碳钢/不锈钢(CS/SS)复合材料兼具两种组元金属材料的优点,力学性能优异、耐蚀性好以及制造成本低廉等,广泛应用于石油化工、交通运输以及海洋工程等领域[1~3]。热轧是制备复合板的重要生产工艺,即轧制前先将碳钢和不锈钢按一定顺序排列组合,焊接组坯后在高温环境中保温一定时间,按照设定工艺轧制生产[4]。然而研究发现[5,6]复合界面产生的氧化物严重影响复合板界面的组织结构,从而影响产品的结合强度。因此真空热轧法成为高强度钢材复合板较为理想的制备工艺。Wang等[7,8]研究了真空热轧不锈钢复合板的微观组织及力学性能,发现随压下率增加,界面氧化物形貌逐渐变为不连续的球状颗粒状,且氧化物占比降低,有利于提高界面结合强度。Liu等[9~11]分析了真空度对不锈钢复合板的组织及性能影响,揭示了界面马氏体层、脱碳层和渗碳层的厚度随真空度增加而增加。研究[12~15]发现真空度不仅影响不锈钢复合板界面氧化物形态、组成及结构;并且随着真空度增加,不锈钢复合板剪切断裂位置会发生变化。而真空热轧复合板之间加入中间层[16,17],中间层阻碍基板复板之间的元素扩散,能够提高界面结合强度。此外,研究者[18~21]也着重围绕轧制过程界面区再结晶演变和界面结合率展开研究,发现轧制工况与复合板的最终力学性能指标密切相关。

本实验制备的真空热轧复合板在长期静置过程中,发现部分试样边缘部位的结合界面发生了局部点蚀氧化。我国主要生产不锈钢复合板的某大型企业也发现类似问题,复合板界面的氧化失效可能会成为其边缘开裂的裂纹起源,目前关于复合板结合界面的氧化问题鲜有报道。因此,本文针对Q235碳钢/304不锈钢复合板界面通过化学腐蚀及电化学腐蚀实验,详细分析电解过程中界面毛细效应及产生气体的附加压力对界面微观组织及元素分布的影响,以及轧制工艺与结合界面不锈钢晶粒晶界能、晶界宽度的关系。根据以上参数的变化,进而探究复合板结合界面的腐蚀氧化机理。

1 实验方法

复合材料选用Q235碳钢为基板(145 mm × 125 mm × 4.5 mm),304不锈钢板为复板(135 mm × 115 mm × 2.5 mm),材料成分见表1,以碳钢/不锈钢//不锈钢/碳钢顺序对称组坯。不锈钢坯料间的结合面涂隔离剂,将板坯四周的凹槽填缝后焊接密封;并预留抽真空管,使用真空泵将坯料抽至真空度10-2 Pa后,用乙炔气体将抽真空管加热烧红,再用液压钳将其钳紧,最后将管口焊接密封。将试样加热至1250 ℃,保温10 min,然后在二辊可逆轧机上进行二道次轧制。轧辊不经预热,轧辊直径为360 mm,轧制速度为0.1 m/s。制定轧制压下量如下:(a) 30%/10%;(b) 30%/20%;(c) 30%/25%;(d) 35%/25%。轧制过程中采用AR892 型非接触式红外测温仪测定轧制前/后复合板上表面温度,轧后空冷。

表1 304不锈钢和Q235碳钢的化学成分

Table 1

| Material | Fe | Cr | Ni | C | Mn | Si | P | S |

|---|---|---|---|---|---|---|---|---|

| 304 stainless steel | 68.95 | 18.5 | 8.5 | 0.025 | 2.0 | 2.0 | 0.045 | 0.05 |

| Q235 carbon steel | 98.91 | - | - | 0.02 | 0.5 | 0.3 | 0.045 | 0.05 |

将4个试样沿轧向线切割,取样大小为10 mm × 5 mm。沿试样轧向表面磨抛后,使用4%硝酸酒精腐蚀观察组织。之后再将试样重新磨抛,使用10%铬酸电解,对其进行电化学表面抛光,此时不锈钢板试样抛光的表面为小阳极;直径为40 mm的不锈钢板作为大阴极,以便电解过程产生三价铬离子,降低电解液对环境的污染,电压30 V,电解时间约20 s。对试样进行背散射电子衍射(EBSD)分析测试,加速电压20 kV,步长 0.3 μm。

2 实验结果

2.1 界面的形貌

图1

图1

硝酸酒精腐蚀后复合板界面的形貌

Fig.1

Interface morphology of the composite plate after corrosion by nitrate alcohol

(a) 30%/10%, (b) 30%/20%, (c) 30%/25%, (d) 35%/25%

图1a为压下率30%/10%的试样,在1 cm长的取样范围内,试样结合界面完全复合,界面基本没有孔洞缺陷。左侧靠近界面的碳钢基体,铁素体晶粒内部析出密集的碳化物颗粒导致表面凹凸不平、较为粗糙,隐约可以看到铁素体晶界;结合界面(JHJM)线条较为平直;界面右侧零散分布几个圆形细小孔洞。图1b为压下率30%/20%的试样,左侧上部铁素体晶粒内部共析出凸起的短条状硬质碳化物(C),但内部未析出含有渗碳体层片的珠光体组织,而是较为均匀平整的碳化物凸台(P);界面呈现出不规则线条状;界面右侧出现不规则的较大较长孔洞(ζ),长度约为5 μm,个别孔洞达到10 μm,大孔洞附近分布较多的直径小于1 μm的细小圆形微孔。图1c试样的压下率为30%/25%,界面左侧碳钢铁素体内部析出的凸起状碳化物颗粒(C)增加;碳钢基体在较大的压下率下,其内部同样未出现含有层片状渗碳体的珠光体组织,而是析出细小密集的碳化物颗粒,成为高于铁素体晶粒的凸台(P);结合界面线条不规则;靠近结合界面右侧不锈钢表面的孔洞(ζ)变小且分布较为均匀,其长度小于5 μm,宽度略微增加,孔洞不连续且形状不规则,这些孔洞附近的细小孔洞大幅减少。图1d试样的压下率为35%/25%,随着压下率继续增大,左侧碳钢中晶粒明显变小,晶界更加清晰;碳钢/不锈钢界面却变得模糊;界面右侧复板不锈钢中出现平行于结合界面的连续微孔(ζ),这些孔洞右侧附近弥散分布一些更加细小的孔洞。

将试样重新磨抛,再次用铬酸溶液电解,得到复合板界面处组织形貌(图2),左侧为基板碳钢,未能观察到其组织;右侧复板不锈钢的奥氏体晶界凹槽清晰可见。图2a试样中,复合板结合界面为略微凸起的条状带,内部含有少许圆形的颗粒状物质。奥氏体晶界电解溶解后形成凹槽,宽度约为2 μm。图2b试样随压下率增大,界面侧不锈钢表层内部的孔洞变大变多,成为连续并排的孔洞,部分孔洞内存在颗粒状物质。孔洞右侧的细小圆孔电解后变成较大的凹坑,少数较大的凹坑内有残留的颗粒。奥氏体晶界电解后同样形成凹槽,宽度约为1.8 μm。图2c试样结合界面区不锈钢表层的孔洞电解后形成连接的凹槽,内部仍含有颗粒状物质;孔洞右侧的凹坑数量增加,更加细小。奥氏体晶界凹槽宽度约为1.3 μm。图2d试样不锈钢表层内部微孔电解后完全变为长条状凹槽,内部有较多的颗粒状物质。奥氏体晶界电解后同样形成凹槽,宽度约为1.5 μm。

图2

图2

电解抛光后复合界面的组织

Fig.2

Composite interface structure after electrolytic polishing

(a) 30%/10%, (b) 30%/20%, (c) 30%/25%, (d) 35%/25%

2.2 界面的成分

使用铬酸作为电解液的电解池,极易使阳极发生电化学反应的金属区域氧化。沿碳钢一侧穿越结合界面至不锈钢区域(如图2a所示)进行EDS线扫描成分测试,发现4个试样界面氧含量都存在较高峰值,表明界面有氧化现象。具体表现为:没有气孔缺陷的(a)试样结合界面,碳钢板与不锈钢板紧密结合,高温复合后金属板材表面的元素在熔融扩散过程中均匀分布,电解过程中与电解液整个接触的试样表面发生反应,电解后主要物质为铁元素,界面物质含有铬元素,能探测到少量的硅元素,结合界面区域氧元素明显高于两侧基体,界面物质有氧化现象。

界面含有微孔的(b~d)试样,电解时微孔附近的金属元素溶解较快成为凹槽,金属元素溶解后剩余物质的铁元素含量较低,相比(a)试样铬、锰元素含量有所升高,界面出现远高于基体氧元素含量的峰值。界面线扫描氧元素测试结果见图3。以上结果表明,电解抛光使复合界面物质的氧含量提高。

图3

图3

电解抛光后界面物质的氧含量

Fig.3

Oxygen content of interface material after electrolytic polishing

(a) 30%/10%, (b) 30%/20%, (c) 30%/25%, (d) 35%/25%

2.3 界面侧奥氏体的晶界能

从图2可以进一步看出,经过电解抛光的试样,微孔缺陷经腐蚀溶解后孔洞变大;靠近结合界面的不锈钢表面奥氏体晶界腐蚀成凹槽。表明微孔处的反应速率比整个平整结合界面区域更快,晶界的反应速率远远高于晶粒内部。而微孔或凹槽处于不锈钢表层内部,因此通过研究不同压下率复合板不锈钢侧的IPF图和晶界图,揭示晶粒变化与晶界能之间的映射关系。

晶界图(图4e、f、g、h)中绿色线代表小角度晶界(LAGBs,晶界取向差2°~15°),黑色线代表大角度晶界(HAGBs,晶界取向差≥ 15°)。(a)试样结合界面附近的不锈钢,奥氏体晶粒大小分布不均匀,包括有100 μm左右的块状、小于5 μm宽的长条状、几微米颗粒状形状各异的晶粒;界面处局部出现小角度晶界,图中黑色线条的大角度晶界较多,如图4e所示。(b)试样中不锈钢奥氏体晶粒变大,主要为100 μm左右的块状晶粒,长条状及颗粒状的奥氏体小晶粒较少;结合界面处小角度晶界增多,不锈钢内部小角度晶界在图中中部出现聚集的趋势(图4f)。压下率继续增加,塑性变形继续加大,图4g中奥氏体以大而长的晶粒为主,这些晶粒有平行于轧向的趋势;大晶粒间弥散分布了一些小晶粒。奥氏体晶粒的小角度晶界分布均匀,数量明显增多。压下率继续增至35%/25%时,界面附近不锈钢基体较大晶粒数量较少,50 μm以下晶粒占比较大;视场范围内部奥氏体晶粒的小角度晶界体积分数减少(图4h)。

图4

图4

复合板界面的IPF图和晶界图

Fig.4

IPF diagram and grain boundary diagram of composite plate interface

(a, e) 30%/10%, (b, f) 30%/20%, (c, g) 30%/25%, (d, h) 35%/25%

图5

图5

复合板不锈钢侧的晶界取向差分布

Fig.5

Distribution of grain boundary orientation difference on stainless steel side of composite plate

(a) 30%/10%, (b) 30%/20%, (c) 30%/25%, (d) 35%/25%

晶界能量与晶界角有关,晶界能γ与取向差θ的关系[24]为

式中G为切变模量,v为泊松比, b 为伯氏矢量,A为积分常数(取为1),其中

表2 界面物质的成分和微孔的参数

Table 2

| Sample | (a) | (b) | (c) | (d) |

|---|---|---|---|---|

| ΔS/μm2 | 0 | 60.6 | 62.3 | 87.7 |

| γ /J·m-2 | 0.346K | 0.271K | 0.222K | 0.264K |

| Ps | 0.21P0 | 0.2106P0 | 0.2108P0 | 0.2115P0 |

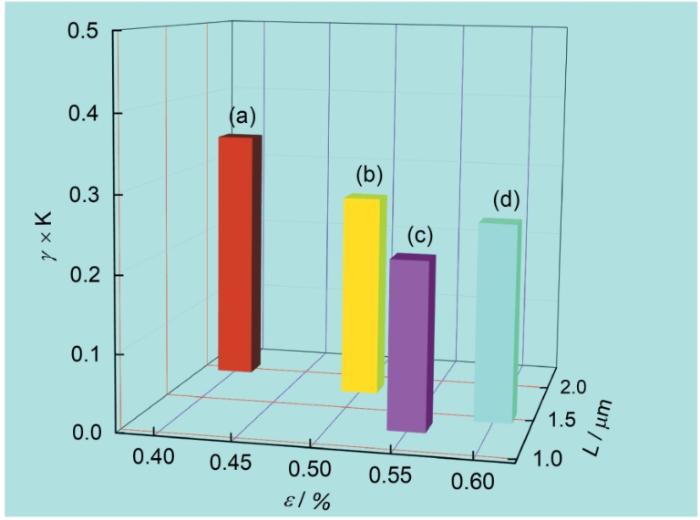

由此得晶界能(γ)与不锈钢侧晶界宽度(L)及压下率(ε)的关系(图6)。(a)试样的小角度晶界占比为69%,大角度晶界占比31%,晶界能为0.346K。(b)试样第二道次压下率增大,大角度晶界迅速降低,小角度晶界占比提高至78%,晶界能下降至0.271K,奥氏体的晶界宽度由2 μm减小至1.8 μm。第二道次压下率继续增大至25%,(c)试样的小角度晶界占比提高至86%,晶界能下降至0.222K,晶界宽度再次减小至1.3 μm。(d)试样第一道次轧制压下率最大,且为35%,第二道次轧制压下率与(c)试样同为25%,小角度晶界下降至79%;晶界能为0.264K,比(c)试样又有所提高,而晶界宽度增大到1.5 μm。

图6

这表明:随着压下率的增大(a~c)三个试样结合界面侧不锈钢的奥氏体晶粒被压碎,小角度晶界逐渐增加,大角度晶界逐渐减小,晶界能降低和性能趋于稳定,晶界宽度逐渐减小;压下率继续增大的(d)试样,小角度晶界数量比(c)试样少,大角度晶界数量有所增多,说明奥氏体晶粒发生了再结晶,晶界能升高而晶界宽度增大。

2.4 奥氏体晶界和结合界面电解反应机理

2.4.1 晶界活泼金属反应

2.4.2 界面毛细效应的机理

表示。式中Ps为微孔处的饱和蒸气压,Pa;P为平液面的氧气饱和蒸气压,Pa;D为平均微孔直径,m;R为气体常数,J·mol-1·K-1;T为温度,K;γ为电解液的表面张力系数60 mN/m[30],N·m-1;Vm为电解液的摩尔体积68.5 m3·mol-1。

试样电解抛光时浸入电解液的试样表面为平面,析出氧时该平面与垂直方向的表面张力之间的夹角为90°,表面张力为0,析出气体的压力为大气中的氧分压0.21P0。

根据实验和测试结果得到平均微孔直径(D)、气泡附加压力(Ps)、界面腐蚀的面积(ΔS)三者之间的关系,在图7中给出。

图7

由图7可知:复合板结合界面微孔的直径为0时附加压力较小,(a)试样界面腐蚀面积几乎为零;(b~d)试样界面微孔的直径逐渐减小,在电解过程中产生的气体其附加压力逐渐增大,腐蚀的面积随之增加。这表明,有微孔的试样与电解液面垂直的孔洞内壁发生了毛细现象,是电化学反应的主要区域。同时,微孔直径越小则微孔内部气泡压力越大,气泡向外部反应扩张的能力越强。这表明,微孔毛细效应是产生附加压力为其向外反应的主要动力,使微孔周围的金属溶解向外扩展,使孔洞变大甚至连接成细长的凹槽。其次,在热轧过程中不锈钢板内的铬、镍等活泼金属向界面偏析聚集,沿着结合界面平行分布,电解时这些活泼元素优先溶解而在结合界面形成了基本平行于轧向的凹槽。

在大气环境中长期放置的复合板,与周围环境很容易组成一个电解池的封闭系统,金属板材作为阳极容易失电子,迫使复合板结合界面被缓慢氧化;而对于含有微孔缺陷的试样,微孔毛细作用将加剧封闭系统的电化学反应,导致界面成为氧化腐蚀的萌生地带,是不锈钢复合板结合界面容易氧化腐蚀的主要原因。而结合界面侧不锈钢表面平整的奥氏体晶界电解后形成凹槽,其反应机理与结合界面相异,有待于进一步研究。

3 结论

(1) 真空热轧碳钢/不锈钢复合板界面是否含有微孔,将严重影响电解反应方式。界面无微孔缺陷的试样,整个界面发生电解反应,反应后界面基本仍为平整表面;然而界面有微孔缺陷的试样,孔洞内壁在毛细效应下发生电化学反应,孔洞电解腐蚀后扩大,形成相互连接的凹槽。且微孔直径越细,电化学反应后孔洞被腐蚀数量越多,形成与结合界面平行的凹槽越宽。

(2) 复合板第一道次轧制压下率30%,二道次轧制压下率由10%分别增加至20%、25%时,奥氏体晶界宽度由2 μm分别减小至1.8 μm、1.3 μm;晶界能由0.346K降低至0.271K、0.222K。说明随压下率增加,晶界能逐步降低,小角度晶界逐渐增加,界面性能趋于稳定。然而当第一道次轧制压下率由30%增大至35%,二道次轧制压下率为25%时,奥氏体晶界宽度增至1.5 μm,晶界能随之增至0.264K,此时高能量能够有效促进奥氏体晶粒发生再结晶。

(3) 根据Kelwin公式计算,复合板结合界面微孔直径为0时,试样电解过程中析出氧的压力为大气压中的氧分压(0.21P0),结合界面电解后界面被氧化。然而对于有微孔缺陷的试样,微孔直径与电解过程中产生气体的附加压力呈负相关,即微孔直径越小,微孔内部气泡压力越大,气泡向外部反应扩张的能力越强,促使微孔周围的金属溶解向外扩展,导致孔洞变大。可见,微孔毛细作用引发的界面氧化是复合板被腐蚀的主要根源。

参考文献

Interface evolution during rolling of Ni-clad stainless steel plate

[J].Plate of Ni-clad 316H stainless steel was prepared via hot rolling process after pre-heating at 1200oC for 120 minutes, then concurrently the rolling process was interrupted after rolling for 3, 5, and 7 passes respectively, while the relevant samples are taken and water-quenched for subsequent characterization in terms of the evolution of their interface-composition and -morphology, as well as the formed oxides there. Results show that until the 3rd rolling pass, the rolling plate temperature was about 1000°C, the two metals were closely bounded with equiaxed grains of slightly distorted microstructure on both sides of the interface and the inter-diffusion of elements for the two metals was not obvious; Until the 5th rolling pass, the plate temperature was about 940°C, the grains of 316H were elongated with significant lattice distortion, whereas, obvious inter-diffusion can be found near the interface; Until the 7th rolling pass, the plate temperature was about 880°C, large number of elongated and distorted grains were observed on the 316H steel side and a fine grain structure crushed by hot rolling distributed near the interface. The elements of Ni, Fe and Cr were fully inter-diffused near the interface, but the less motionable Mo enriched at the 316H side. The grains of Ni layer coarsened obviously. The interface evolution of Ni/stainless steel composite plate during the rolling process follows the so called three-stage theory and N. Bay's theory. The physical contact stage and the physical-chemical contact stage happened between the 3rd and 5th pass. Then the rolling from 5th to 7th pass was the final physical-chemical contact phase, whilst the inter-diffusion begins, that is, the "bulk" mutual phase begins. In the high-temperature and low-oxygen environment, the Mn oxides near the interface might form during the rolling process. The oxide was crushed and squeezed toward the substrate by the rolling force, therefore distributed in chains near the interface eventually.

镍-不锈钢复合板轧制过程中界面的结合机制

[J].采用轧制终止取样法对镍-不锈钢热轧复合板轧制过程中的界面成分、界面组织以及界面处的氧化物进行了表征,研究了轧制过程中界面的结合机制并根据热力学原理解释了高温下选择性内氧化的机理。将复合板坯加热至1200℃,保温120 min后进行轧制,分别在轧制3、5、7道次后中断轧制快速水冷,随后进行取样观察。结果表明,轧制3道次时终轧温度为1000℃左右,金属之间有近距离结合,微观组织有轻微的畸变,界面两侧的板材均为等轴晶粒,元素的扩散不甚明显;轧制至5道次时终轧温度为940℃左右,316H的晶粒被拉长而发生晶格畸变,界面附近出现明显的扩散行为;轧制到7道次时终轧温度为880℃,316H层出现大量拉长的畸变晶粒,界面处主要是轧碎的细晶组织,但Ni层的晶粒粗大,界面附近Ni、Fe和Cr元素充分扩散,微弱扩散的Mo元素在316H界面富集。镍-不锈钢复合板在轧制过程中界面的演化遵循三阶段理论和N.Bay理论,3道次到5道次间处于物理接触阶段、物理化学阶段,轧制7道次时物理化学阶段结束并开始扩散,即开始进入“体”相互阶段,主要元素在此阶段完成相互扩散。在高温低氧环境的轧制条件下,界面处生成Mn的氧化物,该氧化物因轧制而破碎并向基材挤压最终在界面附近成链状分布。

An analytical approach to asymmetrical cold- and hot-rolling of clad sheet using the slab method

[J].

Cladding of low-carbon steel to austenitic stainless steel by hot-roll bonding: microstructure and mechanical properties before and after welding

[J].

Interface-correlated characteristics of stainless steel/carbon steel plate fabricated by AAWIV and hot rolling

[J].

Influence of rolling reduction on interfacial bonding performance of carbon steel/stainless steel clad plate

[J].

轧制压下率对碳钢/不锈钢复合板界面结合性能的影响

[J].

Deformation law and bonding mechanism of 45 carbon steel/316L stainless steel cladding tubes fabricated by three-roll skew rolling bonding process

[J].

Microstructure, mechanical properties and interface bonding mechanism of hot-rolled stainless steel clad plates at different rolling reduction ratios

[J].

The tensile behaviors and fracture characteristics of stainless steel clad plates with different interfacial status

[J].

Interface characteristics and fracture behavior of hot rolled stainless steel clad plates with different vacuum degrees

[J].In order to investigate the effect of vacuum degree on the interface microstructure and mechanical properties of stainless steel clad plate, series of 316L/Q235 clad plates were successfully fabricated by hot rolling with different vacuum degrees of 10(5) Pa, 400 Pa, 10 Pa, 10(-1) Pa and 10(-2) Pa. Interestingly, with the increase of vacuum degree, the interface oxides distribution changed from continuous wall/film to dispersed refined particles, and the thicknesses of martensite layer, decarburized layer and carburized layer were gradually increased. Meanwhile, the interface bonding strength of clad plates can be effectively enhanced by improving the vacuum degree. Due to thin decarburized and carburized layers, the stainless steel clad plate with a low vacuum degree of 10(5) Pa reveals superior yield strength and ultimate strength, while a low fracture elongation was obtained due to severe interface delamination. However, the stainless steel clad plate with a high vacuum degree can obtain a superior tensile ductility, which is attributed to the strong interface and localized necking delaying effect.

Constitutive and transformation kinetics modeling of ε-, α′-Martensite and mechanical twinning in steels containing austenite

[J].

Composition and processing design of medium-Mn steels based on CALPHAD, SFE modeling, and genetic optimization

[J].Medium-Mn steels are being thoroughly investigated as potential candidates for the 3rd generation of advanced high strength steels. Despite the wide experimental work, limited attempts have been presented to systematically optimize the chemical composition and heat treatment process to obtain desired microstructural features. In the present work, CALPHAD-based thermodynamic and kinetic modeling, coupled with multi-objective genetic optimization was adopted for the development of delta-ferrite containing medium-Mn steels with optimized microstructure, meeting set design requirements associated with retained austenite fraction and stability. A new sub-regular solution model for the prediction of the austenite stacking fault energy (SFE) was developed and compared to experimental literature data. A MATLAB implementation of the SFE model is provided as supplementary material. Pareto optimal compositions and associated process windows were identified via thermodynamic modeling coupled with the NSGA-II algorithm. A single optimized steel was selected for further consideration through kinetic simulation of the entire process chain including solidification, hot-rolling, accelerated cooling, quenching, and intercritical annealing, considering the effect of delta-ferrite on retained austenite stability and the martensite to austenite transformation kinetics. Temporal optimization resulted in the selection of an optimal intercritical annealing time. Model predictions were validated with metallographic observations on two different delta-ferrite containing medium-Mn steels, revealing excellent agreement between predicted and observed phase fractions. (C) 2020 Acta Materialia Inc. Published by Elsevier Ltd.

The evolution behavior and constitution characteristics of interfacial oxides in the hot-rolled stainless steel clad plate

[J].

Effect of interface oxides on shear properties of hot-rolled stainless steel clad plate

[J].

A novel strong and ductile TWIP/martensite steel composite

[J].

Effect of mechanical surface treatment on the bonding mechanism and properties of cold-rolled Cu/Al clad plate

[J].

Interfacial microstructure and strengthening mechanism of stainless steel/carbon steel laminated composite fabricated by liquid-solid bonding and hot rolling

[J].

Microstructural evolution of a 304-type austenitic stainless steel during rolling at temperatures of 773-1273 K

[J].

Microstructure and fracture properties of an ultrahigh carbon steel-mild steel laminated composite

[J].

Effect of interfacial micro‐structure on mechanical properties of vacuum rolling clad pure tita‐nium/high strength low alloy steel

[J].

界面微观组织对真空轧制复合纯钛/低合金高强钢界面力学性能的影响

[J].

Interface layer deformation thickening analysis of hot rolling carbon steel-stainless steel clad plate

[J].

Stainless steel microstructural evolution of hot-rolled clad plate

[J].

Research on industrial electrolytic nickel plate by large area EBSD method

[J].

大面积EBSD方法对电解镍板的研究

[J].

Metallurgical characterization of coupled carbon diffusion and precipitation in dissimilar steel welds

[J].

NiCoCrAlY coating of in-situ synthesis by vacuum diffusion and its oxidation resistance

[J].

真空扩散原位合成NiCoCrAlY涂层及其抗氧化性能

[J].

Meso and microscale clad interface characteristics of hot-rolled stainless steel clad plate

[J].Stainless steel clad plate containing corrosion-resistant 304 stainless steel cladding and Q235 carbon steel substrate has been successfully fabricated by vacuum hot rolling at 1150 degrees C. The interface characteristics, microstructure, alloy element distribution and precipitation phases of clad plate were investigated by SEM, EPMA and TEM analysis in detail. Due to the carbon element diffusion, a decarburized layer (60-80 mu m) and a carburized layer (20-40 mu m) were formed at the carbon steel substrate and stainless steel cladding beside the interface, respectively. The uphill diffusion and interface peak value of carbon element are attributed to the differences in the diffusion velocity and solubility of carbon element in the substrate and cladding. Concentration gradient and diffusion coefficient between Cr and Ni elements are different, leading to different diffusion distances. Meanwhile, the grain boundaries of carburized layer were surrounded by Cr23C6 particles. The interface with a thickness of 300-400 nm contains refined grains accompanying with many Cr23C6 and MnSi2O4, SiO2 particles. The sufficient alloy element diffusion behavior and interface oxides, precipitation phases lead to a high interface bonding shear strength (389 MPa).

Theoretical studies of water recovery from flue gas by using ceramic membrane

[J].

多孔陶瓷膜烟气水分回收理论与模型研究

[J].化石燃料燃烧烟气中含有大量水分和潜热,高湿度烟气的直接排放造成极大的资源浪费和环境问题。多孔陶瓷膜是目前烟气水热回收最有前景的技术之一,其水分回收热力学和动力学的定量描述是该技术发展和装置设计的关键所在。分析了水分在多孔陶瓷膜表面及内部传质机理,基于Kelvin理论建立了水分在陶瓷膜内毛细凝聚热力学模型,并选取典型烟气温/湿度条件,得出不同工况下陶瓷膜发生毛细凝聚的临界孔径、凝聚水量及工作孔体积占比;进而基于毛细凝聚的表面传质和孔道输运Hagen-Poiseuille方程建立了陶瓷膜水分传质动力学模型,对典型温/湿度工况下回收水通量进行了计算,结果表明,多孔陶瓷膜的毛细凝聚效应对烟气水分回收的优越性十分明显,其表面回水通量远远大于冷凝法的水通量,孔径越小,表面水通量越高,但及时将孔道内的液态水输运到陶瓷膜另一侧需要的压差也越大,本文计算条件下,膜孔径为20.0 nm的陶瓷膜较为适宜。