1

2012

... 调幅分解,能使材料的成分周期性变化且具有特定波长结构的连续纳米双相组织.这种独特的微观结构能显著提高材料的强度、硬度、抗蠕变性等力学性能[1,2].因此,调幅分解可用于设计性能优异的先进材料.调控调幅分解强化材料的力学性能,一直是国内外科研工作者的重点.相关研究涉及多种合金体系,包括Ti基合金[3,4]、Al基合金[5,6]、Cu基合金[7~9]、Fe-Mn记忆合金[10,11]以及双相钢[12~14]等.Ti基合金体系的Ti-6554[15,16]、Ti-55531[17]和Ti-10V-6Cu[18]等亚稳态β-Ti合金中都存在调幅分解.Yang等[19]在Ti-Al-Mo-V-Cr-Zr合金中构建了β+β'调幅分解片层结构,通过周期性分布的纳米结构阻碍了位错运动使其力学性能显著提高.An等[20]利用调幅分解机制在难熔高熵合金Hf-Nb-Ti-V体系中生成了具有周期性晶格畸变的β'相,在保持高强度的同时显著改善了合金的室温拉伸延展性.Hua等[21]将调幅分解机制引入Zr-Nb-Ti中熵合金体系,使其屈服强度显著提高并降低了弹性模量.同时,许多研究者也在探究调幅分解影响材料性能的机理.Cahn[22,23]建立了预测调幅分解微观结构的理论模型,提出了调幅分解强化理论[24].这个强化理论指出,调幅分解在合金中的强化作用是通过共格组织之间的内应力与位错相互作用实现的.Mott和Nabarro[25]认为,屈服强度取决于调幅分解组织的内应力场.值得注意的是,作为固态相变过程中的一种扩散型相变,调幅分解与传统的形核-长大方式不同,母相的过饱和固溶体在一定温度下通过原子上坡扩散引起的成分涨落产生结构相同、成分不同的两个新相,两相组织根据相变动力学呈现片层状或网格状等不同形貌[26,27].因此,成分起伏是调幅分解的原始驱动力,成分调控在调幅分解中占据主导作用.Park等[28]在铁质中熵合金中引入Cu和Al元素,通过调幅分解结构抑制了应变局域化,在保持良好伸长率的同时使其机械强度提高.Röyset和Ryum[29]在Al-Zn-Mg合金中添加微量Sc元素促进了调幅分解过程生成了纳米级析出相,显著提高了合金的强度和抗腐蚀性能.Guo等[30]在Cu-Ni-Zn合金体系中引入P元素,通过增大溶质与溶剂原子尺寸的差异诱导合金调幅分解而使其硬度提高. ...

1

2012

... 调幅分解,能使材料的成分周期性变化且具有特定波长结构的连续纳米双相组织.这种独特的微观结构能显著提高材料的强度、硬度、抗蠕变性等力学性能[1,2].因此,调幅分解可用于设计性能优异的先进材料.调控调幅分解强化材料的力学性能,一直是国内外科研工作者的重点.相关研究涉及多种合金体系,包括Ti基合金[3,4]、Al基合金[5,6]、Cu基合金[7~9]、Fe-Mn记忆合金[10,11]以及双相钢[12~14]等.Ti基合金体系的Ti-6554[15,16]、Ti-55531[17]和Ti-10V-6Cu[18]等亚稳态β-Ti合金中都存在调幅分解.Yang等[19]在Ti-Al-Mo-V-Cr-Zr合金中构建了β+β'调幅分解片层结构,通过周期性分布的纳米结构阻碍了位错运动使其力学性能显著提高.An等[20]利用调幅分解机制在难熔高熵合金Hf-Nb-Ti-V体系中生成了具有周期性晶格畸变的β'相,在保持高强度的同时显著改善了合金的室温拉伸延展性.Hua等[21]将调幅分解机制引入Zr-Nb-Ti中熵合金体系,使其屈服强度显著提高并降低了弹性模量.同时,许多研究者也在探究调幅分解影响材料性能的机理.Cahn[22,23]建立了预测调幅分解微观结构的理论模型,提出了调幅分解强化理论[24].这个强化理论指出,调幅分解在合金中的强化作用是通过共格组织之间的内应力与位错相互作用实现的.Mott和Nabarro[25]认为,屈服强度取决于调幅分解组织的内应力场.值得注意的是,作为固态相变过程中的一种扩散型相变,调幅分解与传统的形核-长大方式不同,母相的过饱和固溶体在一定温度下通过原子上坡扩散引起的成分涨落产生结构相同、成分不同的两个新相,两相组织根据相变动力学呈现片层状或网格状等不同形貌[26,27].因此,成分起伏是调幅分解的原始驱动力,成分调控在调幅分解中占据主导作用.Park等[28]在铁质中熵合金中引入Cu和Al元素,通过调幅分解结构抑制了应变局域化,在保持良好伸长率的同时使其机械强度提高.Röyset和Ryum[29]在Al-Zn-Mg合金中添加微量Sc元素促进了调幅分解过程生成了纳米级析出相,显著提高了合金的强度和抗腐蚀性能.Guo等[30]在Cu-Ni-Zn合金体系中引入P元素,通过增大溶质与溶剂原子尺寸的差异诱导合金调幅分解而使其硬度提高. ...

1

2010

... 调幅分解,能使材料的成分周期性变化且具有特定波长结构的连续纳米双相组织.这种独特的微观结构能显著提高材料的强度、硬度、抗蠕变性等力学性能[1,2].因此,调幅分解可用于设计性能优异的先进材料.调控调幅分解强化材料的力学性能,一直是国内外科研工作者的重点.相关研究涉及多种合金体系,包括Ti基合金[3,4]、Al基合金[5,6]、Cu基合金[7~9]、Fe-Mn记忆合金[10,11]以及双相钢[12~14]等.Ti基合金体系的Ti-6554[15,16]、Ti-55531[17]和Ti-10V-6Cu[18]等亚稳态β-Ti合金中都存在调幅分解.Yang等[19]在Ti-Al-Mo-V-Cr-Zr合金中构建了β+β'调幅分解片层结构,通过周期性分布的纳米结构阻碍了位错运动使其力学性能显著提高.An等[20]利用调幅分解机制在难熔高熵合金Hf-Nb-Ti-V体系中生成了具有周期性晶格畸变的β'相,在保持高强度的同时显著改善了合金的室温拉伸延展性.Hua等[21]将调幅分解机制引入Zr-Nb-Ti中熵合金体系,使其屈服强度显著提高并降低了弹性模量.同时,许多研究者也在探究调幅分解影响材料性能的机理.Cahn[22,23]建立了预测调幅分解微观结构的理论模型,提出了调幅分解强化理论[24].这个强化理论指出,调幅分解在合金中的强化作用是通过共格组织之间的内应力与位错相互作用实现的.Mott和Nabarro[25]认为,屈服强度取决于调幅分解组织的内应力场.值得注意的是,作为固态相变过程中的一种扩散型相变,调幅分解与传统的形核-长大方式不同,母相的过饱和固溶体在一定温度下通过原子上坡扩散引起的成分涨落产生结构相同、成分不同的两个新相,两相组织根据相变动力学呈现片层状或网格状等不同形貌[26,27].因此,成分起伏是调幅分解的原始驱动力,成分调控在调幅分解中占据主导作用.Park等[28]在铁质中熵合金中引入Cu和Al元素,通过调幅分解结构抑制了应变局域化,在保持良好伸长率的同时使其机械强度提高.Röyset和Ryum[29]在Al-Zn-Mg合金中添加微量Sc元素促进了调幅分解过程生成了纳米级析出相,显著提高了合金的强度和抗腐蚀性能.Guo等[30]在Cu-Ni-Zn合金体系中引入P元素,通过增大溶质与溶剂原子尺寸的差异诱导合金调幅分解而使其硬度提高. ...

1

2010

... 调幅分解,能使材料的成分周期性变化且具有特定波长结构的连续纳米双相组织.这种独特的微观结构能显著提高材料的强度、硬度、抗蠕变性等力学性能[1,2].因此,调幅分解可用于设计性能优异的先进材料.调控调幅分解强化材料的力学性能,一直是国内外科研工作者的重点.相关研究涉及多种合金体系,包括Ti基合金[3,4]、Al基合金[5,6]、Cu基合金[7~9]、Fe-Mn记忆合金[10,11]以及双相钢[12~14]等.Ti基合金体系的Ti-6554[15,16]、Ti-55531[17]和Ti-10V-6Cu[18]等亚稳态β-Ti合金中都存在调幅分解.Yang等[19]在Ti-Al-Mo-V-Cr-Zr合金中构建了β+β'调幅分解片层结构,通过周期性分布的纳米结构阻碍了位错运动使其力学性能显著提高.An等[20]利用调幅分解机制在难熔高熵合金Hf-Nb-Ti-V体系中生成了具有周期性晶格畸变的β'相,在保持高强度的同时显著改善了合金的室温拉伸延展性.Hua等[21]将调幅分解机制引入Zr-Nb-Ti中熵合金体系,使其屈服强度显著提高并降低了弹性模量.同时,许多研究者也在探究调幅分解影响材料性能的机理.Cahn[22,23]建立了预测调幅分解微观结构的理论模型,提出了调幅分解强化理论[24].这个强化理论指出,调幅分解在合金中的强化作用是通过共格组织之间的内应力与位错相互作用实现的.Mott和Nabarro[25]认为,屈服强度取决于调幅分解组织的内应力场.值得注意的是,作为固态相变过程中的一种扩散型相变,调幅分解与传统的形核-长大方式不同,母相的过饱和固溶体在一定温度下通过原子上坡扩散引起的成分涨落产生结构相同、成分不同的两个新相,两相组织根据相变动力学呈现片层状或网格状等不同形貌[26,27].因此,成分起伏是调幅分解的原始驱动力,成分调控在调幅分解中占据主导作用.Park等[28]在铁质中熵合金中引入Cu和Al元素,通过调幅分解结构抑制了应变局域化,在保持良好伸长率的同时使其机械强度提高.Röyset和Ryum[29]在Al-Zn-Mg合金中添加微量Sc元素促进了调幅分解过程生成了纳米级析出相,显著提高了合金的强度和抗腐蚀性能.Guo等[30]在Cu-Ni-Zn合金体系中引入P元素,通过增大溶质与溶剂原子尺寸的差异诱导合金调幅分解而使其硬度提高. ...

Spinodal decomposition of the γ-phase upon quenching in the Ti-Al-Nb ternary alloy system

1

2011

... 调幅分解,能使材料的成分周期性变化且具有特定波长结构的连续纳米双相组织.这种独特的微观结构能显著提高材料的强度、硬度、抗蠕变性等力学性能[1,2].因此,调幅分解可用于设计性能优异的先进材料.调控调幅分解强化材料的力学性能,一直是国内外科研工作者的重点.相关研究涉及多种合金体系,包括Ti基合金[3,4]、Al基合金[5,6]、Cu基合金[7~9]、Fe-Mn记忆合金[10,11]以及双相钢[12~14]等.Ti基合金体系的Ti-6554[15,16]、Ti-55531[17]和Ti-10V-6Cu[18]等亚稳态β-Ti合金中都存在调幅分解.Yang等[19]在Ti-Al-Mo-V-Cr-Zr合金中构建了β+β'调幅分解片层结构,通过周期性分布的纳米结构阻碍了位错运动使其力学性能显著提高.An等[20]利用调幅分解机制在难熔高熵合金Hf-Nb-Ti-V体系中生成了具有周期性晶格畸变的β'相,在保持高强度的同时显著改善了合金的室温拉伸延展性.Hua等[21]将调幅分解机制引入Zr-Nb-Ti中熵合金体系,使其屈服强度显著提高并降低了弹性模量.同时,许多研究者也在探究调幅分解影响材料性能的机理.Cahn[22,23]建立了预测调幅分解微观结构的理论模型,提出了调幅分解强化理论[24].这个强化理论指出,调幅分解在合金中的强化作用是通过共格组织之间的内应力与位错相互作用实现的.Mott和Nabarro[25]认为,屈服强度取决于调幅分解组织的内应力场.值得注意的是,作为固态相变过程中的一种扩散型相变,调幅分解与传统的形核-长大方式不同,母相的过饱和固溶体在一定温度下通过原子上坡扩散引起的成分涨落产生结构相同、成分不同的两个新相,两相组织根据相变动力学呈现片层状或网格状等不同形貌[26,27].因此,成分起伏是调幅分解的原始驱动力,成分调控在调幅分解中占据主导作用.Park等[28]在铁质中熵合金中引入Cu和Al元素,通过调幅分解结构抑制了应变局域化,在保持良好伸长率的同时使其机械强度提高.Röyset和Ryum[29]在Al-Zn-Mg合金中添加微量Sc元素促进了调幅分解过程生成了纳米级析出相,显著提高了合金的强度和抗腐蚀性能.Guo等[30]在Cu-Ni-Zn合金体系中引入P元素,通过增大溶质与溶剂原子尺寸的差异诱导合金调幅分解而使其硬度提高. ...

Phase-field study of the spinodal decomposition rate of β phase in oxygen-added Ti-Nb alloys

1

2020

... 调幅分解,能使材料的成分周期性变化且具有特定波长结构的连续纳米双相组织.这种独特的微观结构能显著提高材料的强度、硬度、抗蠕变性等力学性能[1,2].因此,调幅分解可用于设计性能优异的先进材料.调控调幅分解强化材料的力学性能,一直是国内外科研工作者的重点.相关研究涉及多种合金体系,包括Ti基合金[3,4]、Al基合金[5,6]、Cu基合金[7~9]、Fe-Mn记忆合金[10,11]以及双相钢[12~14]等.Ti基合金体系的Ti-6554[15,16]、Ti-55531[17]和Ti-10V-6Cu[18]等亚稳态β-Ti合金中都存在调幅分解.Yang等[19]在Ti-Al-Mo-V-Cr-Zr合金中构建了β+β'调幅分解片层结构,通过周期性分布的纳米结构阻碍了位错运动使其力学性能显著提高.An等[20]利用调幅分解机制在难熔高熵合金Hf-Nb-Ti-V体系中生成了具有周期性晶格畸变的β'相,在保持高强度的同时显著改善了合金的室温拉伸延展性.Hua等[21]将调幅分解机制引入Zr-Nb-Ti中熵合金体系,使其屈服强度显著提高并降低了弹性模量.同时,许多研究者也在探究调幅分解影响材料性能的机理.Cahn[22,23]建立了预测调幅分解微观结构的理论模型,提出了调幅分解强化理论[24].这个强化理论指出,调幅分解在合金中的强化作用是通过共格组织之间的内应力与位错相互作用实现的.Mott和Nabarro[25]认为,屈服强度取决于调幅分解组织的内应力场.值得注意的是,作为固态相变过程中的一种扩散型相变,调幅分解与传统的形核-长大方式不同,母相的过饱和固溶体在一定温度下通过原子上坡扩散引起的成分涨落产生结构相同、成分不同的两个新相,两相组织根据相变动力学呈现片层状或网格状等不同形貌[26,27].因此,成分起伏是调幅分解的原始驱动力,成分调控在调幅分解中占据主导作用.Park等[28]在铁质中熵合金中引入Cu和Al元素,通过调幅分解结构抑制了应变局域化,在保持良好伸长率的同时使其机械强度提高.Röyset和Ryum[29]在Al-Zn-Mg合金中添加微量Sc元素促进了调幅分解过程生成了纳米级析出相,显著提高了合金的强度和抗腐蚀性能.Guo等[30]在Cu-Ni-Zn合金体系中引入P元素,通过增大溶质与溶剂原子尺寸的差异诱导合金调幅分解而使其硬度提高. ...

Concurrent strengthening of ultrafine-grained age-hardenable Al-Mg alloy by means of high-pressure torsion and spinodal decomposition

1

2017

... 调幅分解,能使材料的成分周期性变化且具有特定波长结构的连续纳米双相组织.这种独特的微观结构能显著提高材料的强度、硬度、抗蠕变性等力学性能[1,2].因此,调幅分解可用于设计性能优异的先进材料.调控调幅分解强化材料的力学性能,一直是国内外科研工作者的重点.相关研究涉及多种合金体系,包括Ti基合金[3,4]、Al基合金[5,6]、Cu基合金[7~9]、Fe-Mn记忆合金[10,11]以及双相钢[12~14]等.Ti基合金体系的Ti-6554[15,16]、Ti-55531[17]和Ti-10V-6Cu[18]等亚稳态β-Ti合金中都存在调幅分解.Yang等[19]在Ti-Al-Mo-V-Cr-Zr合金中构建了β+β'调幅分解片层结构,通过周期性分布的纳米结构阻碍了位错运动使其力学性能显著提高.An等[20]利用调幅分解机制在难熔高熵合金Hf-Nb-Ti-V体系中生成了具有周期性晶格畸变的β'相,在保持高强度的同时显著改善了合金的室温拉伸延展性.Hua等[21]将调幅分解机制引入Zr-Nb-Ti中熵合金体系,使其屈服强度显著提高并降低了弹性模量.同时,许多研究者也在探究调幅分解影响材料性能的机理.Cahn[22,23]建立了预测调幅分解微观结构的理论模型,提出了调幅分解强化理论[24].这个强化理论指出,调幅分解在合金中的强化作用是通过共格组织之间的内应力与位错相互作用实现的.Mott和Nabarro[25]认为,屈服强度取决于调幅分解组织的内应力场.值得注意的是,作为固态相变过程中的一种扩散型相变,调幅分解与传统的形核-长大方式不同,母相的过饱和固溶体在一定温度下通过原子上坡扩散引起的成分涨落产生结构相同、成分不同的两个新相,两相组织根据相变动力学呈现片层状或网格状等不同形貌[26,27].因此,成分起伏是调幅分解的原始驱动力,成分调控在调幅分解中占据主导作用.Park等[28]在铁质中熵合金中引入Cu和Al元素,通过调幅分解结构抑制了应变局域化,在保持良好伸长率的同时使其机械强度提高.Röyset和Ryum[29]在Al-Zn-Mg合金中添加微量Sc元素促进了调幅分解过程生成了纳米级析出相,显著提高了合金的强度和抗腐蚀性能.Guo等[30]在Cu-Ni-Zn合金体系中引入P元素,通过增大溶质与溶剂原子尺寸的差异诱导合金调幅分解而使其硬度提高. ...

On the interaction between Ag-depleted zones surrounding γ plates and spinodal decomposition in an Al-22at.%Ag alloy

1

2002

... 调幅分解,能使材料的成分周期性变化且具有特定波长结构的连续纳米双相组织.这种独特的微观结构能显著提高材料的强度、硬度、抗蠕变性等力学性能[1,2].因此,调幅分解可用于设计性能优异的先进材料.调控调幅分解强化材料的力学性能,一直是国内外科研工作者的重点.相关研究涉及多种合金体系,包括Ti基合金[3,4]、Al基合金[5,6]、Cu基合金[7~9]、Fe-Mn记忆合金[10,11]以及双相钢[12~14]等.Ti基合金体系的Ti-6554[15,16]、Ti-55531[17]和Ti-10V-6Cu[18]等亚稳态β-Ti合金中都存在调幅分解.Yang等[19]在Ti-Al-Mo-V-Cr-Zr合金中构建了β+β'调幅分解片层结构,通过周期性分布的纳米结构阻碍了位错运动使其力学性能显著提高.An等[20]利用调幅分解机制在难熔高熵合金Hf-Nb-Ti-V体系中生成了具有周期性晶格畸变的β'相,在保持高强度的同时显著改善了合金的室温拉伸延展性.Hua等[21]将调幅分解机制引入Zr-Nb-Ti中熵合金体系,使其屈服强度显著提高并降低了弹性模量.同时,许多研究者也在探究调幅分解影响材料性能的机理.Cahn[22,23]建立了预测调幅分解微观结构的理论模型,提出了调幅分解强化理论[24].这个强化理论指出,调幅分解在合金中的强化作用是通过共格组织之间的内应力与位错相互作用实现的.Mott和Nabarro[25]认为,屈服强度取决于调幅分解组织的内应力场.值得注意的是,作为固态相变过程中的一种扩散型相变,调幅分解与传统的形核-长大方式不同,母相的过饱和固溶体在一定温度下通过原子上坡扩散引起的成分涨落产生结构相同、成分不同的两个新相,两相组织根据相变动力学呈现片层状或网格状等不同形貌[26,27].因此,成分起伏是调幅分解的原始驱动力,成分调控在调幅分解中占据主导作用.Park等[28]在铁质中熵合金中引入Cu和Al元素,通过调幅分解结构抑制了应变局域化,在保持良好伸长率的同时使其机械强度提高.Röyset和Ryum[29]在Al-Zn-Mg合金中添加微量Sc元素促进了调幅分解过程生成了纳米级析出相,显著提高了合金的强度和抗腐蚀性能.Guo等[30]在Cu-Ni-Zn合金体系中引入P元素,通过增大溶质与溶剂原子尺寸的差异诱导合金调幅分解而使其硬度提高. ...

Microstructural simulation in spinodally-decomposed Cu-70at.%Ni and Cu-46at.%Ni-4at.%Fe alloys

1

2009

... 调幅分解,能使材料的成分周期性变化且具有特定波长结构的连续纳米双相组织.这种独特的微观结构能显著提高材料的强度、硬度、抗蠕变性等力学性能[1,2].因此,调幅分解可用于设计性能优异的先进材料.调控调幅分解强化材料的力学性能,一直是国内外科研工作者的重点.相关研究涉及多种合金体系,包括Ti基合金[3,4]、Al基合金[5,6]、Cu基合金[7~9]、Fe-Mn记忆合金[10,11]以及双相钢[12~14]等.Ti基合金体系的Ti-6554[15,16]、Ti-55531[17]和Ti-10V-6Cu[18]等亚稳态β-Ti合金中都存在调幅分解.Yang等[19]在Ti-Al-Mo-V-Cr-Zr合金中构建了β+β'调幅分解片层结构,通过周期性分布的纳米结构阻碍了位错运动使其力学性能显著提高.An等[20]利用调幅分解机制在难熔高熵合金Hf-Nb-Ti-V体系中生成了具有周期性晶格畸变的β'相,在保持高强度的同时显著改善了合金的室温拉伸延展性.Hua等[21]将调幅分解机制引入Zr-Nb-Ti中熵合金体系,使其屈服强度显著提高并降低了弹性模量.同时,许多研究者也在探究调幅分解影响材料性能的机理.Cahn[22,23]建立了预测调幅分解微观结构的理论模型,提出了调幅分解强化理论[24].这个强化理论指出,调幅分解在合金中的强化作用是通过共格组织之间的内应力与位错相互作用实现的.Mott和Nabarro[25]认为,屈服强度取决于调幅分解组织的内应力场.值得注意的是,作为固态相变过程中的一种扩散型相变,调幅分解与传统的形核-长大方式不同,母相的过饱和固溶体在一定温度下通过原子上坡扩散引起的成分涨落产生结构相同、成分不同的两个新相,两相组织根据相变动力学呈现片层状或网格状等不同形貌[26,27].因此,成分起伏是调幅分解的原始驱动力,成分调控在调幅分解中占据主导作用.Park等[28]在铁质中熵合金中引入Cu和Al元素,通过调幅分解结构抑制了应变局域化,在保持良好伸长率的同时使其机械强度提高.Röyset和Ryum[29]在Al-Zn-Mg合金中添加微量Sc元素促进了调幅分解过程生成了纳米级析出相,显著提高了合金的强度和抗腐蚀性能.Guo等[30]在Cu-Ni-Zn合金体系中引入P元素,通过增大溶质与溶剂原子尺寸的差异诱导合金调幅分解而使其硬度提高. ...

Suppressing spinodal decomposition by adding Co into Cu-Ni-Si alloy

0

2016

Spinodal decomposition in a melt-spun Cu-15Ni-8Sn alloy

1

2019

... 调幅分解,能使材料的成分周期性变化且具有特定波长结构的连续纳米双相组织.这种独特的微观结构能显著提高材料的强度、硬度、抗蠕变性等力学性能[1,2].因此,调幅分解可用于设计性能优异的先进材料.调控调幅分解强化材料的力学性能,一直是国内外科研工作者的重点.相关研究涉及多种合金体系,包括Ti基合金[3,4]、Al基合金[5,6]、Cu基合金[7~9]、Fe-Mn记忆合金[10,11]以及双相钢[12~14]等.Ti基合金体系的Ti-6554[15,16]、Ti-55531[17]和Ti-10V-6Cu[18]等亚稳态β-Ti合金中都存在调幅分解.Yang等[19]在Ti-Al-Mo-V-Cr-Zr合金中构建了β+β'调幅分解片层结构,通过周期性分布的纳米结构阻碍了位错运动使其力学性能显著提高.An等[20]利用调幅分解机制在难熔高熵合金Hf-Nb-Ti-V体系中生成了具有周期性晶格畸变的β'相,在保持高强度的同时显著改善了合金的室温拉伸延展性.Hua等[21]将调幅分解机制引入Zr-Nb-Ti中熵合金体系,使其屈服强度显著提高并降低了弹性模量.同时,许多研究者也在探究调幅分解影响材料性能的机理.Cahn[22,23]建立了预测调幅分解微观结构的理论模型,提出了调幅分解强化理论[24].这个强化理论指出,调幅分解在合金中的强化作用是通过共格组织之间的内应力与位错相互作用实现的.Mott和Nabarro[25]认为,屈服强度取决于调幅分解组织的内应力场.值得注意的是,作为固态相变过程中的一种扩散型相变,调幅分解与传统的形核-长大方式不同,母相的过饱和固溶体在一定温度下通过原子上坡扩散引起的成分涨落产生结构相同、成分不同的两个新相,两相组织根据相变动力学呈现片层状或网格状等不同形貌[26,27].因此,成分起伏是调幅分解的原始驱动力,成分调控在调幅分解中占据主导作用.Park等[28]在铁质中熵合金中引入Cu和Al元素,通过调幅分解结构抑制了应变局域化,在保持良好伸长率的同时使其机械强度提高.Röyset和Ryum[29]在Al-Zn-Mg合金中添加微量Sc元素促进了调幅分解过程生成了纳米级析出相,显著提高了合金的强度和抗腐蚀性能.Guo等[30]在Cu-Ni-Zn合金体系中引入P元素,通过增大溶质与溶剂原子尺寸的差异诱导合金调幅分解而使其硬度提高. ...

Microstructural change in austenitic Fe-30.0wt%Mn-7.8wt%Al-1.3wt%C initiated by spinodal decomposition and its influence on mechanical properties

1

1997

... 调幅分解,能使材料的成分周期性变化且具有特定波长结构的连续纳米双相组织.这种独特的微观结构能显著提高材料的强度、硬度、抗蠕变性等力学性能[1,2].因此,调幅分解可用于设计性能优异的先进材料.调控调幅分解强化材料的力学性能,一直是国内外科研工作者的重点.相关研究涉及多种合金体系,包括Ti基合金[3,4]、Al基合金[5,6]、Cu基合金[7~9]、Fe-Mn记忆合金[10,11]以及双相钢[12~14]等.Ti基合金体系的Ti-6554[15,16]、Ti-55531[17]和Ti-10V-6Cu[18]等亚稳态β-Ti合金中都存在调幅分解.Yang等[19]在Ti-Al-Mo-V-Cr-Zr合金中构建了β+β'调幅分解片层结构,通过周期性分布的纳米结构阻碍了位错运动使其力学性能显著提高.An等[20]利用调幅分解机制在难熔高熵合金Hf-Nb-Ti-V体系中生成了具有周期性晶格畸变的β'相,在保持高强度的同时显著改善了合金的室温拉伸延展性.Hua等[21]将调幅分解机制引入Zr-Nb-Ti中熵合金体系,使其屈服强度显著提高并降低了弹性模量.同时,许多研究者也在探究调幅分解影响材料性能的机理.Cahn[22,23]建立了预测调幅分解微观结构的理论模型,提出了调幅分解强化理论[24].这个强化理论指出,调幅分解在合金中的强化作用是通过共格组织之间的内应力与位错相互作用实现的.Mott和Nabarro[25]认为,屈服强度取决于调幅分解组织的内应力场.值得注意的是,作为固态相变过程中的一种扩散型相变,调幅分解与传统的形核-长大方式不同,母相的过饱和固溶体在一定温度下通过原子上坡扩散引起的成分涨落产生结构相同、成分不同的两个新相,两相组织根据相变动力学呈现片层状或网格状等不同形貌[26,27].因此,成分起伏是调幅分解的原始驱动力,成分调控在调幅分解中占据主导作用.Park等[28]在铁质中熵合金中引入Cu和Al元素,通过调幅分解结构抑制了应变局域化,在保持良好伸长率的同时使其机械强度提高.Röyset和Ryum[29]在Al-Zn-Mg合金中添加微量Sc元素促进了调幅分解过程生成了纳米级析出相,显著提高了合金的强度和抗腐蚀性能.Guo等[30]在Cu-Ni-Zn合金体系中引入P元素,通过增大溶质与溶剂原子尺寸的差异诱导合金调幅分解而使其硬度提高. ...

The microstructure of near-equiatomic B2/f.c.c. FeNiMnAl alloys

1

2011

... 调幅分解,能使材料的成分周期性变化且具有特定波长结构的连续纳米双相组织.这种独特的微观结构能显著提高材料的强度、硬度、抗蠕变性等力学性能[1,2].因此,调幅分解可用于设计性能优异的先进材料.调控调幅分解强化材料的力学性能,一直是国内外科研工作者的重点.相关研究涉及多种合金体系,包括Ti基合金[3,4]、Al基合金[5,6]、Cu基合金[7~9]、Fe-Mn记忆合金[10,11]以及双相钢[12~14]等.Ti基合金体系的Ti-6554[15,16]、Ti-55531[17]和Ti-10V-6Cu[18]等亚稳态β-Ti合金中都存在调幅分解.Yang等[19]在Ti-Al-Mo-V-Cr-Zr合金中构建了β+β'调幅分解片层结构,通过周期性分布的纳米结构阻碍了位错运动使其力学性能显著提高.An等[20]利用调幅分解机制在难熔高熵合金Hf-Nb-Ti-V体系中生成了具有周期性晶格畸变的β'相,在保持高强度的同时显著改善了合金的室温拉伸延展性.Hua等[21]将调幅分解机制引入Zr-Nb-Ti中熵合金体系,使其屈服强度显著提高并降低了弹性模量.同时,许多研究者也在探究调幅分解影响材料性能的机理.Cahn[22,23]建立了预测调幅分解微观结构的理论模型,提出了调幅分解强化理论[24].这个强化理论指出,调幅分解在合金中的强化作用是通过共格组织之间的内应力与位错相互作用实现的.Mott和Nabarro[25]认为,屈服强度取决于调幅分解组织的内应力场.值得注意的是,作为固态相变过程中的一种扩散型相变,调幅分解与传统的形核-长大方式不同,母相的过饱和固溶体在一定温度下通过原子上坡扩散引起的成分涨落产生结构相同、成分不同的两个新相,两相组织根据相变动力学呈现片层状或网格状等不同形貌[26,27].因此,成分起伏是调幅分解的原始驱动力,成分调控在调幅分解中占据主导作用.Park等[28]在铁质中熵合金中引入Cu和Al元素,通过调幅分解结构抑制了应变局域化,在保持良好伸长率的同时使其机械强度提高.Röyset和Ryum[29]在Al-Zn-Mg合金中添加微量Sc元素促进了调幅分解过程生成了纳米级析出相,显著提高了合金的强度和抗腐蚀性能.Guo等[30]在Cu-Ni-Zn合金体系中引入P元素,通过增大溶质与溶剂原子尺寸的差异诱导合金调幅分解而使其硬度提高. ...

On the history of detection of spinodal predecomposition of supercooled austenite in bainitic iron-carbon alloys

1

2001

... 调幅分解,能使材料的成分周期性变化且具有特定波长结构的连续纳米双相组织.这种独特的微观结构能显著提高材料的强度、硬度、抗蠕变性等力学性能[1,2].因此,调幅分解可用于设计性能优异的先进材料.调控调幅分解强化材料的力学性能,一直是国内外科研工作者的重点.相关研究涉及多种合金体系,包括Ti基合金[3,4]、Al基合金[5,6]、Cu基合金[7~9]、Fe-Mn记忆合金[10,11]以及双相钢[12~14]等.Ti基合金体系的Ti-6554[15,16]、Ti-55531[17]和Ti-10V-6Cu[18]等亚稳态β-Ti合金中都存在调幅分解.Yang等[19]在Ti-Al-Mo-V-Cr-Zr合金中构建了β+β'调幅分解片层结构,通过周期性分布的纳米结构阻碍了位错运动使其力学性能显著提高.An等[20]利用调幅分解机制在难熔高熵合金Hf-Nb-Ti-V体系中生成了具有周期性晶格畸变的β'相,在保持高强度的同时显著改善了合金的室温拉伸延展性.Hua等[21]将调幅分解机制引入Zr-Nb-Ti中熵合金体系,使其屈服强度显著提高并降低了弹性模量.同时,许多研究者也在探究调幅分解影响材料性能的机理.Cahn[22,23]建立了预测调幅分解微观结构的理论模型,提出了调幅分解强化理论[24].这个强化理论指出,调幅分解在合金中的强化作用是通过共格组织之间的内应力与位错相互作用实现的.Mott和Nabarro[25]认为,屈服强度取决于调幅分解组织的内应力场.值得注意的是,作为固态相变过程中的一种扩散型相变,调幅分解与传统的形核-长大方式不同,母相的过饱和固溶体在一定温度下通过原子上坡扩散引起的成分涨落产生结构相同、成分不同的两个新相,两相组织根据相变动力学呈现片层状或网格状等不同形貌[26,27].因此,成分起伏是调幅分解的原始驱动力,成分调控在调幅分解中占据主导作用.Park等[28]在铁质中熵合金中引入Cu和Al元素,通过调幅分解结构抑制了应变局域化,在保持良好伸长率的同时使其机械强度提高.Röyset和Ryum[29]在Al-Zn-Mg合金中添加微量Sc元素促进了调幅分解过程生成了纳米级析出相,显著提高了合金的强度和抗腐蚀性能.Guo等[30]在Cu-Ni-Zn合金体系中引入P元素,通过增大溶质与溶剂原子尺寸的差异诱导合金调幅分解而使其硬度提高. ...

Kinetics study of the spinodal decomposition in the Fe-30.8Cr-12.2Co alloy by M?ssbauer spectrometry

0

1999

Kinetic analysis of spinodal decomposition process in Fe-Cr alloys by small angle neutron scattering

1

2000

... 调幅分解,能使材料的成分周期性变化且具有特定波长结构的连续纳米双相组织.这种独特的微观结构能显著提高材料的强度、硬度、抗蠕变性等力学性能[1,2].因此,调幅分解可用于设计性能优异的先进材料.调控调幅分解强化材料的力学性能,一直是国内外科研工作者的重点.相关研究涉及多种合金体系,包括Ti基合金[3,4]、Al基合金[5,6]、Cu基合金[7~9]、Fe-Mn记忆合金[10,11]以及双相钢[12~14]等.Ti基合金体系的Ti-6554[15,16]、Ti-55531[17]和Ti-10V-6Cu[18]等亚稳态β-Ti合金中都存在调幅分解.Yang等[19]在Ti-Al-Mo-V-Cr-Zr合金中构建了β+β'调幅分解片层结构,通过周期性分布的纳米结构阻碍了位错运动使其力学性能显著提高.An等[20]利用调幅分解机制在难熔高熵合金Hf-Nb-Ti-V体系中生成了具有周期性晶格畸变的β'相,在保持高强度的同时显著改善了合金的室温拉伸延展性.Hua等[21]将调幅分解机制引入Zr-Nb-Ti中熵合金体系,使其屈服强度显著提高并降低了弹性模量.同时,许多研究者也在探究调幅分解影响材料性能的机理.Cahn[22,23]建立了预测调幅分解微观结构的理论模型,提出了调幅分解强化理论[24].这个强化理论指出,调幅分解在合金中的强化作用是通过共格组织之间的内应力与位错相互作用实现的.Mott和Nabarro[25]认为,屈服强度取决于调幅分解组织的内应力场.值得注意的是,作为固态相变过程中的一种扩散型相变,调幅分解与传统的形核-长大方式不同,母相的过饱和固溶体在一定温度下通过原子上坡扩散引起的成分涨落产生结构相同、成分不同的两个新相,两相组织根据相变动力学呈现片层状或网格状等不同形貌[26,27].因此,成分起伏是调幅分解的原始驱动力,成分调控在调幅分解中占据主导作用.Park等[28]在铁质中熵合金中引入Cu和Al元素,通过调幅分解结构抑制了应变局域化,在保持良好伸长率的同时使其机械强度提高.Röyset和Ryum[29]在Al-Zn-Mg合金中添加微量Sc元素促进了调幅分解过程生成了纳米级析出相,显著提高了合金的强度和抗腐蚀性能.Guo等[30]在Cu-Ni-Zn合金体系中引入P元素,通过增大溶质与溶剂原子尺寸的差异诱导合金调幅分解而使其硬度提高. ...

Activation of homogeneous precursors for formation of uniform and refined α precipitates in a high-strength β-Ti alloy

1

2020

... 调幅分解,能使材料的成分周期性变化且具有特定波长结构的连续纳米双相组织.这种独特的微观结构能显著提高材料的强度、硬度、抗蠕变性等力学性能[1,2].因此,调幅分解可用于设计性能优异的先进材料.调控调幅分解强化材料的力学性能,一直是国内外科研工作者的重点.相关研究涉及多种合金体系,包括Ti基合金[3,4]、Al基合金[5,6]、Cu基合金[7~9]、Fe-Mn记忆合金[10,11]以及双相钢[12~14]等.Ti基合金体系的Ti-6554[15,16]、Ti-55531[17]和Ti-10V-6Cu[18]等亚稳态β-Ti合金中都存在调幅分解.Yang等[19]在Ti-Al-Mo-V-Cr-Zr合金中构建了β+β'调幅分解片层结构,通过周期性分布的纳米结构阻碍了位错运动使其力学性能显著提高.An等[20]利用调幅分解机制在难熔高熵合金Hf-Nb-Ti-V体系中生成了具有周期性晶格畸变的β'相,在保持高强度的同时显著改善了合金的室温拉伸延展性.Hua等[21]将调幅分解机制引入Zr-Nb-Ti中熵合金体系,使其屈服强度显著提高并降低了弹性模量.同时,许多研究者也在探究调幅分解影响材料性能的机理.Cahn[22,23]建立了预测调幅分解微观结构的理论模型,提出了调幅分解强化理论[24].这个强化理论指出,调幅分解在合金中的强化作用是通过共格组织之间的内应力与位错相互作用实现的.Mott和Nabarro[25]认为,屈服强度取决于调幅分解组织的内应力场.值得注意的是,作为固态相变过程中的一种扩散型相变,调幅分解与传统的形核-长大方式不同,母相的过饱和固溶体在一定温度下通过原子上坡扩散引起的成分涨落产生结构相同、成分不同的两个新相,两相组织根据相变动力学呈现片层状或网格状等不同形貌[26,27].因此,成分起伏是调幅分解的原始驱动力,成分调控在调幅分解中占据主导作用.Park等[28]在铁质中熵合金中引入Cu和Al元素,通过调幅分解结构抑制了应变局域化,在保持良好伸长率的同时使其机械强度提高.Röyset和Ryum[29]在Al-Zn-Mg合金中添加微量Sc元素促进了调幅分解过程生成了纳米级析出相,显著提高了合金的强度和抗腐蚀性能.Guo等[30]在Cu-Ni-Zn合金体系中引入P元素,通过增大溶质与溶剂原子尺寸的差异诱导合金调幅分解而使其硬度提高. ...

Plastic instability in Ti-6Cr-5Mo-5V-4Al metastable β-Ti alloy containing the β-spinodal decomposition structures

1

2021

... 调幅分解,能使材料的成分周期性变化且具有特定波长结构的连续纳米双相组织.这种独特的微观结构能显著提高材料的强度、硬度、抗蠕变性等力学性能[1,2].因此,调幅分解可用于设计性能优异的先进材料.调控调幅分解强化材料的力学性能,一直是国内外科研工作者的重点.相关研究涉及多种合金体系,包括Ti基合金[3,4]、Al基合金[5,6]、Cu基合金[7~9]、Fe-Mn记忆合金[10,11]以及双相钢[12~14]等.Ti基合金体系的Ti-6554[15,16]、Ti-55531[17]和Ti-10V-6Cu[18]等亚稳态β-Ti合金中都存在调幅分解.Yang等[19]在Ti-Al-Mo-V-Cr-Zr合金中构建了β+β'调幅分解片层结构,通过周期性分布的纳米结构阻碍了位错运动使其力学性能显著提高.An等[20]利用调幅分解机制在难熔高熵合金Hf-Nb-Ti-V体系中生成了具有周期性晶格畸变的β'相,在保持高强度的同时显著改善了合金的室温拉伸延展性.Hua等[21]将调幅分解机制引入Zr-Nb-Ti中熵合金体系,使其屈服强度显著提高并降低了弹性模量.同时,许多研究者也在探究调幅分解影响材料性能的机理.Cahn[22,23]建立了预测调幅分解微观结构的理论模型,提出了调幅分解强化理论[24].这个强化理论指出,调幅分解在合金中的强化作用是通过共格组织之间的内应力与位错相互作用实现的.Mott和Nabarro[25]认为,屈服强度取决于调幅分解组织的内应力场.值得注意的是,作为固态相变过程中的一种扩散型相变,调幅分解与传统的形核-长大方式不同,母相的过饱和固溶体在一定温度下通过原子上坡扩散引起的成分涨落产生结构相同、成分不同的两个新相,两相组织根据相变动力学呈现片层状或网格状等不同形貌[26,27].因此,成分起伏是调幅分解的原始驱动力,成分调控在调幅分解中占据主导作用.Park等[28]在铁质中熵合金中引入Cu和Al元素,通过调幅分解结构抑制了应变局域化,在保持良好伸长率的同时使其机械强度提高.Röyset和Ryum[29]在Al-Zn-Mg合金中添加微量Sc元素促进了调幅分解过程生成了纳米级析出相,显著提高了合金的强度和抗腐蚀性能.Guo等[30]在Cu-Ni-Zn合金体系中引入P元素,通过增大溶质与溶剂原子尺寸的差异诱导合金调幅分解而使其硬度提高. ...

Influence of phase transformation kinetics on the formation of α in a β-quenched Ti-5Al-5Mo-5V-3Cr-1Zr alloy

1

2015

... 调幅分解,能使材料的成分周期性变化且具有特定波长结构的连续纳米双相组织.这种独特的微观结构能显著提高材料的强度、硬度、抗蠕变性等力学性能[1,2].因此,调幅分解可用于设计性能优异的先进材料.调控调幅分解强化材料的力学性能,一直是国内外科研工作者的重点.相关研究涉及多种合金体系,包括Ti基合金[3,4]、Al基合金[5,6]、Cu基合金[7~9]、Fe-Mn记忆合金[10,11]以及双相钢[12~14]等.Ti基合金体系的Ti-6554[15,16]、Ti-55531[17]和Ti-10V-6Cu[18]等亚稳态β-Ti合金中都存在调幅分解.Yang等[19]在Ti-Al-Mo-V-Cr-Zr合金中构建了β+β'调幅分解片层结构,通过周期性分布的纳米结构阻碍了位错运动使其力学性能显著提高.An等[20]利用调幅分解机制在难熔高熵合金Hf-Nb-Ti-V体系中生成了具有周期性晶格畸变的β'相,在保持高强度的同时显著改善了合金的室温拉伸延展性.Hua等[21]将调幅分解机制引入Zr-Nb-Ti中熵合金体系,使其屈服强度显著提高并降低了弹性模量.同时,许多研究者也在探究调幅分解影响材料性能的机理.Cahn[22,23]建立了预测调幅分解微观结构的理论模型,提出了调幅分解强化理论[24].这个强化理论指出,调幅分解在合金中的强化作用是通过共格组织之间的内应力与位错相互作用实现的.Mott和Nabarro[25]认为,屈服强度取决于调幅分解组织的内应力场.值得注意的是,作为固态相变过程中的一种扩散型相变,调幅分解与传统的形核-长大方式不同,母相的过饱和固溶体在一定温度下通过原子上坡扩散引起的成分涨落产生结构相同、成分不同的两个新相,两相组织根据相变动力学呈现片层状或网格状等不同形貌[26,27].因此,成分起伏是调幅分解的原始驱动力,成分调控在调幅分解中占据主导作用.Park等[28]在铁质中熵合金中引入Cu和Al元素,通过调幅分解结构抑制了应变局域化,在保持良好伸长率的同时使其机械强度提高.Röyset和Ryum[29]在Al-Zn-Mg合金中添加微量Sc元素促进了调幅分解过程生成了纳米级析出相,显著提高了合金的强度和抗腐蚀性能.Guo等[30]在Cu-Ni-Zn合金体系中引入P元素,通过增大溶质与溶剂原子尺寸的差异诱导合金调幅分解而使其硬度提高. ...

Phase separation and formation of omega phase in the beta matrix of a Ti-V-Cu alloy

1

2011

... 调幅分解,能使材料的成分周期性变化且具有特定波长结构的连续纳米双相组织.这种独特的微观结构能显著提高材料的强度、硬度、抗蠕变性等力学性能[1,2].因此,调幅分解可用于设计性能优异的先进材料.调控调幅分解强化材料的力学性能,一直是国内外科研工作者的重点.相关研究涉及多种合金体系,包括Ti基合金[3,4]、Al基合金[5,6]、Cu基合金[7~9]、Fe-Mn记忆合金[10,11]以及双相钢[12~14]等.Ti基合金体系的Ti-6554[15,16]、Ti-55531[17]和Ti-10V-6Cu[18]等亚稳态β-Ti合金中都存在调幅分解.Yang等[19]在Ti-Al-Mo-V-Cr-Zr合金中构建了β+β'调幅分解片层结构,通过周期性分布的纳米结构阻碍了位错运动使其力学性能显著提高.An等[20]利用调幅分解机制在难熔高熵合金Hf-Nb-Ti-V体系中生成了具有周期性晶格畸变的β'相,在保持高强度的同时显著改善了合金的室温拉伸延展性.Hua等[21]将调幅分解机制引入Zr-Nb-Ti中熵合金体系,使其屈服强度显著提高并降低了弹性模量.同时,许多研究者也在探究调幅分解影响材料性能的机理.Cahn[22,23]建立了预测调幅分解微观结构的理论模型,提出了调幅分解强化理论[24].这个强化理论指出,调幅分解在合金中的强化作用是通过共格组织之间的内应力与位错相互作用实现的.Mott和Nabarro[25]认为,屈服强度取决于调幅分解组织的内应力场.值得注意的是,作为固态相变过程中的一种扩散型相变,调幅分解与传统的形核-长大方式不同,母相的过饱和固溶体在一定温度下通过原子上坡扩散引起的成分涨落产生结构相同、成分不同的两个新相,两相组织根据相变动力学呈现片层状或网格状等不同形貌[26,27].因此,成分起伏是调幅分解的原始驱动力,成分调控在调幅分解中占据主导作用.Park等[28]在铁质中熵合金中引入Cu和Al元素,通过调幅分解结构抑制了应变局域化,在保持良好伸长率的同时使其机械强度提高.Röyset和Ryum[29]在Al-Zn-Mg合金中添加微量Sc元素促进了调幅分解过程生成了纳米级析出相,显著提高了合金的强度和抗腐蚀性能.Guo等[30]在Cu-Ni-Zn合金体系中引入P元素,通过增大溶质与溶剂原子尺寸的差异诱导合金调幅分解而使其硬度提高. ...

Spinodal decomposition-mediated multi-architectured α precipitates making a metastable β-Ti alloy ultra-strong and ductile

1

2024

... 调幅分解,能使材料的成分周期性变化且具有特定波长结构的连续纳米双相组织.这种独特的微观结构能显著提高材料的强度、硬度、抗蠕变性等力学性能[1,2].因此,调幅分解可用于设计性能优异的先进材料.调控调幅分解强化材料的力学性能,一直是国内外科研工作者的重点.相关研究涉及多种合金体系,包括Ti基合金[3,4]、Al基合金[5,6]、Cu基合金[7~9]、Fe-Mn记忆合金[10,11]以及双相钢[12~14]等.Ti基合金体系的Ti-6554[15,16]、Ti-55531[17]和Ti-10V-6Cu[18]等亚稳态β-Ti合金中都存在调幅分解.Yang等[19]在Ti-Al-Mo-V-Cr-Zr合金中构建了β+β'调幅分解片层结构,通过周期性分布的纳米结构阻碍了位错运动使其力学性能显著提高.An等[20]利用调幅分解机制在难熔高熵合金Hf-Nb-Ti-V体系中生成了具有周期性晶格畸变的β'相,在保持高强度的同时显著改善了合金的室温拉伸延展性.Hua等[21]将调幅分解机制引入Zr-Nb-Ti中熵合金体系,使其屈服强度显著提高并降低了弹性模量.同时,许多研究者也在探究调幅分解影响材料性能的机理.Cahn[22,23]建立了预测调幅分解微观结构的理论模型,提出了调幅分解强化理论[24].这个强化理论指出,调幅分解在合金中的强化作用是通过共格组织之间的内应力与位错相互作用实现的.Mott和Nabarro[25]认为,屈服强度取决于调幅分解组织的内应力场.值得注意的是,作为固态相变过程中的一种扩散型相变,调幅分解与传统的形核-长大方式不同,母相的过饱和固溶体在一定温度下通过原子上坡扩散引起的成分涨落产生结构相同、成分不同的两个新相,两相组织根据相变动力学呈现片层状或网格状等不同形貌[26,27].因此,成分起伏是调幅分解的原始驱动力,成分调控在调幅分解中占据主导作用.Park等[28]在铁质中熵合金中引入Cu和Al元素,通过调幅分解结构抑制了应变局域化,在保持良好伸长率的同时使其机械强度提高.Röyset和Ryum[29]在Al-Zn-Mg合金中添加微量Sc元素促进了调幅分解过程生成了纳米级析出相,显著提高了合金的强度和抗腐蚀性能.Guo等[30]在Cu-Ni-Zn合金体系中引入P元素,通过增大溶质与溶剂原子尺寸的差异诱导合金调幅分解而使其硬度提高. ...

Spinodal-modulated solid solution delivers a strong and ductile refractory high-entropy alloy

1

2021

... 调幅分解,能使材料的成分周期性变化且具有特定波长结构的连续纳米双相组织.这种独特的微观结构能显著提高材料的强度、硬度、抗蠕变性等力学性能[1,2].因此,调幅分解可用于设计性能优异的先进材料.调控调幅分解强化材料的力学性能,一直是国内外科研工作者的重点.相关研究涉及多种合金体系,包括Ti基合金[3,4]、Al基合金[5,6]、Cu基合金[7~9]、Fe-Mn记忆合金[10,11]以及双相钢[12~14]等.Ti基合金体系的Ti-6554[15,16]、Ti-55531[17]和Ti-10V-6Cu[18]等亚稳态β-Ti合金中都存在调幅分解.Yang等[19]在Ti-Al-Mo-V-Cr-Zr合金中构建了β+β'调幅分解片层结构,通过周期性分布的纳米结构阻碍了位错运动使其力学性能显著提高.An等[20]利用调幅分解机制在难熔高熵合金Hf-Nb-Ti-V体系中生成了具有周期性晶格畸变的β'相,在保持高强度的同时显著改善了合金的室温拉伸延展性.Hua等[21]将调幅分解机制引入Zr-Nb-Ti中熵合金体系,使其屈服强度显著提高并降低了弹性模量.同时,许多研究者也在探究调幅分解影响材料性能的机理.Cahn[22,23]建立了预测调幅分解微观结构的理论模型,提出了调幅分解强化理论[24].这个强化理论指出,调幅分解在合金中的强化作用是通过共格组织之间的内应力与位错相互作用实现的.Mott和Nabarro[25]认为,屈服强度取决于调幅分解组织的内应力场.值得注意的是,作为固态相变过程中的一种扩散型相变,调幅分解与传统的形核-长大方式不同,母相的过饱和固溶体在一定温度下通过原子上坡扩散引起的成分涨落产生结构相同、成分不同的两个新相,两相组织根据相变动力学呈现片层状或网格状等不同形貌[26,27].因此,成分起伏是调幅分解的原始驱动力,成分调控在调幅分解中占据主导作用.Park等[28]在铁质中熵合金中引入Cu和Al元素,通过调幅分解结构抑制了应变局域化,在保持良好伸长率的同时使其机械强度提高.Röyset和Ryum[29]在Al-Zn-Mg合金中添加微量Sc元素促进了调幅分解过程生成了纳米级析出相,显著提高了合金的强度和抗腐蚀性能.Guo等[30]在Cu-Ni-Zn合金体系中引入P元素,通过增大溶质与溶剂原子尺寸的差异诱导合金调幅分解而使其硬度提高. ...

Medium-entropy Zr-Nb-Ti alloys with low magnetic susceptibility, high yield strength, and low elastic modulus through spinodal decomposition for bone-implant applications

1

2024

... 调幅分解,能使材料的成分周期性变化且具有特定波长结构的连续纳米双相组织.这种独特的微观结构能显著提高材料的强度、硬度、抗蠕变性等力学性能[1,2].因此,调幅分解可用于设计性能优异的先进材料.调控调幅分解强化材料的力学性能,一直是国内外科研工作者的重点.相关研究涉及多种合金体系,包括Ti基合金[3,4]、Al基合金[5,6]、Cu基合金[7~9]、Fe-Mn记忆合金[10,11]以及双相钢[12~14]等.Ti基合金体系的Ti-6554[15,16]、Ti-55531[17]和Ti-10V-6Cu[18]等亚稳态β-Ti合金中都存在调幅分解.Yang等[19]在Ti-Al-Mo-V-Cr-Zr合金中构建了β+β'调幅分解片层结构,通过周期性分布的纳米结构阻碍了位错运动使其力学性能显著提高.An等[20]利用调幅分解机制在难熔高熵合金Hf-Nb-Ti-V体系中生成了具有周期性晶格畸变的β'相,在保持高强度的同时显著改善了合金的室温拉伸延展性.Hua等[21]将调幅分解机制引入Zr-Nb-Ti中熵合金体系,使其屈服强度显著提高并降低了弹性模量.同时,许多研究者也在探究调幅分解影响材料性能的机理.Cahn[22,23]建立了预测调幅分解微观结构的理论模型,提出了调幅分解强化理论[24].这个强化理论指出,调幅分解在合金中的强化作用是通过共格组织之间的内应力与位错相互作用实现的.Mott和Nabarro[25]认为,屈服强度取决于调幅分解组织的内应力场.值得注意的是,作为固态相变过程中的一种扩散型相变,调幅分解与传统的形核-长大方式不同,母相的过饱和固溶体在一定温度下通过原子上坡扩散引起的成分涨落产生结构相同、成分不同的两个新相,两相组织根据相变动力学呈现片层状或网格状等不同形貌[26,27].因此,成分起伏是调幅分解的原始驱动力,成分调控在调幅分解中占据主导作用.Park等[28]在铁质中熵合金中引入Cu和Al元素,通过调幅分解结构抑制了应变局域化,在保持良好伸长率的同时使其机械强度提高.Röyset和Ryum[29]在Al-Zn-Mg合金中添加微量Sc元素促进了调幅分解过程生成了纳米级析出相,显著提高了合金的强度和抗腐蚀性能.Guo等[30]在Cu-Ni-Zn合金体系中引入P元素,通过增大溶质与溶剂原子尺寸的差异诱导合金调幅分解而使其硬度提高. ...

Phase separation by spinodal decomposition in isotropic systems

2

1965

... 调幅分解,能使材料的成分周期性变化且具有特定波长结构的连续纳米双相组织.这种独特的微观结构能显著提高材料的强度、硬度、抗蠕变性等力学性能[1,2].因此,调幅分解可用于设计性能优异的先进材料.调控调幅分解强化材料的力学性能,一直是国内外科研工作者的重点.相关研究涉及多种合金体系,包括Ti基合金[3,4]、Al基合金[5,6]、Cu基合金[7~9]、Fe-Mn记忆合金[10,11]以及双相钢[12~14]等.Ti基合金体系的Ti-6554[15,16]、Ti-55531[17]和Ti-10V-6Cu[18]等亚稳态β-Ti合金中都存在调幅分解.Yang等[19]在Ti-Al-Mo-V-Cr-Zr合金中构建了β+β'调幅分解片层结构,通过周期性分布的纳米结构阻碍了位错运动使其力学性能显著提高.An等[20]利用调幅分解机制在难熔高熵合金Hf-Nb-Ti-V体系中生成了具有周期性晶格畸变的β'相,在保持高强度的同时显著改善了合金的室温拉伸延展性.Hua等[21]将调幅分解机制引入Zr-Nb-Ti中熵合金体系,使其屈服强度显著提高并降低了弹性模量.同时,许多研究者也在探究调幅分解影响材料性能的机理.Cahn[22,23]建立了预测调幅分解微观结构的理论模型,提出了调幅分解强化理论[24].这个强化理论指出,调幅分解在合金中的强化作用是通过共格组织之间的内应力与位错相互作用实现的.Mott和Nabarro[25]认为,屈服强度取决于调幅分解组织的内应力场.值得注意的是,作为固态相变过程中的一种扩散型相变,调幅分解与传统的形核-长大方式不同,母相的过饱和固溶体在一定温度下通过原子上坡扩散引起的成分涨落产生结构相同、成分不同的两个新相,两相组织根据相变动力学呈现片层状或网格状等不同形貌[26,27].因此,成分起伏是调幅分解的原始驱动力,成分调控在调幅分解中占据主导作用.Park等[28]在铁质中熵合金中引入Cu和Al元素,通过调幅分解结构抑制了应变局域化,在保持良好伸长率的同时使其机械强度提高.Röyset和Ryum[29]在Al-Zn-Mg合金中添加微量Sc元素促进了调幅分解过程生成了纳米级析出相,显著提高了合金的强度和抗腐蚀性能.Guo等[30]在Cu-Ni-Zn合金体系中引入P元素,通过增大溶质与溶剂原子尺寸的差异诱导合金调幅分解而使其硬度提高. ...

... 调幅分解组织中两相的周期性分布可类比为正弦函数,两相组织的宽度之和对应于调幅分解的波长λ[22].依据Porter等的工作[37],调幅分解的特征波长可表示为 ...

On spinodal decomposition

1

1961

... 调幅分解,能使材料的成分周期性变化且具有特定波长结构的连续纳米双相组织.这种独特的微观结构能显著提高材料的强度、硬度、抗蠕变性等力学性能[1,2].因此,调幅分解可用于设计性能优异的先进材料.调控调幅分解强化材料的力学性能,一直是国内外科研工作者的重点.相关研究涉及多种合金体系,包括Ti基合金[3,4]、Al基合金[5,6]、Cu基合金[7~9]、Fe-Mn记忆合金[10,11]以及双相钢[12~14]等.Ti基合金体系的Ti-6554[15,16]、Ti-55531[17]和Ti-10V-6Cu[18]等亚稳态β-Ti合金中都存在调幅分解.Yang等[19]在Ti-Al-Mo-V-Cr-Zr合金中构建了β+β'调幅分解片层结构,通过周期性分布的纳米结构阻碍了位错运动使其力学性能显著提高.An等[20]利用调幅分解机制在难熔高熵合金Hf-Nb-Ti-V体系中生成了具有周期性晶格畸变的β'相,在保持高强度的同时显著改善了合金的室温拉伸延展性.Hua等[21]将调幅分解机制引入Zr-Nb-Ti中熵合金体系,使其屈服强度显著提高并降低了弹性模量.同时,许多研究者也在探究调幅分解影响材料性能的机理.Cahn[22,23]建立了预测调幅分解微观结构的理论模型,提出了调幅分解强化理论[24].这个强化理论指出,调幅分解在合金中的强化作用是通过共格组织之间的内应力与位错相互作用实现的.Mott和Nabarro[25]认为,屈服强度取决于调幅分解组织的内应力场.值得注意的是,作为固态相变过程中的一种扩散型相变,调幅分解与传统的形核-长大方式不同,母相的过饱和固溶体在一定温度下通过原子上坡扩散引起的成分涨落产生结构相同、成分不同的两个新相,两相组织根据相变动力学呈现片层状或网格状等不同形貌[26,27].因此,成分起伏是调幅分解的原始驱动力,成分调控在调幅分解中占据主导作用.Park等[28]在铁质中熵合金中引入Cu和Al元素,通过调幅分解结构抑制了应变局域化,在保持良好伸长率的同时使其机械强度提高.Röyset和Ryum[29]在Al-Zn-Mg合金中添加微量Sc元素促进了调幅分解过程生成了纳米级析出相,显著提高了合金的强度和抗腐蚀性能.Guo等[30]在Cu-Ni-Zn合金体系中引入P元素,通过增大溶质与溶剂原子尺寸的差异诱导合金调幅分解而使其硬度提高. ...

Hardening by spinodal decomposition

1

1963

... 调幅分解,能使材料的成分周期性变化且具有特定波长结构的连续纳米双相组织.这种独特的微观结构能显著提高材料的强度、硬度、抗蠕变性等力学性能[1,2].因此,调幅分解可用于设计性能优异的先进材料.调控调幅分解强化材料的力学性能,一直是国内外科研工作者的重点.相关研究涉及多种合金体系,包括Ti基合金[3,4]、Al基合金[5,6]、Cu基合金[7~9]、Fe-Mn记忆合金[10,11]以及双相钢[12~14]等.Ti基合金体系的Ti-6554[15,16]、Ti-55531[17]和Ti-10V-6Cu[18]等亚稳态β-Ti合金中都存在调幅分解.Yang等[19]在Ti-Al-Mo-V-Cr-Zr合金中构建了β+β'调幅分解片层结构,通过周期性分布的纳米结构阻碍了位错运动使其力学性能显著提高.An等[20]利用调幅分解机制在难熔高熵合金Hf-Nb-Ti-V体系中生成了具有周期性晶格畸变的β'相,在保持高强度的同时显著改善了合金的室温拉伸延展性.Hua等[21]将调幅分解机制引入Zr-Nb-Ti中熵合金体系,使其屈服强度显著提高并降低了弹性模量.同时,许多研究者也在探究调幅分解影响材料性能的机理.Cahn[22,23]建立了预测调幅分解微观结构的理论模型,提出了调幅分解强化理论[24].这个强化理论指出,调幅分解在合金中的强化作用是通过共格组织之间的内应力与位错相互作用实现的.Mott和Nabarro[25]认为,屈服强度取决于调幅分解组织的内应力场.值得注意的是,作为固态相变过程中的一种扩散型相变,调幅分解与传统的形核-长大方式不同,母相的过饱和固溶体在一定温度下通过原子上坡扩散引起的成分涨落产生结构相同、成分不同的两个新相,两相组织根据相变动力学呈现片层状或网格状等不同形貌[26,27].因此,成分起伏是调幅分解的原始驱动力,成分调控在调幅分解中占据主导作用.Park等[28]在铁质中熵合金中引入Cu和Al元素,通过调幅分解结构抑制了应变局域化,在保持良好伸长率的同时使其机械强度提高.Röyset和Ryum[29]在Al-Zn-Mg合金中添加微量Sc元素促进了调幅分解过程生成了纳米级析出相,显著提高了合金的强度和抗腐蚀性能.Guo等[30]在Cu-Ni-Zn合金体系中引入P元素,通过增大溶质与溶剂原子尺寸的差异诱导合金调幅分解而使其硬度提高. ...

An attempt to estimate the degree of precipitation hardening, with a simple model

1

1940

... 调幅分解,能使材料的成分周期性变化且具有特定波长结构的连续纳米双相组织.这种独特的微观结构能显著提高材料的强度、硬度、抗蠕变性等力学性能[1,2].因此,调幅分解可用于设计性能优异的先进材料.调控调幅分解强化材料的力学性能,一直是国内外科研工作者的重点.相关研究涉及多种合金体系,包括Ti基合金[3,4]、Al基合金[5,6]、Cu基合金[7~9]、Fe-Mn记忆合金[10,11]以及双相钢[12~14]等.Ti基合金体系的Ti-6554[15,16]、Ti-55531[17]和Ti-10V-6Cu[18]等亚稳态β-Ti合金中都存在调幅分解.Yang等[19]在Ti-Al-Mo-V-Cr-Zr合金中构建了β+β'调幅分解片层结构,通过周期性分布的纳米结构阻碍了位错运动使其力学性能显著提高.An等[20]利用调幅分解机制在难熔高熵合金Hf-Nb-Ti-V体系中生成了具有周期性晶格畸变的β'相,在保持高强度的同时显著改善了合金的室温拉伸延展性.Hua等[21]将调幅分解机制引入Zr-Nb-Ti中熵合金体系,使其屈服强度显著提高并降低了弹性模量.同时,许多研究者也在探究调幅分解影响材料性能的机理.Cahn[22,23]建立了预测调幅分解微观结构的理论模型,提出了调幅分解强化理论[24].这个强化理论指出,调幅分解在合金中的强化作用是通过共格组织之间的内应力与位错相互作用实现的.Mott和Nabarro[25]认为,屈服强度取决于调幅分解组织的内应力场.值得注意的是,作为固态相变过程中的一种扩散型相变,调幅分解与传统的形核-长大方式不同,母相的过饱和固溶体在一定温度下通过原子上坡扩散引起的成分涨落产生结构相同、成分不同的两个新相,两相组织根据相变动力学呈现片层状或网格状等不同形貌[26,27].因此,成分起伏是调幅分解的原始驱动力,成分调控在调幅分解中占据主导作用.Park等[28]在铁质中熵合金中引入Cu和Al元素,通过调幅分解结构抑制了应变局域化,在保持良好伸长率的同时使其机械强度提高.Röyset和Ryum[29]在Al-Zn-Mg合金中添加微量Sc元素促进了调幅分解过程生成了纳米级析出相,显著提高了合金的强度和抗腐蚀性能.Guo等[30]在Cu-Ni-Zn合金体系中引入P元素,通过增大溶质与溶剂原子尺寸的差异诱导合金调幅分解而使其硬度提高. ...

1

2008

... 调幅分解,能使材料的成分周期性变化且具有特定波长结构的连续纳米双相组织.这种独特的微观结构能显著提高材料的强度、硬度、抗蠕变性等力学性能[1,2].因此,调幅分解可用于设计性能优异的先进材料.调控调幅分解强化材料的力学性能,一直是国内外科研工作者的重点.相关研究涉及多种合金体系,包括Ti基合金[3,4]、Al基合金[5,6]、Cu基合金[7~9]、Fe-Mn记忆合金[10,11]以及双相钢[12~14]等.Ti基合金体系的Ti-6554[15,16]、Ti-55531[17]和Ti-10V-6Cu[18]等亚稳态β-Ti合金中都存在调幅分解.Yang等[19]在Ti-Al-Mo-V-Cr-Zr合金中构建了β+β'调幅分解片层结构,通过周期性分布的纳米结构阻碍了位错运动使其力学性能显著提高.An等[20]利用调幅分解机制在难熔高熵合金Hf-Nb-Ti-V体系中生成了具有周期性晶格畸变的β'相,在保持高强度的同时显著改善了合金的室温拉伸延展性.Hua等[21]将调幅分解机制引入Zr-Nb-Ti中熵合金体系,使其屈服强度显著提高并降低了弹性模量.同时,许多研究者也在探究调幅分解影响材料性能的机理.Cahn[22,23]建立了预测调幅分解微观结构的理论模型,提出了调幅分解强化理论[24].这个强化理论指出,调幅分解在合金中的强化作用是通过共格组织之间的内应力与位错相互作用实现的.Mott和Nabarro[25]认为,屈服强度取决于调幅分解组织的内应力场.值得注意的是,作为固态相变过程中的一种扩散型相变,调幅分解与传统的形核-长大方式不同,母相的过饱和固溶体在一定温度下通过原子上坡扩散引起的成分涨落产生结构相同、成分不同的两个新相,两相组织根据相变动力学呈现片层状或网格状等不同形貌[26,27].因此,成分起伏是调幅分解的原始驱动力,成分调控在调幅分解中占据主导作用.Park等[28]在铁质中熵合金中引入Cu和Al元素,通过调幅分解结构抑制了应变局域化,在保持良好伸长率的同时使其机械强度提高.Röyset和Ryum[29]在Al-Zn-Mg合金中添加微量Sc元素促进了调幅分解过程生成了纳米级析出相,显著提高了合金的强度和抗腐蚀性能.Guo等[30]在Cu-Ni-Zn合金体系中引入P元素,通过增大溶质与溶剂原子尺寸的差异诱导合金调幅分解而使其硬度提高. ...

A theory of nucleation for solid metallic solutions

1

1956

... 调幅分解,能使材料的成分周期性变化且具有特定波长结构的连续纳米双相组织.这种独特的微观结构能显著提高材料的强度、硬度、抗蠕变性等力学性能[1,2].因此,调幅分解可用于设计性能优异的先进材料.调控调幅分解强化材料的力学性能,一直是国内外科研工作者的重点.相关研究涉及多种合金体系,包括Ti基合金[3,4]、Al基合金[5,6]、Cu基合金[7~9]、Fe-Mn记忆合金[10,11]以及双相钢[12~14]等.Ti基合金体系的Ti-6554[15,16]、Ti-55531[17]和Ti-10V-6Cu[18]等亚稳态β-Ti合金中都存在调幅分解.Yang等[19]在Ti-Al-Mo-V-Cr-Zr合金中构建了β+β'调幅分解片层结构,通过周期性分布的纳米结构阻碍了位错运动使其力学性能显著提高.An等[20]利用调幅分解机制在难熔高熵合金Hf-Nb-Ti-V体系中生成了具有周期性晶格畸变的β'相,在保持高强度的同时显著改善了合金的室温拉伸延展性.Hua等[21]将调幅分解机制引入Zr-Nb-Ti中熵合金体系,使其屈服强度显著提高并降低了弹性模量.同时,许多研究者也在探究调幅分解影响材料性能的机理.Cahn[22,23]建立了预测调幅分解微观结构的理论模型,提出了调幅分解强化理论[24].这个强化理论指出,调幅分解在合金中的强化作用是通过共格组织之间的内应力与位错相互作用实现的.Mott和Nabarro[25]认为,屈服强度取决于调幅分解组织的内应力场.值得注意的是,作为固态相变过程中的一种扩散型相变,调幅分解与传统的形核-长大方式不同,母相的过饱和固溶体在一定温度下通过原子上坡扩散引起的成分涨落产生结构相同、成分不同的两个新相,两相组织根据相变动力学呈现片层状或网格状等不同形貌[26,27].因此,成分起伏是调幅分解的原始驱动力,成分调控在调幅分解中占据主导作用.Park等[28]在铁质中熵合金中引入Cu和Al元素,通过调幅分解结构抑制了应变局域化,在保持良好伸长率的同时使其机械强度提高.Röyset和Ryum[29]在Al-Zn-Mg合金中添加微量Sc元素促进了调幅分解过程生成了纳米级析出相,显著提高了合金的强度和抗腐蚀性能.Guo等[30]在Cu-Ni-Zn合金体系中引入P元素,通过增大溶质与溶剂原子尺寸的差异诱导合金调幅分解而使其硬度提高. ...

Periodic spinodal decomposition in double-strengthened medium-entropy alloy

1

2024

... 调幅分解,能使材料的成分周期性变化且具有特定波长结构的连续纳米双相组织.这种独特的微观结构能显著提高材料的强度、硬度、抗蠕变性等力学性能[1,2].因此,调幅分解可用于设计性能优异的先进材料.调控调幅分解强化材料的力学性能,一直是国内外科研工作者的重点.相关研究涉及多种合金体系,包括Ti基合金[3,4]、Al基合金[5,6]、Cu基合金[7~9]、Fe-Mn记忆合金[10,11]以及双相钢[12~14]等.Ti基合金体系的Ti-6554[15,16]、Ti-55531[17]和Ti-10V-6Cu[18]等亚稳态β-Ti合金中都存在调幅分解.Yang等[19]在Ti-Al-Mo-V-Cr-Zr合金中构建了β+β'调幅分解片层结构,通过周期性分布的纳米结构阻碍了位错运动使其力学性能显著提高.An等[20]利用调幅分解机制在难熔高熵合金Hf-Nb-Ti-V体系中生成了具有周期性晶格畸变的β'相,在保持高强度的同时显著改善了合金的室温拉伸延展性.Hua等[21]将调幅分解机制引入Zr-Nb-Ti中熵合金体系,使其屈服强度显著提高并降低了弹性模量.同时,许多研究者也在探究调幅分解影响材料性能的机理.Cahn[22,23]建立了预测调幅分解微观结构的理论模型,提出了调幅分解强化理论[24].这个强化理论指出,调幅分解在合金中的强化作用是通过共格组织之间的内应力与位错相互作用实现的.Mott和Nabarro[25]认为,屈服强度取决于调幅分解组织的内应力场.值得注意的是,作为固态相变过程中的一种扩散型相变,调幅分解与传统的形核-长大方式不同,母相的过饱和固溶体在一定温度下通过原子上坡扩散引起的成分涨落产生结构相同、成分不同的两个新相,两相组织根据相变动力学呈现片层状或网格状等不同形貌[26,27].因此,成分起伏是调幅分解的原始驱动力,成分调控在调幅分解中占据主导作用.Park等[28]在铁质中熵合金中引入Cu和Al元素,通过调幅分解结构抑制了应变局域化,在保持良好伸长率的同时使其机械强度提高.Röyset和Ryum[29]在Al-Zn-Mg合金中添加微量Sc元素促进了调幅分解过程生成了纳米级析出相,显著提高了合金的强度和抗腐蚀性能.Guo等[30]在Cu-Ni-Zn合金体系中引入P元素,通过增大溶质与溶剂原子尺寸的差异诱导合金调幅分解而使其硬度提高. ...

Scandium in aluminium alloys

1

2005

... 调幅分解,能使材料的成分周期性变化且具有特定波长结构的连续纳米双相组织.这种独特的微观结构能显著提高材料的强度、硬度、抗蠕变性等力学性能[1,2].因此,调幅分解可用于设计性能优异的先进材料.调控调幅分解强化材料的力学性能,一直是国内外科研工作者的重点.相关研究涉及多种合金体系,包括Ti基合金[3,4]、Al基合金[5,6]、Cu基合金[7~9]、Fe-Mn记忆合金[10,11]以及双相钢[12~14]等.Ti基合金体系的Ti-6554[15,16]、Ti-55531[17]和Ti-10V-6Cu[18]等亚稳态β-Ti合金中都存在调幅分解.Yang等[19]在Ti-Al-Mo-V-Cr-Zr合金中构建了β+β'调幅分解片层结构,通过周期性分布的纳米结构阻碍了位错运动使其力学性能显著提高.An等[20]利用调幅分解机制在难熔高熵合金Hf-Nb-Ti-V体系中生成了具有周期性晶格畸变的β'相,在保持高强度的同时显著改善了合金的室温拉伸延展性.Hua等[21]将调幅分解机制引入Zr-Nb-Ti中熵合金体系,使其屈服强度显著提高并降低了弹性模量.同时,许多研究者也在探究调幅分解影响材料性能的机理.Cahn[22,23]建立了预测调幅分解微观结构的理论模型,提出了调幅分解强化理论[24].这个强化理论指出,调幅分解在合金中的强化作用是通过共格组织之间的内应力与位错相互作用实现的.Mott和Nabarro[25]认为,屈服强度取决于调幅分解组织的内应力场.值得注意的是,作为固态相变过程中的一种扩散型相变,调幅分解与传统的形核-长大方式不同,母相的过饱和固溶体在一定温度下通过原子上坡扩散引起的成分涨落产生结构相同、成分不同的两个新相,两相组织根据相变动力学呈现片层状或网格状等不同形貌[26,27].因此,成分起伏是调幅分解的原始驱动力,成分调控在调幅分解中占据主导作用.Park等[28]在铁质中熵合金中引入Cu和Al元素,通过调幅分解结构抑制了应变局域化,在保持良好伸长率的同时使其机械强度提高.Röyset和Ryum[29]在Al-Zn-Mg合金中添加微量Sc元素促进了调幅分解过程生成了纳米级析出相,显著提高了合金的强度和抗腐蚀性能.Guo等[30]在Cu-Ni-Zn合金体系中引入P元素,通过增大溶质与溶剂原子尺寸的差异诱导合金调幅分解而使其硬度提高. ...

Effects of P addition on spinodal decomposition and discontinuous precipitation in Cu-15Ni-8Sn alloy

1

2021

... 调幅分解,能使材料的成分周期性变化且具有特定波长结构的连续纳米双相组织.这种独特的微观结构能显著提高材料的强度、硬度、抗蠕变性等力学性能[1,2].因此,调幅分解可用于设计性能优异的先进材料.调控调幅分解强化材料的力学性能,一直是国内外科研工作者的重点.相关研究涉及多种合金体系,包括Ti基合金[3,4]、Al基合金[5,6]、Cu基合金[7~9]、Fe-Mn记忆合金[10,11]以及双相钢[12~14]等.Ti基合金体系的Ti-6554[15,16]、Ti-55531[17]和Ti-10V-6Cu[18]等亚稳态β-Ti合金中都存在调幅分解.Yang等[19]在Ti-Al-Mo-V-Cr-Zr合金中构建了β+β'调幅分解片层结构,通过周期性分布的纳米结构阻碍了位错运动使其力学性能显著提高.An等[20]利用调幅分解机制在难熔高熵合金Hf-Nb-Ti-V体系中生成了具有周期性晶格畸变的β'相,在保持高强度的同时显著改善了合金的室温拉伸延展性.Hua等[21]将调幅分解机制引入Zr-Nb-Ti中熵合金体系,使其屈服强度显著提高并降低了弹性模量.同时,许多研究者也在探究调幅分解影响材料性能的机理.Cahn[22,23]建立了预测调幅分解微观结构的理论模型,提出了调幅分解强化理论[24].这个强化理论指出,调幅分解在合金中的强化作用是通过共格组织之间的内应力与位错相互作用实现的.Mott和Nabarro[25]认为,屈服强度取决于调幅分解组织的内应力场.值得注意的是,作为固态相变过程中的一种扩散型相变,调幅分解与传统的形核-长大方式不同,母相的过饱和固溶体在一定温度下通过原子上坡扩散引起的成分涨落产生结构相同、成分不同的两个新相,两相组织根据相变动力学呈现片层状或网格状等不同形貌[26,27].因此,成分起伏是调幅分解的原始驱动力,成分调控在调幅分解中占据主导作用.Park等[28]在铁质中熵合金中引入Cu和Al元素,通过调幅分解结构抑制了应变局域化,在保持良好伸长率的同时使其机械强度提高.Röyset和Ryum[29]在Al-Zn-Mg合金中添加微量Sc元素促进了调幅分解过程生成了纳米级析出相,显著提高了合金的强度和抗腐蚀性能.Guo等[30]在Cu-Ni-Zn合金体系中引入P元素,通过增大溶质与溶剂原子尺寸的差异诱导合金调幅分解而使其硬度提高. ...

Nanoporous titanium obtained from a spinodally decomposed Ti alloy

2

2016

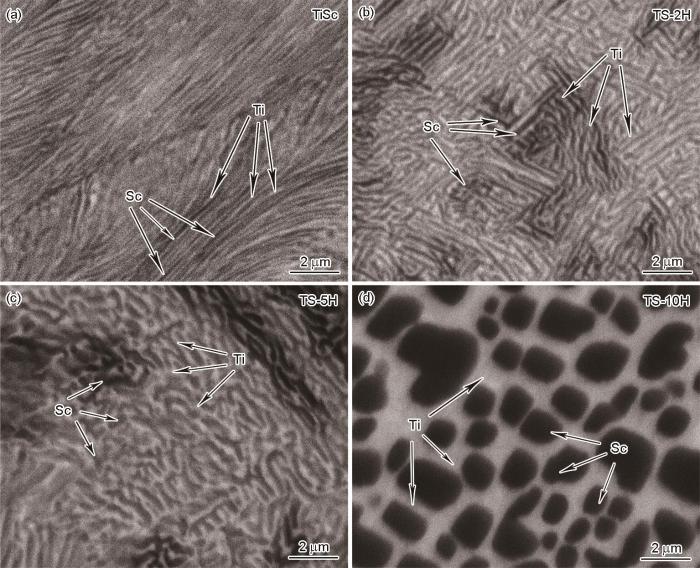

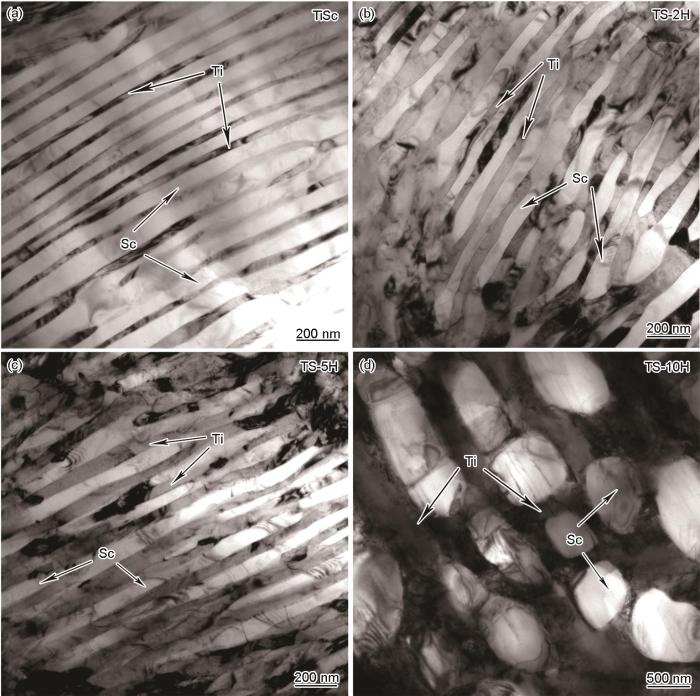

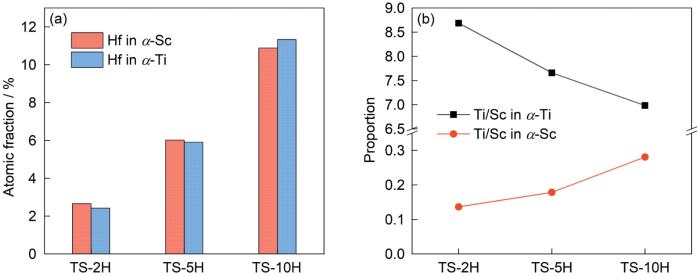

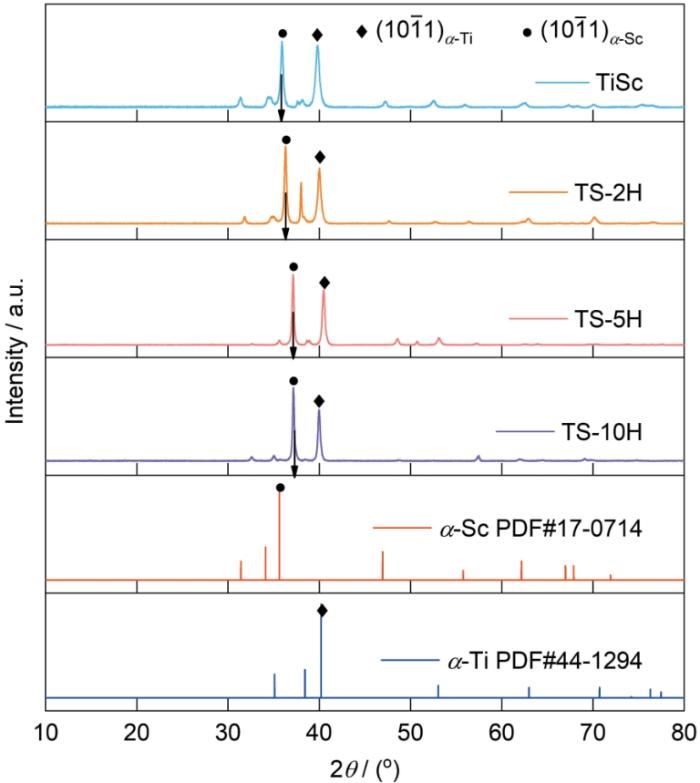

... Panagiotopoulos等[31]的研究结果表明,通过调幅分解可在TiSc二元合金体系中生成由α-Ti(hcp)和α-Sc(hcp)组成的纳米片层结构,为设计和开发高生物相容性骨骼植入材料提供了新思路.本文在TiSc调幅分解合金中添加不同含量的Hf元素[32~36],研究元素掺杂对TiSc合金微观结构和性能的影响及其机理. ...

... 成分为Ti50Sc50(下标为原子百分比)的母合金锭的制备:依据母合金的配比计算所需纯度高于99.99%(质量分数)的块状Sc、Ti的质量,将这些原料放入真空电弧炉中进行电弧熔炼.为了确保合金成分均匀,在熔炼过程中将合金锭翻转熔炼5~6次.对制备出的合金锭进行真空封管处理,以防其在后续热处理过程中氧化.从合金锭上截取试样进行均匀化处理:将试样加热到1200 ℃保温5 h后水淬.根据Ti-Sc相图[31],调幅分解温度为1050 ℃.在水淬冷却的短时间内完成调幅分解. ...

Nanotube formation and morphology change of Ti alloys containing Hf for dental materials use

1

2009

... Panagiotopoulos等[31]的研究结果表明,通过调幅分解可在TiSc二元合金体系中生成由α-Ti(hcp)和α-Sc(hcp)组成的纳米片层结构,为设计和开发高生物相容性骨骼植入材料提供了新思路.本文在TiSc调幅分解合金中添加不同含量的Hf元素[32~36],研究元素掺杂对TiSc合金微观结构和性能的影响及其机理. ...

Grindability of cast Ti-Hf alloys

0

2006

Mechanical properties of cast Ti-Hf alloys

0

2005

Changes in mechanical properties of Ti alloys in relation to alloying additions of Ta and Hf

0

2008

Tensile properties of binary titanium-zirconium and titanium-hafnium alloys

1

1962

... Panagiotopoulos等[31]的研究结果表明,通过调幅分解可在TiSc二元合金体系中生成由α-Ti(hcp)和α-Sc(hcp)组成的纳米片层结构,为设计和开发高生物相容性骨骼植入材料提供了新思路.本文在TiSc调幅分解合金中添加不同含量的Hf元素[32~36],研究元素掺杂对TiSc合金微观结构和性能的影响及其机理. ...

1

2021

... 调幅分解组织中两相的周期性分布可类比为正弦函数,两相组织的宽度之和对应于调幅分解的波长λ[22].依据Porter等的工作[37],调幅分解的特征波长可表示为 ...

Free energy of a nonuniform system. I. interfacial free energy

1

1958

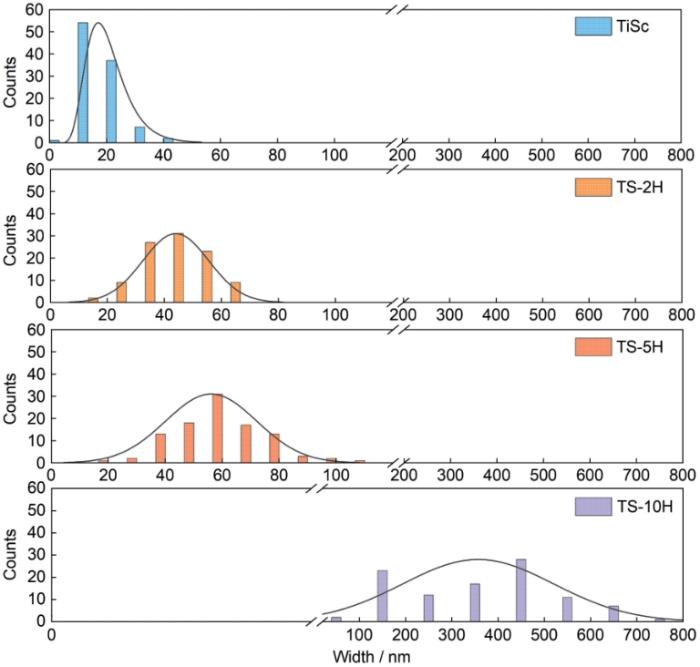

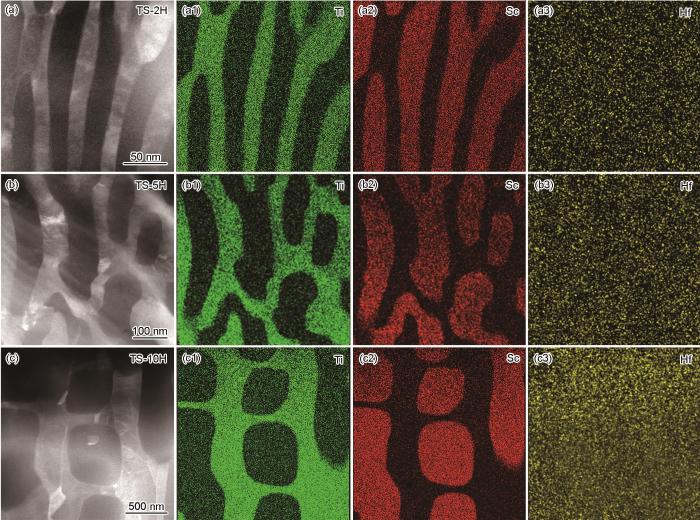

... 其中K为相关比例常数(取决于同类和异类原子对键能的差异),|f''|为化学驱动力,E为弹性模量,Vm为摩尔体积.Hf的原子半径介于Ti与Sc的原子半径之间且其扩散性较差,对E和Vm的影响较小.这表明,本体系中调幅分解的特征波长主要决定于|f''|和η.Hf元素的均匀固溶使体系的混合熵增加,在焓变较为稳定的情况下自由能的降低使自由能曲率变化变缓,即|f''|减小,从而允许更大范围的成分波动[38],即调幅分解特征波长增大.同时,随着Hf元素含量的提高α-Ti与α-Sc两相的晶面间距差值减小.Hf的原子半径(0.158 nm)介于Ti的原子半径(0.146 nm)与Sc的原子半径(0.164 nm)之间,使Hf元素固溶在α-Ti和α-Sc基体中产生相反的晶格变化:在α-Ti中引起晶格膨胀,而在α-Sc中则引起晶格收缩.这降低了Ti与Sc原子间的晶格错配度η,使调幅分解波长增大.以上双重机制的共同作用,使合金在调幅分解时更倾向于形成波长更大的结构,即调幅分解产生的组织片层更宽. ...

Spinodal decomposition in Fe-25Cr-12Co alloys under the influence of high magnetic field and the effect of grain boundary

2

2018

... 图5表明,掺杂Hf元素改变了α-Ti和α-Sc中Ti/Sc比值,即α-Ti中Ti含量降低,α-Sc中Sc含量降低.这一现象,与正常调幅分解时α-Ti与α-Sc两相中富集元素含量随着扩散进行不断提高相反.研究表明,Hf元素对调幅分解过程中Ti与Sc原子的上坡扩散行为具有一定程度的抑制作用.其原因是,低扩散性的Hf元素降低了体系的扩散速率[39]. ...

... 掺杂Hf元素后α-Ti与α-Sc调幅分解结构由片层转变为网格状和块状组织,主要是扩散速率降低所致.原子扩散较快时,溶质原子能在较短时间内长距离迁移.Ti、Sc原子迅速向特定区域扩散使某个方向上的成分较快出现明显的浓度差异,溶质原子优先在这个方向上坡扩散聚集使组织在该方向呈现出明显的层状特征而形成片层组织.而扩散速率较低时Ti、Sc原子难以长距离扩散而在较小范围内波动聚集,成分波动在多个方向上较为均衡而形成网格状组织.这种网格状组织,验证了Zhang等[39]的模拟结果. ...

The role of ordered domains and slip mode of α2 phase in the plastic behaviour of TiAl crystals containing oriented lamellae

1

1993

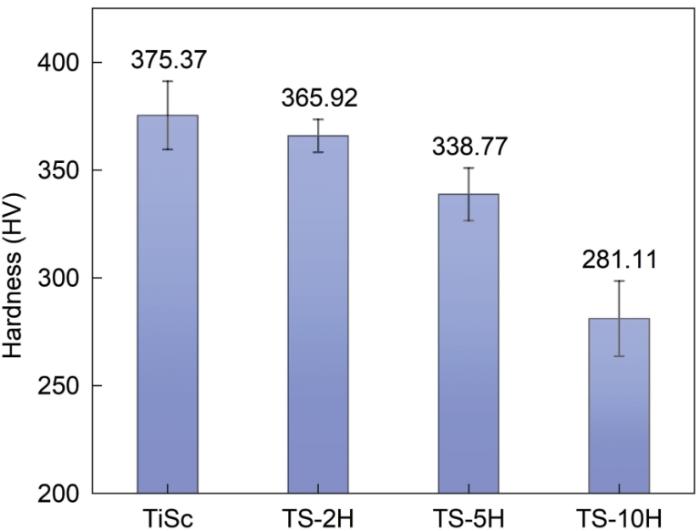

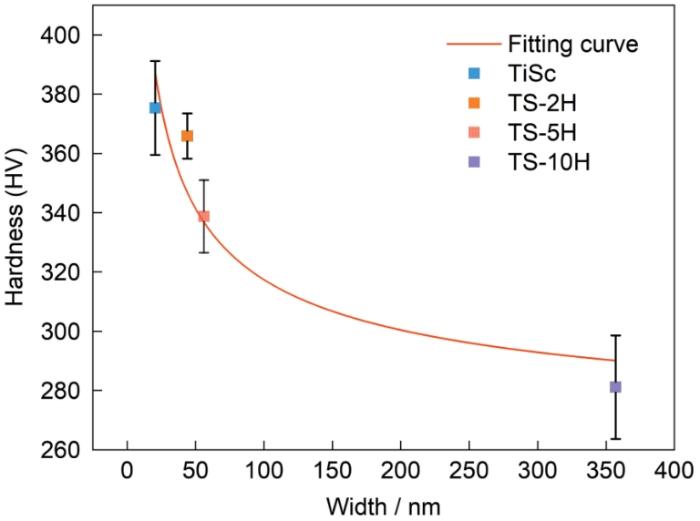

... 从图8可见,Hf元素含量从0提高到10%合金的片层组织宽度增加、维氏硬度降低.可以用经典的Hall-Petch关系[40] ...

The determination of yield strength from hardness measurements

1

1971

... 其中A为硬度与强度换算的比例系数(A ≈ 2.78)[41].依据 式(3)拟合出的维氏硬度与片层宽度的关系曲线,如图8所示.可以看出,4种合金试样的硬度实验值与理论拟合曲线的一致性良好,即硬度与片层宽度的1/2次幂呈负相关.随着Hf含量的提高α-Ti相的Ti/Sc比值从8.69降至6.98,α-Sc相的Ti/Sc比值从0.14升至0.28.这表明,两相中Ti、Sc的富集程度都降低,即成分波动的幅值降低.幅值的降低使α-Ti与α-Sc相的成分差异减小、界面处的半共格应变(内应力场)减弱和位错运动的阻力降低,从而使合金的硬度降低.幅值减小和波长增宽导致的强化效果下降的协同作用,使掺杂Hf后合金的硬度降低. ...