热障涂层材料(TBCs)的主要作用是阻止燃气中的热量传递到发动机的部件从而避免其过热,使燃气轮机、火箭发动机及航空发动机等热端构件的热损失降低而延长其使用寿命,在航空航天、核能和石油工业等领域得到了广泛的应用[1,2]。质量分数为6%~8%氧化钇稳定氧化锆(YSZ)涂层材料的耐热性和抗腐蚀性良好、热导率较低和热膨胀系数较高,得到了广泛的应用[3~5]。但是,YSZ材料在高于1200℃的温度发生由四方相向单斜相的相变和3%~5%的体积膨胀,从而使涂层材料剥落和失效[6~8]。同时,YSZ较高的氧离子透过率促进其高温氧化,严重降低其使用寿命[9]。因此,亟需研发一种既有高温相稳定性和较低的氧离子透过率,又具有优良导热性能的热障涂层材料。

钇铝石榴石Y3Al5O12(简称YAG)的结构属于立方晶系,在化学式Y3Al5O12中Y3+处于与O2-八配位的十二面体格位,Al3+处于与O2-六配位和四配位的八面体和四面体格位。YAG具有优异的高温相稳定性(在低于1970℃的温度不发生相变)和较低的氧离子透过率[10],是一种应用前景极好的热障涂层材料[11~13]。但是,YAG较高的热导率(2.1 W/(m·K))[14]使其应用受到限制。YAG晶胞是由十二面体、八面体和四面体组成的连接网络,很容易被离子半径较大的阳离子替代。因此,可对YAG进行掺杂改性以改善其导热性能。Liu等[15]将Er3+掺杂在YAG十二面体格位制备出热导率较低的Y2ErAl5O12陶瓷材料,在1000℃的热导率约为1.8 W/(m·K)。Wang等[16]分别在YAG的十二面体格位和八面体格位掺杂Yb3+,随着Yb3+在十二面体中的掺杂摩尔浓度从0%提高到20%,其室温热导率从3.28 W/(m·K)降低到2.09 W/(m·K);而随着Yb3+在八面体中的掺杂摩尔浓度从0%提高到2%时其室温热导率从3.28 W/(m·K)降低至2.11 W/(m·K)。由此可以推断,在YAG十二面体和八面体晶格位点同时掺杂可大幅度降低其热导率。

目前,大多数关于YAG掺杂改性的文献都基于单点位单元素掺杂。文献[14]用Er2O3对Y3Al5O12进行十二面体Y位掺杂使其热导率大大降低,其中(Y0.4Er0.6)3Al5O12陶瓷热导率最低,1000℃时约为1.48 W/(m·K)。为了精确控制掺杂位置,取代离子和被取代离子之间的半径差异不应过大。鉴于此,本文用阳离子半径远小于Y3+略大于Al3+的Mn2+同时替代(Y0.4Er0.6)3Al5O12陶瓷材料的八面体及四面体的Al3+,研究其对(Y0.4Er0.6)3Al5O12陶瓷材料的结构和导热性能的影响。

1 实验方法

1.1 样品的制备

用固相合成法制备(Y0.4Er0.6)3(Al1 - y Mn y )5O12 (y = 0,0.02,0.04,0.06,0.08,0.1)陶瓷材料。将实验用原料(质量分数)Y2O3 (99.999%)、Er2O3 (99.99%)、Al(OH)3 (分析纯)、MnCO3 (99.99%)、去离子水和分散剂分别球磨和砂磨,然后烘干得到纳米级粉体原料。将每个组分的原料按比例混合后倒进球磨罐进行二次球磨,将其在80℃干燥24 h后放入电阻炉中1300℃保温3 h,得到Mn掺杂(Y0.4Er0.6)3Al5O12粉体。再将烧结后的各组分粉体分别倒进球磨罐进行三次球磨,然后在80℃干燥24 h。将得到的产物研磨并过200目筛后在6 MPa压力下预压成型和在200 MPa冷等静压成型。将压成的块体送入1300℃电阻炉中保温8 h进行二次烧结,制备出Mn掺杂(Y0.4Er0.6)3Al5O12陶瓷材料。

1.2 性能表征

用X射线衍射仪(XRD,Rigaku Smartlab 9kW)和Rietveld精修方法表征陶瓷材料的物相组成和晶体结构,用X射线光电子能谱仪(XPS,ESCALAB 250Xi)测试和分析样品的化学成分和价态信息,用场发射扫描电子显微镜(FESEM,Sigma300)和X射线能谱仪(EDS,Oxford)观察和分析样品表面的微观形貌和元素分布,用透射电子显微镜(TEM,JEM2100)和高分辨透射电子显微镜(HRTEM)表征材料内部的晶体结构及尺寸等信息。用LFA427型激光导热仪测定各组样品的热扩散系数λ,根据Neumann-Kopp定律计算比热容Cp,用阿基米德排水法测量体积密度ρ,陶瓷材料的热导率[17]为

修正公式为

其中k为导热系数;k0为致密陶瓷材料的导热系数;φ = 1 - ρ/ρt,ρt为理论密度。

2 结果和讨论

2.1 陶瓷材料的物相结构

图1给出了(Y0.4Er0.6)3(Al1 - y Mn y )5O12 (y = 0,0.02, 0.04,0.06,0.08,0.1)陶瓷材料的XRD谱。图1a可以看出,谱中只出现了YAG的衍射峰,表明所有的陶瓷材料均为单一的YAG相结构,2θ = 33.359°、35.039°处的衍射峰分别对应YAG的(420)和(332)晶面。从图1b可见,随着Mn掺杂量的提高衍射峰先向较高的角度移动,然后向较低的角度移动。其原因是,Mn2+的半径(0.083 nm,CN = 6;0.066 nm,CN = 4)大于Al3+的半径(0.054 nm,CN = 6;0.039 nm,CN = 4)[18]。根据Bragg方程nλ = 2dsinθ,Mn掺杂量y = 0 ~ 0.04时Mn替代Al可能使八面体和四面体的对称性发生变化和扭曲而减小晶面间距,使衍射角增大[19];而Mn掺杂量y = 0.04 ~ 0.1时陶瓷材料的晶面间距随着Mn掺杂量的提高而增大,从而使衍射角减小。由此可以推测,在Al位掺杂的Mn固溶进了YAG晶格中。为了验证上述晶面间距的变化和推测,对X射线衍射数据进行了Rietveld精修处理。

图1

图1

(Y0.4Er0.6)3(Al1 - y Mn y )5O12 (y = 0, 0.02, 0.04, 0.06, 0.08, 0.1)陶瓷材料的XRD谱及其局部放大图谱

Fig.1

XRD pattern (a) and local magnified image (b) of (Y0.4Er0.6)3(Al1 - y Mn y )5O12 (y = 0, 0.02, 0.04, 0.06, 0.08, 0.1) ceramic materials

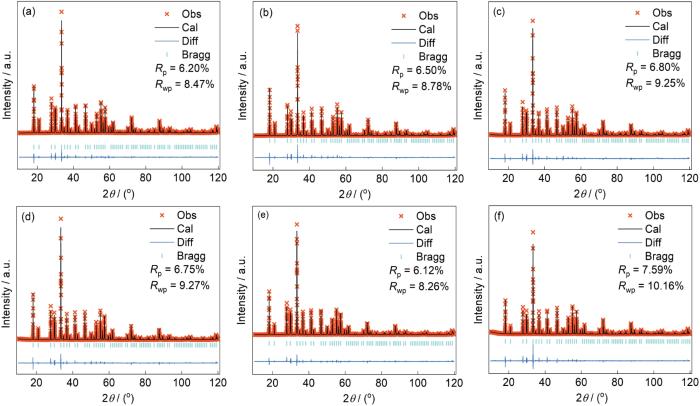

图2给出了(Y0.4Er0.6)3(Al1 - y Mn y )5O12 (y = 0,0.02,0.04,0.06,0.08,0.1)陶瓷材料的Rietveld精修图。可以看出,(Y0.4Er0.6)3(Al1 - y Mn y )5O12陶瓷材料仍为钇铝石榴石结构,与图1a给出的单一YAG相一致。表1列出了(Y0.4Er0.6)3(Al1 - y Mn y )5O12 (y = 0,0.02,0.04,0.06,0.08,0.1)陶瓷材料经Rietveld精修后的晶胞参数和精修数据。可以看出,Mn掺杂量y = 0~0.04时晶格常数从1.19917 nm减小到1.19913 nm,晶胞体积则由1.72441 nm3减小到1.72423 nm3;但是,Mn掺杂量y = 0.04~0.1时晶格常数从1.19913 nm增大到1.20116 nm,晶胞体积则由1.72423 nm3增大到1.73303 nm3。这些结果,给出了XRD谱中衍射峰偏移方向不同的原因。另外,R模式因子Rp处于6.2%~7.59%,而加权轮廓R因子RWP处于8.26%~10.16%,都在合理的范围内。这表明,结构精修结果有良好的可靠性,与实验数据一致。表2列出了(Y0.4Er0.6)3(Al0.94Mn0.06)5O12陶瓷材料的Rietveld全谱拟合结构精修参数。可以看出,Mn掺杂量为y = 0.06时处于八面体格位的Al3+已经被Mn2+取代了21.1%,处于四面体格位的Al3+被Mn2+取代了17.1%。这表明,Mn在八面体和四面体格位的总占比为18.7%,Al的总占比为81.3%。化简后得到离子占比,Er和Y的比例关系约为6∶4,Mn、Al、O的比例约为1∶4∶12,并且保持Y3Al5O12的晶体结构不变。这些结果表明,Mn成功地掺入并固溶进YAG的晶体结构。随着Mn掺杂量的提高晶格常数和晶胞体积先减小后逐渐增大,Mn2+部分占据YAG晶胞中的Al3+的位置,并且保持Y3Al5O12的晶体结构不变。

图2

图2

(Y0.4Er0.6)3(Al1 - y Mn y )5O12陶瓷材料的Rietveld精修

Fig.2

Rietveld refinement results of (Y0.4Er0.6)3(Al1 - y Mn y )5O12 ceramic materials (a) y = 0; (b) y = 0.02; (c) y = 0.04; (d) y = 0.06; (e) y = 0.08; (f) y = 0.1

表1 (Y0.4Er0.6)3(Al1 - y Mn y )5O12陶瓷材料经Rietveld精修的晶胞参数和精修数据

Table 1

| y | a = b = c /nm | α = β = γ / (o) | V / nm3 | RWP / % | Rp / % |

|---|---|---|---|---|---|

| 0 | 1.19917 | 90 | 1.72441 | 8.47 | 6.20 |

| 0.02 | 1.19923 | 90 | 1.72467 | 8.78 | 6.50 |

| 0.04 | 1.19913 | 90 | 1.72423 | 9.25 | 6.80 |

| 0.06 | 1.19951 | 90 | 1.72588 | 9.27 | 6.75 |

| 0.08 | 1.19984 | 90 | 1.72730 | 8.26 | 6.12 |

| 0.1 | 1.20116 | 90 | 1.73303 | 10.16 | 7.59 |

表2 (Y0.4Er0.6)3(Al0.94Mn0.06)5O12陶瓷材料的Rietveld全谱拟合结构精修参数

Table 2

| Label | Elem. | Mult. | x | y | z | Frac. |

|---|---|---|---|---|---|---|

| Mn1 | Mn2+ | 16 | 0 | 0 | 0 | 0.211 |

| Al1 | Al3+ | 16 | 0 | 0 | 0 | 0.789 |

| Mn3 | Mn2+ | 24 | 0.375 | 0 | 0.25 | 0.171 |

| Al2 | Al3+ | 24 | 0.375 | 0 | 0.25 | 0.829 |

| Er3 | Er3+ | 24 | 0.125 | 0 | 0.25 | 0.6 |

| Y1 | Y3+ | 24 | 0.125 | 0 | 0.25 | 0.4 |

| O1 | O2- | 96 | -0.033526 | 0.050789 | 0.148887 | 1 |

图3给出了(Y0.4Er0.6)3(Al1 - y Mn y )5O12 (y = 0.02,0.04,0.06,0.08,0.1)陶瓷材料的XPS全谱。可以看出,在结合能为65~86、150~164、165~174、279~297 eV范围内出现不同强度的吸收峰,分别属于Al2p、Y3d、Er4d、C1s峰。同时,每组样品的结合能为632~661 eV处出现Mn2p的吸收峰。图4给出了(Y0.4Er0.6)3(Al1 - y Mn y )5O12 (y = 0.02,0.04,0.06,0.08,0.1)陶瓷材料的Mn2p XPS精细谱。可以看出,对(Y0.4Er0.6)3(Al0.98Mn0.02)5O12、(Y0.4Er0.6)3(Al0.96Mn0.04)5O12、(Y0.4Er0.6)3(Al0.94Mn0.06)5O12、(Y0.4Er0.6)3(Al0.92Mn0.08)5O12、(Y0.4Er0.6)3(Al0.9Mn0.1)5O12陶瓷材料的Mn2p特征峰进行分峰拟合,结果均分为两个峰。根据文献[20]和XPS标准结合能,Mn2+的2p轨道XPS标准谱线的结合能分别为653和641 eV,分别与这两个拟合峰对应。这表明,MnCO3掺杂在(Y0.4Er0.6)3Al5O12中离子价态没有改变。

图3

图3

(Y0.4Er0.6)3(Al1 - y Mn y )5O12陶瓷材料的XPS全谱

Fig.3

XPS full spectra of (Y0.4Er0.6)3(Al1 - y Mn y )5O12 ceramic materials with different doping contents (a) y = 0.02; (b) y = 0.04; (c) y = 0.06; (d) y = 0.08; (e) y = 0.1

图4

图4

(Y0.4Er0.6)3(Al1 - y Mn y )5O12陶瓷材料的Mn2p XPS精细谱

Fig.4

Mn2p XPS fine spectra of (Y0.4Er0.6)3(Al1 - yMny)5O12 ceramic materials with different doping contents (a) y = 0.02; (b) y = 0.04; (c) y = 0.06; (d) y = 0.08; (e) y = 0.1

2.2 陶瓷材料的微观形貌

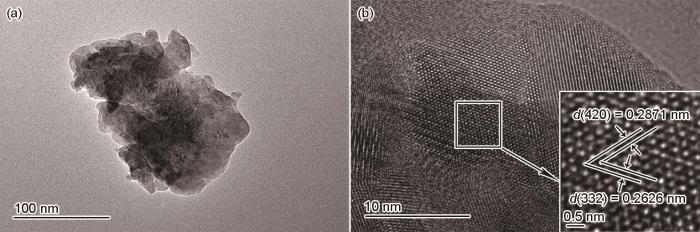

图5给出了(Y0.4Er0.6)3(Al0.94Mn0.06)5O12陶瓷材料的TEM和HRTEM图片。图5a的TEM照片表明,合成的(Y0.4Er0.6)3(Al0.94Mn0.06)5O12陶瓷粉体是由聚集在一起的不规则纳米颗粒组成的。由图5b可以看出,HRTEM照片中YAG的晶格条纹非常清晰;在右下角的局部放大图中标出的晶面间距0.2871和0.2626 nm分别与立方相Y3Al5O12的(420)以及(332)晶面对应,略大于YAG (JCPDS#33-0040)的晶面间距0.2680和0.2561 nm。这进一步说明,Mn成功地掺入了YAG的结构。这些结果,与图1a所标晶面和表1中的 Rietveld晶胞参数变化对应。

图5

图5

(Y0.4Er0.6)3(Al0.94Mn0.06)5O12陶瓷材料的TEM及HRTEM照片

Fig.5

TEM and HRTEM images of (Y0.4Er0.6)3(Al0.94Mn0.06)5O12 ceramic material

图6给出了(Y0.4Er0.6)3(Al1 - y Mn y )5O12 (y = 0,0.02,0.04,0.06,0.08,0.1)陶瓷材料的FESEM图片。可以看出,所有掺杂量组分的陶瓷材料均为不规则的多边形颗粒状结构,晶粒没有异常长大,晶粒大小分布均匀,说明仍为钇铝石榴石相,与XRD分析结果一致;随着Mn掺杂量的提高晶粒尺寸增大,晶界逐渐清晰,孔隙逐渐减少,致密性提高。其原因是,在高温下半径比Al3+大的Mn2+的掺入加剧了晶格畸变,使活性提高和烧结温度降低,使烧结更容易进行,从而提高了陶瓷的烧结致密性。图7给出了(Y0.4Er0.6)3(Al0.94Mn0.06)5O12陶瓷材料的EDS能谱。可以看出,(Y0.4Er0.6)3(Al0.94Mn0.06)5O12陶瓷材料由O、Al、Mn、Y和Er元素组成,元素分布均匀,离子的混合均匀性比较好,未发生元素偏析或堆积且没有出现第二相,与XRD分析和Rietveld精修的结果一致。

图6

图6

不同掺杂量(Y0.4Er0.6)3(Al1 - y Mn y )5O12陶瓷材料的FESEM照片

Fig.6

FESEM images of (Y0.4Er0.6)3(Al1 - y Mn y )5O12 ceramic materials with different doping contents (a) y = 0; (b) y = 0.02; (c) y = 0.04; (d) y = 0.06; (e) y = 0.08; (f) y = 0.1

图7

图7

(Y0.4Er0.6)3(Al0.94Mn0.06)5O12陶瓷材料的EDS能谱

Fig.7

EDS energy spectrum of (Y0.4Er0.6)3(Al0.94Mn0.06)5O12 ceramic material

2.3 陶瓷材料的热导率

根据

表3 (Y0.4Er0.6)3(Al1 - y Mn y )5O12陶瓷材料的热扩散系数λ

Table 3

| y | 25oC | 100oC | 300oC | 500oC | 700oC | 900oC | 1100oC |

|---|---|---|---|---|---|---|---|

| 0 | 0.81 | 0.73 | 0.65 | 0.60 | 0.57 | 0.55 | 0.54 |

| 0.02 | 0.73 | 0.67 | 0.62 | 0.56 | 0.53 | 0.52 | 0.53 |

| 0.04 | 0.71 | 0.67 | 0.62 | 0.57 | 0.53 | 0.54 | 0.50 |

| 0.06 | 0.65 | 0.63 | 0.59 | 0.55 | 0.54 | 0.51 | 0.46 |

| 0.08 | 0.66 | 0.62 | 0.58 | 0.59 | 0.57 | 0.55 | 0.54 |

| 0.1 | 0.60 | 0.58 | 0.58 | 0.52 | 0.54 | 0.52 | 0.50 |

由此可见,在1100℃陶瓷的热导率随着Mn掺杂量的提高先减小后增大。Mn掺杂量y = 0.06的陶瓷热导率最低,1100℃的值约为1.38 W/(m·K),比(Y0.4Er0.6)3Al5O12的热导率(1.48 W/(m·K))降低了约6.8%,比纯YAG陶瓷的热导率(2.1 W/(m·K))降低了约34.6%。这表明,Mn的掺杂使(Y0.4Er0.6)3Al5O12的热导率降低。其原因是,陶瓷材料的热传导机制以声子导热为主[17]。其热导率为

其中Cv 为声子平均热容、v为声子平均速度、l为声子平均自由程。当温度高于德拜温度时前两者的变化不大,因此导热系数的变化主要决定于声子平均自由程。声子的平均自由程为

其中a3 为原子体积、ω为声子频率、c为缺陷浓度、v为横波速度、J为常数、γ为Cruneisen常数、ΔM和ΔR为替代与被替代离子之间的质量差和半径差以及M和R表示平均质量和离子半径。这表明,声子平均自由程主要决定于ΔM和ΔR。根据

图8

图8

(Y0.4Er0.6)3(Al1 - y Mn y )5O12 (y = 0,0.02,0.04,0.06,0.08,0.1)陶瓷材料的热导率

Fig.8

Thermal conductivity of (Y0.4Er0.6)3(Al1 - y Mn y )5O12 (y = 0, 0.02, 0.04, 0.06, 0.08, 0.1) ceramic materials

3 结论

(1) 随着Mn掺杂量的提高,(Y0.4Er0.6)3(Al1 - y Mn y )5O12材料均为单一的YAG相,晶格常数和晶胞体积先减小后增大,Mn2+部分取代Al3+并且Al位占比不断提高,但是Y3Al5O12晶体结构和Mn2+价态均保持不变。

(2) 随着Mn掺杂量的提高,(Y0.4Er0.6)3(Al1 - y Mn y )5O12陶瓷材料的晶粒尺寸增大且分布均匀、晶界逐渐清晰、气孔逐渐减少、致密性提高;掺杂后元素分布均匀,没有元素偏析或堆积且没有出现第二相。

(3) Mn的Al位掺杂显著降低了YAG陶瓷材料的热导率,其中(Y0.4Er0.6)3(Al0.94Mn0.06)5O12的热导率最低,与纯YAG (2.1 W/(m·K))相比降低了约34.6%。

参考文献

Thermal barrier coatings for gas-turbine engine applications

[J].Hundreds of different types of coatings are used to protect a variety of structural engineering materials from corrosion, wear, and erosion, and to provide lubrication and thermal insulation. Of all these, thermal barrier coatings (TBCs) have the most complex structure and must operate in the most demanding high-temperature environment of aircraft and industrial gas-turbine engines. TBCs, which comprise metal and ceramic multilayers, insulate turbine and combustor engine components from the hot gas stream, and improve the durability and energy efficiency of these engines. Improvements in TBCs will require a better understanding of the complex changes in their structure and properties that occur under operating conditions that lead to their failure. The structure, properties, and failure mechanisms of TBCs are herein reviewed, together with a discussion of current limitations and future opportunities.

Thermal barrier coating materials

[J].

Nano-micro-structured 6%~8% YSZ thermal barrier coatings: a comprehensive review of comparative performance analysis

[J].

Physical properties of Er2O3 Doped Gd2(Zr0.8Ti0.2)2O7 ceramic materials

[J].

Er2O3掺杂Gd2(Zr0.8Ti0.2)2O7陶瓷的物理性能

[J].用固相反应法制备(Gd<sub>1-</sub><sub>x</sub>Er<sub>x</sub>)<sub>2</sub>(Zr<sub>0.8</sub>Ti<sub>0.2</sub>)<sub>2</sub>O<sub>7</sub>(摩尔分数x=0,0.2,0.4)陶瓷并测试其晶体结构、显微形貌和物理性能,研究了Er<sub>2</sub>O<sub>3</sub>掺杂的影响。结果表明,(Gd<sub>1-</sub><sub>x</sub>Er<sub>x</sub>)<sub>2</sub>(Zr<sub>0.8</sub>Ti<sub>0.2</sub>)<sub>2</sub>O<sub>7</sub>陶瓷具有立方烧绿石结构,显微结构致密,在室温至1200℃高温相的稳定性良好;Er<sup>3+</sup>掺杂降低了陶瓷材料的热导率和平均热膨胀系数,当x=0.2时,其1000℃的热导率最低(为1.26 W·m<sup>-1</sup>·k<sup>-1</sup>)。同时,Er<sup>3+</sup>掺杂还提高了这种材料的硬度和断裂韧性。

Effects of Nb5+ doping on thermal properties of Gd2(Zr1 - x Nb x )2O7+ x ceramics

[J].

A numerical evaluation and guideline for thermal barrier coatings on gasoline compression ignition engines

[J].

Effects of Er3+ doping on structure and thermal properties of (Sm1 - x Er x )2Zr2O7 ceramics for thermal barrier coating

[J].

Effect of Nb5+ and Cu2+ codoping on thermal properties of Gd2Zr2O7 Ceramic

[J].

Isothermal oxidation and TGO growth behaviors of YAG/YSZ double-ceramic-layer thermal barrier coatings

[J].

Effect of CMAS viscosity on the infiltration depth in thermal barrier coatings of different microstructures

[J].

Corrosion resistant plasma sprayed (Y0.8Gd0.2)3Al5O12/YSZ thermal barrier coatings towards molten calcium-magnesium-alumina-silicate

[J].

Preparation of Pd-doped Y3Al5O12 thermal barrier coatings using cathode plasma electrolytic deposition

[J].

YAG thermal barrier coatings deposited by suspension and solution precursor thermal spray

[J].

Influence of Er3+ doping on the mechanical and thermophysical properties of (Er x Y1 - x )3Al5O12 ceramics

[J].

Y3 - x Er x Al5O12 aluminate ceramics: preparation, thermal properties and theoretical model of thermal conductivity

[J].

Yb3+ doping effects on thermal conductivity and thermal expansion of yttrium aluminium garnet

[J].

Analysis of thermal conductivity behavior of Yb3+ and Er3+ Co-doped Sm2Zr2O7 Ceramics

[J].

Yb3+、Er3+共掺杂Sm2Zr2O7陶瓷导热性能研究

[J].

Preparation and redox performance of nanosized Ce0.92M0.08O2 (M = Co, Mn, Fe, La) solid solutions

[J].

纳米Ce0.92M0.08O2 (M = Co, Mn, Fe, La) 固溶体的制备及其氧化还原性能

[J].

Influence of Yb3+ doping on phase stability and thermophysical properties of (Y1 - x Yb x )3Al5O12 under high temperature

[J].

Preparation and photocatalytic properties of BiFe1 - x Mn x O3 nano-powders

[J].

BiFe1 - x Mn x O3纳米粉末的制备及光催化性能

[J].