Emerging contaminants migration from pipes used in drinking water distribution systems: a review of the scientific literature

1

2022

... 钢管因强度高、塑韧性,在石油化工、食品饮料以及生化制药等领域得到了广泛的应用[1,2].但是,钢管的抗腐蚀性能不高[3,4].钛管的耐腐蚀和比强度高,在海洋运输、航空航天和核工业等领域有广阔的应用前景[5,6].但是,钛管的价格昂贵[7,8].以钢管为基管、外包或内衬钛管的钛钢复合管,兼具高力学性能和耐蚀性能[9]. ...

High-strength steel development for pipelines: a Brazilian perspective

1

2005

... 钢管因强度高、塑韧性,在石油化工、食品饮料以及生化制药等领域得到了广泛的应用[1,2].但是,钢管的抗腐蚀性能不高[3,4].钛管的耐腐蚀和比强度高,在海洋运输、航空航天和核工业等领域有广阔的应用前景[5,6].但是,钛管的价格昂贵[7,8].以钢管为基管、外包或内衬钛管的钛钢复合管,兼具高力学性能和耐蚀性能[9]. ...

Challenges and opportunities in corrosion of steel in concrete

1

2018

... 钢管因强度高、塑韧性,在石油化工、食品饮料以及生化制药等领域得到了广泛的应用[1,2].但是,钢管的抗腐蚀性能不高[3,4].钛管的耐腐蚀和比强度高,在海洋运输、航空航天和核工业等领域有广阔的应用前景[5,6].但是,钛管的价格昂贵[7,8].以钢管为基管、外包或内衬钛管的钛钢复合管,兼具高力学性能和耐蚀性能[9]. ...

Marine atmospheric corrosion of carbon steel: A review

1

2017

... 钢管因强度高、塑韧性,在石油化工、食品饮料以及生化制药等领域得到了广泛的应用[1,2].但是,钢管的抗腐蚀性能不高[3,4].钛管的耐腐蚀和比强度高,在海洋运输、航空航天和核工业等领域有广阔的应用前景[5,6].但是,钛管的价格昂贵[7,8].以钢管为基管、外包或内衬钛管的钛钢复合管,兼具高力学性能和耐蚀性能[9]. ...

Effective design of high performance corrosion resistant systems for oceanic environments using titanium

1

2000

... 钢管因强度高、塑韧性,在石油化工、食品饮料以及生化制药等领域得到了广泛的应用[1,2].但是,钢管的抗腐蚀性能不高[3,4].钛管的耐腐蚀和比强度高,在海洋运输、航空航天和核工业等领域有广阔的应用前景[5,6].但是,钛管的价格昂贵[7,8].以钢管为基管、外包或内衬钛管的钛钢复合管,兼具高力学性能和耐蚀性能[9]. ...

Microstructure and Corrosion Property of Prepared CoCrW Coatings on the TC4 Surface by Laser Cladding

1

2023

... 钢管因强度高、塑韧性,在石油化工、食品饮料以及生化制药等领域得到了广泛的应用[1,2].但是,钢管的抗腐蚀性能不高[3,4].钛管的耐腐蚀和比强度高,在海洋运输、航空航天和核工业等领域有广阔的应用前景[5,6].但是,钛管的价格昂贵[7,8].以钢管为基管、外包或内衬钛管的钛钢复合管,兼具高力学性能和耐蚀性能[9]. ...

Study of internal pressure strength of the titanium-steel composite tube based on yield and shear failure mechanisms

1

2019

... 钢管因强度高、塑韧性,在石油化工、食品饮料以及生化制药等领域得到了广泛的应用[1,2].但是,钢管的抗腐蚀性能不高[3,4].钛管的耐腐蚀和比强度高,在海洋运输、航空航天和核工业等领域有广阔的应用前景[5,6].但是,钛管的价格昂贵[7,8].以钢管为基管、外包或内衬钛管的钛钢复合管,兼具高力学性能和耐蚀性能[9]. ...

Manufacturing technology and application trends of titanium clad steel plates

1

2015

... 钢管因强度高、塑韧性,在石油化工、食品饮料以及生化制药等领域得到了广泛的应用[1,2].但是,钢管的抗腐蚀性能不高[3,4].钛管的耐腐蚀和比强度高,在海洋运输、航空航天和核工业等领域有广阔的应用前景[5,6].但是,钛管的价格昂贵[7,8].以钢管为基管、外包或内衬钛管的钛钢复合管,兼具高力学性能和耐蚀性能[9]. ...

Microstructural and mechanical properties of hot roll bonded titanium alloy/low carbon steel plate

1

2018

... 钢管因强度高、塑韧性,在石油化工、食品饮料以及生化制药等领域得到了广泛的应用[1,2].但是,钢管的抗腐蚀性能不高[3,4].钛管的耐腐蚀和比强度高,在海洋运输、航空航天和核工业等领域有广阔的应用前景[5,6].但是,钛管的价格昂贵[7,8].以钢管为基管、外包或内衬钛管的钛钢复合管,兼具高力学性能和耐蚀性能[9]. ...

Theoretical and experimental study of the thermal strength of anticorrosive lined steel pipes

2

2014

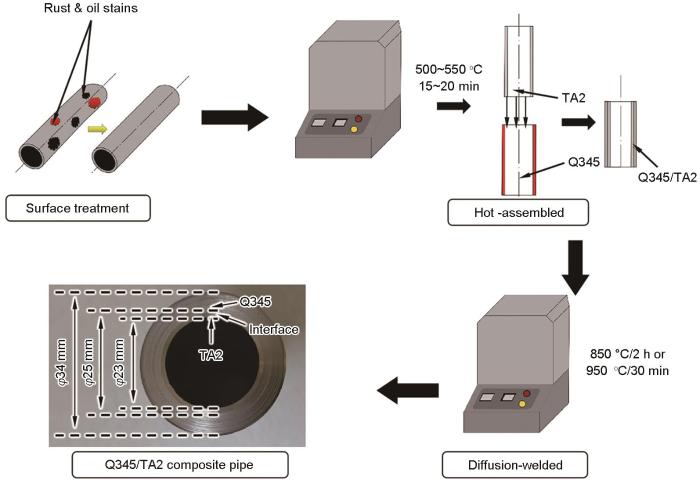

... 用液压膨胀法制备的双金属复合管,其界面结合强度为4~6.5 MPa.理论计算和剪切实验结果表明,在液压成型过程中复合管的结合强度取决于基管和衬管的塑性变形[10].分别将基管和衬管在220 ℃低温退火后经1000 ℃热挤压制备TA2/Q235复合管,低温处理可降低复合界面的硬度并提高界面结合强度[11].分别用Fe和Nb为中间层用热挤压工艺制备的TC11/Fe/CrMo与170 MPa TC11/Nb/CrMo复合管剪切强度为185 MPa,其界面结合强度决定于界面晶粒的不均匀变形和中间相的脆性[12].用Cu为中间层用拉拔+热扩散法制备的TA2/Cu/20钛钢复合管,其界面结合强度高达310 MPa[13].将复合板轧制、卷管和焊接,也能制备钛钢复合管.将TA10/Q235R复合板爆炸焊接,再将其在550 ℃退火1.5 h,得到的复合板的抗拉强度可达463.27 MPa[14].分别将TA2/SUS304复合板平轧制(FR)和辊轧+平轧(CFR + FR),用CFR + FR制备的复合板非均匀塑性变形后界面呈波浪形,其剪切强度从FR的140 MPa提高到245 MPa[15].在900 ℃扩散焊制备的Ti-6Al-4V钛合金和微双相不锈钢复合板,其剪切强度高达400 MPa[16];在钛/钢之间加Ni过渡层,使界面组织由Fe-Ti系化合物转变为脆性较小的Ni-Ti系化合物,可将界面剪切强度提高到460 MPa[17].这些结果表明,当前钛钢复合管的研究主要集中在制备技术创新和界面结合特性的研究.用机械法制备的双金属复合管其界面结合强度只取决于衬管与基管的塑性变形,结合强度低于10 MPa且易发生衬管塌陷[18],而用冶金法制备的双金属复合管,其结合强度不同且工艺复杂.本文利用金属热胀冷缩原理(即红装工艺)制备钛/钢复合管并对其进行扩散焊,研究扩散焊接头的力学性能并揭示其机理. ...

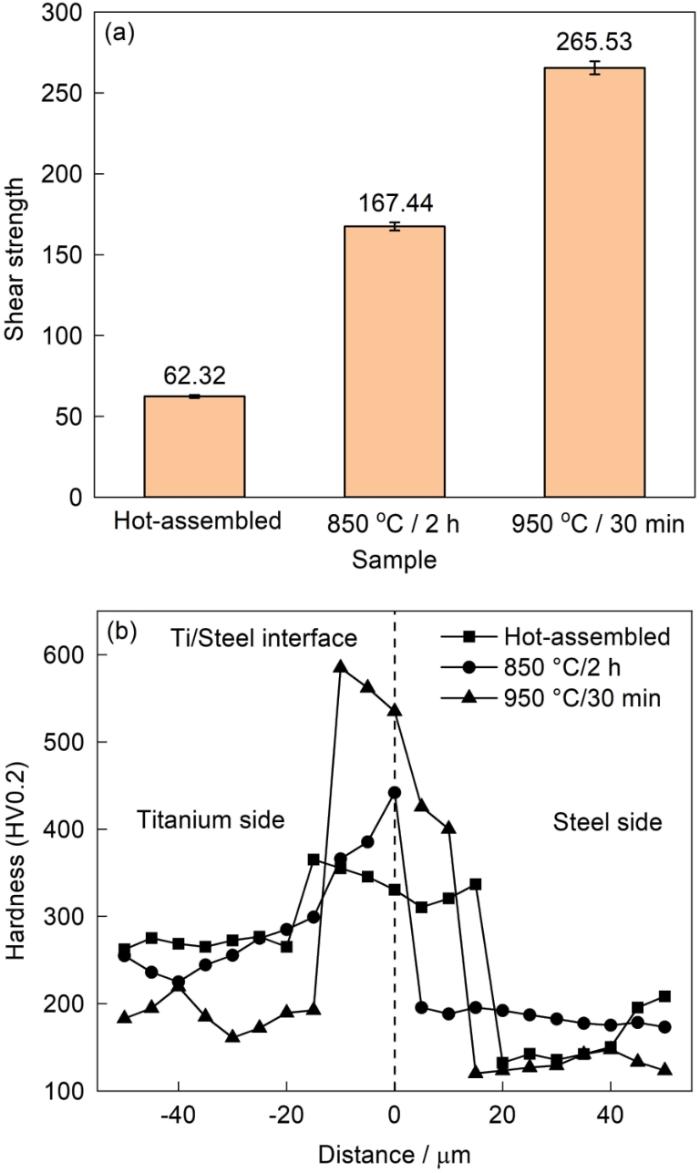

... 图8给出了TA2/Q345复合管的力学性能.由图8a可见,红装后TA2/Q345复合管的剪切强度为62.32 MPa,远高于传统机械复合管的剪切强度(4~6.5 MPa)[10].其原因是,红装时热应力为[35] ...

Microstructure and properties of hot extruded titanium/steel composite tubes

2

2023

... 用液压膨胀法制备的双金属复合管,其界面结合强度为4~6.5 MPa.理论计算和剪切实验结果表明,在液压成型过程中复合管的结合强度取决于基管和衬管的塑性变形[10].分别将基管和衬管在220 ℃低温退火后经1000 ℃热挤压制备TA2/Q235复合管,低温处理可降低复合界面的硬度并提高界面结合强度[11].分别用Fe和Nb为中间层用热挤压工艺制备的TC11/Fe/CrMo与170 MPa TC11/Nb/CrMo复合管剪切强度为185 MPa,其界面结合强度决定于界面晶粒的不均匀变形和中间相的脆性[12].用Cu为中间层用拉拔+热扩散法制备的TA2/Cu/20钛钢复合管,其界面结合强度高达310 MPa[13].将复合板轧制、卷管和焊接,也能制备钛钢复合管.将TA10/Q235R复合板爆炸焊接,再将其在550 ℃退火1.5 h,得到的复合板的抗拉强度可达463.27 MPa[14].分别将TA2/SUS304复合板平轧制(FR)和辊轧+平轧(CFR + FR),用CFR + FR制备的复合板非均匀塑性变形后界面呈波浪形,其剪切强度从FR的140 MPa提高到245 MPa[15].在900 ℃扩散焊制备的Ti-6Al-4V钛合金和微双相不锈钢复合板,其剪切强度高达400 MPa[16];在钛/钢之间加Ni过渡层,使界面组织由Fe-Ti系化合物转变为脆性较小的Ni-Ti系化合物,可将界面剪切强度提高到460 MPa[17].这些结果表明,当前钛钢复合管的研究主要集中在制备技术创新和界面结合特性的研究.用机械法制备的双金属复合管其界面结合强度只取决于衬管与基管的塑性变形,结合强度低于10 MPa且易发生衬管塌陷[18],而用冶金法制备的双金属复合管,其结合强度不同且工艺复杂.本文利用金属热胀冷缩原理(即红装工艺)制备钛/钢复合管并对其进行扩散焊,研究扩散焊接头的力学性能并揭示其机理. ...

... 图8b给出了红装和扩散焊后TA2/Q345复合管界面的显微硬度曲线,可见过渡区的硬度高于基材,因为与红装相比钛与钢的反应热使扩散在过渡区生成了更多的TiC、FeTi和Fe2Ti等本征脆性相[15,16].红装、850 ℃扩散焊和950 ℃扩散焊后,TA2/Q345复合管过渡区的硬度最大硬度值分别为360HV、442HV和585HV.钢侧的硬度比基材的低,是钢中的碳向界面扩散所致.由图5可见,与950 ℃扩散焊相比红装的界面脱碳加剧,使其硬度显著降低.红装和850 ℃扩散焊后近过渡层钛侧的硬度与基体的硬度基本相同,而在950 ℃扩散焊后此处的硬度有所下降,是α-Ti向同素异构β-Ti转变所致[11,13,17]. ...

热挤压钛/钢复合管的微观组织和性能

2

2023

... 用液压膨胀法制备的双金属复合管,其界面结合强度为4~6.5 MPa.理论计算和剪切实验结果表明,在液压成型过程中复合管的结合强度取决于基管和衬管的塑性变形[10].分别将基管和衬管在220 ℃低温退火后经1000 ℃热挤压制备TA2/Q235复合管,低温处理可降低复合界面的硬度并提高界面结合强度[11].分别用Fe和Nb为中间层用热挤压工艺制备的TC11/Fe/CrMo与170 MPa TC11/Nb/CrMo复合管剪切强度为185 MPa,其界面结合强度决定于界面晶粒的不均匀变形和中间相的脆性[12].用Cu为中间层用拉拔+热扩散法制备的TA2/Cu/20钛钢复合管,其界面结合强度高达310 MPa[13].将复合板轧制、卷管和焊接,也能制备钛钢复合管.将TA10/Q235R复合板爆炸焊接,再将其在550 ℃退火1.5 h,得到的复合板的抗拉强度可达463.27 MPa[14].分别将TA2/SUS304复合板平轧制(FR)和辊轧+平轧(CFR + FR),用CFR + FR制备的复合板非均匀塑性变形后界面呈波浪形,其剪切强度从FR的140 MPa提高到245 MPa[15].在900 ℃扩散焊制备的Ti-6Al-4V钛合金和微双相不锈钢复合板,其剪切强度高达400 MPa[16];在钛/钢之间加Ni过渡层,使界面组织由Fe-Ti系化合物转变为脆性较小的Ni-Ti系化合物,可将界面剪切强度提高到460 MPa[17].这些结果表明,当前钛钢复合管的研究主要集中在制备技术创新和界面结合特性的研究.用机械法制备的双金属复合管其界面结合强度只取决于衬管与基管的塑性变形,结合强度低于10 MPa且易发生衬管塌陷[18],而用冶金法制备的双金属复合管,其结合强度不同且工艺复杂.本文利用金属热胀冷缩原理(即红装工艺)制备钛/钢复合管并对其进行扩散焊,研究扩散焊接头的力学性能并揭示其机理. ...

... 图8b给出了红装和扩散焊后TA2/Q345复合管界面的显微硬度曲线,可见过渡区的硬度高于基材,因为与红装相比钛与钢的反应热使扩散在过渡区生成了更多的TiC、FeTi和Fe2Ti等本征脆性相[15,16].红装、850 ℃扩散焊和950 ℃扩散焊后,TA2/Q345复合管过渡区的硬度最大硬度值分别为360HV、442HV和585HV.钢侧的硬度比基材的低,是钢中的碳向界面扩散所致.由图5可见,与950 ℃扩散焊相比红装的界面脱碳加剧,使其硬度显著降低.红装和850 ℃扩散焊后近过渡层钛侧的硬度与基体的硬度基本相同,而在950 ℃扩散焊后此处的硬度有所下降,是α-Ti向同素异构β-Ti转变所致[11,13,17]. ...

Influence of interlayer materials Fe and Nb on the interface and shear strength of high-strength titanium-steel composite tubes

1

... 用液压膨胀法制备的双金属复合管,其界面结合强度为4~6.5 MPa.理论计算和剪切实验结果表明,在液压成型过程中复合管的结合强度取决于基管和衬管的塑性变形[10].分别将基管和衬管在220 ℃低温退火后经1000 ℃热挤压制备TA2/Q235复合管,低温处理可降低复合界面的硬度并提高界面结合强度[11].分别用Fe和Nb为中间层用热挤压工艺制备的TC11/Fe/CrMo与170 MPa TC11/Nb/CrMo复合管剪切强度为185 MPa,其界面结合强度决定于界面晶粒的不均匀变形和中间相的脆性[12].用Cu为中间层用拉拔+热扩散法制备的TA2/Cu/20钛钢复合管,其界面结合强度高达310 MPa[13].将复合板轧制、卷管和焊接,也能制备钛钢复合管.将TA10/Q235R复合板爆炸焊接,再将其在550 ℃退火1.5 h,得到的复合板的抗拉强度可达463.27 MPa[14].分别将TA2/SUS304复合板平轧制(FR)和辊轧+平轧(CFR + FR),用CFR + FR制备的复合板非均匀塑性变形后界面呈波浪形,其剪切强度从FR的140 MPa提高到245 MPa[15].在900 ℃扩散焊制备的Ti-6Al-4V钛合金和微双相不锈钢复合板,其剪切强度高达400 MPa[16];在钛/钢之间加Ni过渡层,使界面组织由Fe-Ti系化合物转变为脆性较小的Ni-Ti系化合物,可将界面剪切强度提高到460 MPa[17].这些结果表明,当前钛钢复合管的研究主要集中在制备技术创新和界面结合特性的研究.用机械法制备的双金属复合管其界面结合强度只取决于衬管与基管的塑性变形,结合强度低于10 MPa且易发生衬管塌陷[18],而用冶金法制备的双金属复合管,其结合强度不同且工艺复杂.本文利用金属热胀冷缩原理(即红装工艺)制备钛/钢复合管并对其进行扩散焊,研究扩散焊接头的力学性能并揭示其机理. ...

中间层材料Fe和Nb对高强钛-钢复合管界面及剪切强度的影响

1

... 用液压膨胀法制备的双金属复合管,其界面结合强度为4~6.5 MPa.理论计算和剪切实验结果表明,在液压成型过程中复合管的结合强度取决于基管和衬管的塑性变形[10].分别将基管和衬管在220 ℃低温退火后经1000 ℃热挤压制备TA2/Q235复合管,低温处理可降低复合界面的硬度并提高界面结合强度[11].分别用Fe和Nb为中间层用热挤压工艺制备的TC11/Fe/CrMo与170 MPa TC11/Nb/CrMo复合管剪切强度为185 MPa,其界面结合强度决定于界面晶粒的不均匀变形和中间相的脆性[12].用Cu为中间层用拉拔+热扩散法制备的TA2/Cu/20钛钢复合管,其界面结合强度高达310 MPa[13].将复合板轧制、卷管和焊接,也能制备钛钢复合管.将TA10/Q235R复合板爆炸焊接,再将其在550 ℃退火1.5 h,得到的复合板的抗拉强度可达463.27 MPa[14].分别将TA2/SUS304复合板平轧制(FR)和辊轧+平轧(CFR + FR),用CFR + FR制备的复合板非均匀塑性变形后界面呈波浪形,其剪切强度从FR的140 MPa提高到245 MPa[15].在900 ℃扩散焊制备的Ti-6Al-4V钛合金和微双相不锈钢复合板,其剪切强度高达400 MPa[16];在钛/钢之间加Ni过渡层,使界面组织由Fe-Ti系化合物转变为脆性较小的Ni-Ti系化合物,可将界面剪切强度提高到460 MPa[17].这些结果表明,当前钛钢复合管的研究主要集中在制备技术创新和界面结合特性的研究.用机械法制备的双金属复合管其界面结合强度只取决于衬管与基管的塑性变形,结合强度低于10 MPa且易发生衬管塌陷[18],而用冶金法制备的双金属复合管,其结合强度不同且工艺复杂.本文利用金属热胀冷缩原理(即红装工艺)制备钛/钢复合管并对其进行扩散焊,研究扩散焊接头的力学性能并揭示其机理. ...

Interfacial organisation and properties of titanium-copper-stainless steel diffusion composite tubes

2

2013

... 用液压膨胀法制备的双金属复合管,其界面结合强度为4~6.5 MPa.理论计算和剪切实验结果表明,在液压成型过程中复合管的结合强度取决于基管和衬管的塑性变形[10].分别将基管和衬管在220 ℃低温退火后经1000 ℃热挤压制备TA2/Q235复合管,低温处理可降低复合界面的硬度并提高界面结合强度[11].分别用Fe和Nb为中间层用热挤压工艺制备的TC11/Fe/CrMo与170 MPa TC11/Nb/CrMo复合管剪切强度为185 MPa,其界面结合强度决定于界面晶粒的不均匀变形和中间相的脆性[12].用Cu为中间层用拉拔+热扩散法制备的TA2/Cu/20钛钢复合管,其界面结合强度高达310 MPa[13].将复合板轧制、卷管和焊接,也能制备钛钢复合管.将TA10/Q235R复合板爆炸焊接,再将其在550 ℃退火1.5 h,得到的复合板的抗拉强度可达463.27 MPa[14].分别将TA2/SUS304复合板平轧制(FR)和辊轧+平轧(CFR + FR),用CFR + FR制备的复合板非均匀塑性变形后界面呈波浪形,其剪切强度从FR的140 MPa提高到245 MPa[15].在900 ℃扩散焊制备的Ti-6Al-4V钛合金和微双相不锈钢复合板,其剪切强度高达400 MPa[16];在钛/钢之间加Ni过渡层,使界面组织由Fe-Ti系化合物转变为脆性较小的Ni-Ti系化合物,可将界面剪切强度提高到460 MPa[17].这些结果表明,当前钛钢复合管的研究主要集中在制备技术创新和界面结合特性的研究.用机械法制备的双金属复合管其界面结合强度只取决于衬管与基管的塑性变形,结合强度低于10 MPa且易发生衬管塌陷[18],而用冶金法制备的双金属复合管,其结合强度不同且工艺复杂.本文利用金属热胀冷缩原理(即红装工艺)制备钛/钢复合管并对其进行扩散焊,研究扩散焊接头的力学性能并揭示其机理. ...

... 图8b给出了红装和扩散焊后TA2/Q345复合管界面的显微硬度曲线,可见过渡区的硬度高于基材,因为与红装相比钛与钢的反应热使扩散在过渡区生成了更多的TiC、FeTi和Fe2Ti等本征脆性相[15,16].红装、850 ℃扩散焊和950 ℃扩散焊后,TA2/Q345复合管过渡区的硬度最大硬度值分别为360HV、442HV和585HV.钢侧的硬度比基材的低,是钢中的碳向界面扩散所致.由图5可见,与950 ℃扩散焊相比红装的界面脱碳加剧,使其硬度显著降低.红装和850 ℃扩散焊后近过渡层钛侧的硬度与基体的硬度基本相同,而在950 ℃扩散焊后此处的硬度有所下降,是α-Ti向同素异构β-Ti转变所致[11,13,17]. ...

钛-铜-不锈钢扩散复合管界面组织与性能

2

2013

... 用液压膨胀法制备的双金属复合管,其界面结合强度为4~6.5 MPa.理论计算和剪切实验结果表明,在液压成型过程中复合管的结合强度取决于基管和衬管的塑性变形[10].分别将基管和衬管在220 ℃低温退火后经1000 ℃热挤压制备TA2/Q235复合管,低温处理可降低复合界面的硬度并提高界面结合强度[11].分别用Fe和Nb为中间层用热挤压工艺制备的TC11/Fe/CrMo与170 MPa TC11/Nb/CrMo复合管剪切强度为185 MPa,其界面结合强度决定于界面晶粒的不均匀变形和中间相的脆性[12].用Cu为中间层用拉拔+热扩散法制备的TA2/Cu/20钛钢复合管,其界面结合强度高达310 MPa[13].将复合板轧制、卷管和焊接,也能制备钛钢复合管.将TA10/Q235R复合板爆炸焊接,再将其在550 ℃退火1.5 h,得到的复合板的抗拉强度可达463.27 MPa[14].分别将TA2/SUS304复合板平轧制(FR)和辊轧+平轧(CFR + FR),用CFR + FR制备的复合板非均匀塑性变形后界面呈波浪形,其剪切强度从FR的140 MPa提高到245 MPa[15].在900 ℃扩散焊制备的Ti-6Al-4V钛合金和微双相不锈钢复合板,其剪切强度高达400 MPa[16];在钛/钢之间加Ni过渡层,使界面组织由Fe-Ti系化合物转变为脆性较小的Ni-Ti系化合物,可将界面剪切强度提高到460 MPa[17].这些结果表明,当前钛钢复合管的研究主要集中在制备技术创新和界面结合特性的研究.用机械法制备的双金属复合管其界面结合强度只取决于衬管与基管的塑性变形,结合强度低于10 MPa且易发生衬管塌陷[18],而用冶金法制备的双金属复合管,其结合强度不同且工艺复杂.本文利用金属热胀冷缩原理(即红装工艺)制备钛/钢复合管并对其进行扩散焊,研究扩散焊接头的力学性能并揭示其机理. ...

... 图8b给出了红装和扩散焊后TA2/Q345复合管界面的显微硬度曲线,可见过渡区的硬度高于基材,因为与红装相比钛与钢的反应热使扩散在过渡区生成了更多的TiC、FeTi和Fe2Ti等本征脆性相[15,16].红装、850 ℃扩散焊和950 ℃扩散焊后,TA2/Q345复合管过渡区的硬度最大硬度值分别为360HV、442HV和585HV.钢侧的硬度比基材的低,是钢中的碳向界面扩散所致.由图5可见,与950 ℃扩散焊相比红装的界面脱碳加剧,使其硬度显著降低.红装和850 ℃扩散焊后近过渡层钛侧的硬度与基体的硬度基本相同,而在950 ℃扩散焊后此处的硬度有所下降,是α-Ti向同素异构β-Ti转变所致[11,13,17]. ...

Investigation on microstructure and mechanical properties of TA10-Q245R composite plate formed by explosive welding

1

2019

... 用液压膨胀法制备的双金属复合管,其界面结合强度为4~6.5 MPa.理论计算和剪切实验结果表明,在液压成型过程中复合管的结合强度取决于基管和衬管的塑性变形[10].分别将基管和衬管在220 ℃低温退火后经1000 ℃热挤压制备TA2/Q235复合管,低温处理可降低复合界面的硬度并提高界面结合强度[11].分别用Fe和Nb为中间层用热挤压工艺制备的TC11/Fe/CrMo与170 MPa TC11/Nb/CrMo复合管剪切强度为185 MPa,其界面结合强度决定于界面晶粒的不均匀变形和中间相的脆性[12].用Cu为中间层用拉拔+热扩散法制备的TA2/Cu/20钛钢复合管,其界面结合强度高达310 MPa[13].将复合板轧制、卷管和焊接,也能制备钛钢复合管.将TA10/Q235R复合板爆炸焊接,再将其在550 ℃退火1.5 h,得到的复合板的抗拉强度可达463.27 MPa[14].分别将TA2/SUS304复合板平轧制(FR)和辊轧+平轧(CFR + FR),用CFR + FR制备的复合板非均匀塑性变形后界面呈波浪形,其剪切强度从FR的140 MPa提高到245 MPa[15].在900 ℃扩散焊制备的Ti-6Al-4V钛合金和微双相不锈钢复合板,其剪切强度高达400 MPa[16];在钛/钢之间加Ni过渡层,使界面组织由Fe-Ti系化合物转变为脆性较小的Ni-Ti系化合物,可将界面剪切强度提高到460 MPa[17].这些结果表明,当前钛钢复合管的研究主要集中在制备技术创新和界面结合特性的研究.用机械法制备的双金属复合管其界面结合强度只取决于衬管与基管的塑性变形,结合强度低于10 MPa且易发生衬管塌陷[18],而用冶金法制备的双金属复合管,其结合强度不同且工艺复杂.本文利用金属热胀冷缩原理(即红装工艺)制备钛/钢复合管并对其进行扩散焊,研究扩散焊接头的力学性能并揭示其机理. ...

Effect of inhomogeneous plastic deformation on the interfacial microstructure and properties of titanium/stainless steel

3

2023

... 用液压膨胀法制备的双金属复合管,其界面结合强度为4~6.5 MPa.理论计算和剪切实验结果表明,在液压成型过程中复合管的结合强度取决于基管和衬管的塑性变形[10].分别将基管和衬管在220 ℃低温退火后经1000 ℃热挤压制备TA2/Q235复合管,低温处理可降低复合界面的硬度并提高界面结合强度[11].分别用Fe和Nb为中间层用热挤压工艺制备的TC11/Fe/CrMo与170 MPa TC11/Nb/CrMo复合管剪切强度为185 MPa,其界面结合强度决定于界面晶粒的不均匀变形和中间相的脆性[12].用Cu为中间层用拉拔+热扩散法制备的TA2/Cu/20钛钢复合管,其界面结合强度高达310 MPa[13].将复合板轧制、卷管和焊接,也能制备钛钢复合管.将TA10/Q235R复合板爆炸焊接,再将其在550 ℃退火1.5 h,得到的复合板的抗拉强度可达463.27 MPa[14].分别将TA2/SUS304复合板平轧制(FR)和辊轧+平轧(CFR + FR),用CFR + FR制备的复合板非均匀塑性变形后界面呈波浪形,其剪切强度从FR的140 MPa提高到245 MPa[15].在900 ℃扩散焊制备的Ti-6Al-4V钛合金和微双相不锈钢复合板,其剪切强度高达400 MPa[16];在钛/钢之间加Ni过渡层,使界面组织由Fe-Ti系化合物转变为脆性较小的Ni-Ti系化合物,可将界面剪切强度提高到460 MPa[17].这些结果表明,当前钛钢复合管的研究主要集中在制备技术创新和界面结合特性的研究.用机械法制备的双金属复合管其界面结合强度只取决于衬管与基管的塑性变形,结合强度低于10 MPa且易发生衬管塌陷[18],而用冶金法制备的双金属复合管,其结合强度不同且工艺复杂.本文利用金属热胀冷缩原理(即红装工艺)制备钛/钢复合管并对其进行扩散焊,研究扩散焊接头的力学性能并揭示其机理. ...

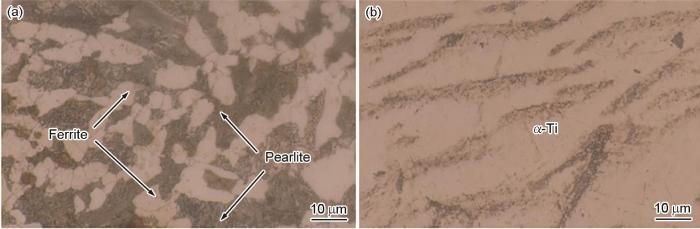

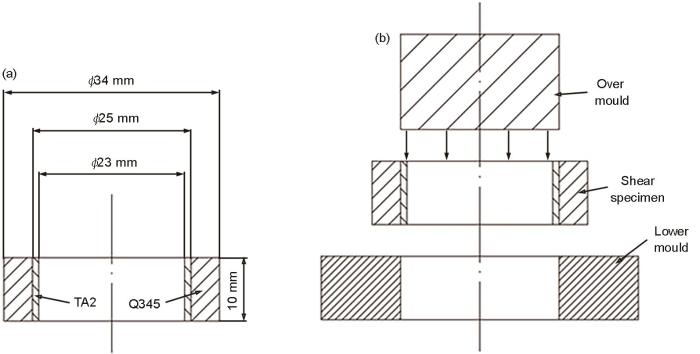

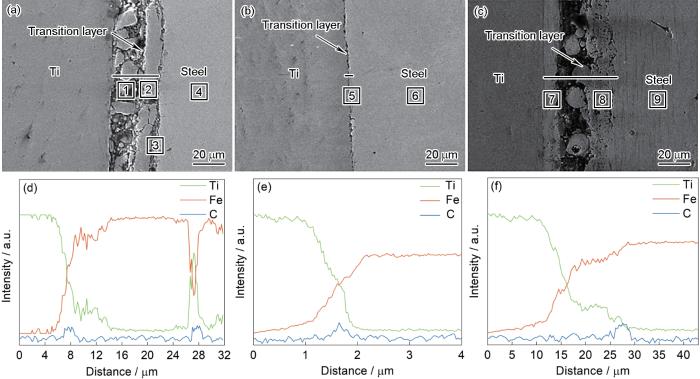

... 图4给出了红装和扩散焊后钛钢复合管界面的OM照片.由图4可见,Ti衬管与钢基管之间有明显的结合界面,界面两侧的组织与未处理前(图1)相比变化不大.图4a给出了红装TA2与Q345钢界面的金相组织,可见有一个宽度为20~25 μm的过渡层,钢侧靠近结合界面有一个宽度约25 μm的光亮区,可能是红装时钢表面的碳原子扩散到钛侧.钛是强碳化物生成元素,在500 ℃红装温度即能与碳反应生成TiC.同时,在如此高的温度和短时间内钢内的碳原子来不及扩散到表面而在钢侧形成光亮区[15].图4b给出了在850 ℃扩散2 h后复合管的结合界面.可以看出,在钢侧的组织中晶粒明显长大,过渡层的宽度比图4a中过渡层的宽度明显减小且光亮区消失.其原因是,在高温下钢组织消耗了界面处的位错能使界面能降低[19,20],继而降低了C向Ti侧扩散的驱动力[21].同时,铁素体中的C原子在850 ℃的扩散系数是α-Ti的33倍[22],因此钢基体内的C原子扩散到表面使光亮区消失.图4c给出了950 ℃/30 min扩散焊连接钛钢复合管的界面组织.与红装时相比,其过渡层的宽度增加到40 μm,光亮区的宽度增大到80 μm.其原因是,Ti和Fe原子在950 ℃的扩散系数提高,促进了二者间的互扩散;同时,在950 ℃,α-Ti到β-Ti的转变降低了C原子在Ti中的溶解度,使其更易于在钛钢界面富集而生成TiC [23].在950 ℃,TiC的标准生产吉布斯自由能(ΔGθ)(-175 kJ/mol)小于Fe3C的ΔGθ (-5 kJ/mol) [24,25],即在此温度下TiC更易生成.光亮区变宽的原因是,在较短的时间内钢内部的碳原子尚未扩散到表面. ...

... 图8b给出了红装和扩散焊后TA2/Q345复合管界面的显微硬度曲线,可见过渡区的硬度高于基材,因为与红装相比钛与钢的反应热使扩散在过渡区生成了更多的TiC、FeTi和Fe2Ti等本征脆性相[15,16].红装、850 ℃扩散焊和950 ℃扩散焊后,TA2/Q345复合管过渡区的硬度最大硬度值分别为360HV、442HV和585HV.钢侧的硬度比基材的低,是钢中的碳向界面扩散所致.由图5可见,与950 ℃扩散焊相比红装的界面脱碳加剧,使其硬度显著降低.红装和850 ℃扩散焊后近过渡层钛侧的硬度与基体的硬度基本相同,而在950 ℃扩散焊后此处的硬度有所下降,是α-Ti向同素异构β-Ti转变所致[11,13,17]. ...

Interface microstructure and strength properties of Ti-6Al-4V and microduplex stainless steel diffusion bonded joints

2

2011

... 用液压膨胀法制备的双金属复合管,其界面结合强度为4~6.5 MPa.理论计算和剪切实验结果表明,在液压成型过程中复合管的结合强度取决于基管和衬管的塑性变形[10].分别将基管和衬管在220 ℃低温退火后经1000 ℃热挤压制备TA2/Q235复合管,低温处理可降低复合界面的硬度并提高界面结合强度[11].分别用Fe和Nb为中间层用热挤压工艺制备的TC11/Fe/CrMo与170 MPa TC11/Nb/CrMo复合管剪切强度为185 MPa,其界面结合强度决定于界面晶粒的不均匀变形和中间相的脆性[12].用Cu为中间层用拉拔+热扩散法制备的TA2/Cu/20钛钢复合管,其界面结合强度高达310 MPa[13].将复合板轧制、卷管和焊接,也能制备钛钢复合管.将TA10/Q235R复合板爆炸焊接,再将其在550 ℃退火1.5 h,得到的复合板的抗拉强度可达463.27 MPa[14].分别将TA2/SUS304复合板平轧制(FR)和辊轧+平轧(CFR + FR),用CFR + FR制备的复合板非均匀塑性变形后界面呈波浪形,其剪切强度从FR的140 MPa提高到245 MPa[15].在900 ℃扩散焊制备的Ti-6Al-4V钛合金和微双相不锈钢复合板,其剪切强度高达400 MPa[16];在钛/钢之间加Ni过渡层,使界面组织由Fe-Ti系化合物转变为脆性较小的Ni-Ti系化合物,可将界面剪切强度提高到460 MPa[17].这些结果表明,当前钛钢复合管的研究主要集中在制备技术创新和界面结合特性的研究.用机械法制备的双金属复合管其界面结合强度只取决于衬管与基管的塑性变形,结合强度低于10 MPa且易发生衬管塌陷[18],而用冶金法制备的双金属复合管,其结合强度不同且工艺复杂.本文利用金属热胀冷缩原理(即红装工艺)制备钛/钢复合管并对其进行扩散焊,研究扩散焊接头的力学性能并揭示其机理. ...

... 图8b给出了红装和扩散焊后TA2/Q345复合管界面的显微硬度曲线,可见过渡区的硬度高于基材,因为与红装相比钛与钢的反应热使扩散在过渡区生成了更多的TiC、FeTi和Fe2Ti等本征脆性相[15,16].红装、850 ℃扩散焊和950 ℃扩散焊后,TA2/Q345复合管过渡区的硬度最大硬度值分别为360HV、442HV和585HV.钢侧的硬度比基材的低,是钢中的碳向界面扩散所致.由图5可见,与950 ℃扩散焊相比红装的界面脱碳加剧,使其硬度显著降低.红装和850 ℃扩散焊后近过渡层钛侧的硬度与基体的硬度基本相同,而在950 ℃扩散焊后此处的硬度有所下降,是α-Ti向同素异构β-Ti转变所致[11,13,17]. ...

Diffusion bonding of titanium alloy to micro-duplex stainless steel using a nickel alloy interlayer: Mater. Des.

2

2012

... 用液压膨胀法制备的双金属复合管,其界面结合强度为4~6.5 MPa.理论计算和剪切实验结果表明,在液压成型过程中复合管的结合强度取决于基管和衬管的塑性变形[10].分别将基管和衬管在220 ℃低温退火后经1000 ℃热挤压制备TA2/Q235复合管,低温处理可降低复合界面的硬度并提高界面结合强度[11].分别用Fe和Nb为中间层用热挤压工艺制备的TC11/Fe/CrMo与170 MPa TC11/Nb/CrMo复合管剪切强度为185 MPa,其界面结合强度决定于界面晶粒的不均匀变形和中间相的脆性[12].用Cu为中间层用拉拔+热扩散法制备的TA2/Cu/20钛钢复合管,其界面结合强度高达310 MPa[13].将复合板轧制、卷管和焊接,也能制备钛钢复合管.将TA10/Q235R复合板爆炸焊接,再将其在550 ℃退火1.5 h,得到的复合板的抗拉强度可达463.27 MPa[14].分别将TA2/SUS304复合板平轧制(FR)和辊轧+平轧(CFR + FR),用CFR + FR制备的复合板非均匀塑性变形后界面呈波浪形,其剪切强度从FR的140 MPa提高到245 MPa[15].在900 ℃扩散焊制备的Ti-6Al-4V钛合金和微双相不锈钢复合板,其剪切强度高达400 MPa[16];在钛/钢之间加Ni过渡层,使界面组织由Fe-Ti系化合物转变为脆性较小的Ni-Ti系化合物,可将界面剪切强度提高到460 MPa[17].这些结果表明,当前钛钢复合管的研究主要集中在制备技术创新和界面结合特性的研究.用机械法制备的双金属复合管其界面结合强度只取决于衬管与基管的塑性变形,结合强度低于10 MPa且易发生衬管塌陷[18],而用冶金法制备的双金属复合管,其结合强度不同且工艺复杂.本文利用金属热胀冷缩原理(即红装工艺)制备钛/钢复合管并对其进行扩散焊,研究扩散焊接头的力学性能并揭示其机理. ...

... 图8b给出了红装和扩散焊后TA2/Q345复合管界面的显微硬度曲线,可见过渡区的硬度高于基材,因为与红装相比钛与钢的反应热使扩散在过渡区生成了更多的TiC、FeTi和Fe2Ti等本征脆性相[15,16].红装、850 ℃扩散焊和950 ℃扩散焊后,TA2/Q345复合管过渡区的硬度最大硬度值分别为360HV、442HV和585HV.钢侧的硬度比基材的低,是钢中的碳向界面扩散所致.由图5可见,与950 ℃扩散焊相比红装的界面脱碳加剧,使其硬度显著降低.红装和850 ℃扩散焊后近过渡层钛侧的硬度与基体的硬度基本相同,而在950 ℃扩散焊后此处的硬度有所下降,是α-Ti向同素异构β-Ti转变所致[11,13,17]. ...

Buckling failure mechanism of liner pipe in bimetal mechanical clad pipe under complex loading

1

2022

... 用液压膨胀法制备的双金属复合管,其界面结合强度为4~6.5 MPa.理论计算和剪切实验结果表明,在液压成型过程中复合管的结合强度取决于基管和衬管的塑性变形[10].分别将基管和衬管在220 ℃低温退火后经1000 ℃热挤压制备TA2/Q235复合管,低温处理可降低复合界面的硬度并提高界面结合强度[11].分别用Fe和Nb为中间层用热挤压工艺制备的TC11/Fe/CrMo与170 MPa TC11/Nb/CrMo复合管剪切强度为185 MPa,其界面结合强度决定于界面晶粒的不均匀变形和中间相的脆性[12].用Cu为中间层用拉拔+热扩散法制备的TA2/Cu/20钛钢复合管,其界面结合强度高达310 MPa[13].将复合板轧制、卷管和焊接,也能制备钛钢复合管.将TA10/Q235R复合板爆炸焊接,再将其在550 ℃退火1.5 h,得到的复合板的抗拉强度可达463.27 MPa[14].分别将TA2/SUS304复合板平轧制(FR)和辊轧+平轧(CFR + FR),用CFR + FR制备的复合板非均匀塑性变形后界面呈波浪形,其剪切强度从FR的140 MPa提高到245 MPa[15].在900 ℃扩散焊制备的Ti-6Al-4V钛合金和微双相不锈钢复合板,其剪切强度高达400 MPa[16];在钛/钢之间加Ni过渡层,使界面组织由Fe-Ti系化合物转变为脆性较小的Ni-Ti系化合物,可将界面剪切强度提高到460 MPa[17].这些结果表明,当前钛钢复合管的研究主要集中在制备技术创新和界面结合特性的研究.用机械法制备的双金属复合管其界面结合强度只取决于衬管与基管的塑性变形,结合强度低于10 MPa且易发生衬管塌陷[18],而用冶金法制备的双金属复合管,其结合强度不同且工艺复杂.本文利用金属热胀冷缩原理(即红装工艺)制备钛/钢复合管并对其进行扩散焊,研究扩散焊接头的力学性能并揭示其机理. ...

Phase transformation and dynamic recrystallization behaviors in a Ti55511 titanium alloy during hot compression

1

2019

... 图4给出了红装和扩散焊后钛钢复合管界面的OM照片.由图4可见,Ti衬管与钢基管之间有明显的结合界面,界面两侧的组织与未处理前(图1)相比变化不大.图4a给出了红装TA2与Q345钢界面的金相组织,可见有一个宽度为20~25 μm的过渡层,钢侧靠近结合界面有一个宽度约25 μm的光亮区,可能是红装时钢表面的碳原子扩散到钛侧.钛是强碳化物生成元素,在500 ℃红装温度即能与碳反应生成TiC.同时,在如此高的温度和短时间内钢内的碳原子来不及扩散到表面而在钢侧形成光亮区[15].图4b给出了在850 ℃扩散2 h后复合管的结合界面.可以看出,在钢侧的组织中晶粒明显长大,过渡层的宽度比图4a中过渡层的宽度明显减小且光亮区消失.其原因是,在高温下钢组织消耗了界面处的位错能使界面能降低[19,20],继而降低了C向Ti侧扩散的驱动力[21].同时,铁素体中的C原子在850 ℃的扩散系数是α-Ti的33倍[22],因此钢基体内的C原子扩散到表面使光亮区消失.图4c给出了950 ℃/30 min扩散焊连接钛钢复合管的界面组织.与红装时相比,其过渡层的宽度增加到40 μm,光亮区的宽度增大到80 μm.其原因是,Ti和Fe原子在950 ℃的扩散系数提高,促进了二者间的互扩散;同时,在950 ℃,α-Ti到β-Ti的转变降低了C原子在Ti中的溶解度,使其更易于在钛钢界面富集而生成TiC [23].在950 ℃,TiC的标准生产吉布斯自由能(ΔGθ)(-175 kJ/mol)小于Fe3C的ΔGθ (-5 kJ/mol) [24,25],即在此温度下TiC更易生成.光亮区变宽的原因是,在较短的时间内钢内部的碳原子尚未扩散到表面. ...

Effect of interface microstructure on the bond strength of the diffusion welded joints between titanium and stainless steel

1

2005

... 图4给出了红装和扩散焊后钛钢复合管界面的OM照片.由图4可见,Ti衬管与钢基管之间有明显的结合界面,界面两侧的组织与未处理前(图1)相比变化不大.图4a给出了红装TA2与Q345钢界面的金相组织,可见有一个宽度为20~25 μm的过渡层,钢侧靠近结合界面有一个宽度约25 μm的光亮区,可能是红装时钢表面的碳原子扩散到钛侧.钛是强碳化物生成元素,在500 ℃红装温度即能与碳反应生成TiC.同时,在如此高的温度和短时间内钢内的碳原子来不及扩散到表面而在钢侧形成光亮区[15].图4b给出了在850 ℃扩散2 h后复合管的结合界面.可以看出,在钢侧的组织中晶粒明显长大,过渡层的宽度比图4a中过渡层的宽度明显减小且光亮区消失.其原因是,在高温下钢组织消耗了界面处的位错能使界面能降低[19,20],继而降低了C向Ti侧扩散的驱动力[21].同时,铁素体中的C原子在850 ℃的扩散系数是α-Ti的33倍[22],因此钢基体内的C原子扩散到表面使光亮区消失.图4c给出了950 ℃/30 min扩散焊连接钛钢复合管的界面组织.与红装时相比,其过渡层的宽度增加到40 μm,光亮区的宽度增大到80 μm.其原因是,Ti和Fe原子在950 ℃的扩散系数提高,促进了二者间的互扩散;同时,在950 ℃,α-Ti到β-Ti的转变降低了C原子在Ti中的溶解度,使其更易于在钛钢界面富集而生成TiC [23].在950 ℃,TiC的标准生产吉布斯自由能(ΔGθ)(-175 kJ/mol)小于Fe3C的ΔGθ (-5 kJ/mol) [24,25],即在此温度下TiC更易生成.光亮区变宽的原因是,在较短的时间内钢内部的碳原子尚未扩散到表面. ...

Dislocation evolution in titanium during surface severe plastic deformation

1

2009

... 图4给出了红装和扩散焊后钛钢复合管界面的OM照片.由图4可见,Ti衬管与钢基管之间有明显的结合界面,界面两侧的组织与未处理前(图1)相比变化不大.图4a给出了红装TA2与Q345钢界面的金相组织,可见有一个宽度为20~25 μm的过渡层,钢侧靠近结合界面有一个宽度约25 μm的光亮区,可能是红装时钢表面的碳原子扩散到钛侧.钛是强碳化物生成元素,在500 ℃红装温度即能与碳反应生成TiC.同时,在如此高的温度和短时间内钢内的碳原子来不及扩散到表面而在钢侧形成光亮区[15].图4b给出了在850 ℃扩散2 h后复合管的结合界面.可以看出,在钢侧的组织中晶粒明显长大,过渡层的宽度比图4a中过渡层的宽度明显减小且光亮区消失.其原因是,在高温下钢组织消耗了界面处的位错能使界面能降低[19,20],继而降低了C向Ti侧扩散的驱动力[21].同时,铁素体中的C原子在850 ℃的扩散系数是α-Ti的33倍[22],因此钢基体内的C原子扩散到表面使光亮区消失.图4c给出了950 ℃/30 min扩散焊连接钛钢复合管的界面组织.与红装时相比,其过渡层的宽度增加到40 μm,光亮区的宽度增大到80 μm.其原因是,Ti和Fe原子在950 ℃的扩散系数提高,促进了二者间的互扩散;同时,在950 ℃,α-Ti到β-Ti的转变降低了C原子在Ti中的溶解度,使其更易于在钛钢界面富集而生成TiC [23].在950 ℃,TiC的标准生产吉布斯自由能(ΔGθ)(-175 kJ/mol)小于Fe3C的ΔGθ (-5 kJ/mol) [24,25],即在此温度下TiC更易生成.光亮区变宽的原因是,在较短的时间内钢内部的碳原子尚未扩散到表面. ...

Hot roll bonding between commercially pure titanium and high-strength low-alloy steel using Fe interlayer

1

2019

... 图4给出了红装和扩散焊后钛钢复合管界面的OM照片.由图4可见,Ti衬管与钢基管之间有明显的结合界面,界面两侧的组织与未处理前(图1)相比变化不大.图4a给出了红装TA2与Q345钢界面的金相组织,可见有一个宽度为20~25 μm的过渡层,钢侧靠近结合界面有一个宽度约25 μm的光亮区,可能是红装时钢表面的碳原子扩散到钛侧.钛是强碳化物生成元素,在500 ℃红装温度即能与碳反应生成TiC.同时,在如此高的温度和短时间内钢内的碳原子来不及扩散到表面而在钢侧形成光亮区[15].图4b给出了在850 ℃扩散2 h后复合管的结合界面.可以看出,在钢侧的组织中晶粒明显长大,过渡层的宽度比图4a中过渡层的宽度明显减小且光亮区消失.其原因是,在高温下钢组织消耗了界面处的位错能使界面能降低[19,20],继而降低了C向Ti侧扩散的驱动力[21].同时,铁素体中的C原子在850 ℃的扩散系数是α-Ti的33倍[22],因此钢基体内的C原子扩散到表面使光亮区消失.图4c给出了950 ℃/30 min扩散焊连接钛钢复合管的界面组织.与红装时相比,其过渡层的宽度增加到40 μm,光亮区的宽度增大到80 μm.其原因是,Ti和Fe原子在950 ℃的扩散系数提高,促进了二者间的互扩散;同时,在950 ℃,α-Ti到β-Ti的转变降低了C原子在Ti中的溶解度,使其更易于在钛钢界面富集而生成TiC [23].在950 ℃,TiC的标准生产吉布斯自由能(ΔGθ)(-175 kJ/mol)小于Fe3C的ΔGθ (-5 kJ/mol) [24,25],即在此温度下TiC更易生成.光亮区变宽的原因是,在较短的时间内钢内部的碳原子尚未扩散到表面. ...

New strategy to grow TiC coatings on titanium alloy: Contact solid carburization by cast iron

2

2018

... 图4给出了红装和扩散焊后钛钢复合管界面的OM照片.由图4可见,Ti衬管与钢基管之间有明显的结合界面,界面两侧的组织与未处理前(图1)相比变化不大.图4a给出了红装TA2与Q345钢界面的金相组织,可见有一个宽度为20~25 μm的过渡层,钢侧靠近结合界面有一个宽度约25 μm的光亮区,可能是红装时钢表面的碳原子扩散到钛侧.钛是强碳化物生成元素,在500 ℃红装温度即能与碳反应生成TiC.同时,在如此高的温度和短时间内钢内的碳原子来不及扩散到表面而在钢侧形成光亮区[15].图4b给出了在850 ℃扩散2 h后复合管的结合界面.可以看出,在钢侧的组织中晶粒明显长大,过渡层的宽度比图4a中过渡层的宽度明显减小且光亮区消失.其原因是,在高温下钢组织消耗了界面处的位错能使界面能降低[19,20],继而降低了C向Ti侧扩散的驱动力[21].同时,铁素体中的C原子在850 ℃的扩散系数是α-Ti的33倍[22],因此钢基体内的C原子扩散到表面使光亮区消失.图4c给出了950 ℃/30 min扩散焊连接钛钢复合管的界面组织.与红装时相比,其过渡层的宽度增加到40 μm,光亮区的宽度增大到80 μm.其原因是,Ti和Fe原子在950 ℃的扩散系数提高,促进了二者间的互扩散;同时,在950 ℃,α-Ti到β-Ti的转变降低了C原子在Ti中的溶解度,使其更易于在钛钢界面富集而生成TiC [23].在950 ℃,TiC的标准生产吉布斯自由能(ΔGθ)(-175 kJ/mol)小于Fe3C的ΔGθ (-5 kJ/mol) [24,25],即在此温度下TiC更易生成.光亮区变宽的原因是,在较短的时间内钢内部的碳原子尚未扩散到表面. ...

... 图5给出了红装和扩散焊后钛钢复合管界面处的SEM照片和EDS线扫描图,表2列出了线扫描结果.由图5a可见,在钛钢界面处形成了30 μm宽的过渡区,灰色颗粒是TiC,黑色大颗粒是Fe-Ti系化合物,靠近钢侧的灰色长条状结构是钢侧基体组织,与文献[26]中的Fe-Ti-C三元相图的结果相同,点4为对应图3光亮区的点扫描结果,在该区域C元素的含量比基体明显降低,表明发生了脱碳.图5d中的线扫结果表明,钛钢各元素间的扩散使过渡层的宽度与金相组织基本相同.产生上述现象的原因是,在红装过程中钛与钢的界面因热挤压而产生塑性变形,使界面处的组织缠结形成过渡层[27];塑性变形引起的位错密度提高和红装的高温虽然在一定程度上促进了各原子间的扩散[28,29],但是扩散温度较低且时间较短使过渡层只是在近钛侧和钢侧形成冶金结合区,其余部分仍为机械结合,近钢侧基体因C原子向过渡层扩散而形成脱碳区.在850 ℃/2 h条件下的扩散焊产生的过渡层呈平直状(图5b).图5e中的线扫描结果表明,过渡层的厚度约为1 μm.过渡层的点扫描结果(点5)表明,在此温度界面处可能存在TiC和Fe-Ti系化合物.界面处钢侧的点扫描结果(点6)表明,脱碳明显减弱.其原因是,在高温下界面处位错密度的降低减小了C向Ti侧扩散的驱动力,塑性变形生成的灰色大块物质因界面能的降低而消失[30].适当的温度和扩散时间使钛钢结合面处的珠光体和中间相的组织细化[23].图5c给出的界面形貌与图5f中的线扫描结果表明,在950 ℃/30 min条件下扩散焊连接的TA2/Q345过渡层加宽.结合点扫描结果(点7、点8)推断,在过渡层近钛侧的组织为Fe-Ti系化合物,在近钢侧形成了TiC层.与红装相比,点9表明在此温度下界面脱碳加剧.其原因是,Ti在950 ℃的扩散系数比Fe的高,使钢侧Ti原子的扩散更深,将碳原子困在钢中生成了比Fe-Ti系化合物更厚的TiC层[31]. ...

Effect of carbon content on interfacial microstructure and mechanical properties of a vacuum hot-compressed bonding titanium-steel composite

1

2021

... 图4给出了红装和扩散焊后钛钢复合管界面的OM照片.由图4可见,Ti衬管与钢基管之间有明显的结合界面,界面两侧的组织与未处理前(图1)相比变化不大.图4a给出了红装TA2与Q345钢界面的金相组织,可见有一个宽度为20~25 μm的过渡层,钢侧靠近结合界面有一个宽度约25 μm的光亮区,可能是红装时钢表面的碳原子扩散到钛侧.钛是强碳化物生成元素,在500 ℃红装温度即能与碳反应生成TiC.同时,在如此高的温度和短时间内钢内的碳原子来不及扩散到表面而在钢侧形成光亮区[15].图4b给出了在850 ℃扩散2 h后复合管的结合界面.可以看出,在钢侧的组织中晶粒明显长大,过渡层的宽度比图4a中过渡层的宽度明显减小且光亮区消失.其原因是,在高温下钢组织消耗了界面处的位错能使界面能降低[19,20],继而降低了C向Ti侧扩散的驱动力[21].同时,铁素体中的C原子在850 ℃的扩散系数是α-Ti的33倍[22],因此钢基体内的C原子扩散到表面使光亮区消失.图4c给出了950 ℃/30 min扩散焊连接钛钢复合管的界面组织.与红装时相比,其过渡层的宽度增加到40 μm,光亮区的宽度增大到80 μm.其原因是,Ti和Fe原子在950 ℃的扩散系数提高,促进了二者间的互扩散;同时,在950 ℃,α-Ti到β-Ti的转变降低了C原子在Ti中的溶解度,使其更易于在钛钢界面富集而生成TiC [23].在950 ℃,TiC的标准生产吉布斯自由能(ΔGθ)(-175 kJ/mol)小于Fe3C的ΔGθ (-5 kJ/mol) [24,25],即在此温度下TiC更易生成.光亮区变宽的原因是,在较短的时间内钢内部的碳原子尚未扩散到表面. ...

Hot roll bonding between commercially pure titanium and high-strength low-alloy steel using Fe interlayer

1

2019

... 图4给出了红装和扩散焊后钛钢复合管界面的OM照片.由图4可见,Ti衬管与钢基管之间有明显的结合界面,界面两侧的组织与未处理前(图1)相比变化不大.图4a给出了红装TA2与Q345钢界面的金相组织,可见有一个宽度为20~25 μm的过渡层,钢侧靠近结合界面有一个宽度约25 μm的光亮区,可能是红装时钢表面的碳原子扩散到钛侧.钛是强碳化物生成元素,在500 ℃红装温度即能与碳反应生成TiC.同时,在如此高的温度和短时间内钢内的碳原子来不及扩散到表面而在钢侧形成光亮区[15].图4b给出了在850 ℃扩散2 h后复合管的结合界面.可以看出,在钢侧的组织中晶粒明显长大,过渡层的宽度比图4a中过渡层的宽度明显减小且光亮区消失.其原因是,在高温下钢组织消耗了界面处的位错能使界面能降低[19,20],继而降低了C向Ti侧扩散的驱动力[21].同时,铁素体中的C原子在850 ℃的扩散系数是α-Ti的33倍[22],因此钢基体内的C原子扩散到表面使光亮区消失.图4c给出了950 ℃/30 min扩散焊连接钛钢复合管的界面组织.与红装时相比,其过渡层的宽度增加到40 μm,光亮区的宽度增大到80 μm.其原因是,Ti和Fe原子在950 ℃的扩散系数提高,促进了二者间的互扩散;同时,在950 ℃,α-Ti到β-Ti的转变降低了C原子在Ti中的溶解度,使其更易于在钛钢界面富集而生成TiC [23].在950 ℃,TiC的标准生产吉布斯自由能(ΔGθ)(-175 kJ/mol)小于Fe3C的ΔGθ (-5 kJ/mol) [24,25],即在此温度下TiC更易生成.光亮区变宽的原因是,在较短的时间内钢内部的碳原子尚未扩散到表面. ...

Thermodynamic optimisation of Fe-Ti-C ternary system

1

2018

... 图5给出了红装和扩散焊后钛钢复合管界面处的SEM照片和EDS线扫描图,表2列出了线扫描结果.由图5a可见,在钛钢界面处形成了30 μm宽的过渡区,灰色颗粒是TiC,黑色大颗粒是Fe-Ti系化合物,靠近钢侧的灰色长条状结构是钢侧基体组织,与文献[26]中的Fe-Ti-C三元相图的结果相同,点4为对应图3光亮区的点扫描结果,在该区域C元素的含量比基体明显降低,表明发生了脱碳.图5d中的线扫结果表明,钛钢各元素间的扩散使过渡层的宽度与金相组织基本相同.产生上述现象的原因是,在红装过程中钛与钢的界面因热挤压而产生塑性变形,使界面处的组织缠结形成过渡层[27];塑性变形引起的位错密度提高和红装的高温虽然在一定程度上促进了各原子间的扩散[28,29],但是扩散温度较低且时间较短使过渡层只是在近钛侧和钢侧形成冶金结合区,其余部分仍为机械结合,近钢侧基体因C原子向过渡层扩散而形成脱碳区.在850 ℃/2 h条件下的扩散焊产生的过渡层呈平直状(图5b).图5e中的线扫描结果表明,过渡层的厚度约为1 μm.过渡层的点扫描结果(点5)表明,在此温度界面处可能存在TiC和Fe-Ti系化合物.界面处钢侧的点扫描结果(点6)表明,脱碳明显减弱.其原因是,在高温下界面处位错密度的降低减小了C向Ti侧扩散的驱动力,塑性变形生成的灰色大块物质因界面能的降低而消失[30].适当的温度和扩散时间使钛钢结合面处的珠光体和中间相的组织细化[23].图5c给出的界面形貌与图5f中的线扫描结果表明,在950 ℃/30 min条件下扩散焊连接的TA2/Q345过渡层加宽.结合点扫描结果(点7、点8)推断,在过渡层近钛侧的组织为Fe-Ti系化合物,在近钢侧形成了TiC层.与红装相比,点9表明在此温度下界面脱碳加剧.其原因是,Ti在950 ℃的扩散系数比Fe的高,使钢侧Ti原子的扩散更深,将碳原子困在钢中生成了比Fe-Ti系化合物更厚的TiC层[31]. ...

Fe-Ti-C三元系热力学优化

1

2018

... 图5给出了红装和扩散焊后钛钢复合管界面处的SEM照片和EDS线扫描图,表2列出了线扫描结果.由图5a可见,在钛钢界面处形成了30 μm宽的过渡区,灰色颗粒是TiC,黑色大颗粒是Fe-Ti系化合物,靠近钢侧的灰色长条状结构是钢侧基体组织,与文献[26]中的Fe-Ti-C三元相图的结果相同,点4为对应图3光亮区的点扫描结果,在该区域C元素的含量比基体明显降低,表明发生了脱碳.图5d中的线扫结果表明,钛钢各元素间的扩散使过渡层的宽度与金相组织基本相同.产生上述现象的原因是,在红装过程中钛与钢的界面因热挤压而产生塑性变形,使界面处的组织缠结形成过渡层[27];塑性变形引起的位错密度提高和红装的高温虽然在一定程度上促进了各原子间的扩散[28,29],但是扩散温度较低且时间较短使过渡层只是在近钛侧和钢侧形成冶金结合区,其余部分仍为机械结合,近钢侧基体因C原子向过渡层扩散而形成脱碳区.在850 ℃/2 h条件下的扩散焊产生的过渡层呈平直状(图5b).图5e中的线扫描结果表明,过渡层的厚度约为1 μm.过渡层的点扫描结果(点5)表明,在此温度界面处可能存在TiC和Fe-Ti系化合物.界面处钢侧的点扫描结果(点6)表明,脱碳明显减弱.其原因是,在高温下界面处位错密度的降低减小了C向Ti侧扩散的驱动力,塑性变形生成的灰色大块物质因界面能的降低而消失[30].适当的温度和扩散时间使钛钢结合面处的珠光体和中间相的组织细化[23].图5c给出的界面形貌与图5f中的线扫描结果表明,在950 ℃/30 min条件下扩散焊连接的TA2/Q345过渡层加宽.结合点扫描结果(点7、点8)推断,在过渡层近钛侧的组织为Fe-Ti系化合物,在近钢侧形成了TiC层.与红装相比,点9表明在此温度下界面脱碳加剧.其原因是,Ti在950 ℃的扩散系数比Fe的高,使钢侧Ti原子的扩散更深,将碳原子困在钢中生成了比Fe-Ti系化合物更厚的TiC层[31]. ...

Microstructure and mechanical properties of the bonding interface of explosively welded TA2/Q235 composite under dynamic shear loading

1

2022

... 图5给出了红装和扩散焊后钛钢复合管界面处的SEM照片和EDS线扫描图,表2列出了线扫描结果.由图5a可见,在钛钢界面处形成了30 μm宽的过渡区,灰色颗粒是TiC,黑色大颗粒是Fe-Ti系化合物,靠近钢侧的灰色长条状结构是钢侧基体组织,与文献[26]中的Fe-Ti-C三元相图的结果相同,点4为对应图3光亮区的点扫描结果,在该区域C元素的含量比基体明显降低,表明发生了脱碳.图5d中的线扫结果表明,钛钢各元素间的扩散使过渡层的宽度与金相组织基本相同.产生上述现象的原因是,在红装过程中钛与钢的界面因热挤压而产生塑性变形,使界面处的组织缠结形成过渡层[27];塑性变形引起的位错密度提高和红装的高温虽然在一定程度上促进了各原子间的扩散[28,29],但是扩散温度较低且时间较短使过渡层只是在近钛侧和钢侧形成冶金结合区,其余部分仍为机械结合,近钢侧基体因C原子向过渡层扩散而形成脱碳区.在850 ℃/2 h条件下的扩散焊产生的过渡层呈平直状(图5b).图5e中的线扫描结果表明,过渡层的厚度约为1 μm.过渡层的点扫描结果(点5)表明,在此温度界面处可能存在TiC和Fe-Ti系化合物.界面处钢侧的点扫描结果(点6)表明,脱碳明显减弱.其原因是,在高温下界面处位错密度的降低减小了C向Ti侧扩散的驱动力,塑性变形生成的灰色大块物质因界面能的降低而消失[30].适当的温度和扩散时间使钛钢结合面处的珠光体和中间相的组织细化[23].图5c给出的界面形貌与图5f中的线扫描结果表明,在950 ℃/30 min条件下扩散焊连接的TA2/Q345过渡层加宽.结合点扫描结果(点7、点8)推断,在过渡层近钛侧的组织为Fe-Ti系化合物,在近钢侧形成了TiC层.与红装相比,点9表明在此温度下界面脱碳加剧.其原因是,Ti在950 ℃的扩散系数比Fe的高,使钢侧Ti原子的扩散更深,将碳原子困在钢中生成了比Fe-Ti系化合物更厚的TiC层[31]. ...

Explosive cladding and post-weld heat treatment of mild steel and titanium

2

2016

... 图5给出了红装和扩散焊后钛钢复合管界面处的SEM照片和EDS线扫描图,表2列出了线扫描结果.由图5a可见,在钛钢界面处形成了30 μm宽的过渡区,灰色颗粒是TiC,黑色大颗粒是Fe-Ti系化合物,靠近钢侧的灰色长条状结构是钢侧基体组织,与文献[26]中的Fe-Ti-C三元相图的结果相同,点4为对应图3光亮区的点扫描结果,在该区域C元素的含量比基体明显降低,表明发生了脱碳.图5d中的线扫结果表明,钛钢各元素间的扩散使过渡层的宽度与金相组织基本相同.产生上述现象的原因是,在红装过程中钛与钢的界面因热挤压而产生塑性变形,使界面处的组织缠结形成过渡层[27];塑性变形引起的位错密度提高和红装的高温虽然在一定程度上促进了各原子间的扩散[28,29],但是扩散温度较低且时间较短使过渡层只是在近钛侧和钢侧形成冶金结合区,其余部分仍为机械结合,近钢侧基体因C原子向过渡层扩散而形成脱碳区.在850 ℃/2 h条件下的扩散焊产生的过渡层呈平直状(图5b).图5e中的线扫描结果表明,过渡层的厚度约为1 μm.过渡层的点扫描结果(点5)表明,在此温度界面处可能存在TiC和Fe-Ti系化合物.界面处钢侧的点扫描结果(点6)表明,脱碳明显减弱.其原因是,在高温下界面处位错密度的降低减小了C向Ti侧扩散的驱动力,塑性变形生成的灰色大块物质因界面能的降低而消失[30].适当的温度和扩散时间使钛钢结合面处的珠光体和中间相的组织细化[23].图5c给出的界面形貌与图5f中的线扫描结果表明,在950 ℃/30 min条件下扩散焊连接的TA2/Q345过渡层加宽.结合点扫描结果(点7、点8)推断,在过渡层近钛侧的组织为Fe-Ti系化合物,在近钢侧形成了TiC层.与红装相比,点9表明在此温度下界面脱碳加剧.其原因是,Ti在950 ℃的扩散系数比Fe的高,使钢侧Ti原子的扩散更深,将碳原子困在钢中生成了比Fe-Ti系化合物更厚的TiC层[31]. ...

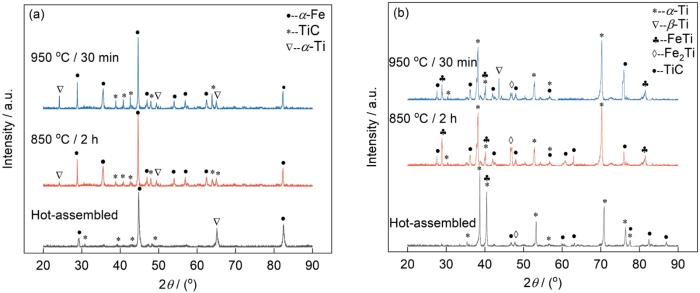

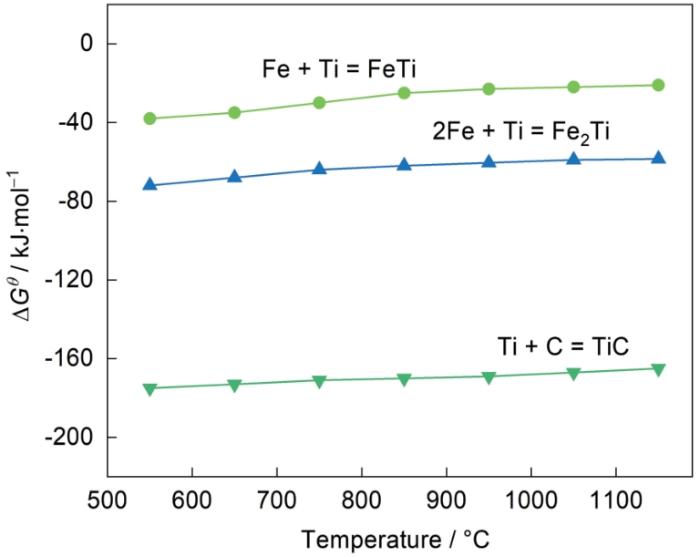

... XRD谱中钢侧α-Ti的峰强度变化的排序为:850 ℃扩散焊<红装<950 ℃扩散焊,而TiC峰强度变化的排序则为:红装<850 ℃<扩散焊950 ℃扩散焊.红装时的塑性变形和热扩散促进了α-Ti原子向钢侧扩散,而红装的较低温度使扩散到钢侧界面处的Ti多以α-Ti的形式存在,TiC的数量较少[28];在850 ℃扩散焊使C原子的扩散激活能升高,从而促进了界面上TiC的形核和长大.因此,在此温度下TiC峰的强度升高,而α-Ti的消耗使其峰强度略微降低;但是,温度继续提高到950 ℃使C元素大量消耗并难以补充,以致没有足够的C原子与扩散过来的Ti反应[32],这部分钛就以α-Ti的形式聚集在界面.在各温度钛侧TiC的峰强度都比FeTi和Fe2Ti的高,因为C、Fe原子在与Ti的反应扩散过程中存在竞争机制[33].在不同温度下Fe3C、TiC、FeTi与Fe2Ti的ΔGθ 曲线如图7所示[34],可见三种中间相ΔGθ 大小的排序为TiC < Fe2Ti < FeTi < 0.于是,在反应扩散过程中TiC优先在界面生成,而C、Fe原子在与Ti生成化合物的过程中存在竞争.因此,这部分优先生成的TiC成为Ti原子和Fe原子反应扩散的屏障,阻碍了FeTi和Fe2Ti的生成. ...

Interfacial bonding mechanism and mechanical performance of Ti/steel bimetallic clad sheet produced by explosive welding and annealing

1

2017

... 图5给出了红装和扩散焊后钛钢复合管界面处的SEM照片和EDS线扫描图,表2列出了线扫描结果.由图5a可见,在钛钢界面处形成了30 μm宽的过渡区,灰色颗粒是TiC,黑色大颗粒是Fe-Ti系化合物,靠近钢侧的灰色长条状结构是钢侧基体组织,与文献[26]中的Fe-Ti-C三元相图的结果相同,点4为对应图3光亮区的点扫描结果,在该区域C元素的含量比基体明显降低,表明发生了脱碳.图5d中的线扫结果表明,钛钢各元素间的扩散使过渡层的宽度与金相组织基本相同.产生上述现象的原因是,在红装过程中钛与钢的界面因热挤压而产生塑性变形,使界面处的组织缠结形成过渡层[27];塑性变形引起的位错密度提高和红装的高温虽然在一定程度上促进了各原子间的扩散[28,29],但是扩散温度较低且时间较短使过渡层只是在近钛侧和钢侧形成冶金结合区,其余部分仍为机械结合,近钢侧基体因C原子向过渡层扩散而形成脱碳区.在850 ℃/2 h条件下的扩散焊产生的过渡层呈平直状(图5b).图5e中的线扫描结果表明,过渡层的厚度约为1 μm.过渡层的点扫描结果(点5)表明,在此温度界面处可能存在TiC和Fe-Ti系化合物.界面处钢侧的点扫描结果(点6)表明,脱碳明显减弱.其原因是,在高温下界面处位错密度的降低减小了C向Ti侧扩散的驱动力,塑性变形生成的灰色大块物质因界面能的降低而消失[30].适当的温度和扩散时间使钛钢结合面处的珠光体和中间相的组织细化[23].图5c给出的界面形貌与图5f中的线扫描结果表明,在950 ℃/30 min条件下扩散焊连接的TA2/Q345过渡层加宽.结合点扫描结果(点7、点8)推断,在过渡层近钛侧的组织为Fe-Ti系化合物,在近钢侧形成了TiC层.与红装相比,点9表明在此温度下界面脱碳加剧.其原因是,Ti在950 ℃的扩散系数比Fe的高,使钢侧Ti原子的扩散更深,将碳原子困在钢中生成了比Fe-Ti系化合物更厚的TiC层[31]. ...

Interfacial characteristics of cumulative stacked welded TA1/Q235 steel composite plates

1

2008

... 图5给出了红装和扩散焊后钛钢复合管界面处的SEM照片和EDS线扫描图,表2列出了线扫描结果.由图5a可见,在钛钢界面处形成了30 μm宽的过渡区,灰色颗粒是TiC,黑色大颗粒是Fe-Ti系化合物,靠近钢侧的灰色长条状结构是钢侧基体组织,与文献[26]中的Fe-Ti-C三元相图的结果相同,点4为对应图3光亮区的点扫描结果,在该区域C元素的含量比基体明显降低,表明发生了脱碳.图5d中的线扫结果表明,钛钢各元素间的扩散使过渡层的宽度与金相组织基本相同.产生上述现象的原因是,在红装过程中钛与钢的界面因热挤压而产生塑性变形,使界面处的组织缠结形成过渡层[27];塑性变形引起的位错密度提高和红装的高温虽然在一定程度上促进了各原子间的扩散[28,29],但是扩散温度较低且时间较短使过渡层只是在近钛侧和钢侧形成冶金结合区,其余部分仍为机械结合,近钢侧基体因C原子向过渡层扩散而形成脱碳区.在850 ℃/2 h条件下的扩散焊产生的过渡层呈平直状(图5b).图5e中的线扫描结果表明,过渡层的厚度约为1 μm.过渡层的点扫描结果(点5)表明,在此温度界面处可能存在TiC和Fe-Ti系化合物.界面处钢侧的点扫描结果(点6)表明,脱碳明显减弱.其原因是,在高温下界面处位错密度的降低减小了C向Ti侧扩散的驱动力,塑性变形生成的灰色大块物质因界面能的降低而消失[30].适当的温度和扩散时间使钛钢结合面处的珠光体和中间相的组织细化[23].图5c给出的界面形貌与图5f中的线扫描结果表明,在950 ℃/30 min条件下扩散焊连接的TA2/Q345过渡层加宽.结合点扫描结果(点7、点8)推断,在过渡层近钛侧的组织为Fe-Ti系化合物,在近钢侧形成了TiC层.与红装相比,点9表明在此温度下界面脱碳加剧.其原因是,Ti在950 ℃的扩散系数比Fe的高,使钢侧Ti原子的扩散更深,将碳原子困在钢中生成了比Fe-Ti系化合物更厚的TiC层[31]. ...

TA1/Q235钢复合板累积叠轧焊界面特性

1

2008

... 图5给出了红装和扩散焊后钛钢复合管界面处的SEM照片和EDS线扫描图,表2列出了线扫描结果.由图5a可见,在钛钢界面处形成了30 μm宽的过渡区,灰色颗粒是TiC,黑色大颗粒是Fe-Ti系化合物,靠近钢侧的灰色长条状结构是钢侧基体组织,与文献[26]中的Fe-Ti-C三元相图的结果相同,点4为对应图3光亮区的点扫描结果,在该区域C元素的含量比基体明显降低,表明发生了脱碳.图5d中的线扫结果表明,钛钢各元素间的扩散使过渡层的宽度与金相组织基本相同.产生上述现象的原因是,在红装过程中钛与钢的界面因热挤压而产生塑性变形,使界面处的组织缠结形成过渡层[27];塑性变形引起的位错密度提高和红装的高温虽然在一定程度上促进了各原子间的扩散[28,29],但是扩散温度较低且时间较短使过渡层只是在近钛侧和钢侧形成冶金结合区,其余部分仍为机械结合,近钢侧基体因C原子向过渡层扩散而形成脱碳区.在850 ℃/2 h条件下的扩散焊产生的过渡层呈平直状(图5b).图5e中的线扫描结果表明,过渡层的厚度约为1 μm.过渡层的点扫描结果(点5)表明,在此温度界面处可能存在TiC和Fe-Ti系化合物.界面处钢侧的点扫描结果(点6)表明,脱碳明显减弱.其原因是,在高温下界面处位错密度的降低减小了C向Ti侧扩散的驱动力,塑性变形生成的灰色大块物质因界面能的降低而消失[30].适当的温度和扩散时间使钛钢结合面处的珠光体和中间相的组织细化[23].图5c给出的界面形貌与图5f中的线扫描结果表明,在950 ℃/30 min条件下扩散焊连接的TA2/Q345过渡层加宽.结合点扫描结果(点7、点8)推断,在过渡层近钛侧的组织为Fe-Ti系化合物,在近钢侧形成了TiC层.与红装相比,点9表明在此温度下界面脱碳加剧.其原因是,Ti在950 ℃的扩散系数比Fe的高,使钢侧Ti原子的扩散更深,将碳原子困在钢中生成了比Fe-Ti系化合物更厚的TiC层[31]. ...

Effect of rolling temperature on microstructure and mechanical properties of Ti/steel clad plates fabricated by cold spraying and hot-rolling

1

2020

... 图5给出了红装和扩散焊后钛钢复合管界面处的SEM照片和EDS线扫描图,表2列出了线扫描结果.由图5a可见,在钛钢界面处形成了30 μm宽的过渡区,灰色颗粒是TiC,黑色大颗粒是Fe-Ti系化合物,靠近钢侧的灰色长条状结构是钢侧基体组织,与文献[26]中的Fe-Ti-C三元相图的结果相同,点4为对应图3光亮区的点扫描结果,在该区域C元素的含量比基体明显降低,表明发生了脱碳.图5d中的线扫结果表明,钛钢各元素间的扩散使过渡层的宽度与金相组织基本相同.产生上述现象的原因是,在红装过程中钛与钢的界面因热挤压而产生塑性变形,使界面处的组织缠结形成过渡层[27];塑性变形引起的位错密度提高和红装的高温虽然在一定程度上促进了各原子间的扩散[28,29],但是扩散温度较低且时间较短使过渡层只是在近钛侧和钢侧形成冶金结合区,其余部分仍为机械结合,近钢侧基体因C原子向过渡层扩散而形成脱碳区.在850 ℃/2 h条件下的扩散焊产生的过渡层呈平直状(图5b).图5e中的线扫描结果表明,过渡层的厚度约为1 μm.过渡层的点扫描结果(点5)表明,在此温度界面处可能存在TiC和Fe-Ti系化合物.界面处钢侧的点扫描结果(点6)表明,脱碳明显减弱.其原因是,在高温下界面处位错密度的降低减小了C向Ti侧扩散的驱动力,塑性变形生成的灰色大块物质因界面能的降低而消失[30].适当的温度和扩散时间使钛钢结合面处的珠光体和中间相的组织细化[23].图5c给出的界面形貌与图5f中的线扫描结果表明,在950 ℃/30 min条件下扩散焊连接的TA2/Q345过渡层加宽.结合点扫描结果(点7、点8)推断,在过渡层近钛侧的组织为Fe-Ti系化合物,在近钢侧形成了TiC层.与红装相比,点9表明在此温度下界面脱碳加剧.其原因是,Ti在950 ℃的扩散系数比Fe的高,使钢侧Ti原子的扩散更深,将碳原子困在钢中生成了比Fe-Ti系化合物更厚的TiC层[31]. ...

Interfacial modification of titanium/steel composites and its effect on the growth pattern of Fe-Ti compounds

1

2024

... XRD谱中钢侧α-Ti的峰强度变化的排序为:850 ℃扩散焊<红装<950 ℃扩散焊,而TiC峰强度变化的排序则为:红装<850 ℃<扩散焊950 ℃扩散焊.红装时的塑性变形和热扩散促进了α-Ti原子向钢侧扩散,而红装的较低温度使扩散到钢侧界面处的Ti多以α-Ti的形式存在,TiC的数量较少[28];在850 ℃扩散焊使C原子的扩散激活能升高,从而促进了界面上TiC的形核和长大.因此,在此温度下TiC峰的强度升高,而α-Ti的消耗使其峰强度略微降低;但是,温度继续提高到950 ℃使C元素大量消耗并难以补充,以致没有足够的C原子与扩散过来的Ti反应[32],这部分钛就以α-Ti的形式聚集在界面.在各温度钛侧TiC的峰强度都比FeTi和Fe2Ti的高,因为C、Fe原子在与Ti的反应扩散过程中存在竞争机制[33].在不同温度下Fe3C、TiC、FeTi与Fe2Ti的ΔGθ 曲线如图7所示[34],可见三种中间相ΔGθ 大小的排序为TiC < Fe2Ti < FeTi < 0.于是,在反应扩散过程中TiC优先在界面生成,而C、Fe原子在与Ti生成化合物的过程中存在竞争.因此,这部分优先生成的TiC成为Ti原子和Fe原子反应扩散的屏障,阻碍了FeTi和Fe2Ti的生成. ...

Thermodynamic study of titanium oxycarbide

3

2012

... XRD谱中钢侧α-Ti的峰强度变化的排序为:850 ℃扩散焊<红装<950 ℃扩散焊,而TiC峰强度变化的排序则为:红装<850 ℃<扩散焊950 ℃扩散焊.红装时的塑性变形和热扩散促进了α-Ti原子向钢侧扩散,而红装的较低温度使扩散到钢侧界面处的Ti多以α-Ti的形式存在,TiC的数量较少[28];在850 ℃扩散焊使C原子的扩散激活能升高,从而促进了界面上TiC的形核和长大.因此,在此温度下TiC峰的强度升高,而α-Ti的消耗使其峰强度略微降低;但是,温度继续提高到950 ℃使C元素大量消耗并难以补充,以致没有足够的C原子与扩散过来的Ti反应[32],这部分钛就以α-Ti的形式聚集在界面.在各温度钛侧TiC的峰强度都比FeTi和Fe2Ti的高,因为C、Fe原子在与Ti的反应扩散过程中存在竞争机制[33].在不同温度下Fe3C、TiC、FeTi与Fe2Ti的ΔGθ 曲线如图7所示[34],可见三种中间相ΔGθ 大小的排序为TiC < Fe2Ti < FeTi < 0.于是,在反应扩散过程中TiC优先在界面生成,而C、Fe原子在与Ti生成化合物的过程中存在竞争.因此,这部分优先生成的TiC成为Ti原子和Fe原子反应扩散的屏障,阻碍了FeTi和Fe2Ti的生成. ...

... 式中Δσ为材料的热应力,E为材料的弹性模量,α为线膨胀系数,ΔT为加热温度,E为(1.96~2.06) × 105 MPa,α为8.6 × 10-6/ ℃[36].显然,在500 ℃红装过程中钛管和钢管在热胀冷缩过程中产生的高于1200 MPa的挤压力远超TA2工业纯钛的屈服强度(550 MPa[35]),从而使其表面发生显著的塑性变形而使两种异质金属由点、线接触变成面、线接触,局部甚至出现焊合,实现了钛与钢间的机械嵌合[37];同时,在红装后的冷却过程中Ti、Fe、C等原子的扩散在界面生成了一定量的TiC、FeTi与Fe2Ti中间相,加强了界面的原子键合[38].机械键合和原子键合使红装钛钢复合管的剪切强度远超传统机械复合管.在850 ℃/2 h和950 ℃/30 min条件下扩散焊后,复合管的结合强度分别提高到167.44 MPa和265.53 MPa.由图8可见,与红装相比,更高温度的扩散焊使界面TiC相的数量更多,因而使扩散焊后复合界面的结合强度更高[33].与在850 ℃/2 h条件下的扩散焊相比,在950 ℃/30 min条件下的扩散焊在复合界面生成的TiC层更厚,大量的FeTi和Fe2Ti降低了钛钢界面的结合强度,而竞争机制使更厚的TiC层降低了FeTi和Fe2Ti的数量,从而提高了界面结合强度[33,39,40]. ...

... [33,39,40]. ...

Effect of vacuum level on microstructure and mechanical properties of titanium-steel vacuum roll clad plates

1

2018

... XRD谱中钢侧α-Ti的峰强度变化的排序为:850 ℃扩散焊<红装<950 ℃扩散焊,而TiC峰强度变化的排序则为:红装<850 ℃<扩散焊950 ℃扩散焊.红装时的塑性变形和热扩散促进了α-Ti原子向钢侧扩散,而红装的较低温度使扩散到钢侧界面处的Ti多以α-Ti的形式存在,TiC的数量较少[28];在850 ℃扩散焊使C原子的扩散激活能升高,从而促进了界面上TiC的形核和长大.因此,在此温度下TiC峰的强度升高,而α-Ti的消耗使其峰强度略微降低;但是,温度继续提高到950 ℃使C元素大量消耗并难以补充,以致没有足够的C原子与扩散过来的Ti反应[32],这部分钛就以α-Ti的形式聚集在界面.在各温度钛侧TiC的峰强度都比FeTi和Fe2Ti的高,因为C、Fe原子在与Ti的反应扩散过程中存在竞争机制[33].在不同温度下Fe3C、TiC、FeTi与Fe2Ti的ΔGθ 曲线如图7所示[34],可见三种中间相ΔGθ 大小的排序为TiC < Fe2Ti < FeTi < 0.于是,在反应扩散过程中TiC优先在界面生成,而C、Fe原子在与Ti生成化合物的过程中存在竞争.因此,这部分优先生成的TiC成为Ti原子和Fe原子反应扩散的屏障,阻碍了FeTi和Fe2Ti的生成. ...

2

2021

... 图8给出了TA2/Q345复合管的力学性能.由图8a可见,红装后TA2/Q345复合管的剪切强度为62.32 MPa,远高于传统机械复合管的剪切强度(4~6.5 MPa)[10].其原因是,红装时热应力为[35] ...

... 式中Δσ为材料的热应力,E为材料的弹性模量,α为线膨胀系数,ΔT为加热温度,E为(1.96~2.06) × 105 MPa,α为8.6 × 10-6/ ℃[36].显然,在500 ℃红装过程中钛管和钢管在热胀冷缩过程中产生的高于1200 MPa的挤压力远超TA2工业纯钛的屈服强度(550 MPa[35]),从而使其表面发生显著的塑性变形而使两种异质金属由点、线接触变成面、线接触,局部甚至出现焊合,实现了钛与钢间的机械嵌合[37];同时,在红装后的冷却过程中Ti、Fe、C等原子的扩散在界面生成了一定量的TiC、FeTi与Fe2Ti中间相,加强了界面的原子键合[38].机械键合和原子键合使红装钛钢复合管的剪切强度远超传统机械复合管.在850 ℃/2 h和950 ℃/30 min条件下扩散焊后,复合管的结合强度分别提高到167.44 MPa和265.53 MPa.由图8可见,与红装相比,更高温度的扩散焊使界面TiC相的数量更多,因而使扩散焊后复合界面的结合强度更高[33].与在850 ℃/2 h条件下的扩散焊相比,在950 ℃/30 min条件下的扩散焊在复合界面生成的TiC层更厚,大量的FeTi和Fe2Ti降低了钛钢界面的结合强度,而竞争机制使更厚的TiC层降低了FeTi和Fe2Ti的数量,从而提高了界面结合强度[33,39,40]. ...

2

2021

... 图8给出了TA2/Q345复合管的力学性能.由图8a可见,红装后TA2/Q345复合管的剪切强度为62.32 MPa,远高于传统机械复合管的剪切强度(4~6.5 MPa)[10].其原因是,红装时热应力为[35] ...

... 式中Δσ为材料的热应力,E为材料的弹性模量,α为线膨胀系数,ΔT为加热温度,E为(1.96~2.06) × 105 MPa,α为8.6 × 10-6/ ℃[36].显然,在500 ℃红装过程中钛管和钢管在热胀冷缩过程中产生的高于1200 MPa的挤压力远超TA2工业纯钛的屈服强度(550 MPa[35]),从而使其表面发生显著的塑性变形而使两种异质金属由点、线接触变成面、线接触,局部甚至出现焊合,实现了钛与钢间的机械嵌合[37];同时,在红装后的冷却过程中Ti、Fe、C等原子的扩散在界面生成了一定量的TiC、FeTi与Fe2Ti中间相,加强了界面的原子键合[38].机械键合和原子键合使红装钛钢复合管的剪切强度远超传统机械复合管.在850 ℃/2 h和950 ℃/30 min条件下扩散焊后,复合管的结合强度分别提高到167.44 MPa和265.53 MPa.由图8可见,与红装相比,更高温度的扩散焊使界面TiC相的数量更多,因而使扩散焊后复合界面的结合强度更高[33].与在850 ℃/2 h条件下的扩散焊相比,在950 ℃/30 min条件下的扩散焊在复合界面生成的TiC层更厚,大量的FeTi和Fe2Ti降低了钛钢界面的结合强度,而竞争机制使更厚的TiC层降低了FeTi和Fe2Ti的数量,从而提高了界面结合强度[33,39,40]. ...

Thermomechanics of Composites under High Temperatures

1

2013

... 式中Δσ为材料的热应力,E为材料的弹性模量,α为线膨胀系数,ΔT为加热温度,E为(1.96~2.06) × 105 MPa,α为8.6 × 10-6/ ℃[36].显然,在500 ℃红装过程中钛管和钢管在热胀冷缩过程中产生的高于1200 MPa的挤压力远超TA2工业纯钛的屈服强度(550 MPa[35]),从而使其表面发生显著的塑性变形而使两种异质金属由点、线接触变成面、线接触,局部甚至出现焊合,实现了钛与钢间的机械嵌合[37];同时,在红装后的冷却过程中Ti、Fe、C等原子的扩散在界面生成了一定量的TiC、FeTi与Fe2Ti中间相,加强了界面的原子键合[38].机械键合和原子键合使红装钛钢复合管的剪切强度远超传统机械复合管.在850 ℃/2 h和950 ℃/30 min条件下扩散焊后,复合管的结合强度分别提高到167.44 MPa和265.53 MPa.由图8可见,与红装相比,更高温度的扩散焊使界面TiC相的数量更多,因而使扩散焊后复合界面的结合强度更高[33].与在850 ℃/2 h条件下的扩散焊相比,在950 ℃/30 min条件下的扩散焊在复合界面生成的TiC层更厚,大量的FeTi和Fe2Ti降低了钛钢界面的结合强度,而竞争机制使更厚的TiC层降低了FeTi和Fe2Ti的数量,从而提高了界面结合强度[33,39,40]. ...

Review on mechanical joining by plastic deformation

1

2022

... 式中Δσ为材料的热应力,E为材料的弹性模量,α为线膨胀系数,ΔT为加热温度,E为(1.96~2.06) × 105 MPa,α为8.6 × 10-6/ ℃[36].显然,在500 ℃红装过程中钛管和钢管在热胀冷缩过程中产生的高于1200 MPa的挤压力远超TA2工业纯钛的屈服强度(550 MPa[35]),从而使其表面发生显著的塑性变形而使两种异质金属由点、线接触变成面、线接触,局部甚至出现焊合,实现了钛与钢间的机械嵌合[37];同时,在红装后的冷却过程中Ti、Fe、C等原子的扩散在界面生成了一定量的TiC、FeTi与Fe2Ti中间相,加强了界面的原子键合[38].机械键合和原子键合使红装钛钢复合管的剪切强度远超传统机械复合管.在850 ℃/2 h和950 ℃/30 min条件下扩散焊后,复合管的结合强度分别提高到167.44 MPa和265.53 MPa.由图8可见,与红装相比,更高温度的扩散焊使界面TiC相的数量更多,因而使扩散焊后复合界面的结合强度更高[33].与在850 ℃/2 h条件下的扩散焊相比,在950 ℃/30 min条件下的扩散焊在复合界面生成的TiC层更厚,大量的FeTi和Fe2Ti降低了钛钢界面的结合强度,而竞争机制使更厚的TiC层降低了FeTi和Fe2Ti的数量,从而提高了界面结合强度[33,39,40]. ...

Mechanical behaviour of laminated metal composites

1

1996

... 式中Δσ为材料的热应力,E为材料的弹性模量,α为线膨胀系数,ΔT为加热温度,E为(1.96~2.06) × 105 MPa,α为8.6 × 10-6/ ℃[36].显然,在500 ℃红装过程中钛管和钢管在热胀冷缩过程中产生的高于1200 MPa的挤压力远超TA2工业纯钛的屈服强度(550 MPa[35]),从而使其表面发生显著的塑性变形而使两种异质金属由点、线接触变成面、线接触,局部甚至出现焊合,实现了钛与钢间的机械嵌合[37];同时,在红装后的冷却过程中Ti、Fe、C等原子的扩散在界面生成了一定量的TiC、FeTi与Fe2Ti中间相,加强了界面的原子键合[38].机械键合和原子键合使红装钛钢复合管的剪切强度远超传统机械复合管.在850 ℃/2 h和950 ℃/30 min条件下扩散焊后,复合管的结合强度分别提高到167.44 MPa和265.53 MPa.由图8可见,与红装相比,更高温度的扩散焊使界面TiC相的数量更多,因而使扩散焊后复合界面的结合强度更高[33].与在850 ℃/2 h条件下的扩散焊相比,在950 ℃/30 min条件下的扩散焊在复合界面生成的TiC层更厚,大量的FeTi和Fe2Ti降低了钛钢界面的结合强度,而竞争机制使更厚的TiC层降低了FeTi和Fe2Ti的数量,从而提高了界面结合强度[33,39,40]. ...

Chemical composition, microstructure and sintering temperature modifications on mechanical properties of TiC-based cermet-A review

1

2015

... 式中Δσ为材料的热应力,E为材料的弹性模量,α为线膨胀系数,ΔT为加热温度,E为(1.96~2.06) × 105 MPa,α为8.6 × 10-6/ ℃[36].显然,在500 ℃红装过程中钛管和钢管在热胀冷缩过程中产生的高于1200 MPa的挤压力远超TA2工业纯钛的屈服强度(550 MPa[35]),从而使其表面发生显著的塑性变形而使两种异质金属由点、线接触变成面、线接触,局部甚至出现焊合,实现了钛与钢间的机械嵌合[37];同时,在红装后的冷却过程中Ti、Fe、C等原子的扩散在界面生成了一定量的TiC、FeTi与Fe2Ti中间相,加强了界面的原子键合[38].机械键合和原子键合使红装钛钢复合管的剪切强度远超传统机械复合管.在850 ℃/2 h和950 ℃/30 min条件下扩散焊后,复合管的结合强度分别提高到167.44 MPa和265.53 MPa.由图8可见,与红装相比,更高温度的扩散焊使界面TiC相的数量更多,因而使扩散焊后复合界面的结合强度更高[33].与在850 ℃/2 h条件下的扩散焊相比,在950 ℃/30 min条件下的扩散焊在复合界面生成的TiC层更厚,大量的FeTi和Fe2Ti降低了钛钢界面的结合强度,而竞争机制使更厚的TiC层降低了FeTi和Fe2Ti的数量,从而提高了界面结合强度[33,39,40]. ...

Structural modification of TA2/Q355B composite interface and study of TiC stability mechanism

1

2023

... 式中Δσ为材料的热应力,E为材料的弹性模量,α为线膨胀系数,ΔT为加热温度,E为(1.96~2.06) × 105 MPa,α为8.6 × 10-6/ ℃[36].显然,在500 ℃红装过程中钛管和钢管在热胀冷缩过程中产生的高于1200 MPa的挤压力远超TA2工业纯钛的屈服强度(550 MPa[35]),从而使其表面发生显著的塑性变形而使两种异质金属由点、线接触变成面、线接触,局部甚至出现焊合,实现了钛与钢间的机械嵌合[37];同时,在红装后的冷却过程中Ti、Fe、C等原子的扩散在界面生成了一定量的TiC、FeTi与Fe2Ti中间相,加强了界面的原子键合[38].机械键合和原子键合使红装钛钢复合管的剪切强度远超传统机械复合管.在850 ℃/2 h和950 ℃/30 min条件下扩散焊后,复合管的结合强度分别提高到167.44 MPa和265.53 MPa.由图8可见,与红装相比,更高温度的扩散焊使界面TiC相的数量更多,因而使扩散焊后复合界面的结合强度更高[33].与在850 ℃/2 h条件下的扩散焊相比,在950 ℃/30 min条件下的扩散焊在复合界面生成的TiC层更厚,大量的FeTi和Fe2Ti降低了钛钢界面的结合强度,而竞争机制使更厚的TiC层降低了FeTi和Fe2Ti的数量,从而提高了界面结合强度[33,39,40]. ...

Effect of carbon content on the microstructure and bonding properties of hot-rolling pure titanium clad carbon steel plates

1

2021

... 图9给出了TA2/Q345复合管剪切断裂后钛侧和钢侧断口的形貌.从图9a~f中的低倍照片可见,在两侧断口的表面出现由中间相组成的岛状结构.由图9a'~f'中的高倍断口照片可见,钛钢复合管的断口发生在界面近钢侧并出现了大量穿晶韧窝(图9a'),为典型的韧性断裂;图9b',c'中的断口为准解理断口(图7b),出现脆性断裂倾向 [41]. ...