随着信息技术特别是4G、5G网络的发展,电磁辐射引起的安全问题受到了极大的关注。目前常用的电磁屏蔽材料,有金属、导电聚合物和碳基材料。金属材料的导电性能优异,能高效反射屏蔽电磁波但其密度较高、易腐蚀和耐弯折差,严重影响其应用。导电聚合物的电导率低,且较难加工。碳基材料(如碳纤维、碳纳米管、石墨烯等)轻质高强、化学稳定性高和成型简便,已经应用在多个领域。碳纤维毡(Carbon fiber felt, CFF)是由短切碳纤维随机排列形成的多孔片层薄膜[1],具有轻薄、柔软、强度高、导电导热性强等优点,在多个领域(包括电磁屏蔽)有广阔的应用前景。

进行表面改性可使CFF的电磁屏蔽性能提高,常见的改性方法有:(1)用电镀或磁控溅射等工艺在CFF表面沉积Ni、Cu、Ag等金属[2~4],使其表面电导率和电磁波界面的反射性能提高。但是,金属涂层的密度较高、结合力较弱,且操作复杂、制备效率低,使其大规模应用受到限制。(2)在CFF表面涂覆或喷涂功能性无机填料,如零维的炭黑[5]、磁性粒子(如Fe3O4)[6,7]、一维碳纳米管(Carbon nanotubes, CNTs)[8~10]、纳米碳纤维(Carbon nanofibers, CNF)[11]、碳化硅纳米线[12]、二维石墨烯纳米片及其衍生物(如氧化或功能化石墨烯等)[13~17]、金属碳化物/氮化物等,生成高导电性、高比表面积的多孔结构和产生界面极化效应,使电磁波发生多重反射和吸收,从而提高其电磁屏蔽性能。

MXene是一种过渡金属碳化物/氮化物二维片状材料[18],(其通式为M n + 1X n T x,M为过渡金属,X为C或者N,T为表面端基),具有优异的导电性能和表面亲水性[19,20],将其涂覆于基底表面形成致密的功能层,可显著提高其导电性和电磁屏蔽性能[21~23]。Liu等[24]将MXene涂覆于棉织物表面使其具有高导电性和力敏响应特性,可应用于可穿戴设备和制造压力传感器;Hu等[25]通过电泳沉积将MXene涂覆于碳纤维丝束表面形成具有核-壳结构的复合材料,使其具有较高的电磁屏蔽效能(EMI SE为34.4 dB);Duan等[26]将MXene雾化沉积在碳纤维平纹织物表面并与热塑性聚氨酯片材复合制备出复合材料,其电磁屏蔽效能可达40.4 dB。本文用喷涂雾化沉积工艺将MXene二维纳米材料均匀涂覆于CFF表面制备MXene@CFF多孔复合薄膜,研究MXene含量对这种复合结构导电性和电磁屏蔽性能的影响。

1 实验方法

1.1 MXene@CFF复合薄膜的制备

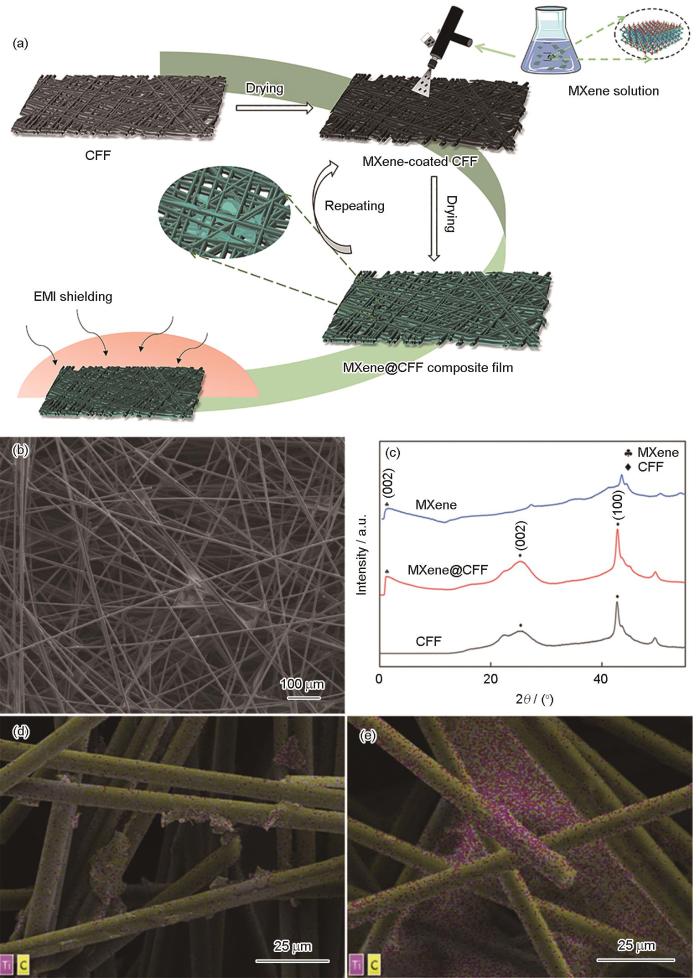

用雾化喷涂沉积工艺制备MXene@CFF复合薄膜。先用无水乙醇(分析纯)将5 mg/mL的MXene水溶液(用氟化锂/盐酸体系将Ti2AlC前驱体刻蚀后得到的浓度为5 mg/mL的Ti3C2T x 水溶液,片径尺寸为500~2000 nm,厚度小于5层,本征导电率为3500 ± 500 S/cm)稀释到浓度为0.1 mg/mL,在压缩空气作用下用直径为0.5 mm的喷嘴将MXene溶液雾化并均匀喷涂于聚丙烯腈基碳纤维毡(CFF,型号KCM-050,面密度50 g/m²,单根纤维直径6~7 μm、长度6 mm)表面。每喷涂一层用红外灯将其烘烤至完全干燥,再喷涂下一层。喷涂适当次数后得到MXene的质量分数分别为0.38%、0.82%、1.22%和2.37%的MXene@CFF复合薄膜。

图1

图1

MXene@CFF复合薄膜的制备流程图、SEM形貌、XRD谱以及EDS图像

Fig.1

Fabrication schematics (a), SEM (b), XRD (c), and EDS images (d, e) of the MXene@CFF composite films

1.2 复合薄膜结构和性能的表征

用高精度电子分析天平(Mettler Toledo,ME55)测量喷涂前后薄膜的质量。用场发射扫描电子显微镜(SEM,Verios G4 UC)观察碳纤维毡与其表面涂覆MXene后的微观形貌,并通过能量散射X射线光谱(EDS)分析MXene在CFF表面的元素分布。用X射线衍射仪(XRD,D/Max-2400)测试复合薄膜的XRD谱。使用四探针电阻率测试仪(RTS-9)测量CFF和MXene@CFF复合薄膜的表面电阻率[27]。用矢量网络分析仪(N5242A)波导法测量复合薄膜(尺寸30 mm × 30 mm × 0.25 mm)在8.2~12.4 GHz (X波段)的电磁散射参数(S11和S21),并计算电磁屏蔽性能(SE)[28]:

式中R、A、T分别为反射、吸收与透射系数;SER、SEA、SEM及SET分别对应复合薄膜的反射、吸收、多重反射与总电磁屏蔽效能。电磁屏蔽总性能SET大于10 dB时,多重反射损耗效能SEM可忽略不计。

2 结果和讨论

2.1 MXene@CFF复合薄膜的结构

从图1b可见,MXene弥散均匀分布在CFF表面,其部分聚集在纤维交叉节点处形成团簇体。在干燥过程中,MXene团簇液滴在表面张力的作用下逐渐收缩,使相邻的碳纤维形成紧密的物理连接,这种“锚固焊接”作用降低了纤维间的接触电阻,提高了涂覆MXene的CFF导电性能。从图1c中的XRD谱可见,复合薄膜的谱中有与CFF和MXene对应的特征峰,表明涂覆在CFF表面的MXene晶型结构没有变化。同时,附着的二维MXene使碳纤维表面的粗糙度明显提高,有利于电磁波的多重反射产生损耗。图1d和e给出的EDS元素分析结果也表明,MXene的均匀分布和在纤维交叉处的局部富集形成了异质界面结构。这种结构有利于产生电磁波的界面极化损耗,从而使复合薄膜的电磁屏蔽性能提高。

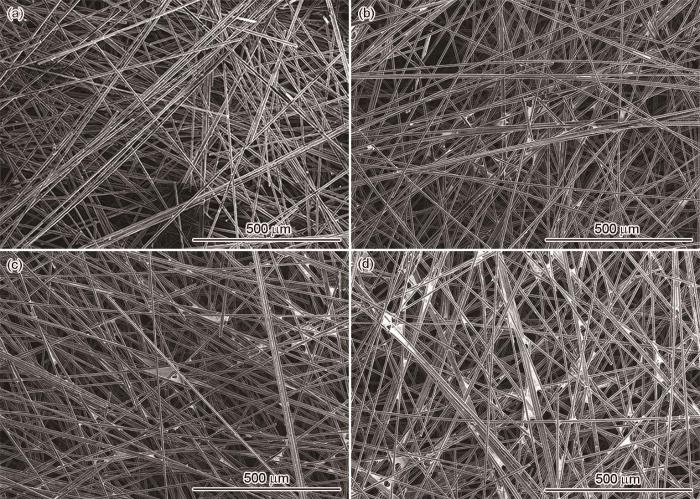

图2

图2

MXene@CFF复合薄膜的SEM照片

Fig.2

SEM images of MXene@CFF composite films with MXene loadings of 0 (a), 0.82% (b), 1.22% (c), and 2.37% (d)

2.2 MXene@CFF复合薄膜的导电性能

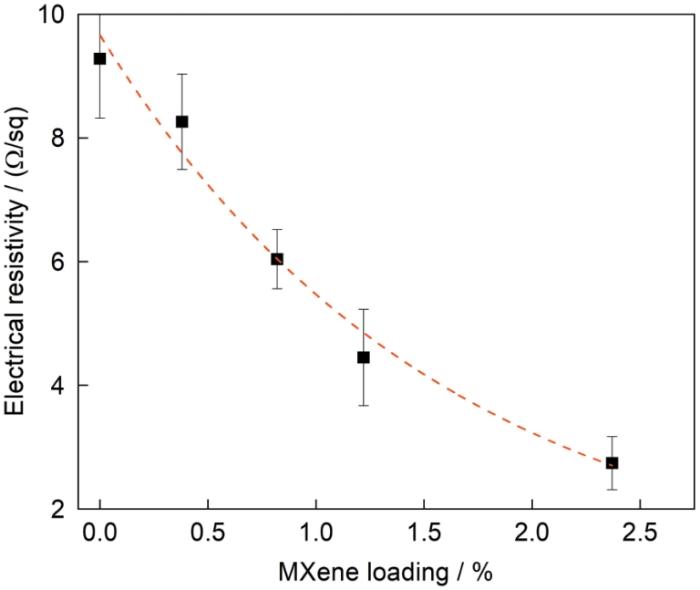

图3给出了MXene@CFF复合薄膜的表面电阻率。与碳纤维毡(其表面电阻率为9.3 Ω/sq)相比,表面涂覆MXene的复合薄膜其电阻率显著降低。MXene含量为2.37%的复合薄膜其表面电阻率降低到2.7 Ω/sq,比CFF降低了71%。这表明,MXene涂覆能显著提高复合薄膜的导电性能。其原因是,MXene的本征导电性(电导率达3500 S/cm)较高, MXene在碳纤维交叉节点处的收缩聚集使碳纤维之间的接触更为紧密,从而使碳纤维间的接触电阻降低。MXene@CFF复合薄膜网络骨架电学性能的提高有助于增强电磁波的表面反射以及复合薄膜内的多重反射与损耗吸收,从而使其具有优异的电磁屏蔽性能。

图3

图3

MXene@CFF复合薄膜的表面电阻率

Fig.3

Surface electrical resistivity of MXene@CFF composite films

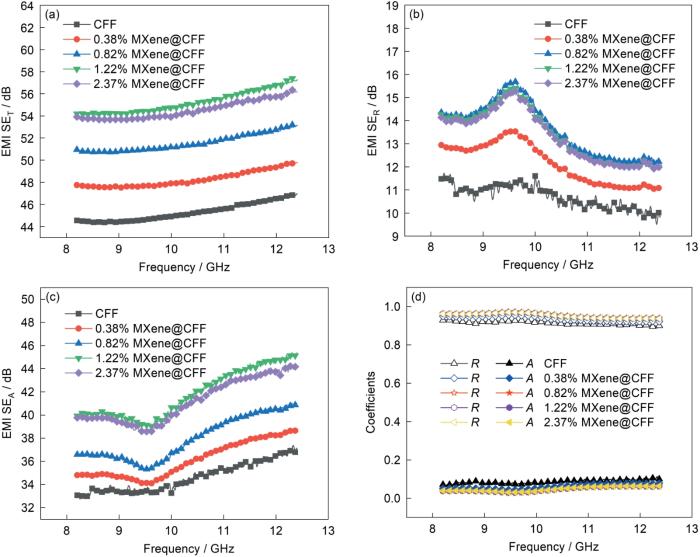

2.3 MXene@CFF复合薄膜的电磁屏蔽性能

图4给出了用波导法测得的MXene@CFF复合薄膜在X波段(8.2~12.4 GHz)的电磁屏蔽性能。从图4a可见,CFF的总平均电磁屏蔽性能为45.3 dB,因为CFF具有较高的导电性能和丰富的孔结构。在CFF表面喷涂MXene使复合薄膜的电磁屏蔽性能提高,其平均总屏蔽性能提高到57.9 dB,比碳纤维提高了27.8%。这表明,涂覆MXene能提高CFF的电磁屏蔽性能。其原因是,MXene使CFF网络的电学性能提高、MXene包覆使表面粗糙度提高(有利于电磁波多重反射)以及产生MXene-碳纤维的界面极化和吸收损耗。从图4b和c可见,表面涂覆MXene使复合薄膜的反射效能(SER)和吸收效能(SEA)都提高了。MXene涂覆提高了复合薄膜的导电性能,使其对电磁波的反射能力提高(SER增大);同时,MXene与碳纤维形成类似于“微电容”的界面异质结构,易于在交变电场中发生界面诱导极化而产生吸收损耗[28,29];MXene包覆能提高碳纤维导电性能和表面粗糙度,进一步增强了电磁波在薄膜内部的多重反射和吸收损耗。图4d给出了复合薄膜的反射和吸收系数曲线。可以看出,复合薄膜的反射系数R高达0.95(远高于吸收系数A),且随着MXene含量的提高而逐渐提高。这表明,复合薄膜屏蔽电磁波的机制主要是电磁波的反射。从图4b和c可见,MXene含量为2.37%的复合薄膜,其SEA和SER的增大并不显著甚至略有降低,因为过量的MXene堵塞了部分孔隙,使多重反射和吸收损耗降低。

图4

图4

MXene@CFF复合薄膜的电磁屏蔽性能

Fig.4

Total (a), reflection (b), and absorption (c) shielding effectiveness, and the corresponding reflection and absorption coefficients (d) of MXene@CFF composite films in the range of 8.2~12.4 GHz

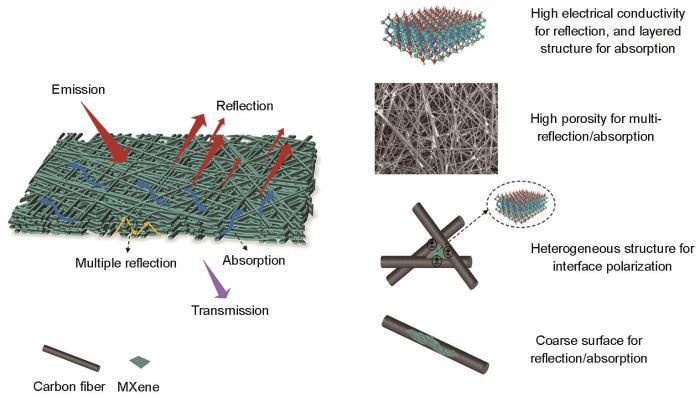

图5给出了MXene@CFF复合薄膜电磁屏蔽机理的示意图。电磁波入射到复合薄膜表面,外部自由空间与薄膜表面的阻抗失配[30],部分电磁波发生反射,只有少部分进入复合薄膜内部。电磁波的反射依赖材料的电导率,碳纤维涂覆MXene的薄膜其电导率较高,从而显著提高了对电磁波的反射性能。网络骨架的高导电性和丰富的多层次孔结构(图5),使进入复合薄膜内的电磁波发生多重反射,与MXene和碳纤维的相互作用使电磁波的能量衰减。MXene与CFF产生了大量的异质界面结构在交变电场中发生界面偶极极化,从而产生电磁波的吸收损耗[31];同时,在碳纤维表面涂覆MXene引入了大量的凸起褶皱结构(使表面粗糙度提高),进一步增强了电磁波的多重反射和损耗,使MXene@CFF复合薄膜具有较高的电磁屏蔽性能。

图5

图5

MXene@CFF复合薄膜的电磁屏蔽机理示意图

Fig.5

Mechanism schematics on electromagnetic shielding of MXene@CFF composite films

3 结论

进行喷涂雾化沉积将MXene溶液均匀涂覆在碳纤维毡(CFF)表面,可制备具有高导电性和高电磁屏蔽性能的MXene@CFF复合薄膜。这种复合薄膜较高的电磁屏蔽性能,可归因于其多层次孔结构、MXene包覆后碳纤维网络较高的电导率以及MXene与碳纤维形成的异质结构产生的电磁波多重反射和界面极化吸收损耗。

参考文献

Electromagnetic shielding property of carbon fiber felt made of different types of short-chopped carbon fibers

[J].

Effect of nickel electroplating followed by a further copper electroplating on the micro-structure and mechanical properties of high modulus carbon fibers

[J].

Metallic composite coatings by electroless technique-a critical review

[J].

Electroless nickel plating and spontaneous infiltration behavior of woven carbon fibers

[J].

Use of carbon black as a reinforcing Nano-filler in conductivity-reversible elastomer composites

[J].

Effect of carbon nanofiller dimension on synergistic EMI shielding network of epoxy/metal conductive foams

[J].

Enhancement of electrical and thermal conductivities of a polysiloxane/metal complex with metal oxides

[J].

Improving resistance-strain effects of conductive polymer composites modified by multiscale fillers: Short carbon fiber and carbon nanotube

[J].

Piezoresistive Effect of conductive and non-conductive fillers in bi-layer hybrid CNT composites under extreme strain

[J].

Preparation and comparison of reduced graphene oxide and carbon nanotubes as fillers in conductive natural rubber for flexible electronics

[J].Conductive natural rubber (NR) nanocomposites were prepared by solvent-casting suspensions of reduced graphene oxide (rGO) or carbon nanotubes (CNTs), followed by vulcanization of the rubber composites. Both rGO and CNT were compatible as fillers in the NR as well as having sufficient intrinsic electrical conductivity for functional applications. Physical (thermal) and chemical reduction of GO were investigated, and the results of the reductions were monitored by X-ray photoelectron spectroscopy for establishing a reduction protocol that was useful for the rGO nanocomposite preparation. Field-emission scanning electron microscopy showed that both nanofillers were adequately dispersed in the main NR phase. The CNT composite displays a marked mechanical hysteresis and higher elongation at break, in comparison to the rGO composites for an equal fraction of the carbon phase. Moreover, the composite conductivity was always ca. 3-4 orders of magnitude higher for the CNT composite than for the rGO composites, the former reaching a maximum conductivity of ca. 10.5 S/m, which was explained by the more favorable geometry of the CNT versus the rGO sheets. For low current density applications though, both composites achieved the necessary percolation and showed the electrical conductivity needed for being applied as flexible conductors for a light-emitting diode.

The effect of milled carbon fibre filler on electrical conductivity in highly conductive polymer composites

[J].

High-resilience conductive PVA+AgNW/PDMS nanocomposite via directional freeze-drying

[J].

Effect of natural surfactant on the performance of reduced graphene oxide conductive ink

[J].

Facile green path to interconnected Nano-graphite networks to overtake graphene as conductive fillers

[J].

High-efficiency electromagnetic interference shielding realized in nacre-mimetic graphene/polymer composite with extremely low graphene loading

[J].

Highly conductive polyimide nanocomposite prepared using a graphene oxide liquid crystal scaffold

[J].

Ultra-Stiff graphene foams as three-dimensional conductive fillers for epoxy resin

[J].Conductive epoxy composites are of great interest due to their applications in electronics. They are usually made by mixing powdered conductive fillers with epoxy. However, the conductivity of the composite is limited by the low filler content because increasing filler content causes processing difficulties and reduces the mechanical properties of the epoxy host. We describe here the use of ultra-stiff graphene foams (uGFs) as three-dimensional (3D) continuous conductive fillers for epoxy resins. The powder metallurgy method was used to produce the dense uGFs monoliths that resulted in a very high filler content of 32 wt % in the uGF-epoxy composite, while the density of epoxy was only increased by 0.09 g/cm. The composite had an electrical conductivity of 41.0 ± 6.3 S/cm, which is among the highest of all of the polymer-based composites with non-conductive polymer matrices and comparable with the conductive polymer matrices reported to date. The compressive modulus of the composite showed a remarkable improvement of >1700% compared to pure epoxy. We have demonstrated that the 3D uGF filler substantially improves the conductivity and reinforces the polymer matrix with a high filler content while retaining a density similar to that of the epoxy alone.

Research progress of MXene used in lithium sulfur battery

[J].As an emerging two-dimensional transition metal carbide or carbonitride, MXene exhibits excellent metallic conductivity, abundant surface functional groups and ultrathin two-dimensional structure, which endows it great potential in electrochemical energy storage. Lithium-sulfur batteries have a high theoretical specific capacity and become a very competitive choice in the new generation of energy storage devices. Two-dimensional MXenes and the assembled three-dimensional materials, as advanced sulfur carriers, can effectively improve the inherent poor conductivity and serious dissolution of discharge products of lithium-sulfur batteries. This paper reviews the current applications of MXene materials with two-dimensional and three-dimensional structures in lithium-sulfur batteries, analyzes the relationship between different structures and performance, summarizes the current challenges and difficulties, and gives a view on the direction to proceed for future designs.

MXene在锂硫电池中应用的研究进展

[J].MXene是一种新兴的二维过渡金属碳化物或碳氮化物,优异的金属导电性、丰富的表面官能团和超薄二维结构使其在电化学储能方面的应用有巨大的潜力。锂硫电池的理论比容量较高,在新一代储能器件中极具竞争力。二维MXene及其组装的三维材料作为一种先进的硫载体可通过多种途径克服锂硫电池固有的导电性差和放电产物溶解严重的问题。本文综述了目前二维和三维结构的MXene材料在锂硫电池中的应用,分析了性能与结构之间的关系,总结了目前存在的挑战和困难并对未来的设计方向提出一些看法。

Preparation of ultrastrong and highly conductive Mxene-based film for electromagnetic interference shielding

[D].

高强高导电MXene基电磁屏蔽薄膜的制备

[D].

Tetramethylammonium hydroxide modified MXene as a functional nanofiller for electrical and thermal conductive rubber composites

[J].

MXene fillers and silver flakes filled epoxy resin for new hybrid conductive adhesives

[J].

Ti3C2 MXene as a new nanofiller for robust and conductive elastomer composites

[J].

MXene-coated air-permeable pressure-sensing fabric for smart wear

[J].

Highly conductive and mechanically robust MXene@CF core-shell composites for in-situ damage sensing and electromagnetic interference shielding

[J].

Mechanically robust Ti3C2T x MXene/carbon fiber fabric/thermoplastic polyurethane composite for efficient electromagnetic interference shielding applications

[J].

Three-dimensional reduced graphene oxide foam modified with ZnO nanowires for enhanced microwave absorption properties

[J].

Ultralight graphene foam/conductive polymer composites for exceptional electromagnetic interference shielding

[J].

Electromagnetic wave absorption in graphene nanoribbon nanocomposite foam by multiscale electron dissipation of atomic defects, interfacial polarization and impedance match

[J].

Synergistic effect of carbon nanotubes with zinc oxide nanowires for enhanced electromagnetic shielding performance of hybrid carbon fiber/epoxy composites

[J].Developing advanced composites with high electromagnetic shielding effectiveness is of great significance to ensure safety and reliability of electronic devices in complex electromagnetic environments. We proposed a novel strategy to fabricate carbon fiber-based hybrid composites by in-situ growing zinc oxide (ZnO) nanowires onto carbon fiber (CF) and subsequently depositing carbon nanotubes (CNT), and infiltrating epoxy (EP) into laminated layers through vacuum-assisted resin transfer molding technique. Microstructures, electrical conductivity, and electromagnetic shielding performance of the acquired CNT-ZnO-CF/EP hybrid composites were investigated in detail. The hybrid composites of 2 mm thickness exhibited excellent electromagnetic shielding performance, and their total electromagnetic shielding effectiveness was up to 50 dB in the 8.2~12.4 GHz band, increasing by 51.52% in comparison to the CF/EP composites. Such high performance is mainly attributed to the high dielectric loss of ZnO nanowires, high electrical conductivity of continuous CNT films, and multiple reflection/absorption losses between laminated structures and multi-component interfaces. This work paves a way for development of advanced composites with high-efficiency electromagnetic shielding and structure/function integration.

碳纳米管/氧化锌协同增强碳纤维复合材料的电磁屏蔽性能

[J].

Silver-coated conductive composite fabric with flexible, anti-flaming for electromagnetic interference shielding

[J].

Negative permittivity enhanced reflection and adsorption of electromagnetic waves from carbon fiber felt/carbon nanotubes

[J].

Multifunctional and recyclable aerogel/fiber building insulation composites with sandwich structure

[J].

Ti3C2T x MXene/Fe3O4/carbon fiber fabric/water polyurethane composite fabrics for electromagnetic interference shielding and thermal management

[J].

Multilayer-structured carbon fiber fabric/graphene oxide/Fe3O4/epoxy composite for highly efficient mechanical and electromagnetic interference shielding

[J].