传统的中子屏蔽材料有金属材料、无机非金属材料和高分子材料,例如含硼钢[6]、混凝土[7]、铅硼聚乙烯[8]。硼钢和B4C-Al等金属材料的比模量高、导热性良好且具有一定的热中子吸收和快中子慢化性能。但是,温度的提高使硼刚的力学性能降低。无机非金属材料的屏蔽性能良好,但是其机械强度低、成本高且制造工艺复杂。高分子材料的氢元素含量高,氢的原子序数较低和电子密度较高,可用作中子缓速剂,但是其热稳定性较低。具有三维网络结构的多孔陶瓷基复合材料的孔隙率和化学稳定性较高、导热系数和体积密度较低、强度高和耐高温,是核屏蔽隔热一体化候选材料[9]。制备多孔陶瓷的常用方法,有成孔剂法[10,11]、聚合物海绵复制法[12~14]、凝胶注模法[15,16]、冷冻注模法[17,18]及泡沫凝胶注模法[19,20]等。与其他方法相比,用泡沫凝胶注模工艺制备的多孔陶瓷其力学强度显著提高。Han等[20]将泡沫-凝胶注模和微波烧制相结合在1100~1300℃热处理30 min,制备出的多孔莫来石陶瓷机械强度较高。在1100℃制备的多孔莫来石,其孔隙率为76.6%、抗折和耐压强度值分别高达3.8和15.2 MPa,热导率低至0.269 W/(m·K)。

1 实验方法

1.1 实验用原料

图1

表1 玻璃纤维和玻璃颗粒的化学成分

Table 1

| SiO2 | CaO | Al2O3 | MgO | Na2O | Fe2O3 | TiO2 | SrO | |

|---|---|---|---|---|---|---|---|---|

| Fiberglass | 57.6 | 21.7 | 17.2 | 1.3 | 0.5 | 0.2 | 0.8 | 0.7 |

| Glass particles | 67.8 | 8.4 | 21.4 | 1.5 | 0.2 | 0.1 | 0.1 | 0.5 |

图2

图2

原料玻璃纤维和玻璃颗粒的SEM照片

Fig.2

SEM micrographs of the fiberglass and glass particles (a) fiberglass, (b) glass particles

1.2 样品的制备和性能表征

将质量分数为48.75%的玻璃纤维、16.25%的玻璃颗粒、0.25%的Isobam(分散剂)、0.1%的CMC(稳泡剂)、0.6%的SDS(发泡剂)和34.05%的去离子水(溶剂)组成的陶瓷浆料300 mL加到行星球磨罐中,再加入占陶瓷浆料质量分数1.0%~6.0%的中子屏蔽填料Gd2O3后球磨发泡10 min,球料比约为3∶1,球磨机转速为350 r/min。将发泡后的陶瓷浆料注入到体积为25 mm × 25 mm × 125 mm的模具中成型,然后将其80℃烘箱内干燥24 h,脱模后在700~800℃热处理3 h,随炉冷却至室温后即得试样。

用D8ADVANCE型X射线衍射仪(XRD)测试多孔陶瓷的物相组成;用Archimedes排水法测量样品的容重和开口气孔率;用万能试验机(DKZ-600,跨度为60 mm,加载速率为0.5 mm/min)测量样品的抗折强度,样品的尺寸为25 mm × 25 mm × 125 mm;用万能试验机测试样品的耐压强度,十字头的速度为0.5 mm/min,样品的尺寸为25 mm × 25 mm × 125 mm;用扫描电子显微镜(SEM,NANO SEM430)表征样品的显微结构;使用Image Pro Plus软件测量至少300个孔的孔径取其平均值;用热常数分析仪(Hot Disk TPS 2500S,Hot Disk AB)测量多孔陶瓷试样(尺寸为20 mm × 20 mm × 5 mm)的热导率值,使用241Am-Be中子源/3He正比计数器(感应体积:ϕ2 cm × 12.7 cm)测试样品的中子屏蔽性能,样品的尺寸为40 mm × 40 mm × 10 mm,厚度为10 mm。测量每组样品的中子透射率6次,取其结果的平均值。

2 结果与讨论

2.1 热处理温度对玻璃纤维多孔陶瓷的组成和性能的影响

2.1.1 对物相组成的影响

图3给出了热处理温度不同的玻璃纤维多孔陶瓷的XRD谱。可以看出,随着热处理温度从700℃提高到800℃,多孔陶瓷中β-石英相衍射峰的强度逐渐增强,表明在高温下玻璃纤维由非晶态转化为晶态。热处理温度为800℃时,玻璃纤维与玻璃颗粒中的氧化物反应生成了钙长石,因此谱中出现了钙长石的衍射峰。生成钙长石的三种氧化物的理想组成范围,分别为CaO(15%~40%)、Al2O3(20%~45%)和SiO2(40%~65%)。对玻璃纤维及玻璃颗粒化学分析的结果表明,三种氧化物的范围分别为CaO (18.39%)、Al2O3 (18.22%)、SiO2 (57.6%)。钙长石的强度高于玻璃纤维和玻璃颗粒,因此钙长石的生成使多孔陶瓷的强度提高[24]。

图3

图3

热处理温度不同的多孔陶瓷的XRD谱

Fig.3

XRD patterns of porous ceramics prepared at different heat treatment temperatures

2.1.2 对微观结构的影响

图4

图4

热处理温度不同的多孔陶瓷的SEM照片

Fig.4

SEM images of porous ceramics prepared at different heat treatment temperatures (a) 700oC, (b) 725oC, (c) 750oC, (d) 775oC, (a) 800oC

图5

图5

热处理温度不同的多孔陶瓷的宏观结构、微观结构和孔径分布

Fig.5

Macrostructure, microstructure and pore size distribution of porous ceramics prepared at different heat treatment temperatures (a1~a3) 700oC, (b1~b3) 725oC, (c1~c3) 750oC, (d1~d3) 775oC; (e1~e3) 800oC

2.1.3 对力学性能、线收缩、气孔率和体积密度的影响

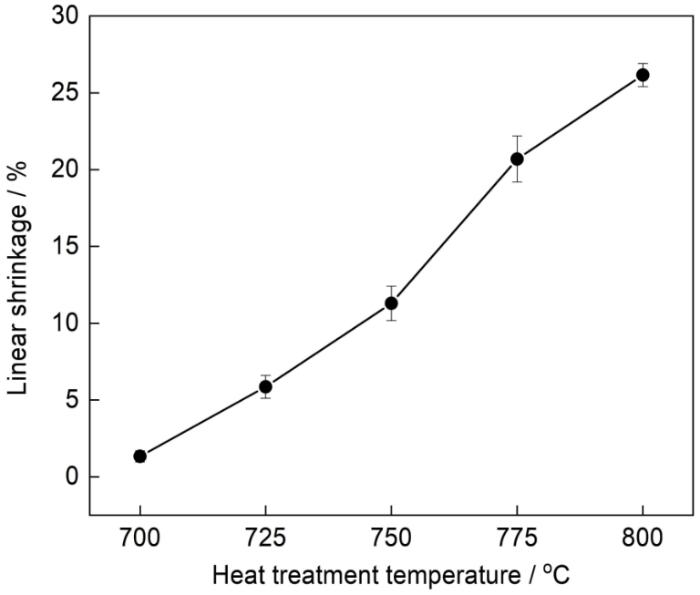

图6给出了热处理温度不同的多孔陶瓷的线收缩率。可以看出,随着热处理温度的提高多孔陶瓷的线收缩增大。图7a给出了热处理温度不同的多孔陶瓷的气孔率和体积密度的变化。可以看出,随着热处理温度的提高多孔陶瓷的气孔率从85%降低到61%,体积密度从0.40 g/cm3提高到0.95 g/cm3。气孔率降低的主要原因是,多孔陶瓷在高温下线收缩增大,试样内的小孔隙被液相填充使孔体积变小甚至部分孔隙消失,使气孔率进一步降低。气孔率影响多孔陶瓷的耐压强度,气孔率越高则耐压强度越低。由图7b可见,随着热处理温度的提高多孔陶瓷的抗折强度从0.3 MPa提高到5.1 MPa,耐压强度从0.75 MPa提高到10.7 MPa。热处理温度高于750℃的多孔陶瓷,其力学性能显著提高。其原因有:(1) 热处理温度的提高多孔陶瓷收缩使其气孔率降低和体积密度提高;(2) 在高温下玻璃纤维自反应生成高强度钙长石,使多孔陶瓷的强度提高[25];(3) 热处理温度的提高使玻璃纤维的表面由固相转化为熔融相的驱动力增大,生成的液相增多,使试样内的纤维间距离变小并紧密结合,从而使其机械强度提高。

图6

图6

热处理温度不同的多孔陶瓷的线收缩率

Fig.6

Linear shrinkage of porous ceramics prepared at different heat treatment temperatures

图7

图7

热处理温度不同的多孔陶瓷的孔隙率、体积密度、抗折强度及耐压强度

Fig.7

Porosity, bulk density, flexural and compressive strength of porous ceramics prepared at different heat treatment temperatures (a) porosity and bulk density, (b) flexural strength and compressive strength

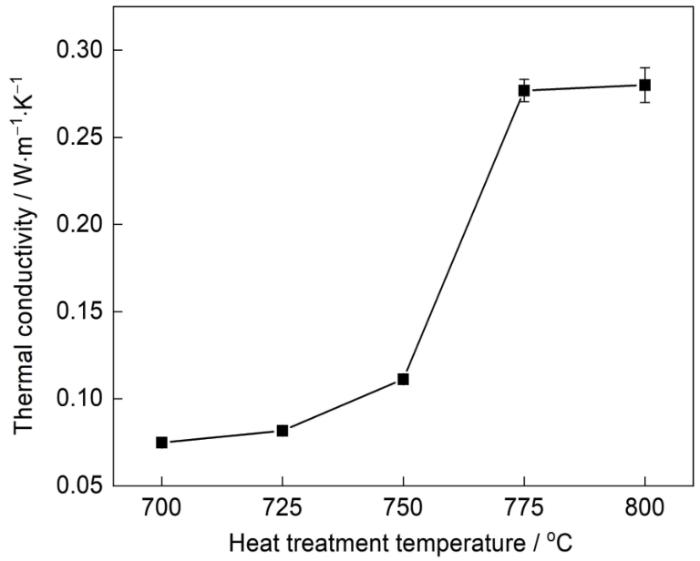

2.1.4 对热导率的影响

图8给出了热处理温度不同的多孔陶瓷试样的导热系数。影响多孔陶瓷热导率的主要因素有组成、致密度以及气孔率等[23],其中气孔率的影响最为显著,气孔率越高其导热系数越低。从图8可见,随着热处理温度的提高试样的导热系数从0.075 W/(m·K)提高到0.28 W/(m·K)。热处理温度为750℃的多孔陶瓷其导热系数为0.11 W/(m·K)。热处理温度高于750℃的试样其导热系数显著提高,可归因于气孔率的显著降低。较高的热处理温度破坏了玻璃纤维的微观结构,且高温下产生的液相将玻璃纤维紧密连接并包裹,使纤维之间的连接更紧密,试样的致密度和热导率随之提高。虽然生成的钙长石的热导率较低但是其变化趋势仍然是提高,表明试样的热导率主要受气孔率的影响。

图8

图8

热处理温度不同的多孔陶瓷的热导率

Fig.8

Thermal conductivity of porous ceramics prepared at different heat treatment temperatures

表2总结了文献中的多孔陶瓷孔隙率和热导率。相比于其它气孔率相近的多孔陶瓷,本文制备的玻璃纤维基隔热多孔陶瓷热导率更低,还具有较高的强度。

表2 本文所制备的多孔陶瓷和文献中的多孔陶瓷的热导率

Table 2

2.2 氧化钆含量对多孔陶瓷复合材料的组成和性能的影响

2.2.1 对物相组成的影响

图9

图9

氧化钆含量不同的多孔陶瓷的XRD谱

Fig.9

XRD patterns of porous ceramics prepared with different gadolinium oxide contents

2.2.2 对物理性能的影响

图10a给出了热处理温度为750℃、氧化钆含量不同的多孔陶瓷试样的气孔率和体积密度。可以看出,随着氧化钆的含量(质量分数,下同)从0提高到6%多孔陶瓷试样的气孔率稍有降低、体积密度略有增加和体积收缩降低。其主要原因是,随着氧化钆含量的提高陶瓷浆料的固相含量提高,浆料粘度也随之提高,限制了多孔陶瓷的起泡性,使试样的气孔率降低和体积密度提高。图10b给出了氧化钆含量不同的多孔陶瓷试样的力学性能。可以看出,随着氧化钆含量的提高多孔陶瓷的抗折强度和耐压强度都降低。未添加氧化钆的多孔陶瓷其抗折强度约为1.34 ± 0.01 MPa,耐压强度约为2.20 ± 0.13 MPa;氧化钆含量为6.0%的多孔陶瓷其抗折强度仅为0.63 ± 0.01 MPa,耐压强度仅为0.86 ± 0.02 MPa。其原因可能是,引入的纳米氧化钆吸附在玻璃纤维和玻璃颗粒的表面,使高温下生成的液相不能将纤维粘连,使玻璃纤维之间的结合强度降低。虽然加入的氧化钆填充了部分孔隙使致密化度提高,但是其结合强度仍然较低,从而使多孔陶瓷的力学性能有所降低。

图10

图10

氧化钆含量不同的复合材料的气孔率、体积密度、抗折和耐压强度

Fig.10

Porosity, bulk density, flexural and compressive strength of composites prepared with different gadolinium oxide contents (a) porosity and bulk density, (b) flexural strength and compressive strength

2.2.3 对微观结构的影响

图11给出了氧化钆含量不同的多孔陶瓷试样的SEM照片。可以看出,氧化钆含量的提高使浆料的固含量提高和气孔率略有降低。在不加氧化钆或者氧化钆含量较低时,玻璃纤维在碱性氧化物CaO和Na2O的作用下产生部分液相。纳米氧化钆的半径小和离子键较强,因此在高温下限制了多孔陶瓷中液相的生成。同时,纳米氧化钆吸附在玻璃纤维和玻璃颗粒的表面使纤维之间的结合强度降低,部分纳米氧化钆填充了部分孔隙而使气孔率也有所降低。

图11

图11

氧化钆含量不同的复合材料的微观结构

Fig.11

Microstructure of composites with different gadolinium oxide contents (a) 1%, (b) 2%, (c)3%, (d) 4%, (d) 5%, (e) 6%

图12给出了氧化钆含量不同的多孔陶瓷试样的孔结构SEM照片。可以看出,随着氧化钆的含量从1.0%提高到6.0%多孔陶瓷的孔径分布更为均匀。其主要原因是,氧化钆的加入使陶瓷浆料的起泡性能降低和气孔率下降。在发泡浆料中纳米氧化钆起颗粒稳泡作用,纳米氧化钆吸附在玻璃纤维表面有利于改善陶瓷浆料的触变性进而提高浆料的稳定性。因此,氧化钆的加入使多孔陶瓷的孔结构更均匀。

图12

图12

氧化钆含量不同的复合材料的孔结构

Fig.12

Pore structure of composites with different gadolinium oxide contents: (a1, a2) 1%, (b1, b2) 2%, (c1, c2) 3%, (d1, d2)4%; (e1, e2) 5%, (f1, f2) 6%

2.2.4 对屏蔽性能的影响

图13给出了多孔陶瓷复合材料对中子和热中子的屏蔽效率。可以看出,随着氧化钆含量的提高多孔陶瓷试样对中子和热中子的屏蔽效率提高。氧化钆含量为6.0%的试样其中子屏蔽率达到50.8%,热中子屏蔽率达到82.9%,因为钆元素的热(n,γ)吸收截面(46000 barn)[29,30]较大。复合材料对中子的屏蔽主要有两个过程:(1) 入射高能中子与Gd发生非弹性散射,迅速将中子能量降低到约2 MeV;部分减速的中子与玻璃纤维碰撞数次后变成热中子;(2) 热中子被中子吸收截面较大的钆通过辐射俘获反应吸收。值得注意的是,复合材料中的氧化钆具有中子慢化和中子吸收两个作用[31],纳米氧化钆在多孔陶瓷浆料中的均匀分散是复合材料热中子屏蔽性能提高的重要原因。

图13

图13

氧化钆含量不同的复合材料的中子和热中子屏蔽率

Fig.13

Neutron and thermal neutron shielding efficiency of composites prepared with different gadolinium oxide contents

2.2.5 对热导率的影响

图14给出了氧化钆含量不同的多孔陶瓷试样的导热系数。可以看出,氧化钆含量较低的多孔陶瓷其导热系数基本上不变。氧化钆添加量超过4.0%的复合材料其导热系数略有提高,因为氧化钆的导热系数高于玻璃纤维,并且加入氧化钆的试样其显气孔率有所下降,使热导率提高。

图14

图14

氧化钆含量不同的复合材料的热导率

Fig.14

Thermal conductivity of composites prepared with different gadolinium oxide contents

3 结论

(1) 以玻璃纤维和玻璃颗粒为原料,Isobam为分散剂,CMC为稳泡剂,SDS作为发泡剂,Gd2O3为中子屏蔽材料,采用泡沫凝胶注模法可制备机械强度高、导热系数低和中子屏蔽率高的玻璃纤维基隔热多孔陶瓷复合材料。

(2) 热处理温度的提高,使多孔陶瓷的孔壁从松散结构逐渐转变为致密结构,且液相含量逐渐增加。热处理温度的提高使复合材料的平均孔径降低、多孔陶瓷的强度、体积密度和热导率显著提高、气孔率降低。

(3) 氧化钆添加量的提高使多孔陶瓷复合材料的强度降低、对中子的屏蔽效率逐渐提高,但是不影响多孔陶瓷的热导率。

参考文献

Thermoelectric conversion performance of combined thermoions system for space nuclear power supply

[J].

Investigation of gamma-ray attenuation parameters of some materials used in dental applications

[J].Radiological parameters of composite filler, zirconium and acrylic coating materials used in dental treatment are determined. Mass attenuation coefficients (mu(m)) of these materials have been experimentally determined for 9 different gamma energies emitting from Ra-226 and Eu-152 radioactive sources by using gamma spectrometry system with (3 '' x 3 '') NaI(Tl) detector. Effective atomic and electron numbers (Z(eff), N-eff), atomic and electronic cross sections (sigma(t,a) and sigma(t,el)) have been also obtained for these materials. The obtained results were compared with the NIST database and EGSnrc Monte Carlo (MC) code. It is found that general trends of these parameters are consistent with the literature. The maximum attenuation occurs at 122 keV and it has been found for 1 mm thick samples that 21%, 10% and 2% of the incident radiation have been absorbed by the zirconium, composite and acrylic samples, respectively.

Nuclear power plants with artificial intelligence in industry 4.0 era: top-level design and current applications—A systemic review

[J].

Preparation and performance of gadolinium-enriched ODS-316L steel for thermal neutron shielding

[D].

热中子屏蔽用富钆ODS-316L钢的制备与性能研究

[D].

Effect of low-dose fast neutrons on the protein components of peripheral blood mononuclear cells of whole-body irradiated Wistar rats

[J].

The produce, property research and Monte-Carlo simulation of B4C/Al neutron absorber composites

[D].

B4C/Al中子吸收复合材料的制备、性能测试与蒙特卡罗模拟

[D].

Gamma ray and neutron shielding characteristics of polypropylene fiber-reinforced heavyweight concrete exposed to high temperatures

[J].

Polyethylene/boron-containing composites for radiation shielding

[J].

Lanthanum zirconate porous ceramics with controllable secondary pores for high-temperature thermal insulation

[J].

Al2TiO5-mullite porous ceramics from particle stabilized wet foam

[J].

Performance study of foam ceramics prepared by direct foaming method using red mud and K-feldspar washed waste

[J].

A novel design of Al2O3-ZrO2 reticulated porous ceramics with hierarchical pore structures and excellent properties

[J].

A novel approach to prepare reticulated porous TiN ceramics with high strength and high porosity by in-situ synthesis

[J].

Enhanced mechanical strength of SiC reticulated porous ceramics via addition of in-situ chopped carbon fibers

[J].

Permeability and thermal expansion properties of porous LAS ceramic prepared by gel-casting method

[J].

Preparation of porous MgAl2O4 ceramics by a novel pectin gel-casting process

[J].

Freeze-cast porous Al2O3 ceramics strengthened by up to 80% ceramics fibers

[J].

Preparation of porous YSZ ceramics by ball milling foaming-freeze drying process

[J].

Preparation of porous halloysite nanotube ceramics with high porosity and low thermal conductivity by foam-gelcasting

[J].

Preparation of high strength porous mullite ceramics via combined foam-gelcasting and microwave heating

[J].

High-strength thermal insulating mullite nanofibrous porous ceramics

[J].

Evaluation of the contributions to the effective thermal conductivity of an open-porous-type foamed glass

[J].

Residual gas analysis in vacuum insulation panel (VIP) with glass fiber core and investigation of getter for VIP

[J].

Characteristics of anorthite-pyroxene ceramics made from hot-poured steelmaking slag

[J].

Effect of sintering temperature on structure and properties of porous ceramics from tungsten ore tailings

[J].

Preparation and characterization of porous mullite ceramics via foam-gelcasting

[J].

Fabrication and properties of freeze-cast mullite foams derived from coal-series kaolin

[J].

Thermal conductivity of highly porous mullite materials

[J].

Study on preparation and properties of gadolinium oxide ceramics for neutron absorption materials

[D].

氧化钆中子吸收材料制备及性能研究

[D].

Research progress of rare earth composite shielding materials

[J].

Surface modified-gadolinium/boron/polyethylene composite with high shielding performance for neutron and gamma-ray

[J].