Ti65高温钛合金是一种Ti-Al-Sn-Zr-Mo-Si-Nb-Ta-W-C系近α型合金,是在Ti60合金的基础上研制出来的,长时使用温度为650 ℃,短时大应力条件下使用温度为650 ℃~750 ℃,其密度低、比强度高和高温性能好,可用于制造高超声速飞行器[11~16]。但是,Ti65钛合金的室温变形抗力大、回弹大,用传统的热成形方法难以制造复杂薄壁结构件。超塑成形不仅能降低成形变形抗力,使材料变形均匀,成形件质量稳定,不会有回弹等零件成形后的变形问题。目前针对Ti65钛合金的研究工作集中于板材的热处理和力学性能。吴汐玥等[13]研究了不同热处理条件下Ti65钛合金板材的显微组织和织构的变化规律,分析了板材织构的类型和热处理影响拉伸强度的机制;岳颗等[14]研究了固溶冷速对Ti65钛合金显微组织和室温力学性能的影响,以及材料的蠕变变形行为和微观变形机制;李萍等[15]开展了Ti65钛合金的等温恒应变速率热压缩试验,研究了材料的热变形行为并建立材料的本构方程。本文进行Ti65合金的高温超塑性拉伸实验,根据微观组织研究变形温度和应变速率对其超塑变形行为的影响并揭示超塑性变形机制。

1 实验方法

表1 Ti65钛合金主要化学成分

Table 1

| Elements | Al | Sn | Zr | Mo | Si | Ta | Nb | W | C | Ti |

|---|---|---|---|---|---|---|---|---|---|---|

| Content | 5.5~6.5 | 3.0~4.0 | 2.0~4.0 | 0.2~1.0 | 0.2~0.5 | 0.5~2.5 | 0.2~1.0 | 0.5~1.5 | 0.02~0.08 | Bal. |

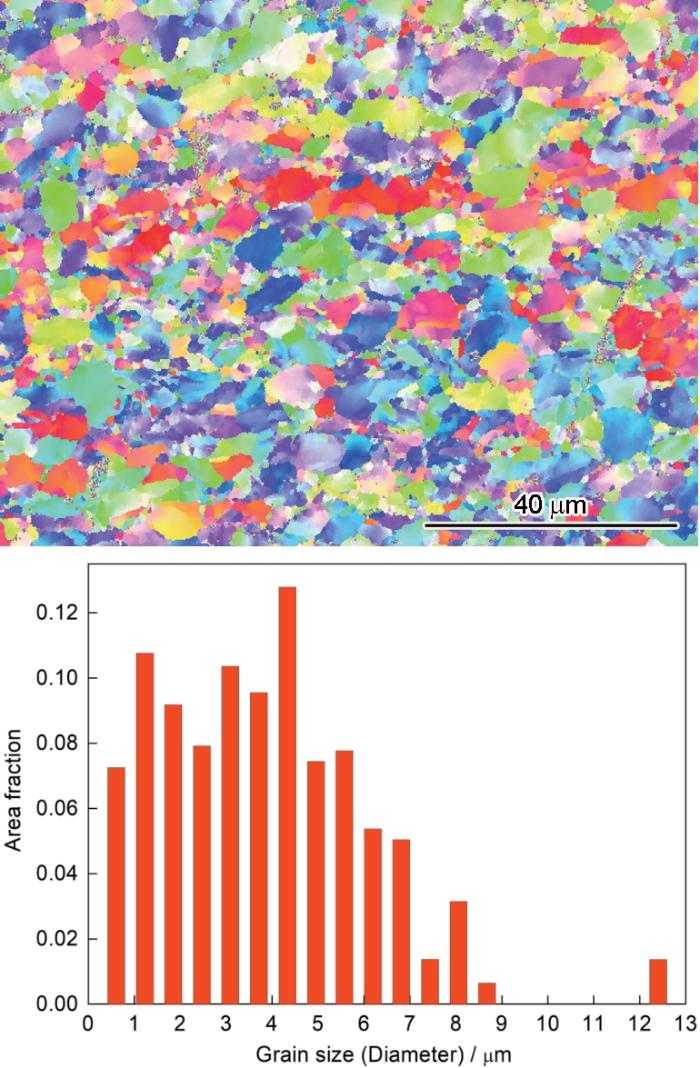

图1

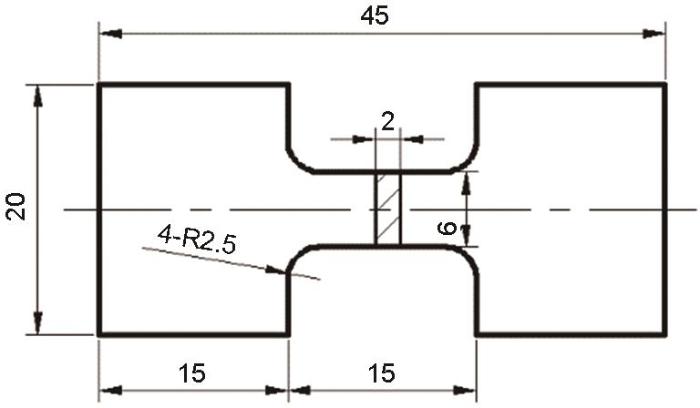

使用LETRYDL-20T型电子万能拉伸实验机进行Ti65钛合金的高温超塑性拉伸实验,实验机配有三段式控温加热炉,温度误差小于± 2 ℃。沿板料的轧制方向截取试样,其尺寸如图2所示。打磨加工试样的标距,确保变形区表面光滑,为了避免试样在高温拉伸过程中过度氧化,在变形的标距段表面涂覆玻璃防护润滑剂。

图2

超塑性拉伸实验的变形温度分别为900、920、940和960 ℃,应变速率为0.001、0.003、0.01和0.03 s-1。在拉伸过程中夹头的速度不变,拉断后快速水淬以保留其高温变形组织。高温超塑性拉伸实验结束后,对试样进行镶嵌、机械磨抛和电解抛光,然后进行背散射衍射(EBSD)以观察和分析微观组织。

2 实验结果

2.1 超塑性变形行为

2.1.1 真应力-真应变曲线

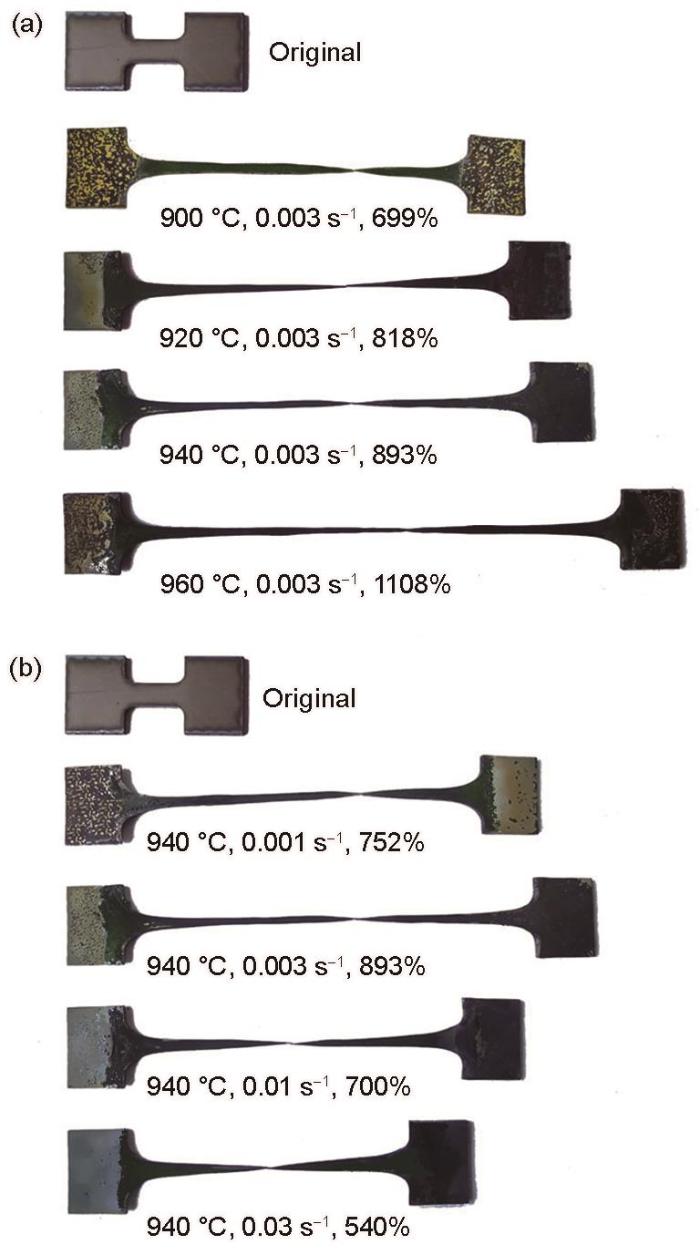

图3给出了Ti65钛合金试样在不同温度和应变速率下超塑拉伸变形前后的宏观形貌,可见所有的断口均较尖,没有明显的缩颈。这表明,Ti65钛合金在实验条件下的均匀变形能力较好,载荷达到最大值试样仍能准稳定变形。当变形温度为960 ℃、应变速率为0.003 s-1时材料的伸长率达到最大(为1108%),表明在此变形条件下材料具有最佳超塑性。

图3

图3

在不同变形条件下拉伸后试样的宏观形貌

Fig.3

Macroscopic images for elongated specimens under different temperatures at stain rate of 0.003 s-1 (a) and under different strain rates at temperature of 940 oC (b)

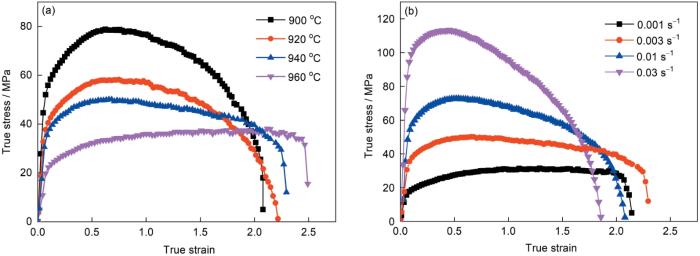

Ti65钛合金在不同变形条件下超塑性拉伸后的真应力-真应变曲线,如图4所示。可以看出,在实验条件下Ti65钛合金的应力-应变曲线均表现出明显的超塑性变形特征:变形量较小时应力随着应变的增加迅速升高至峰值应力,硬化效应明显;随着变形的进行材料进入软化阶段,应力缓慢增大。材料的加工硬化和软化达到动态平衡时,材料进入稳态流变阶段;最后,发生颈缩或断裂时应力加速减小。

图4

图4

在不同变形条件下Ti65钛合金超塑拉伸应力-应变曲线

Fig.4

True stress-true strain curves of Ti65 alloy under different temperatures at stain rate of 0.003 s-1 (a) and under different strain rates at temperature of 940 oC (b)

在应变速率为0.003 s-1条件下(图4a),变形温度低于940 ℃时原子的动能较小,应力软化作用小于加工硬化效应,应力达到峰值后缓慢减小,准稳态变形阶段均较短;提高变形温度到940 ℃,应力达到峰值后便进入稳态阶段,较高的温度促进了动态再结晶,动态再结晶的发生使位错密度减小,位错密度的减小削弱了加工硬化效应,温度越高则稳态流变阶段越长,在960 ℃材料的伸长率最大。而在960 ℃变形后期应力又增大,可能是在高温下再结晶晶粒聚集长大所致。

在变形温度为940 ℃的条件下(图4b)且应变速率小于0.003 s-1时,应力-应变曲线也出现稳态增长的趋势。其原因是,应变速率较低使材料有足够的时间进行能量积累和缩颈转移,动态再结晶的软化与加工硬化达到了动态平衡;而应变速率大于0.01 s-1时,由于材料的变形时间缩短加工硬化程度明显大于动态再结晶的软化效应,使材料的应力达到峰值后便急速减小,未出现准稳态变形过程。

2.1.2 变形参数对超塑性的影响

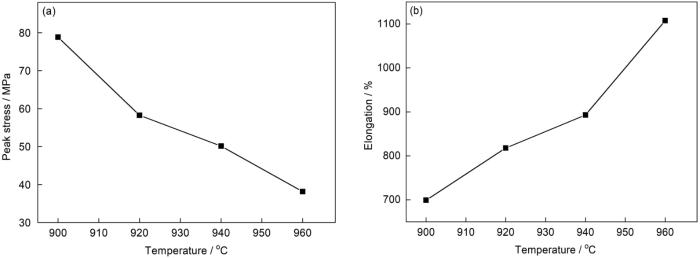

图5给出了变形温度对Ti65钛合金超塑性能的影响。可以看出,在应变速率为0.003 s-1的条件下,随着变形温度的提高峰值应力减小,由78.8 MPa减小到38.1 MPa。其原因是,变形温度的提高增大了原子的平均动能、促进了位错运动和晶界滑移,增强了变形过程中晶界的协调变形能力,从而使流变应力减小和伸长率增大。随着变形温度从900 ℃提高到960 ℃,Ti65合金的超塑伸长率由699%增大到1108%。这表明,变形温度提高60 ℃使伸长率提高了58.5%,可见材料的超塑性对温度的变化较为敏感。

图5

图5

变形温度对Ti65合金峰值应力和伸长率的影响

Fig.5

Effect of different temperatures on peak stress (a) and elongation (b) of Ti65 alloy

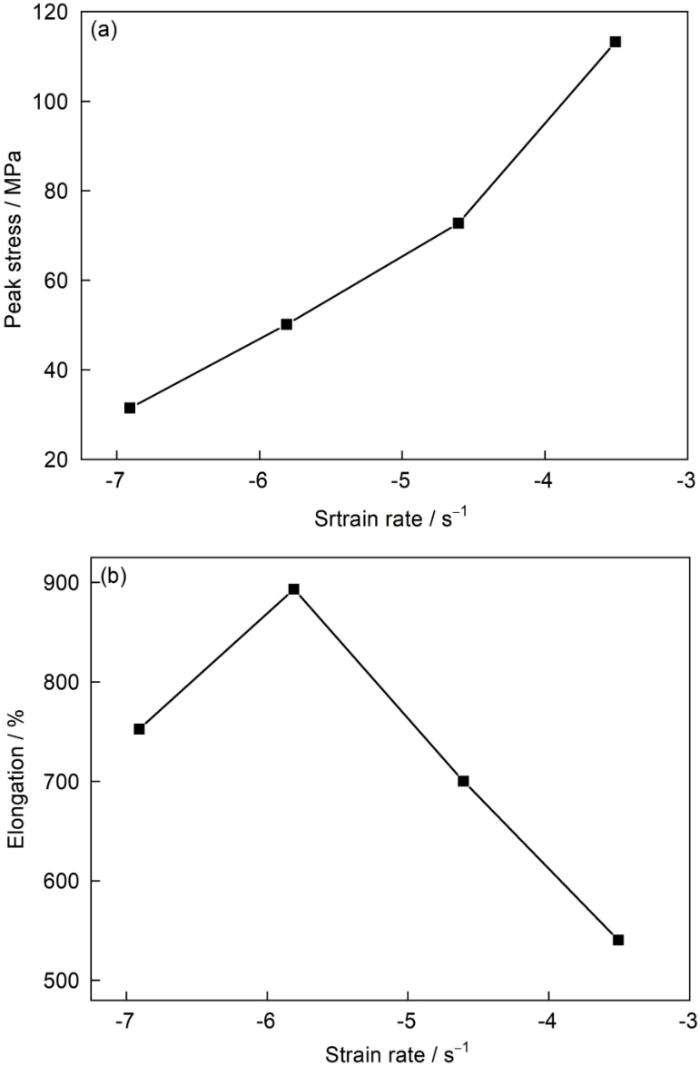

图6给出了应变速率对Ti65高温钛合金超塑性能的影响。可以看出,在变形温度为940 ℃的条件下,随着应变速率的提高峰值应力增大。其原因是,较高的应变速率使位错密度快速提高,导致位错塞积。变形过程中的扩散蠕变和位错滑移来不及调节晶界滑移,使部分应力集中难以释放,导致流变应力增大。应变速率较低(为0.001 s-1)时伸长率为752%,而应变速率提高到0.003 s-1时则伸长率提高到893%。其原因是,应变速率的提高使畸变能和动态再结晶驱动力增大,提高了动态再结晶的程度,软化效应大于硬化效应增强了材料的变形能力,使伸长率较高;应变速率高于0.003 s-1时,随着应变速率的增加加工硬化效应增强和伸长率减小。但是,应变速率为0.03 s-1时伸长率仍达到540%。由此可见,Ti65钛合金板材的超塑性变形能力较好,能进行超塑成形制造复杂的薄壁类结构零件。

图6

图6

应变速率对Ti65合金峰值应力和伸长率的影响

Fig.6

Effect of different strain rates on peak stress (a) and elongation (b) of Ti65 alloy

2.2 应变速率敏感性指数 m 和变形激活能 Q

式中A为材料常数;n为应力指数,n = 1/m,m为应变速率敏感性指数;Q为变形激活能;R为气体常数,R = 8.314 J/(mol·K);T为绝对温度。

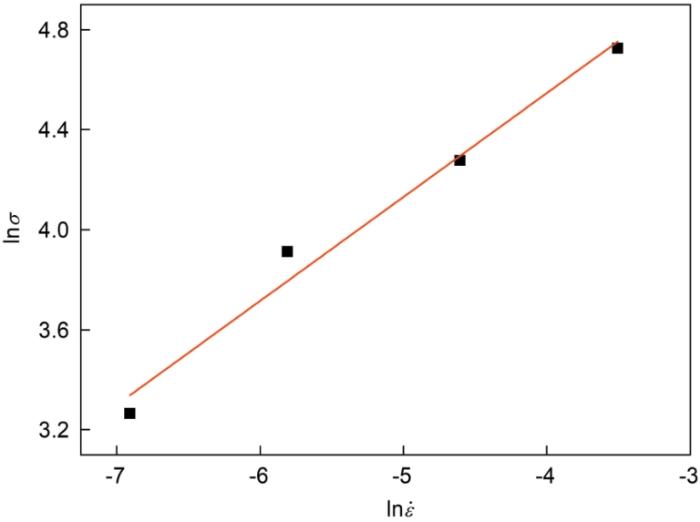

对

在一定的变形温度和应变条件下,

图7

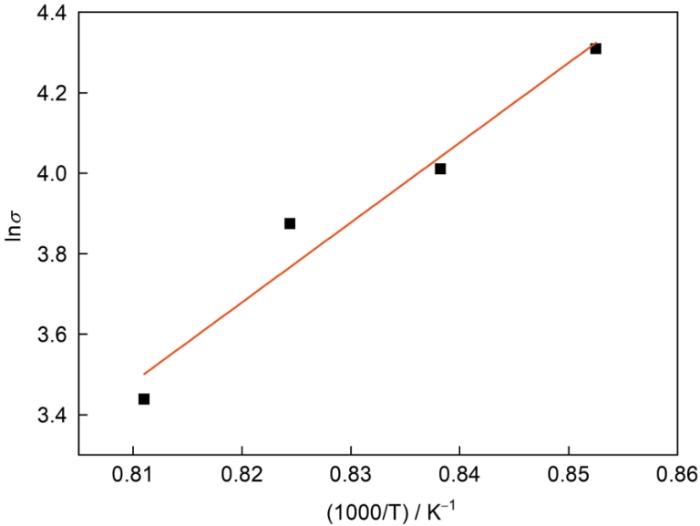

对于一定的应变和应变速率,

图8

2.3 微观组织演变

2.3.1 变形温度的影响

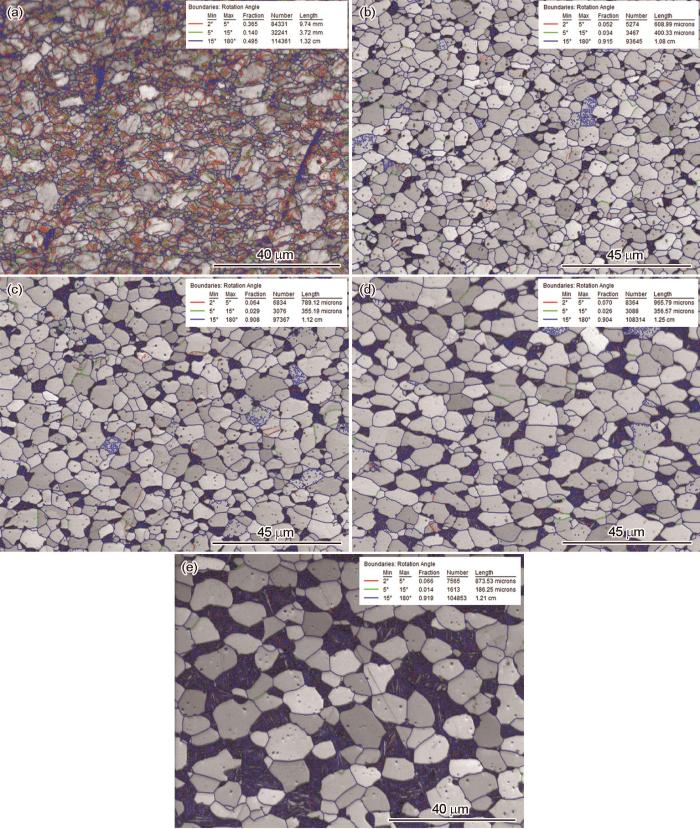

图9和10给出了Ti65钛合金在应变速率为0.003 s-1不同温度下超塑拉伸后断口附近均匀变形段的微观组织和取向分布,图10中的红色和绿色线条分别表示取向差为5°及以下、5°~15°的小角度晶界,蓝色线条表示取向差为15°~180°的大角度晶界。可以看出,在不同温度变形材料内部的初始组织均被动态再结晶生成的等轴晶取代,相邻晶粒的取向分布较分散,没有明显的变形织构。在原始材料中(图10a),晶粒内有占比达到50.5%的小角度晶界;材料在900 ℃变形后内部只有小部分晶粒含有小角度晶界,大角度晶界的占比达到90.8%;随着变形温度的提高晶粒内的小角度晶界逐渐减少,晶界周围的再结晶细小晶粒越来越多。其原因是,在高温下位错运动和晶界滑移有足够的能量和驱动力,促进了动态再结晶。温度越高再结晶越充分,变形温度达到960 ℃晶界出现了大量的大角度晶界,表明动态再结晶后的组织又发生了不连续动态再结晶[24~26],即在该温度材料的变形能力最强。

图9

图9

在不同变形温度下Ti65钛合金晶粒的形貌

Fig.9

Grain morphology distributions of Ti65 alloy at different temperatures

(a) 900 oC (b) 920 oC (c) 940 oC (d) 960 oC

图10

图10

在不同变形温度下Ti65钛合金的取向分布

Fig.10

Misorientation distributions of Ti65 alloy at different temperatures

(a) original (b) 900 oC (c) 920 oC (d) 940 oC (e) 960 oC

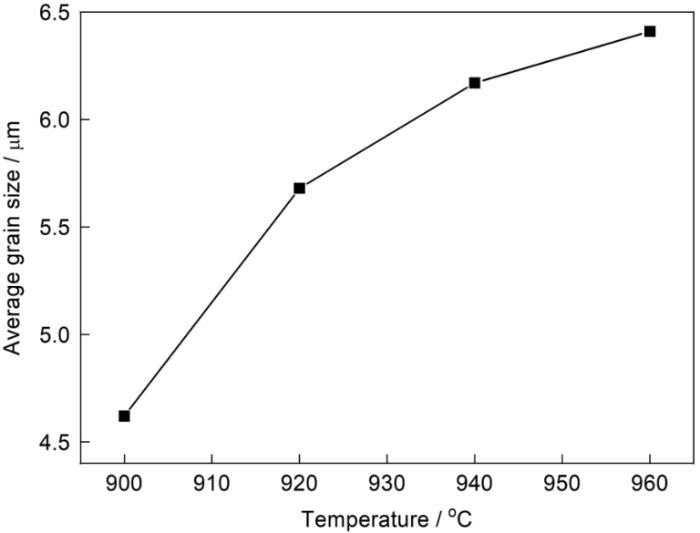

图11给出了平均晶粒尺寸与变形温度的关系。可以看出,随着变形温度的提高平均晶粒尺寸随之增大。变形温度为900 ℃的断口附近组织均匀,α相晶粒呈等轴状,平均晶粒尺寸为4.62 μm。其原因是,在超塑变形过程中发生动态再结晶生成了细小的等轴晶粒;变形温度的提高促进了原子扩散、位错滑移和晶界迁移,使材料的动态再结晶较早完成,而生成的细小晶粒在高温下发生聚集长大。因此,变形温度为960 ℃时,过高的温度使晶粒显著长大,最大的平均晶粒尺寸为6.41 μm。

图11

图11

平均晶粒尺寸与变形温度的关系

Fig.11

Relationship curve between average grain sizes and temperatures

2.3.2 应变速率的影响

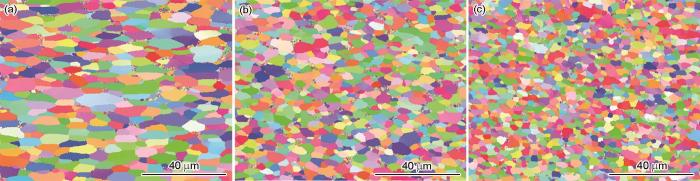

Ti65钛合金在940 ℃不同应变速率超塑拉伸后断口附近的微观组织,如图12和13所示。可以看出,变形后的组织为随机织构,晶粒取向分散。在较低的应变速率(例如0.001 s-1和0.003 s-1)下大部分晶粒内有少量或几乎没有小角度晶界和亚晶粒,表明在高温应变速率条件下变形,大部分晶粒因完全动态再结晶而细化。应变速率为0.001 s-1时晶粒沿拉伸方向变形为长条状,因为在低应变速率条件下变形,较小的畸变能提供的动态再结晶的驱动力不足以在完全动态再结晶后发生再结晶;在应变速率为0.003 s-1条件下(图9c),在部分再结晶晶界上出现了呈“链条”状分布的晶界。这表明,在完全动态再结晶的晶界上发生了不连续动态再结晶,使材料的伸长率达到最大;应变速率较高(例如0.01 s-1和0.03 s-1)时在晶粒内出现了大量的小角度晶界,而连续动态再结晶需要大量的小角度晶界使亚晶粒连续转动形核[27,28],因此连续动态再结晶的程度逐渐提高,使晶粒明显细化。

图12

图12

应变速率不同的Ti65钛合金的晶粒形貌

Fig.12

Grain morphology distributions of Ti65 alloy at different strain rates

(a) 0.001 s-1 (b) 0.01 s-1 (c) 0.03 s-1

图13

图13

应变速率不同的Ti65钛合金的取向分布

Fig.13

Misorientation distribution of Ti65 alloy at different strain rates (a) 0.001 s-1, (b) 0.01 s-1, (c) 0.03 s-1

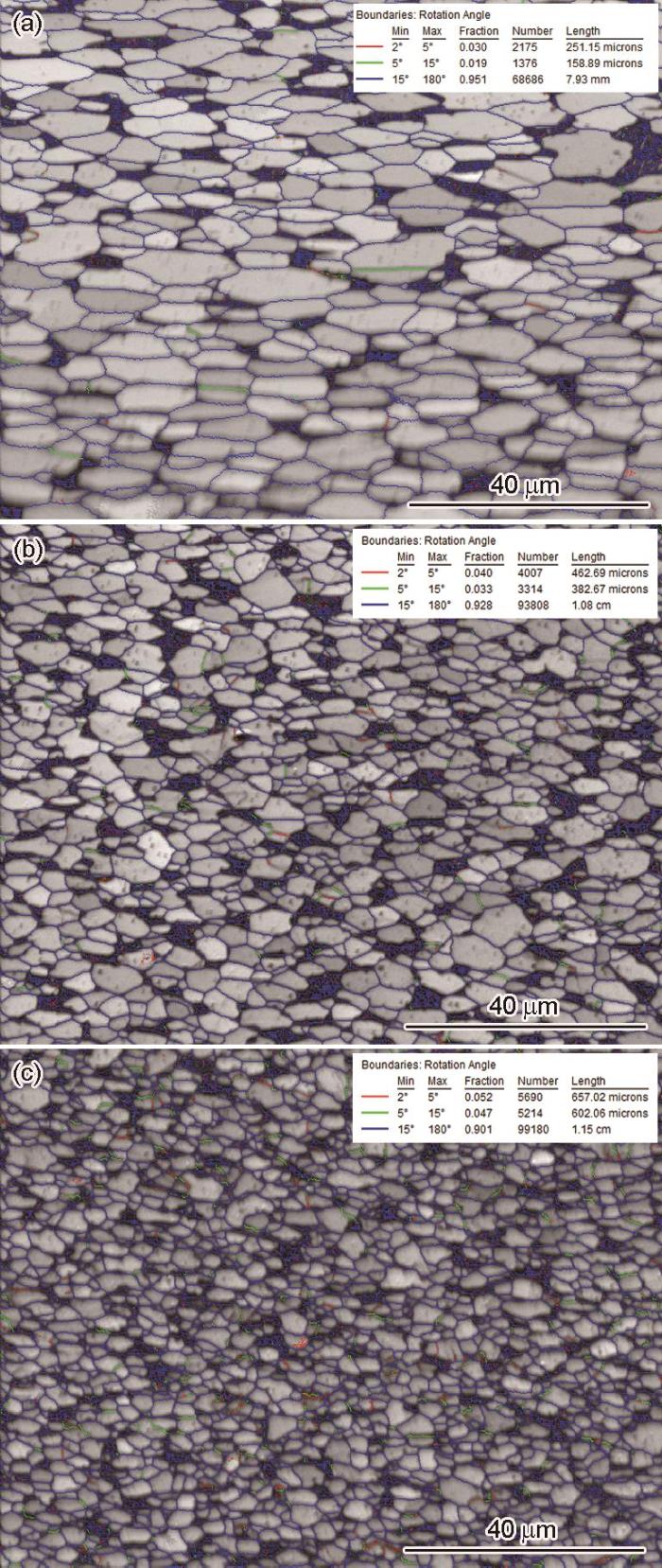

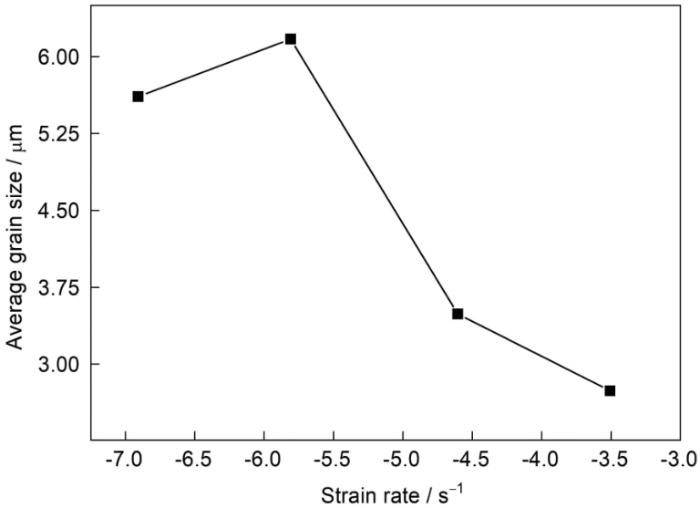

图14给出了平均晶粒尺寸与应变速率的关系。可以看出,随着应变速率的提高平均晶粒尺寸先增大后减小。应变速率为0.001 s-1时平均晶粒尺寸为5.61 μm,低于0.003 s-1时为6.17 μm。其原因是,应变速率较低(0.003 s-1)时材料的伸长率较大,所以变形程度较高,应变诱导晶粒粗化。应变速率较高(高于0.003 s-1)时,过高的应变速率缩短了材料的变形时间,以致动态再结晶细化后的晶粒来不及聚集长大而使晶粒尺寸逐渐减小。

图14

图14

平均晶粒尺寸与应变速率的关系

Fig.14

Relationship curve between average grain sizes and strain rates

3 结论

(1) 随着变形温度的提高和应变速率的降低,Ti65钛合金的超塑变形的峰值应力逐渐减小,而断后伸长率随着变形温度的提高而增加,随应变速率的降低先减小后增加。在变形温度为960 ℃、应变速率为0.003 s-1的条件下Ti65钛合金的伸长率最大(为1108%),表明其超塑变形性能较好。

(2) 理论计算出Ti65钛合金超塑变形应变速率敏感指数m = 0.42,表明其超塑变形机制不止是晶界滑动;Ti65钛合金的应力指数n = 2.5,表明其晶界滑动和位错滑移为主要变形机制;超塑变形激活能(Q = 393 kJ/mol)高于晶界自扩散自由能,表明其超塑变形还受动态再结晶、动态回复等机制的影响。

(3) 在Ti65钛合金的超塑变形过程中发生了连续动态再结晶生成了细小等轴晶粒,而且随着变形温度的提高和应变速率的降低不连续动态再结晶程度提高。

(4) 随着变形温度的提高,Ti65钛合金超塑拉伸后细小等轴晶的晶粒长大;在提高应变速率和缩短变形时间的条件下,Ti65合金超塑拉伸后晶粒尺寸随着应变速率的提高先增大后减小。

参考文献

Effects of deformation parameters on the superplastic behavior and microstructure evolution of TA32 alloy

[J].

变形参数对TA32合金的超塑性变形行为及微观组织演化的影响

[J].

Development of fine-grain size titanium 6Al-4V alloy sheet material for low temperature superplastic forming

[J].

Advanced superplastic forming and diffusion bonding of titanium alloy

[J].

High temperature flow behavior and microstructure evolution of TC31 titanium alloy sheets

[J].

TC31钛合金板材高温流变行为及组织演变研究

[J].

Flow behavior of TA32 titanium alloy at high temperature and its constitutive model

[J].In order to study the flow behavior of TA32 titanium alloy, a constitutive model was set up at high temperature. A tensile experiment was carried out at temperatures of 650 similar to 850 degrees C and strain rates of 0.1 similar to 0.0001 s(-1). The result indicates that the TA32 titanium alloy maintains a relatively good comprehensive performance at high temperature. Work hardening and dynamic recovery are exhibited in the tensile process in the temperature range of 650 similar to 750 degrees C and low strain rate range of 10(-1)similar to 10(-3) s(-1). However, the elongation of TA32 increases enormously and strength decreases clearly as the temperature rises to 800 degrees C; at the mean time, a steady stage of stress occurs. The constitutive model of Arrhenius-type was constructed by a specific correction method based on statistics and regularization. The comparison shows a more accurate flow predicted stress through the modified model compared to the conventional least squares model.

TA32新型钛合金高温流变行为及本构模型研究

[J].

Present situation and prospect of 600 oC high-temperature Titanium alloys

[J].

600 ℃高温钛合金发展现状与展望

[J].

Hot working behavior of near-α alloy IMI834

[J].

Effect of temperature on tensile properties of near-α alloy Timetal 834

[J].

An overview on the use of titanium in the aerospace industry

[J].

Current research status and development of high-temperature Titanium alloys

[J].

高温钛合金的研究现状及其发展

[J].

Research on 650 oC high temperature titanium alloy technology for aero-engine

[J].

航空发动机用耐650 ℃高温钛合金研究现状与进展

[J].

High temperature titanium alloys: status and perspective

[J].

高温钛合金的现状与前景

[J].简要回顾国内外固溶强化型高温钛合金材料的发展历史,分析英、美、俄等国的高温钛合金研究与应用情况及发展趋势。介绍国内自主研制、使用温度在550~650℃范围内的三种钛合金新材料及其相关技术发展,对国内高温钛合金材料进行初步梳理。参考国外高温钛合金研究、应用经验及发展趋势,结合国内实际情况,对国内高温钛合金材料体系的建立及完善提出具体建议,并展望国内高温钛合金近期研究重点和未来发展方向。

Effects of heat treatment on microstructure, texture and tensile properties of Ti65 alloy

[J].Microstructure- and texture-evolution of Ti65 Ti-alloy plate were investigated, and the tensile deformation mechanism of the plate after heat treatment with different texture were discussed. The results show that heat treatment has a significant influence on the evolution of microstructure and texture of the plate. Equiaxed-, duplex- and lamellar-microstructure would be obtained after different heat treatment. The plate with equiaxed microstructure presented a B/T texture, while the c-axis of the α-phase and the rolling direction (RD) met at a 70°~90° angle; similar texture could be found in duplex- and lamellar-microstructure, meanwhile a new texture that the c-axis of the α-phase paralleled to RD could be found in the alloy. Room temperature tensile strength of plates with duplex microstructure could be enhanced by the dislocations and sub-structures, while had little effect on tensile properties at high temperature. Texture was found to be the main factor affecting the anisotropy of tensile properties of Ti65 plates, the plate would possess good tensile properties without obvious anisotropy in tensile strength after heat treatment of 980℃/1 h/AC+700℃/4 h/AC.

热处理对Ti65钛合金板材的显微组织,织构及拉伸性能的影响

[J].研究了不同热处理条件下Ti65钛合金板材的显微组织和织构的变化规律,分析了板材织构的类型和热处理影响拉伸强度的机制。结果表明,热处理对板材的显微组织和织构类型具有显著的影响。通过热处理可分别得到具有等轴组织、双态组织或片层组织的板材。等轴组织板材的织构为晶体c轴与板材RD方向呈现70°~90°夹角的B/T型织构,双态组织和片层组织板材的主要织构类型与等轴组织类似,且出现晶体学c轴与RD方向平行的织构。双态组织板材内的位错和亚结构使板材的室温拉伸强度提高,但是对高温拉伸变形的阻碍能力有限。板材中的织构是影响合金力学性能各向异性的主要因素。经980℃/1 h/AC+700℃/4 h/AC热处理后的板材横、纵向拉伸强度的差异最小,且都具有较高的室温拉伸性能和最佳的650℃拉伸性能。

Study on microstructure and key high temperature mechanical properties of Ti65 alloy

[D].

Ti65合金显微组织及关键高温力学性能研究

[D].

Hot deformation behavior and constitutive equation of Ti65 titanium alloy

[J].

Ti65钛合金热变形行为及本构方程

[J].

Effect of a NiCrAlSiY coating on cyclic oxidation and room temperature tensile properties of Ti65 alloy plate

[J].Cyclic oxidation resistance is an essential factor affecting the reliable use of Ti65 Ti-alloy plates in aerospace vehicles. In this paper, the cyclic oxidation resistance of Ti65 plates was investigated by cyclic oxidation testing at 650℃~800℃. The results showed that the NiCrAlSiY coated Ti65 plate was composed of three regions after 500 cycles of oxidation test: coating, diffusion layer, and substrate region. The interface of coating/plate was relatively compact, and the coated plate exhibited a fully antioxidant level. The major oxide on the surface of coated plate was found to be Al2O3, while TiO2 was detected when oxidation temperature increased to 800℃. During cyclic oxidation, the elements diffusion between coating and substrate were mainly Ni and Ti, while the diffusion of a small amount of Cr occurred when temperature increased to 800℃. The inter-diffusion of Ni and Ti were thought to lead to the generation of Ti2Ni and TiNi at coating/plate interface. After cyclic oxidation, the tensile strength retention of both coated and as-received plates were more than 90%, while the elongation of coated plates was only about 30% of the original plates (before cyclic oxidation). The plates without coating were failed by brittle fracture after cyclic oxidation, obviously, the significant reduction of tensile elongation might be due to the brittleness caused by infiltration of oxygen element at high temperature on the plate surface.

一种NiCrAlSiY涂层对Ti65钛合金板材循环氧化和室温力学性能的影响

[J].

Superplasticity in a large-grained TiAl alloy

[J].

High temperature deformation behaviour of TC17 titanium alloy

[J].

TC17钛合金高温变形行为研究

[J].

Micro-orientation evolution and deformation mechanism of Al-Li alloy 5A90 during superplastic deformation

[D].

5A90铝锂合金超塑性变形微取向演变及变形机理

[D].

Microstructure evolution and fracture behavior in superplastic deformation of hot-rolled AZ31 Mg alloy

[J].

热轧AZ31镁合金超塑变形中的微观组织演变及断裂行为

[J].通过热轧工艺制备了具有细晶微观组织的AZ31镁合金薄板.在250-450℃的温度范围和0.7×10-3~1.4×10-1s-1的初始应变速率范围内研究了热轧AZ31镁合金板的超塑性流变行为.分别通过光学显微镜和扫描电镜(SEM)观察了AZ31镁合金超塑性变形中的微观组织演变和断裂行为,并计算了不同温度下的变形激活能.结果表明,从300℃开始,热轧AZ31镁合金开始表现出超塑性的流变特征.在400℃,0.7×10-3s-1的变形条件下,最大延伸率可达362.5%,显示了良好的超塑性能.在300-400℃的超塑变形温度范围内,AZ31镁合金超塑变形的主要机制是由晶界扩散控制的晶界滑移,而变形温度和应变速率对AZ31镁合金断裂行为的影响主要体现在变形机制从晶内滑移到晶界滑移的转变.

Study on fine-grain size titanium 6Al-4V alloy material for low temperature superplasticity

[D].

细晶TC4合金的低温超塑性变形研究

[D].

Hot Deformation Behavior of TC2 Titanium Alloy

[J].

TC2钛合金的高温热变形行为

[J].对TC2钛合金的高温变形行为进行了有限元模拟和热压缩实验研究,使用有限元自洽模型模拟提高流动应力曲线修正精度,分析材料的应力应变曲线特征,得到其高温流动本构方程和激活能,并进行了光学显微镜观察研究其微观组织演变规律,发现在高温低应变速率下α相的球化程度较高。绘制出TC2钛合金的功率耗散图和热加工图,结合应变速率敏感系数m研究了受m值控制的不同变形机制,最终确定了TC2钛合金的最佳加工窗口:(I)760~825℃、0.007~0.024 s<sup>-1</sup>;(II)850~900℃、0.018~0.37 s<sup>-1</sup>;(III)900~950℃、1~10 s<sup>-1</sup>,在此区间功率耗散因子较大,在材料变形过程中发生充分动态再结晶,试样的微观组织呈细小等轴状。

The identification of dynamic recrystallization type during hot deformation process

[J].

高温变形过程中的动态再结晶类型识别

[J].

EBSD analysis of evolution of dynamic recrystallization grains and δ phase in a nickel-based superalloy during hot compressive deformation

[J].

Dynamic and post-dynamic recrystallization under hot, cold and severe plastic deformation conditions

[J].

Development of dynamic recrystallization theory

[J].

The microstructure evolution and nucleation mechanisms of dynamic recrystallization in hot-deformed Inconel 625 superalloy

[J].

Flow behavior and microstructures of superalloy 718 during high temperature deformation

[J].