TC4钛合金,是不含气孔和夹杂物的纯净合金。Neal等基于对钛合金的疲劳试验断口的观测提出,疲劳寿命为3 × 106∼2.5 × 107周次的试样中裂纹均萌生于基体,基体内的α晶粒解理形成解理刻面(Facet)是裂纹萌生的根本原因[14~17] 。洪友士等基于Ti-6Al-4V的超高周疲劳实验结果,将失效模式分为表面解理失效、表面滑移失效和内部解理失效[18]。表面解理和表面滑移失效的相同点是裂纹均由表面缺陷诱发,不同点是表面解理失效试样的裂纹源附近有大量解理刻面出现,而表面滑移失效没有这个特征。内部失效的裂纹先起源于单个α相解理,然后若干个α相解理形成粗糙的裂纹萌生区域(Rough area)。洪友士等进一步指出,分析TC4钛合金的竞争失效机制必须先明确滑移与解理之间的竞争关系,然后分析表面解理与内部解理的竞争关系[19]。Chandran等[21]根据平均缺陷密度和泊松分布构建了与缺陷密度有关的竞争失效模型,并基于蒙特卡罗方法对其有效性进行了验证。刘福林等[22]基于XCT扫描结果得到了Ti-6Al-4V内部的缺陷体积密度,进一步构建以缺陷体积密度为变量的竞争失效模型并分析了在不同内部体积统计下竞争失效曲线的变化趋势。刘小龙等[23]基于与最大应力(σmax)有关的正态分布函数和两参数泊松分布构建了Ti-6Al-4V的竞争失效模型。结果表明,随着σmax的增大表面滑移失效概率逐渐降低至0%,表面解理失效概率逐渐提高至100%,内部解理失效概率先提高后降低。张震宇[24]研究了TC4钛合金的失效模式与应力比的关系,发现随着应力比的增大表面滑移失效概率降低,表面解理失效概率提高和内部解理失效概率先提高后降低,并构建了计及σmax的竞争失效模型。

但是,TC4钛合金的竞争失效机制尚不明确、构建的竞争失效模型计及的因素过少、无法量化竞争失效模型的参数对失效概率的影响且计算结果也没有较强的说服力。鉴于此,本文进一步明确TC4钛合金疲劳失效机理、量化竞争关系并构建一个计及多因素(控制体积、微观组织、缺陷特征、应力比、最大应力)对失效机理影响的竞争失效模型,并用控制变量法研究TC4钛合金微观组织特性对滑移-解理竞争失效机制的影响。

1 实验方法

表1 TC4钛合金的化学成分

Table 1

| Material | C | N | H | Fe | O | Al | V | Ti |

|---|---|---|---|---|---|---|---|---|

| TC4 | 0.05 | 0.03 | 0.01 | 0.15 | 0.13 | 5.83 | 4.09 | Bal. |

图1

用质量分数为3.5%硝酸和5%氢氟酸和91.5%水组成的腐蚀液腐蚀TC4钛合金金相试样的待测截面,用LEICA DM4000M光学显微镜(OM)和JSM-6610LV扫描电子显微镜(SEM)观察其微观组织。

用QBG-100型高频疲劳试验机进行TC4钛合金的超高周疲劳实验,加载频率约为100 Hz,施加的应力比(R)分别为-1、-0.3和0.1。

2 结果和分析

2.1 TC4钛合金的微观组织和力学性能

图2

图2

TC4钛合金的微观形貌

Fig.2

Microstructure of TC4 titanium alloy (a) OM mophology; (b) SEM mophology

2.2 TC4钛合金的 S-N 曲线

图3给出了TC4钛合金的S-N曲线,三种应力比分别为-1、-0.3和0.1。结合SEM观察,可将TC4钛合金的失效模式分为无刻面的表面滑移失效(Surface slip failure without facets,S-Sli)、有刻面的表面解理失效(Surface cleavage failure with facets,S-Sur)和有刻面的内部解理失效(Interior cleavage failure with facets,Int)。

图3

图3

TC4钛合金的S-N曲线

Fig.3

S-N curves of TC4 titanium alloy under three stress ratios (a) sing stress amplitude as the ordinate; (b) using maximum stress as the ordinate

应力比为-1的S-N曲线大部分数据点失效模式均为S-Sli,只有一个数据点失效模式为Int,S-N曲线的形状是明显的阶梯形,在传统意义上R = -1的疲劳极限在图3中用黑色虚线表示。

应力比为-0.3和0.1的S-N曲线,由表面缺陷诱发失效和内部缺陷诱发失效两条相互独立的S-N曲线描述,即“双重S-N曲线”[25~27]。由图3可见,两种应力比的表面失效试样均有明显的表面失效疲劳极限,应力比R = -0.3的疲劳极限用红色虚线表示,应力比R = -0.1的疲劳极限用蓝色虚线表示。内部失效试样的S-N曲线呈持续下降趋势,定义疲劳寿命109周次所对应的载荷大小为内部失效疲劳极限。对比不同应力比的S-N曲线可见,对于一定的应力幅值(σa)随着应力比的增大疲劳寿命减小。对于给定的疲劳寿命,随着应力比的增大疲劳强度降低。同时,在应力幅值相同的条件下,随着应力比的增大疲劳寿命增加。但是,在应力比为R = -0.3和R = 0.1的条件下,对于相同的最大应力,随着应力比的增大疲劳寿命的变化趋势相同。

2.3 TC4钛合金疲劳断口的形貌

TC4钛合金具有代表性的疲劳断口形貌,如图4所示。图4给出了失效模式为S-Sli的断口照片。图4a给出了整个断口的形貌,依据裂纹的特征可将疲劳断口分为短裂纹扩展区、长裂纹扩展区和失稳扩展区三部分。从图4b可见,在整个断口中短裂纹扩展区的面积占比很小,但是比较明亮。图4c给出了使用SEM观察到的更高放大倍数的短裂纹扩展区,可见疲劳裂纹起源于表面缺陷(Surface defect,SD),由图中的红色线条标记,疲劳裂纹整体以表面缺陷为原点呈放射状向试样内生长。图4c1给出了裂纹源附近的放大照片,可见在表面缺陷附近有明显的晶粒滑移线,如图中的箭头所示。其原因是,表面缺陷使施加的应力在缺陷周围集中。作用在晶体上的外部应力使晶格结构中产生应力场,当应力强度高于晶格结构的强度极限但是未超过晶格内原子塑性应变的应力时,晶体中原子的位移使晶体发生滑移变形[28]。微裂纹沿着滑移面向内扩展,不同位置的微裂纹相互结合形成小裂纹,并进入长裂纹扩展阶段。图4a给出了长裂纹扩展区的形貌,可见整个长裂纹扩展区域较为平坦,长裂纹扩展区之外称为失稳扩展区。

图4

图4

TC4钛合金的典型失效断口

Fig.4

Typical failure fractures of TC4 titanium alloy (a) macroscopic fracture observation; (b) short crack propagation region; (c) surface defects; (c1) slip characteristic; (d) macroscopic fracture observation; (e) short crack propagation region; (f) surface defects; (f1) facets; (g) macroscopic fracture observation; (h) ICIA; (i) ICIA; (i1) facets

图4d~f给出了表面解理失效模式S-Sur的断口照片。图4d给出了低倍SEM照片,可见R = 0.1的失效模式为S-Sur的整个断裂面。根据疲劳裂纹的生长特征,可将整个断裂面分为表面粗糙不均匀区(Surface coarse inhomogeneous area,SCIA)、长裂纹扩展区和失稳扩展区。图4f给出了SCIA区域的高倍SEM照片。与S-Sli裂纹的起裂原因相同,清晰的表面裂纹源,裂纹也起源于表面缺陷,表现为试样表面出现凹坑。图4f给出了SCIA区域的高倍SEM照片。与S-Sli不同的是,失效模式为在S-Sur断口内裂纹源附近出现大量的刻面,如图4f1所示,解理刻面的形成正是在应力作用下金属原子链遭到破坏而使晶体产生的一种穿晶断裂,其面积约等于晶粒横截面积。这些刻面随机分布在表面的缺陷附近,形成了SCIA。随着载荷的持续施加,当裂纹尖端的ΔK超过小裂纹扩展门槛值时微裂纹扩展,即相邻的α晶粒内的微裂纹沿晶界生长并连结在一起形成小裂纹。随着循环载荷的持续作用,疲劳裂纹进入长裂纹扩展阶段。整个长裂纹扩展区域较为平坦,长裂纹扩展区之外称为失稳扩展区。图4d给出了长裂纹扩展区的形貌。

图4g~I给出了内部解理失效模式Int的断口照片。依据疲劳裂纹特征将内部失效试样断口分为内部粗糙不均匀区域(Interior coarse inhomogeneous area,ICIA),鱼眼(Fisheye),快速扩展区以及失稳扩展区。SEM高倍率观测鱼眼内部(图4h),发现一个形貌起伏较大且几乎位于鱼眼正中心的区域,如图4i所示,该区域即为ICIA。其原因是,对ICIA内部放大观测发现(图4i1),施加的应力在α相周围集中。当应力强度因子达到α晶粒穿晶断裂应力门槛值时,形成解理刻面。进一步,当裂纹尖端的ΔK超过小裂纹扩展门槛值时微裂纹扩展,即相邻的α晶粒内的微裂纹沿晶界生长并连结在一起形成小裂纹。当所有的微裂纹萌生、结合运动结束后,即形成ICIA。随着载荷的持续施加疲劳裂纹进入长裂纹扩展阶段,裂纹以区域为中心呈放射状向外稳定扩展形成鱼眼,结果如图4g、h所示。如图4g所示,鱼眼之外的首个区域称为快速扩展区。两区域形貌的对比表明,鱼眼内部的裂纹较为细密,而快速扩展区的裂纹较粗糙,裂纹在快速扩展区内经历的周次极短;当裂纹生长至快速扩展区的边界时,试样立即失效。

2.4 裂纹的特征尺寸

图5

图5

TC4钛合金的裂纹特征示意图

Fig.5

Sketch map of crack characteristics of TC4 titanium alloy (a) feature morphology of S-Sli, (b) feature morphology of S-Sur, (c) feature morphology of Int

2.4.1 表面失效的裂纹特征尺寸

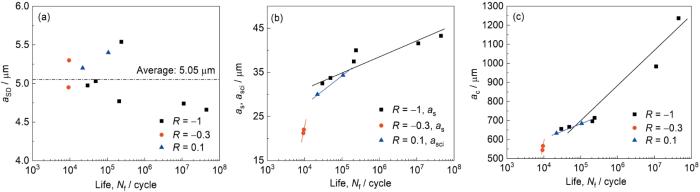

根据SEM断口照片上的比例尺,使用ImageJ图形处理软件得到了表面失效断口内各种裂纹的特征尺寸,图6给出了所有应力比下的aSD、as、asci、ac与疲劳寿命Nf的关系。由图6a可见,无论是随着疲劳寿命的增大或随着应力比的改变aSD都没有明显的变化规律,平均值为5.05 μm。这表明,表面缺陷的大小只与试样表面的粗糙度有关。结合图3中的S-N曲线和图6b可见,随着疲劳寿命的增大同一应力比下的as和asci分别呈逐渐增大趋势。其原因是,在裂纹扩展的整个过程中小裂纹扩展占疲劳寿命的90%,随着疲劳寿命的增大as和asci也随之增大。对于给定的疲劳寿命,as的值随着应力比R的增大而增大。R越大则最大应力(σmax)越大,裂纹扩展速率越高。因此,在寿命一定的条件下应力比越大则as越大。由图6c可见,对于同一的应力比,表面起裂试样的ac随着疲劳寿命的增大呈明显增大的趋势。

图6

图6

TC4钛合金表面失效特征尺寸

Fig.6

Surface failure characteristic size of TC4 titanium alloy (a) relationship between aSD and Nf (b) relationship between as,aICIA and Nf (c) relationship between ac and Nf

2.4.2 内部失效裂纹的特征尺寸

在所有应力比下的各种内部裂纹特征尺寸分类统计结果见图7。

图7

图7

TC4钛合金内部失效特征尺寸

Fig.7

Surface failure characteristic size of TC4 titanium alloy (a) relationship between rfacet and Nf (b) relationship between rICIA and Nf (c) relationship between rfisheye and Nf (d) relationship between rc and Nf

由图7a可见,R = -1时只有一个点为内部失效且该试样的解理刻面尺寸为5.1 μm。与其它试样的rfacet失效数据对比,此疲劳试样的rfacet偏大。这表明,该试样较大的内部缺陷使内部疲劳失效。在三种应力比下,所有疲劳试样的rfacet均值为3.97 μm。该尺寸近似等于α晶粒的半径,证实解理刻面源于α晶粒解理。

2.5 最大缺陷的尺寸

广义帕累托(GP)分布是一种累积分布函数,可用于评估独立随机变量的最大值或最小值。假设表面缺陷尺寸服从GP分布,则其累积分布函数为[19]

式中a、λ和η分别为尺寸参数、阈值和位置参数。基于GP分布函数预测的缺陷尺寸为

基于前文中的aSD值并使用1stOpt软件的Levenberg-Marquardt优化算法计算aSD特征尺寸的GP累积分布函数参数,可得到两种分布函数的各参数值。

表2 GP分布下参数值评估

Table 2

| Parameters | aSD |

|---|---|

| λ2 | 4.59 |

| α2 | 0.79 |

| η2 | -0.72 |

根据决定系数R2评估预测结果与实际值的相关程度,R2越接近1表明函数的自变量对因变量的解越符合实际。计算R2的公式为

式中FUV为未解释方差分数,RSS为剩余平方和,TSS为总平方和,yi 为实际值,fi 为预测值,ŷ为实际值均值。

建立的aSD与GP分布函数的累积概率分布曲线,如图8所示。

图8

图8

aSD的累积概率分布函数关系曲线

Fig.8

Cumulative probability distribution function curve of feature size

3 TC4钛合金的滑移-解理竞争失效模型

3.1 控制体积内晶粒解理的个数

图9

图9

TC4钛合金控制体积以及区域划分示意图

Fig.9

Schematic diagram of TC4 titanium alloy control volume and area division

式中V为控制体积;d为试样最小截面直径,取值4.5 mm;rα 为α晶粒的半径平均值,取值0.004 mm。

试样的区域划分示意图,如图9b所示。定义

为试样可能发生内部失效的潜在体积,定义

为试样可能发生表面失效的潜在体积。计及材料的微结构特征,定义W为VSur的厚度,为GP分布函数99.9%失效概率的aSD预测值,取值5.69 μm。

则晶粒发生解理的累计概率分布函数F(σmax)可由

其中

和

3.2 控制体积内滑移-解理的概率

基于Poisson分布,在TC4钛合金的控制体积V内n个α晶粒满足解理条件并发生解理断裂的概率为

而在控制体积V内无α晶粒解理以及有α晶粒发生解理的概率可分别使用

和

计算。当控制体积V内无α晶粒满足解理条件时解理,则发生滑移失效。

结合图3中的S-N曲线分析可得,随着σmax由600 MPa增大至780 MPa则TC4钛合金疲劳试样发生失效的点多数为表面滑移失效。同时,随着σmax由780 MPa增大至925 MPa,TC4钛合金疲劳试样发生失效的点多数为内部解理失效。σmax增大至925 MPa以后,TC4钛合金疲劳试样发生失效的点多数为表面解理失效。

因此,在循环载荷作用下,当Vsur内有一个α晶粒达到解理的力学条件时,裂纹就从该处萌生并最终使试样失效。因此,基于与σmax有关的正态分布统计和泊松分布,将

当Vsur内所有的α晶粒受到的σmax值不满足自身解理强度时,处在VInt内的晶粒便发生解理,即内部解理失效的概率可表示为

当Vsur和VInt内所有晶粒受到的σmax值均不满足解理条件时,疲劳试样将不发生任和模式的解理失效。裂纹由疲劳试样表面初始缺陷诱发,发生表面滑移失效的概率为

3.3 竞争失效模型的预测结果

基于公式(

图10

图10

三种失效模式的失效概率随σmax的变化情况

Fig.10

Change of failure probability of three failure modes with σmax

由图10可见,随着σmax由600 MPa增大至800 MPa,TC4钛合金疲劳试样发生表面滑移失效的概率由100%骤降至0%且随着max的增大保持0%概率失效;随着σmax由790 MPa增大至920 MPa疲劳试样发生表面解理失效的概率由0%增大至100%,且随着σmax增大不再改变;计算结果表明,随着σmax由710 MPa增大至920 MPa,TC4钛合金发生内部解理失效的概率呈先增大后减小的趋势,并且当σmax增大至810 MPa时发生内部解理失效的概率达到接近100%的峰值。与S-N曲线对比并计及材料晶粒特性、试样控制体积,基于与σmax有关的正态分布函数和泊松分布得到的TC4钛合金竞争失效模型计算结果,与实验结果的σmax之间有较好的一致性。

4 材料参数对滑移-解理竞争失效的影响

4.1 W 值对滑移-解理的影响

采用控制变量法,控制晶粒含量为80%和晶粒尺寸为4 μm,则W = 5.69 μm、放大10倍后W = 56.9 μm、放大百倍W = 569 μm且计及σmax的竞争失效模型,如图11所示。

图11

图11

与σmax有关的三种失效模式的失效概率随W的变化情况

Fig.11

Change of failure probability with W for the three failure modes related to σmax (a) surface slip and internal cleavage failure (b) surface slip and surface cleavage failure

从图11可见,表面解理失效:随着W扩大十倍和百倍,表面解理失效打破0%概率状态对应的σmax值分别为740和720 MPa。对比结果表明,随着W值的升高TC4钛合金发生表面解理失效的概率提前由0%升至100%。对于内部解理失效:首先,随着W值扩大十倍和百倍发生内部解理失效的概率峰值由97.2%分别下降至81.2%以及28.7%;其次,随着W值增大至56.9和569 μm,发生内部解理失效对应的σmax范围逐步缩小。对于表面滑移失效:其概率曲线并不受W的影响,因为W值的改变只影响VSur和VInt在控制体积V内的占比而不影响控制体积V。

4.2 α 晶粒半径对滑移-解理的影响

图12

图12

与σmax有关的三种失效模式的失效概率随a晶粒尺寸的变化情况

Fig.12

Change of failure probability with a grain size for the three failure modes related to σmax (a) surface slip failure (b) surface cleavage failure (c) internal cleavage failure

由图12可见,α晶粒尺寸影响各失效模式的概率,但是不影响内部解理失效的峰值。随着α晶粒的尺寸由4 μm减小至3 μm三种失效模式的失效概率曲线均同等幅度的向右横移,随着α晶粒由4 μm增大至10 μm三种失效模式的失效概率曲线均同等幅度的向左横移。这表明,α晶粒的半径越小则TC4钛合金发生表面解理、内部解理以及表面滑移所需的σmax值越大。其原因是,双态结构TC4钛合金α晶粒的尺寸越小则基体内部的晶界越多,即对位错运动的阻碍越大,使金属抵抗塑性变形的能力越强,则疲劳强度随之提高,结果是竞争失效概率曲线的区间向右横移。

4.3 α 晶粒的含量对滑移-解理的影响

图13

图13

与σmax有关的三种失效模式的失效概率与α晶粒含量的关系

Fig.13

Change of failure probability with α grain content for the three failure modes related to σmax (a) surface slip failure, (b) surface cleavage failure, (c) internal cleavage failure

由图13可见,α晶粒含量不影响失效概率的峰值,只影响各失效模式发生时σmax的范围。随着α晶粒的含量由30%提高到90%,三种失效模式的失效概率曲线均同等幅度地向右横移。这表明,α晶粒的含量越高则发生疲劳失效所需的σmax越大,相应的发生各种失效模式的所需σmax越大。其原因是,TC4钛合金基体内的α晶粒是阻碍裂纹萌生或扩展的主要因素。α晶粒的含量越高则基体内的位错滑移越困难,α晶粒对裂纹生长的阻碍越大,使材料的疲劳强度较高,其结果是推迟了TC4钛合金的竞争失效。

5 结论

(1) 在应力比分别为-1、-0.3以及0.1下的加载条件下TC4钛合金有S-Sli、S-Sur和Int三种失效模式。

(2) 基于试样的控制体积、计及外载荷大小、试样控制体积、TC4钛合金α晶粒特性,以及与σmax有关的正态分布函数以及泊松分布和滑移解理竞争机制,构建的滑移-解理竞争失效模型其预测结果与实验数据有较好的相关性。

(3) W的取值不影响表面滑移失效概率,α晶粒尺寸的增大或α晶粒含量的降低均有利于TC4钛合金发生表面滑移失效。

(4) 较小的W值、较大的α晶粒尺寸以及较低的α晶粒含量均有利于TC4钛合金发生内部解理失效;较大的W值、较大的α晶粒尺寸以及较低的α晶粒含量均有利于TC4钛合金发生表面解理失效。

参考文献

Dynamic recrystallization of Ti-6Al-4V alloy during hot compression

[J].The stress-strain curves of Ti-6Al-4V alloy during hot deformation by applied strain rate within the range of 5×10-4~5×10-2 s-1 at 870~960°C were measured via single-pass isothermal compression test. The dynamics characteristics of rheological stress, critical strain capacity and structure evolution of the alloy during dynamic recrystallization were systematically illustrated by means of KM model, Poliak-Jonas model, and Avrami model. Then a concept of volume fraction of the microstructure transformation, i.e., the portion of the alloy that has been underwent microstructure transformation during dynamic recrystallization, was introduced into the so called prasad power dissipation rate model, thus the energy variation of the alloy during dynamic recrystallization was acquired. Further, taking both of the acquired energy variation and the observed microstructure evolution characteristics together into consideration, the dynamic recrystallization mechanism of Ti-6Al-4V alloy may be revealed. It follows that the critical strain capacity of Ti-6Al-4V during dynamic recrystallization decreased and the structural transformation volume fraction increased following the rise of deformation temperature or the decline of strain rate. The power dissipation rate upon complete dynamic recrystallization is larger than 0.34, and the forming mechanism is a dislocation-induced arcuation nucleation mechanism.

Ti-6Al-4V合金热压缩过程中的动态再结晶

[J].

Structure and properties of Cu2O doped micro arc oxidation coating on TC4 titanium alloy

[J].The microarc oxidation coating doped with coprous oxide was prepared on the surface of TC4 Ti-alloy by adding different amount of cuprous oxide particles into the electrolyte. The microstructure and properties of the cuprous oxide doped microarc oxidation coating were investigated by means of scanning electron microscope (SEM), X-ray diffractometer (XRD), X-ray photoelectron spectroscope (XPS) and microhardness tester. The results show that the surface of the microarc oxidation coating doped with cuprous oxide is porous, but the number and size of micropores are small. However the doped Cu oxides are present in the coating in two forms, namely copper oxide and cuprous oxide. Compared with the microarc oxidation coating without doping of cuprous oxide, the wear resistance and antibacterial performance of microarc oxidation coating doped with different amount of cuprous oxide are significantly improved in artifitial seawater, but their corrosion resistance degraded.

TC4钛合金表面氧化亚铜掺杂微弧氧化层的结构和性能

[J].

Effect of anneal treatment on microstructure, texture and mechanical properties of TC4 alloy plates

[J].The effect of the anneal temperature on the microstructure, micro-texture and mechanical properties of the hot rolled Ti-6Al-4V alloy were investigated. The results show that the as rolled Ti-6Al-4V alloy presents a bimodal microstructure. The content of equiaxed α-phase increased after annealing. The content of secondary α-phase tented to decrease, whilst to be gradually spheroidized. The microstructure transformed into equiaxed structure after annealing at 900℃. With the increase of anneal temperature, the preferred orientation of α-phase were changed. Correspondingly, the micro-texture changed from B-type to mixed texture, then to B-type again. The crystal directions dispersed when the sample anneal at 800℃. The texture consisted of {0001}<31¯2¯0>, {0001}<98¯1¯0>, {0001}<31¯2¯0> and {0001}<12¯10>. The relationship between the mechanical performance and the annealing temperature were assessed via tensile tests. It follows that with the increased of annealing temperature, the tensile strength increased but the yield strength decreased, spontaneously, the ratio of yield strength to tensile strength decreased. In a word, the comprehensive mechanical properties of the alloy may be enhanced through proper annealing process.

退火温度对TC4钛合金热轧板材的显微组织、织构和力学性能影响

[J].

Present status and development trend of aircraft turbine engine

[J].

航空涡轮发动机现状及未来发展综述

[J].

Research development of titanium alloy in aerospace industry

[J].

航空用钛合金研究进展

[J].

Effects of defects, inclusions and inhomogeneities on fatigue strength

[J].

A fatigue assessment approach involving small crack growth modelling for structural alloy steels with interior fracture behavior

[J].

A quick and simple method for orienting cubic single crystals from Laue back-reflection photographs

[J].

Research on fatigue crack propagation and remain fatigue life prediction of aero-engine blade TC4 titaniumalloy

[J].

航空发动机叶片TC4钛合金振动疲劳裂纹扩展研究及剩余寿命预测

[J].

Gigacycle fatigue of ferrous alloys

[J].

Prediction for fatigue strength and distribution features of inclusion of carburized Cr-Mn steel

[J].

渗碳Cr-Mn钢的夹杂分布特性及疲劳强度预测

[J].

Review and prospects for current studies on very high cycle fatigue of metallic materials for machine structural use

[J].

An investigation of small-crack and long-crack propagation behavior in titanium alloy TC4 and aluminum alloy 7475-T7351

[J].

TC4钛合金和7475铝合金的长裂纹和小裂纹扩展特性的研究

[J].研究了TC4钛合金和7475铝合金在应力比R=0.5,0和-1恒幅载荷下的长裂纹和小裂纹的扩展行为。小裂纹试验采用单边缺口拉伸试样,裂纹从半圆形缺口根部自然萌生。研究结果显示,TC4钛合金在恒幅载荷下,未显示出小裂纹效应。该现象与小裂纹扩展初期出现明显的裂纹偏析和分叉有关。小裂纹起始寿命较长,裂纹起始寿命约占疲劳寿命的20%~55%。7475-T7351铝合金在低应力比(R≤0)下的低应力强度因子范围内,存在经典的小裂纹效应,小裂纹起始于孔壁表面的第二相质点团或空洞处,夹杂质点团较之单个杂质点对裂纹的萌生更有害,裂纹起始寿命约占疲劳寿命的15%~29%。

Faceted crack initiation characteristics for high-cycle and very-high-cycle fatigue of a titanium alloy under different stress ratios

[J].

Subsurface crack initiation in high cycle fatigue in Ti6A14V and in a typical martensitic stainless steel

[J].

Effect of microstructure on ultra-high cycle fatigue behavior of Ti-6Al-4V

[J].

Internal fatigue origins in α-β titanium alloys

[J].

Propensities of crack interior initiation and early growth for very-high-cycle fatigue of high strength steels

[J].

A review on mechanisms and models for very-high-cycle fatigue of metallic materials

[J].

合金材料超高周疲劳的机理与模型综述

[J].

An unusual fatigue phenomenon: duality of the S-N fatigue curve in the β-titanium alloy Ti-10V-2Fe-3Al

[J].

Effects of defects on tensile and fatigue behaviors of selective laser melted titanium alloy in very high cycle regime

[J].

Faceted crack initiation characteristics for high-cycle and very-high-cycle fatigue of a titanium alloy under different stress ratios

[J].

Comparative study of very high cycle tensile and torsional fatigue in TC17 titanium alloy

[J].

Effect of stress ratio on very high cycle fatigue properties of Ti-10V-2Fe-3Al alloy with duplex microstructure

[J].In fatigue critical applications, Ti-10V-2Fe-3Al alloy components are expected to endure cyclic loading with cycles above 109. To assess their operating safety, S-N relations of Ti-10V-2Fe-3Al alloy in very high cycle fatigue (VHCF) regime are of concern and have been investigated in this work. Fatigue behavior including S-N curves and crack initiation mechanisms is reported. Two transitions of fatigue crack initiation mechanism, from internal crack initiation to surface crack initiation and from αp cleavage to αs/β decohesion, occur when the stress ratio (R) and stress level are reduced. Fatigue limits exist at Nf = 6 × 107 cycles for all stress ratios except for 0.5. In the VHCF regime two kinds of internal crack initiation mechanisms exist, i.e., coalescence of cluster of αp facets and αs/β decohesion. Their mutual competition depends on the stress ratio and can be interpreted in terms of different stress character required for promotion on different internal crack initiation mechanism. Small crack propagation is discussed to be life controlling process under the stress ratio range from -0.5 to 0.1 during VHCF regime while under the stress ratio 0.5 VHCF, life almost refers to the life required for crack initiation.

Microscopic and nanoscopic observations of metallurgical structures around inclusions at interior crack initiation site for a bearing steel in very high-cycle fatigue

[J].

Non-propagation conditions for fatigue cracks and fatigue in the very high-cycle regime

[J].

Effect of loading condition on very high cycle fatigue behavior in a high strength steel

[J].

Microstructure evolution during high temperature deformation of Ti-6Al-4V alloy

[J].

TC4钛合金高温变形时的微观组织演变(英文)

[J].

Simulation of deformation at and initiation of crack tip prior to cleavage fracture by means of finite element method

[J].

解理断裂前裂纹尖端变形与开裂的有限元模拟

[J].

Life time and cyclic slip of copper in the VHCF regime

[J].