TC4、TC17和TC21等α + β钛合金的强度和塑性在很大程度上取决于其成分,对其调整能显著改变合金的相比例、晶粒尺寸和晶体结构,从而影响其性能。Zhang等[8]基于TC4合金设计开发了一种含Cr、Fe和低V的新型α + β钛合金(Ti-6Al-2V-1Cr-1Fe),其晶粒细小,强度较高且塑性良好。陈志鹏[9]等设计了一种Ti-Al-V-Mo-Nb-Zr合金,发现随着Zr含量的提高其强度提高而延伸率先提高后降低。刘畅[10]等改变Ti-xAl-3.5Fe-0.1B合金中Al元素的含量,发现随着Al含量的提高其中的初生αp相的片层厚度明显减小、合金的组织明显细化、片层厚度更加均匀,强度大幅度提高。但是也有研究发现,Al含量超过7%会生成一种Ti3Al金属间化合物质,使合金的塑性降低[11, 12]。

α + β钛合金的性能高度依赖加工工艺,锻造、挤压和热处理等手段能在很大程度上改善钛合金的显微组织和力学性能。许多学者对α + β钛合金的塑性变形进行了大量研究。Shi[13]等对TC21钛合金进行近等温锻造加工成形,发现成形速率显著影响其力学性能。随着变形速率的提高合金的强度呈提高的趋势,而塑性则明显降低。Zhu[14]等对比了多向轧制和单向轧制对Ti-5.2Mo-4.8Al-2.5Zr-1.7Cr合金组织及力学性能的影响,发现多向轧制能生成细小的等轴αp相和纳米级αs相,使其动态抗压强度和塑性同时提高。另一方面,热处理可精确控制钛合金中不同相组织的含量和微观形态,进而提高其综合性能。朱宁远[15]等研究了在相变点附近的温度进行固溶对TC11钛合金的显微组织和显微硬度的影响,发现随着固溶温度提高到相变点附近,初生等轴α相的含量迅速降低,硬度则先降低然后逐渐趋于稳定。Wang[16]等研究了退火温度对TC21钛合金冲击韧性的影响,发现随着退火温度的提高TC21钛合金的冲击韧性先提高后降低。叶先伟[17]等研究了时效温度对TC21钛合金力学性能的影响,发现时效温度不改变β晶粒的大小,但是随着时效温度的提高αs的尺寸增大而体积分数降低,有利于减少位错积累和降低应力集中。Zeng[18]等对TC4合金进行不同温度的固溶处理以改变相体积分数并用纳米压痕技术测定了初生αp相的强度。结果表明,随着初生αp相体积分数的提高其强度降低,这一结果可归因于Al和V元素的分配效应。Zhu[19]研究发现,时效温度决定α + β钛合金中次生αs相的大小和体积分数,时效温度越低次生αs相的间距越小其强度越高。适当的热处理是使α + β钛合金具有优异综合力学性能的关键因素之一。

Ti-6Al-2Mo-2V-3Nb-2Fe-1Zr合金是一种新型α + β钛合金,具有高强度和高韧性,适用于低温、高速冲击等极端条件。本文对这种合金制定若干种热处理工艺,研究热处理对其微观组织和力学性能的影响。

1 实验方法

1.1 实验用合金的制备

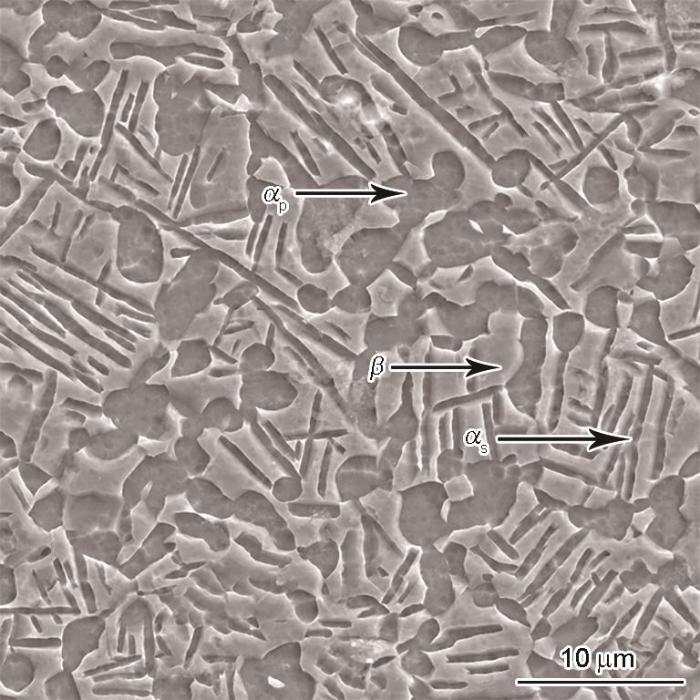

实验用材料是Ti-6Al-2Mo-2V-3Nb-2Fe-1Zr合金铸锭,其成分列于表1。对合金铸锭坯料进行热轧加工,工艺路线为:(1) 在β相区(920℃)进行变形量约40%的热轧开坯;(2) 在α + β相区(850℃)进行二次热轧,得到直径为20 mm长度为2 m的棒材。图1给出了热轧棒材的微观组织。可以看出,热轧棒材的组织由等轴状初生αp相和转变β相组成,其中转变β相包括残余β相和次生αs相。因相组织形状不一,引入平均等效直径(

表1 Ti-6Al-2Mo-2V-3Nb-2Fe-1Zr合金主要化学成分

Table 1

| Ti | Al | Nb | Fe | Cr | Zr | Mo | V | N | H | O |

|---|---|---|---|---|---|---|---|---|---|---|

| Bal | 5.8 | 3.0 | 1.2 | 0.8 | 1.0 | 1.5 | 2.0 | 0.006 | 0.001 | 0.095 |

图1

图1

Ti-6Al-2Mo-2V-3Nb-2Fe-1Zr合金热轧棒材的微观组织

Fig.1

Hot rolled rod microstructure of Ti-6Al-2Mo-2V-3Nb-2Fe-1Zr alloy

表2 热处理工艺制度

Table 2

| Heat treatment | Heat treatment parameter |

|---|---|

| ST1 | 850oC × 0.5 h WQ |

| SA1 | 850oC × 0.5 h WQ + 580oC × 4 h AC |

| SA2 | 850oC × 0.5 h WQ + 750oC × 0.5 h FC + 580oC × 4 h AC |

| SA3 | 850oC × 0.5 h WQ + 750oC × 1 h FC + 580oC × 4 h AC |

| SA4 | 850oC × 0.5 h WQ + 750oC × 2 h FC + 580oC × 4 h AC |

1.2 性能表征

用MTS810型万能试验机进行热处理态试样的室温拉伸实验,应变率为0.002 s-1。拉伸试样的尺寸在图2中给出。为了确保结果的可靠性,每组样品进行4次重复性实验。

图2

用Smart Lab SE型X射线衍射仪分析试样的物相,靶材为铜靶,扫描速率为3 (°)/min,扫描角度为 20°~85°,电压和电流分别为40 kV和40 mA。用SU5000型场发射扫描电镜(SEM)观察试样的显微组织。样品准备:研磨(400#、800#、1200#、2000#砂纸)后抛光,最后用Kroll试剂(HNO3∶HF∶H2O = 1∶3∶16)蚀刻。使用Image-pro plus 6.0软件统计显微组织中初生αp相和次生αs相的体积分数和尺寸。使用SEM观察拉伸断裂试样断口的形貌。

2 实验结果

2.1 Ti-6Al-2Mo-2V-3Nb-2Fe-1Zr合金的组织

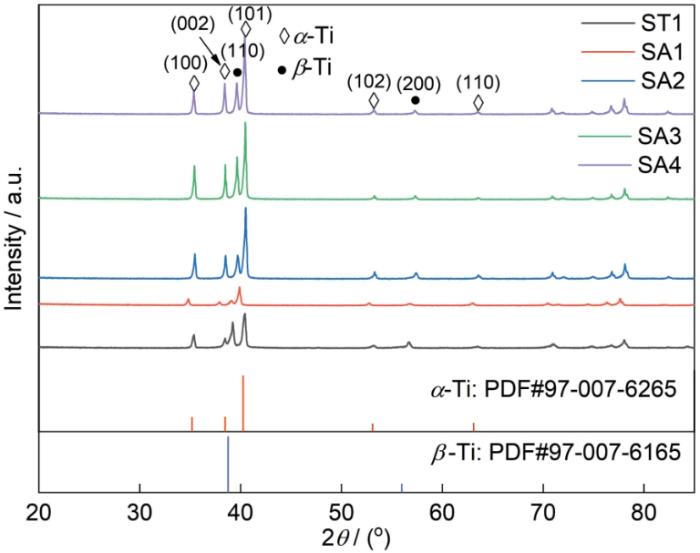

图3给出了不同热处理后Ti-6Al-2Mo-2V-3Nb-2Fe-1Zr合金试样的XRD谱。不同样品的谱中对应的衍射峰强度或位置有所不同,表明热处理后样品其相组成发生了变化。ST1试样的谱中出现了明显的(002) α 、(110) β 、(101) α 峰,表明其主要有α相和β相。单级时效试样的(110) β 峰强度较低,表明固溶后的亚稳β相发生了转变。在双级时效试样的谱中,衍射角发生约0.6°的偏移。其原因是,高温时效时试样在高温长时间保温,原子的热运动加剧使原子间距离增大和晶格畸变。随着时效时间的延长衍射峰增强,SA4试样的(101) α 衍射峰的强度几乎是(110) β 峰的3倍。这表明,在炉冷过程中亚稳β相分解发生β→α相变,使初生αp相和次生αs析出相的体积分数增大。

图3

图4给出了Ti-6Al-2Mo-2V-3Nb-2Fe-1Zr合金在(α + β)双相区(850℃)固溶后的显微组织。可以看出,固溶后的热轧组织相的体积分数和晶粒尺寸改变,部分原先的β相转变为α相,由亚稳β相、等轴状初生αp相和粗大片状的次生αs相组成,其中初生αp相的体积分数为36%,等轴初生αp相的等效直径为1.1 μm,次生αs相的体积分数为15%,次生αs相的间距0.3 μm。与原始热轧态相比,晶粒尺寸明显增大。值得注意的是,在850℃固溶后未出现明显的针状马氏体α′相,表明此时的β相为亚稳定相,未发生相转变。

图4

图4

Ti-6Al-2Mo-2V-3Nb-2Fe-1Zr合金在850℃固溶后的组织

Fig.4

Microstructure of Ti-6Al-2Mo-2V-3Nb-2Fe-1Zr alloy after solution treatment at 850oC

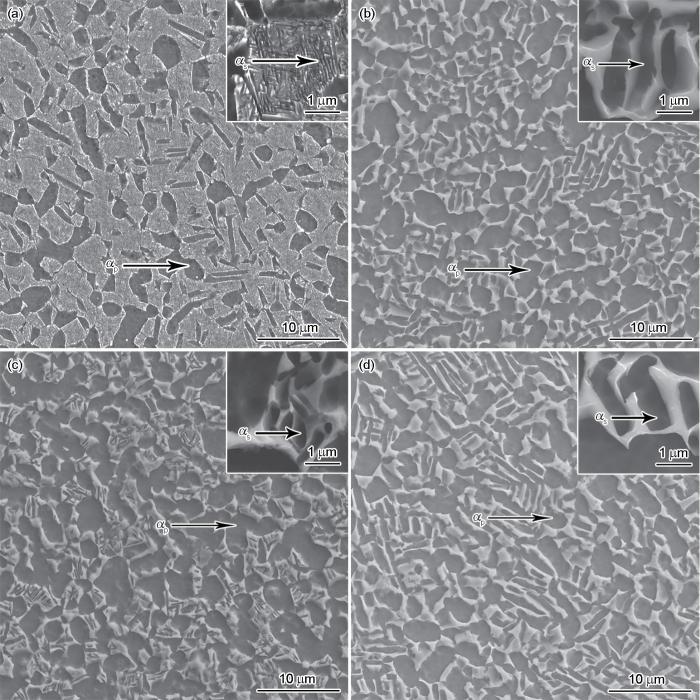

图5给出了固溶时效后Ti-6Al-2Mo-2V-3Nb-2Fe-1Zr合金的微观组织。可以看出,尽管时效处理后的组织均为双态组织且组成相有初生αp相、次生αs相和β相,但是相应的等轴初生αp相和次生αs相的晶粒尺寸和相体积分数仍有一定程度的不同。与单级时效相比,双级时效后的α相体积分数和晶粒尺寸分别明显提高和增大(表3)。由表3可见,单级时效初生αp相的体积分数为33%,次生αs相的体积分数为19%。较低的时效温度不利于析出相的生成和降低了长大速率[20],在β组织中析出大量纳米级的细针状次生αs相组织,且相邻次生αs相间距较小(约为0.03 μm),初生αp相的等效直径为1.2 μm。单级时效后生成的较小次生αs相间隔能阻止位错滑移但是使相界面间产生应力集中。进行双级时效时,双级时效第一阶段的高温时效和长时间的保温使更多的固溶体分解生成初生αp相,在随后的低温时效阶段晶粒进一步长大和发生相变[21],使α相的体积分数提高了约20%,初生αp相和次生αs相组织尺寸发生不同程度的增长,初生αp相的等轴半径增加,细小的次生αs相组织粗化成片状和短棒状。随着双级时效时间的延长初生αp相和次生αs相的组织尺寸逐渐增大,部分次生αs相的尺寸增大后发生了晶粒合并而形成了球状结构。

图5

图5

Ti-6Al-2Mo-2V-3Nb-2Fe-1Zr合金在850℃固溶+时效后的组织

Fig.5

Microstructure of Ti-6Al-2Mo-2V-3Nb-2Fe-1Zr alloy after 850oC solution+aging treatment (a) SA1; (b) SA2; (c) SA3; (d) SA4

表3 不同制度热处理后钛合金微观组织的变化

Table 3

| Heat treatment | αp phase volume fraction | αp phase equivalent diameter λ / μm | αs phase volume fraction | αs phase interval λ / μm |

|---|---|---|---|---|

| Hot rolled | 22 | 1.0 | 21 | 0.08 |

| ST1 | 36 | 1.1 | 15 | 0.3 |

| SA1 | 33 | 1.2 | 19 | 0.03 |

| SA2 | 42 | 1.8 | 27 | 0.08 |

| SA3 | 42 | 1.8 | 29 | 0.08 |

| SA4 | 43 | 1.9 | 30 | 0.1 |

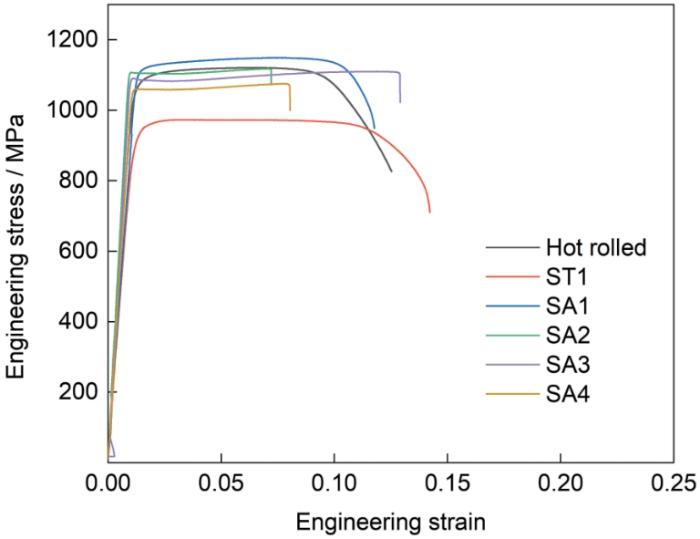

2.2 力学性能

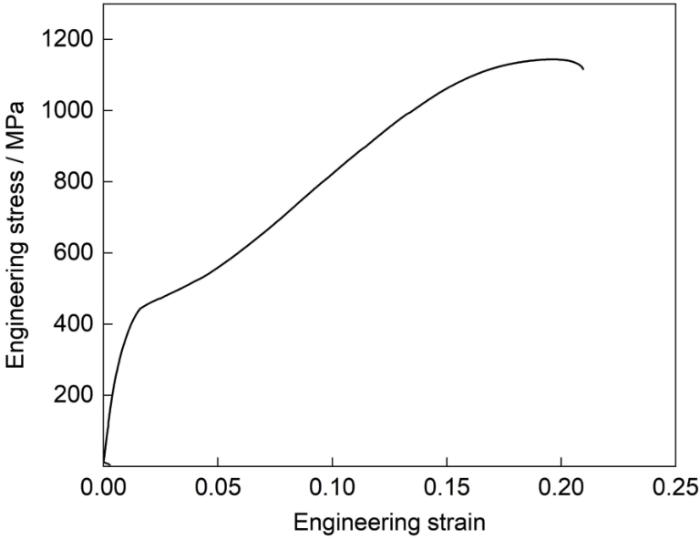

图6给出了不同状态Ti-6Al-2Mo-2V-3Nb-2Fe-1Zr合金的拉伸应力-应变曲线。由图6可见,各个曲线的变化趋势不同,表明合金的力学行为有一定的差别:在弹性阶段各条曲线的重合度较高,固溶试样的屈服点较低。这表明。这种材料在较低的应力就开始发生塑性变形,而与原始热轧态和固溶态试样相比经过时效后的试样出现一个明显的屈服行为。在塑性阶段,各试样的流变应力都增长缓慢,表现出类似的塑性力学行为,到达极限应力后即发生颈缩和断裂。力学性能的数据,列于表4。由表4可见,ST1试样的抗拉强度和屈服强度分别为973 MPa和916 MPa,断后延伸率达到15.4%。与原始热轧态试样相比,延伸率略有提高而强度却相差较大。其原因是,固溶后次生αs相的体积分数减少和晶粒尺寸变大使合金的强度降低,而初生αp相体积分数的提高则有助于提高合金的延伸率。单级时效使组织内生成了大量的细小αs析出相,使晶界的阻碍增大和提高位错密度,从而使抗拉强度和屈服强度有较大的提高,分别达到了1149 MPa和1111 MPa,断后延伸率与原始热轧态接近而呈现出更佳的强度-塑性平衡。

图6

图6

不同制度热处理后钛合金的拉伸工程应力-应变曲线

Fig.6

Tensile engineering stress-strain curve of titanium alloy under different heat treatment conditions

表4 Ti-6Al-2Mo-2V-3Nb-2Fe-1Zr合金的力学性能

Table 4

| Heat treatment | Mechanical property | ||

|---|---|---|---|

| UTS / MPa | YS / MPa | EL / % | |

| Hot rolled | 1120 | 1054 | 14.4 |

| ST1 | 973 | 916 | 15.4 |

| SA1 | 1149 | 1111 | 14.3 |

| SA2 | 1118 | 1106 | 8.2 |

| SA3 | 1109 | 1090 | 11.3 |

| SA4 | 1085 | 1070 | 11.4 |

| Common titanium alloys | |||

| TC4 | 933 | 894 | 8.7 |

| TC11 | 1030 | 910 | 9 |

| TC16 | 1087 | 920 | 16 |

| TC18 | 1101 | 1049 | 12 |

| SP700 | - | 1192 | 5.5 |

2.3 断口的形貌

断口的形貌反映材料的塑性。根据热处理态试样塑性的不同,观察了塑性排序为高、中、低的ST1、SA1和SA2试样的断口。图7给出了不同热处理状态Ti-6Al-2Mo-2V-3Nb-2Fe-1Zr合金的拉伸断口形貌。从各试样的微观形貌(图7a、b、c)可见,断口上分布着大量韧窝,固溶试样的韧窝尺寸更大。过时效试样的断口有两种不同的形貌。从图7d可见,在850℃固溶的试样主要由β晶粒组成,随着塑性变形量的不断增大细小的微孔出现在β晶粒间并不断合并长大,使断口上的韧窝较深、数量较多且分布均匀,形貌等轴状为主,具有明显的韧性断裂特征。由图7e可见,固溶+单级时效试样的表面附近区域其断口形貌主要为鱼鳞状。这种鱼鳞状断口形貌的形成与多种因素有关,最重要的是裂纹在微观尺度上的传播方式。当裂纹按照特定的晶粒方向或层状结构传播时,会产生鱼鳞状断口。断口中心区域则高低不平,韧窝更深。由图7f可见,经过固溶+双级时效处理的试样,其韧窝的尺寸变小,意味着塑性降低。

图7

图7

不同制度热处理后合金的断口形貌

Fig.7

Fracture morphology of specimens with different states (a、d) ST1; (b、e) SA1; (c、f) SA2

3 讨论

3.1 加工硬化率

拉伸实验结果表明,单级时效后的Ti-6Al-2Mo-2V-3Nb-2Fe-1Zr合金其特点是高强度高塑性,而在750℃双级时效的合金其强度和塑性略微降低。合金的延展性与加工硬化行为密切相关。根据Considère准则,满足塑性不稳定性准则时就会发生颈缩。对真实应力应变曲线求导,可得如图8所示的加工硬化率曲线。可以看出,加工硬化曲线总体上呈现出“S型”,可分为三个阶段:Ⅰ初始塑性变形阶段:随着应变的增加,应变硬化率迅速下降。Ⅱ平稳变形阶段:随着应变的增加,应变硬化率下降变缓。Ⅲ塑性断裂阶段:达到最大抗拉强度后,应变继续增大直至断裂。Ⅱ阶段的持续时间更长时,试样发生了持续的加工硬化,发生颈缩的时间更晚,有利于提高试样的延伸率。ST1试样比其他试样更晚进入II阶段,且持续时间最长。其可能的原因是,在ST1中有大量的β不稳定相,而拉伸应变诱导的马氏体相变使晶体结构和位错分布改变。这些相变使强度提高,还能引起持续的加工硬化,最终使其断后延伸率较高。SA1试样中的位错在较硬相的边界(αs/β)高速累积,表现出较高的加工硬化率,且进入第Ⅱ阶段更晚。这意味着,高密度纳米级次生αs相的结构使其加工硬化能力较高[28]。而SA2、SA3、SA4试样进入II阶段更早,因此与其他热处理试样相比,双级时效后会更早地进入颈缩状态。

图8

图8

Ti-6Al-2Mo-2V-3Nb-2Fe-1Zr合金的加工硬化速率-应变曲线

Fig.8

Work hardening rate-strain curves of the Ti-6Al-2Mo-2V-3 Nb-2Fe-1Zr alloy (a) Tensile hardening curve; (b) Change pattern of the hardening curve

3.2 组织结构对力学性能的影响

根据拉伸应力-应变曲线和显微组织形貌,合金中初生αp相的等效直径和次生αs相间距越小则其屈服强度越高。根据Hall-Petch强化机制,晶界是位错不可逾越的,因此在变形过程中相邻两晶界间的位错不断累计激活位错源而产生排斥应力场,这些排斥力是削弱跨边界扩散能量壁垒的驱动力。而减小两晶界之间的间距可减少边界处堆积的位错量,从而增大位错移动穿过晶界所需的应力。可以发现,屈服强度与次生αs相晶粒间距之间存在反比关系,次生αs相晶粒间距越小则越能抑制位错运动,屈服强度越高。

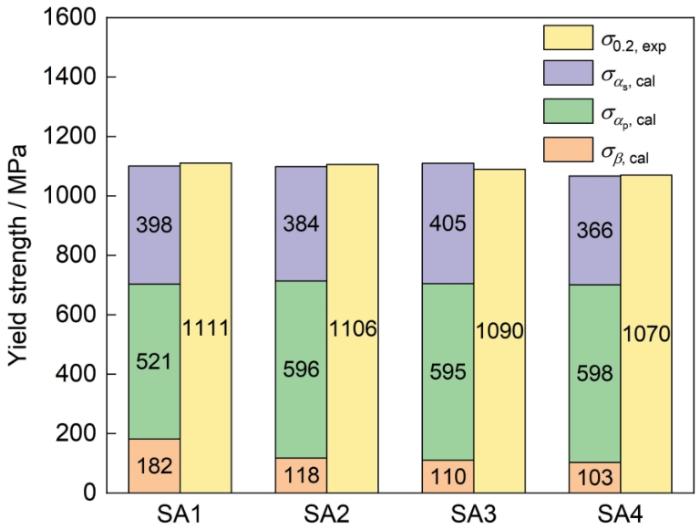

合金的强化机制,可概括为固溶强化、晶界强化、αp边界强化和αs的沉淀强化。因此,新型合金的屈服应力是不同机制的强化贡献之和,即

其中σ0.2为屈服强度,Vβ 、

式中

为了产生β相组织对合金的强化贡献,对单相区910℃固溶态试样进行准静态拉伸,并观察其微观组织。图9给出了固溶试样的微观组织。可以看出,与在850℃固溶态的试样不同,910℃固溶态试样主要由交错弥散分布的针状马氏体α′和β基体组成,因为水淬的高速冷却使相变来不及进行。同时,在β晶界处仍有极少量的初生αp相。图10给出了在910℃固溶的Ti-6Al-2Mo-2V-3Nb-2Fe-1Zr合金的应力-应变曲线。与850℃固溶态试样相比,910℃固溶态试样的抗拉强度和延伸率更高,但是其屈服强度较低,在380 MPa进入了屈服阶段,屈服后应力继续上升,抗拉应力达到1144 MPa,断后延伸率达到17.1%。于是,得到 σβ = 380 MPa。

图9

图9

Ti-6Al-2Mo-2V-3Nb-2Fe-1Zr合金在910℃固溶后的微观组织

Fig.9

Microstructures of Ti-6Al-2Mo-2V-3Nb-2Fe-1Zr alloy after solution at 910oC

图10

图10

Ti-6Al-2Mo-2V-3Nb-2Fe-1Zr合金在910℃固溶后的应力-应变曲线

Fig.10

Tensile engineering stress-strain curve of Ti-6Al-2Mo-2V-3Nb-2Fe-1Zr alloy after 910oC solution

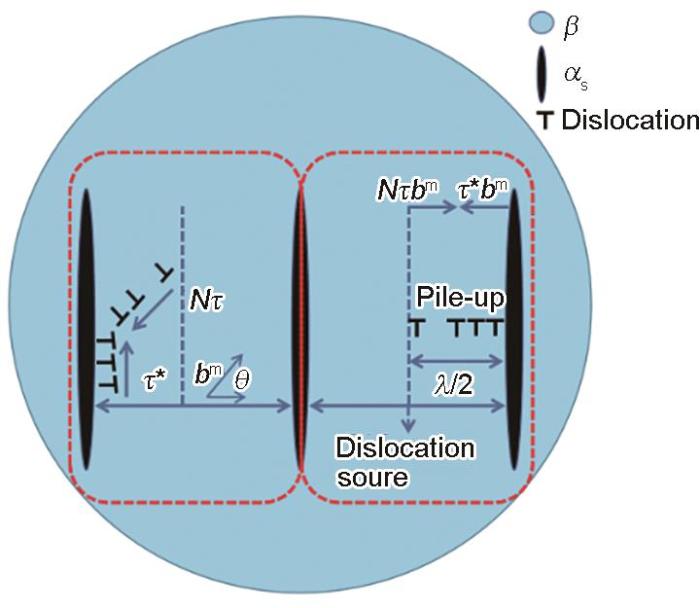

在两相钛合金(αp + β)的准静态拉伸过程中,随着应变的增加变形贯穿αp和β相,表明α/β界面对滑移传输几乎没有阻力[31]。而对于三相钛合金(αp + αs + β),随着应变的增加变形先出现在αp中,此时转变βtrans区并未出现变形。随着应变持续增加且达到一定临界值,转变βtrans区相邻次生αs相的运动位错遇到障碍形成位错堆积,此时αs/β界面能显著抑制位错运动。如图11所示,在平衡状态下作用在位错上的合力为0。当位错源产生一局部应力σ1 = Nτbm(其中N、τ和bm分别位错数量、施加应力和Burgers矢量)时,次生αs晶界边缘的堆积位错产生的排斥力σ2 = τ*bm与之平衡,即

图11

图11

位错运动在次生αs相间距中的示意图

Fig.11

Schematic illustration of dislocation movement in αs spacing

式中位错数量为[32]

式中Gm和vm为材料的剪切模量和泊松比,λ为两个次生αs相界面的距离,位错传播的临界应力为

相应的,统计初生αp的平均等效直径h可得

将先前测得的ST1、ST2、ST3和ST4各相体积分数和显微组织尺寸代入

图12

图12

不同微观组织合金的强度分配拟合值与实际值的对比

Fig.12

Fitting and actual value comparison of different microscopic tissue intensity assignments

随着时效时间的延长β相的强度贡献显著下降,而α相的强度贡献增加,对应时效过程中不稳定的β相向α相的转变。同时,随着时效时间的延长次生αs相间距增大,使其强化作用有所下降。

4 结论

(1) 固溶、固溶+单级时效与固溶+双级时效热处理,对Ti-6Al-2Mo-2V-3Nb-2Fe-1Zr合金的相含量和组织有显著的影响。在双相区固溶的热轧态合金中原先的αp和αs相部分转变为β相,由亚稳β相、等轴状初生αp相和粗大片状的次生αs相组成。单级时效后,大量的纳米级细针状次生αs相均匀地析出在β相基体上。双级时效后,α相的体积分数明显提高,随着时效时间的延长初生αp相的等效半径增大,次生αs相的相间距逐渐粗化并发生晶粒合并。

(2) 与热轧态相比,双相区固溶态试样在较低应力水平就发生屈服。单级时效使试样的抗拉强度和屈服强度有较大的提高,表现出更佳的强度-塑性平衡。随着双级时效时长的增加,试样的抗拉强度和屈服强度降低而延伸率提高。

(3) 热处理几乎不影响Ti-6Al-2Mo-2V-3Nb-2Fe-1Zr合金的断裂模式,所有的合金均表现出典型的韧性断裂,但是其断口形貌有一定的差别。在固溶态试样断口上出现大量韧窝,单级时效态试样的断口中心区域的韧窝高低不平且尺寸更小,双级时效的样品断口上的韧窝尺寸进一步减小。

(4) 基于实验结果拟合出修正的Hall-Petch本构模型:

参考文献

Effect of microstructure evolution of Ti6Al4V alloy on its cavitation erosion and corrosion resistance in artificial seawater

[J].

Vacuum diffusion bonding of α titanium alloy to stainless steel for aerospace applications: Interfacial microstructure and mechanical characteristics

[J].

Additive manufacturing of titanium alloys-Enabling re-manufacturing of aerospace and biomedical components

[J].

Investigation of deformation behavior, microstructure evolution, and hot processing map of a new near-α Ti alloy

[J].

Unusual stress-induced martensite transformation in Ti-6Al-4V alloy enabled by solution treatment in the lower α + β regime

[J].

A pathway to significantly improve the ductility of a high strength PM α + β titanium alloy by short GB α layers and refined α WGB colonies

[J].

Effect of aging temperature on mechanical properties of TC21 alloy with multi-level lamellar microstructure

[J].

A new α + β Ti-alloy with refined microstructures and enhanced mechanical properties in the as-cast state

[J].

An ultra-high-strength Ti-Al-V-Mo-Nb-Zr alloy designed from Ti-6Al-4V cluster formula

[J].The near-α dual-phase Ti-Al-V-Mo-Nb-Zr alloy series were designed and prepared by copper-mold suction casting in this paper. Their compositions fall within the composition framework previously determined for Ti-6Al-4V: the α and β formulas satisfy the ratio of 12:5, but the β part can be further stabilized, by using multi-element alloying and especially by varying the addition amount of Zr, into the form of [Al-Ti14-x Zr x ](Mo0.6Nb0.2V1.2Al), x = 0.6~3. The as-cast alloys are all characterized by a basket-weave microstructure containing a large number of α' martensite needles. With increasing Zr content the α' needles are gradually refined, and the strength and hardness increase accordingly. Among them a Ti-6.7Al-2.2V-2.1Mo-0.7Nb-10.0Zr alloy achieves the ultra-high strength level, with the ultimate tensile strength of 1404 MPa and Vickers-hardness of 451HV, close to the typical ultra-high-strength β-21s after heat-treatment. In comparison with Ti-6Al-4V prepared in the identical conditions, the strength and hardness of this alloy exceeds those of Ti-6Al-4V by 52% and 39%, and the specific strength and hardness are increased by 45% and 33% respectively.

基于Ti-6Al-4V团簇式设计的超高强Ti-Al-V-Mo-Nb-Zr合金

[J].设计并用真空铜模吸铸制备了近α型双相Ti-Al-V-Mo-Nb-Zr合金系列,其成分框架满足Ti-6Al-4V的α+β双相团簇式,即α和β相团簇式的比例为12:5。同时,通过多元合金化尤其是改变Zr含量,可将后者改造成具有更高β稳定性的形式[Al-Ti<sub>14-</sub><sub>x</sub> Zr <sub>x</sub> ](Mo<sub>0.6</sub>Nb<sub>0.2</sub>V<sub>1.2</sub>Al),x=0.6~3。这些合金的铸态组织其特征为网篮状,并含有大量针状α'马氏体。随着Zr含量的提高这些合金的晶粒细化,其强度和硬度也随之提高,Zr含量最高的Ti-6.7Al-2.2V-2.1Mo-0.7Nb-10.0Zr合金达到超高强水平,其铸态的拉伸强度为1404 MPa,维氏硬度为451HV,与热处理后的典型超高强钛合金β-21S的性能接近,与在相同条件下制备的Ti-6Al-4V相比其强度和硬度分别提高52%和39%,比强度和比硬度分别提高45%和33%。

Microstructure evolution and mechanical properties of new Ti-Al-Fe-B titanium alloy with high strength and ductility

[J].

新型高强韧Ti-Al-Fe-B系钛合金组织和性能研究

[J].

Pore formation mechanism and intermetallic phase transformation in Ti-Al alloy during reactive sintering

[J].

Kinetic and thermodynamic description of intermediary phases formation in Ti-Al system during reactive sintering

[J].

Microstructure and mechanical properties of TC21 titanium alloy by near-isothermal forging

[J].

Influence of hot-rolling on the microstructure and mechanical properties of a near β-type Ti-5.2Mo-4.8Al-2.5Zr-1.7Cr alloy

[J].

Effect of solution treatment and aging on microstructure and hardness of TC11 titanium alloy

[J].Effects of solution temperature and solution time on microstructure and microhardness of TC11 titanium alloy bar under the same aging treatment processes were studied. The results show that when the TC11 titanium alloy is solution treated below the phase transition point, the content of equiaxed primary α phase increases with the increase of solution temperature. When the solution temperature approaches the phase transition point, the content of equiaxed primary α phase decreases rapidly. When the solution temperature is 950℃, with the increase of solution time, the grain boundary α phase begins to grow, and the lamellar α phase turns into the mixed microstructure of bulk α phase and equiaxed α phase. When the solution time is fixed, the hardness of the TC11 titanium alloy decreases first and then tends to be stable with the increase of solution temperature. The hardness reaches the maximum value when solution temperature is 950℃ and solution time is 120 min.

固溶时效处理对TC11钛合金显微组织和硬度的影响

[J].研究了在相同时效处理制度下,不同的固溶温度、固溶时间对粗锻态TC11钛合金棒材显微组织和显微硬度的影响。结果表明,对TC11钛合金在相变点以下进行固溶处理时,随着固溶温度的升高,等轴初生α相的含量增多;当固溶温度接近相变点时,等轴初生α相的含量迅速减少;当固溶温度为950℃时,随着固溶时间的增加,晶界α相开始长大,片状α相转变为块状α相与等轴α相的混合组织;当固溶时间一定时,TC11钛合金的硬度随着固溶温度的升高呈现出先下降然后逐渐趋于稳定的趋势;在固溶温度为950℃,固溶时间为120 min时的硬度达到最高。

Effect of annealing temperature on mechanical properties of TC21 titanium alloy with multilevel lamellar microstructure

[J].

Effect of aging temperature on mechanical properties of TC21 alloy with multi-level lamellar microstructure

[J].

Influence of alloy element partitioning on strength of primary α phase in Ti-6Al-4V alloy

[J].The partitioning effect of Al (α-phase stabilizer) and V elements (β-phase stabilizer) on strength of the primary α phases in the α/β Ti-6Al-4V alloy with the bimodal microstructure was investigated. It was found that partitioning of Al and V elements took place in the Ti-6Al-4V alloy during the recrystallization process, leading to the variation of the content of Al and V elements in the primary α phases with changing the volume fraction of the primary α phase. Nanoindentation tests reveal a general trend that the strength of the primary α phases increases with decreasing the volume fraction of the primary α phases, and such trend is independent on the loading direction relative to the c-axis of the α phase. The enhanced strength is attributed to the increase of the content of Al element in the primary α phase, but it is not dominated evidently by the change of the V content. The solid solution strengthening contributed from both the elastic strain introduced by the solute atoms and the variation of the density of states was estimated theoretically.

Microstructural dependence of strength and ductility in a novel high strength β titanium alloy with Bi-modal structure

[J].

Microstructure and properties of SP-700 titanium alloy after high temperature solid solution and aging with different processes

[J].SP-700 titanium alloy was treated by solid solution in β phase region at 1 000℃ for 15 min, and then was cooled to (α+β) phase region for solid solution at different temperatures (650-900℃) for different times (3-10 min) or was treated by single stage aging and or double stage aging including 280℃ low temperature pre-aging and the second aging at different temperatures (370-650℃) for different times (15, 90 min). The microstructure and properties of the alloy under different processes were studied. The results show that the volume fraction of α phase in the alloy after 850℃ solid solution increased with the solid solution time; when the solid solution time was 5 min, the alloy had good strong plastic matching. Under solid solution time of 5 min, the volume fraction of α phase decreased with increasing solid solution temperature; when the solid solution temperature was 650℃, the alloy had good strong-plastic matching. After β phase region solid solution and single/double stage aging, the alloy was basically composed of β grain, α phase and acicular martensite. After single stage aging at aging temperature of 650℃ for 90 min or double stage aging at aging temperature of 650℃ for 15 min, the alloy showed good strong-plastic matching.

不同工艺高温固溶与时效处理后SP-700钛合金的组织与性能

[J].

Influence of quenching and aging temperature on microstructure andmechanical properties of TC4 titanium alloy

[J].

淬火、时效温度对TC4钛合金组织和力学性能的影响

[J].

Effect of heat treatment process on structures and properties of SP-700 titanium alloy

[J].

热处理工艺对SP-700钛合金组织性能的影响

[J].

Aging precipitate of beta forged TC17 titanium alloy for aero-engine

[J].

航空发动机用β锻TC17钛合金时效析出行为研究

[J].

Study on solution-Aging heat treatment of ZTC4 titanium alloys

[J].

ZTC4钛合金固溶时效热处理工艺研究

[J].

Microstructure and properties of TC4 titanium alloy hot-rolled sheet by electron beam cold bed furnace melting

[J].

EB炉熔炼TC4钛合金热轧板材的组织性能

[J].

Research of microstructure evolution and mechanical properties of SP700 titanium alloy sheet

[J].

SP700钛合金板轧制过程的组织演变和力学性能研究

[J].

Microstructural dependence of strength and ductility in a novel high strength β titanium alloy with Bi-modal structure

[J].

Microstructural tailoring and mechanical properties of a multi-alloyed near β titanium alloy Ti-5321 with various heat treatment

[J].

Elastic properties of in-situ processed Ti-TiB composites measured by impulse excitation of vibration

[J].

Slip transmission behavior across α/β interface and strength prediction with a modified rule of mixtures in TC21 titanium alloy

[J].