随着高温合金体系的发展和完善,新型高温合金的研发从具有更高的使用温度变为具有高功能性、高环境适应性。钴基高温合金具有优异的可焊性、良好的抗热腐蚀、热疲劳特性,是开发航空发动机和燃气轮机用高耐蚀结构材料的新方向[1,2]。同时,钴基高温合金具有较宽的热加工范围和优异的焊接性能,也使其成为开发新型涡轮盘件和增材制造关键热端部件的重要材料[3,4]。传统钴基高温合金以碳化物强化为主,2006年日本Sato等在Co-Al-W三元合金中发现了与镍基高温合金中的γʹ-(Ni3Al)相类似的Co3(Al,W)相。Co3(Al,W)相弥散分布在基体中并与基体共格,有沉淀强化作用[5]。基于此,钴基高温合金的高温强度显著提高,从而发展出多种以Co3(Al,W)为强化相的新型钴基高温合金,其中部分钴基和钴镍基单晶高温合金的高温力学性能已经与二代单晶高温合金接近[6~8]。

1 实验方法

1.1 实验用合金试样的制备

实验用合金的名义成分为:Co-15Ni-4Al-15W-5Cr-5Ta-1Ti-0.15C-0.024B-0.02Zr (%,质量分数)。按照合金的名义成分配料后,用10 kg真空感应炉(型号为ZG-001)熔炼后浇注成母合金铸锭。用X射线荧光光谱和碳硫仪检测出母合金的实测成分为:Co-15.19Ni-3.98Al-15.06W-4.98Cr-5.15Ta-0.96Ti-0.15C-0.03B-0.02Zr (%,质量分数)。

将母合金进行二次熔炼后浇注成拉伸试棒。二次熔炼工艺:在1550 ℃精炼3 min后降温至1500 ℃后浇注,型壳的预热温度为1000 ℃。

1.2 DSC测试

用STA449F3型超高温综合热分析仪进行差示扫描量热(DSC)测试合金析出相的转变温度。从母合金上切割直径为3 mm厚度为2 mm的DSC测试样品,用砂纸打磨样品的表面直至露出金属光泽。DSC测试在动态高纯度Ar气氛中使用高纯度Al2O3坩埚进行,以最大限度地减少氧化。试样经受如下的加热和冷却循环:室温→以30 ℃/min升温至800 ℃→在800 ℃等温保持10 min→以10 ℃/min升温至1450 ℃→在1450 ℃等温保持10 min→以10 ℃/min的速度冷却至800 ℃→以30 ℃/min的速度冷却到室温。

1.3 热处理制度确定

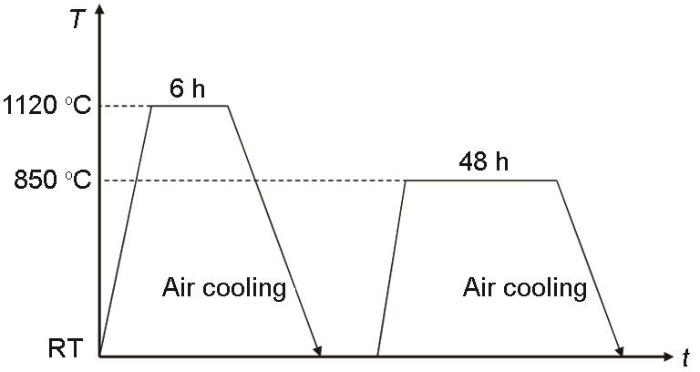

对合金进行固溶加时效热处理。根据DSC曲线得到合金的初熔温度,在初熔温度选取6个温度点进行初熔实验,在相应温度点保温30 min后水淬,观察初熔样品的金相组织,从而选取合适的固溶处理温度。初熔/固溶/时效处理样品的尺寸为10 mm × 10 mm × 10 mm。初熔和固溶实验在1500 ℃高温箱式炉中进行,时效处理在1100 ℃高温箱式炉中进行。确定合金的热处理制度后,对拉伸试棒进行固溶和时效处理。

1.4 显微组织的表征

用线切割切取直径为10 mm厚度为2 mm的样品用于组织观察。将样品表面依次用180、400、1000、2000#的金相砂纸打磨并配合LAP-2MV金相磨抛机用DNW2.5水溶金刚石研磨膏将其抛光,然后进行电解腐蚀,腐蚀剂配比(体积比)为42H3PO4∶34H2SO4∶24H2O,电压为5 V,电解时间约为5 s。腐蚀后用Leica DMC 4500光学显微镜和Apreo 2C扫描电子显微镜观察组织。

用EBSD并结合EDS能谱鉴定析出相的类型。EBSD样品直径为5 mm厚度为2 mm。样品机械抛光后进行振动抛光以去除表面应力,所用抛光液的粒径为50 nm。用配备UltimMax65 & Symmetry的Zeiss Gemini SEM 300场发射扫描电镜鉴别相组成,样品的倾斜角度为70°,加速电压为20 kV,扫描步长为1.5 μm。用Channel 5软件解析EBSD数据。

1.5 力学性能的测试

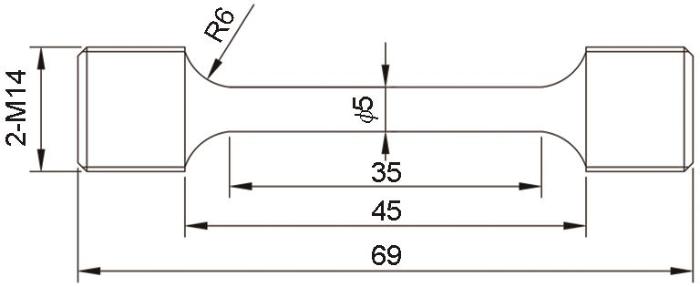

将铸态和热处理态的合金试棒加工成标准拉伸样品,其尺寸如图1所示。根据标准GB/T 228.1-2021用TSE 105D微机控制电子万能实验机进行室温拉伸实验;根据国家标准GB/T 228.2-2015用MTS E45.105万能实验机进行950 ℃高温拉伸实验,拉伸前将试样在950 ℃保温10 min。为了确保测试数值的准确性,最少用2根样品进行平行测试,取其结果的平均值。

图1

观察拉伸断裂后样品较短的一侧断口的形貌,观察前将样品用酒精进行超声波清洗5 min。将拉伸断裂试样较长的一侧沿着应力轴方向切取长约5 mm的样品,机械研磨抛光后进行电解腐蚀。用Apreo 2C扫描电子显微镜观察纵剖面,以分析合金的裂纹萌生扩展机制。

2 结果和讨论

2.1 铸态合金的组织

图2

图2

铸态合金的OM组织

Fig.2

OM micrographs of as-cast alloy (a) low magnification, (b) high magnification

表1 铸态合金中析出相的EPMA结果

Table 1

| Phase | Co | Ni | Cr | Ti | C | B | Ta | W | |

|---|---|---|---|---|---|---|---|---|---|

| MC | Mass fraction% | 1.69 | 0.21 | 0.12 | 10.83 | 9.38 | - | 75.88 | 20.24 |

| Atom fraction% | 1.82 | 0.23 | 0.15 | 14.39 | 49.72 | - | 26.69 | 7.01 | |

| M3B2 | Mass fraction% | 4.54 | 3.08 | 1.54 | 2.45 | - | 4.73 | 44.45 | 37.22 |

| Atom fraction% | 4.88 | 4.74 | 2.67 | 4.62 | - | 39.54 | 22.69 | 18.78 |

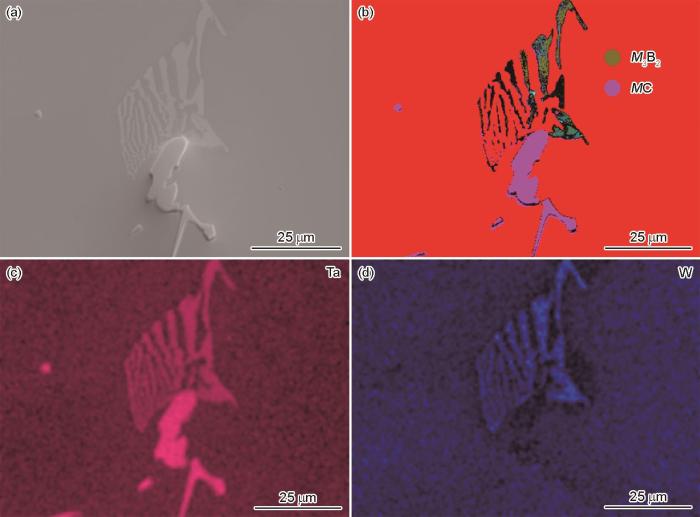

图3

图3

铸态组织EBSD相的鉴别

Fig.3

Phase identification of as-cast microstructure with EBSD (a) SEM image, (b) M3B2 phase identification, (c-d) M3B2 EDS mapping

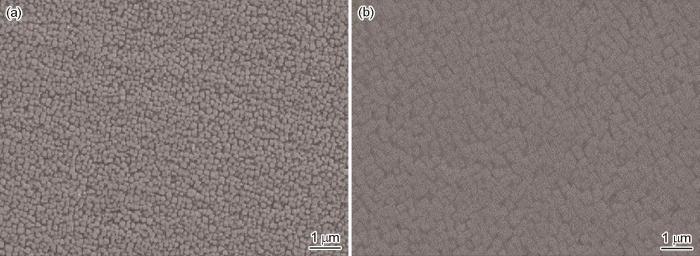

图4给出了铸态合金中枝晶干和枝晶间区域γʹ相的形貌。在铸态高温合金的凝固过程中出现的成分微观偏析使枝晶干和枝晶间析出的γʹ相形状不规则和大小不均匀,枝晶干中的γʹ相尺寸(133 nm)明显小于枝晶间的γʹ相尺寸(232 nm)。

图4

图4

铸态合金中枝晶干和枝晶间区域γʹ相的形貌

Fig.4

SEM images of γʹ precipitates in as-cast alloy (a) dendritic core area, (b) interdendritic area

2.2 热处理对合金组织的影响

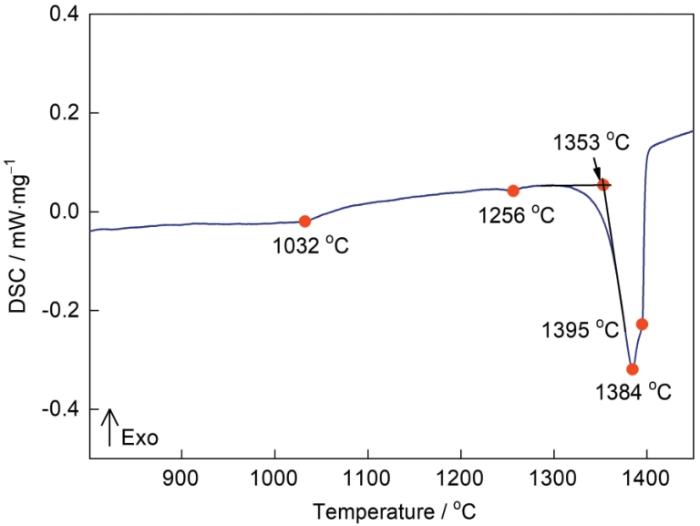

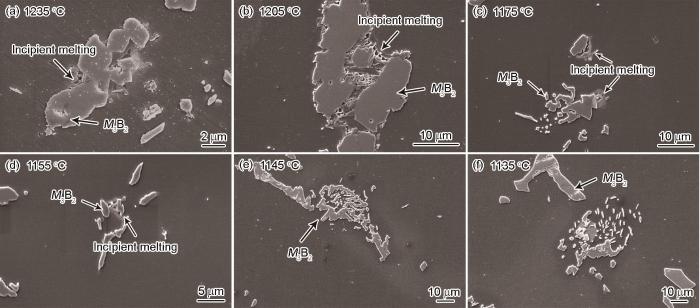

为了使合金中的有害相回溶和提高合金化学均匀性,对合金进行了固溶处理。固溶处理温度高于γʹ相的固溶温度并尽量接近且低于初熔温度。根据铸态合金的DSC升温曲线(图5)得到合金的初熔温度为1256 ℃。在DSC测试时须达到一定的相变量才能检测出吸放热峰,因此用金相法进一步确定合金的初熔温度。在1256 ℃以下选取6个温度点(1235、1205、1175、1155、1145和1135 ℃)进行初熔实验。初熔实验后合金的金相组织在图6中给出。可以看出,在1135 ℃和1145 ℃试样没有发生初熔,而温度高于1155 ℃时合金发生了明显的初熔。在试样枝晶间M3B2相附近的区域出现了熔池,且温度越高合金中出现的熔池越多。因此,结合DSC曲线和金相法显微组织确定了该合金的初熔温度为1145~1155 ℃。为了不使合金发生初熔并考虑到热处理炉内温度的波动,确定合金的固溶处理温度为1120 ℃。

图5

图6

图6

在不同温度初熔后合金的SEM图像

Fig.6

SEM images of incipient melting at different temperatures (a) 1235 oC, (b) 1205 oC, (c) 1175 oC, (d) 1155 oC, (e) 1145 oC, (f) 1135 oC

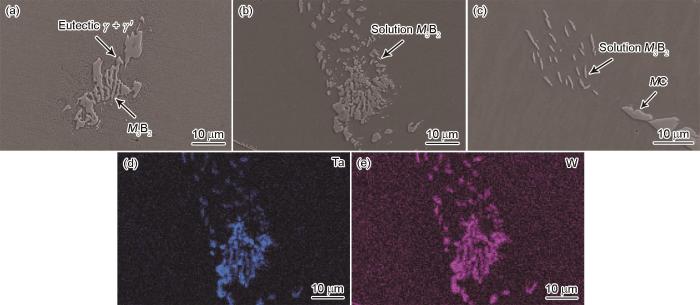

图7

图7

合金的铸态组织、1120 ℃/3 h固溶处理后的组织以及1120 ℃/6 h固溶处理后的组织

Fig.7

SEM micrographs of as-cast alloy (a), the heat-treated microstructure after solutioned at 1120 oC for 3 h (b) and the heat-treated microstructure after solutioned at 1120 oC for 6 h (c)

图8

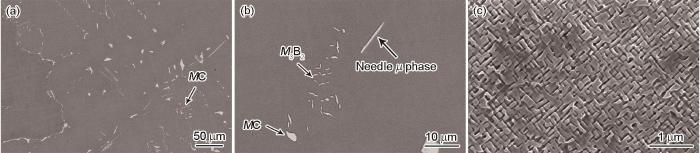

图9

图9

完全热处理后合金的组织

Fig.9

Microstructure of heat-treatment alloy (a) low magnification SEM image, (b) high magnification SEM image, (c) γʹ precipitates

2.3 铸态和热处理态合金不同温度下的拉伸性能

不同状态合金在不同条件下拉伸的力学性能参数,列于表2。可以看出,与铸态合金相比,热处理态合金的室温拉伸屈服强度由690 MPa下降到576 MPa,拉伸强度由999 MPa下降到884 MPa,但是塑性略有提高;在950 ℃高温拉伸,热处理态合金的屈服强度没有明显的变化,拉伸强度由471 MPa提高到497 MPa,延伸率和断面收缩率有一定程度的提高。上述结果表明,热处理在一定程度上提高了合金的高温性能。热处理态合金室温强度的降低,可能与热处理后析出的针状μ相有关。热处理态合金高温强度的提高,可能与热处理后枝晶间低熔点的共晶和M3B2硼化物回溶有关。后文拉伸断口纵截面的组织,证实了这一推测。

表2 不同状态合金在不同拉伸条件下的力学性能

Table 2

| Alloy | Temperature / oC | Rp0.2 / MPa | Rm / MPa | A / % | Z / % |

|---|---|---|---|---|---|

| As-cast | RT | 690 | 999 | 8.5 | 16 |

| Heat-treatment | RT | 576 | 884 | 9.0 | 17 |

| As-cast | 950 | 362 | 471 | 8.0 | 16 |

| Heat-treatment | 950 | 367 | 497 | 10.0 | 35 |

2.4 铸态和热处理态合金不同温度下的拉伸断裂组织

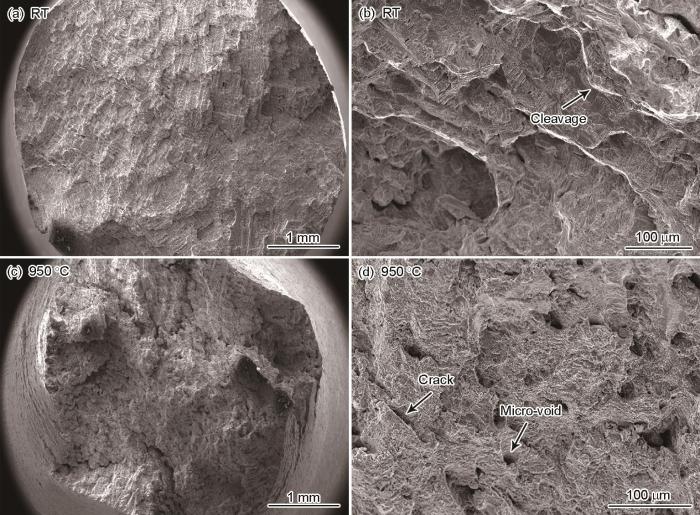

图10

图10

铸态合金在不同温度拉伸断口的形貌

Fig.10

Tensile fracture surface morphologies of as-cast alloy at different temperatures (a) low magnification micromorphology at RT, (b) high magnification micromorphology at RT, (c) low magnification micromorphology at 950 oC, (d) high magnification micromorphology at 950 oC

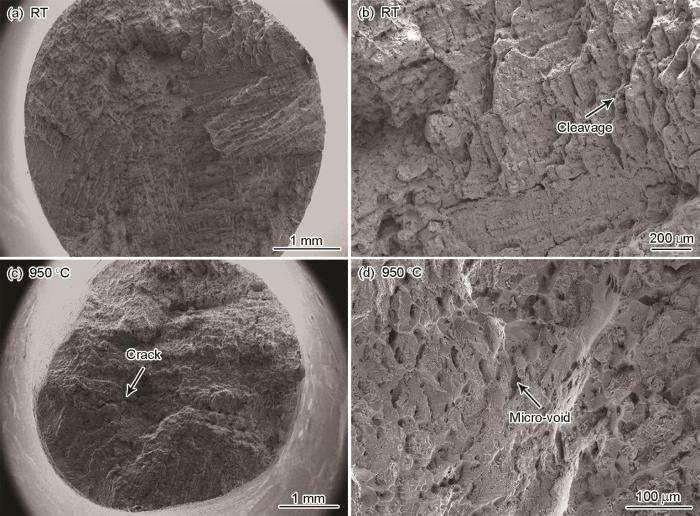

图11

图11

合金在不同温度热处理态的拉伸断口形貌

Fig.11

Tensile fracture surface morphologies of heat-treatment alloy at different temperatures (a) low magnification micromorphology at RT, (b) high magnification micromorphology at RT, (c) low magnification micromorphology at 950 oC, (d) high magnification micromorphology at 950 oC

图12

图12

铸态合金在不同温度拉伸断裂后近断口区域的纵截面形貌

Fig.12

Microstructure of the longitudinal section near the fracture after tensile rupture to fracture of as-cast alloy at different temperatures (a~c) RT, (d~f) 950 oC

热处理态合金在室温和950 ℃高温条件下拉伸断裂后,近断口区域的纵截面组织如图13所示。从图13a~c可见,热处理合金的室温拉伸断口组织与铸态合金相似。在拉伸应力作用下,枝晶间MC碳化物、未回溶的硼化物和μ相发生撕裂。因此,热处理态合金在室温拉伸期间的薄弱区域为MC碳化物、少量未回溶的硼化物和热处理后析出的少量μ相。这些结果与表2中热处理后室温强度下降的结果一致。与铸态合金相比,热处理后析出的μ相是室温拉伸裂纹的扩展源[25]。前文的合金组织特征表明,硼化物在铸态合金的枝晶间大量聚集,而热处理后大部分硼化物回溶。因此,与铸态合金相比,热处理态合金高温拉伸时裂纹减少(图13d~f)。热处理态合金高温拉伸的薄弱区域,是MC碳化物和少量未回溶的硼化物。

图13

图13

热处理态合金在不同温度拉伸断裂后近断口区域纵截面的形貌

Fig.13

Microstructure of the longitudinal section near the fracture after tensile rupture to fracture of heat-treatment alloy at different temperatures (a~c) RT, (d~f) 950 oC

3 结论

(1) 钴基高温合金Co-15Ni-4Al-15W-5Cr-5Ta-1Ti-0.15C-0.024B-0.02Zr的铸态组织包含γ基体、γʹ相、MC碳化物以及聚集在枝晶间区域的γ/γʹ共晶和M3B2相;铸态合金的γʹ相形状不规则,大小不均匀,其中枝晶干区域的γʹ相尺寸为133 nm,枝晶间区域的γʹ相尺寸为232 nm;铸态合金固溶处理后共晶完全消除,γʹ强化相溶解,M3B2相基本回溶,时效处理后合金基体中重新析出尺寸均匀的γʹ相,并析出少量针状μ相。

(2) 与铸态合金相比,热处理态合金的室温拉伸强度下降,塑性略有提高,而高温拉伸强度和塑性提高。

(3) 这种合金铸态和热处理态的室温拉伸断裂机制均为以解离断裂特征为主的脆性断裂,高温拉伸断裂机制均为微孔聚集性的韧性断裂;铸态合金的室温拉伸裂纹萌生源为块状、骨架状及短棒状MC碳化物,而高温拉伸的裂纹萌生源为硼化物;热处理态合金在室温拉伸期间的薄弱区域为MC碳化物、少量未回溶的硼化物及热处理后析出的少量μ相,而高温拉伸期间的薄弱区域为MC碳化物及少量未回溶的硼化物。

参考文献

Overview of mechanical, microstructural, oxidation properties and high-temperature applications of superalloys

[J].

A review on machining of high temperature aeronautics super-alloys using WEDM

[J].

High-temperature oxidation behavior of a novel Co-base superalloy

[J].

CoNi-base superalloys with improved high temperature properties and 3D printability

[D].

Cobalt-base high-temperature alloys

[J].We have identified cobalt-base superalloys showing a high-temperature strength greater than those of conventional nickel-base superalloys. The cobalt-base alloys are strengthened by a ternary compound with the L1(2) structure, gamma' Co3(Al,W), which precipitates in the disordered gamma face-centered cubic cobalt matrix with high coherency and with high melting points. We also identified a ternary compound, gamma' Ir3(Al,W), with the L1(2) structure, which suggests that the Co-Ir-Al-W-base systems with gamma+gamma' (Co,Ir)3(Al,W) structures offer great promise as candidates for next-generation high-temperature materials.

Phase equilibria and microstructure on γʹ phase in Co-Ni-Al-W system

[J].

Microstructure and creep strength of different γ/γʹ-strengthened Co-base superalloy variants

[J].

Directional coalescence of γ' precipitates during long time aging of CoNiAlW superalloy

[J].

On the grain boundary strengthening effect of boron in γ/γ′ Cobalt-base superalloys

[J].

Investigation of effect mechanism of hafnium and zirconium in high temperature materials

[J].

Hf和Zr在高温材料中作用机理研究

[J].

在高温合金中,元素Hf和Zr可以促进γ+γ′共晶、MC(2)碳化物、M2SC碳硫化物和Ni5M相的形成,改变草书状MC和M3B2成为块状并且通过净化晶界或枝晶间自由态的S来提高这些薄弱部位的结合强度,从而延迟裂纹的形成和扩展。Hf和Zr可提高铸造高温合金室温拉伸和中温持久的强度和塑性。Hf,Zr抑制次生碳化物M23C6和M6C的生成,从而提高了合金在高温长时热暴露时的显微组织稳定性。Hf,Zr降低合金的初熔温度,Ni5Hf和Ni5Zr相的初熔被认为是Hf,Zr影响初熔的主要原因。通过1150℃/8h的预处理,Ni5Hf以Ni5Hf+γ(C)→MC(2)+γ反应或者固溶两种方式被消除。元素Hf可以缩小枝晶间失去毛细管补缩能力和固相线之间的温度范围,还能降低枝晶间液池沟通所需的液体量。在凝固后期枝晶间的富Hf熔体具有很好的流动性、浸润性和趋肤效应,这些都是降低合金热裂倾向、提高合金可铸性和焊接性能的有利因素。具有高的化学活性的富Hf液膜容易在铸件表面形成Hf2O薄层。Hf和Zr是钎焊用中间层合金的降熔点元素。根据凝固过程中富Hf,Zr熔体的成分最终发展出Ni-18.6Co-4.5Cr-4.7W-25.6Hf和Ni-10Co-8Cr-4W-13Zr两种中间层合金,使单晶高温合金的无Si、B连接成为现实。还发展出了定向凝固片状Ni3Al/Ni7Hf2共晶合金,成分为Ni-5.8Al-32Hf和Ni-4Al-26Hf-8Cr-4W。Ni-5.8Al-32Hf合金的最佳凝固条件为温度梯度G=250℃·cm-1和凝固生长速率R=5μm.s-1;Ni-4Al-26Hf-8Cr-4W,凝固条件为G=350℃·cm-1和R=1μm·s-1。

Alloying effects in polycrystalline γʹ strengthened Co-Al-W base alloys

[J].

New generation thermal barrier coatings for ultrahigh temperature applications

[J].

新一代超高温热障涂层研究

[J].

Study of tensile fracture mechanisms of a Ni-base superalloy supercast 247A

[J].

Effects of precipitated phases on the crack propagation behaviour of a Ni-based superalloy

[J].

Thermodynamic study on equilibrium precipitation phases in a novel Ni-Co base superalloy

[J].<p>Thermodynamic properties of the traditional U720Li alloy and the new Ni-Co base superalloy have been studied using JMatPro and the latest relevant database for Ni base superalloys. The effects of chemical composition on the equilibrium precipitation phases, process-ability and <em>γ</em>/<em>γ</em>' mismatch have been analyzed. It is found that the <em>γ</em>/<em>γ</em>' mismatch increases with the increase of Ti/Al (atomic ratio). The volume fraction of <em>γ</em>' is proportional to the Ti+Al contents (atomic fraction). Therefore, by increasing the Ti/Al ratio and Ti+Al content, the yield strength of alloys can be improved. On the other hand, the <em>γ</em>' solvus temperature decreases by Co additions. As a result, the range of processing temperature is extended. The <em>γ</em>/<em>γ</em>' mismatch also increases with Co additions, which adds additional strengthening to the alloy. Moreover, high Ti/Al ratio or low Co content promotes the precipitation of <em>η</em> phase. Thus, Ni-Co base superalloys with high Ti+Al content, Ti/Al ratio and Co content bear an improved strength, phase stabilities and process-ability.</p>

新型Ni-Co基高温合金中平衡析出相的热力学研究

[J].

Thermodynamics calculation and analysis of oxide inclusion formation in single crystal superalloy DD6

[J].Calculation and analysis on the thermodynamics conditions for the formation of oxide inclusion during the vacuum induction melting of Ni-based single crystal superalloy DD6 have been carried out by using Thermo-calc thermodynamics software and JMatPro analysis software. The results show that the main oxide inclusion is Al<sub>2</sub>O<sub>3</sub>. Under the thermodynamic equilibrium state, the value of oxygen activity during the melting and solidification stages is within (3.21-14.0)×10<sup>-7</sup> and (1.63-4.89)×10<sup>-8</sup>. It will cause increasing oxygen in the molten liquid and the formation of Al<sub>2</sub>O<sub>3</sub> inclusion by using CaO crucible when the vacuum level is 0.1Pa. In order to make the content of Al<sub>2</sub>O<sub>3</sub> inclusion reduce to less than 10×10<sup>-6</sup>, it is necessary to control oxygen content below 4.709×10<sup>-6</sup> before alloying treatment.

DD6 单晶高温合金氧化物夹杂形成的热力学计算及分析

[J].

Estimation of the effect of hafnium on equilibrium phases in FGH97 PM superalloy

[J].

铪对FGH97合金平衡相影响的评估

[J].

Modelling of the thermo-physical and physical properties for solidification of Ni-based superalloys

[J].

K.Z., Li X,

et al. Using JMatPro to model materials properties and behavior [J].

Thermodynamic simulation calculation of Co-8.8Al-9.8W alloy with different B content based on JMatPro software

[J].

基于JMatPro软件不同B含量下Co-8

.8Al-9.8W合金析出相的热力学模拟计算 [J].

Phase composition and cracking behavior on TIG cladding layer of Co-8.8Al-9.8W-0.2B superalloy based on JMatPro software

[J].

基于JMatPro软件TIG堆焊层Co-8.8Al-9.8W-0.2B合金的相组成及开裂行为

[J].

Effects of Mo on the evolution of microstructures and mechanical properties in Co-Al-W base superalloys

[J].

Phase-field simulation of γʹ coarsening behavior in cobalt-based superalloy

[J].

Effect of hafnium on the structure and properties of nickel alloys

[J].

High temperature tensile properties of a series of nickel-base superalloys on a γ/γ′ tie line

[J].

Room temperature tensile behaviour of K640S Co-based superalloy

[J].

Carbides evolution and mechanical behavior of Co-Cr-Nb-W wear-resistance alloy

[J].

Co-Cr-Nb-W合金碳化物组织转变及力学性能研究

[J].

Influence of type and morphology of carbides on stress-rupture behavior of a cast cobalt-base superalloy

[J].