多主元合金(Multi-principal element alloy,MPEA)突破了传统合金以单一元素为基体的合金设计理念,其优异的力学性能使其展现出在结构材料领域应用的巨大潜力[1~3]。研究初期,具有单相面心立方(Face-center cubic,FCC)或体心立方(Body-center cubic,BCC)结构的多主元合金受到广泛关注。但是,具有单相FCC结构的多主元合金虽塑性较好,但其强度较低[4~8];而单相BCC多主元合金强度较高,但塑性较差[9~13]。因此,探寻获得优异强塑性匹配的有效手段是多主元合金重要的研究方向。对于FCC多主元合金而言,提升强度是其研究的重点,研究人员最早借助传统强化手段对合金进行强化,例如固溶强化[14,15],沉淀强化[16,17],细晶强化[18,19],形变强化[20,21]。上述强化手段均能有效的提升合金强度,但会不同程度降低合金塑性。BCC多主元合金的研究重点则是如何提升其塑性,但其手段较为有限,例如,通过改变合金价电子浓度(VEC)可以调控以BCC为基体的难熔高熵合金的塑性,研究表明,VEC值影响着理论解理强度和剪切强度的数值,通过调节VEC数值可降低合金的理论剪切强度,使位错能够在断裂之前形成,合金可通过位错滑移进行变形,提升合金的变形能力[22,23]。虽然上述方法可以实现较为理想的强塑性匹配,但仍然无法克服强塑性此消彼长的倒置关系。

近些年,合金中的异质结构因其独特的组织与力学行为而受到广泛关注。从力学性能角度出发,合金的异质结构主要由其内部两个强度相差较大的区域构成[24,25]。在外力作用下,两个区域的变形不均匀,先变形的软区域内部位错塞积在异质界面处,产生的背应力将使软区域得到有效强化[26,27],同时又使合金具有一定的变形能力,这种不均匀的变形特点使合金兼具较高的强度与优异的塑性。Wu等[28]通过简单的冷轧退火工艺在纯Ti中构建了由粗晶与细晶组成的异质结构,值得注意的是,这种结构的强度与塑性均优于超细晶Ti。计算表明,粗晶区承受了更大应变,是合金塑性的主要来源,同时,由于位错塞积产生的背应力强化,也使得粗晶区得到了额外的强化,这也是其强度高于超细晶结构的主要原因。此外,FCC+BCC双相合金由于两相强度相差较大,也可视为异质结构。AlCoCrFeNi2.1合金为典型的FCC/B2共晶多主元合金,其铸态结构本身就可视为异质结构。研究人员通过冷轧退火工艺在FCC层片内部构建了由细小FCC晶粒与B2相组成的二级异质结构,这种多级异质结构的强塑性要显著优于超细晶 AlCoCrFeNi2.1合金[29]。在Fe20Co20Ni41Al19共晶多主元合金中也发现了同样的现象[30]。由此可见,构建有效的异质结构将有望实现多主元合金强塑性的协同提升。

FeCrNi系多主元合金具有优异的力学性能与耐腐蚀性能[31~33]。由于不含Co元素,合金成本较低,表现出极大的应用潜力。目前,多数研究主要集中于FCC结构的FeCrNi系多主元合金[31,34,35]。但此类合金屈服强度较低,很难满足工程应用。例如,具有单相FCC结构的等摩尔比FeCrNi合金室温拉伸屈服强度不足200 MPa[31],尽管合金具有优异的塑性与韧性,但与实际工程应用仍具有较大差距。为解决单相FCC结构FeCrNi合金低强度的问题,本课题组设计并制备了具有BCC+FCC的双相Fe40Cr40Ni20(原子分数,%)多主元合金,并获得了较为优异的力学性能[36~38]。为进一步提升Fe40Cr40Ni20合金强度,用3%的Al元素代替Cr元素进行合金化,合金强度提升的同时塑性急剧降低。基于异质结构理念,本文通过冷轧退火工艺构建了不同形态的双重BCC/FCC异质结构,实现了合金强度与塑性的协同提升,深入揭示了相关强化及变形机制。

1 实验方法

实验用原料,是纯度高于99.99% (质量分数)的金属Fe、Cr、Ni和Al。用真空电弧熔炼炉制备Fe40Cr37Ni20Al3(原子分数,%)多主元合金,在高纯度氩气保护下熔炼五次以使其成分均匀。将铸锭在1200 ℃固溶处理24 h后淬火。截取部分铸锭冷轧成板材,变形量为70%。将冷轧板在850℃退火1 h,然后淬火。将固溶态和冷轧退火态试样分别记为SS和CA合金。

用扫描电子显微镜(SEM)观察合金的显微组织。SEM试样的尺寸为8 mm × 8 mm × 3 mm,将其用240#~3000#砂纸打磨后在93 mL C2H5OH + 7 mL HClO4混合溶液中进行电解抛光,抛光电压为30 V,时间为20 s。将其电解抛光后在室温进行化学腐蚀,腐蚀液为75 mL HNO3 + 25 mL HCL,腐蚀时间约为15~20 s。用FEI Tecnai F30型透射电镜(TEM)分析试样的微观结构、强化机制及变形机制。用离子减薄制备TEM试样,其直径为3 mm,长度为60 μm。

用型号为AG-X Plus 250kN/50kN的拉伸实验机进行CA合金试样的室温拉伸实验,应变速率为1 × 10-3 s-1,拉伸应变为16%时停止测试。拉伸试样的厚度为1.2 mm,标距长为14 mm,标距段宽度为2 mm。在拉伸试样的标距段中心位置切取长为4 mm的料棒,将其制成直径为3 mm长度为60 μm的试样用于TEM观察。

2 实验结果

2.1 SS合金的显微组织

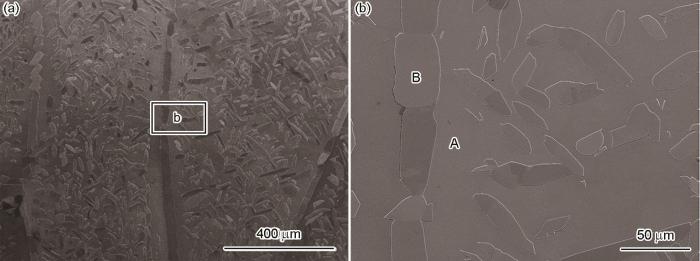

图1

图1

SS 合金 的SEM 显微组织

Fig.1

SEM micrographs of SS alloy (a) dual-phase structure, (b) high magnification of region b in (a)

表1 SS合金中两相的化学成分

Table 1

| Sample | Figure | Phase/Region | Element | |||

|---|---|---|---|---|---|---|

| Fe | Cr | Ni | Al | |||

| SS | Matrix phase | 38.74 | 41.84 | 16.34 | 3.10 | |

| Second phase | 40.49 | 30.90 | 24.32 | 4.31 | ||

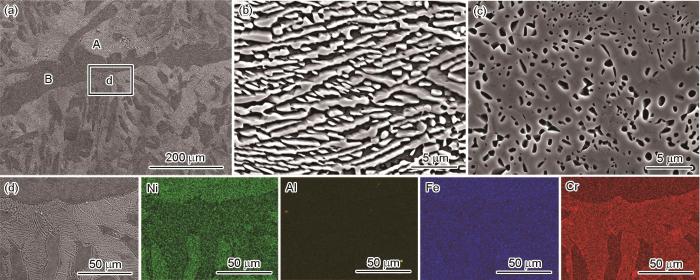

图2

图2

CA合金的SEM显微组织

Fig.2

SEM micrographs of CA alloy (a) low magnification SEM picture, (b) high magnification of the region A in (a), (c) high magnification of region B in (a), (d) high magnification SEM micrograph and the corresponding EDS elemental maps of region d in (a)

表2 CA合金不同区域的化学成分

Table 2

| Sample | Figure | Region | Element | |||

|---|---|---|---|---|---|---|

| Fe | Cr | Ni | Al | |||

| CA | A | 39.74 | 37.24 | 19.75 | 3.27 | |

| B | 41.59 | 27.82 | 26.20 | 4.41 | ||

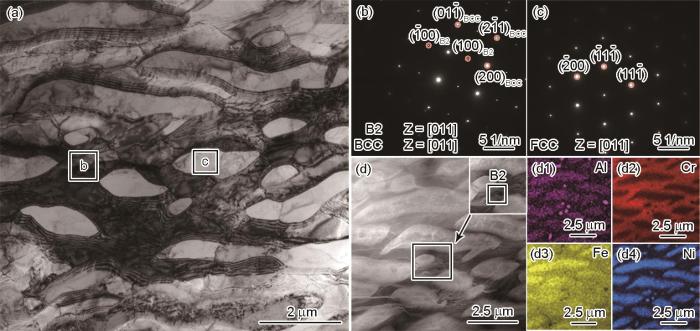

根据TEM照片分析了CA合金中A、B两个区域的相组成。图3a给出了A区域的明场像,可见其为基体相包裹另一相。图3b给出了基体的衍射斑点,可知A区域基体为BCC相。{100}衍射斑点的出现意味着,BCC基体中存在有序相。图3c中的衍射斑点则表明,A区域中被包裹的相是FCC相。图3d给出了A区域的高角环形暗场相(HAADF)和对应选区的元素分布,可见BCC基体中保留了冷变形产生的位错和没有再结晶特征,表明其仍处于变形态和新生成的FCC相没有畸变。同时,在非再结晶BCC基体内析出了球形颗粒相。图3d1~d4给出了所选区域的元素分布,可见FCC相中富集了Ni元素和Fe、Al的含量偏高,BCC基体中Cr的含量较高。同时, BCC基体中的颗粒相中Ni、Al两元素的含量偏高。元素分布和衍射斑点表明,BCC基体中生成的球形颗粒相为富Ni、Al的B2相。表3列出了A区域三种相的化学成分。与SS合金中的BCC相成分相比,Cr和Ni元素在两相间重新分配,BCC相中Cr含量高达55.7%,Ni在FCC相中的含量约为25.7%。

图3

图3

CA合金基体区的TEM照片

Fig.3

TEM images of the matrix region in the CA alloy (a) BF image of region A in Fig.2a, (b) SAED pattern of the BCC matrix, (c) SAED pattern of the FCC phase, (d) HAADF-STEM image of region A in Fig.2a with elemental distribution mapping

表3 CA合金中不同区域相的化学成分

Table 3

| Sample | Region | Phase | Element | |||

|---|---|---|---|---|---|---|

| Fe | Cr | Ni | Al | |||

| CA | A | BCC matrix | 35.78 | 55.70 | 7.14 | 1.39 |

| FCC phase | 43.05 | 27.09 | 25.76 | 4.10 | ||

| B2 phase | 19.34 | 19.64 | 36.81 | 24.21 | ||

| B | FCC | 43.61 | 27.26 | 26.29 | 2.84 | |

| BCC | 34.85 | 56.86 | 7.10 | 1.19 | ||

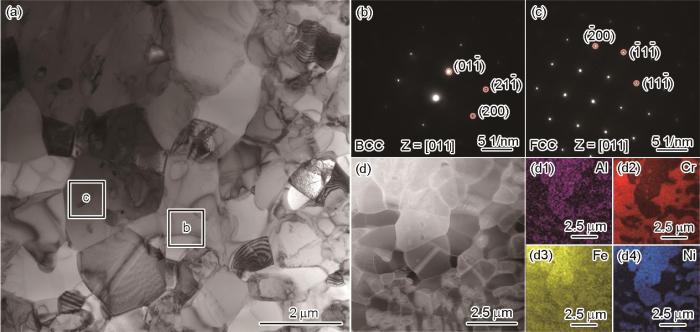

图4

图4

CA合金中再结晶区的TEM照片

Fig.4

TEM images of the recrystallized region in the CA alloy (a) BF image of region B in Fig.2a, (b) SAED pattern of BCC grains, (c) SAED pattern of the FCC matrix, (d) HAADF-STEM image of region B in Fig.2a with corresponding elemental distribution mapping

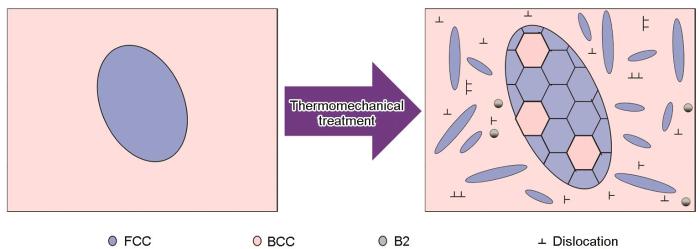

以上结果表明,Fe40Cr37Ni20Al3合金的固溶态具有BCC基体+FCC相的双相组织。冷轧退火后,两相内的组织都发生了变化。原BCC相转变为A区域,其内有未再结晶的BCC基体、富Ni、Al的B2相和新析出的FCC相;原FCC相转变为B区域,在退火过程中此区域中的FCC相发生再结晶和BCC相发生重结晶,成为FCC晶粒与BCC晶粒的混晶结构。图5给出了Fe40Cr37Ni20Al3合金的组织转变示意图。

图5

图5

Fe40Cr35Ni20Al3合金的组织演变示意图

Fig.5

Schematic diagram of microstructure evolution in Fe40Cr35Ni20Al3 alloy

2.2 CA合金的力学性能

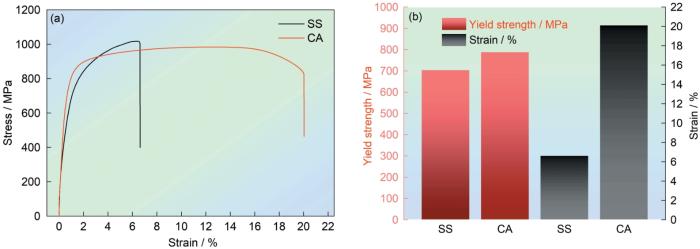

图6

图6

两种合金的室温拉伸应力-应变曲线以及屈服强度和延伸率的比较

Fig.6

Room-temperature tensile stress-strain curves of the two alloys (a) and comparison of the yield strength and elongation of the two alloys (b)

3 讨论

固溶处理后的合金具有BCC相包裹FCC相的双相异质结构。在变形过程中,强度的较大差异使变形不均匀。强度较低的FCC相先变形,其内部的位错在异质界面受阻塞积形成长程背应力,使其中的后续位错难以运动进而强化。这种因非均匀变形而产生的强化称为HDI强化(hetero-deformation-induced strengthening)[24]。文献[37]的研究表明,这种硬BCC相包裹软FCC相的异质结构,在拉伸过程中FCC相的变形受到限制,使其HDI强化效果较好。另一方面,FCC相被全方位约束使位错在界面严重塞积,使裂纹易在界面萌生并沿BCC基体扩展直至断裂。固溶态Fe40Cr37Ni20Al3合金BCC基体的变形能力较差,不能缓解FCC相内因位错塞积产生的应力集中而使裂纹易萌生并迅速扩展。这是SS合金塑性较低的原因。

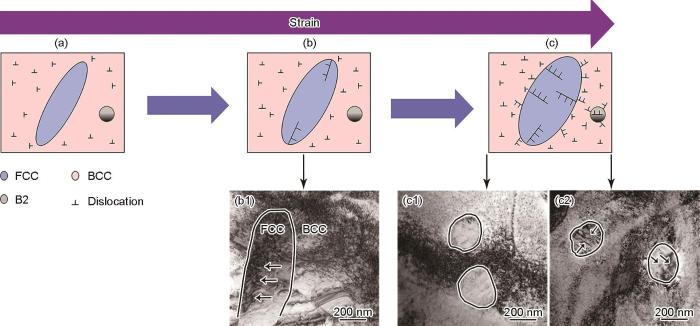

冷轧退火使CA合金的塑性大幅度提高和屈服强度小幅度提高,即强塑性协同提高。为了明确其原因和其不同区域的强化机制和变形机制,根据CA合金的TEM照片对其变形组织进行了分析。图7给出了CA合金中A区域变形过程的示意图和变形组织的TEM照片。A区域的初始组织,是未再结晶BCC基体包裹着新生成的FCC相和BCC基体中的少量B2析出相。外部应力较低时BCC基体和FCC相滑移系均不开动,其组织没有变化,如图7a所示。随着外部应力的增大,当外部应力超过强度较低的FCC相的屈服强度时,其内部的滑移系率先开动进入塑性变形阶段,而BCC基体没有变形。其原因是,本征强度较高的BCC基体相内残留了密度较高的位错,开动其滑移系所需的应力较高。但是,被BCC基体包裹的FCC相内的位错滑移在两相界面终止,使位错在相界面FCC一侧塞积。图7b1给出了CA合金A区域的变形组织,可见FCC相内的位错在相界面塞积,如图中箭头所示。图7b给出了此阶段A区域的变形组织示意图。可以看出,随着应力的进一步增大塞积在FCC相内界面的位错数量增加,产生的应力作用BCC基体相上。外部应力和位错塞积产生的应力的共同作用,使BCC基体内的滑移系开动而进入塑性变形阶段。图7c1、c2给出了A区域BCC基体的变形组织形貌。可以看出,变形量较小时大量位错塞积在BCC/B2界面;变形量较大时,位错切入B2相使其与BCC基体协调变形。图7c给出了大应变时A区域的变形组织示意图。

图7

图7

CA合金中A区域的变形过程示意图

Fig.7

Schematic diagram of the deformation process in Region A of CA alloy

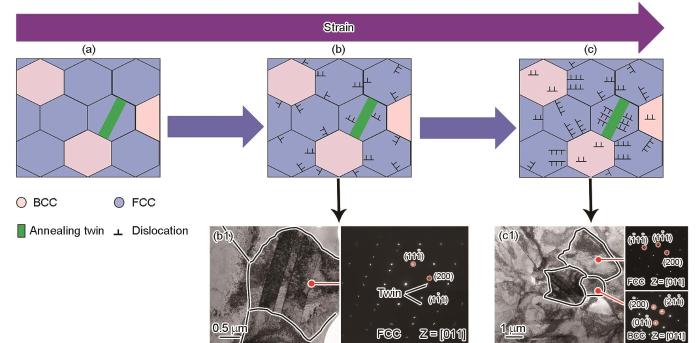

图8给出了CA合金B区域的变形过程示意图和变形组织的TEM照片。此区域为FCC和BCC混合晶粒组织,部分FCC晶粒中生成退火孪晶,如图8a所示。外部应力较小时FCC晶粒先屈服,FCC晶粒内的滑移系被激活,位错运动在晶界、FCC/BCC相界面和孪晶界面受阻。此时,与FCC晶粒相邻的BCC晶粒因强度较高仍保持原状,图8b给出了此阶段的变形组织示意图。图8b1给出了FCC晶粒的变形组织和位错在晶界、孪晶界的塞积。随着外部应力的增大BCC相也产生塑性变形,其内的位错开始运动。此时,FCC的晶界和孪晶界的位错密度也逐渐提高。图8c给出了此阶段的变形组织示意图。图8c1给出了B区域的变形组织TEM照片,其中包含了不含退火孪晶的FCC晶粒(右上)、含退火孪晶的FCC晶粒(左下)以及BCC晶粒。明显可见位错在不同种类界面前塞积,如图中的箭头所示。

图8

图8

CA合金中B区域的变形过程示意图

Fig.8

Schematic diagram of the deformation process in Region B of the CA alloy

根据上述对变形组织的分析,与原BCC相相比A区域的变形能力显著改善,均匀分布在未再结晶BCC基体内的FCC相先变形。这种FCC相相当于在硬基体上的无数细小的显微易变形单元,使此区域的变形更加均匀而使其变形能力提高[24]。Wu等[28]在纯钛中得到了细晶区(硬区)包裹粗晶区(软区)的异质结构,计算结果表明软区域在塑性变形过程中的变形量较大,其应变值远高于整个区域的实测应变值,而硬区域的变形量则较小。这意味着,此类异质结构中软区的变形较为重要。这表明,原BCC相转变为“硬包软”型异质结构,是CA合金的塑性比SS合金大幅提高的重要原因。另一方面,B区域的“混晶”型异质结构也对合金的塑性有重要贡献。依据文献[37],SS合金中的FCC相先发生塑性变形,其内的位错迅速增殖,位错滑移至相界面受阻而大量塞积,应力超过相界面结合力时裂纹在BCC基体与FCC相界面萌生,随后沿BCC基体扩展导致断裂。CA合金中的“混晶”型异质结构比SS合金中原FCC相显著细化并生成了一些BCC相。这表明,在此“混晶”型异质结构中位错仍先在FCC晶粒中形成,但是晶粒细化和BCC相的生成产生了更多的界面,使到达A区域/B区域界面的位错大幅度减少。BCC相的生成阻碍FCC晶粒间的协调变形,延缓了晶粒之间的位错传递,使A区域/B区域界面(原BCC与FCC相界面处)的应力集中程度降低而延缓了裂纹的萌生。

CA合金塑性大幅提高而屈服强度小幅度提高,主要与两种不同形态异质结构的形成有关。(1) A区域的“硬包软”型异质结构。与原BCC相相比,虽然此区域中析出了大量的FCC相,但是FCC相被BCC基体包围,与其他软区相连接的异质结构不同。即使FCC相内多个滑移系均开动,但是所有滑移方向上的位错终将在界面塞积,FCC相的变形被限制,产生的较强HDI强化使FCC相强化。尽管SS合金也具有此类“硬包软”型异质结构,但其强化程度远不如A区域。一方面,A区域的“硬包软”型异质结构中软FCC相的尺寸较小,位错运动的平均自由程的大幅度降低使FCC相内位错迅速累积,使HDI的强化效果显著提高。另一方面,A区域的“硬包软”型异质结构中的硬BCC相没有再结晶,且其内析出的B2相强度也显著高于SS合金中的BCC基体。(2) B区域的“混晶”型异质结构。此区域由原FCC相转变而来。一方面,SS合金中的FCC相尺寸较大且为单一晶粒,此区域中的FCC相发生再结晶使晶粒细化。另一方面,这种“混晶”型的异质结构引入了FCC/BCC的异质界面,发生的HDI效应使FCC相强化。

4 结论

(1) 固溶态Fe40Cr37Ni20Al3合金具有BCC(基体)+FCC双相结构;冷轧退火后BCC相转变为非再结晶BCC基体(含B2相)+FCC相的“硬包软”型异质结构,FCC相转变为FCC+BCC晶粒的“混晶”型异质结构而成双形态异质结构组织。冷轧退火后,Fe40Cr37Ni20Al3合金的强度和塑性协同提高。

(2) 强塑性协同提高,主要源于冷轧退火后合金成为双形态异质结构。“硬包软”型异质结构中的FCC相使整体组织变形更加均匀而改善了原BCC相的变形能力,是合金塑性提升的主要原因。合金强度的提高,主要源于两种形态异质结构产生的HDI强化效应和组织细化。

参考文献

Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes

[J].

Microstructure and mechanical properties of CrMoVNbFe x high-entropy alloys

[J].

CrMoVNbFe x 高熵合金微观组织结构与力学性能

[J].

Novel as-cast Ti-rich refractory complex concentrated alloys with superior tensile properties

[J].

Design of a twinning-induced plasticity high entropy alloy

[J].

A novel, single phase, non-equiatomic FeMnNiCoCr high-entropy alloy with exceptional phase stability and tensile ductility

[J].

Tensile and compressive mechanical behavior of a CoCrCuFeNiAl0.5 high entropy alloy

[J].

Nano-twin mediated plasticity in carbon-containing FeNiCoCrMn high entropy alloys

[J].

Effects of Ti on microstructures and properties of CoCrNi series medium/high entropy alloys containing single-phase FCC

[J].

Ti对单相FCC的CoCrNi体系中/高熵合金组织与性能的影响

[J].

Size-dependent plasticity in an Nb25Mo25Ta25W25 refractory high-entropy alloy

[J].

Refractory high-entropy alloys

[J].

Mechanical properties of Nb25Mo25Ta25W25 and V20Nb20Mo20Ta20W20 refractory high entropy alloys

[J].

Kr ions irradiation damage behavior of AlNbMoZrB refractory high-entropy alloy

[J].As a burnable poison element, boron (B) has been successfully added into the AlNbMoZr based refractory high-entropy alloy (RHEA) via arc melting method, thus a novel high strength nuclear RHEA material with neutron toxic properties was developed. Hence, the alloy was subjected to irradiation of Kr ions of 4 MeV intensity to assess its irradiation damage behavior in terms of its microstructure and mechanical property evolution. The results of room temperature compression testing show that AlNbMoZrB alloy has excellent mechanical property with compression yield strength ~1180 MPa, fracture strength ~1274 MPa, and plasticity ~4.8%. By comparatively examining the phase structure and microstructure evolution of AlNbMoZrB alloy before and after irradiation, it is found that AlNbMoZrB alloy has a typical dendrite structure, in which the dendrite region is a matrix phase with disordered BCC structure, and the interdendrite region is composed of FCC structure Al-Zr phase and α-Zr phase. After irradiation with Kr ions, the α-Zr phase underwent an amorphous transformation. At the same time, high density <100> and 1/2<111> dislocation loops are also generated. The volume density of the dislocation loop is ~4.11×1022 m-3 and the size is between 12 nm and 16 nm after subjected Kr ions irradiation at room temperature. The volume density of the dislocation loop decreased to ~1.63×1022 m-3 and the size increased to 23~27 nm after subjected the same Kr ions irradiation at 300℃.

AlNbMoZrB系难熔高熵合金的Kr离子辐照损伤行为

[J].基于电弧熔炼法将可燃毒物硼(B)元素添加到AlNbMoZr基难熔高熵合金(RHEA)中,制备出一种具有中子毒物特性的高强度新型核用RHEA材料。对其进行强度为4 MeV的Kr离子辐照实验,研究了这种材料的Kr离子辐照损伤行为。室温压缩结果表明,AlNbMoZrB合金具有优异的力学性能,其压缩屈服强度可达1180 MPa,压缩强度约为1274 MPa,塑性约为4.8%。对辐照前后这种合金的相结构和显微组织演化的分析结果表明,AlNbMoZrB合金具有典型的枝晶组织,其中枝晶区为无序BCC结构基体相,枝晶间区由FCC结构的Al-Zr相及α-Zr相组成,经Kr离子辐照后α-Zr相发生非晶化转变,还产生了高密度<100>和1/2<111>型位错环。在室温辐照条件下位错环的体积密度约为4.11×10<sup>22</sup> m<sup>-3</sup>,尺寸为12~16 nm;在300℃辐照条件下位错环的体积密度降低到约1.63×10<sup>22</sup> m<sup>-3</sup>,尺寸增大到23~27 nm。

Microstructure and mechanical properties of NbMoTiVSi x refractory high entropy alloy

[J].

NbMoTiVSi x 难熔高熵合金组织结构及力学性能

[J].

Microstructure and mechanical properties of Co36Ni(37- x)Cr20Al3Ti2Nb x medium-entropy alloys

[J].

Co36Ni(37- x)Cr20Al3Ti2Nb x 中熵合金的微观组织和力学性能

[J].

Solid solution strengthening in single-phase Au-Cu-Ni-Pd-Pt-based high-entropy alloys

[J].

Effect of γ′ phase coarsening on tensile properties during long-term aging of NiCoCrFeAlTiMoW alloy

[J].A γ′ phase strengthened NiCoCrFeAlTiMoW alloy was prepared in a vacuum arc melting furnace, and X-ray diffractometer (XRD), scanning electron microscope (SEM), energy dispersive spectrometer (EDS) and tensile testing machine were used to investigate the coarsening behavior and the evolution law and mechanism of mechanical properties of the γ′ phase after 200 h long-term aging at 750, 850 ℃ and 950 ℃.The results show that γ′ phase remains spherical during the aging process when the aging time is extended, γ′ phase size gradually increases and the solidification phenomenon occurs at 750, 850 ℃ and 950 ℃. The alloy has a high diffusion activation energy with a value of 357 kJ/mol.This is mainly due to the fact that the matrix is a high entropy solid solution with complex composition, and the diffusion of Al and Ti atoms in the matrix becomes difficult due to the hysteresis diffusion effect. The yield strength of the alloy gradually increases after aging at 750 ℃, the yield strength after aging at 850 ℃ first increases and then decreases, and gradually decreases after aging at 950 ℃. The change in the yield strength of the alloy is caused by the increase in the size of the γ′ phase, which leads to a shift in the precipitation strengthening mechanism of the alloy.

NiCoCrFeAlTiMoW合金长期时效过程中γ′相粗化对拉伸性能的影响

[J].采用真空电弧熔炼炉制备一种γ′相强化型NiCoCrFeAlTiMoW合金, 利用X射线衍射仪(XRD)、扫描电镜(SEM)、能谱仪(EDS)及拉伸试验机研究合金在750, 850, 950 ℃下, 经200 h长期时效后γ′相的粗化行为与力学性能的演变规律及机制。结果表明:随时效时间的延长, γ′相在时效过程中始终为球形, γ′相尺寸逐渐增大, 且在750, 850, 950 ℃均发生凝并现象。合金具有较高的扩散激活能, 其值为357 kJ/mol, 这主要是由于基体为成分复杂的高熵固溶体, 受迟滞扩散效应影响, Al, Ti原子在基体中的扩散变得困难。合金经750 ℃时效后屈服强度逐渐提高, 经850 ℃时效后的屈服强度先升高后降低, 经950 ℃时效后的屈服强度逐渐降低, 合金屈服强度的改变是由γ′相尺寸增加导致合金的沉淀强化机制发生转变所引起的。

Microstructural origin of the superior strength–ductility synergy of γ′-strengthened high-entropy alloy with heterogeneous grain structure and discontinuous precipitation configuration

[J].

Grain growth and the Hall–Petch relationship in a high-entropy FeCrNiCoMn alloy

[J].

Strengthening methods of room and cryogenic temperatures mechanical properties of Fe45Mn15Cr15Ni25 high entropy alloy

[J].

Fe45Mn15Cr15Ni25高熵合金室温及低温力学性能强化方式

[J].

Effects of rolling and annealing on microstructure and mechanical properties of FeCoCrNiN0.07 high-entropy alloy

[J].

轧制及退火对FeCoCrNiN0.07高熵合金组织及力学性能的影响

[J].

Effect of cold rolling on microstructure and mechanical behavior of Fe35Ni35Cr20Mn10 high-entropy alloy

[J].

Tuning ideal tensile strengths and intrinsic ductility of bcc refractory alloys

[J].

The limits of strength and toughness in steel

[J].

Heterostructured materials

[J].

Architecture design and strengthening-toughening mechanisms in heterogeneous-structured medium/high entropy alloys

[J].

中高熵合金的异构设计及其强韧化机理

[J].

Strengthening-toughening mechanism and mechanical properties of span-scale heterostructure high-entropy alloy

[J].High-entropy alloys overcome the limitations posed by traditional alloys due to features such as high strength, toughness, high wear resistance, and corrosion resistance. These alloys are novel metallic materials with excellent application potential; however, typically an inverse relationship is observed between the strength and ductility of a metal, which includes high-entropy alloys. Therefore, the design and development of high entropy alloys with high strength and high ductility have become a limitation in current research. Recently, heterostructure design has achieved great success in strengthening and toughening traditional metallic materials. Heterostructured and high-entropy alloys has garnered much attention and research interest to realize the strength and toughness of high-entropy alloys with high strength and high ductility. This study reviews the existing design models for heterostructures from the heterostructure scale perspective. Furthermore, the effects of different heterostructures on the strengthening and toughening mechanism and mechanical properties were analyzed, and future microstructural designs with high strength and toughness were anticipated.

高熵合金跨尺度异构强韧化及其力学性能研究进展

[J].高熵合金突破了传统合金设计理念的桎梏,具有高强度、高硬度、高耐磨性及抗腐蚀性,是一种具有巨大发展前景的新型金属材料。然而,金属材料的强度与塑性之间存在倒置矛盾关系,高熵合金仍受困于这一难题。因此,设计开发兼具高强度与高塑性的高熵合金材料已成为目前研究热点与难点。近年来,异构设计理念在传统金属材料强韧化这一问题上得到发展,如何设计异构高熵合金以实现高熵合金强韧化,使合金兼具高强度与高塑性,引起了科研人员的重视。本文从异构显微组织尺度出发,综述了目前存在的异构显微结构设计方法,分析了不同异构组织对其强韧化机制及力学性能的影响,并对未来高强韧高熵合金显微结构设计进行了展望。

Hierarchical crack buffering triples ductility in eutectic herringbone high-entropy alloys

[J].In human-made malleable materials, microdamage such as cracking usually limits material lifetime. Some biological composites, such as bone, have hierarchical microstructures that tolerate cracks but cannot withstand high elongation. We demonstrate a directionally solidified eutectic high-entropy alloy (EHEA) that successfully reconciles crack tolerance and high elongation. The solidified alloy has a hierarchically organized herringbone structure that enables bionic-inspired hierarchical crack buffering. This effect guides stable, persistent crystallographic nucleation and growth of multiple microcracks in abundant poor-deformability microstructures. Hierarchical buffering by adjacent dynamic strain-hardened features helps the cracks to avoid catastrophic growth and percolation. Our self-buffering herringbone material yields an ultrahigh uniform tensile elongation (~50%), three times that of conventional nonbuffering EHEAs, without sacrificing strength.Copyright © 2021 The Authors, some rights reserved; exclusive licensee American Association for the Advancement of Science. No claim to original U.S. Government Works.

Heterogeneous lamella structure unites ultrafine-grain strength with coarse-grain ductility

[J].Grain refinement can make conventional metals several times stronger, but this comes at dramatic loss of ductility. Here we report a heterogeneous lamella structure in Ti produced by asymmetric rolling and partial recrystallization that can produce an unprecedented property combination: as strong as ultrafine-grained metal and at the same time as ductile as conventional coarse-grained metal. It also has higher strain hardening than coarse-grained Ti, which was hitherto believed impossible. The heterogeneous lamella structure is characterized with soft micrograined lamellae embedded in hard ultrafine-grained lamella matrix. The unusual high strength is obtained with the assistance of high back stress developed from heterogeneous yielding, whereas the high ductility is attributed to back-stress hardening and dislocation hardening. The process discovered here is amenable to large-scale industrial production at low cost, and might be applicable to other metal systems.

Enhanced strength-ductility synergy in ultrafine-grained eutectic high-entropy alloys by inheriting microstructural lamellae

[J].Realizing improved strength-ductility synergy in eutectic alloys acting as in situ composite materials remains a challenge in conventional eutectic systems, which is why eutectic high-entropy alloys (EHEAs), a newly-emerging multi-principal-element eutectic category, may offer wider in situ composite possibilities. Here, we use an AlCoCrFeNi EHEA to engineer an ultrafine-grained duplex microstructure that deliberately inherits its composite lamellar nature by tailored thermo-mechanical processing to achieve property combinations which are not accessible to previously-reported reinforcement methodologies. The as-prepared samples exhibit hierarchically-structural heterogeneity due to phase decomposition, and the improved mechanical response during deformation is attributed to both a two-hierarchical constraint effect and a self-generated microcrack-arresting mechanism. This work provides a pathway for strengthening eutectic alloys and widens the design toolbox for high-performance materials based upon EHEAs.

Multistage work hardening assisted by multi-type twinning in ultrafine-grained heterostructural eutectic high-entropy alloys

[J].

Effects of temperature on mechanical properties and deformation mechanisms of the equiatomic CrFeNi medium-entropy alloy

[J].

A novel supersaturated medium entropy alloy with superior tensile properties and corrosion resistance

[J].

Dynamic deformation behavior of a FeCrNi medium entropy alloy

[J].Deformation behavior of a FeCrNi medium entropy alloy (MEA) prepared by powder metallurgy (P/M) method was investigated over a wide range of strain rates. The FeCrNi MEA exhibits high strain-hardening ability, which can be attributed to the multiple deformation mechanisms, including dislocation slip, deformation induced stacking fault and mechanical twinning. The shear localization behavior of the FeCrNi MEA was also analyzed by dynamically loading hat-shaped specimens, and the distinct adiabatic shear band cannot be observed until the shear strain reaches ~14.5. The microstructures within and outside the shear band exhibit different characteristics: the grains near the shear band are severely elongated and significantly refined by dislocation slip and twinning; inside the shear band, the initial coarse grains completely disappear, and transform into recrystallized ultrafine equiaxed grains by the classical rotational dynamic recrystallization mechanism. Moreover, microvoids preferentially nucleate in the central areas of the shear band where the temperature is very high and the shear stress is highly concentrated. These microvoids will coalesce into microcracks with the increase of strain, which eventually leads to the fracture of the shear band.

Heterogeneous lamella design to tune the mechanical behaviour of a new cost-effective compositionally complicated alloy

[J].A heterogeneous lamella (HL) design strategy was applied to manipulate mechanical properties of a new cost-effective Fe35Ni35Cr25Mo5 compositionally complicated alloy (CCA). The HL structure was produced by single-step heat treatment (800 °C for 1 h) after cold rolling. This HL structure consists of alternative lamellae regions of coarse-grained FCC matrix (5‒20 μm), and regions containing ultra-fine grains or subgrains (200‒500 nm) together with nanoprecipitates (20‒500 nm) and annealing twins. As compared with other cost-effective CCAs, the 800 °C annealed sample with HL structure demonstrated a comparable tensile property, with yield strength over 1.0 GPa and total elongation of ~13%. Formation of the annealing twins and nanoprecipitates decorated HL structure was a result of the concurrent partial recrystallization and precipitation of σ phase at the shear bands with a high density of lattice defects (e.g. high-density dislocation walls and deformation twins). The latter restricted the growth of recrystallized grains, leading to the formation of ultrafine subgrains within the HL structure. The high yield strength resulted from the multistage hetero-deformation induced (HDI) strengthening and precipitation strengthening associated with heterogeneous lamella structures containing nanoprecipitates. The ductility was originated from the coexistence of multiple deformation mechanisms, which started with dislocation slip and formation of stacking faults at the initial stage, followed by nano-twinning at the higher strain level. This HL design strategy, comprising composition and thermomechanical process designs, and the resultant microstructure tuning, open a broader window for the development of cost-effective CCAs with enhanced performance.

High-temperature age-hardening of a novel cost-effective Fe45Ni25Cr25Mo5 high entropy alloy

[J].

Enhancing mechanical properties of high Cr dual-phase FeCrNi medium-entropy alloy through mutual phase transformation and grain refinement

[J].

Enhancing cryogenic mechanical properties of a cost-effective FeCrNi dual-phase multi-principal element alloy by fully constrained heterostructure and deformation twinning

[J].