在不改变外形的条件下提高传统回火高强钢综合力学性能的方法,主要是进行热处理调控其基体组织或促使纳米第二相析出。与传统回火高强钢相比,为了提高其可焊性并实现强度与韧性的良好匹配,含Cu低合金高强钢的碳含量和其它合金元素的含量都处于较低级别[1,2]。但是,较低的碳含量影响其强度。钢的强度和低温韧性都决定于其基体组织的均匀性、晶粒大小、析出相的数量密度及分布[3,4]。添加0.2%~0.8%的Cu元素制备的HSLA-80/100、ASTMA710等含Cu钢,是制造现代海洋装备的主要钢材[5,6]。Cu元素在钢中的状态、析出形式以及分布特征对于提高其耐蚀性和韧性至关重要。在时效处理前基体中的Cu元素主要以固溶原子的形式存在,而在时效处理过程中Cu原子则从过饱和的基体中析出,形成高密度纳米级富Cu析出相可提高其综合力学性能,还能极大的提高其耐腐蚀性能[1,7~9]。但是,Cu的熔点较低且在热加工过程中易产生铜脆。在钢中加入Ni元素可提高Cu在基体中的固溶度,并能避免高温轧制和热处理过程中出现热裂。研究表明[10~12],Ni元素还能降低形核过程中富Cu析出相与钢基体之间的应变能、界面能、临界形核功以及奥氏体向铁素体的转变温度,有利于晶粒细化从而提高其强度和韧性。

与小规格钢板的低温轧制不同,大型结构钢的尺寸较大,其低温轧制的形变抗力和对轧机的负荷都大幅度增大,以致使低温轧制难以进行。以传统的低碳钢为例,较低的轧制温度将使其发生低温相变,基体组织由奥氏体转变成贝氏体铁素体和针状铁素体甚至出现马氏体/奥氏体(M/A),严重影响其组织的均一性。同时,M/A组元是使钢板断裂失效的主要因素,所以应避免或降低其占比[13,14]。提高轧制温度,可使钢板软化而大幅度降低轧制形变抗力。同时,在较高的温度轧制时组成第二相粒子的合金元素大多固溶而在后续热处理时大量弥散析出,从而使钢板的强度大幅度提高。鉴于此,本文对在不同温度轧制的含Cu低合金高强钢进行调质处理,研究其对钢的显微组织、富Cu相的析出以及力学性能的影响。

1 实验方法

实验用低碳含Cu低合金钢的成分,列于表1。用50 kg真空感应炉冶炼实验用钢,将其浇铸成钢锭并锻造成140 mm × 110 mm × 110 mm方坯。将钢坯装炉后随炉加热至1200 ℃,保温2 h进行均质化处理。再将实验钢分别加热至1000、1050、1100、1150、1200和1250 ℃,保温90 min后进行7道次轧制成厚度为12 mm的钢板,终轧温度为850 ℃,轧后空冷至室温。对轧板进行调质热处理:将轧板加热至900 ℃保温1 h后水淬至室温,再将淬火后的轧板加热至660 ℃保温2 h后空冷至室温。根据轧制温度将热轧钢板分别命名为R1~R6,对应的调质处理后的轧板分别命名为T1~T6。

表1 实验用钢的化学成分

Table 1

| C | Si | Mn | Cr | Ni+Cu+Mo | Ti | Nb | Fe |

|---|---|---|---|---|---|---|---|

| 0.05 | 0.18 | 0.64 | 0.62 | 3.5~4.0 | 0.014 | 0.027 | Bal. |

用HITACHI SU-5000型扫描电子显微镜(SEM)和FEI Talos F200X型透射电子显微镜(TEM)观察分析实验钢的组织和第二相粒子的分布。使用SAXSess MC2型小角X射线散射仪(SAXS)对比分析实验钢中第二相粒子的体积分数。SEM试样的尺寸为10 mm × 10 mm × 10 mm,将其依次用400#、800#、1500#、2500#砂纸磨抛后,用4%的硝酸酒精溶液进行室温腐蚀。TEM试样和SAXS试样的尺寸为10 mm × 10 mm × 1 mm,用上述砂纸磨至厚度为60 μm。TEM试样为ϕ3 mm的小圆片,用10%高氯酸酒精溶液进行电解双喷进一步减薄,电解电压为20 V,温度为-25 ℃。依据GB/T229-2020标准Charpy冲击试样的尺寸为10 mm × 10 mm × 55 mm (V型缺口深度为2 mm),用JBN-300B型冲击试验机在-40、-84 ℃下测试冲击性能。依据GB/T228.1-2021标准棒状拉伸试样的直径为5 mm,使用WE-300型拉伸试验机测试实验钢的拉伸性能。

2 实验结果

2.1 实验钢的力学性能

热轧态试样和经调质处理后试样的室温拉伸力学性能以及在-40、-84 ℃下的冲击功,分别列于表2和表3,表中的数据为三个平行试样结果的平均值。由表2可见,随着轧制温度的提高热轧态试样的强度略呈提高的趋势,而调质处理后试样的抗拉强度明显降低,但是屈服强度大幅提高,延性变好。从表3可见,热轧试样和调质处理试样在-40 ℃的冲击韧性都明显优于在-84 ℃的冲击韧性。轧制温度对热轧态试样的低温冲击韧性影响较大,且随着轧制温度的提高冲击功降低,但是轧制温度对调质处理试样低温冲击韧性的影响可以忽略。对比热轧态和调质态试样的低温冲击韧性可见,调质处理能大幅度提高试验钢的低温冲击韧性:一是大幅度提高了-84 ℃的低温韧性,二是改善了高轧制温度试样的低温韧性。综合室温拉伸和低温冲击实验结果可以发现,调质处理虽然降低了试验钢的抗拉强度,但是提高了屈服强度和低温冲击韧性,并一定程度上降低了轧制温度对力学性能的影响。

表2 热轧态R1~R6试样的力学性能

Table 2

| Samples | R1 | R2 | R3 | R4 | R5 | R6 | |

|---|---|---|---|---|---|---|---|

| Strength | Rp0.2 / MPa | 544 | 563 | 544 | 576 | 551 | 571 |

| Rm / MPa | 796 | 805 | 795 | 827 | 805 | 820 | |

| A / % | 16 | 21 | 17 | 21 | 19 | 21 | |

| Z / % | 77 | 76 | 74 | 73 | 76 | 73 | |

| Impact energy | AKv(-40 oC) / J | 157 | 129 | 100 | 126 | 49 | 36 |

| AKv(-84 oC) / J | 55 | 28 | 14 | 22 | 14 | 13 | |

表3 调质态T1~T6试样的力学性能

Table 3

| Samples | T1 | T2 | T3 | T4 | T5 | T6 | |

|---|---|---|---|---|---|---|---|

| Strength | Rp0.2 / MPa | 686 | 717 | 680 | 700 | 690 | 691 |

| Rm / MPa | 727 | 751 | 725 | 736 | 735 | 730 | |

| A / % | 18.5 | 21 | 18 | 21 | 20 | 21 | |

| Z / % | 75 | 74.5 | 73.5 | 73.5 | 74.5 | 73 | |

| Impact energy | AKv(-40 oC) / J | 236 | 264 | 264 | 258 | 267 | 254 |

| AKv(-84 oC) / J | 213 | 201 | 216 | 198 | 182 | 199 | |

2.2 实验钢的组织

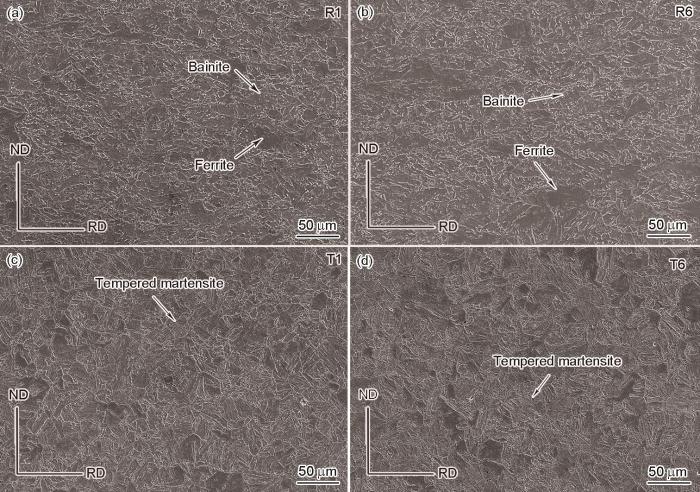

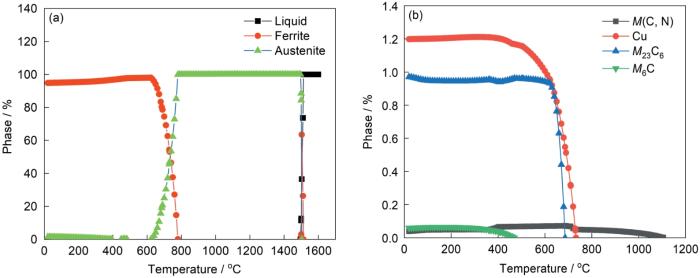

图1给出了调质前后钢板的显微组织。对比分析轧制温度为1000和1250 ℃的热轧板坯(R1、R6)和调质处理板坯(T1、T6),热轧板空冷至室温后的组织均为铁素体+贝氏体的混合组织,空冷是贝氏体生成的主要原因(图1a、b)。图2a给出了实验钢的相变温度和在不同温度下各相占比的JMatPro计算结果。据此可以推断,热轧试验钢板在900 ℃保温1 h完全奥氏体化后进行淬火,得到马氏体组织。再在660 ℃保温2 h后空冷至室温,马氏体组织分解而形成回火马氏体组织,仍然可见马氏体板条特征(图1c和d)。回火温度的提高有利于回火马氏体/贝氏体比例的提高,且本文的实验钢含Ni元素和Cu元素,铁素体向奥氏体转变的相变温度因此而降低,近而促使其在回火过程中的短时间内淬火马氏体分解,使淬火残余应力得以松弛。结合图2a的计算结果和文献[15]的结果,本文的实验钢在660 ℃回火后回火马氏体/贝氏体的比例相对较高,且晶粒长大并不明显,有利于调质态试样良好的强韧性匹配。

图1

图1

热轧态试样和调制态试样的显微组织

Fig.1

Microstructure of hot-rolled and tempered sample (a) R1, (b) R6, (c) T1, (d) T6

图2

图2

用JMatPro软件计算的实验用的相变温度和第二相析出温度

Fig.2

Phase transition temperature (a) and precipitation temperature (b) of the test steel calculated by JMatPro software

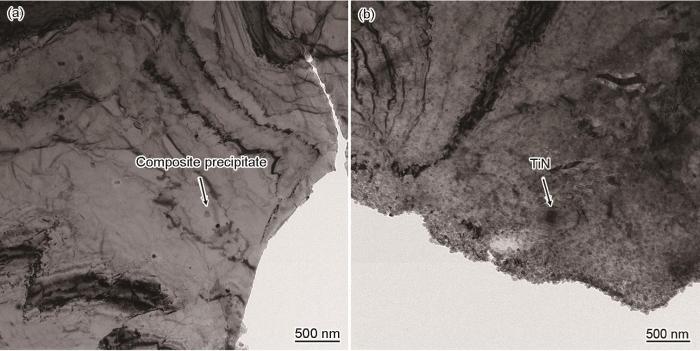

图3

图3

R1和R6试样中析出相的TEM照片

Fig.3

TEM micrographs of precipitates in R1 (a) and R6 (b) sample

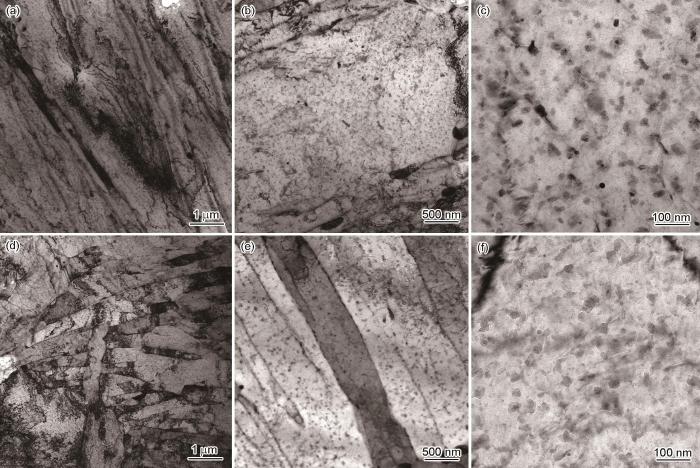

图4

图4

T1和T6试样的基体组织和析出相的TEM照片

Fig.4

TEM images of microstructure (a, d) and precipitates (b, c, e, f) in T1 and T6 sample (a~c) T1 (d~f) T6

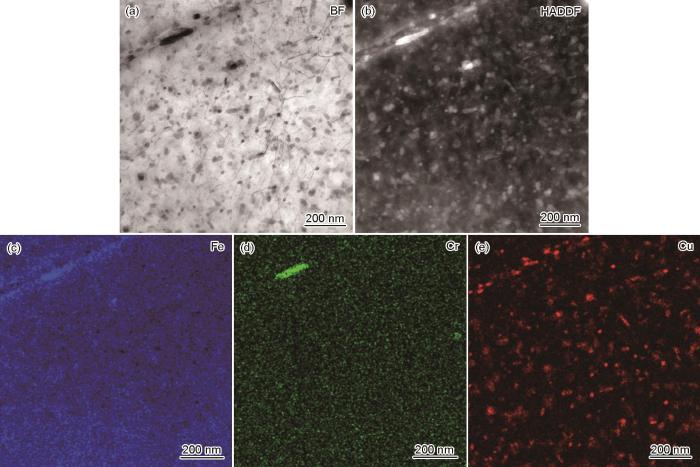

图5给出了T1试样的扫描透射电子显微镜高角度环形暗场像(STEM-HAADF)和能谱(EDS)分析。从图5a的TEM的明场相可以看出,在回火过程中析出的第二相粒子都均匀弥散的分布在回火马氏体板条内,部分粒子与位错之间有强烈的交互作用。同时,在回火马氏体的板条束界上还有尺寸约为200 nm的长条状第二相粒子。第二相粒子及其分布可由图5b中的暗场像进一步确认。对观察区域进行EDS分析,重点观察了Fe、Cr、Cu等元素的分布况,如图5c~e所示。可以看出,回火马氏体板条内弥散分布的第二相粒子以富Cu相为主,而回火马氏体板条束界上的长条状第二相粒子则为富Cr相。结合图2b的计算,推测其为Cr23C6型粒子。Cr23C6型粒子的生成,可能因轧制温度较低(1000℃)在铸坯冷却过程中生成的粗大富Cr相粒子没有完全回溶进基体,也有可能是回火马氏体的小角晶界板条束界与基体组织之间有一定的晶体学位相差角,为富Cr型碳化物的析出或未溶相的粗化提供了必要的能量条件[16,17]。

图5

图5

T1试样的STEM照片和EDS能谱分析

Fig.5

STEM images and EDS analysis of precipitates in T1 sample (a) bright-field STEM (BF-STEM) micrograph of T1 sample, (b) STEM-HAADF micrograph of T1 sample, (c~e) element distribution images in EDS

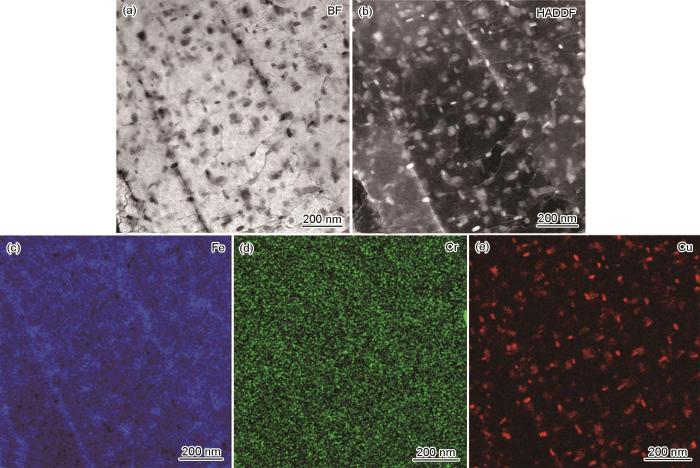

图6

图6

T6试样中第二相粒子的STEM照片和EDS能谱分析

Fig.6

STEM images and EDS analysis of precipitates in T6 sample (a) BF-STEM micrograph of T6 sample, (b) HAADF-STEM micrograph of T6 sample, (c~e) element distribution images in EDS

3 讨论

3.1 轧制温度对轧制态试样析出相类型的影响

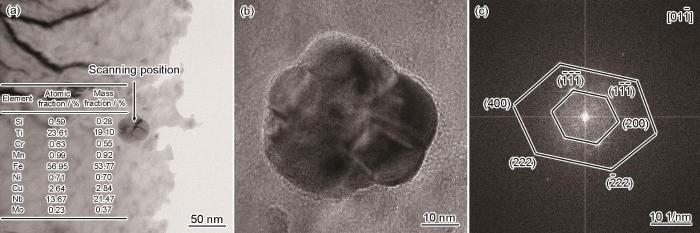

图7

图7

R1试样中析出相的TEM照片和EDS能谱分析

Fig.7

TEM images and EDS spectrum analysis of precipitates in R1 sample (a) precipitates in R1 sample, (b) HRTEM micrograph of precipitates in R1 sample, (c) fast Fourier transform (FFT) of R1 sample

在中厚板的生产过程中,铸坯的厚度较大使压缩比不足且轧制的变形量较小,导致位错密度过低而不能为第二相粒子提供足够的非均质形核点。TiN粒子的生成温度较高,在铸造过程中基本上可完成形核和长大,但是在R1轧制温度下(1000 ℃)短时间内不能长大。由于均质形式所需的形核功较大和时间较长,在短时间内不能以均质形核析出,因此第二相粒子基本上以非均质形核析出。基体中的位错密度较少,为第二相粒子提供的非均质形核的位点较少,而TiN粒子与基体的界面能显著降低第二相粒子的形核功、所需时间和表面能,为轧制过程中第二相粒子的快速析出提供了新的非均质形核位点。于是,在压缩比受限、第二相粒子非均质形核位点较少的情况下,R1轧态试样中的第二相粒子大部分以复合形式析出。同时,复合析出相的尺寸及数目与预先存在的TiN粒子的尺寸与数目有关。细小而弥散的析出相,有利于提高试样的综合力学性能。

3.2 轧制温度对调质态试样析出相类型的影响

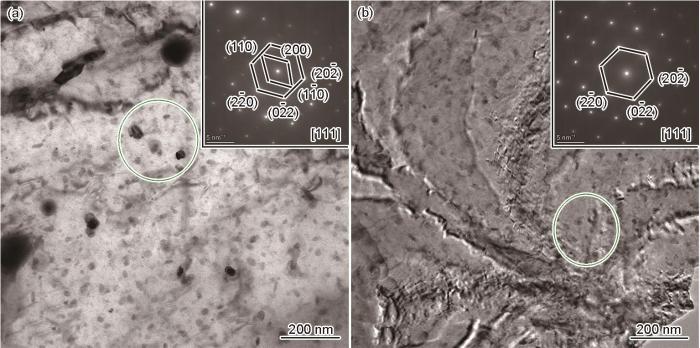

对比图5和6可见,在调质后的试样中弥散分布着大量纳米级富Cu相粒子,但是在轧制温度为1000 ℃的T1试样内回火马氏体板条束界上生成了少量长条状富Cr相粒子。结合图2b给出的计算结果,在理论上,在660 ℃回火的试验钢内能同时析出一定数量的富Cu相粒子和Cr23C6粒子。分别对T1和T6试样中回火马氏体板条内的细小第二相粒子进行选区衍射(SAED)分析,其结果如图8所示。可以看出,无论是在T1试样还是T6试样中,回火马氏体板条内的细小第二相粒子都生成了M23C6粒子。结合图5和图6中的EDS分析,在调质后试验钢中的回火马氏体板条内弥散分布着纳米级的富Cu相粒子和M23C6粒子。在淬火过程中,在原始奥氏体晶粒内的富碳区容易生成高碳马氏体,在贫碳区则生成低碳马氏体。于是,在富碳马氏体和低碳马氏体的界面处产生了碳浓度梯度,在后续的回火过程中部分碳原子从富碳马氏体中脱溶析出生成碳化物。靠近低碳马氏体界面处的碳原子则向马氏体板条束界迁移,在界面处有足够的能量和形核位点,与低碳马氏体侧的强碳化物形成元素结合,在沿着板条束界的小范围内析出连续碳化物。而碳原子扩散的范围有限,较高的回火温度(660 ℃)使Cr元素在铁素体中的扩散速率提高,在回火马氏体板条内析出弥散细小的碳化物颗粒。同时,碳化物中的Cr含量高于一定值使其晶格结构将发生转变。保温时间的延长使小尺寸的碳化物溶解和大尺寸的碳化物颗粒长大,富Cr碳化物粒子易在能量较高的相界面连续析出。这是实验钢中富Cr碳化物粒子形貌和分布不同的主要原因[19]。

图8

图8

T1和T6试样的选区电子衍射(SAED)照片

Fig.8

Selected area electron diffraction (SAED) images of T1 (a) and T6 (b) sample

Wang等[20]的研究表明,低碳钢中富Cu析出相对低碳钢的强度、韧性和可焊性的提高有重要的作用。富Cu析出相的复杂内部结构使其析出行为不同,对钢的强化有较大的影响。分别对T1和T6试样中的富Cu相粒子进行高分辨TEM观察,结果如图9所示。可以看出,不同试样中的富Cu相粒子形貌不同,但是其尺寸都小于20 nm。图9a给出了T1试样中的富Cu析出相,与基体组织呈现非共格关系,其形貌呈人字形条纹图案,与基体保持K-S取向关系,HRTEM图像局部放大后可明显观察到孪晶特征。孪晶面的产生使析出相与基体之间的界面能降低,并使析出相趋于稳定[21]。相邻孪晶带之间的夹角为122°,单层孪晶厚度为0.512 nm。由HRTEM局部放大图可见,该粒子单层孪晶结构由4排原子堆垛而成,其单层原子间距为d = 0.17 nm,符合9R Cu析出相的d(002) = 0.18 nm的原子间距[22]。结合形貌分析可以推断,T1试样中的富Cu粒子为多孪晶型9R Cu粒子,由bcc结构转变为9R结构,在转变过程中生成的孪晶,使其与基体之间的界面能降低,因形核势垒较小可在短时间内大量稳定析出[21]。局部区域大量的层错和严重的晶格畸变产生了大量较高能量的缺陷,出现了向9R多重孪晶结构转变的趋势[23]。

图9

图9

T1和T6试样的STEM-HRTEM图像和FFT图

Fig.9

STEM-HRTEM micrographs of (a) T1 and (c) T6 sample, (b) FFT of Fig.9a, (d) FFT of Fig.9c

而在轧制温度不同的试样中,由于轧制温度高于富Cu相固溶温度,轧制并不影响富Cu相的类型及分布方式。对富Cu相的尺寸、分布及类型的影响,主要取决于后续时效的温度和时间。时效温度和时间影响富Cu相的转变进程及分布方式,进而影响富Cu相的类型。在含Cu低合金高强钢中,富Cu析出相有两种转变方式[24~26]。第一种:按照富Cu纳米有序团簇(bcc Cu)→9R Cu→退孪晶9R Cu→9R Cu + fcc Cu(过渡相)→fcc Cu的结构进行转变。第二种:按照富铜纳米有序团簇(bcc Cu)→非孪晶9R Cu→fcc Cu。本文的实验结果表明,T1和T6试样中的富Cu第二相粒子均为9R型,T6试样中的非孪晶结构9R Cu尺寸略大于T1试样中孪晶结构的9R Cu。总之,第二相粒子越细小、越弥散,产生的析出强化效果越好,越能显著提高材料的力学性能。细化富Cu第二相粒子和控制其转变类型,使其稳定和弥散析出是提高含Cu时效钢冲击韧性的有效途径。

3.3 调质对实验钢力学性能的影响

含Cu低合金高强钢的强化方式为晶界强化和析出强化,因此调质前后力学性能的差异与其基体组织和第二相粒子的分布密切相关。图1表明,热轧态的组织为铁素体+贝氏体,而调质态的组织为回火马氏体,两种组织较大的差异和晶界强化不同,使其力学性能有较大的不同。

调质后淬火生成的马氏体在后续高温回火过程中快速分解,随着回火时间的延长应力得以释放。同时,Ti、Nb微合金化元素的加入提高了位错和板条边界密度并降低了碳在奥氏体中的扩散速率,使碳原子只能在小范围位移,最终基体组织转变为回火马氏体而使抗拉强度降低[30~32]。但是,在回火过程中析出了大量富Cu颗粒(图4)。析出强化效果大幅增强,使回火后的屈服强度显著提高。根据平衡热力学及图2b给出的计算结果,富Cu相在732 ℃开始从过饱和基体中脱溶析出。本文实验中不同的轧制温度和调质前的保温温度(900 ℃)均高于732 ℃,因此在回火前Cu原子作为过饱和溶质原子固溶于基体中而没有富Cu析出相析出。由调质处理的淬火过程引起的马氏体转变在实验钢基体组织中产生大量高密度位错,其亚结构往往为位错胞。这些位错胞中大量的位错结为元素扩散和第二相粒子的生成提供了扩散通道和形核点[33]。随着回火时间的延长Cu原子从过饱和基体脱溶析出并占据高能位错位置而生成了纳米级富Cu析出相。这一结论,可由图5和6中的TEM照片证实。这些纳米级富Cu相粒子强烈阻碍变形过程中的位错运动,使其屈服强度和低温冲击韧性比轧制态试样明显提高。同时,基体组织转变为回火马氏体,其相界面明显多于铁素体组织。在冲击过程中这些因素阻碍位错运动和裂纹扩展[34],是调质态试样的屈服强度和低温冲击韧性明显高于热轧态试样低温冲击韧性的主要原因。轧温度不同并不影响富Cu粒子对提高冲击功的贡献和析出状态(图4~6),调质处理及其过程生成的大量富Cu相粒子对提高该类型实验钢的综合力学性能有重要贡献。力学性能测试结果表明,调质处理中基体组织的变化和大量富Cu相的析出不仅提高了实验钢的综合力学性能,还改善了轧制温度对其冲击韧性不均匀的影响。

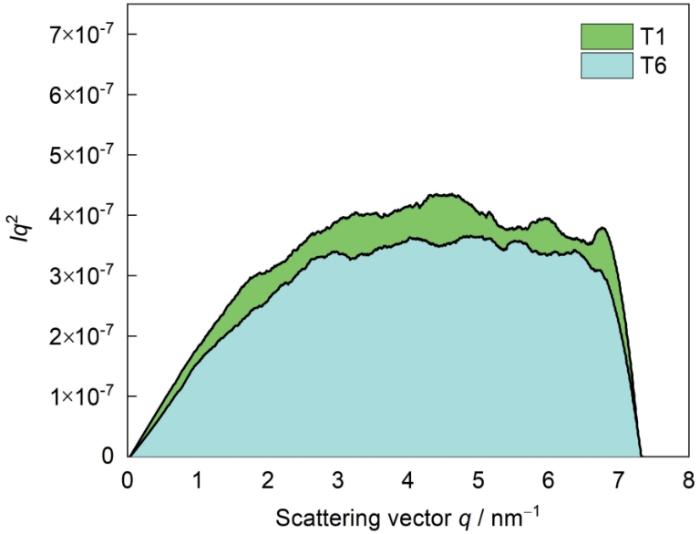

3.4 析出相的体积分数

图10

图10

T1和T6试样的小角X射线散射(SAXS)谱

Fig.10

Small-angle X-ray scattering (SAXS) results of T1 and T6 samples

可计算总析出相的体积分数

为析出相与基体之间物理参量的差值,与材料本身的物理化学性质相关。式中,

本文实验钢为含Cu时效钢,其基体的组成元素为Fe,其

4 结论

(1) 对含Cu低合金高强钢进行调质热处理可使其综合力学性能显著提高,调质态的屈服强度比热轧板显著提高,而抗拉强度略有降低,低温冲击韧性(尤其是-84 ℃温度下)亦有明显提高且基本上不受轧制温度的影响。

(2) 含Cu低合金高强钢调质处理后其基体组织为回火马氏体,析出相包括纳米级Cu粒子和富Cr碳化物。富Cu相以孪晶9R型和非孪晶9R型析出,轧制温度对析出的富Cu相粒子的体积分数影响不大。在高轧制温度下Cr的碳化物以晶内纳米析出相为主,而在低轧制温度下在基体组织的板条束界上出现少量尺寸较大的条状Cr碳化物。含Cu低合金高强钢中析出的大量富Cu纳米相是其屈服强度和低温韧性提高的主要原因。

参考文献

Synergistic effects of Cu and Ni on nanoscale precipitation and mechanical properties of high-strength steels

[J].

Precipitation mechanism and mechanical properties of an ultra-high strength steel hardened by nanoscale NiAl and Cu particles

[J].

Hardening mechanisms and impact toughening of a high-strength steel containing low Ni and Cu additions

[J].Aging treatments at 400-550 degrees C are commonly used to attain a peak strengthening for the Cu-rich nanocluster-strengthened high-strength low-alloy (HSLA) steels. However, these temperatures fall within the dangerous 300-600 degrees C temper-embrittlement regime, leading to poor impact toughness. On the other hand, aging at temperatures above the embrittlement regime can improve the impact toughness but at a great expense of strength. In this work, the strengthening mechanisms as well as the toughening of a low cost weldable HSLA steel with a low content of carbon (C similar to 0.08 wt.%), nickel (Ni = 0.78 wt.%), and copper (Cu = 1.3 wt.%) were carefully investigated. Our findings show that the low-C-Ni-Cu HSLA steel is insensitive to the aging temperatures and can achieve a yield strength (YS) and ultimate tensile strength (UTS) over 1000 and 1100 MPa, respectively, with tensile ductility >10% (reduction of area >60%) at a heat-treat temperature of 640 degrees C through multiple strengthening mechanisms. Besides, a good low-temperature (similar to 40 degrees C) impact performance(similar to 200 J) with high YS (similar to 900 MPa) and UTS (similar to 1000 MPa) can be obtained by seeking a strength balance among the fine grain size (similar to 2.5 gm), medium-sized (similar to 14 nm) overaged Cu-rich precipitates, tempered martensite, and fresh martensite (or carbides). Moreover, a relatively lower YS (similar to 800 MPa) and UTS (similar to 900 MPa) useful for steel manufacturing can be attained by a prolonged aging at 640 degrees C. In addition, the dislocation-precipitate interactions were also explored based on the dislocation theories in this study. (C) 2019 Acta Materialia Inc. Published by Elsevier Ltd.

Microstructure and mechanical properties of a Cu/NiAl nanoprecipitate strengthened dual-phase steel

[J].

Interrelationships between yield strength, low-temperature impact toughness, and microstructure in low-carbon, copper-precipitation strengthened, high-strength low-alloy plate steels

[J].

Effect of tempering temperatures on the mechanical properties and microstructures of HSLA-100 type copper-bearing steels

[J].

The effect of increasing Cu and Ni on a significant enhancement of mechanical properties of high strength low alloy, low carbon steels of HSLA-100 type

[J].

Copper bearing microalloyed ultrahigh strength steel on a pilot scale: microstructure and properties

[J].

Microstructure, properties, and age hardening behavior of a thermomechanically processed ultralow-carbon Cu-bearing high-strength steel

[J].

Behaviour of copper during high temperature oxidation of steel containing copper

[J].

Effects of nickel on the oxide/metal interface morphology and oxidation rate during high-temperature oxidation of Fe-Cu-Ni alloys

[J].

Thermo-mechanically controlled processed ultrahigh strength steel: Microstructure, texture and mechanical properties

[J].

Effect of rolling temperature and ultrafast cooling rate on microstructure and mechanical properties of steel plate

[J].

Effect of dissolution and precipitation of Nb on the formation of acicular ferrite/bainite ferrite in low-carbon HSLA steels

[J].

A quantitative atom probe study of the Nb excess at prior austenite grain boundaries in a Nb microalloyed strip-cast steel

[J].

Precipitation behavior and kinetics in Nb-V-bearing low-carbon steel

[J].

Revealing morphology rules of MX precipitates in Ti-V-Nb multi-microalloyed steels

[J].

Effect of tempering temperature on carbide and mechanical properties in a Fe-Cr-Ni-Mo high-strength steel

[J].The variation of carbides with tempering temperature in a Fe-Cr-Ni-Mo high-strength steel and their effect on mechanical properties are investigated by means of TEM and three-dimensional atom probe (3DAP). The results show that there mainly appear M3C and M7C3 when tempering temperature is rather low (400 ℃), the former is thick with a length of about 1 μm and the latter is fine and the length is less than 200 nm, and M is composed of Fe, Cr and Mn. Tempering at 500 and 600 ℃, the amount of carbide increases gradually, and there appear M2C and M6C types of carbide which are both less than 200 nm in length, simultaneously M3C becoming fine or disappear. When tempering temperature further increases to 650 ℃, besides M2C there also appears MC type of carbide. The size of both M2C and MC are less than 100 nm, meanwhile the amount of carbide decreases. The M of M2C, M6C and MC is a combination mainly of Cr, Mo and V. The strength of the Fe-Cr-Ni-Mo high-strength steel gradually reduces with increasing tempering temperature, but the downtrend of strength is rather small when tempering temperature is in the range of 500~600 ℃, owing to secondary hardening induced by the appearance of V-carbide. In short, the high-strength steel could obtain better combination of strength and impact toughness after tempering at about 530~600 ℃.

回火温度对一种Fe-Cr-Ni-Mo高强钢碳化物及其力学性能的影响

[J].

The role of copper in microstructure and toughness of intercritically reheated coarse grained heat affected zone in a high strength low alloy steel

[J].

Atomic structure of the Cu precipitates in two stages hardening in maraging steel

[J].

Direct observations on the crystal structure evolution of nano Cu-precipitates in an extremely low carbon steel

[J].

Characterization on a complex crystal structure of nano-rich Cu phase in low alloy ferritic steel

[J].

低合金铁素体钢中纳米富Cu相复杂晶体结构的表征

[J].

Effect of Ni on the features of Cu-rich precipitates in high-strength low alloy steel

[J].

Ni对高强度低合金钢中富Cu相析出特征的影响

[J].

Solid phase transition of Cu precipitates in a low carbon TRIP assisted steel

[J].

Cross-section effect of Ni-Cr-Mo-B ultra-heavy steel plate for offshore platform

[J].With the increasing demand and exploitation depth for offshore oil and gas, offshore platforms are becoming larger and the performance requirements and size for offshore platform of ultra-heavy plates are also increasing. Due to the large plate thickness and the limitation of manufacturing techniques, inhomogeneous microstructures and mechanical properties along thickness direction are great challenges for offshore platform of ultra-heavy plates. In this work, variation of microstructure and its effect on mechanical properties for the 117 mm-thick Ni-Cr-Mo-B industrial ultra-heavy plate were investigated by means of OM, SEM, TEM and EBSD observation, in combination with the tensile and impact toughness test. The results show that yield strength reduces gradually from the surface (798 MPa) to the center (718 MPa) and elongation almost keeps constant around 20.0%~22.0% for the 117 mm-thick plate. It is noted that impact energy at -60 ℃ increases first from 35 J at the surface and reaches its peak 160 J at the depth of 1/8T (T—thickness of plate), and then drops to the minimum about 20 J at the center, which suggests that impact energy curve along the whole section varies sharply and exhibits like letter 'M'. Lath width, boundary carbide size and intragranular carbide size are all gradually increasing from the surface to the center, i.e., from 198.7 nm to 500.6 nm, 130.6 nm to 226.6 nm, 45.8 nm to 106.2 nm, respectively, and there are also some blocky areas at the center, all those indicate that refinement strengthening and precipitation strengthening would decrease, as well as the gradual decrease of yield strength. Also, from the surface to the center, effective grain size (EGS) decreases first and then increases. The surface and the center have larger EGS (2.2 μm and 2.7 μm, respectively), which indicates that they have weaker resistance to cleavage crack and exhibit lower impact energy. However, the 1/8T position has smaller EGS (1.7 μm) while obtains higher impact energy.

海洋平台用Ni-Cr-Mo-B超厚钢板的截面效应

[J].采用OM、SEM、TEM、EBSD、拉伸和冲击等分析和检测技术,研究了工业生产的117 mm厚Ni-Cr-Mo-B超厚钢板在厚度方向上微观组织的变化及其对力学性能的影响。结果表明,从表层到芯部,超厚板的屈服强度逐渐降低,表层和芯部的屈服强度分别为798和718 MPa;延伸率变化不大,为20.0%~22.0%;然而超厚板的-60 ℃冲击功变化较大,其中表层、1/8T (T代表板厚)和芯部的冲击功分别为35、160和20 J,使得整个厚度方向上的冲击功变化曲线呈现“M”型。从表层到芯部,超厚板的板条宽度(198.7~500.6 nm)、界面碳化物尺寸(130.6~226.6 nm)和晶内碳化物尺寸(45.8~106.2 nm)均逐渐增加,芯部还存在一定的块状区,板条的细晶强化和碳化物的析出强化效果均减小,使得屈服强度从表层到芯部逐渐降低。从表层到芯部,有效晶粒尺寸先减小后增加,表层(2.2 μm)和芯部(2.7 μm)的有效晶粒尺寸较大,对解理裂纹扩展的阻碍作用较弱,使得表层和芯部的冲击功较低;而1/8T位置具有较小的有效晶粒尺寸(1.7 μm),对解理裂纹的阻碍作用较强,从而获得较高的冲击功。

Improvement of Cu-rich precipitation strengthening for high-strength low carbon steel strengthened via Ti-microalloying

[J].

Refinement of Cu-M2C precipitates and improvement of strength and toughness by Ti microalloying in a Cu-bearing steel

[J].

Effects of nano precipitates in austenite on ferrite transformation start temperature during continuous cooling in Nb-Ti micro-alloyed steels

[J].

Suppression of strain-induced precipitation of NbC by epitaxial growth of NbC on pre-existing TiN in Nb-Ti microalloyed steel

[J].

Delamination effect on impact properties of ultrafine-grained low-carbon steel processed by warm caliber rolling

[J].

Quantitative SAXS analysis of precipitate characteristics limiting hot ductility in HSLA steels containing V, Nb & NbTi

[J].

Revealing precipitate development during hot rolling and cooling of a Ti-Nb micro-alloyed high strength low-alloy steel through X-ray scattering

[J].

Hardening precipitation in a Mg-4Y-3RE alloy

[J].