近年来,国内外对V-Ti[7,14]、Nb-V-Ti[10,15]和Ti-V-Mo[16]等复合微合金钢中纳米析出相的晶体结构、位相关系及强化机制进行了深入研究。结果表明,优化复合微合金钢的控轧控冷工艺可使其复合纳米析出相体积分数大、平均尺寸小、热稳定性高和沉淀强化效果好[17]。Zhang等[18]研究了卷曲温度对Ti-V-Mo钢纳米相和力学性能的影响,发现适当改变卷曲温度可显著改变纳米析出相的数量和尺寸。卷曲温度为600 ℃时纳米析出相的析出量较多且平均尺寸细小,沉淀强化效果最好。He等[19]研究了等温温度对Ti-Mo微合金钢力学性能的影响,发现降低等温温度可使其硬度提高。Fu等[20]研究了轧制温度对Ti-V-Mo钢的组织演变和析出相的影响,发现降低轧制温度能促进(Ti, V, Mo)C相的析出和使铁素体晶粒细化,从而提高抗拉强度和屈服强度。Yi等[21]研究了不同卷曲温度Nb-V-Ti复合微合金钢的力学性能,发现在400~500 ℃卷曲时其屈服强度和延伸率较高。本文对Ti-V-Mo复合微合金钢进行热模拟,研究终冷温度对析出相、组织和硬度的影响并分析其机理。

1 实验方法

实验用钢的化学成分列于表1。用50 kg真空冶炼炉冶炼实验用钢并将钢锭轧制成厚度为30 mm的钢板,用线切割机切取直径为8 mm、长度15 mm的试样。使用热力学软件(TCFE7)计算实验钢平衡状态的相变点,Ae1为758 ℃,Ae3为878 ℃,未再结晶温度为Tnr ≈ 970 ℃。

表1 实验钢的化学成分

Table.1

| C | Si | Mn | Ti | V | Mo | P | S | N | Fe |

|---|---|---|---|---|---|---|---|---|---|

| 0.16 | 0.16 | 1.04 | 0.20 | 0.41 | 0.44 | 0.0041 | 0.0052 | 0.0046 | Bal. |

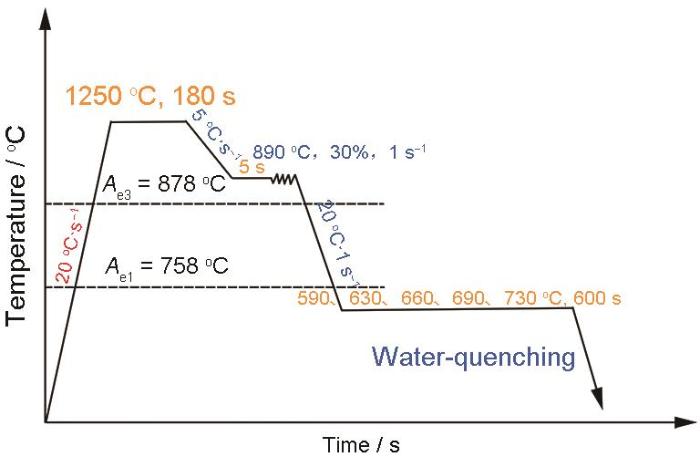

用Gleeble-3800热模拟实验机以20 ℃/s的速率将实验钢加热至1250 ℃,保温180 s后以5 ℃/s的速率冷却至890 ℃保温5 s,然后以1 s-1的应变速率进行30%的压缩变形。压缩变形后以20 ℃/s的速率分别冷却至(终冷温度)590 ℃、630 ℃、660 ℃、690 ℃和730 ℃,保温600 s后等温淬火至室温。图1给出了实验钢的热模拟工艺示意图。

图1

图1

Ti-V-Mo实验用钢的热模拟工艺示意图

Fig.1

Schematic diagram of thermal simulation process of Ti-V-Mo experimental steel

用砂纸将热模拟后的实验钢打磨后抛光至镜面,再将其放置在4%的硝酸酒精溶液中腐蚀10 s,然后用GX 51型光学显微镜(OM)和NANO SEM430型场发射扫描电子显微镜(SEM)观察其组织形貌。用型号为Talos F200X带能谱仪(EDS)的透射电子显微镜(TEM)观察实验钢中纳米析出相的形貌和成分。用线切割机床将选取的试样切成厚度为0.5 mm的薄片,再用砂纸反复打磨至厚度为40~50 μm,随后用冲样器裁剪成半径为1.5 mm的薄片。用MTP-1A型磁力驱动双喷电解减薄仪将圆形薄片离子减薄,制成薄膜透射试样。电解双喷试液为8%的高氯酸乙醇溶液,电解温度为-20 ℃,电流为50 mA,双喷时间为70~80 s。用VH5 Vickers维氏硬度计测定样品的硬度,加载时间为10 s,载荷为500 g。测试15个点的硬度,去除最大值和最小值后取其余结果的平均值。

2 结果和讨论

2.1 实验钢的显微组织

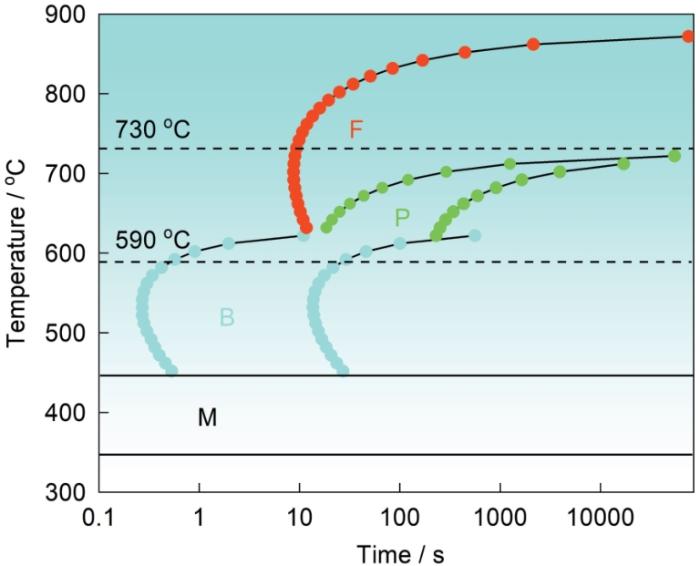

图2给出了使用JMatPro软件模拟计算出的实验钢中过冷奥氏体的等温转变曲线。可以看出,在590 ℃保温26 s后钢中的奥氏体发生贝氏体转变得到贝氏体组织。而在630 ℃、660 ℃和690 ℃保温后,奥氏体依次发生先共析铁素体转变和珠光体转变,得到先共析铁素体和珠光体组织,珠光体相变完成时间分别为288.6、403.4和1423.3 s。在730 ℃保温10 s奥氏体发生先共析铁素体转变但是不发生珠光体转变(因为完成先共析铁素体转变需要很长的时间),因此保温冷却后只能得到马氏体和先共析铁素体组织。

图 2

图 2

实验钢过冷奥氏体的等温转变曲线

Fig.2

Experimental steel supercooled austenite isothermal transformation curve

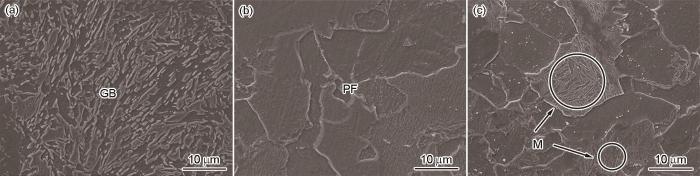

图3给出了不同终冷温度实验钢的OM像,图4给出了SEM像。可以看出,终冷温度为590 ℃的实验钢,其组织中的铁素体晶粒呈块状或针状,其中分布有颗粒状的马奥岛(图3a),图4a中的SEM照片进一步印证了粒状贝氏体(GB)显微组织。终冷温度为630 ℃的实验钢,其组织中不同铁素体晶粒的晶界呈多边形状且较为清晰(图3b),表明其组织为多边形铁素体。随着终冷温度由630 ℃提高到690 ℃,其组织均为多边形铁素体(PF),且平均晶粒尺寸逐渐增大(图3b~d),几乎没有珠光体组织。其原因是,在等温过程中实验钢中的大量强碳化物形成元素Ti、V和Mo充分与钢中的C元素结合生成纳米析出相,抑制了珠光体和渗碳体的生成[22]。使用软件进行理论计算,得到的参数只有奥氏体化温度与奥氏体化时间,没有终冷前的热模拟压缩变形过程(图1),这是实际结果与模拟结果不同的原因。Zhang等[18]研究发现,在奥氏体区压缩变形时,奥氏体的加工硬化率越高产生的位错和缺陷越多,铁素体的形核位置增多抑制了珠光体的生成,进一步解释了模拟与实际结果的差别。终冷温度为730 ℃的实验钢,其组织为铁素体加马氏体(M,图4c),与图2给出的结果一致。

图3

图3

不同终冷温度实验钢的OM像

Fig.3

OM images of experimental steel at different final cooling temperatures (a) 590 ℃, (b) 630 ℃, (c) 660 ℃, (d) 690 ℃, (e) 730 ℃

图4

图4

不同终冷温度实验钢的SEM像

Fig.4

SEM images of experimental steel at different final cooling temperatures (a) 590 ℃, (b) 690 ℃, (c) 730 ℃

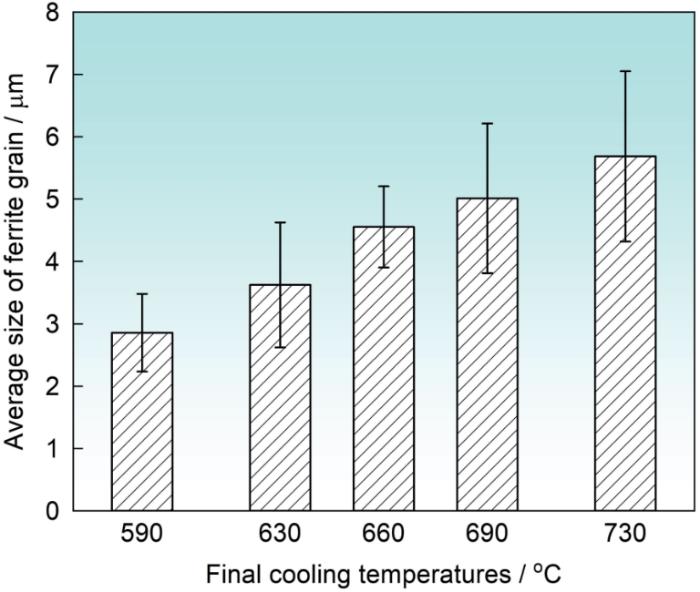

图5给出了不同终冷温度实验钢中铁素体的平均晶粒尺寸。可以看出,随着终冷温度的提高铁素体的平均晶粒尺寸增大,终冷温度为590 ℃实验钢,其平均晶粒尺寸最小(约为2.9 μm),终冷温度为730 ℃实验钢,其平均晶粒尺寸最大(约为5.7 μm)。其原因是,随着终冷温度的提高原子的扩散能力和晶界的迁移速率提高,使铁素体晶粒长大的速率提高。根据文献[23]中的Hall-Petch公式,铁素体的晶粒越小其细晶强化效果越好。随着终冷温度由590 ℃提高到730 ℃,实验钢中铁素体晶粒的平均晶粒逐渐增大,因为在奥氏体向铁素体转变过程中铁素体晶粒的长大与碳原子的扩散速度密切相关[24]。终冷温度为590 ℃时,较低的温度限制了晶界的运动而阻碍了铁素体晶粒的长大[25]。同时,在等温过程中,碳原子的扩散速率较低使富碳奥氏体保留在多边形铁素体内。随着时间的增加过饱和的碳重新分配到岛状奥氏体周围,抑制了奥氏体的转变而形成了粒状小岛[26],其结果是等温淬火后得到粒状贝氏体。在630~690 ℃终冷时,温度的提高使碳原子的扩散系数增大,奥氏体中的碳浓度的降低使富碳奥氏体区消失。同时,实验钢中大量的强碳化物形成元素与碳结合而抑制了渗碳体的析出,使奥氏体几乎全部转变为铁素体[27]。特别是,温度的提高增强了晶界的移动能力,促进了铁素体晶粒的形核,使奥氏体更容易向铁素体转变,因此得到了完全的铁素体组织。终冷温度提高到730 ℃时,虽然原子的扩散系数增大但是其相变驱动力降低,使铁素体在奥氏体中的形核率降低,结果是剩余奥氏体等温淬火后得到马氏体[28]。这表明,终冷温度越高铁素体的晶粒尺寸越大,组织的粗化越显著(图5)。

图5

图5

不同终冷温度实验钢中铁素体晶粒的平均尺寸

Fig.5

Average size of ferrite grains in experimental steel at different final cooling temperatures

2.2 不同终冷温度钢中的析出相

图6

图6

在660 ℃ 终冷实验钢中纳米析出相的HRTEM像、Fourier变换衍射谱和EDS

Fig.6

HRTEM images, Fourier-transform diffraction patterns and EDS of nano-precipitates at 660 oC (a) HRTEM images, (b) magnified HRTEM image of (a), (c) the fast Fourier transformation diffractogram, (d) EDS analysis

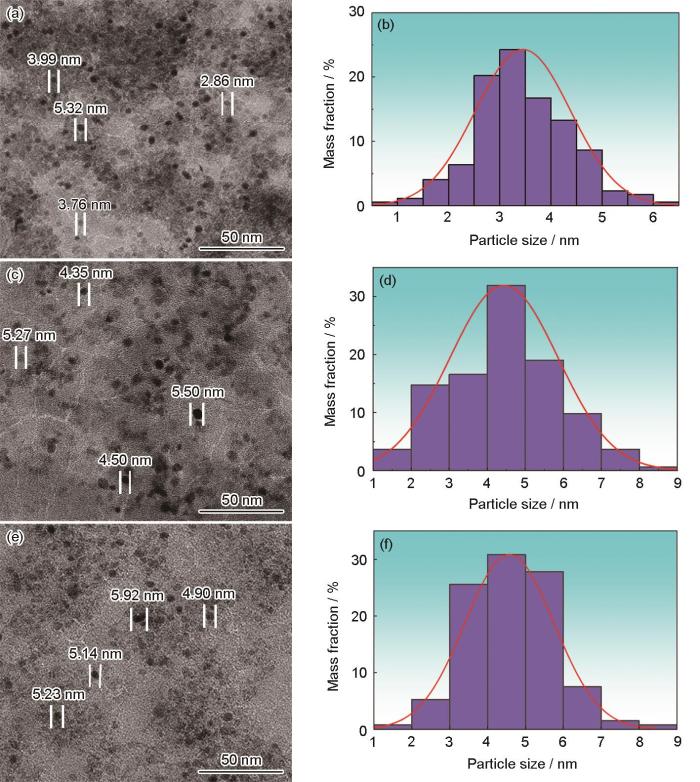

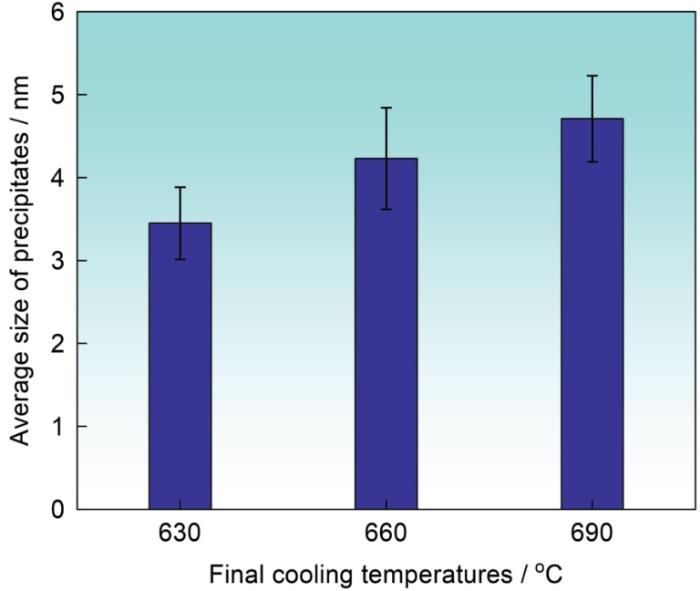

图7给出了不同终冷温度实验钢的TEM像。可以看出,(Ti, V, Mo)C析出相为圆形或者椭圆形,为链状或者胞状分布[29,30],终冷温度分别为630 ℃、660 ℃和690 ℃的实验钢中(Ti, V, Mo)C粒子的尺寸范围分别为2.9~5.3 nm (图7a)、4.4~5.5 nm (图7c)和4.9~5.9 nm (图7e)。终冷温度为630 ℃的钢中(Ti, V, Mo)C尺寸为3.0~3.5 nm的比例最大为24%(图7b)。终冷温度为660 ℃的钢中(Ti, V, Mo)C尺寸为4.0~4.5 nm的比例最大为32% (图7d)。终冷温度为690 ℃的钢中(Ti, V, Mo)C尺寸为4.0~5.0 nm的比例最大为31%(图7f)。(Ti, V, Mo)C粒子最大范围比例的尺寸分布不断增大(图7b, d, f),但是其平均尺寸均小于10 nm。文献[31, 32]的结果表明,铁素体基体中的(Ti, V, Mo)C粒子一般为相间析出和弥散析出,其尺寸小于10 nm,对基体的沉淀强化效果较好。图8给出了不同终冷的温度钢中(Ti, V, Mo)C的平均尺寸。可以看出,随着终冷温度的提高钢中(Ti, V, Mo)C粒子的平均尺寸增大。终冷温度为630 ℃、660 ℃和690 ℃钢中的(Ti, V, Mo)C粒子,其平均尺寸分别为3.45、4.23和4.71 nm (图8)。

图7

图7

不同终冷温度实验钢的TEM像和尺寸分布

Fig.7

TEM images and size distribution of experimental steel at different final cooling temperatures (a, b) 630 oC, (c, d) 660 oC, (e, f) 690 oC

图8

图8

不同终冷温度实验钢中纳米析出相的平均尺寸

Fig.8

Average size of nano-sized precipitates at different final cooling temperatures

随着终冷温度的提高(Ti, V, Mo)C析出相的平均尺寸增大,其机制为:(1) 在高温下原子的热激活扩散速率显著提高,加速了(Ti, V, Mo)C的粗化[33,34]。(2) (Ti, V, Mo)C的形核位置在晶界和位错等缺陷处,温度越低铁素体的晶粒尺寸越小(图5),晶界和位错等缺陷增加则(Ti, V, Mo)C的形核位置增多,析出的(Ti, V, Mo)C较为细小弥散。同时,较高的冷速能抑制微合金碳氮化物的析出,使铁素体基体中的微合金元素的过饱和度提高。因此,终冷温度越高,(Ti, V, Mo)C的尺寸越大[35]。(3) 温度越高,合金元素的扩散能力越强,使(Ti, V, Mo)C粒子长大和粗化则纳米析出相的尺寸更大 [29]。同时,铁素体晶粒越大,晶界减少、位错密度和(Ti, V, Mo)C的形核率降低,使等温过程中原子的扩散速度提高和(Ti, V, Mo)C粒子偏聚长大[36]。最后,根据析出动力学和文献[27, 37]的结果,与终冷温度为690 ℃的钢相比,终冷温度为630~660 ℃的钢中(Ti, V, Mo)C析出相的形核率较大,其析出相的数量更多,平均尺寸更小。这个结果与图7和8给出的铁素体基体中纳米析出相的变化趋势一致。

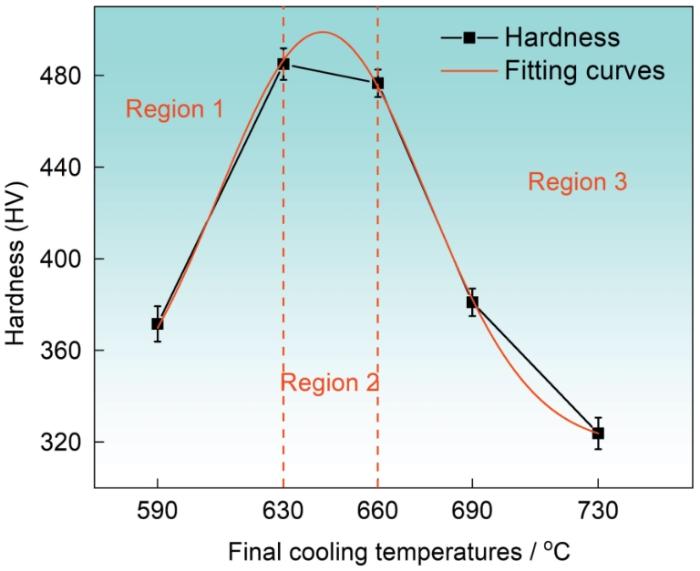

2.3 不同终冷温度实验钢的硬度

图9给出了不同终冷温度实验钢的硬度。可以看出,硬度的变化有3个阶段。阶段1:随着终冷温度由590 ℃提高到630 ℃,实验钢的硬度由372HV提高到485HV,终冷温度为630 ℃的实验钢其硬度最高。阶段2:终冷温度为630和660 ℃的实验钢,其硬度分别为485HV和477HV,硬度的变化很小。阶段3:随着终冷温度由660 ℃提高到730 ℃,实验钢的硬度从477HV降低到324HV。

图9

图9

不同终冷温度实验钢的硬度及其拟合曲线

Fig.9

Hardness and fitting curves of hardness for experimental steel at different final cooling temperature

阶段1硬度提高的主要原因是:第一,随着铁素体晶粒的长大(图5),细晶强化效果降低,但是铁素体基体中析出的(Ti, V, Mo)C的增加使沉淀强化对硬度的影响占据主导,因此硬度呈提高趋势[38]。第二,终冷温度为590 ℃时,较低的温度使粒状贝氏体中的(Ti, V, Mo)C产生的沉淀强化减弱[35]。第三,以铁素体为基体的低碳微合金钢中,铁素体中(Ti, V, Mo)C的最大形核率温度为630~650 ℃。与590 ℃相比,终冷温度为630和660 ℃的钢中(Ti, V, Mo)C粒子的形核率更大。大量的(Ti, V, Mo)C均匀弥散析出,使沉淀强化效果增强[39],因此硬度呈上升趋势。以铁素体为基体的复合微合金钢,其强化方式有细晶强化和第二相强化等方式。阶段2的硬度变化可根据公式

根据

3 结论

(1) 终冷温度为590 ℃的实验钢其组织为粒状贝氏体,终冷温度为630~690 ℃的组织为多边形铁素体,终冷温度为730 ℃的组织为铁素体和马氏体。实验钢中铁素体的平均晶粒尺寸随着终冷温度的升高而增大,由590 ℃时的2.9 μm增大到730 ℃时的5.7 μm。实验钢中铁素体平均晶粒尺寸的变化和(Ti, V, Mo)C粒子析出行为的改变,是导致其硬度变化的重要因素。

(2) 随着终冷温度由630 ℃提高到690 ℃,实验钢中铁素体的平均晶粒尺寸由3.62 μm增大到5.01 μm,(Ti, V, Mo)C粒子的平均尺寸由3.45 nm增大到4.71 nm,由于铁素体晶粒尺寸增大引起的细晶强化效果减弱和纳米析出相粗化导致的沉淀强化效果的下降,使得钢材硬度降低。终冷温度为630和660 ℃的实验钢其硬度接近,因为此温度范围接近(Ti, V, Mo)C的最大形核率温度,其沉淀强化效果的增加显著大于细晶强化效果的下降。

(3) 终冷温度由590 ℃提高到730 ℃实验钢的硬度呈现先较快增加再相对平稳又快速下降的趋势。硬度

参考文献

Isothermal transformation and precipitation behaviors of titanium microalloyed steels

[J].

Effect of Zr on deformed austenite recrystallization and precipitates in Ti-microalloyed low carbon steel

[J].The recrystallization and precipitates of deformed austenite for three Ti-microalloyed low carbon steels with different amount of Zr and Ti in the temperature range of 950°C to 1050°C were investigated by means of multi-pass compression test to simulate the actual rolling situation, in order to acquire the optimum deformation temperature for the alloys. The results show that the increase of Ti content will retard the occurrence of the recrystallization of deformed austenite and the recrystallization grain growth in Ti-microalloyed steels, while the addition of Zr will also retard the occurrence of recrystallization of deformed austenite in Ti-microalloy steel, and inhibit the growth of recrystallization grains. Besides, the addition of Zr increases the number of precipitates in Ti-microalloyed steel, and improves the size uniformity of precipitated phase, so that the Ti-Zr microalloyed steel consists of a relatively uniform austenite microstructure. When the deformation temperature is 1000℃, the Ti-Zr microalloyed steel has the finest uniform austenite microstructure.

Zr对Ti微合金化低碳钢形变奥氏体再结晶和析出相的影响

[J].通过多道次模拟压缩实验,研究不同Zr和Ti含量的三种Ti微合金化低碳钢在950℃~1050℃形变奥氏体再结晶和析出相的变化和最佳变形温度。结果表明,Ti含量的提高和Zr的加入使Ti微合金钢形变奥氏体的再结晶和晶粒长大延迟。Zr的加入还能增加Ti微合金钢中析出相的数量、改善析出相尺寸分布的均匀性进而得到相对均匀的奥氏体组织。变形温度为1000℃时的Ti-Zr微合金钢奥氏体组织最细小均匀。

Effect of cluster chemistry on the strengthening of Al alloys

[J].

Grain boundary diffusion in a compositionally complex alloy: interplay of segregation, precipitation and interface structures in a Ni-Cr-Mo alloy

[J].

Influence of Cr and Cr+Nb on the interphase precipitation and mechanical properties of V-Mo microalloyed steels

[J].

High-temperature mechanical properties and strengthening mechanism of new secondary hardened steel 25CrMo3NiTiVNbZr

[J].A novel secondary hardened steel 25CrMo3NiTiVNbZr was developed via optimization the chemical composition of the 25Cr3Mo3NiNbZr steel bymeans of the so called JMatpro and Thermo-Calc software. Then the microstructure, phase composition, morphology of precipitates and mechanical performance at 700℃ of the 25CrMo3NiTiVNbZr steel were characterized by means of transmission electron microscopy (TEM), electron backscattering diffraction (EBSD), while its the high-temperature streng-thening mechanism was also elucidated. The results show that the tensile strength and yield strength of 25CrMo3NiTiVNbZr steel at 700oC are 543 MPa and 409 MPa, respectively, which are 139 MPa and 123 MPa higher than that of 25Cr3Mo3NiNbZr steel. The high-temperature strengthening of the 25CrMo3NiTiVNbZr steel may mainly ascribed to themechanism, precipitation strengthening. In the process of being stretched at 700oC, the precipitation strengthening increment derived from the precipitation of the strengthening phase for the 25CrMo3NiTiVNbZr steel reached 367 MPa, which was 147 MPa higher than that of the 25Cr3Mo3NiNbZr steel. This is mainly due to the higher thermal stability and smaller size (average size at 7.93 nm) of the precipitated strengthening phases in the 25CrMo3NiTiVNbZr steel. After high-temperature stretching, the average size of precipitates remained at 8.14 nm.

新型二次硬化钢25CrMo3NiTiVNbZr的高温力学性能和强化机理

[J].使用JMatpro和Thermo-Calc软件优化25Cr3Mo3NiNbZr钢的成分,使用透射电镜(TEM)、电子背散射衍射(EBSD)和相分析等手段表征在700℃高温拉伸前后试样的显微组织和析出相以研究其高温强化机理。结果表明:25CrMo3NiTiVNbZr钢700℃的高温抗拉强度和屈服强度分别为543 MPa、409 MPa,比25Cr3Mo3NiNbZr钢提高了139 MPa和123 MPa。根据对这种钢高温强化机理的分析,析出强化是主要强化方式。在700℃高温拉伸25CrMo3NiTiVNbZr钢其析出强化增量为367 MPa,比25Cr3Mo3NiNbZr钢提高147 MPa,其主要原因是在25CrMo3NiTiVNbZr中析出了热稳定性更高、尺寸更小(平均尺寸为7.93 nm)的析出相。

Effect of high heat input welding on the microstructures, precipitates and mechanical properties in the simulated coarse grained heat affected zone of a low carbon Nb-V-Ti-N microalloyed steel

[J].

Influence of cryogenic treatment time on the mechanical properties of AZ31 magnesium alloy sheets after cross-rolling

[J].

Effect of cooling medium on the κ carbide precipitation behavior, microstructure and impact properties of FeMnAlC low-density steel

[J].

Effect of Nb on inclusions and phase transformation in simulated high heat input coarse-grain HAZ of Nb/Ti low carbon microalloyed steel

[J].

Quantitative analysis of precipitation and strengthening mechanisms of V and V-Ti hot-rolled microalloyed steels

[J].

Evolution of the microstructure and mechanical properties of a V-containing microalloyed steel during coiling

[J].

Effect of ausforming on the bainitic transformation and microstructure in medium carbon V-N micro-alloyed steel

[J].

Effects of rapid heating on the phase transformation and grain refinement of a low-carbon mciroalloyed steel

[J].

Strain-induced precipitation behavior and microstructure evolution of Ti-V-Mo complex microalloyed steel

[J].

Precipitates and their strengthening in Ti-V-Mo microalloyed 22MnB5 steel

[J].

Ti-V-Mo微合金化22MnB5钢中析出相及其强化作用

[J].

Effect of isothermal holding time on microstructure, precipitates and hardness of Ti-V-Mo microalloyed steel during coiling process

[J].

Development of Ti-V-Mo complex microalloyed hot-rolled 900-MPa-grade high-strength steel

[J].

On the correlation among isothermal transformation, interphase precipitation behaviour and elements partitioning in Ti-Mo microalloyed steel

[J].

Microstructure evolution and precipitation behavior of hot-rolled high-strength Ti-Mo-V micro-alloyed steel

[J].

Development of Nb-V-Ti hot-rolled high strength steel with fine ferrite and precipitation strengthening

[J].

Study on the nano-precipitation behavior, microstructure and mechanical properties of Ti-V-Mo complex microalloyed steel

[D].

Ti-V-Mo复合微合金钢纳米相析出行为及组织硬度研究

[D].

Deciphering the quantitative relationships between age-induced hierarchical microstructure characteristics and tensile properties of Ti20C alloy

[J].

A phase-field investigation of the effect of grain-boundary diffusion on austenite to ferrite transformation

[J].

Research on microstructure and mechanical properties of HG550 beam steel under ultra-fast cooling conditions

[D].

超快冷条件下大梁钢HG550组织性能研究

[D].

Microstructure and mechanical properties of an austempered nanostructured bainitic steel

[J].Based on Thermo-Calc calculation, a nanostructured bainite steel, which is suitable for making steel wire, with composition of Fe-0.8C-2Mn-1.5Si-1.5Cr-0.25Mo-0.25Ni-1Al-0.25Co-0.1V was designed. The influence of austempering treatment on microstructure and mechanical properties of the steel was investigated by means of scanning electron microscope (SEM), X-ray diffractometer (XRD), transmission electron microscope (TEM), thermal dilatometer, and tensile tester in terms of microstructures, thermal and mechanical properties etc. Results show that after austempering at lower temperature, the microstructure of the nanostructured bainitic steel is composed of nanostructured bainite ferrite lath, retained austenite and a little proportion of martensite. With the increase of austempering temperature, the transformation rate and the volume fraction of bainite ferrite increase. As the austempering time increases, the volume fraction of bainite ferrite increases, while the amount of undercooled austenite decreases, and the size and volume fraction of the massive M/A islands obtained at room temperature decrease. Due to the carbon partitioning sufficiently between the bainite ferrite and austenite, the stability of undercooled austenite is improved, and the proportion of brittle martensite in M/A islands is reduced significantly. This induces the transition of tensile fracture from mixed fracture to quasi-cleavage fracture. After being heated at 230oC for 48 hours, the tensile strength and yield strength of the experimental steel were 1625 and 1505 MPa, respectively, with an elongation of 34.5%, indicating the best match for strength and toughness.

等温淬火对纳米贝氏体钢的组织和力学性能的影响

[J].依据Thermo-Calc计算设计了一种成分为Fe-0.8C-2Mn-1.5Si-1.5Cr-0.25Mo-0.25Ni-1Al-0.25Co-0.1V可用于制造钢丝的纳米贝氏体钢,使用热膨胀相变仪、扫描电镜(SEM)、X射线衍射(XRD)、透射电镜(TEM)和拉伸实验等手段研究了等温淬火温度和时间对其组织和力学性能影响。结果表明:这种纳米贝氏体钢低温等温淬火后的组织,由纳米结构的贝氏体铁素体板条、残余奥氏体和少量的马氏体组成。随着等温淬火温度的提高相变速率随之提高,贝氏体铁素体的体积分数增大。随着等温淬火时间的延长,贝氏体铁素体的体积分数增大而过冷奥氏体的量减少,在室温下生成的块状M/A岛的尺寸减小和体积分数降低,碳的配分使过冷奥氏体的稳定性提高,M/A岛中的脆性马氏体比例大幅度降低,拉伸断口由混合型断裂向准解理断裂转变。将这种钢在230℃保温48 h后强塑性匹配最佳,其抗拉强度和屈服强度分别达到1625和1505 MPa,延伸率达到34.5%。

Effect of cooling rate on microstructure evolution and mechanical properties of Ti-V-Mo complex microalloyed steel

[J].Nanoscale co-precipitation strengthening in steels has attracted increasing attention in recent years and has become a new cornerstone for the development of advanced high performance steels with superior combination of strength and ductility. Rolling process, finishing temperature, cooling rate and coiling temperature are the main factors which affect the mechanical properties of microalloyed steels by changing the volume fraction and particle size of precipitates. Nevertheless, the influence of cooling rate on microstructure evolution, precipitates and mechanical properties of complex microalloyed ferritic Ti-V-Mo steel has been rarely reported. In this work, the precipitation law of (Ti, V, Mo)C carbides at different cooling rates and its effect on microstructue evolution and mechanical properties of Ti-V-Mo complex miroalloyed steel were studied by OM, EBSD, HRTEM and Vickers-hardness test. The results indicated that the hardness first increased quickly and then increased slowly as the cooling rate increased (lower than 20 ℃/s); the mean size of (Ti, V, Mo)C particles decreased from 13.2 nm to 6.9 nm and the average size of ferrite grain reduced from 5.06 μm to 2.97 μm; the hardness of Ti-V-Mo steel was improved by the means of grain refinement hardening and precipitation hardening. However, when the cooling rate increased from 20 ℃/s to 30 ℃/s, its effects on grain refinement hardening and precipitation hardening has become saturated, so the hardness was kept flat and achieved a maximum vlaue of 410 HV, and the yield strength reached as high as 1090 MPa. The hardness y of Ti-V-Mo microalloyed steel and cooling rates x accord with a exponential decay relationship: y=-229exp(-x/5)+412.

冷却速率对Ti-V-Mo复合微合金钢组织转变及力学性能的影响

[J].

Precipitation behavior and microstructural evolution of ferritic Ti-V-Mo complex microalloyed steel

[J].

The effect of silicon, vanadium and nitrogen on the microstructure and hardness of air cooled medium carbon low alloy steels

[J].

Quantitative analysis of microstructures and strength of Nb-Ti microalloyed steel with different Ti additions

[J].

Microstructural characterization and strengthening behavior of nanometer sized carbides in Ti-Mo microalloyed steels during continuous cooling process

[J].

Effect of rare earth elements on austenite-ferrite phase transformation kinetics of low carbon steels

[J].With the increasing cleanliness of steels in recent years, it has made possible for making micro-alloyed steels with rare earth elements. It is found that the addition of rare earths has a significant effect on the solid-state phase transformation behavior of steels, especially for low-carbon low-alloy steels. The effectiveness in modifying the inclusions and inducing nucleation by RE addition has been studied intensively and approved substantially. Whereas, the micro-alloying effect of RE on the ferrite phase transformation of steel is still unclear. The effect of rare earth elements (RE) on austenite-ferrite transformation temperature during continuous cooling, and the isothermal transformation kinetics of Fe-C alloys and Fe-C-Si-Mn low carbon steels has been investigated in this article. It is found that a tiny amount of RE addition can reduce the starting point temperature of proeutectoid ferrite during continuous cooling. Additionally, the addition of RE also changes the ferrite transformation kinetics in the isothermal process: for Fe-C-(RE) alloys, the addition of RE slows down the transformation rate during the whole transformation process due to the pinning carbon diffusion effect; For Fe-C-Si-Mn alloys, RE elements can play a double role of pinning carbon diffusion and changing grain boundary energy, and then prolong the incubation period and decreases the rate of phase transformation during the initial stage, while increase the phase transformation rate during the middle and late of phase transformation.

稀土元素对低碳钢中奥氏体-铁素体相变动力学的影响

[J].

Heat-resistant Al alloys: microstructural design and preparation

[J].Aluminum (Al) alloys, a typical lightweight material, are limited to applications at temperatures below about 200 oC. The high-temperature range of 300-400 oC has been a longstanding bottleneck for traditional Al alloys. In this study, the underlying mechanisms of this service bottleneck are first discussed, and key scientific solutions aimed at overcoming the bottleneck are proposed. A new microstructure designing strategy is proposed to develop advanced heat-resistant Al alloys through phase transformation that couples rapidly diffusing solute atoms with slowly diffusing ones. This strategy leads to three design approaches for thermal stability: (1) interfacial solute segregation at the nanoprecipitate/matrix interfaces, (2) interstitial solute ordering within the coherent nanoprecipitates, and (3) multiple interfacial coherency coupling with multiscale microstructural features. By manipulating the microalloying effect at the atomic length scale, a series of 300-400 oC heat-resistant Al alloys were developed. Furthermore, the potential development directions of the heat-resistant Al alloys are also explored as possible references for future work.

耐热铝合金: 组织设计与合金制备

[J].

Interphase precipitation hardening of a TiMo microalloyed dual-phase steel produced by continuous cooling

[J].

Precipitation of nanoscale carbides in Ti-Mo microalloyed steel during tempering process

[J].

Ti-Mo微合金钢回火过程中纳米碳化物析出行为

[J].利用透射电镜对含Ti微合金钢热轧及回火后的析出相分布、形貌和尺寸进行了观察和分析,结合拉伸试验结果研究了回火过程中纳米析出颗粒的变化特征及其对试验钢强度变化的影响。结果表明,600℃回火2h试验钢的屈服强度达到最大值,这是由于除了热轧后空冷形成的高体积分数相间析出以外,回火过程中又形成了大量的过饱和析出,此时纳米析出相体积分数较其他温度增加约3%~5%,颗粒平均尺寸为5~6nm,分布最均匀。随着回火温度的升高和回火时间的延长,2类析出颗粒均发生了不同程度的粗化,相间析出颗粒尺寸均在8nm以下,较过饱和析出颗粒具有较好的热稳定性,析出强化作用更明显。

Effect of composition and isothermal holding temperature on the precipitation hardening in Vanadium-microalloyed steels

[J].

Effect of coiling temperature on micro-structure and mechanical properties of Ti-V-Mo complex microalloyed ultra-high strength steel

[J].Among various hardening factors of steels, precipitation hardening has the least embrittlement vector value except grain refinement hardening. Giving full play to the precipitation hardening of microalloyed carbonitrides is an important aspect in the development of microalloyed high strength steels. Recently, the research on behaviors of precipitation and development of microalloyed high strength steels is mainly focused on these relatively simple microalloyed steels including single V, single Ti, Ti-V and Ti-Mo microalloyed steels, while paid less attention on complex microalloyed steels such as Ti-V-Mo steels. Therefore, it is expected to provide a theoretical basis and a practical significance for the development of Ti-V-Mo microalloyed high strength steel. Various hardening increments at different coiling temperatures were calculated. Meanwhile, the effect of coiling temperatures on yield strength and the influence of MC particles on uniform elongation were discussed by means of OM, EBSD, TEM, XRD and physical-chemical phase analysis. The results show that Ti-V-Mo steel has the best mechanical properties with ultimate tensile strength of 1134 MPa, yield strength of 1080 MPa, elongation of 13.2% and uniform elongation of 6.8% at coiling temperature of 600 ℃. The precipitation hardening increment was high to about 444~487 MPa due to the mass fraction of about 72.6% of total precipitates with a size of ?10 nm. In addition, precipitation hardening and grain refinement hardening are the main mechanisms to improve the strength of Ti-V-Mo steel, while the variation in precipitation hardening increment causes a significent difference in yield strength. With the coiling temperature increases from 500 ℃ to 600 ℃, the ultimate tensile strength and yield strength increase continuously, but the uniform elongation increases slowly instead of decreasing, which is mainly attributed to an increase of precipitation hardening increment.

卷取温度对Ti-V-Mo复合微合金化超高强度钢组织及力学性能的影响

[J].

Development of Ti and Mo micro-alloyed hot-rolled high strength sheet steel by controlling thermomechanical controlled processing schedule

[J].

Correlation of yield strength and tensile strength with hardness for steels

[J].