用表面渗碳[1~5]方法强化齿轮、齿轮轴和花键等传动部件,使其表面的硬度和耐磨性高而心部保持优异的韧性,可提高其承载能力和抗擦伤磨损性能。但是服役过程中的高频振动、轴线不对中和循环扭矩等因素引起的微动磨损,使其服役寿命降低。因此,为了提高这类零件的耐磨性能和服役寿命,发展新的涂层强化技术极为迫切。用电弧离子镀、磁控溅射和化学气相沉积(CVD)等表面强化技术制备的CrN[6]、TiN[7]与WC[8]涂层等硬质涂层,可提高基体的耐磨性能。但是,用电弧离子镀制备的硬质涂层容易产生大颗粒或微孔等表面缺陷影响涂层的质量;磁控溅射的沉积速率较低且靶材容易毒化;用CVD法制备涂层沉积温度较高,可能降低基体材料的性能。电镀不受工件尺寸的限制,其沉积温度较低、设备简单且易操作。复合电镀是在电镀液中引入Al2O3[9~14]、金刚石[15,16]、BN[17,18]等第二相颗粒,基质金属与第二相颗粒共沉积使复合涂层兼具基质金属和第二相硬质颗粒的性能,从而制备出高耐磨性、自润滑、抗高温氧化、耐腐蚀的复合涂层[19~21]。

随着纳米材料的发展,用复合电镀技术可制备综合性能良好的纳米复合镀层。但是,比表面积和表面化学活性较高的纳米颗粒容易团聚且随着颗粒浓度的提高团聚程度随之提高[22],使制备出的涂层颗粒分布不均匀而降低其性能。王红美等[23]用高能机械化学法配置纳米Al2O3颗粒镍基复合镀液制备了Ni-Al2O3复合涂层,其纳米Al2O3颗粒的含量(质量分数,下同)为2.6%;姜广粉等[24]用脉冲电沉法制备了Ni-Al2O3复合涂层,其纳米Al2O3颗粒的含量为6.4%;Rasooli等[25]用含(2~8) g/L的纳米Cr2O3溶液制备出纳米Ni-Fe/Cr2O3复合涂层,其颗粒含量随着溶液中纳米Cr2O3浓度(在(2~6) g/L的范围内)的提高而提高,最高的颗粒含量为7%。纳米颗粒含量较低的复合涂层不能充分发挥出颗粒的作用,限制了涂层的强化作用[26]。为了提高涂层中耐磨颗粒的含量,Ogihara等[27]引入3.5 μm金刚石颗粒制备出Ni-B/Diamond复合涂层,其颗粒含量(体积分数)约为14%;Mehr等[28]发现,Ni-B/SiC (3 μm)复合涂层的最高颗粒含量(14.8%)高于Ni-B/SiC (100 nm)的最高颗粒含量(9.6%)。这表明,引入微米级颗粒更容易提高复合涂层中颗粒含量从而提高涂层的性能。但是目前复合涂层耐磨性能的磨损机制尚不清楚。鉴于此,本文在镀液中同时引入高硬度的纳米氧化铝与微米金刚石颗粒,用复合电镀技术实现镍、氧化铝与金刚石颗粒的共沉积制备Ni-Al2O3/Diamond复合涂层,研究涂层的组织结构、结合强度、力学性能及其摩擦磨损性能。

1 实验方法

将电镀用的基体(9310渗碳钢)切割成直径为25.4 mm厚度为4 mm的样片,再将其进行超声清洗,吹干后备用。电镀时以纯Ni板为阳极,基体为阴极;使用的颗粒是粒径为(30~50) nm的氧化铝颗粒和粒径约为1 μm的金刚石颗粒;电镀液是含硫酸镍240 g/L、氯化镍35 g/L、硼酸35 g/L的Watts液。电镀的电流密度为(2~5) A/dm2,电镀溶液的温度为45 ℃,电镀时间为120 min。

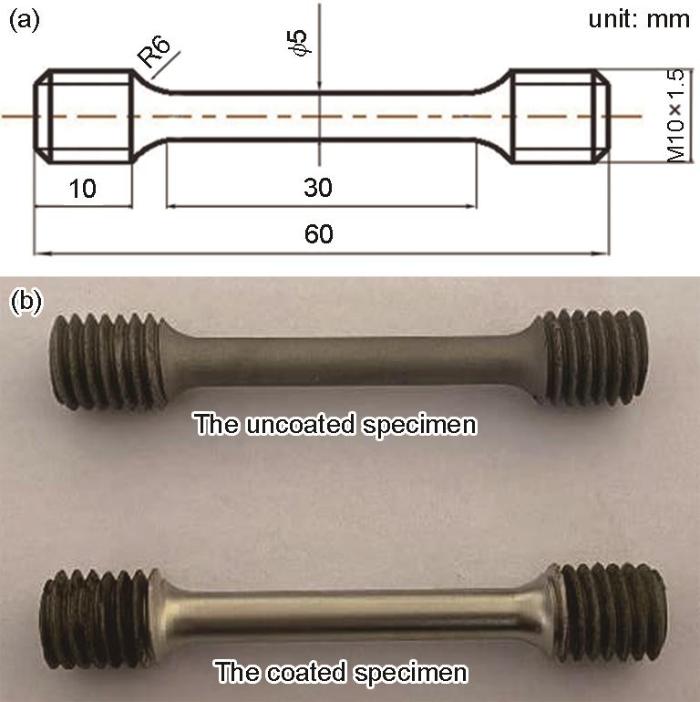

用Merlin Compact扫描电子显微镜/能谱仪(SEM/EDS)、D/Max-2500PC型X射线衍射仪(XRD)表征复合涂层的形貌、结构和成分。用TY8000系列电子万能试验机进行拉伸实验测试涂层的结合强度,用薄膜树脂胶(E7胶)将试样与测试工装粘接,将其在125 ℃恒温干燥箱中保温4 h使其固化。加载速率为0.5 mm/min;用AG-100kNG型电子万能实验机测试拉伸性能,用3个未渗碳处理的基体拉伸试样、3个渗碳处理的基体试样和3个涂层试样(图1)。实验参照GB/T 228.1-2021标准进行,加载速率为0.5 mm/min。用INNOVATEST维氏硬度计测试显微硬度,载荷为0.49 N,保持时间为10 s;在MS-T3000型球盘式旋转摩擦磨损仪上进行摩擦磨损实验,使用直径为4 mm的Al2O3磨球,摩擦载荷为10 N,旋转半径为2.5 mm,旋转速率为200 r/min,实验时间为60 min。用接触式表面轮廓仪(Alphastep IQ KLA Tencor)分析磨痕尺寸,用SEM和EDS表征磨痕的表面形貌和成分。

图1

2 结果和讨论

2.1 复合涂层的形貌和组织结构

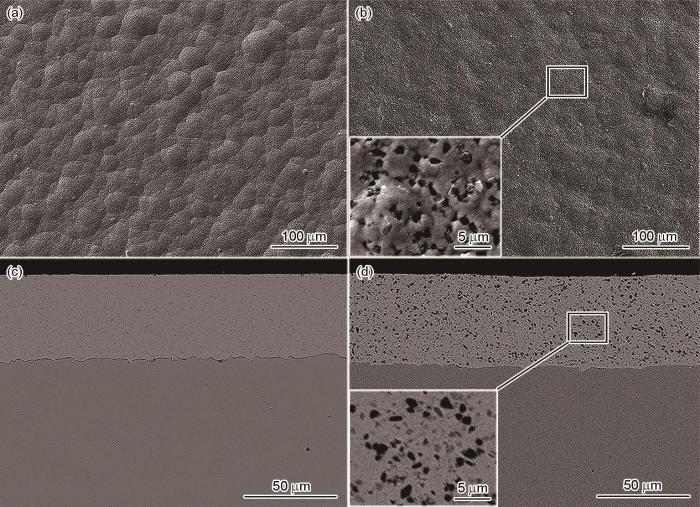

图2

图2

复合涂层的表面形貌和截面形貌

Fig.2

Surface morphologies (a, b), cross-section morphologies (c, d) of Ni-Al2O3/Diamond composite coating, (a, c) Ni-Al2O3, (b, d) Ni-Al2O3/Diamond

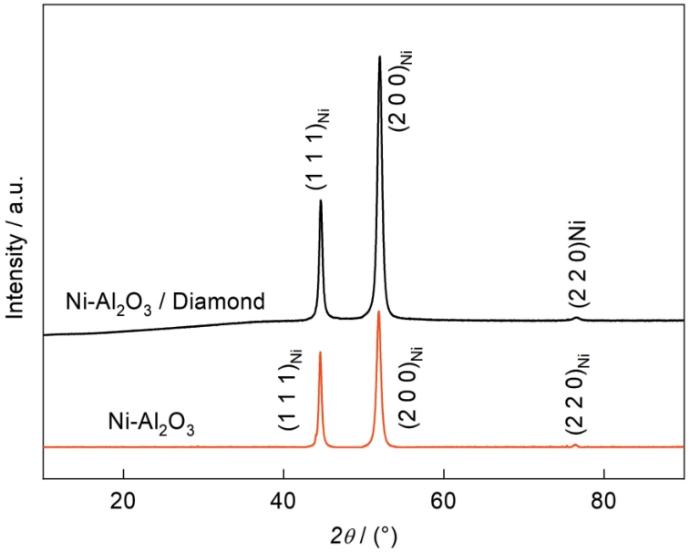

图3给出了两种复合涂层的XRD衍射谱。Ni-Al2O3复合涂层的衍射谱中2θ为44.5°、51.8°与76.4°处出现三个特征衍射峰,分别对应Ni(111)、(200)与(220)晶面;Ni-Al2O3/Diamond复合涂层的谱中2θ为44.6°、52.0°与76.6°处出现三个特征衍射峰,分别对应Ni(111)、(200)与(220)晶面。这表明,金刚石颗粒的引入没有改变涂层的晶格取向,但是衍射峰的宽度略有提高和主衍射峰强度提高。这意味着,加入金刚石颗粒后基质金属的晶粒尺寸略有减小,即晶粒细化了。Ni-Al2O3/Diamond复合涂层的涂层的硬度为510HV0.05,Ni-Al2O3复合涂层的硬度(408HV0.05)比Ni-Al2O3复合涂层的硬度提高了25%。其原因是,金刚石的引入使晶粒细化,根据Hall-Petch关系其维氏硬度提高。

图3

图3

Ni-Al2O3涂层和Ni-Al2O3/Diamond复合涂层的XRD谱

Fig.3

XRD patterns of coatings of Ni-Al2O3 composite coating and Ni-Al2O3/Diamond composite coating

2.2 复合涂层的力学性能

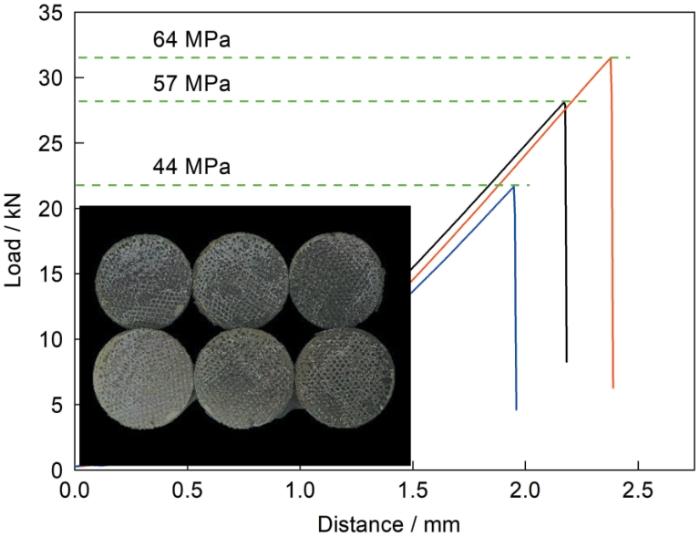

图4

图4

涂层的拉伸断口形貌和结合强度

Fig.4

Tensile fracture morphology and bonding strength of coatings

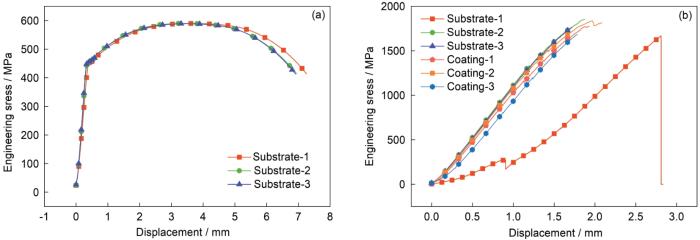

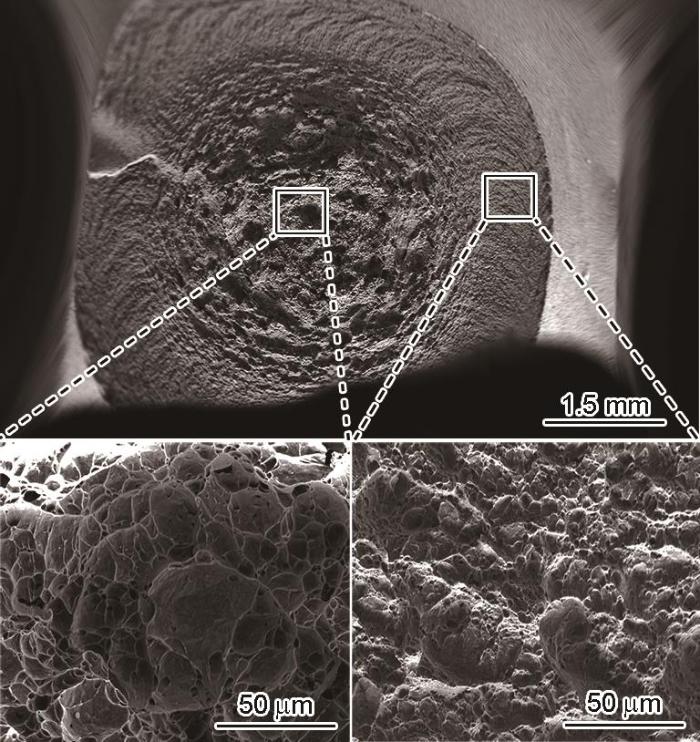

为了研究复合涂层对9310渗碳钢基体拉伸性能的影响,分别用未渗碳的9310钢、渗碳的包覆复合镀层和未包覆复合涂层的3种拉伸试样进行实验。图5给出了拉伸性能测试曲线,拉伸性能列于表1。在9310渗碳钢基体上制备Ni-Al2O3/Diamond复合涂层后,其抗拉强度的变化为0.3%,表明复合涂层对基体抗拉强度的影响很小。未渗碳的9310钢基体拉伸试样发生了韧性断裂,渗碳处理的两种样品发生了脆性断裂。图6给出了渗碳处理的两种样品的拉伸断口形貌。可以看出,两种样品断口的形貌基本相同,没有出现剪切唇,断口心部有较多韧窝。这表明,拉伸样品心部的韧性良好,渗碳层区域的韧窝很少表明其韧性较差。拉伸载荷达到样品的强度极限时,其塑性变形很小,而此时的拉伸应力已经远超心部的强度极限,使拉伸样品均发生了脆性断裂而没有出现“颈缩”,因此只能测出样品的抗拉强度。

图5

图5

基体未渗碳和渗碳涂层的拉伸性能

Fig.5

Tensile properties test curve (a) uncarburized matrix, (b) carburizing substrate

表1 9310钢和9310渗碳钢的拉伸性能

Table 1

| Samples | Rm / MPa | Rp0.2 / MPa | A / % | Z / % |

|---|---|---|---|---|

| 9310 steel | 590 | 454 | 26.2 | 78 |

| 9310 carburizing steel | 1760 | / | / | / |

| Coating | 1765 | / | / | / |

图6

2.3 复合涂层的摩擦磨损性能

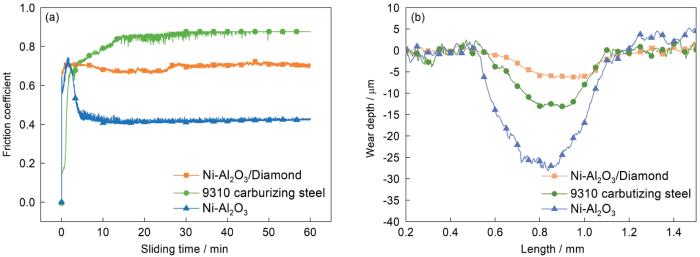

图7给出了复合涂层的摩擦系数曲线和磨痕截面的形貌。测量结果表明,基体、Ni-Al2O3复合涂层和Ni-Al2O3/Diamond复合涂层的磨损体积分别为0.0738、0.1755和0.0415 mm3。涂层的磨损率为W = V/(LF),式中V为磨损体积,L为摩擦路程,F为摩擦载荷。计算结果表明,基体、Ni-Al2O3复合涂层和Ni-Al2O3/Diamond复合涂层的磨损率分别为3.92 × 10-8、9.32 × 10-8和2.20 × 10-8 mm3·N-1·mm-1。与基体和Ni-Al2O3复合涂层相比,Ni-Al2O3/Diamond复合涂层的磨损率分别降低了43.8%、76.4%,表明硬质颗粒金刚石的加入使涂层的耐磨性能显著提高。

图7

图7

基体和复合涂层的摩擦系数随时间变化曲线和磨痕截面形貌

Fig.7

Friction coefficient vs time curves (a) and cross-section morphologies of wear tracks for substrate and coatings (b)

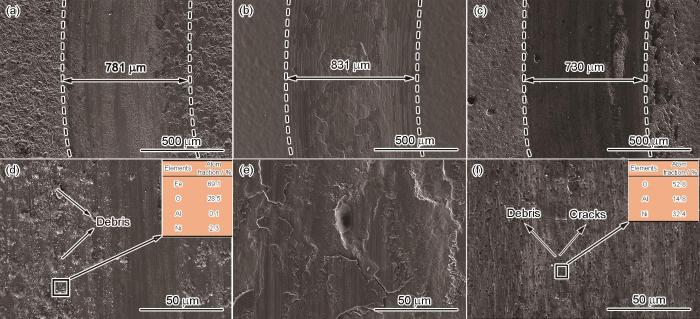

图8

图8

基体、Ni-Al2O3涂层以及Ni-Al2O3 /Diamond涂层的磨痕形貌

Fig.8

Low (a, b, c) and high (d, e, f) magnified worn surface morphologies of the substrate (a, d), Ni-Al2O3 coating (b, e) and Ni-Al2O3 /Diamond coating (c, f)

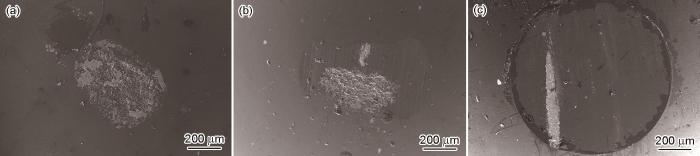

图9

图9

基体、Ni-Al2O3涂层以及Ni-Al2O3 /Diamond涂层对应的磨球表面形貌

Fig.9

Worn surface of Al2O3 balls (a) Substrate, (b) Ni-Al2O3 coating, (c) Ni-Al2O3 /Diamond coating

Ni-Al2O3涂层的磨痕宽度为831 μm (图8b),深度为28.8 μm (图7b),与其磨损率较为一致。在磨痕表面发生了严重的塑性变形,产生了大量犁沟和磨屑。涂层的硬度低于磨球,因此涂层使磨球产生的损伤很小(图9b)。相反,磨球使涂层产生了严重的磨损。加入金刚石颗粒,使复合涂层的磨痕宽度和深度分别减小到730 μm (图8c)和6.9 μm (图7b)。如图8c所示,与基体和Ni-Al2O3涂层相比,复合涂层的磨痕表面犁沟和磨粒较少,表明其磨粒磨损程度较低。如图9c所示,磨球的磨损表面呈圆形,与图9a、b相比,复合涂层使磨球产生了较大程度的损伤,而磨球使复合涂层产生的损伤较小。这表明,Ni-Al2O3/Diamond复合涂层的耐磨性能较高。

三种涂层样品表面都有一定的凸起,在磨损初期凸起部分与磨球的接触面积很小,局部较大的压力使涂层被剥离产生磨粒。而基体的磨痕表面分布着大量的磨粒,这些磨粒参与磨损,其切削作用使基体表面产生大量犁沟,表明其磨损机制主要为磨粒磨损。EDS分析结果(图8插图)表明,磨粒内有Al元素,说明摩擦副发生了转移。对于Ni-Al2O3涂层,载荷把磨粒压平并粘附在涂层表面,降低了涂层表面的粗糙度,因此其摩擦系数较小。应力集中使磨粒底部的材料发生严重的塑性变形和脱落,加速了涂层的磨损[30]。特别是,Ni-Al2O3/Diamond复合涂层的平均硬度(510HV0.05)比9310渗碳钢的平均硬度(819HV0.05)低,但是其耐磨性能却较高。其原因是,复合涂层中的硬质颗粒硬度较高,使涂层在摩擦磨损过程中不易产生刮伤、切削等塑性变形,使磨痕表面产生的磨粒、犁沟数量减少,因此摩擦系数降低;同时,硬质颗粒能支撑载荷,在对磨球的垂直压力作用下磨粒产生塑性变形被压平并粘附在涂层表面,避免了磨球直接作用在涂层表面,从而降低了磨损速率[31],也表明粘着磨损的存在。上述分析表明,颗粒的性质使复合涂层的耐磨性能比9310渗碳钢的高。磨粒含14.8% Al元素,表明摩擦副的成分发生了转移。这表明,Ni-Al2O3/Diamond复合涂层的磨损机制为磨粒磨损和粘着磨损。

3 结论

用复合电镀法可制备Ni-Al2O3/Diamond复合涂层,其表面没有气孔和裂纹、厚度均匀连续、硬质颗粒分布均匀。这种复合涂层对基体材料的拉伸强度影响很小,其磨损率比渗碳基体和Ni-Al2O3复合涂层都低。这种复合涂层的磨损机制,是磨粒磨损和粘着磨损。

参考文献

Effect of laser shock peening on bending fatigue performance of AISI 9310 steel spur gear

[J].

Rolling-sliding contact fatigue failure and associated evolutions of microstructure, crystallographic orientation and residual stress of AISI 9310 gear steel

[J].

The heat treatment effect on the surface characteristics of 9310 steel gear

[J].

Surface crack analysis of the steering shaft gear after carburizing and quenching

[J].

Evaluation of pre-shot peening on improvement of carburizing heat treatment of AISI 9310 gear steel

[J].

Tribological properties of CrN coatings prepared by physical vapor deposition

[J].

物理气相沉积法制备的CrN涂层的摩擦学性能

[J].

Impact resistance and wear resistance of nitride coatings on bearing steel by arc ion plating

[J].

轴承钢表面电弧离子镀氮化物涂层的抗冲击性能和耐磨性能

[J].

Corrosion and cracking behavior of high strength steel covered with high-velocity oxygen-fuel spraying WC coating in marine environment

[J].In order to explore the adaptability and failure mechanism of landing gear materials for amphibious aircraft in the marine environment. By preparing a high-speed flame sprayed WC coating on the surface of hot-rolled 300M high-strength steel, the corrosion behavior of the coating in an artificial seawater environment was studied using electrochemical testing, salt spray testing, tensile testing, fatigue testing, and characterization by SEM, EDS, XRD, and CLSM. The research results indicate that the WC coating undergoes significant passivation and exhibits good corrosion resistance in an artificial seawater environment with pH value 8.2, which is related to the passivation of Co in the coating under alkaline conditions. The long-term electrochemical impedance results indicate that the corrosion resistance of the coating increases after soaking for 28 days, which is related to the oxide formed by the surface binder. Compared with the 300 M substrate, the tensile strength of the sprayed material slightly increases, which is related to the residual stress releasing inside the coating. Its cracking in artificial seawater is mainly controlled by the anodic dissolution process. As the pre corrosion time increases, the fatigue life of the material significantly decreases. The corrosive medium from the environment enters the interior of the coating during the pre corrosion process, which increases the number of defects, causes premature failure of the coating, and leads to an increase in material fracture sensitivity. WC coatings have good corrosion resistance, and the release of residual stress during the tensile process slightly increases the tensile strength of the material. The coating fails prematurely after pre corrosion, which results in a reduced fatigue life of the material.

起落架用高速火焰喷涂WC涂层覆盖高强钢海水环境腐蚀与开裂行为

[J].为探究水陆两栖飞机用起落架材料海洋环境适应性及其失效机制。通过在热轧300M高强钢表面制备高速火焰喷涂WC涂层, 使用电化学测试、盐雾实验、拉伸实验、疲劳实验, 并通过SEM, EDS, XRD以及CLSM表征, 开展其在人工海水环境中的腐蚀行为研究。研究结果表明, 在pH值为8.2的人工海水环境中, WC涂层发生明显的钝化, 具有较好的耐蚀性, 这与在碱性环境下涂层中的Co发生钝化有关。长周期电化学阻抗结果表明, 浸泡28天后, 涂层耐蚀性上升, 这与表面黏结剂形成的氧化物有关。与300M基材相比, 喷涂后的材料抗拉强度略微升高, 这与涂层内部的残余应力释放有关, 其在人工海水中的开裂主要受阳极溶解过程控制。随着预腐蚀时间的增加, 材料的疲劳寿命发生明显降低, 在预腐蚀过程中, 环境中的腐蚀性介质进入涂层内部, 增加了缺陷的数量, 使得涂层提前发生失效, 导致材料断裂敏感性增加。WC涂层有较好的耐蚀性, 拉伸过程中残余应力的释放使材料的抗拉强度略微升高, 经过预腐蚀后涂层提前发生失效, 使得材料疲劳寿命降低。

Study on Properties of Ni-P-Al2O3 composite coating with Al2O3 content

[J].

Al2O3含量对Ni-P-Al2O3复合涂层性能的研究

[J].

Electrodeposition of nanocrystalline Ni-W coatings strengthened by ultra fine alumina particles

[J].

Preparation and wear resistance of pulse electrodeposited Ni-W/Al2O3 composite coatings

[J].

Electrodeposition of multilayer Ni-W and Ni-W-alumina nanocomposite coatings

[J].

Tribological properties of tertiary Al2O3/CNT/nano Diamond pulse delec-trodeposited Ni-W, nanocomposite

[J].

Research on preparation of Ni-Al2O3 nanocomposite coatings and its properties

[D].

Ni-Al2O3纳米复合涂层制备及性能研究

[D].

Preparation and wear resistance of electrodeposited Ni-W/Diamond co-mposite coatings

[J].

Research on the Ni-diamond composite coating by electrophoretic-electrochemical deposition and It's Wear Resistance

[J].

电泳-电镀Ni-金刚石复合涂层及其耐磨性能研究

[J].

Tribological and electrochemical corrosion behavior of Ni-W/BN(hexagonal) nano-composite coatings

[J].

Ni-W/BN(h) electrodeposited nanocomposite coating with functionally graded microstructure

[J].

Effect of high energy ball milling on strengthening of Cu-ZrO2 nanocomposites

[J].

Experimental and numerical investigation on strengthening mechanisms of nanostructured Al-SiC composites

[J].

Tribological behaviour of SiC particle-reinforced copper matrix composites

[J].

Microstructure Preparation and Hardness test of electrodeposited nickel/Diamond composite coatings

[J].

电镀镍/金刚石复合涂层微结构制备及硬度测试

[J].

Preparation and Micro Mechanical Properties of Nano-Al2O3 Particles Reinforced Ni Matrix Composite Coatings

[J].

纳米Al2O3颗粒增强镍基复合涂层的制备及微观力学性能

[J].

Study on process parameters and properties of pulse electr-odeposited Ni-Al2O3 composite coating

[J].

脉冲电镀Ni-Al2O3复合涂层的工艺参数及性能研究

[J].

Electrodeposited Ni-Fe-Cr2O3 nanocomposite coatings: A survey of influences of Cr2O3 nanoparticles loadings in the electrolyte

[J].

Effect of electrodeposition conditions on the properties of Cu-Si3N4 composite coatings

[J].

Effect of electrodeposition conditions on hardness of Ni-B/diamond composite films

[J].

Electrodeposited Ni-B/SiC micro- and nano-composite coatings: A comparative study

[J]. J.

Effect of feedstock powders on microstructure and properties of CoNiCrAlY coatings

[J].Two type powders of CoNiCrAlY alloy were prepared by gas atomization (GA) and water atomization (WA) respectively, then which were used as feedstock powders to further prepared the corresponding coatings on a directionally solidified high temperature alloy DZ411by using high velocity oxygen fuel (HVOF) technique and subsequently they were subjected to proper subsequent vacuum heat treatment. The flowability and apparent density of the prepared powders were measured according to GB/T 1484 and GB/T 1479. Meanwhile, the phase composition, microstructure, microhardness, and adhesive strength to the substrate of the prepared coatings were characterized via optical microscopy and scanning electron microscopy, automatic hardness tester, and universal testing machine. The high temperature oxidation performance of the coatings/ DZ411 was assessed in air at 1050oC for 200 h. The results show that compared with WA, the CoNiCrAlY powder prepared by GA is spherical or nearly spherical, with good flowability and high apparent density. The prepared GA coating has a dense and uniform structure with high β phase content, low porosity, high adhesive strength and high microhardness. After vacuum heat treatment, mutual fusion of particles was clearly observed within the two coatings, while the amount of β phase increases and its distribution becomes much more uniform, correspondingly, their porosity and microhardness decrease. The adhesive strength of WA coating after vacuum heat treatment has been improved, but there are still larger pores within the coating. The vacuum heat treated GA coating presents much better oxidation resistance.

喷涂粉末对CoNiCrAlY涂层组织和性能的影响

[J].

Effect of phosphorous content and heat treatment on the structure, hardness and wear behavior of Co-P coatings

[J].Cobalt-Phosphorous (Co-P) alloy coatings with different P contents were successfully prepared on plain steel by DC electrodeposition. The structure and morphology of coatings were changed by adjusting P content in the coating. Amorphous, nanocrystalline and mixed amorphous-nanocrystalline Co-P coatings were obtained with 9.5, 6 and 2.5 wt% phosphorous, respectively. The structures of the coatings were also affected by annealing. The effect of the P content and hence phase structure on the morphology, grain size, hardness and wear resistance of the coating were studied before and after annealing. Scanning electron microscopy (SEM), energy dispersion spectroscopy (EDS) and X-ray diffraction (XRD) were used to study the surface morphology, chemical composition and phase structure of the coatings, respectively. Pin-on-disk test was used to investigate wear resistance of the coatings. Increasing phosphorous content up to 9.5 wt% resulted in enhancement of hardness regardless of annealing. As an unexpected finding, in coating with P content of more than 5.6 wt% no increase in wear resistance was detected due to an increase in hardness. However, annealed coatings followed the Archard's equation, where amorphous Co-P coatings showed superior wear resistance after heat treatment due to their higher hardness.

Sliding wear properties of laser melt deposited Cr13Ni5Si2/γ -Ni base Alloy

[J].

激光熔化沉积Cr13Ni5Si2/γ-Ni基合金的耐磨性能

[J].采用激光熔化连续沉积工艺制备出了以Cr13Ni5Si2为初生相、以γ-Ni基固溶体为增韧相的金属硅化物耐磨合金, 在室温干滑动磨损条件下测试了Cr13Ni5Si2/γ-Ni合金的耐磨性能并讨论了其磨损机理. 结果表明, 由于Cr13Ni5Si2/γ合金优良的强韧性配合以及在磨损过程中磨损表面上稳定氧化物转移覆盖层的快速形成,合金在室温干滑动磨损条件下具有优异的耐磨性能和很低的载荷敏感系数.