锻造态GCr15轴承钢的组织中有大量片层状珠光体和粗大的网状渗碳体,使轴承钢强度和硬度高、脆性大,但是易产生应力集中而使工件的使用寿命和可加工性降低。因此,在加工和使用前必须对其进行球化处理,以降低硬度、提高延展性和可加工性[7,8]。但是,为了得到更好的使用性能,球化处理后的轴承钢还要进行淬火和低温回火形成回火马氏体、球状渗碳体及残余奥氏体组织。渗碳体(Fe₃C)是GCr15轴承钢的主要强化相,对其性能有重要的影响。渗碳体的粒径和分布影响钢的硬度、韧性和耐磨性等力学性能。进行合理的热处理调控渗碳体的粒径及其分布,可优化GCr15轴承钢的综合性能。在球化退火过程中未溶解的渗碳体将遗传到淬火和回火过程中,因此必须控制淬火和回火前渗碳体的形态、大小、数量及分布[8]。

合理的热处理工艺可使试验钢的组织、相结构、亚结构类型以及组织中的各相含量、比例、形态和分布发生变化,最大程度地提高其性能。

用适当的工艺控制GCr15轴承钢组织中球状渗碳体的尺寸、含量和分布,一直是研究的热点[8~19]。Yang等[9]研究了周期球化退火的退火周期对热变形GCr15轴承钢中碳化物球化行为的影响,发现三周期球化退火后得到的碳化物最细小,球化效果最理想;Nagao等[10]使用高频感应加热研究钢板中渗碳体的析出行为,发现在773~873 K快速加热有助于渗碳体细化;Revilla等[11]控制低合金钢感应回火过程中的加热速率以细化碳化物。轴承钢中细小且均匀分布的渗碳体可提高材料的强度和硬度,而较大的渗碳体颗粒则可能提高材料的脆性和降低其延展性和可加工性,而细小的碳化物则有利于提高轴承钢的滚动接触疲劳性能[9]。但是,渗碳体的粒径并不是越小越好。材料中过小的第二相颗粒,使其耐磨性和塑韧性降低。小颗粒第二相与基体接触面积小,嵌入基体较浅,容易剥落,在磨损过程中造成磨损消耗。小颗粒渗碳体之间的间距较短,使材料受到冲击时裂纹的扩展距离和时间大幅度缩短,裂纹在短时间内同时扩展使材料的韧性降低[12]。因此,为了达到使用要求,新型高碳钢须进行合适的热处理使渗碳体适当粗化,以得到合适的强度、硬度、耐磨性和塑韧性的匹配。等温球化退火处理控制加热、保温和冷却过程使材料中的碳化物分布更加均匀,从不规则形状转变为更小、更圆润的颗粒。该方法是现阶段轴承钢球化退火的主要方法,但是其退火时间较长。缩短球化退火时间提高生产效率还能调控渗碳体的粒径,有助于提高GCr15轴承钢的使用性能。奥氏体化后淬火再进行高温回火,能促进离异共析转变得到较好的球化效果[13]。关于马氏体钢在高温回火过程中发生的渗碳体粗化和球化,已经有较多的研究[16~19]。本文先对GCr15轴承钢进行奥氏体化固溶处理,然后进行淬火+高温回火,控制高温回火时间改变渗碳体粒径,随后进行淬火+低温回火得到最终组织,系统研究渗碳体的粒径和分布对其硬度的影响。

1 实验方法

实验用材料是直径为80 mm的长棒状热锻态GCr15轴承钢,其化学成分(质量分数,%)为:C 0.96,Si 0.28,Mn 0.38,Cr 1.52,Ni 0.027,余量为Fe。

从轴承钢棒材切取4组尺寸为20 mm × 20 mm × 80 mm的试样,将其置于KSL 1400X科晶箱式炉中进行热处理。进行淬火+高温回火将初始态GCr15轴承钢中的渗碳体球化,然后进行淬火和回火硬化处理。

将试样放入箱式炉中升温至930 ℃并保温1 h,然后油冷至室温。随后,再将试样放入箱式炉中升温至700 ℃分别保温6、12、24和48 h后油冷至室温。将上述球化处理后的试样进行淬火+低温回火处理。淬火时将试样随炉升温至840 ℃后保温10 min然后油冷至室温,再将试样随炉升温至160 ℃保温2 h后空冷至室温。试样的编号和热处理工艺列于表1。

表1 试样的编号和热处理工艺

Table 1

| Sample | Quenching | Tempering | Quenching | Tempering |

|---|---|---|---|---|

| SP1 | 930 oC × 1 h + oil quenching | 700 oC × 6 h + oil quenching | ||

| SP2 | 930 oC × 1 h + oil quenching | 700 oC × 12 h + oil quenching | ||

| SP3 | 930 oC × 1 h + oil quenching | 700 oC × 24 h + oil quenching | ||

| SP4 | 930 oC × 1 h + oil quenching | 700 oC × 48 h+ oil quenching | ||

| QT1 | 930 oC × 1 h + oil quenching | 700 oC × 6 h + oil quenching | 840 oC × 10 min + oil quenching | 160 oC × 2 h + air cooling |

| QT2 | 930 oC × 1 h + oil quenching | 700 oC × 12 h + oil quenching | 840 oC × 10 min + oil quenching | 160 oC × 2 h + air cooling |

| QT3 | 930 oC × 1 h + oil quenching | 700 oC × 24 h + oil quenching | 840 oC × 10 min + oil quenching | 160 oC × 2 h + air cooling |

| QT4 | 930 oC × 1 h + oil quenching | 700 oC × 48 h + oil quenching | 840 oC × 10 min + oil quenching | 160 oC × 2 h + air cooling |

从热锻态试样、一次淬火+高温回火球化的试样和经二次淬火+低温回火处理的试样分别切取尺寸为20 mm × 10 mm × 5 mm的金相试样,将其研磨、抛光后用4% (体积分数)的硝酸酒精溶液腐蚀,用金相显微镜(OM, OLYMPUS BX53M)和扫描电子显微镜(SEM,ZEISS-Sigma300)观察热锻态试样和热处理后试样的微观组织。分别使用Photoshop和Image pro plus软件将SEM显微组织图片中的渗碳体染色和统计粒径。用Smartlab 9kW型X射线衍射仪(XRD)测试电解抛光的试样的XRD谱,扫描角度范围30°~135°,扫描速度5(°)/min。使用MDI jade 6软件根据XRD谱分析试样的物相并确定衍射谱中衍射峰的积分强度,并使用公式[20]

计算钢中残余奥氏体的含量和残余奥氏体的体积分数。式中Vγ 为钢中残余奥氏体的体积分数;Iα(hkl)和Iγ(hkl)分别为钢中α相和γ相衍射峰的积分强度;根据YB/T 5338-2019中的五线六对法计算,涉及的五段衍射峰分别是(200) α,(211) α,(200) γ,(220) γ,(311) γ。

统计淬火-回火组织(SEM照片)中碳化物的含量得到钢中碳化物的体积分数Vθ,用公式

计算出马氏体的含量VM。

选取金相试样的合适的区域,将其机械研磨至表面光滑,并进行电解抛光去除表面层,用于电子背散射衍射(EBSD,FEI Apreo2S)和电子探针显微分析(EPMA,JEOL JXA-8530F),得到使用的组织特征和元素分布。

用FM-810显微硬度仪测定试样的硬度,加载载荷4.90 N,测试每种试样30个计数点的硬度,取其结果的平均值。使用AZtacCrystal软件分析EBSD图像,得到有关晶体取向及相分布的信息;使用Origin 2021软件统计渗碳体的粒径和硬度。

2 实验结果

2.1 一次淬火+高温回火后的球化组织和渗碳体的粒径

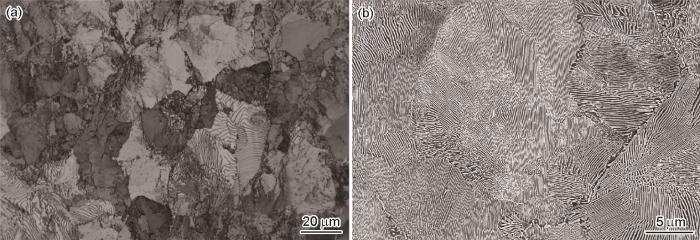

图1给出了这种钢的金相组织和扫描电镜显微组织。可以看出,初始组织由片层状珠光体和位于晶界的网状渗碳体组成。

图1

图1

热锻态GCr15轴承钢的微观组织

Fig.1

Microstructure of hot forged GCr15 bearing steel detected by OM (a) and SEM (b)

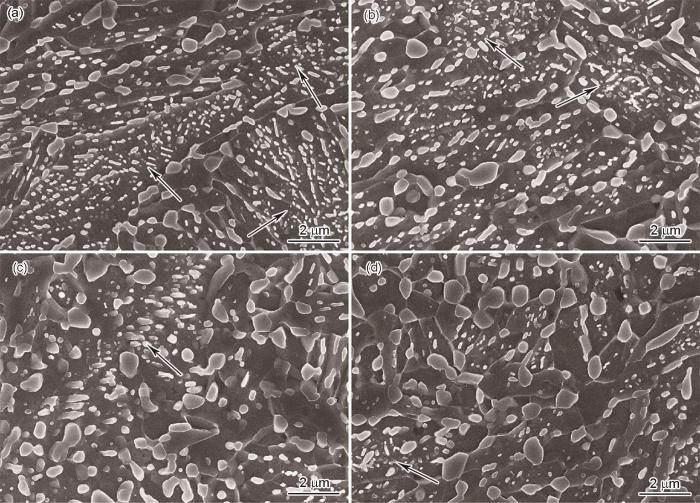

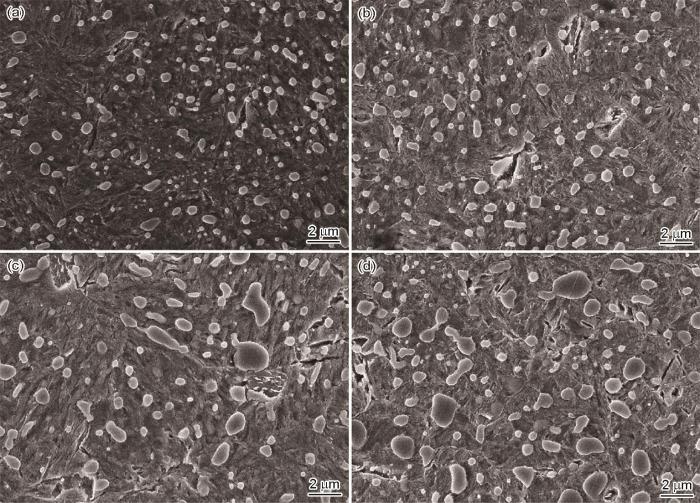

一次淬火+高温回火后的GCr15轴承钢其微观组织如图2所示。可以看出,高温回火后原始组织中的马氏体消失,从马氏体中析出的渗碳体球化后分布在铁素体基体中。组织中有较大的球状渗碳体和超细、聚集分布的棒状渗碳体(如图中箭头所示),前者是奥氏体化后剩余的碳化物在回火时长大,后者是高温回火时在马氏体片内C浓度集中区析出的[21]。基于SEM形貌统计析出渗碳体的总体积分数为13.7%~15.8%。随着高温回火时间的延长,较大的球状渗碳体颗粒更圆整、尺寸更大且分布更均匀;而细小的棒状渗碳体聚集区的体积分数不断降低,其中高温回火6、12、24、48 h的细小棒状渗碳体密集区的体积分数分别为3.2%、1.7%、0.7%和0.5%。

图2

图2

一次淬火+高温回火保温不同时间后GCr15轴承钢的SEM照片

Fig.2

SEM images of GCr15 bearing steel after first quenching and high-temperature tempering at 700 oC for SP1 (a), SP2 (b), SP3 (c) and SP4 (d)

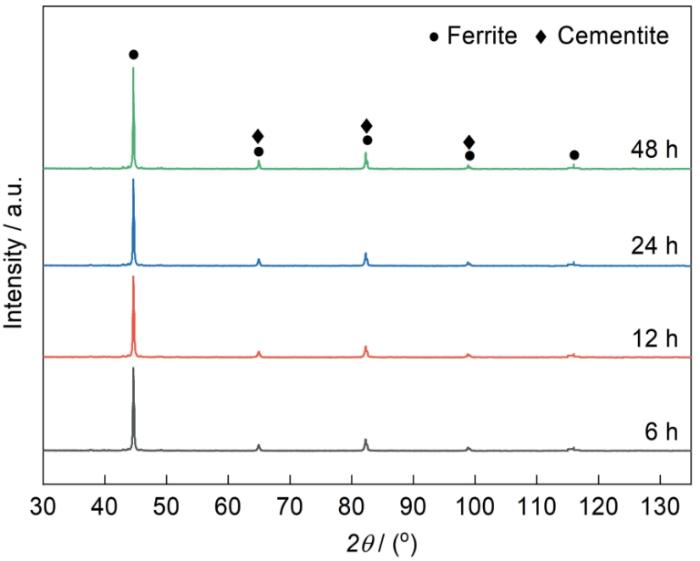

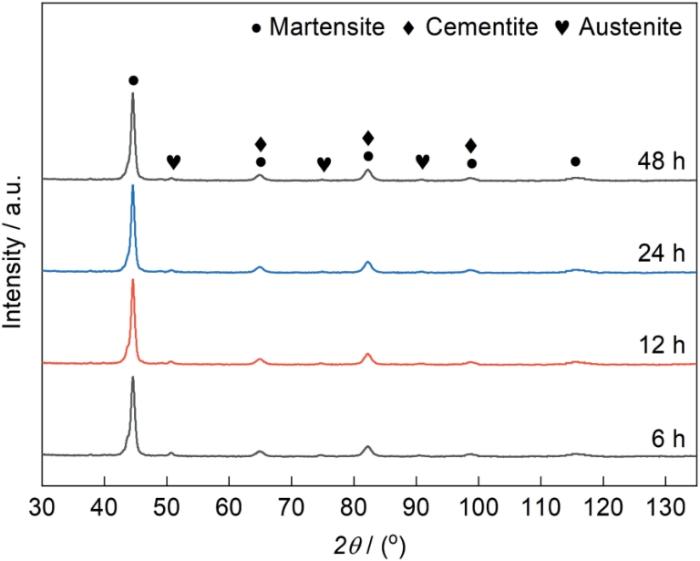

图3

图3

一次淬火+高温回火保温不同时间后GCr15轴承钢的XRD谱

Fig.3

XRD patterns of GCr15 bearing steel after first quenching and high-temperature tempering at 700 oC for different time

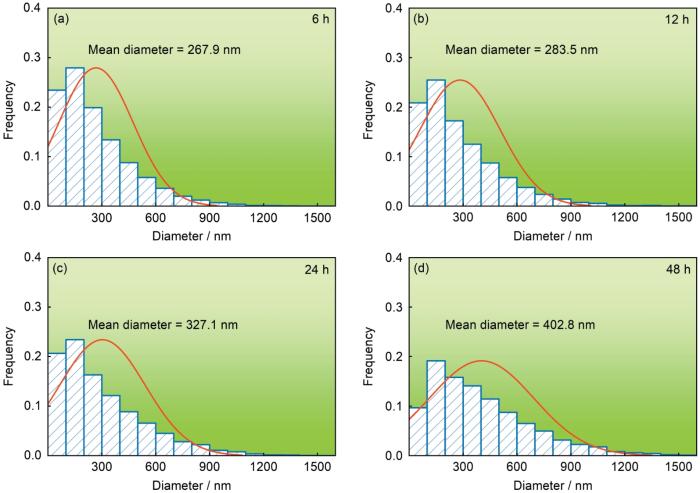

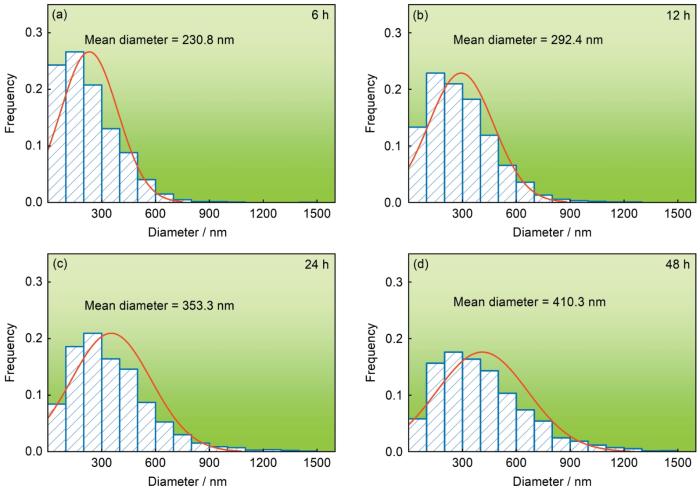

图4

图4

一次淬火+高温回火保温不同时间后GCr15轴承钢中球状渗碳体的粒径统计

Fig.4

Statistical diagram of spherical cementite particle size of GCr15 bearing steel after first quenching and high-temperature tempering at 700 oC for SP1 (a), SP2 (b), SP3 (c), and SP4 (d)

2.2 二次淬火+低温回火后的组织和渗碳体的粒径统计

图5

图5

二次淬火+低温回火后GCr15轴承钢的SEM照片

Fig.5

SEM images of GCr15 bearing steel after secondary quenching and low-temperature tempering treatment(a) QT1, (b) QT2, (c) QT3, (d) QT4

图6

图6

二次淬火+低温回火后GCr15轴承钢的XRD谱

Fig.6

XRD patterns of GCr15 bearing steel after secondary quenching and low-temperature tempering treatment

表2 二次淬火+低温回火后GCr15轴承钢中各相的含量

Table 2

| Sample | Vθ | Vγ | VM |

|---|---|---|---|

| QT1 | 4.2 | 28.4 | 67.4 |

| QT2 | 4.9 | 22.4 | 72.7 |

| QT3 | 6.4 | 19.4 | 74.2 |

| QT4 | 6.7 | 16.1 | 77.2 |

对球状渗碳体粒径分布的统计结果如图7所示。可以看出,二次淬火和回火后渗碳体的粒径更加符合正态分布,与红线的差别变小,渗碳体的平均直径增大。对试样中粒径小于200 nm的球状渗碳体的统计结果表明,随着一次淬火后高温回火时间的延长渗碳体颗粒的粒径增大,二次淬火和回火使粒径小于200 nm的球状渗碳体的比例降低。随着前一次淬火后高温回火时间从6 h延长至48 h,粒径小于200 nm的球状渗碳体的比例分别为50.9%、36.2%、27.0%、21.4%,其逐渐降低的趋势与一次淬火+高温回火后的趋势相同。

图7

图7

二次淬火+低温回火后GCr15轴承钢中球状渗碳体的粒径统计

Fig.7

Statistical diagram of spherical cementite particle size of GCr15 bearing steel after secondary quenching and low-temperature tempering treatment (a) QT1, (b) QT2, (c) QT3, (d) QT4

2.3 球化组织、二次淬火+回火组织和元素分布

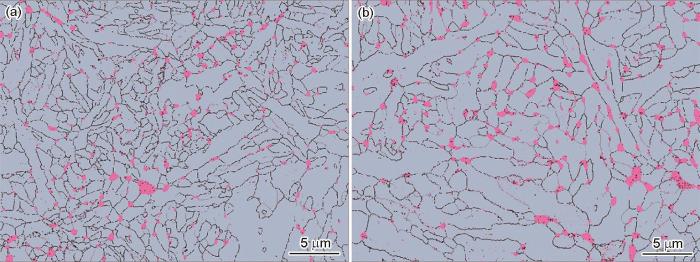

用EBSD分析球化过程中保温时间(6和48 h)对GCr15轴承钢微观结构的影响,结果如图8所示。可以看出,球状渗碳体在铁素体基体中均匀分布,晶界较为清晰。在高温回火6 h的组织中,渗碳体颗粒比铁素体的晶粒更小。高温回火时间的延长使铁素体晶粒的尺寸变化不大,但是使大尺寸渗碳体颗粒的比例提高,与一次淬火+高温回火试样的组织(SEM照片)和XRD谱的结果相同。

图8

图8

一次淬火+高温回火保温不同时间后GCr15轴承钢的EBSD相组成

Fig.8

EBSD phase map of GCr15 bearing steel after first quenching and high-temperature tempering at 700 oC for SP1 (a) and SP4 (b)

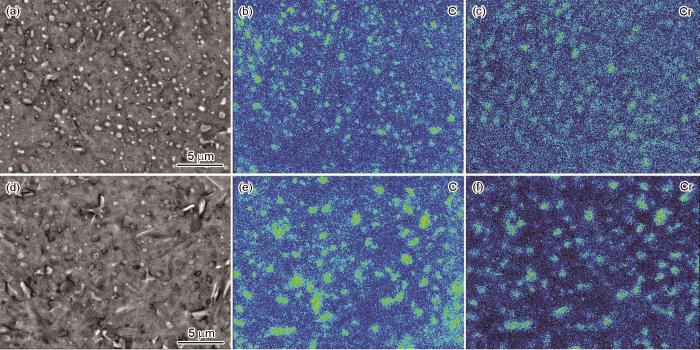

EPMA探测的二次淬火+低温回火试样的元素分布结果,如图9所示。其中图9a~c分别给出了一次淬火后高温回火6 h然后再二次淬火+低温回火的BSE图、相应区域中的C和Cr元素分布,图9d~f分别给出了一次淬火后高温回火48 h然后再二次淬火+低温回火试样的BSE图、相应区域中C和Cr元素的分布。可以看出,C和Cr元素在渗碳体中富集。这表明,在渗碳体的生成过程中,从基体偏析出来的C和Cr元素生成了富含这些元素的硬质相。这种富集,使材料的硬度和耐磨性提高。与一次淬火后高温回火6和48 h时的元素分布对比结果表明,随着高温回火时间的延长渗碳体颗粒逐渐增大,而细小棒状渗碳体密集区的体积分数降低。这个结果,与前述二次淬火+低温回火试样的SEM照片给出的结果一致。

图9

图9

二次淬火+低温回火后GCr15轴承钢中元素的分布

Fig.9

Elemental mapping of GCr15 bearing steel after secondary quenching and low-temperature tempering treatment (a-c) QT1, (d-f) QT4

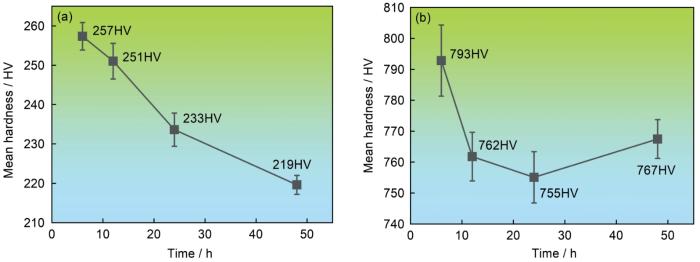

2.4 球化处理后试样的硬度

图10

图10

GCr15轴承钢的维氏硬度

Fig.10

Vickers hardness of GCr15 bearing steel under different heat treatment states (a) first quenching and high-temperature tempering, (b) secondary quenching and low-temperature tempering

3 讨论

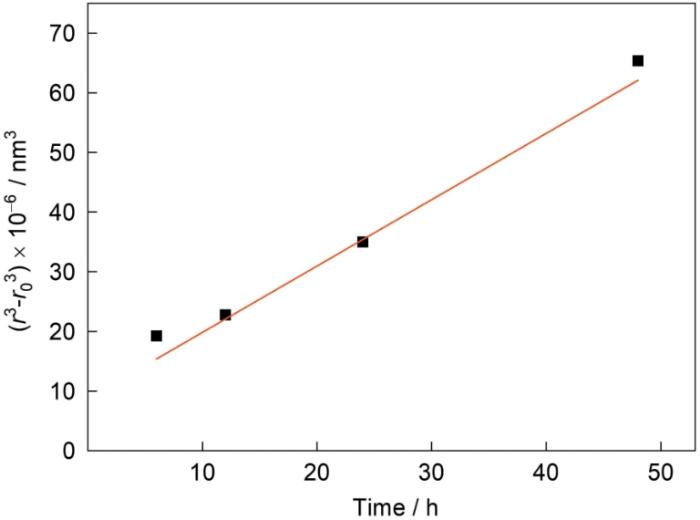

3.1 一次淬火+高温回火的试样中球状渗碳体的粗化

在高温回火过程中球状渗碳体的粗化使试样的力学性能发生变化,这种粗化可用Ostwald熟化解释。Gibbs-Thomson方程

本文实验中一次淬火后的高温回火时间较短,组织中存在大量短棒状渗碳体的密集区,渗碳体的平均直径较小。随着高温回火时间的延长,组织中短棒状渗碳体细小密集区逐渐缩少,短棒状渗碳体的平均直径呈增大的趋势。其原因是,球化处理保温时间较短使细小的碳化物与铁素体基体间的相界面较多因此界面能很高。为了使整个系统的能量降低以达到稳定状态,在后续的保温过程中溶质元素向大颗粒周围扩散,使小颗粒溶解收缩并最终消失,而大颗粒不断地长大[26],最终的结果是球状渗碳体的粗化。

图11

图11

球状渗碳体平均半径的立方与高温回火时间的拟合曲线

Fig.11

Fit curve between the cubic of the average radius of spherical cementite and the high-temperature tempering time

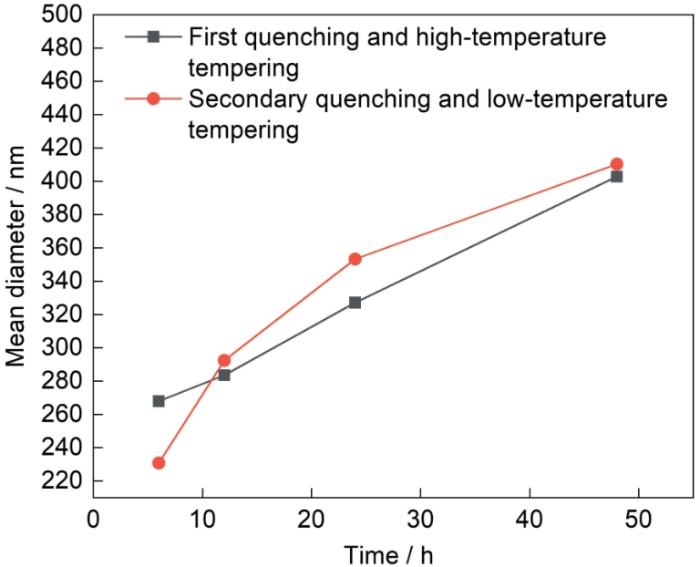

3.2 二次淬火+低温回火过程中试样中球状渗碳体粗化的规律

二次淬火+低温回火后渗碳体的粒径与两相区奥氏体化和低温回火有关。渗碳体的体积分数由一次淬火+高温回火后的13.7%~15.8%降低到二次淬火+低温回火后的4.2%~6.7%。同时,比较二次淬火和回火后渗碳体平均粒径与一次淬火和高温回火处理后渗碳体平均粒径(如图12所示),发现一次淬火后高温回火6 h,二次淬火和回火试样中的渗碳体平均粒径减小,一次淬火后高温回火12、24和48 h,二次淬火和回火后渗碳体的平均粒径增大。其原因是,二次淬火的奥氏体化温度(840 ℃)高于GCr15轴承钢的Ac1温度。在此温度保温过程中细小密集区中短棒状渗碳体大量溶解,部分粗大的球状渗碳体也发生溶解(图5),使渗碳体的含量降低。实际上,在随后的低温回火过程中,C元素短程扩散在碳原子偏聚区生成细小的ε-碳化物[23]。因为没有发现ε-碳化物,二次淬火和回火试样中渗碳体的平均粒径主要由两相区奥氏体化过程中碳化物的溶解和粗化决定。在两相区保温过程中,碳化物颗粒溶解时还因Ostwald熟化而发生粗化[26,41~44]。与一次淬火和高温回火后试样中渗碳体平均粒径的变化比较,两个因素共同作用使二次淬火和回火后试样中渗碳体的平均粒径先减小后增大。

图12

图12

不同热处理的GCr15轴承钢的平均粒径

Fig.12

Comparison of mean particle size of GCr15 bearing steel after different heat treatments

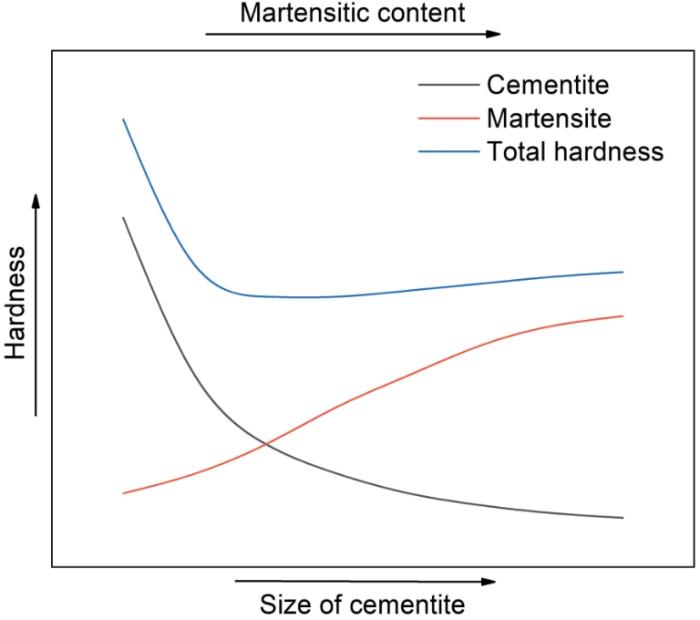

3.3 GCr15轴承钢的硬度

图13

图13

硬度与马氏体含量和渗碳体尺寸的关系

Fig.13

Hardness variation with martensite content and cementite size

GCr15轴承钢的硬度与耐磨性之间是正相关的[45]。在轴承的应用中,高硬度有助于降低表面的磨损,尤其是接触应力较大时。二次淬火+低温回火的试样其最终组织中的板条马氏体、球状渗碳体以及少量残余奥氏体,共同决定了轴承钢的耐磨性。硬度较高的马氏体使钢具有良好的耐磨性能。钢中均匀分布在基体中的球状渗碳体,使其抗磨损性能提高。同时,钢中适量的残余奥氏体能在一定程度上提高其韧性和减少裂纹扩展,也有利于提高其耐磨性。随着球化过程中高温回火时间的延长,球状渗碳体的粗化使渗碳体颗粒之间的间距增大而使其硬化效果降低,但是马氏体含量的提高有助于缓解渗碳体粗化所致的硬度下降,从而可能提高其耐磨性能。

4 结论

(1) GCr15轴承钢经一次淬火(930 ℃保温1 h进行奥氏体化固溶处理加水淬)+高温回火(700 ℃保温6、12、24、48 h)球化后,其组织由铁素体基体和弥散分布的球状渗碳体构成。随着高温回火时间的延长GCr15轴承钢中的球状渗碳体颗粒粗化,粗化动力学遵循现代Ostwald熟化规律。随着渗碳体的粗化和间距的增大,对位错运动的阻碍减弱而使轴承钢的硬度降低。

(2) GCr15轴承钢二次淬火(840 ℃保温10 min)+低温回火(160 ℃保温2 h)后的组织是板条马氏体、球状渗碳体以及少量的残余奥氏体。轴承钢在两相区奥氏体化过程中碳化物的溶解和粗化,使二次淬火和回火后GCr15轴承钢中渗碳体的含量降低,二次淬火和回火后渗碳体的平均粒径比一次淬火和高温回火后渗碳体的平均粒径略有增大。

(3) 在球化过程中一次淬火后高温回火时间的延长使二次淬火+回火的渗碳体含量提高、尺寸变大和硬度降低,但是析出渗碳体的增加使奥氏体更易于转变为马氏体,组织中马氏体含量的提高使其硬度提高。

参考文献

Semi-macrosegregation and carbide banding in high-carbon chromium bearing steels: Characteristics, evolution, and control

[J].

Research status and development trend of bearing steel

[J].

轴承钢研究现状及发展趋势

[J].

Structure and properties of GCr15 modified by multiphase ceramic nanoparticles/Fe-C composite inoculants

[J].

Comparison of wear behavior of GCr15 bearing steel prepared by selective laser melting (SLM) and electron beam melting (EBM)

[J].

Microstructure and corrosion behavior of hot-rolled GCr15 bearing steel

[J].

Development of and perspective on high-performance nanostructured bainitic bearing steel

[J].

Effect of prior microstructures on cementite dissolution behavior during subcritical annealing of high carbon steels

[J].

Ostwald growth of carbides in cyclic annealing process of GCr15 bearing steel

[J].

Refinement of cementite in high strength steel plates by rapid heating and tempering

[J].

Carbide size refinement by controlling the heating rate during induction tempering in a low alloy steel

[J].

Effect of refined cementite on nanostructured bainitic bearing steel

[J].

细化渗碳体对高碳纳米贝氏体轴承钢的影响

[J].研究了GCr15Si1Mo轴承钢中渗碳体细化后,对材料微观组织、常规力学性能、耐磨性及滚动接触疲劳性能的影响。通过工艺的调控,使材料组织中的渗碳体尺寸从0.49细化到了0.20 μm,贝氏体铁素体板条尺寸从66细化至41 nm,并且渗碳体的分布密度也随之提高。随后通过SEM、TEM、XRD、硬度、冲击、摩擦磨损及滚动接触疲劳等试验,得到了材料的宏观性能与微观组织。研究结果表明,细化渗碳体后,材料的耐磨性能和滚动接触疲劳性能比常规工艺的优异,但是韧性相对于常规工艺有显著降低。研究证明了较细小渗碳体可以对轴承钢的组织结构、常规力学性能、耐磨性能及疲劳性能产生一定的影响,为后期轴承钢中渗碳体的调控研究提供支持。

Spheroidizing treatment and austenitizing research of GCr15 bearing steel

[D].

GCr15轴承钢球化处理工艺及其奥氏体化研究

[D].

Effect of YSZ particle size and content on microstructure, mechanical and tribological properties of (CoCrFeNiAl)1- x (YSZ) x high entropy alloy composites

[J].

Effect of particle size on mechanical properties and tribological behaviour of aluminium/fly ash composites

[J].

Effects of tempering mode on the structural changes of martensite

[J].

Coarsening behavior of cementite particles at a subcritical temperature in a medium carbon steel

[J].

The novel process of spheroidizing-critical annealing used to optimize the properties of carburized steel and its effect on hardening mechanism of quenching and tempering

[J].

Carbide evolution behavior of GCr15 bearing steel during aging process

[J].The evolution behavior of carbides in GCr15 bearing steel and its influence on the impact toughness during long-term aging at 170oC have been investigated by means of SEM, TEM, and XRD, aiming to meet the requirements of vacuum dry pump bearings. The results demonstrate that after quenching at 840oC and the tempering at 230oC, the hardness of GCr15 steel remains above 59 HRC with minimal retained austenite, which is favorable to the enhancement of performance and dimensional stability for the steel at 170oC. During the aging process, carbon atom partitioning and carbide precipitation lead to a decrease in carbon concentration, lattice distortion and micro-zone stress strain of the matrix, while transitional carbides precipitate, coarsen and then transform into non-coherent cementite. The resultant effect of these microstructural variation is a reduction in material hardness, while the impact toughness initially increasing and then decreasing. However, the cooperative effect of the decarbonization of martensite and carbide type transformation makes hardness of steels remain stable or even increase a little in between 1000 h and 2000 h during the aging process. To improve the microstructure and performance stability during the aging process, cryogenic treatment was conducted after quenching. The introduction of high-density defects promotes effective carbon distribution during tempering and aging, which gives rise to uniform distribution and size control of fine carbides. Cryogenic treatment reduces the carbide growth rate from 298 nm3/h to 229.5 nm3/h, which delays the performance decline effectively and makes the GCr15 bearing steel satisfied with demands of vacuum dry pump bearings.

GCr15轴承钢时效过程碳化物的演化行为

[J].对GCr15轴承钢进行170℃时效处理,使用SEM、TEM、XRD等手段对其表征,研究了这种钢在时效过程中碳化物的演化行为及其对性能的影响。结果表明,在840℃淬火后再在230℃回火,钢的硬度不低于59 HRC,冲击韧性大幅度提高,钢中的残余奥氏体基本上消除,可保障其170℃的性能和尺寸稳定性。在时效过程中发生的碳原子配分和碳化物析出,使钢基体中碳的浓度、晶格畸变、微区应力应变先降低后稳定,过渡碳化物向非共格的渗碳体转变和粗化。这两个因素的耦合作用使钢的硬度降低、冲击韧性先升高后降低。马氏体的碳脱溶和碳化物类型的转变相互协调,使钢时效1000 h到2000 h间硬度有所回升。为了提高时效过程中钢的显微组织和性能的稳定性,淬火后又进行了深冷处理以引入高密度缺陷,促进了回火和时效过程中碳元素的配分,使析出的碳化物细小弥散并抑制了其在时效过程中的长大与粗化。深冷处理使碳化物的长大速率由298 nm<sup>3</sup>/h降低到229.5 nm<sup>3</sup>/h,在一定程度上延缓了性能的衰退、提高了GCr15轴承钢在真空干泵高温环境中的性能稳定性。

The effects of carbon contents and MS temperatures on the hardness of martensitic Fe-Ni-C alloys

[J].

Investigation on spheroidized microstructure of 1.41%C ultra-high carbon steel after quenching and high tempering treatment

[J].

1.41%C超高碳钢淬火高温回火球化组织的研究

[J].

Mechanism of cementite decomposition in 100Cr6 bearing steels during high pressure torsion

[J].Severe plastic deformation leads to cementite decomposition in pearlitic and martensitic alloys, resulting in high-strength nanocrystalline ferrite. This effect can be employed to strengthen pearlitic wires but it can also be associated with material failure by white etching cracks (WECs) that are primarily known to concern bearings or rails. We investigate the decomposition of spheroidal cementite in the martensitic bearing steel 100Cr6 with 62 Rockwell hardness during high pressure torsion at 9.5 GPa applied pressure. The hard martensitic matrix and the even harder spheroidal cementite precipitates behave plastically very differently. The enforced macroscopic plastic deformation is almost entirely carried by the matrix. Plastic material flow of the matrix around the spheroidal cementite leads to wear of the spheroidal cementite as indicated by continuously increasing levels of chromium in the matrix. Plastic deformation of spheroidal cementite via dislocation gliding supposedly accelerates this process as slip steps generated thereby are preferential sites of wear at the matrix/cementite interface. Larger spheroidal cementite precipitates are more prone to plastic deformation and to decomposition than smaller ones. The mechanism likely holds true in general for multiphase materials with large strain difference between phases subjected to high pressure torsion. Although the formation of WECs in 100Cr6 bearings might be slowed down by reducing the size of the spheroidal cementite precipitates, it is unlikely that this could entirely prevent this failure mechanism. (C) 2020 Acta Materialia Inc. Published by Elsevier Ltd.

Effect of the microstructure and residual stress on tribological behavior of induction hardened GCr15 steel

[J].

Review progress in Ostwald ripening theories and their applications to nickel-base superalloys Part I: Ostwald ripening theories

[J].

The effect of volume fraction of secondary phase on Ostwald ripening in two phase system

[J].

两相体系中第二相体积分数对其Ostwald熟化的影响

[J].

The kinetics of precipitation from supersaturated solid solutions

[J].

Theorie der alterung von niederschlägen durch umlösen (Ostwald‐Reifung)

[J].

The effect of volume fraction on particle coarsening: theoretical considerations

[J].

The dependence of Ostwald ripening kinetics on particle volume fraction

[J].

The effect of volume fraction of precipitate on Ostwald ripening

[J].

Coarsening models incorporating both diffusion geometry and volume fraction of particles

[J].

Kinetics of phase transitions: theory of Ostwald ripening

[J].

Statistical-mechanical theory of coarsening of spherical droplets

[J].

Ostwald ripening during liquid phase sintering-effect of volume fraction on coarsening kinetics

[J].

Finite volume fraction effects on Ostwald ripening

[J].

Theory and simulation of Ostwald ripening

[J].

Effect of cold rolling and first precipitates on the coarsening behavior of γ″-phases in Inconel 718 alloy

[J].

On conventional versus direct ageing of Alloy 718

[J].

Ostwald ripening of solid-liquid Pb-Sn dispersions

[J].

Ostwald ripening of Pb nanocrystalline phase in mechanically milled Al-Pb alloys and the influence of Cu additive

[J].

On the spheroidized carbide dissolution and elemental partitioning in high carbon bearing steel 100Cr6

[J].

Morphology of cementite decomposition in an Fe-Cr-C alloy

[J].

In situ X-ray phase analysis and computer simulation of carbide dissolution of ball bearing steel at different austenitizing temperatures

[J].

The relationship between hardness and abrasive wear resistance of electrodeposited nanocrystalline Ni-Pcoatings

[J].