相互作用使空位缺陷保持良好的流动性而使晶粒减小.这两种因素,使Pr值减小[37,38].EC的变化规律与Pr类似,即随着x的增加先增大后减小,并在x = 0.04时达到最大值.这表明,R-O-T三相共存使陶瓷具有良好的铁电性[39, 40].从图9c可见,d33和εrPr的变化趋势相同,x = 0.04陶瓷的d33和εrPr最优,符合唯像理论Pr ∝ d33εr.这表明,压电、介电与铁电相互依赖,掺杂一定量的BYLZ有助于提高陶瓷的电性能.表2列出了一些KNN基压电陶瓷的电性能.可以看出,本文制备的陶瓷其各项电性能更好的满足实际应用的要求. ...

Understanding the piezoelectricity of high-performance potassium sodium niobate ceramics from diffused multi-phase coexistence and domain feature

0

2019

The intrinsic piezoelectric properties of materials – a review with a focus on biological materials

1

2021

... 图9给出了(1-x)KNNT-xBYLZ陶瓷的铁电性能.从图9a中陶瓷的电滞回线可以看出,0.0 ≤ x ≤ 0.04的陶瓷,其电滞回线逐渐饱和,表明随着掺杂量的增加陶瓷的铁电性逐渐增强;0.04 < x ≤ 0.05的陶瓷,其电滞回线出现细化.从图9b可见,0.0 ≤ x ≤ 0.04的陶瓷,其剩余极化Pr逐渐增大.其原因是,Zr4+与Nb5+离子半径接近,Nb5+被Zr4+取代形成缺陷(),产生的氧空位缺陷()钉扎畴壁使Pr值增大[32~34].的作用是烧结过程中的电荷补偿: ...

Evaluation of the lubricating power of chemical modified Sesame oil additivated with Cu and Al2O3 nanoparticles

1

2018

... 0.04 < x ≤ 0.05的陶瓷其Pr值减小,因为和阳离子空位缺陷()产生了不可移动的中性缺陷复合物[32],如 式(3)所示,这些缺陷复合物在晶界处偏析产生了钉扎效应[35,36];同时,畴壁与空位缺陷之间较弱的相互作用使空位缺陷保持良好的流动性而使晶粒减小.这两种因素,使Pr值减小[37,38].EC的变化规律与Pr类似,即随着x的增加先增大后减小,并在x = 0.04时达到最大值.这表明,R-O-T三相共存使陶瓷具有良好的铁电性[39, 40].从图9c可见,d33和εrPr的变化趋势相同,x = 0.04陶瓷的d33和εrPr最优,符合唯像理论Pr ∝ d33εr.这表明,压电、介电与铁电相互依赖,掺杂一定量的BYLZ有助于提高陶瓷的电性能.表2列出了一些KNN基压电陶瓷的电性能.可以看出,本文制备的陶瓷其各项电性能更好的满足实际应用的要求. ...

Techniques used to improve the tribological performance of the piston ring-cylinder liner contact

1

2019

... 0.04 < x ≤ 0.05的陶瓷其Pr值减小,因为和阳离子空位缺陷()产生了不可移动的中性缺陷复合物[32],如 式(3)所示,这些缺陷复合物在晶界处偏析产生了钉扎效应[35,36];同时,畴壁与空位缺陷之间较弱的相互作用使空位缺陷保持良好的流动性而使晶粒减小.这两种因素,使Pr值减小[37,38].EC的变化规律与Pr类似,即随着x的增加先增大后减小,并在x = 0.04时达到最大值.这表明,R-O-T三相共存使陶瓷具有良好的铁电性[39, 40].从图9c可见,d33和εrPr的变化趋势相同,x = 0.04陶瓷的d33和εrPr最优,符合唯像理论Pr ∝ d33εr.这表明,压电、介电与铁电相互依赖,掺杂一定量的BYLZ有助于提高陶瓷的电性能.表2列出了一些KNN基压电陶瓷的电性能.可以看出,本文制备的陶瓷其各项电性能更好的满足实际应用的要求. ...

Relationship between poling characteristics and phase boundaries of potassium-sodium niobate ceramics

1

2016

... 0.04 < x ≤ 0.05的陶瓷其Pr值减小,因为和阳离子空位缺陷()产生了不可移动的中性缺陷复合物[32],如 式(3)所示,这些缺陷复合物在晶界处偏析产生了钉扎效应[35,36];同时,畴壁与空位缺陷之间较弱的相互作用使空位缺陷保持良好的流动性而使晶粒减小.这两种因素,使Pr值减小[37,38].EC的变化规律与Pr类似,即随着x的增加先增大后减小,并在x = 0.04时达到最大值.这表明,R-O-T三相共存使陶瓷具有良好的铁电性[39, 40].从图9c可见,d33和εrPr的变化趋势相同,x = 0.04陶瓷的d33和εrPr最优,符合唯像理论Pr ∝ d33εr.这表明,压电、介电与铁电相互依赖,掺杂一定量的BYLZ有助于提高陶瓷的电性能.表2列出了一些KNN基压电陶瓷的电性能.可以看出,本文制备的陶瓷其各项电性能更好的满足实际应用的要求. ...

High piezoelectric performance and cost-effective Pb(Mn1/3Nb2/3)O3-Pb(Zr,Ti)O3 piezoelectric ceramics

1

2023

... 0.04 < x ≤ 0.05的陶瓷其Pr值减小,因为和阳离子空位缺陷()产生了不可移动的中性缺陷复合物[32],如 式(3)所示,这些缺陷复合物在晶界处偏析产生了钉扎效应[35,36];同时,畴壁与空位缺陷之间较弱的相互作用使空位缺陷保持良好的流动性而使晶粒减小.这两种因素,使Pr值减小[37,38].EC的变化规律与Pr类似,即随着x的增加先增大后减小,并在x = 0.04时达到最大值.这表明,R-O-T三相共存使陶瓷具有良好的铁电性[39, 40].从图9c可见,d33和εrPr的变化趋势相同,x = 0.04陶瓷的d33和εrPr最优,符合唯像理论Pr ∝ d33εr.这表明,压电、介电与铁电相互依赖,掺杂一定量的BYLZ有助于提高陶瓷的电性能.表2列出了一些KNN基压电陶瓷的电性能.可以看出,本文制备的陶瓷其各项电性能更好的满足实际应用的要求. ...

Effects of MnO2-doping on growth, structure and electrical properties of lead-free piezoelectric K0.5Na0.5NbO3-BiAlO3 single crystals

1

2023

... 0.04 < x ≤ 0.05的陶瓷其Pr值减小,因为和阳离子空位缺陷()产生了不可移动的中性缺陷复合物[32],如 式(3)所示,这些缺陷复合物在晶界处偏析产生了钉扎效应[35,36];同时,畴壁与空位缺陷之间较弱的相互作用使空位缺陷保持良好的流动性而使晶粒减小.这两种因素,使Pr值减小[37,38].EC的变化规律与Pr类似,即随着x的增加先增大后减小,并在x = 0.04时达到最大值.这表明,R-O-T三相共存使陶瓷具有良好的铁电性[39, 40].从图9c可见,d33和εrPr的变化趋势相同,x = 0.04陶瓷的d33和εrPr最优,符合唯像理论Pr ∝ d33εr.这表明,压电、介电与铁电相互依赖,掺杂一定量的BYLZ有助于提高陶瓷的电性能.表2列出了一些KNN基压电陶瓷的电性能.可以看出,本文制备的陶瓷其各项电性能更好的满足实际应用的要求. ...

Ferroelectric polycrystals: Structural and microstructural levers for property-engineering via domain-wall dynamics

1

2023

... 0.04 < x ≤ 0.05的陶瓷其Pr值减小,因为和阳离子空位缺陷()产生了不可移动的中性缺陷复合物[32],如 式(3)所示,这些缺陷复合物在晶界处偏析产生了钉扎效应[35,36];同时,畴壁与空位缺陷之间较弱的相互作用使空位缺陷保持良好的流动性而使晶粒减小.这两种因素,使Pr值减小[37,38].EC的变化规律与Pr类似,即随着x的增加先增大后减小,并在x = 0.04时达到最大值.这表明,R-O-T三相共存使陶瓷具有良好的铁电性[39, 40].从图9c可见,d33和εrPr的变化趋势相同,x = 0.04陶瓷的d33和εrPr最优,符合唯像理论Pr ∝ d33εr.这表明,压电、介电与铁电相互依赖,掺杂一定量的BYLZ有助于提高陶瓷的电性能.表2列出了一些KNN基压电陶瓷的电性能.可以看出,本文制备的陶瓷其各项电性能更好的满足实际应用的要求. ...

Improving electromechanical properties in KNANS-BNZ ceramics by the synergy between phase structure modification and grain orientation

1

2020

... Comparison of the experimental data with the electrical properties of other KNN-based piezoelectric ceramics

Table 2| Material | d33pC/N | ECkV·cm-1 | PrμC·cm-2 | εr | TCoC | Reference |

|---|

| 0.95(Na0.5K0.5)NbO3-0.05SrTiO3 | 130 | 14.2 | 13.8 | 1352 | 308 | [25] |

| 0.95(K0.6Na0.4)NbO3-0.05(Bi0.5Na0.5)ZrO3 | 340 | | 19.58 | | | [4] |

| 0.97(K0.5Na0.5)0.98-Ag0.02(Nb0.96Sb0.04)O3-0.03(Bi0.5Na0.5)ZrO3 | 550 | | | | 250 | [41] |

| 0.96K0.5Na0.5NbO3-0.04CaSnO3 | 430 | | | 32168 | 297 | [42] |

| 0.865(K0.5Na0.5)0.98Ag0.02Nb0.96Ta0.04O3-0.035CuO-0.01Na2O | 343 | 19.2 | 24.9 | 1382 | 306 | [43] |

| 0.96(K0.5Na0.5)NbO3-0.04[NaSbO3 +Bi0.5(Na0.8K0.2)0.5(Zr0.5Hf0.5)O3] | 452 | | | 4414 | | [44] |

| 0.96K0.5Na0.5(Nb0.95Ta0.05)O3-0.04(Bi0.5Yb0.5)0.95Li0.05 ZrO3 | 305 | 20.67 | 34.63 | 1710 | 340 | This work |

<strong>3</strong> 结论(1) 用传统固相法可制备具有R-O-T多相共存的(1-x)K0.5Na0.5(Nb0.95Ta0.05)O3-x(Bi0.5Yb0.5)0.95Li0.05ZrO3陶瓷.随着BYLZ含量的提高A、B位的离子半径和电荷的不同使晶格显著失配,空位(缺陷)上的局域化电子和空穴对铁电畴壁的钉扎降低了畴壁的可动性,使其铁电性提高. ...

Synthesis and investigation of (1-x)K0.5Na0.5NbO3-(x)CaSnO3 lead free perovskite ceramics of high dielectric and piezoelectric properties for transducer applications

1

2022

... Comparison of the experimental data with the electrical properties of other KNN-based piezoelectric ceramics

Table 2| Material | d33pC/N | ECkV·cm-1 | PrμC·cm-2 | εr | TCoC | Reference |

|---|

| 0.95(Na0.5K0.5)NbO3-0.05SrTiO3 | 130 | 14.2 | 13.8 | 1352 | 308 | [25] |

| 0.95(K0.6Na0.4)NbO3-0.05(Bi0.5Na0.5)ZrO3 | 340 | | 19.58 | | | [4] |

| 0.97(K0.5Na0.5)0.98-Ag0.02(Nb0.96Sb0.04)O3-0.03(Bi0.5Na0.5)ZrO3 | 550 | | | | 250 | [41] |

| 0.96K0.5Na0.5NbO3-0.04CaSnO3 | 430 | | | 32168 | 297 | [42] |

| 0.865(K0.5Na0.5)0.98Ag0.02Nb0.96Ta0.04O3-0.035CuO-0.01Na2O | 343 | 19.2 | 24.9 | 1382 | 306 | [43] |

| 0.96(K0.5Na0.5)NbO3-0.04[NaSbO3 +Bi0.5(Na0.8K0.2)0.5(Zr0.5Hf0.5)O3] | 452 | | | 4414 | | [44] |

| 0.96K0.5Na0.5(Nb0.95Ta0.05)O3-0.04(Bi0.5Yb0.5)0.95Li0.05 ZrO3 | 305 | 20.67 | 34.63 | 1710 | 340 | This work |

<strong>3</strong> 结论(1) 用传统固相法可制备具有R-O-T多相共存的(1-x)K0.5Na0.5(Nb0.95Ta0.05)O3-x(Bi0.5Yb0.5)0.95Li0.05ZrO3陶瓷.随着BYLZ含量的提高A、B位的离子半径和电荷的不同使晶格显著失配,空位(缺陷)上的局域化电子和空穴对铁电畴壁的钉扎降低了畴壁的可动性,使其铁电性提高. ...

Structure and properties of (K0.5Na0.5)0.98Ag0.02Nb0.96Ta0.04O3 piezoelectric ceramics doped by CuO

1

2018

... Comparison of the experimental data with the electrical properties of other KNN-based piezoelectric ceramics

Table 2| Material | d33pC/N | ECkV·cm-1 | PrμC·cm-2 | εr | TCoC | Reference |

|---|

| 0.95(Na0.5K0.5)NbO3-0.05SrTiO3 | 130 | 14.2 | 13.8 | 1352 | 308 | [25] |

| 0.95(K0.6Na0.4)NbO3-0.05(Bi0.5Na0.5)ZrO3 | 340 | | 19.58 | | | [4] |

| 0.97(K0.5Na0.5)0.98-Ag0.02(Nb0.96Sb0.04)O3-0.03(Bi0.5Na0.5)ZrO3 | 550 | | | | 250 | [41] |

| 0.96K0.5Na0.5NbO3-0.04CaSnO3 | 430 | | | 32168 | 297 | [42] |

| 0.865(K0.5Na0.5)0.98Ag0.02Nb0.96Ta0.04O3-0.035CuO-0.01Na2O | 343 | 19.2 | 24.9 | 1382 | 306 | [43] |

| 0.96(K0.5Na0.5)NbO3-0.04[NaSbO3 +Bi0.5(Na0.8K0.2)0.5(Zr0.5Hf0.5)O3] | 452 | | | 4414 | | [44] |

| 0.96K0.5Na0.5(Nb0.95Ta0.05)O3-0.04(Bi0.5Yb0.5)0.95Li0.05 ZrO3 | 305 | 20.67 | 34.63 | 1710 | 340 | This work |

<strong>3</strong> 结论(1) 用传统固相法可制备具有R-O-T多相共存的(1-x)K0.5Na0.5(Nb0.95Ta0.05)O3-x(Bi0.5Yb0.5)0.95Li0.05ZrO3陶瓷.随着BYLZ含量的提高A、B位的离子半径和电荷的不同使晶格显著失配,空位(缺陷)上的局域化电子和空穴对铁电畴壁的钉扎降低了畴壁的可动性,使其铁电性提高. ...

Phase coexistence induced strong piezoelectricity in K0.5Na0.5NbO3-based lead-free ceramics

1

2019

... Comparison of the experimental data with the electrical properties of other KNN-based piezoelectric ceramics

Table 2| Material | d33pC/N | ECkV·cm-1 | PrμC·cm-2 | εr | TCoC | Reference |

|---|

| 0.95(Na0.5K0.5)NbO3-0.05SrTiO3 | 130 | 14.2 | 13.8 | 1352 | 308 | [25] |

| 0.95(K0.6Na0.4)NbO3-0.05(Bi0.5Na0.5)ZrO3 | 340 | | 19.58 | | | [4] |

| 0.97(K0.5Na0.5)0.98-Ag0.02(Nb0.96Sb0.04)O3-0.03(Bi0.5Na0.5)ZrO3 | 550 | | | | 250 | [41] |

| 0.96K0.5Na0.5NbO3-0.04CaSnO3 | 430 | | | 32168 | 297 | [42] |

| 0.865(K0.5Na0.5)0.98Ag0.02Nb0.96Ta0.04O3-0.035CuO-0.01Na2O | 343 | 19.2 | 24.9 | 1382 | 306 | [43] |

| 0.96(K0.5Na0.5)NbO3-0.04[NaSbO3 +Bi0.5(Na0.8K0.2)0.5(Zr0.5Hf0.5)O3] | 452 | | | 4414 | | [44] |

| 0.96K0.5Na0.5(Nb0.95Ta0.05)O3-0.04(Bi0.5Yb0.5)0.95Li0.05 ZrO3 | 305 | 20.67 | 34.63 | 1710 | 340 | This work |

<strong>3</strong> 结论(1) 用传统固相法可制备具有R-O-T多相共存的(1-x)K0.5Na0.5(Nb0.95Ta0.05)O3-x(Bi0.5Yb0.5)0.95Li0.05ZrO3陶瓷.随着BYLZ含量的提高A、B位的离子半径和电荷的不同使晶格显著失配,空位(缺陷)上的局域化电子和空穴对铁电畴壁的钉扎降低了畴壁的可动性,使其铁电性提高. ...