近年来,许多研究者研究了P-GMAW脉冲焊接。Reddy等[5]和Kumar等[6]研究了脉冲参数对5083铝合金接头力学性能的影响。结果表明,脉冲频率和脉冲持续时间的优化能提高材料的抗拉强度。Kuang等[7]研究了超高频脉冲对铝合金焊接的影响,发现不同模式和频率的超高频脉冲其焊缝性能较高。随着脉冲频率的提高,焊缝(Welded zone,WZ)和热影响区(Heat affected zone,HAZ)的晶粒尺寸减小,并在一定程度上抑制了WZ中的元素偏析。Wang等[8]研究了脉冲频率和脉冲时间对铝合金WZ组织的影响,发现脉冲能促进WZ中生成更细晶体组织,脉冲频率的提高可改善接头的力学性能。但是,朱轩等[9]研究发现,在相同的实验条件下随着脉冲个数的增加焊接热输入增大,使WZ晶粒的尺寸增大。

上述研究结果表明,电弧脉冲在一定程度上影响WZ的组织和力学性能。焊接时引入脉冲,一方面使熔池产生震荡从而促进WZ组织均匀并细化晶粒,另一方面增大了焊接热输入使焊缝形成粗大的组织。但是,多数脉冲研究很少考虑到焊接热输入的影响。相同热输入条件下P-GMAW和恒流模式(Constant current gas metal arc welding,CC-GMAW)对焊缝成形、气孔缺陷和组织性能的影响机理尚不明确。鉴于此,本文在焊接热输入相同的条件下对比研究P-GMAW和CC-GMAW两种焊接模式对5083-H111铝合金焊接接头宏观成型、微观组织以及力学性能的影响。

1 实验方法

实验用5083-H111(轧制硬化态)板材的尺寸为300 mm × 150 mm × 4 mm,开45°单边V形坡口并留1 mm钝边,坡口间隙为1.2 mm。焊接方向平行于轧制方向。ER5087焊丝的直径为1.2 mm,用Optima 7300DV电感耦合等离子体发射光谱仪测量(ICP-OES)板材和焊丝取样的成分,结果列于表1。

表1 5083-H111铝合金和ER5087焊丝的主要化学成分

Table 1

| Name | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Zr | Al |

|---|---|---|---|---|---|---|---|---|---|---|

| 5083-H111 | 0.07 | 0.25 | 0.04 | 0.66 | 4.13 | 0.08 | 0.02 | 0.03 | 0.20 | Bal. |

| ER5087 | 0.09 | 0.18 | 0.03 | 0.71 | 4.71 | 0.08 | 0.01 | 0.08 | 0.12 | Bal. |

两种焊接模式的热输入相同,焊接电压、送丝速度都采用Fronius-TPS 400i焊接电源一元化自匹配参数,焊接工艺参数列于表2,焊接过程采用直流反接。

表2 焊接工艺参数

Table 2

| Group | Name | Heat input / J·mm-1 | Current / A | Voltage / V | Gas flow / L·min-1 | Wire feed rate / m·min-1 | Welding speed / mm·s-1 |

|---|---|---|---|---|---|---|---|

| 1# | P-GMAW Ⅰ | 276 | 130 | 19.0 | 20-25 | 7.5 | 7.5 |

| CC-GMAW Ⅰ | 265 | 140 | 15.7 | 20-25 | 9.7 | 7.5 | |

| 2# | P-GMAW Ⅱ | 307 | 140 | 19.5 | 20-25 | 8.0 | 7.5 |

| CC-GMAW Ⅱ | 318 | 150 | 16.9 | 20-25 | 9.9 | 7.5 |

焊接前用钢丝刷将5083-H111铝合金板焊接区域周围30 mm的表面氧化膜去除,然后用丙酮清洗以去除油脂和油污。在焊接过程中用DH5908N型采集器采集焊接过程中的焊接电流、焊接电压,并计算焊接的实际热输入。采集频率为10 kHz。选取0.3 s时间范围的焊接电流电压数据,两种焊接方法四组焊接参数(表2)的焊接热输入为

式中

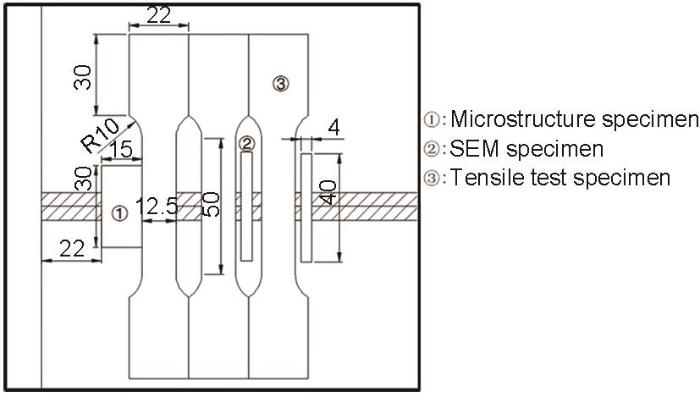

焊接后对WZ进行整体X射线探伤,然后按照图1取样。在电压30 V、电流0.25 A条件下用16.8 g/L的氟硼酸溶液进行电解抛光腐蚀30 s,得到的WZ、HAZ以及母材的金相组织,用ZETSS Axio ObserverA1倒置金相显微镜观察。在SHIMADZU AGX-100kN型材料力学试验机上进行拉伸实验,拉伸速率为1 mm/min。沿焊缝截面的直线打点方式测量硬度,从左至右间距为0.5 mm加载1 kg (保持10 s),在每组试样中打70个点。用配有能谱仪(EDS)的Sigma 300扫描电子显微镜(SEM)观察焊接接头的组织和断口形貌。

图1

2 实验结果和分析

2.1 焊接电流和电压的波形

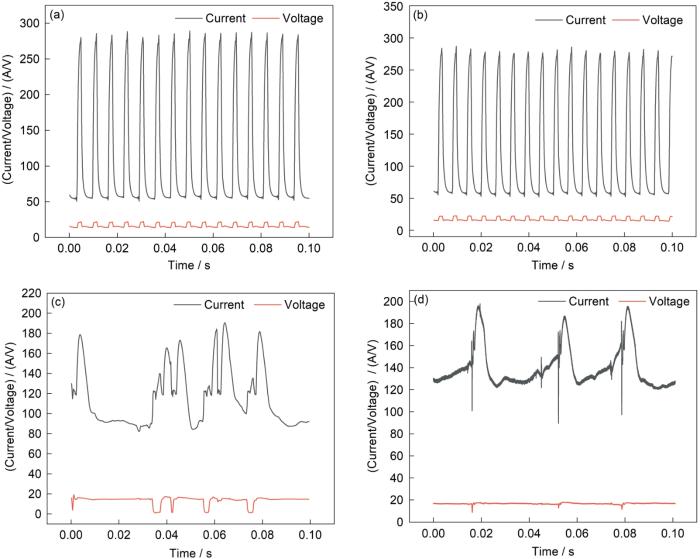

图2分别给出了P-GMAW和CC-GMAW两种模式焊接的焊接电流和焊接电压的变化。图2表明:在P-GMAW模式下焊接电流和电压都呈周期性变化,焊接电流处于峰值Ip时焊接电压同步处于峰值,电流与电压的波形略有不同,焊接电压为矩形波,焊接电流为尖波。随着设定电流参数由130 A增加至140 A,焊接电流基值由59 A增加至63 A,脉冲周期由6.3 ms减小至5.6 ms,峰值电流没有明显的变化。在CC-GMAW模式下焊接电流增大时焊接电压减小,表明熔滴是以短路过渡的方式向熔池过渡。熔滴长大后下坠并与熔池接触,使电流和电压瞬间增大和降低。随着设定电流参数由140 A增加至150 A基值电流由89 A增加至127 A,峰值电流由189 A增加至197 A,电流周期变化不明显,但是电流的峰宽明显减小。这表明,随着CC-GMAW焊接过程中电流的增大熔滴过渡时间缩短。由此推断,更大的焊接电流和更高的送丝速度条件下,在P-GMAW模式下提高脉冲的频率可提高填充金属向熔池的过渡效率,而在CC-GMAW模式下在相同频率下形成更大体积的熔滴可提高过渡效率[10]。

图2

图2

焊接电流电压的波形

Fig.2

Welding current and voltage waveforms (a) P-GMAW I, (b) P-GMAW II, (c) CC-GMAW I, (d) CC-GMAW II

2.2 焊缝的质量

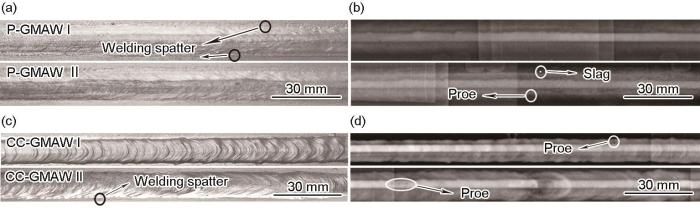

图3给出了两种焊接模式的WZ表面成型和探伤结果。从图3a、c可见,P-GMAW焊接模式的WZ成型较好,WZ表面平整只有较浅的鱼鳞纹,随着热输入的增加WZ表面特征没有明显的变化。CC-GMAW模式的焊缝表面鱼鳞纹比P-GMAW模式的鱼鳞纹更深,热输入增加时WZ宽度和鱼鳞纹的长度随之增加,但是焊缝余高的均匀一致性变差,其原因可能是热输入的增加和前文分析的熔滴体积的增大。两种接头的X射线探伤结果如图3b、d所示,可见P-GMAW WZ中基本上没有焊接气孔,而CC-GMAW焊接模式的两组WZ中都有少许气孔(图3中的白色标记)。气孔的形成,与焊接时的气体保护和电弧脉冲有关。为了分析焊接模式和热输入对WZ中气孔率的影响,针对探伤结果根据公式

图3

统计WZ中的气孔,结果列于表3。

表3 不同焊接模式WZ内的气孔率

Table 3

| Group | Name | Weld porosity / % | Maximum pore diameter / mm |

|---|---|---|---|

| 1# | P-GMAW Ⅰ | 0 | - |

| CC-GMAW Ⅰ | 0.1 | 1.2 | |

| 2# | P-GMAW Ⅱ | 0.1 | 1.6 |

| CC-GMAW Ⅱ | 0.2 | 0.9 |

2.3 接头的微观组织

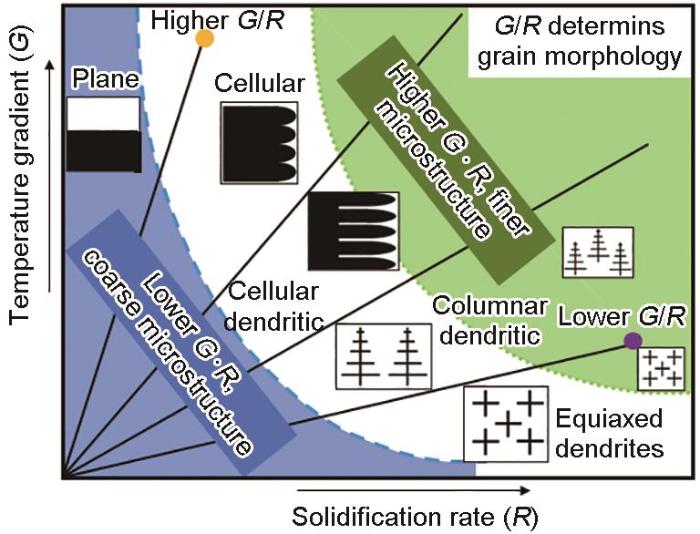

式中

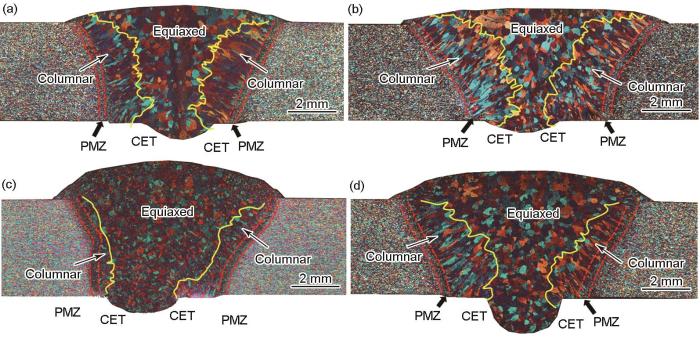

图4

图4

WZ截面的偏光组织

Fig.4

Microstructure of weld section (a) P-GMAW I, (b) P-GMAW II, (c) CC-GMAW I, (d) CC-GMAW II

图5

利用偏光的金相照片统计的WZ平均晶粒尺寸,列于表4。1#中P-GMAW和CC-GMAW WZ的平均晶粒尺寸分别为276和170 μm,2#为328和246 μm。母材的平均晶粒尺寸为20.5 μm。两组热输入相同的条件下P-GMAW焊接模式生成的WZ平均晶粒尺寸更大。同时,P-GMAW模式中较低热输入的P-GMAW Ⅰ WZ晶粒尺寸比CC-GMAW模式中较高热输入的CC-GMAW Ⅱ WZ晶粒尺寸更大。

表4 WZ组织的统计

Table 4

| Group | Name | Average grain size / μm | Proportion of columnar area / % | Proportion of equiaxed area / % |

|---|---|---|---|---|

| 1# | P-GMAW Ⅰ | 276 | 43.8 | 56.2 |

| CC-GMAW Ⅰ | 170 | 17.8 | 82.2 | |

| 2# | P-GMAW Ⅱ | 328 | 56.5 | 43.5 |

| CC-GMAW Ⅱ | 246 | 31.7 | 68.3 |

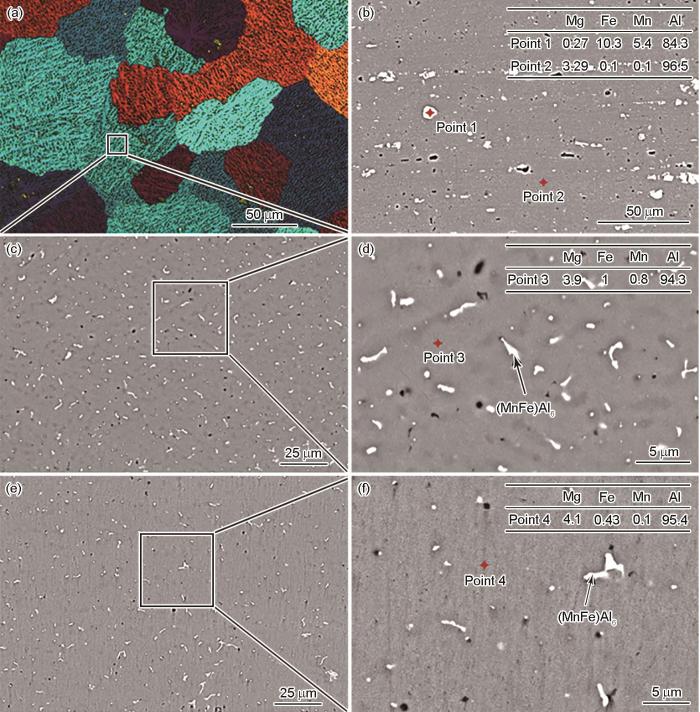

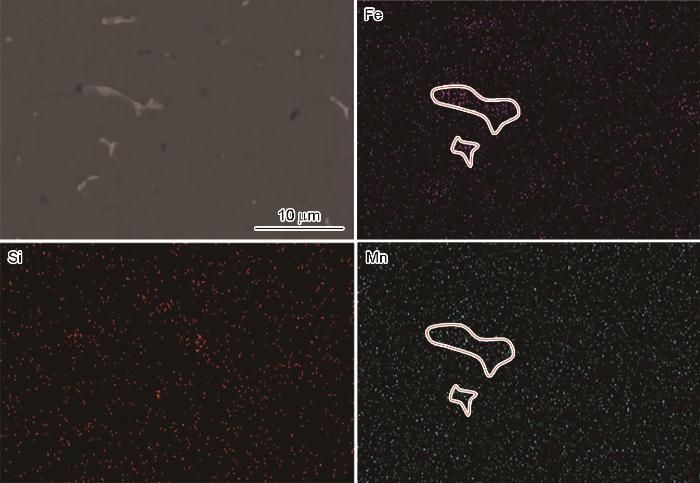

图6

图6

WZ和母材组织

Fig.6

Welded and base metal microstructure (a) P-GMAW I microstructure, (b) Base metal, (c, d) P-GMAW I welded, (e, f) CC-GMAW I welded

图7

2.4 接头的力学性能

2.4.1 接头的硬度

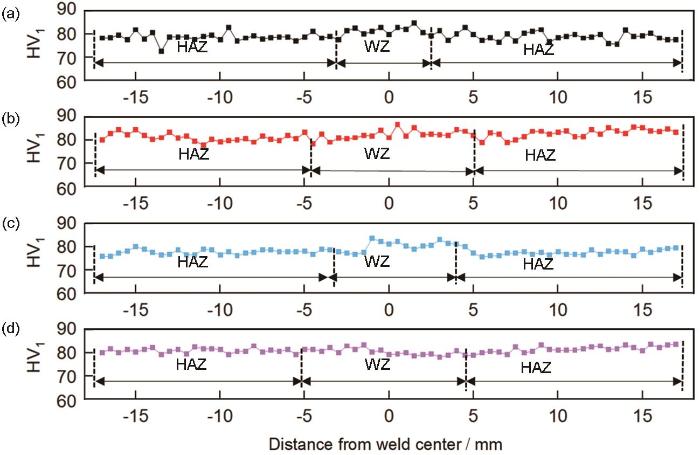

图8

图8

接头截面硬度的分布

Fig.8

Hardness distribution of the joint section (a) P-GMAW I, (b) P-GMAW II, (c) CC-GMAW I, (d) CC-GMAW II

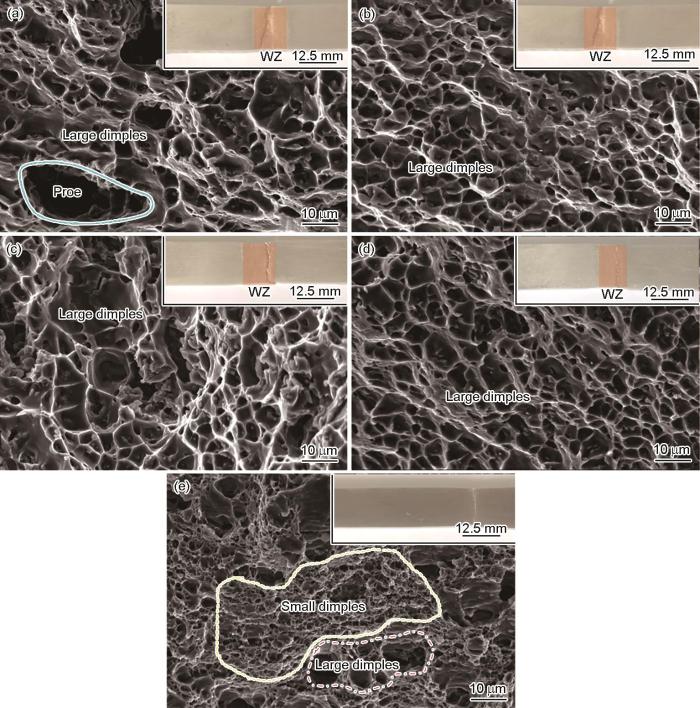

2.4.2 拉伸断口

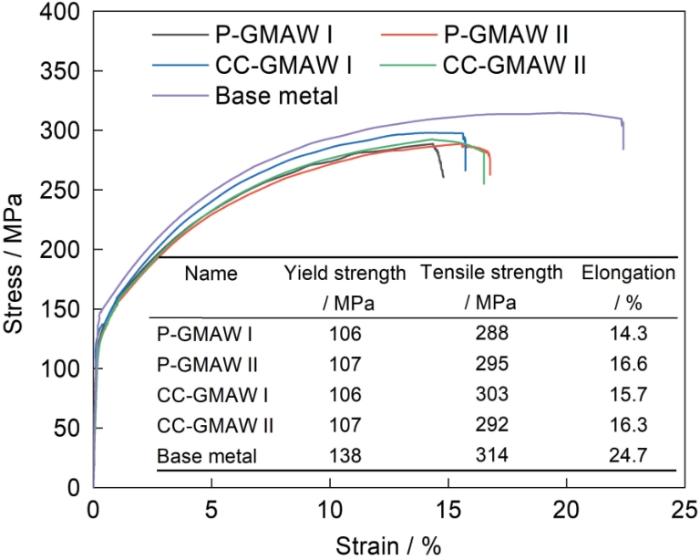

图9给出了焊接接头和母材的应力-应变曲线。可以看出,焊接接头的屈服强度、抗拉强度和延伸率比母材的低。同时,两种焊接模式不同热输入的接头其强度相当,四组焊接接头的抗拉强度和屈服强度都相近,屈服强度和抗拉强度分别为106~107 MPa和288~303 MPa,分别达到了母材强度的75%和90%。四组接头之间的延伸率也相近,分布为14.3%~16.6%,而母材的延伸率为24.7%。这表明,焊接模式和焊接热输入对5083-H111焊接接头的强度没有显著的影响。

图9

图10

图10

断口的组织

Fig.10

Fracture microstructures (a) P-GMAW I, (b) P-GMAW II, (c) CC-GMAW I, (d) CC-GMAW II, (e) base metal

图11

图11

WZ和母材的细晶强化效应的统计

Fig.11

Statistical figure of fine grain strengthening effect of weld and base metal

3 结论

(1) 脉冲电弧对5083-H111铝合金熔池的震荡使P-GMAW模式比CC-GMAW热源形成的WZ表面更加平整,两种焊接模式的WZ中气孔率均小于0.3%。

(2) 在热输入相同条件下P-GMAW 模式焊接熔池的温度梯度和形成的WZ内柱状晶面积更大,具有更大的WZ组织。两种模式的WZ组织中细小的(FeMn)Al6相和Mg2Si相在晶内弥散分布。

(3) 两种模式的接头中WZ和HAZ的硬度与母材的硬度相当。P-GMAW模式高、低热输入的接头断口组织都有大小均匀的韧窝。强度降低的主要原因是WZ的凝固组织粗大且内部有气孔。

参考文献

Microstructure and properties of 5083 and 6061 aluminum alloy dissimilar stir friction welded joints

[J].

5083和6061铝合金异种搅拌摩擦焊接接头的组织和性能

[J].以不同的转速对6 mm厚的5083和6061铝合金进行搅拌摩擦焊接,研究了焊接参数对接头组织和性能的影响。结果表明,控制焊接参数可获得良好的焊接质量,接头强度系数为85%。随着转速的升高5083和6061铝合金的晶粒尺寸都逐渐增大,但是在焊核区内5083铝合金的晶粒尺寸比6061铝合金的小;在6061铝合金一侧的热影响区,随着转速的增加析出相的尺寸和密度都逐渐增大。5组焊接参数的焊接接头的最低硬度区均出现在6061铝合金一侧的热影响区,随着转速的升高接头的最低硬度也逐渐提高;焊接接头均断裂在最低硬度区,且随着转速的升高接头的抗拉强度也逐渐提高。

Precipitation behavior of the phase in Al-5083

[J].

Superplastic behavior of an Al-Mg alloy at elevated temperatures

[J].

Influence of melting current pulse duration on microstructural features and mechanical properties of AA5083 alloy weldments

[J].

Optimisation of pulse frequency in pulsed current gas tungsten arc welding of aluminium-lithium alloy sheets

[J].

Effect of welding parameters on mechanical properties and optimization of pulsed TIG welding of Al-Mg-Si alloy

[J].

Effect of pulse mode and frequency on microstructure and properties of 2219 aluminum alloy by ultrahigh-frequency pulse Metal-Inert Gas Welding

[J].

Influence of low-pulsed frequency on arc profile and weld formation characteristics in double-pulsed VPTIG welding of aluminium alloys

[J].

Effect of arc pulse on the microstructure and properties of 6005A-T6 aluminum alloy CMT-P welded joints

[J].

电弧脉冲对6005A-T6铝合金CMT-P焊接接头组织和性能的影响

[J].

Research on droplet transition behavior and weld formation of aluminum alloy GMAW welding

[D].

铝合金GMAW焊接熔滴过渡行为及焊缝成形研究

[D].

How ultra high frequency of pulsed gas tungsten arc welding affects weld porosity of Ti-6Al-4V alloy

[J].

Improvement of elevated-temperature strength and recrystallization resistance via Mn-containing dispersoid strengthening in Al-Mg-Si 6082 alloys

[J].The precipitation behavior of Mn-containing dispersoids in Al-Mg-Si 6082 alloys with different Mn contents (0, 0.5 and 1.0 wt%) during various heat treatments (300-500 ℃) was investigated. The effects of dispersoids on elevated-temperature strength and recrystallization resistance during hot-rolling and post-rolling annealing were evaluated. The results showed that the dispersoids in the Mn-containing alloys (0.5 and 1.0%) began to precipitate at 350 ℃ and reached the optimum conditions after 2-4 h at 400 ℃. However, the dispersoids coarsened with increasing holding time at temperatures above 450 ℃. After the peak precipitation treatment at 400 ℃ for 2 h, the yield strength at 300 ℃ increased from 28 MPa (base alloy free of Mn) to 55 MPa (alloy with 0.5% Mn) and 70 MPa (alloy with 1% Mn), respectively, demonstrating a significant dispersoid strengthening effect at elevated temperature. In addition, the dispersoids were thermally stable at 300 ℃ for up to 1000 h holding owing to its relative high precipitation temperature (350-400 ℃), leading to the superior constant mechanical performance at elevated temperature during the long service life. During hot rolling and post-rolling annealing, the presence of a large amount of dispersoids results in the higher Zener drag PZ compared with base alloy and then significantly improved the recrystallization resistance. The alloy containing 0.5% Mn exhibited the highest recrystallization resistance among three experimental alloys studied during the post-rolling process, likely resulted from the lower coarsening rate of dispersoids and the lower dispersoids free zone.

The effect of TIG welding techniques on microstructure, properties and porosity of the welded joint of 2219 aluminum alloy

[J].

Failure analysis of blowholes in welded boiler water walls

[J].

Microstructure and properties of 2195-2219 heterogeneous aluminum alloy welded joints

[J].

2195-2219异种铝合金焊接接头的微观组织和性能

[J].用钨极氩弧焊(TIG)和变极性等离子弧焊(VPPA)对2195与2219异种铝合金进行平板对接焊,研究了不同焊接方法和在有无保护气氛条件下焊接接头的显微组织和性能。结果表明,在用TIG和VPPA工艺焊接的接头区域都没有出现宏观热裂纹,能量密度高、焊接快和热输入量小的VPPA工艺使焊缝区域较窄;异种铝合金焊缝接头熔合线附近的主要析出相为θ相,在焊缝区域有α-Al与θ相组成的共晶组织;在TIG工艺和有气氛保护的VPPA工艺的焊接接头区域没有出现局部软化现象,焊缝区域的硬度与2219侧母材相同。TIG工艺的焊接接头,其抗拉强度更高。