目前,有多种研究金属材料氢脆行为的实验方法。例如,氢气环境中的慢应变速率拉伸试验[12]、疲劳试验和断裂韧性测试试验等[13~17]。这些方法类似于常见的材料机械性能测试,不同之处在于实验前使氢进入材料内(常采用电化学充氢或气相充氢),或在含氢环境中进行实验。但是,用电化学充氢难以模拟真实输送管道中的临氢状态,而采用气相氢环境测试又难以实现氢气密封和测试设备价格高昂、技术要求极高。因此,研究人员尝试进行小冲头实验研究金属材料的氢脆敏感性[18]。有学者将小冲头实验结果与拉伸试验结果对比,证明用此法可评估结构钢因氢脆产生的拉伸性能恶化[19];还有研究人员用此法测试了多种材料在氢环境中的氢脆敏感性,并进行了小冲头实验的数值模拟分析[20]。小冲头实验不仅适用于金属焊缝材料,其结果也能反映材料在氢气环境中某些机械性能的变化(尤其是塑性的变化),且所需气体少、测试设备简单、和节省实验用材料。可用电化学方法对测试试样进行预充氢[18],但是在空气中进行压缩测试时试样内的氢迅速扩散到空气中影响测试结果的准确性[21]。也有研究者进行电化学充氢的同时进行测试,但是电化学充氢毕竟易于气相充氢,两者的测试结果的差异较大。因此,有的研究人员进行原位小冲头实验时将试样夹在夹具中间,使试样一侧直接暴露在有一定压力的氢气或掺氢天然气环境中,而另一侧直接与空气中的小压头接触;夹具气腔与阀门和压力表相连,以测量和控制气腔内的压力[22]。

应变速率显著影响金属材料的氢脆行为,且主要通过位错运动影响材料的氢脆行为。de Almeida等[23]的小冲头实验结果表明,随着压缩速率的降低42CrMo4-700钢的氢脆敏感性提高;Han等[24]认为,氢决定了材料中可移动位错的密度进而影响材料的氢脆敏感性。为了研究材料内部位错运动对氢运动的影响,齐晓琳[25]等比较了高锰TWIP钢预充氢后不同应变速率的拉伸曲线和断口形貌,并结合理论计算发现,这种钢的氢脆敏感性随着应变速率的降低而显著提高;K.Wada等[26]在高压气态氢环境中进行工业级纯镍(NI-201)在不同温度和应变速率下的拉伸测试,发现在100 MPa的氢气环境中纯镍的氢脆敏感性受应变率和测试温度的共同影响。也有研究人员认为,应变速率只在一定范围内影响材料的氢脆行为[27]。本文在4 MPa氮气和氢气环境中进行X65管线钢的原位小冲头实验,研究压缩速率对其氢脆敏感性的影响。

1 实验方法

1.1 实验用材料

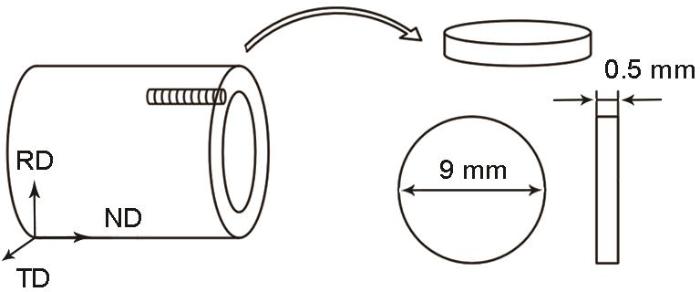

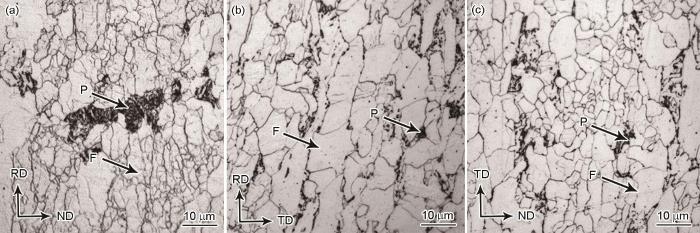

实验用X65管线钢的化学成分列于表1。X65管线钢的屈服强度为490 MPa,抗拉强度为570 MPa,在-20 ℃下的冲击韧性为450 J/cm2。使用线切割沿管道轴向取样(图1),将其初加工成圆片试样并用水相砂纸将表面逐级打磨至2000#,最终的直径为9 mm、厚度为0.5 mm。再切取尺寸为10 mm × 10 mm × 10 mm的块试样,也使用砂纸将其各面逐级打磨至2000#,用抛光膏将其机械抛光后用5%的硝酸酒精溶液刻蚀,用Axio Observer. Z1m光学显微镜观察其显微组织。X65管线钢不同方向的显微组织图如图2所示,其中ND为轴向方向、RD为径向方向、TD为周向。X65管线钢的显微组织主要由铁素体(Ferrite, F)和少量珠光体(Pearlite, P)组成,不同方向上的显微组织没有明显的差别。

表1 X65管线钢的化学成分

Table 1

| C | Mn | Cu | Ni | Cr | Mo | Nb | Ti | Fe |

|---|---|---|---|---|---|---|---|---|

| 0.04 | 1.23 | 0.15 | 0.15 | 0.25 | 0.06 | 0.04 | 0.01 | Bal. |

图1

图1

压缩试样的取样方式和尺寸示意图

Fig.1

Sampling method and schematic diagram with dimensions of compressed specimen

图2

图2

X65管线钢中不同方向上的显微组织

Fig.2

Microstructure images of X65 pipeline steel in different directions (a) RD-ND plane; (b) RD-TD plane; (c) TD-ND plane (P—pearlite; F—ferrite)

1.2 原位小冲头压缩实验

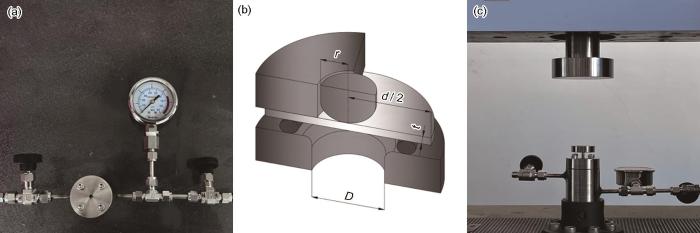

图3给出了原位小冲头实验的夹具实物图、内部示意图以及压缩设备实物图。原位小冲头压缩实验的第一步,是将圆片试样安装到夹具中:先将O型环(外径8 mm、线径1.5 mm)放入下夹具凹槽内以确保气腔的气密性,然后将打磨好的圆片试样用酒精超声清洗10 min后放置在O型环的正上方;最后用螺钉固定住上、下夹具。第二步:在腔内充满实验用气体。先将进气口连接于气瓶出气口,再将出气口连接于与室外相通的管道,打开两侧气阀;用实验用纯氮或纯氢气体吹扫气腔5 min后将夹具的出气阀关闭,使气腔气压达到4 MPa,静置5 min后把出气阀缓慢打开放气,重复上述操作2次;然后关闭出气口,待气腔气压达到实验所需压力后关闭进气口。第三步:把夹具安装到实验机(岛津AUTOGRAPH AG-X)上,再将夹具的压头和钢球放置在夹具上,使压头缓慢下降到与夹具压头接触(预紧力为10 N);设置压缩速率并开始实验。实验条件列于表2。小冲头压缩实验结束后,用扫描电子显微镜(SEM, FEI XL30)观察试样的破裂形貌和截面形貌。

图3

图3

夹具装置实物图、夹具内部示意图和压缩设备实物图

Fig.3

Physical illustration of the fixture device (a); internal schematic diagram of the fixture (b) and physical illustration of the compression equipment (c)

表2 原位小冲头压缩实验条件

Table 2

| Test conditions | Test parameters |

|---|---|

| Specimen dimension / mm | ϕ9 × 0.5 |

Ball diameter / mm Gas environment Gas pressure / MPa Compression rate / mm·min-1 Test temperature | 2.5 N2(99.999%), H2(99.999%) 4.0 1.0, 0.1, 0.01, 0.004 Room temperature |

2 实验结果

2.1 压缩曲线和SP能量值

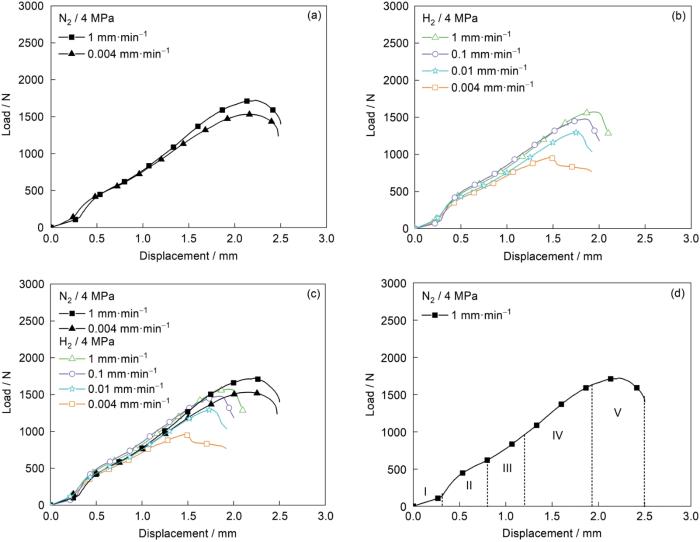

图4a给出了在4 MPa氮气中原位小冲头实验得到的载荷-位移曲线。可以看出,在氮气环境中不同压缩速率下的载荷-位移曲线的变化趋势基本相同,破裂位移基本一致,高压缩速率下的最大载荷值更大。这表明,压缩速率对载荷-位移曲线的影响不大。

图4

图4

在4 MPa氮气及氢气环境中不同压缩速率下的载荷-位移曲线、在不同气体环境中不同压缩速率的载荷-位移曲线以及在4 MPa氮气环境中压缩速率为1 mm·min-1的载荷-位移曲线分区图

Fig.4

Load-displacement curves under different compression rates in nitrogen environment at 4 MPa (a); load-displacement curves under different compression rates in hydrogen environment at 4 MPa (b); load-displacement curves under different gas environments and compression rates (c) and load-displacement curve partition map under a compression rate of 1 mm·min-1 in nitrogen environment at 4 MPa (d)

由原位小冲头实验得到的载荷-位移曲线可分为五个区域,如图4d所示。第Ⅰ阶段为弹性弯曲阶段(Elastic bending,阶段Ⅰ),曲线为线性,试样发生弹性变形;第Ⅱ阶段为塑性弯曲阶段(Plastic bending,阶段Ⅱ),曲线出现明显的突起,试样开始塑形形变;第Ⅲ阶段为过渡阶段(Transition,阶段Ⅲ),试样从塑性弯曲阶段过渡到下一阶段;第Ⅳ阶段为膜伸张阶段(Membrane stretching,阶段Ⅳ),随着位移量的增大载荷值随之增大,裂纹开始萌生;第Ⅴ阶段为破裂阶段(Final fracture,阶段Ⅴ),试样发生破裂[20]。由图4c可见,在氮气环境中不同压缩速率载荷-位移曲线的五个区域基本重合;而在临氢条件下试样发生了氢脆,使载荷-位移曲线第Ⅳ阶段的位移量减小。同时,随着压缩速率的降低,第Ⅳ区域的位移量减小。

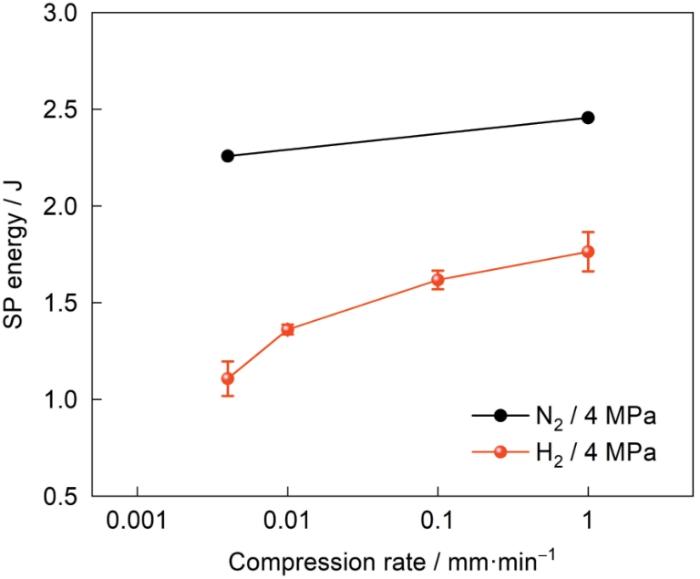

为了评价X65管线钢的氢脆敏感性,计算了每个试样从开始压缩到破裂(气体泄漏)吸收的能量,即载荷-位移曲线的积分。在实验过程中,因为不能确定破裂点或气体泄漏点的准确时刻,将最大载荷下降20%对应的位移点定义为破裂点[28]。为了减小实验误差,在氢气环境中每个压缩速率下的实验均重复两次。在不同气体环境中和不同压缩速率下的SP能量值,如图5所示。可以看出,因为在氮气环境中的实验中没有发生氢脆,SP能量值较高,压缩速率对SP能量值的影响也比较小。而在临氢环境中试样发生了氢脆,材料塑性的降低使SP能量值显著降低,即用较小的能量试样就发生破裂;同时,在临氢环境中,随着压缩速率的降低试样的SP能量值也随之降低,表明试样的氢脆敏感性逐渐提高。根据不同条件下的载荷-位移曲线测量或计算出的最大载荷值(Fm)、破裂位移(σm)及SP能量值(Esp)汇总于表3,其中最大载荷值和破裂位移由图4中的载荷-位移曲线统计得到,SP能量值为重复实验后计算出的平均值。

图5

图5

在不同气体环境中不同压缩速率的SP能量值

Fig.5

SP energy values under different gas environments and compression rates

表3 在不同气体环境中不同压缩速率的实验结果汇总

Table 3

| Compression rate / mm·min-1 | Gas environment | p / MPa | Fm/ N | σm/ mm | Esp/ J |

|---|---|---|---|---|---|

| 1.0 | N2 | 4 | 1723.62 | 2.50 | 2.45 |

| 0.004 | 1530.76 | 2.47 | 2.26 | ||

| 1.0 | H2 | 4 | 1572.68 | 2.10 | 1.76 |

| 0.1 | 1477.60 | 2.00 | 1.62 | ||

| 0.01 | 1294.53 | 1.92 | 1.36 | ||

| 0.004 | 959.31 | 1.92 | 1.11 |

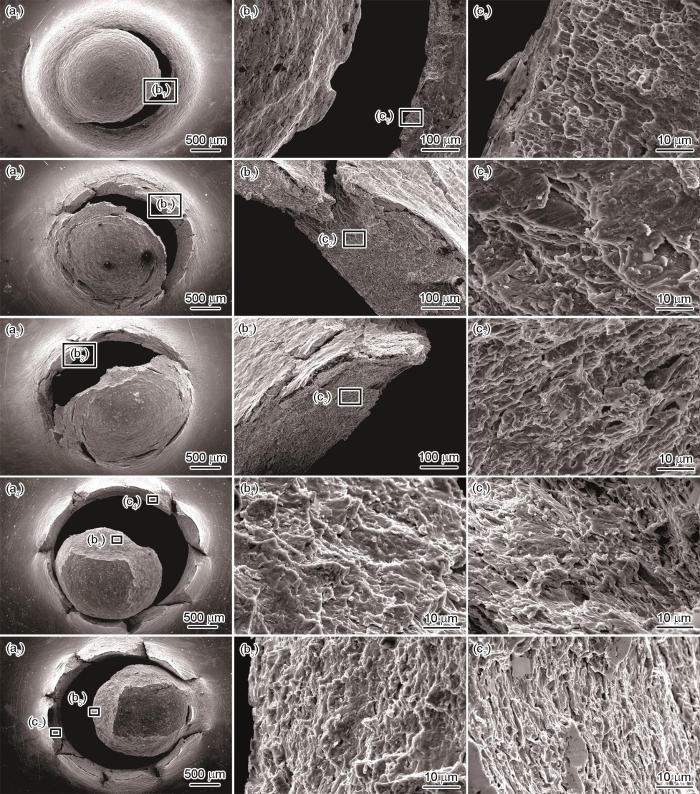

2.2 压缩试样的形貌

图6

图6

在不同条件下破裂试样的SEM照片

Fig.6

SEM images of fractured specimens under different conditions (a1~c1) 4 MPa nitrogen, compression rate of 1 mm·min-1; (a2~c2) 4 MPa hydrogen, compression rate of 1 mm·min-1; (a3~c3) 4 MPa hydrogen, compression rate of 0.1 mm·min-1; (a4~c4) 4 MPa hydrogen, compression rate of 0.01 mm·min-1; (a5~c5) 4 MPa hydrogen, compression rate of 0.004 mm·min-1

2.3 不同压缩阶段试样的形貌

图7

图7

在4 MPa的氮气及氢气环境中第Ⅰ压缩阶段试样表面的SEM照片

Fig.7

SEM images of specimen surface in compression stage Ⅰ in nitrogen environment (a) and hydrogen environment (b) at 4 MPa

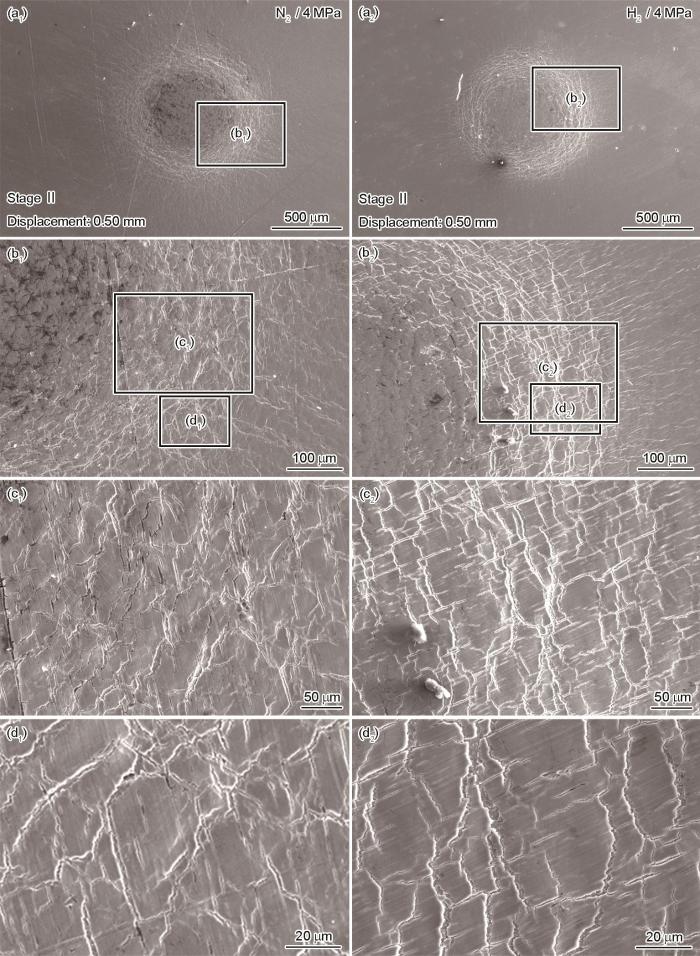

在两种气氛环境中压缩到第Ⅱ阶段压头的下压位移仍保持一致(0.50 mm),两个试样的表面微观形貌如图8所示。可以看出,由于发生了明显的塑性变形在两者表面均产生了大量的变形条带,但是形貌明显不同。在氮气环境中变形条带呈台阶状,过渡较为平缓;在氢气环境中变形条带则呈现龟裂状,生成了大量微裂纹。这表明,在第Ⅱ阶段氢对试样的破裂已经开始产生影响。

图8

图8

在4 MPa的氮气及氢气环境中第Ⅱ压缩阶段试样表面的SEM照片

Fig.8

SEM images of specimen surface in compression stage Ⅱ in nitrogen environment (a1~d1) and hydrogen environment (a2~d2) at 4 MPa

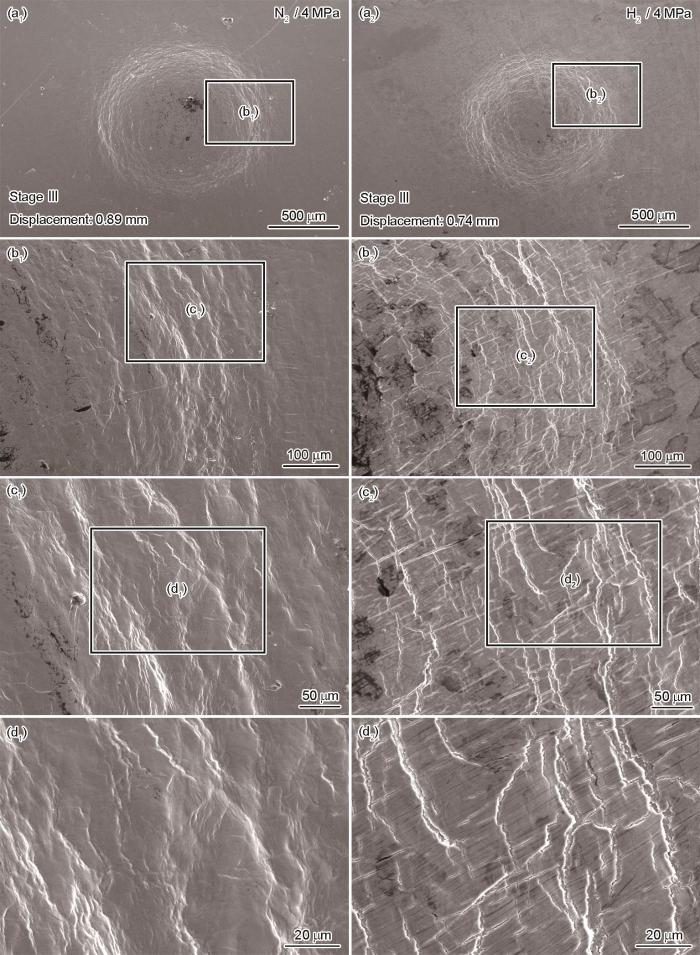

图9

图9

在4 MPa的氮气及氢气环境中第Ⅲ压缩阶段试样表面的SEM照片

Fig.9

SEM images of specimen surface in compression stage Ⅲ in nitrogen environment (a1~d1) and hydrogen environment (a2~d2) at 4 MPa

而当试样压缩到第Ⅳ阶段(图10),在氮气环境中压头下降位移为1.43 mm,试样表面与第Ⅲ阶段的形貌特征类似,但是局部微裂纹增多。而在氢气环境中压缩到第Ⅳ阶段时在试样表面产生了明显的裂纹;虽然压头下降位移只有1.04 mm,但是却出现了更深的裂纹。这表明,与氮气环境中的试样相比,氢气环境中的试样显然具有更高的氢脆敏感性。

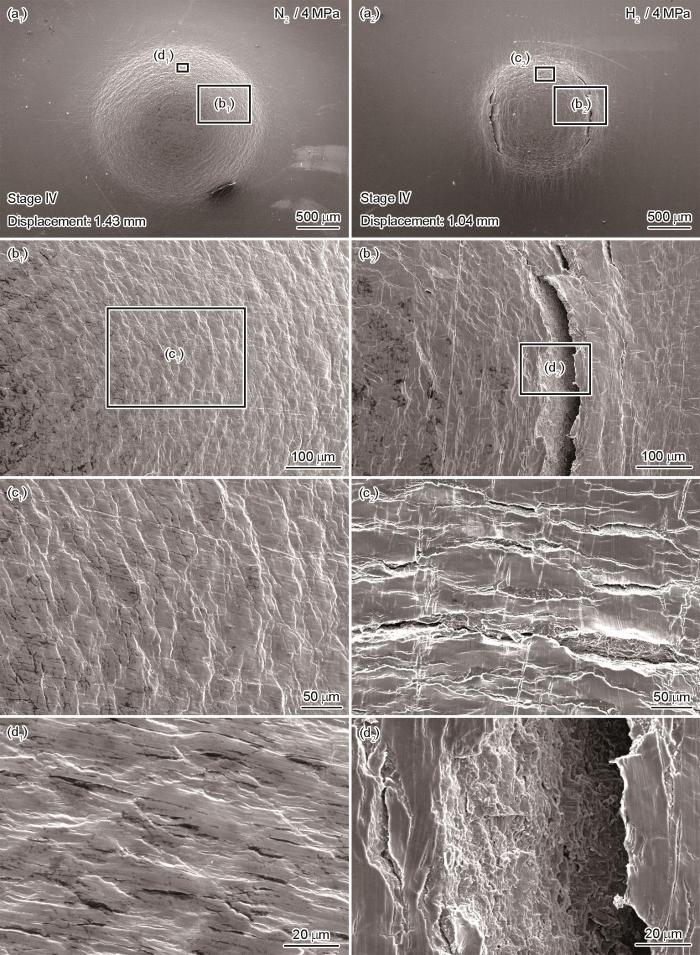

图10

图10

在4 MPa的氮气及氢气环境中第IV压缩阶段试样表面的SEM照片

Fig.10

SEM images of specimen surface in compression stage IV in nitrogen environment (a1~d1) and hydrogen environment (a2~d2) at 4 MPa

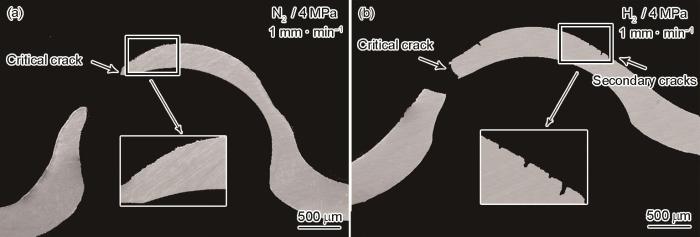

图11

图11

压缩速率为1 mm·min-1条件下在4 MPa氮气及氢气环境中试样的破裂截面图

Fig.11

Cross-sectional diagram of specimen fracture under a compression rate of 1 mm·min-1 in nitrogen environment (a) and hydrogen environment (b) at 4 MPa

3 讨论

其中ρ为可动位错的密度,ω为比例常数,b为柏氏矢量,v为位错运动速率,ε为应变速率。这表明,在可动位错密度一定的情况下应变速率与位错运动速率呈正相关。由此可推测,当压缩速率较高时氢在金属内部的扩散速率远低于位错的运动速率,位错周围的氢不能靠扩散跟上位错的运动,而氢原子在金属内部也来不及自扩散至裂纹尖端,因此试样的氢脆特征不明显。但是在压缩速率较低的情况下氢的扩散能跟上位错的运动,位错带着氢气团一起运动至裂纹尖端而引发显著的氢脆。

4 结论

(1) 在氮气环境中进行X65管线钢的原位小冲头实验,在试样破裂口出现大量的剪切型韧窝,呈韧性断裂特征;在临氢环境中试样破裂口则表现出显著的准解理特征,氢脆现象显著。在不同气体环境中相同压缩速率的载荷-位移曲线和SP能量值也明显不同。在临氢条件下压缩速率从1 mm·min-1降低到0.004 mm·min-1 X65管线钢的氢脆敏感性呈增高的趋势。

(2)在压缩初期(第Ⅰ阶段)试样在各种工况下的载荷-位移曲线基本重叠,氢的作用不显著;在第Ⅱ阶段开始发生显著的塑性变形,试样的表面形貌开始出现显著的不同;随着压缩的进行位错密度提高并促进氢的扩散和迁移,在应力集中区氢不断累积使局部原子间的结合力降低,进而促进裂纹萌生并发生破裂。

参考文献

Hydrogen production through renewable and non-renewable energy processes and their impact on climate change

[J].

China's hydrogen development strategy in the context of double carbon targets

[J].

The role of hydrogen in the transition from a petroleum economy to a low-carbon society

[J].

Hydrogen embrittlement in hydrogen-blended natural gas transportation systems: a review

[J].

Hydrogen production in Mexico: state of the art, future perspectives, challenges, and opportunities

[J].

A review of technical and regulatory limits for hydrogen blending in natural gas pipelines

[J].

Hydrogen embrittlement of metals

[J].

Hydrogen related degradation in pipeline steel: a review

[J].

Evaluation of stress corrosion cracking and hydrogen embrittlement in an API grade steel

[J].

Investigation of environment fracture from dislocation point of view

[J].

环断裂境的位错层次研究

[J].从位错层次评述了断裂和环境断裂微裂纹的形核过程。对于金属材料、人和断裂过程(韧断,本质脆断,氢脆,应力腐蚀,液体金属脆)均以位错发射、运动为先导,只有局部塑性应变发展道临界条件,应力集中使局部应力等于原子键合力时才出现微裂纹的形核。环境(氢,腐蚀介质,液体金属)通过促进局部塑性变形引起低应力脆断。不同环境促进位错发射、运动的原因不同。

Cost assessment and evaluation of various hydrogen delivery scenarios

[J].

Hydrogen embrittlement of 20# seamless steel in medium and low pressure gaseous hydrogen

[J].

Evaluation of hydrogen embrittlement susceptibility of temper embrittled 2.25Cr–1Mo steel by SSRT method

[J].

Effects of hydrogen on the fracture toughness of CrMo and CrMoV steels quenched and tempered at different temperatures

[J].

Hydrogen-assisted crack propagation in α-iron during elasto-plastic fracture toughness tests

[J].

Investigation of role of alloy microstructure in hydrogen-assisted fracture of AISI 4340 steel using circumferentially notched cylindrical specimens

[J].

Investigation of hydrogen embrittlement susceptibility and fracture toughness drop after in situ hydrogen cathodic charging for an X65 pipeline steel

[J].

SPT analysis of hydrogen embrittlement in CrMoV welds

[J].

Small punch test methodologies for the analysis of the hydrogen embrittlement of structural steels

[J].

Numerical analysis for characterizing hydrogen embrittlement behaviors induced in STS316L stainless steel using an in-situ small-punch test

[J].

Effect of internal hydrogen on the fatigue crack growth rate in the coarse-grain heat-affected zone of a CrMo steel

[J].

Evaluation of hydrogen related degradation of API X42 pipeline under hydrogen/natural gas mixture conditions using small punch test

[J].

Effect of test velocity on the tensile strength of high strength steels using the small punch test in a hydrogen environment

[J].

Coupling effect of hydrogen and strain rate on 2.25Cr1Mo0.25V steel deformed over wide strain rate ranges

[J].

Effect of hydrogen transportation by dislocations on hydrogen embrittlement of materials

[J].

位错载氢运动对材料氢脆行为的影响

[J].

Hydrogen-induced intergranular cracking of pure nickel under various strain rates and temperatures in gaseous hydrogen environment

[J].

Hydrogen embrittlement of 30CrMnSiA steel subjected to slow dynamic strain

[J].

30CrMnSiA钢的慢应变速率动载氢脆

[J].

Quantitative evaluation of hydrogen embrittlement susceptibility in various steels for energy use using an in-situ small punch test

[J].

Establishment of an in-situ small punch test method for characterizing hydrogen embrittlement behaviors under hydrogen gas environments and new influencing factor

[J].

Hydrogen embrittlement behavior of HSLA line pipe steel under cathodic protection

[J].

Study of the influence of current density and displacement rate on hydrogen embrittlement using small punch tests

[J].

The effects of dislocations on the trapping and transport of hydrogen in 3.3Ni-1.6Cr steel during plastic deformation

[J].

Evidence for the transport of impurity hydrogen with gliding dislocations in aluminum

[J].

Effect of stress triaxiality on hydrogen embrittlement susceptibility of quenched boron steel B1500HS

[J].The Hydrogen embrittlement (HE) susceptibility of the quenched boron steel B1500HS before and after being electrochemical hydrogen charging by applying different stresses, such as simple shear, uniaxial tensile and analogous plane strain, respectively was investigated via slow strain rate tensile test. Meanwhile, the stress-strain curves for both the H-free and H-charged steels were acquired and then the HE susceptibility of the test steels was calculated based on the equivalent plastic strain to reveal the effects of the stress state on the HE susceptibility of the quenched boron steel. Furthermore, the fracture features of the steels were characterized by SEM and EBSD to analyze the HE mechanism for the different applied stress. The results show that the HE mechanisms of the quenched boron steel by simple shear stress is substantial different to those by tensile stress, which indicated that the HE susceptibility during testing by simple shear stress is much lower than that by tensile stress.

应力三轴度对淬火态硼钢氢脆敏感性的影响

[J].对硼钢进行电化学充氢和低应变率拉伸,分别画出了纯剪切、单向拉伸及近似平面应变状态下淬火态硼钢充氢前后的应力-应变曲线,并基于等效塑性应变量化了硼钢的氢脆敏感性,研究了应力三轴度对淬火态硼钢的力学性能和氢脆敏感性的影响。用SEM及EBSD表征试样断口的微观组织,根据淬火态硼钢充氢前后断裂模式的变化分析了硼钢在不同应力状态下的氢脆机理。结果表明,淬火态硼钢在剪应力状态下的氢脆机理与拉伸应力状态显著不同,使其氢脆敏感性比拉伸应力状态显著降低。