进行单轴拉伸蠕变实验可获取材料的蠕变参数。压痕蠕变实验,是用恒定载荷将圆柱形压头推入固体的平面。与传统的蠕变实验相比,压痕蠕变实验的优点是:(1) 实验用样品较小且只要有一个平坦的表面。(2) 压痕蠕变实验还可用于表征薄膜或复合材料颗粒的局部变形。与其他压痕技术(例如使用维氏压头进行维氏硬度测试)相比,圆柱形压头的优势在于:在恒定载荷测试中,压头下的截面应力是恒定的。使用圆柱形压头进行压痕蠕变实验可避免极高的局部应力集中[4]。

对于Sanicro25合金,大多用常规的拉伸蠕变实验数据评价其蠕变性能。Zhang等[5] 用拉伸实验数据研究了Sanicro25合金的高温变形和断裂机理,得到蠕变活化能为271.6 kJ/mol和真实应力指数为3,还观察到存在纳米级MX和Cu析出相。阈值应力的理论计算结果证实,纳米级Cu析出相在973 K发生剪切,而位错在973~1023 K向MX析出相爬升。吕德超等[6]也用拉伸实验结果分析了蠕变的本构方程、组织结构和断裂特征以深入理解Sanicro25钢的蠕变变形机制,确定了材料的真实应力指数为5,激活能为286 kJ/mol。Dymáček等[7]对Sanicro25钢进行了恒定变形率、恒定力和恒定变形(应力松弛)下的小冲孔实验。结果表明,恒定挠曲率实验结果与在室温和700 ℃进行的单轴拉伸实验结果之间存在若干经验关系,并确定了力/应力比Ψ和kSP参数。对恒定挠度小冲孔实验结果和单轴应力松弛实验结果的相关性分析表明,其结果相同。

本文将压痕蠕变实验结果与常规拉伸蠕变结果比较,研究奥氏体耐热钢Sanicro25的高温压痕蠕变行为。

1 实验方法

实验用Sanicro25钢(奥氏体耐热钢)的名义化学成分(质量分数,%)为:Ni(23.5~26.6)-Cr(21.5~23.5)W(2.0~4.0)-Cu(2.0~3.5)-Co(1.0~2.0)-Nb(0.30~0.60)-N(0.15~0.30)-C(0.04~0.1)-Mn(0.6)-Si(0.4)-S(0.015)(最大值)和Fe(余量)。实验用材料是经过固溶(1417~1523 K)处理的无缝钢管(外径为54 mm,壁厚为9 mm)。用线切割机将钢管切成尺寸为9 mm × 8 mm × 5 mm的试样,将其依次用400#、800#、1000#、1500#、2000#的砂纸打磨,然后用粒度为1.5 μm的抛光膏抛光。

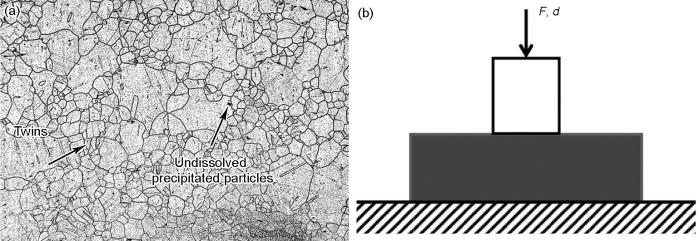

Sanicro25的原始组织图是由大量退火孪晶、等轴奥氏体以及未溶解的富Nb、Cr和N的沉淀颗粒组成(图1a)。

图1

图1

Sanicro25钢的原始金相组织和压痕蠕变示意图

Fig.1

Original metallographic organization (a) and indentation creep schematic diagram (b) of Sanicro25 steel

使用机械式蠕变实验机进行蠕变实验。这种蠕变实验机配备氮化硅平头圆柱压头(直径1 mm,硬度2200HV),加载速率为0.5 mm/min。抛光后的试样表面粗糙度Ra < 0.1 μm。这种实验机配备一个三区分割炉,用于进行恒定载荷压痕实验。平头圆柱压头安装在位于垂直加载杆中心的支架上。5 mm厚的试样位于冲头下方的平台上,试样和压头容纳在高温炉中,实验中向炉中通入氮气防止其氧化。在温度为973~1073 K、冲压应力为273~765 MPa (表1)(停留时间最长为70000 s)的条件下,对每个Sanicro25钢试样进行压痕蠕变测试。施加载荷后,用传感器自动测量压痕深度作为时间的函数并用计算机获取数据。位移传感器的精度为0.0001 mm。图1b给出了压痕蠕变示意图。

表1 实验条件与参数

Table 1

| Material | Temperature, T/K | Applied stress,σ/MPa |

|---|---|---|

973 | 510 638 765 | |

998 | 383 510 638 765 | |

| Sanicro25 steel | 1023 | 383 510 638 765 |

1073 | 273 510 638 765 |

2 结果和讨论

2.1 压痕蠕变行为

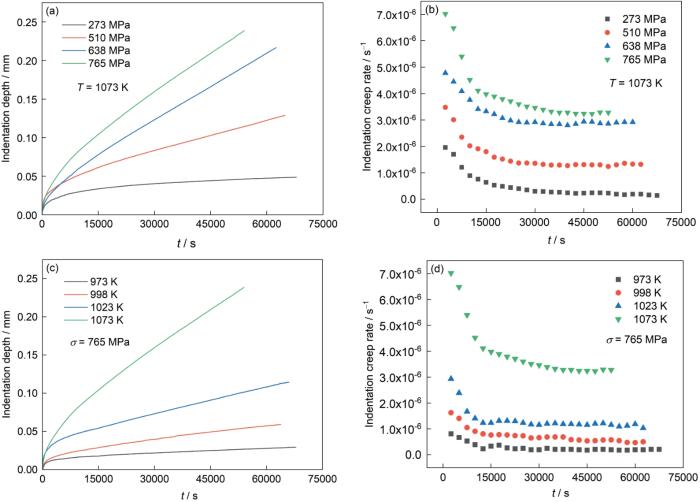

图2给出了Sanicro25钢的压痕蠕变和速率的曲线,可见温度和应力水平对材料的蠕变特性有显著的影响:随着温度的升高和应力的增大,压痕深度增大和蠕变速率提高,源于热激活促进了位错运动。根据蠕变速率的演变特征,压痕蠕变过程可分为两个典型阶段:第一阶段,始于瞬时弹性变形后的应变积累,其特征为初始阶段的蠕变速率极高。随着压痕时间的延长,材料内位错增殖和交互作用产生加工硬化,使变形抗力持续增大和蠕变速率指数降低。在此过程中,材料的加工硬化机制与动态回复机制竞争,二者达到动态平衡时系统进入第二阶段——稳态蠕变阶段。在稳态蠕变阶段压痕深度与时间呈现良好的线性关系。值得注意的是,与传统拉伸蠕变实验不同,压痕蠕变没有加速蠕变阶段(第三阶段),因为压痕实验特有的三维压应力抑制了试样的颈缩和断裂。

图2

图2

Sanicro25钢的压痕蠕变曲线

Fig.2

Indentation depth-time (a, c) and indentation creep rate-time (b, d) curves for Sanicro25 steel at different stresses (a, c) and different temperatures (b, d)

为了确保实验数据的可靠性,在试样表面随机选取测试点,对510~765 MPa应力区间(温度恒定为1073 K)进行三次重复测试。图3a表明,各次测试的蠕变曲线高度一致,相对误差小于5%,表明实验方法的可重复性和数据的可靠性。

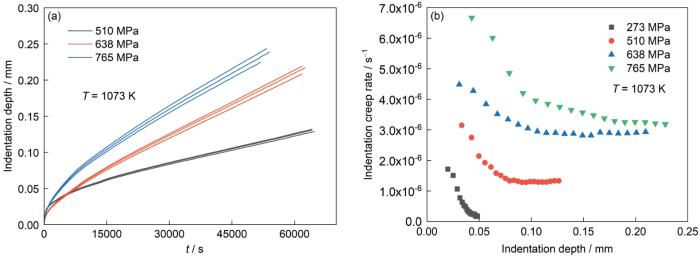

图3

图3

Sanicro25钢在1073 K的压痕蠕变曲线

Fig.3

Sanicro25 indentation creep curves at 1073 K (a) repeated three measurement curves at different stresses at 1073 K, (b) indentation creep rate-depth

图3b揭示了温度为1073 K不同应力下的压痕蠕变速率随着压入深度的演化规律。曲线的特征显示,在所有的应力下蠕变速率都经历初始阶段的高速衰减过程,达到临界压入深度后进入速率稳定区,标志着稳态蠕变阶段的开始。

2.2 压痕蠕变参数

对于常规拉伸实验,通常使用最小蠕变速率。对于压痕蠕变实验,因为没有第三蠕变阶段而用稳态蠕变速率

在压痕蠕变实验中,用直径为“2r”的扁圆柱压头在试样表面施加恒定载荷“L”。于是,作用在试样表面的应力和压痕速率分别为[8]

和

式中σind为净截面应力即压头下方的压痕应力,vind为压头的压入速度,h为t时刻的压入深度。

式中

应力相关因子α相当于约束因子,与材料的硬度和单轴流变应力有关[16]。在应力恒定的常规拉伸蠕变中,蠕变速率随温度的变化遵循Arrhenius幂律关系

式中

式中n为压痕蠕变应力指数,Qind为压痕蠕变激活能。

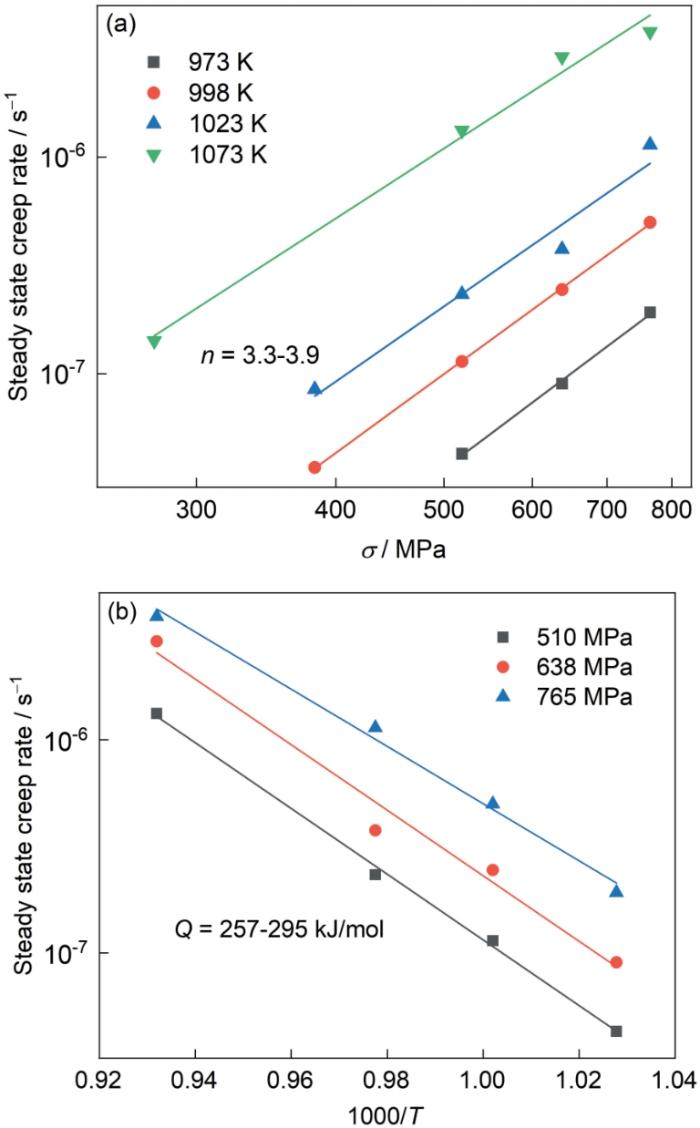

针对不同的应力指数和激活能,提出了不同的蠕变机制。根据

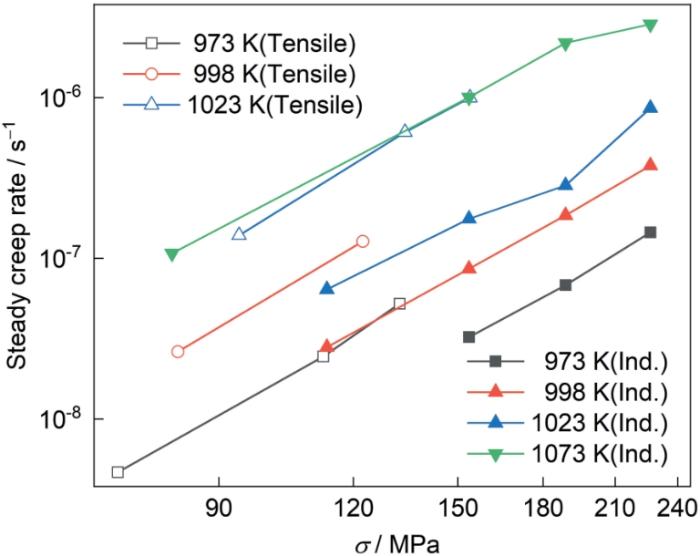

图4

图4

Sanicro25钢的稳态蠕变速率与温度和应力的关系

Fig.4

Steady state creep rate of Sanicro25 steel as a function of temperature and stress (a) steady state creep rate-stress, (b) steady state creep rate-temperature

图5

图5

拉伸蠕变与转换后压痕蠕变速率-应力图

Fig.5

Tensile creep vs. corrected indentation creep rate-stress plot

2.3 压痕的形貌和组织

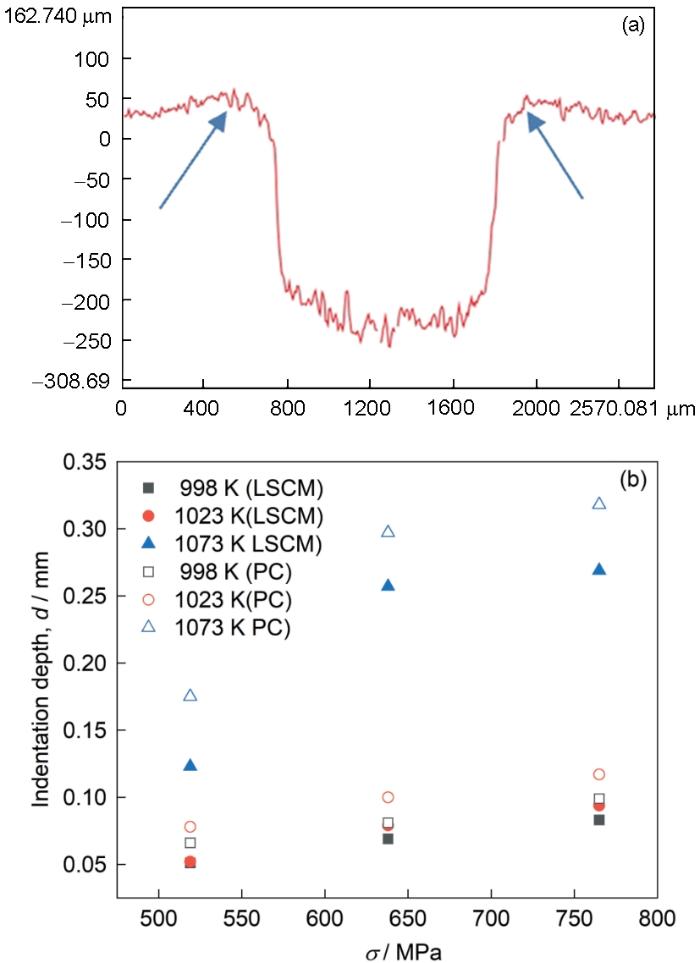

图6

图6

在温度为1073 K和压力为765 MPa条件下压痕的纵向激光共聚焦图与实测深度和计算机记录深度的对比

Fig. 6

Longitudinal laser confocal map of indentation at 1073 K-765 MPa vs. measured and computer-recorded depths (a) laser confocal, (b) measured depth vs. recorded depth

图6b给出了用共聚焦测出的实际压痕深度与计算机记录的压痕深度的对比。可以看出,实测的压痕深度普遍小于计算机记录的深度。其原因是,在常温下测量时金属的热胀冷缩使试样的体积缩减,但是相差不大。这表明,该设备的精度较高,测量误差较小。

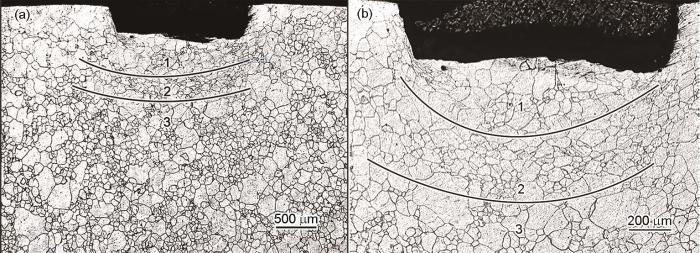

图7a和图7b分别给出了在1073 K/765 MPa条件下压痕蠕变试样50倍和100倍放大倍率的光学显微组织。显微分析显示,压头下方的材料呈现出显著的区域化变形特征,黑色线区分三个特征区域的界面。其中区域1(压头正下方)表现为典型的"死区"形态,晶粒的几何形貌与原始组织基本上相同,未发生晶格畸变或位错结构演化,表明此区域主要承受静水压力。与其不同的是,区域2(过渡变形区)存在明显的塑性应变梯度分布,晶粒沿最大剪切应力方向发生择优取向,原始等轴晶粒压缩为椭球状,证实了位错滑移主导的塑性流动机制。区域3 (外围未变形区)则完整保留了材料的原始显微组织特征,其晶界形貌与晶粒尺寸分布与基体完全相同,印证了压痕塑性区范围是有限的。

图7

图7

Sanicro25钢在温度为1073 K和压力为765 MPa的条件下蠕变后的金相显微组织

Fig.7

Metallographic microstructure of Sanicro25 steel after creep at 1073 K-765 MPa

3 结论

(1) Sanicro25钢的稳态蠕变速率与加载应力符合幂率关系,其应力指数和激活能与单轴拉伸实验的结果吻合较好,表明可用局部压痕蠕变结果表征材料的蠕变行为。Sanicro25钢的压痕和拉伸数据的相关性较好,可用转换因子α和β将其关联。

(2) 试样表面材料的堆积与材料在压头底部形成完全塑性区域后沿压头方向的塑性流动有关。在压头下方形成了三个区域,过渡区(区域2)内的晶粒发生了明显的变形。

参考文献

Oxidation behavior of austenitic steel Sanicro25 and TP347HFG in supercritical water

[J].

Precipitation behavior of Cu-rich phase in 18Cr9-Ni3CuNbN austenitic heat-resistant steel at early aging stage

[J].

18Cr9Ni3CuNbN奥氏体耐热钢中富Cu相的早期析出行为

[J].应用三维原子探针技术研究了600℃超超临界电站锅炉过热器/再热器用18Cr9Ni3CuNbN奥氏体耐热钢中强化相富Cu相的早期析出行为, 并绘制出富Cu相在18Cr-9Ni型奥氏体耐热钢中的C曲线。结果表明: 在高温时效过程中富Cu相无论在650℃还是在700℃均能较快地析出, 其形成过程都是在短时间内先形成富Cu偏聚区, 随着时效时间的延长Cu原子继续扩散到富Cu偏聚区, 其它原子如Fe, Cr, Ni等则被排出富Cu偏聚区而扩散到奥氏体基体中, 最终形成富Cu相。

Effect of cold deformation on Microstructure and properties of Sanicro25 austenitic heat-resistant steel

[J].

冷变形对Sanicro25奥氏体耐热钢组织和性能的影响

[J].对Sanicro 25奥氏体耐热钢进行变形量分别为0,20%,50%的冷轧变形,通过组织观察、电子背散射衍射、X射线衍射、拉伸试验和硬度测试等方法研究了冷变形对该钢显微组织、织构和力学性能的影响。结果表明:在试验条件下冷变形时试验钢中未形成新相;随冷变形量的增加,试验钢中孪晶数量和位错密度增加;试验钢在反极图z方向上的晶粒取向〈111〉,〈001〉为不稳定取向,冷变形导致了新的{112}〈110〉织构产生;随着冷变形量的增大,试验钢的Rotated cube{001}〈110〉和Goss{110}〈001〉织构的强度总体呈减弱趋势,抗拉强度、屈服强度和硬度增大,抵抗塑性变形能力减弱。

Creep of a TiAl alloy: a comparison of indentation and tensile testing

[J].

High-temperature deformation and fracture mechanisms of an advanced heat resistant Fe-Cr-Ni alloy

[J].

Creep behavior and fracture characteristic of austenitic heat-resistant steel Sanicro25

[J].The creep behavior at 130~240 MPa /973~1023 K of Sanicro25 steel for ultra-supercritical power plants were investigated by OM, SEM and TEM. The results showed that the minimum creep rate increases with the increasing temperature and applied stress. Based on the characteristics of the minimum creep rate, the stress exponents of 7.6~8.2 and the apparent activation energy of 496.7~531.8 kJ/mol can be acquired for the creep process. Nano-scale Cu-rich phase and MX phase precipitated in the matrix imped the dislocation motion, thus resulted in the emerging of creep threshold stress. The creep threshold stresses can be estimated by the linear extrapolation method, and which decrease with the increase in temperature. By invoking the concept of the threshold stresses to modify the constitutive equation, $\dot{\varepsilon}_{\min }=A_{2}\left[\left(\sigma-\sigma_{\mathrm{th}}\right) / G\right]^{n} \exp (-Q / R T)$, the normalization of the minimum creep rate can be acquired at various temperatures; Meanwhile, the true stress exponent (n=5) and the true apparent activation energy (Q=286.6kJ/mol approximately equal to the γ-Fe self-diffusion activation energy) can be identified. The creep rate-controlling mechanism was determined to be dislocation climbing mechanism assisted by lattice self-diffusion.

奥氏体耐热钢Sanicro25蠕变行为和断裂特征

[J].用OM、SEM和TEM等方法研究了超超临界电站用Sanicro25钢的蠕变机制。结果表明,这种钢的最小蠕变速率随着温度的升高和应力的增大而提高。根据最小蠕变速率特征得出表观应力指数为7.6~8.2,表观激活能为496.7~531.8 kJ/mol。在蠕变过程中在晶内弥散析出的纳米级Cu-rich相和MX相阻碍位错运动,导致蠕变门槛值应力的出现。用线性外延法求出的门槛值应力,随着温度的升高而减小。用门槛值将蠕变本构方程修正为$\dot{\varepsilon}_{\min }=A_{2}\left[\left(\sigma-\sigma_{\mathrm{th}}\right) / G\right]^{n} \exp (-Q / R T)$,可将不同温度下的最小蠕变速率归一化;同时确定真实应力指数(n=5)和真实表观激活能(Q=286.6 kJ/mol约等于γ-Fe自扩散激活能),从而判别出实验参数下材料的蠕变机制为点阵自扩散协助的位错攀移。

Small punch testing of Sanicro25 steel and its correlation with uniaxial tests

[J].

Impression creep; a new creep test

[J].

A simple theory of static and dynamic hardness

[J].

Computer simulation of impression creep by the finite element method

[J].

Impression creep of β-tin single crystals

[J].

Impression creep behaviour of different zones of pulsed gas tungsten arc welded Ti-6Al-4V alloy

[J].

Tensile and creep properties of Al-7Si-0.3 Mg alloy with Zr and Er addition

[J].The combined and singular effects of Zr and Er addition on the microstructure, tensile and impression creep behaviour of the cast A356 alloy were investigated. The Zr and Er refined the α-Al dendrites and secondary dendrite arm spacing (SDAS) and modified the eutectic morphology. The simultaneous addition of Zr and Er exhibited the smallest α-Al dendrites and SDAS with a fibrous eutectic morphology, resulting in the highest yield (∼118 MPa) and tensile (∼190 MPa) strength, and the largest creep resistance. The stress exponent, and the activation energy, were within the range of 6.28–7.22 and between 121.6 and 148.2 kJ mol−1, respectively. The lattice self-diffusion climb-controlled creep was the dominant creep mechanism. The constitutive creep equation was developed for each alloy.

Creep of AZ31 Mg alloy: a comparison of impression and tensile behavior

[J].

The correlation of indentation experiments

[J].

Deformation behavior of dilute SnBi (0.5 to 6 at. pct) solid solutions

[J].

Identifiying creep mechanisms at low stresses

[J].

Determination of creep parameters from indentation creep experiments: a parametric finite element study for single phase materials

[J].

Interpretation of impression creep data using a reference stress approach

[J].