将杂环引入对位芳纶结构,成为具有独特分子结构的芳纶Ⅲ。芳纶Ⅲ具有低密度、超高强度、超高模量、耐高温、高抗冲击性和耐磨性以及高透波性等性能[1~5],有广阔的应用前景[6~12]。芳纶的结晶度高、表面光滑、化学惰性强,使芳纶增强复合材料(AFRP)的纤维与树脂之间界面的粘结强度低。为了提高纤维与树脂之间的界面粘结强度,可将纤维表面改性:引入化学活性基团或改变表面的微观形貌,以增强纤维与树脂之间的相互作用[13~15]。常用的纤维表面改性方法有物理方法和化学方法。化学改性有化学氧化[16]、化学接枝[17]、偶联剂改性[18]等方法。Rodríguez-Uicab等[19,20]使用硝酸、硫酸的混合物和氯磺酸处理芳纶,在芳纶纤维表面产生氧化刻蚀,提高了纤维表面的粗糙度和含氧基团的含量以及纤维与氧化碳纳米管涂层之间的相互作用;Cheng等[21]将PBIA纤维表面氟化生成C-F为亲核取代的活性位点,借助硅烷偶联剂接枝引入胺基和环氧基团。改性后的PBIA纤维与环氧树脂之间的IFSS值分别提高了46.7%和40.0%。将物理方法与化学方法相结合,也能提高纤维表面活性和粗糙度。Gong等[22]在芳纶纤维表面涂覆了一层聚多巴胺并将天然环氧橡胶接枝在涂层上,使复合处理后的芳纶纤维与橡胶的之间界面强度提高了37% (达到86.17 MPa)。

1 实验方法

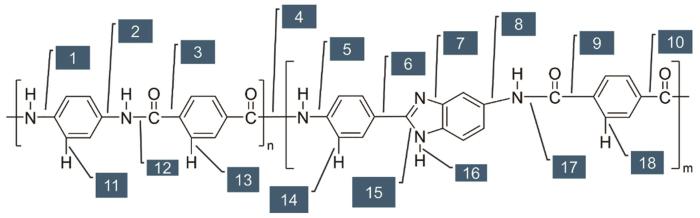

实验用材料有:芳纶Ⅲ纤维(F-368,不含上浆剂,其分子结构如图1所示)、树脂基体环氧树脂(L285)和固化剂(L287)。

图1

芳Ⅲ/环氧复合材料的制备和测试,如图2所示。等离子体处理前先将纤维进行预处理。将纤维束缠绕在光滑洁净的玻璃框上,放置在容器中。去除纤维表面灰尘和有机污染物:加入丙酮溶液至浸没纤维,静置24 h后用去离子水洗涤并浸泡24 h。将纤维取出后放在100 ℃烘箱中烘烤3 h以使纤维充分干燥,最后用真空袋密封。

图2

用射频13.56 MHz电感耦合等离子体(Inductively Coupled Plasma, ICP)激发等离子体,处理芳Ⅲ纤维。放电介质:氩气;放电功率:200 W;工作气压:30 Pa;处理时间:0、5、10、15、20、25、30 min,共七组样品。

用型号为Thermo Fisher Scientific-ESCALAB 250 Xi的XPS仪测试芳Ⅲ表面元素组成和表面官能团。用型号为BRUKER Dimension Icon的AFM观察芳Ⅲ纤维表面的形貌和粗糙度。用型号为ZQ980B的电子万能材料试验机依照GB/T 31290-2022标准测试芳Ⅲ纤维单丝拉伸强度。试样标距25 mm,拉伸速率5 mm/min,每组样品测试取35组有效数据,单丝拉伸强度为

式中

式中

表1 水和二碘甲烷的表面能

Table 1

| Liquid | |||

|---|---|---|---|

| Water | 72.3 | 53.6 | 18.7 |

| Diiodomethane | 50 | 2.6 | 47.4 |

用微滴脱粘方法测试芳Ⅲ/环氧复合材料的界面剪切强度。将环氧树脂(L285)和环氧固化剂(L287)以100∶40混合后在室温下固化48 h制得成树脂滴。用电子万能材料试验机测试芳Ⅲ单根纤维与环氧树脂滴之间界面脱粘力,挡板运动速率为0.5 mm/min,每组样品测试10组有效数据,界面剪切强度(IFSS)为

式中

2 结果和分析

2.1 等离子体处理对芳III纤维表面化学组成的影响

氩气等离子体处理会破坏纤维表面较弱的化学键产生新的反应位点,接枝引入一些活性基团改变了纤维表面的化学性质。图3给出了芳Ⅲ的XPS全扫描图像和元素含量。可以看出,芳Ⅲ原丝表面由C、N、O三种元素组成,占比分别为81.24%、5.97%、12.79%。氩气等离子体处理5 min使占比明显变化,纤维表面的N、O的占比分别提高到9.71%和17.41%,C的占比降低到72.88%。延长处理时间到15 min、20 min时,N含量分别提高到12.34%和12.22%,O含量分别为18.28%和18.32%。由此可以推断,在氩气等离子体处理过程中打破了纤维表面的化学键引入了一些含N和含O的活性基团。引入的含O基团,比含N基团更容易饱和。

图3

图3

氩气等离子体处理后芳Ⅲ的XPS全谱扫描结果

Fig.3

XPS survey scans of AF-Ⅲ treated for different time by argon plasma

(a) Scanning images (b) Content and proportion of elements

图4

图4

氩气等离子体处理后芳Ⅲ的C1s分峰谱

Fig.4

C1s spectra of AF-Ⅲ treated for different time by argon plasma

(a) 0 min (b) 5 min (c) 10 min (d) 15 min (e) 20 min (f) 25 min (g) 30 min (h) Changes in functional group content

随着处理时间的延长―C―C―的含量持续降低,处理15 min、20 min时分别降低到61.38%、55.33%,等离子体处理20 min时―C―N―、―C―O―、―C=O和―COO―的含量分别提高到17.87%、7.77%、11.35%、7.68%。―C―C―含量的降低和C―O、COO的生成,表明氩气等离子体可能使纤维表面的―C―C―受到破坏,接枝等离子体中的自由基形成新的活性基团使纤维的稳定性和表面惰性降低,化学活性提高。这一系列的变化,有助于提高纤维表面的浸润性能和增强纤维与基体的反应能力,使界面强度提高。

但是,等离子体处理的时间过长,可能破坏接枝的活性基团。等离子体处理25 min、30 min的XPS结果表明,N、O原子及其官能团含量比等离子体处理20 min时略微降低。同时,等离子体处理5~20 min的接枝效果也并不完全是逐渐增强的。等离子体处理10 min时,N、O原子及其官能团的含量比处理5 min明显降低,其原因可能是发生了H转移,芳Ⅲ中较弱的C-H、N-H断裂形成的H⋅转移占据了N、O活性基团的接枝位点,发生了反应。

图5给出了对N1s的分峰结果。可以看出,芳Ⅲ原丝的N1s只有两个潜在的峰,分别归属于389.3 eV处的N杂环(―N=C/N―C)和连接苯环的―NH―CO(400 eV)。等离子体处理对―NH―CO的破坏使其整体浓度降低,等离子体处理5 min其浓度由84.1%降低至73.49%并在401.4 eV处生成了新的基团―NH2,而N杂环得益于其稳定的结构,―N=C/N―C的占比并没有特殊的变化。这表明,等离子体处理后的纤维表面含N官能团中仅有―NH―CO的稳定性降低并生成―NH2。同时,在等离子体处理20~30 min的纤维表面,―NH―CO的含量随处理时间的延长有一定程度的回升,可能是部分游离的⋅NH2与断键后的⋅C=O重新结合所致。

图5

图5

氩气等离子体处理后芳Ⅲ表面N1s分峰谱

Fig.5

N1s spectra of AF-Ⅲ treated for different time by argon plasma

(a) 0 min (b) 5 min (c) 10 min (d) 15 min (e) 20 min (f) 25 min (g) 30 min (h) Changes in functional group content

图6给出了对O1s的分峰结果。可以看出,未处理的芳Ⅲ其O1s只有O=CNH一个潜在峰,等离子体处理后其含量降低。等离子体处理5 min其含量由100%降低到60.20%并新增了O=C―O、HO―C两种含氧基团,可能是产生的⋅OH与酰胺断键后形成⋅C=O结合,生成新的基团O=C―O或者与苯环结合形成HO―C。新生成的O=C―O和HO―C有利于提高纤维表面浸润性能和化学结合能力。三种含氧基团结合能的参考位置,分别为531.6 eV (O=CNH)、532.8 eV (O=C―O)、533.7 eV (HO―C)。

图6

图6

氩气等离子体处理后芳Ⅲ表面的O1s分峰谱

Fig.6

O1s spectra of AF-Ⅲ treated for different time by argon plasma

(a) 0 min (b) 5 min (c) 10 min (d) 15 min (e) 20 min (f) 25 min (g) 30 min (h) Changes in functional group content

2.2 等离子体处理对芳III纤维表面形貌的影响

图7从纤维表面的二维、三维图像、起伏线和粗糙度Ra、Rq值显示了氩气等离子体的物理刻蚀作用。可以看出,短时间的等离子体刻蚀最多作用于纤维表面几百纳米深。与原丝光滑的表面相比,等离子体处理后的纤维表面凹凸不平,使粗糙度提高。等离子体处理5 min的纤维表面出现细长的褶皱,大幅度增加了纤维表面的表面积;等离子体处理10 min的纤维表面形貌变化最显著,因刻蚀产生的沟槽高低落差达到50 nm;延长等离子体处理时间使等离子体刻蚀逐渐均匀和沟槽深度变浅,直至处理20 min时(图e)在纤维表面形成密集的点状刻蚀,刻蚀深度减小到5 nm;等离子体处理25 min、30 min时,纤维表面的刻蚀又出现加深的趋势。刻蚀痕迹的变化,表明随着氩气等离子体处理时间的延长芳Ⅲ纤维的表面形貌呈周期性变化。

图7

图7

氩气等离子体处理后芳Ⅲ的AFM

Fig.7

AFM results of AF-III treated for different time by argon plasma

(a) 0 min (b) 5 min (c) 10 min (d) 15 min (e) 20 min (f) 25 min (g) 30 min (h) Ra (i) Rq

2.3 等离子体处理对芳III纤维力学性能的影响

单根纤维的拉伸强度分布较为分散,为了研究等离子体处理的影响,采用双参数威布尔分布(图8a)和算数平均值(图8b)表征芳Ⅲ的单丝拉伸强度。结果表明:芳Ⅲ纤维拉伸强度随等离子体处理时间的增加而缓慢降低。芳Ⅲ原丝拉伸强度的平均值为5.06 GPa,等离子体处理5 min拉伸强度略降至4.90 GPa (降低了约3%)。等离子体处理10~20 min纤维的拉伸强度逐渐降低,先后降低到4.75 GPa、4.62 GPa、4.60 GPa,下降最多的约9%,等离子体处理25 min和30 min的纤维损伤较严重,拉伸强度分别降低到4.35 GPa和4.21 GPa,降低了约15%。等离子体处理纤维虽然大幅度提高其表面的润湿性能,但是也破坏了其稳定的化学结构,影响了分子链的排列和取向。同时,纤维表面的刻蚀沟槽可能使纤维在拉伸时应力分布不均匀而使纤维断裂的概率提高。因此,等离子体处理时间不应过长。长时间的刻蚀弱化纤维高强度的优势,不利于复合材料性能的发挥。

图8

图8

氩气等离子体处理不同时间后芳Ⅲ的拉伸强度

Fig.8

Tensile strength of AF-Ⅲ treated for different time by argon plasma

(a) Weibull (b) Average

2.4 等离子体处理对表面润湿性能的影响

纤维表面的润湿性能与表面能密切相关,表面能越高纤维表面润湿性能越强,树脂越容易浸润纤维形成稳定牢固的界面。由图9b可见,氩气等离子体处理5 min的芳Ⅲ其润湿性极大地提高,表面能达到68.52 mJ/m2,比原丝的46.14 mJ/m2,提高了48.50%。在此过程中极性分量起主导作用,从图9a可见芳Ⅲ对水的接触角由原丝的71.93°急剧降低至26.57°,但是对二碘甲烷的接触角变化并不明显。对水的接触角受多方面因素的影响。极性官能团含量和表面形貌都影响接触角,氩气等离子体处理不仅提高纤维表面的C―O、C=O、COOH、―NH2亲水基团的含量,也刻蚀纤维表面增大液体对纤维的润湿面积,从物理、化学两方面提高芳Ⅲ表面的润湿性。但是,随着等离子体处理时间的增加水的接触角和芳Ⅲ的表面能的变化趋势与表面粗糙度的变化趋势一致。这表明,对于提高芳Ⅲ表面润湿性能,与化学作用相比,氩气等离子体处理的物理刻蚀对提高纤维表面的润湿性能更为重要。

图9

图9

氩气等离子体处理后芳Ⅲ 的动态接触角和表面能

Fig.9

Surface wettability of AF-Ⅲ treated for different time by argon plasma

(a) Dynamic contact angle (b) Surface energy

2.5 等离子体处理时间对芳Ⅲ/环氧界面的影响

微滴脱粘的界面剪切强度(IFSS)计算公式表明,环氧树脂滴的大小不影响界面剪切强度的结果。为了验证微滴脱粘实验设计的可靠性,使用长度为200~500 μm的环氧微滴测试并观察结果分布,如图10a所示。不同尺寸的微滴脱粘力呈线性分布,对其进行线性回归拟合(拟合优度R2为0.96),结果表明斜率IFSS的测试结果稳定,实验可靠。图10b给出了芳Ⅲ经氩气等离子体处理不同时间后与环氧树脂滴之间IFSS的变化。未经等离子体处理样品的IFSS只有28.51 MPa,氩气等离子体处理使界面强度显著提高。随着处理时间的增加IFSS呈现先增加后降低的趋势,等离子体处理5 min的样品,IFSS的提高较少,为34.85 MPa,仅提高了22.24%,其原因可能是处理时间短,处理不均匀;等离子体处理10 min的IFSS为38.02 MPa,提高了33.36%,此时等离子体的改性效果基本达到最佳。延长处理时间,等离子体处理处理15 min和20 min的IFSS比等离子体处理10 min的提高不足1 MPa,等离子体处理25 min和30 min的IFSS值反而降低,分别为36.15 MPa和36.56 MPa。

图10

图10

微滴脱粘

Fig.10

Microdroplet debonding

(a) Effect of microdroplet length (b) IFSS (c) Stress-strain curve (d) Failure stage

图10c给出了纤维经等离子体处理纤维不同时间后300 μm的环氧微滴的脱粘曲线,应力-应变下的面积为微滴脱粘消耗的能量。等离子体处理后的样品脱粘时,纤维与树脂之间的界面结合力增加,树脂滴从纤维上脱粘耗散更多的能量,并且脱粘过程伴随的纤维拉伸变形使脱粘曲线中的应变距离远大于300 μm。同时,微滴脱粘是一个循序渐进的过程,界面损伤演化的不同阶段能量耗散的速率也有所变化。图10d中的脱粘曲线出现两个较为明显的拐点,由此可将界面损伤分为五个阶段。第一阶段,界面弹性响应,微滴脱粘消耗的能量使纤维和微滴变形,而界面没有任何损伤;第二阶段,在微滴弯月面处裂纹成核、萌生,界面损伤由此开始;第三阶段,微裂纹沿纤维轴向在界面区域扩展,界面损伤开始演化扩展;第四阶段,微裂纹贯穿整个微滴,界面处于脱粘前的临界状态;第五阶段,界面发生脱粘,载荷快速下降[35,36]。

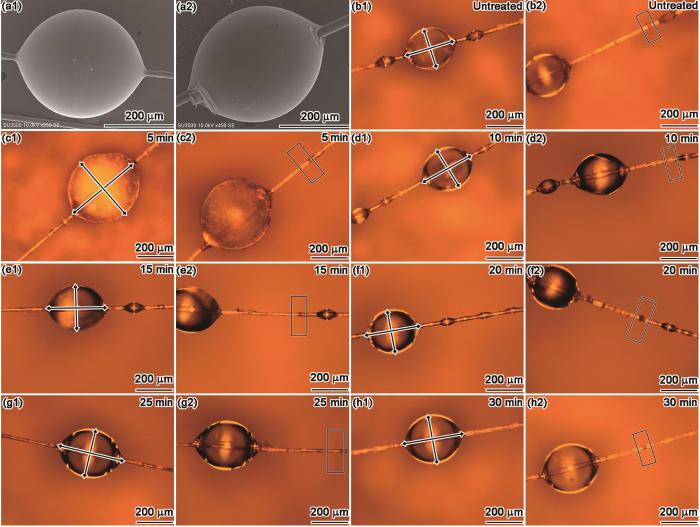

氩气等离子体处理纤维不同时间后,芳Ⅲ/环氧微滴脱粘前后的图像如图11所示,其中a1~h1为脱粘前的树脂微滴。可以看出,环氧微滴的形状近似椭圆,实验前测量微滴的长、短径并计算其比值。结果表明,在等离子体处理不同时间后的纤维上制得的树脂滴形状较为均匀,长、短径之比约为1.3,保持不变。这表明,等离子体处理纤维的时间对制得的树脂滴的形状影响不大。

图11

图11

芳Ⅲ/环氧微滴脱粘显微镜照片

Fig.11

Microscope images of AF-Ⅲ/epoxy treated for different time by argon plasma (a1~g1) before microdroplet debonding (a2~g2) after microdroplet debonding

图12

图12

微滴脱粘前后芳Ⅲ的SEM图像

Fig.12

SEM images of AF-Ⅲ treated for different time by argon plasma (a1~g1) before microdroplet debonding (a2~g2) after microdroplet debonding

氩气等离子体处理纤维不同时间后微滴脱粘前后芳Ⅲ纤维表面的形貌,如图12所示。图12a1~g1给出了氩气等离子体处理对芳Ⅲ表面形貌的影响。芳Ⅲ原丝的表面光滑均匀,氩气等离子体处理后纤维表面出现刻蚀沟槽和凸起。等离子体处理5 min (图12b1)沟槽细小短浅,数量少、不均匀散乱;处理30 min (图12g1)沟槽数量增多,深度长度增加,互相连成一片。虽然这些沟槽可能被视为纤维的缺陷而影响其拉伸性能,但也会增加树脂基体的润湿周长,有利于界面结合。等离子体处理10 min纤维表面形貌起伏较大(图12c1),对纤维树脂两相之间形成机械互锁提高界面强度有关键作用。此外,等离子体处理15 min(图12d1)和20 min(图12e1)后纤维表面起皮,期原因可能是纤维具有“皮芯”结构,而等离子体作用产生的凸起部分在高能粒子更高频率的碰撞刻蚀下逐渐被“清洗”脱落,从而显露出更加平整光滑的新表面。延长处理时间将加深刻蚀,进入下一个周期的循环。

图12a2~g2给出了氩气等离子体处理纤维不同时间后芳Ⅲ/环氧的界面结合。未经等离子体处理的纤维与树脂间存在明显空隙,难以形成牢固界面;经过氩气等离子体处理后(除了等离子体处理10 min的样品可能由于极性基团含量较少导致界面结合较差外),纤维和树脂结合紧密,界面结合良好。另外,虽然等离子体处理10 min的界面结合较差,但是凹凸不平的纤维表面形成机械互锁使其IFSS仍然较高。

图12a3~g3给出了氩气等离子体处理不同时间芳Ⅲ脱粘后纤维表面环氧树脂的残留。未经等离子体处理的样品脱粘后纤维表面光滑,此时为粘结失效,脱粘力小,脱粘时耗散较少的能量;氩气等离子体处理的样品脱粘后,芳Ⅲ表面因树脂残留变得不平整,此为内聚力失效,脱粘力大,脱粘耗散了较多的能量。界面强度(IFSS)较高的样品脱粘时失效发生在树脂内部,裂纹在树脂内部较深处沿着纤维轴向曲折扩展,较大的耗散能量使脱粘后的纤维表面被厚厚的树脂层覆盖,如图12d3、e3所示;界面强度(IFSS)稍弱的样品脱粘时失效也发生在树脂内部,裂纹在树脂内较浅处沿着纤维轴向曲折扩展,残留较薄的树脂层,如图12c3、f3、g3所示;界面强度(IFSS)更弱的样品脱粘时,失效发生在纤维和树脂之间的界面处,裂纹沿着界面扩展,只残留少量树脂,如图12b3所示。

2.6 对机理的分析

图13

图13

计算芳Ⅲ中解离能的化学键位置

Fig.13

Positions in AF-Ⅲ where dissociation energy need to be calculated

表2 芳Ⅲ的解离能

Table 2

| Number | Chemical bond | Bond energy |

|---|---|---|

| 1 | C―N | 467.49 |

| 2 | C―N | 466.09 |

| 3 | C―C | 412.94 |

| 4 | C―N | 335.89 |

| 5 | C―N | 458.13 |

| 6 | C―C | 517.59 |

| 7 | C―N | 859.41 |

| 8 | C―N | 436.38 |

| 9 | C―C | 410.09 |

| 10 | C―C | 426.14 |

| 11 | C―H | 492.79 |

| 12 | C―N | 331.08 |

| 13 | C―H | 501.19 |

| 14 | C―H | 488.76 |

| 15 | C―N | 802.54 |

| 16 | N―H | 384.53 |

| 17 | C―N | 342.76 |

| 18 | C―H | 501.96 |

图14

图14

氩气等离子体处理芳Ⅲ时可能发生的反应

Fig.14

Possible reactions of AF-Ⅲ treated after argon plasma

3 结论

(1) 用氩气等离子体处理芳Ⅲ纤维,适当的处理时间能大幅度增加纤维表面极性基团含量、粗糙度以及润湿性能,芳Ⅲ的润湿性能与其表面粗糙度密切相关。增加极性基团含量可使芳Ⅲ和环氧微滴之间结合的更加紧密,凹凸不平的表面可增强两者之间的机械互锁。随着处理时间的增加,芳Ⅲ的单丝拉伸性能缓慢降低,IFSS先增加后降低。氩气等离子体处理使芳Ⅲ/环氧的界面失效模式由粘接失效向内聚力失效转变。

(2) 氩气等离子体处理芳Ⅲ,纤维的表面粗糙度随着处理时间的延长具有周期性。在等离子体处理过程中,纤维表面的刻蚀效果与纤维的“皮-芯”结构密切相关。

(3) 氩气等离子体处理芳Ⅲ有4种可供接枝的反应位点,分别为C―C、C―N、C―H、N―H断裂,接枝―OH、―NH2,―H,新生成C―O、COO和C―NH2极性基团。

参考文献

Surface and interface modification of aramid fiber and its reinforcement for polymer composites: A review

[J].

Aramid fiber with excellent interfacial properties suitable for resin composite in a wide polarity range

[J].

Assessment of F-Ⅲ and F-12 aramid fiber/epoxy interfacial adhesions based on fiber bundle specimens

[J].

Constructing a new tear-resistant skin for aramid fiber to enhance composites interfacial performance based on the interfacial shear stability

[J].

Research progress on interfacial modification technology of para-aramid fiber

[J].

对位芳纶纤维界面改性技术研究进展

[J].

Surface properties of domesic aramid fiber III modified by oxygen plasma treatment

[J].Oxygen plasma treatment was used to modify the surface of aramid fiber III. The changes of fiber surface before and after oxygen plasma treatment was investigated in this paper. The surface chemical structure, element composition, surface morphology, surface roughness and surface wettability before and after oxygen plasma treatment were analyzed by FTIR, X-ray photoelectron spectroscopy (XPS), scanning electronic microscopy (SEM), atomic force microscopy (AFM) and dynamic contact angle analysis (DCAA), respectively. It was found that oxygen plasma treatment introduced some newly polar groups such as (C-O and O-C=O) to fiber surface, the content of which were 20.1% and 8.1%, respectively. After oxygen plasma treatment, the roughness of fiber surface increased and surface grooves and ups and downs were increased obviously. It was also shown that the fiber surface wettability was improved significantly by oxygen plasma treatment. The total surface free energy increased from 49.9 mJ/m2 to 67.1 mJ/m2.

氧等离子体处理对国产芳III纤维表面性能的影响

[J].

High-performance aramids with intrinsic bactericide activity

[J].

Synthesis of heterocyclic aramid nanofibers and high performance nanopaper

[J].

High-strength, super-tough, and durable nacre-inspired MXene/heterocyclic aramid nanocomposite films for electromagnetic interference shielding and thermal management

[J].

Lightweight, robust, porous heterocyclic para-aramid aerogel hollow fibers for multifunctional applications

[J].

Carbon nanotube‐directed 7 GPa heterocyclic aramid fiber and its application in artificial muscles

[J].

Holey reduced graphene oxide scaffolded heterocyclic aramid fibers with enhanced mechanical performance

[J].

Aramid fiber coated with aramid nanofiber coating to improve its interfacial properties with polycarbonate

[J].

Enhanced interfacial strength of aramid fiber reinforced composites through adsorbed aramid nanofiber coatings

[J].Aramid fibers are well-known for their excellent tensile properties and low density but are limited in composite applications due to their inert surface which leads to poor interfacial properties. One method that has shown promise in recent years is the application of nanoscale reinforcements to the surface of the fibers to improve mechanical interaction with the matrix. With aramid fibers, it is ideal to perform an interfacial reinforcement utilizing the dense hydrogen bonding which is responsible for the fibers strength. Here, it is demonstrated that recently developed aramid nanofibers (ANFs) can adsorb onto the surface of macroscale aramid fibers to enhance the interfacial properties through mechanical interlocking with the matrix. A simple and rapid dip -coating process is used to deposit the ANFs on the aramid fiber surface. These ANFs bond with the fiber through physisorption and hydrogen bonding, yielding a 70.27% increase in interfacial shear strength and a 25.6% increase in short beam shear strength in composites prepared by dip-coating unidirectional tape into a solution of ANFs. Notably, the interfacial gains are made while fully preserving the strength of the aramid fiber following the treatment, therefore ensuring in-plane properties of the composite are maintained. This work shows that the introduction of an ANF interphase may present a novel and convenient method to improve the interfacial strength of aramid reinforced composites, enabling cost-effective and simplified production of stronger structural materials.

Enhanced interfacial bonding of AF/PEEK composite based on CNT/aramid nanofiber multiscale flexible-rigid structure

[J].The application of aramid fiber (AF)/polyetheretherketone (PEEK) composites is currently hindered by the inert surface and poor wettability of AF, resulting in weak interfacial adhesion and poor mechanical properties. Surface coating and the introduction of nanostructures have been proven to be effective approaches to address this problem. Herein, a simple hybrid sizing agent has been developed to modify the AF surface, consisting of soluble polyimide (PI) as a compatibilizer, carboxyl-functionalized carbon nanotubes (CNT-COOH) as a rigid unit, and aramid nanofibers (ANF) as a flexible component. The synergetic effects of PI and the multiscale flexible-rigid structure (CNT-COOH/ANF) contribute to the formation of chemical and physical bonds between AF and PEEK matrix, further improving the interfacial adhesion and stress transfer efficiency. Attributed to the enhanced wettability and roughness of AF, compared with unsized AF, the flexural strength (220.97 MPa), modulus (13.26 GPa), ILSS (13.36 MPa), and storage modulus (12.93 GPa) of the AF/PEEK composite increase by 132.60 %, 99.00 %, 18.97 %, and 82.70 % respectively. Additionally, the flexible-rigid nanonetwork facilitates the penetration of the PEEK resin into pore spaces. This simple and effective approach exhibits promising potential in enhancing the interfacial bonding of AF/PEEK composites.

Effect of surface treatment on the structure and properties of para-aramid fibers by phosphoric acid

[J].

Surface modification of aramid fibers by amino functionalized silane grafting to improve interfacial property of aramid fibers reinforced composite

[J].

Reinforcing effect of aramid fibers on fatigue behavior of SBR/aramid fiber composites

[J].

Deposition of carbon nanotubes onto aramid fibers using as-received and chemically modified fibers

[J].

Influence of aramid fiber treatment and carbon nanotubes on the interfacial strength of polypropylene hierarchical composites

[J].

Covalent modification of Aramid fibers' surface via direct fluorination to enhance composite interfacial properties

[J].

Dopamine-modified aramid fibers reinforced epoxidized natural rubber nanocomposites

[J].

Adhesion of carbon fibers to amine hardened epoxy resin: Influence of ammonia plasma functionalization of carbon fibers

[J].

Studies of physio-chemical changes of dielectric barrier discharge plasma treated aramid fibers

[J].

Green, simple, and rapid construction of coating on aramid fiber surfaces and their effects on the mechanical properties of aramid fiber/rubber composite interfaces

[J].

Multifunctional and ultrastrong MXene modified aramid fibers

[J].

Investigation into the reaction mechanism underlying the atmospheric low-temperature plasma-induced oxidation of cellulose

[J].

Research on the application of dielectric barrier discharge low temperature technique in surface modification of para-aramid fibers

[D].

采用介质阻挡放电低温等离子体技术改性对位芳纶表面

[D].

Comparison between helium and argon plasma jets on improving the hydrophilic property of PMMA surface

[J].

Improvement of PET surface modification using an atmospheric pressure plasma jet with different shielding gases

[J].

Degradation of diclofenac and 4-chlorobenzoic acid in aqueous solution by cold atmospheric plasma source

[J].

Wettability distribution on the surface treated by plasma jet at different flow rates for microfluidic applications

[J].

Surface activation of poly (methyl methacrylate) with atmospheric pressure Ar + H2O plasma

[J].

Strengthening the interface between individual aramid fibers and polymer at room and elevated temperatures

[J].

3D interfacial debonding during microbond testing: Advantages of local strain recording

[J].

Prediction of interfacial behaviour of single flax fiber bonded to various matrices by simulation of microdroplet test

[J].