电子产品的广泛应用,产生了严重的电磁污染。开发具有高效、超薄、宽频吸收特性的电磁吸波材料,极为迫切[1~5]。已经研发了磁性吸波材料,如磁性金属微粉、金属氧化物和铁氧体等,但是这些材料的趋肤效应、高密度、高填充量、吸波频带窄和易团聚等因素制约其发展和应用[6~8]。将其轻量化是微波吸收材料的发展趋势。碳纳米管具有特殊的结构和介电性能以及轻质、导电性可调、高温抗氧化等特点[9,10]。但是,单一的碳基吸波材料其损耗机制单一,对入射电磁波的衰减性能难以满足实际应用的要求。将轻质导电性能优异的碳纳米管与磁性金属粒子复合,可实现超宽频的电磁响应、显著提高碳纳米管的电磁波吸收性能和拓宽吸波频段[11~13]。元素掺杂也能提高碳纳米管材料的介电性能和产生偶极极化、缺陷极化等损耗机理,进一步提高材料的吸波性能。

过渡金属盐和双氰胺混合物的热解是一种原位制备N元素掺杂Fe3O4@CNTs的新方法,可制备催化、环境修复和析氢等领域的材料。鉴于此,本文基于一步原位热解工艺,使用过渡金属盐作为催化剂、三聚氰胺为氮源和碳源制备N元素掺杂的碳纳米管原位封装磁性粒子功能化复合材料,研究其微波吸收性能。

1 实验方法

1.1 实验用原材料

无水乙醇(CH3CH2OH)、三氯化铁(FeCl3·6H2O)和三聚氰胺(C3H6N6)。

1.2 氮元素掺杂磁功能化碳纳米管复合材料(Fe3O4@NCNTs)的制备

采用一步原位热解工艺同步催化碳纳米管生长构筑Fe3O4@NCNTs。将金属盐FeCl3·6H2O超声溶解在60 mL无水乙醇中,然后加入三聚氰胺超声分散10 min得到均匀悬浊液。将悬浊液置于75℃的恒温水浴锅内持续搅拌,乙醇完全挥发后将其放入干燥箱烘干。将原料比例为1∶2的干燥混合物前驱体(Fe3+/C3H6N6)研磨后置于充Ar气的管式炉中,以3℃/min速率将炉温升至不同温度(650℃、750℃、850℃)高温煅烧热解,保温2 h后得到产物,命名为Fe3O4@NCNTs-X,X代表热解温度。

1.3 性能表征

用粉末X射线衍射谱(XRD)表征复合材料的晶体结构和组成;用拉曼光谱分析表征复合材料碳元素的微观结构变化;用扫描电镜(SEM)和透射电镜(TEM)表征复合材料的形貌和微观结构;使用振动样品磁强计(VSM)测试样品的室温磁性能;将复合材料样品与石蜡均匀混合(质量比:复合材料/石蜡 = 10/90)后压制成同轴圆环(ϕout: 7.00 mm,ϕin: 3.04 mm),基于同轴法用矢量网络分析仪(Agilent 8720ET)测试在不同温度(650℃、750℃、850℃)煅烧的复合材料的电磁参数;使用Matlab软件模拟计算吸波剂在各种条件下的反射损耗。

2 结果和讨论

2.1 结构和物相组成

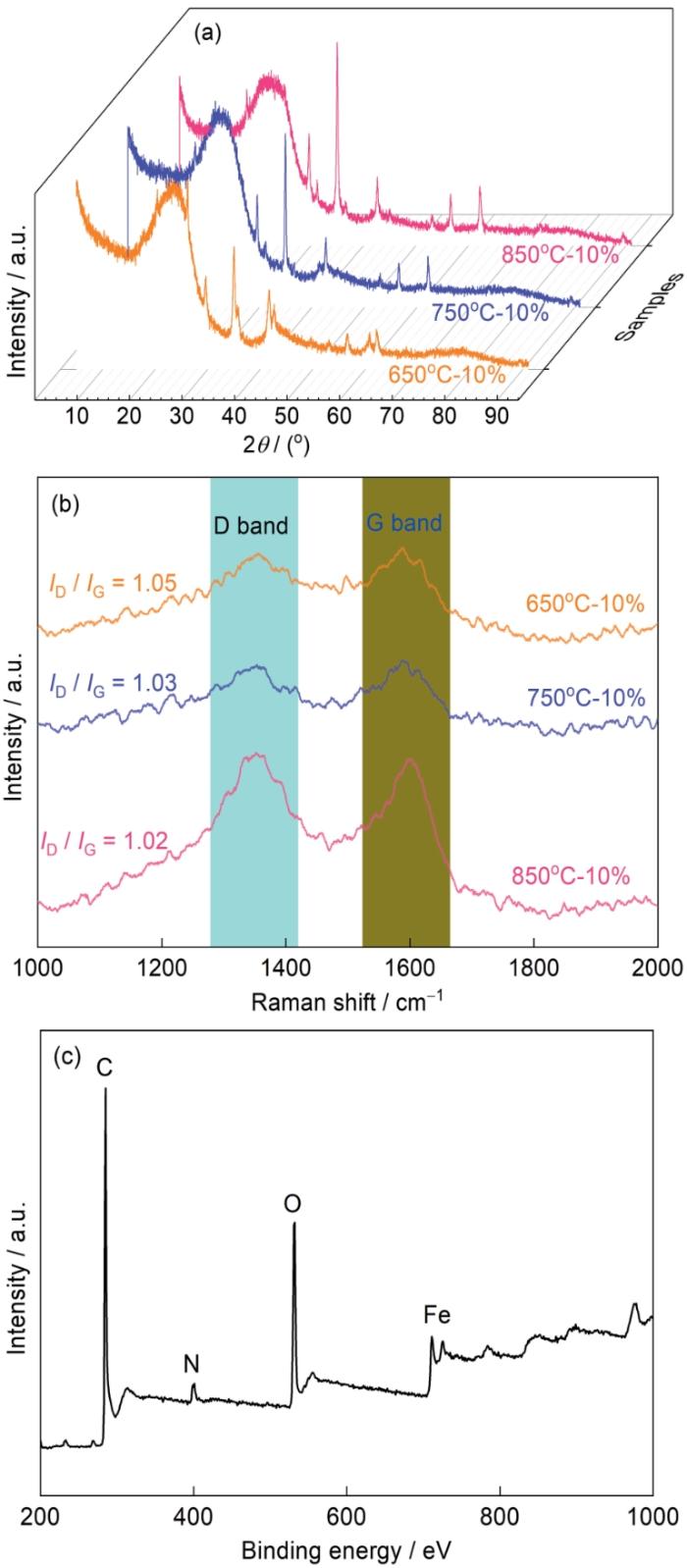

图1给出了Fe3O4@NCNTs复合材料的粉末XRD谱和拉曼谱。从图1a可见,合成的Fe3O4@NCNTs复合材料与立方结构Fe3O4的衍射峰对应,表明Fe3+/C3H6N6已经转化成对应的Fe3O4@NCNTs复合材料。在衍射角2θ = 30.5°、35.0°、43.4°、53.5°、57.0°、63.5°处的特征衍射峰分别对应立方结构Fe3O4的(220)、(311)、(400)、(422)、(511)和(440)衍射晶面,且结晶性随着温度的提高而增强。在衍射角2θ = 23°附近较宽的衍射峰对应碳材料的(002)衍射晶面。为了证实存在NCNTs,对其进行拉曼谱测试。图1b给出了在不同温度煅烧的Fe3O4@NCNTs复合材料的拉曼谱,用比值ID/IG衡量碳材料骨架结构的变化。在拉曼谱中出现碳材料两个明显的峰,即位于1350 cm-1和1580 cm-1处的峰,分别代表碳材料的无序化结构和石墨化结构,比值ID/IG越高表明缺陷越多。使用Origin软件进行面积积分得到Fe3O4@NCNTs-650、Fe3O4@NCNTs-750和Fe3O4@NCNTs-850的ID/IG比值分别为1.05、1.03、1.02。这些数据表明,随着煅烧温度的提高Fe3O4@NCNTs-X复合材料的有序度随之提高,缺陷减少。图1c给出了在750℃煅烧的Fe3O4@NCNTs复合材料的XPS谱。可以看出,这种复合材料主要由C,N,O和Fe元素组成,N元素的掺杂可增强材料的极化损耗和导电损耗,有助于提高其微波吸收性能。

图1

图1

在不同温度煅烧的Fe3O4@NCNTs复合材料的XRD谱、拉曼谱和Fe3O4@NCNTs-750的XPS全谱

Fig.1

XRD, Raman patterns and XPS of Fe3O4@NCNTsunder different calcination temperatures

2.2 微观结构

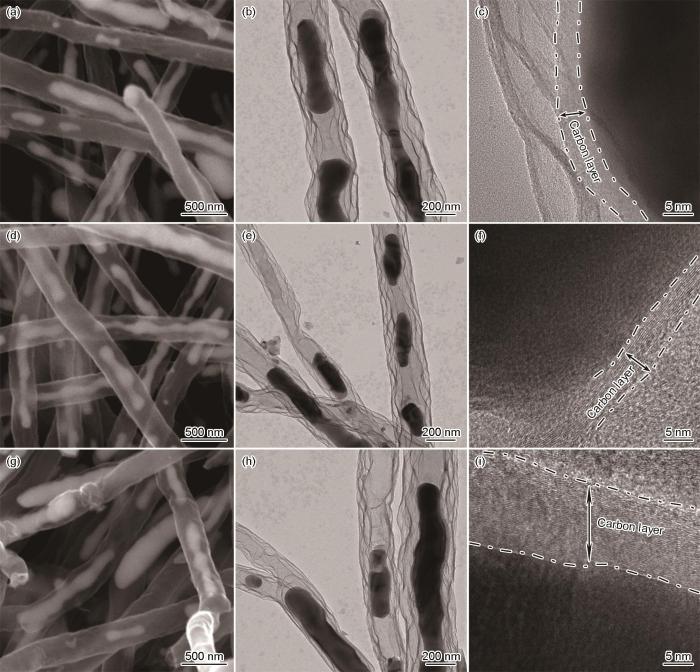

图2a给出了用扫描电镜(SEM)和透射电镜(TEM)观察到的样品的形貌和内部结构特征。从图中可见Fe3O4@CNTs-750复合材料规则的纳米管状形态,直径约为250 nm,表明高温煅烧后混合物前驱体(Fe3+/C3H6N6)转化为Fe3O4@CNTs,Fe3O4粒子被原位碳热还原封装入氮掺杂碳纳米管内。TEM照片进一步证实上述论证,几乎所有的铁元素都包裹在三聚氰胺衍生的NCNTs内,外表面没有附着纳米颗粒(图2b)。同时,这些纳米粒子不连续地分散在NCNTs内部,形成豌豆状的微观结构,且金属粒子表面还有连续的碳包覆层(图2c)。特殊的豌豆状核壳结构具有丰富的非均相界面,有助于提高复合材料的微波吸收性能[14]。

图2

图2

Fe3O4@NCNTs-X复合材料的SEM和TEM照片

Fig.2

SEM and TEM images of Fe3O4@NCNTs-650 (a, b, c), Fe3O4@NCNTs-750 (d, e, f) and Fe3O4@NCNTs-850 (g, h, i)

2.3 吸波性能

和

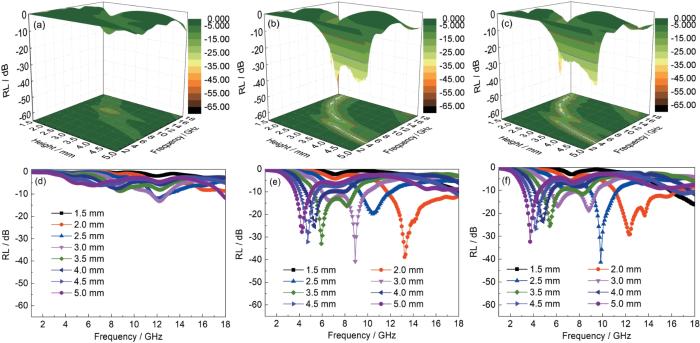

计算反射损耗(RL),式中Zin、Z0、f、d、c、μr和εr分别为吸波剂的输入阻抗、自由空间波阻抗、电磁波频率、吸波剂匹配厚度、光速、相对复磁导率常数和相对复介电常数。图3分别给出了在不同温度煅烧的Fe3O4@NCNTs复合材料在不同匹配厚度、10%填充比例条件下的微波吸收性能。可以看出,随着煅烧温度的提高同等填充比例的复合材料其微波吸收性能先增强后减弱。在750℃煅烧的Fe3O4@NCNTs复合材料(Fe3O4@NCNTs-750),其微波吸收性能最佳。匹配厚度为1.8 mm时,Fe3O4@NCNTs-750复合材料的最小反射损耗值(RLmin)为-57.7 dB,有效吸收频带(EAB)为5.0 GHz;匹配厚度为2.0 mm时,最宽有效吸收频带达到6.4 GHz。随着匹配厚度的增大,最小反射损耗值出峰位置向低频移动。

图3

图3

三维和不同匹配厚度条件下的反射损耗

Fig.3

Reflection loss diagrams of three dimensions and with different matching thicknesses for 650-10% (a, d), 750-10% (b, e) and 850-10% (c, f)

2.4 电磁吸波机理

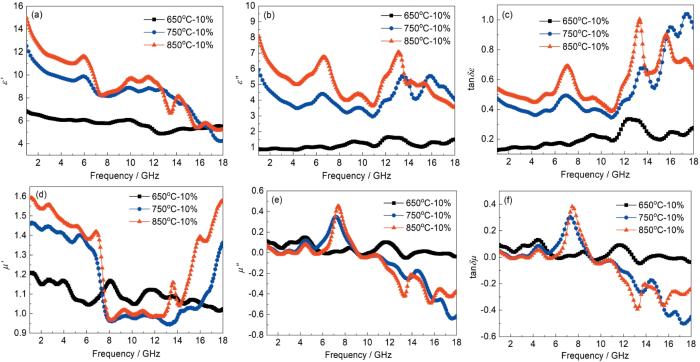

相对复介电常数(ε′、ε″)和相对复磁导率(μ′、μ″),是表征吸波材料性能的主要电磁参数。复介电常数和复磁导率的实部(ε′和μ′)分别表征材料储存电场能和磁场能的能力,虚部(ε″和μ″)分别表征材料衰减损耗电场能和磁场能的能力[17,18]。图4表明,Fe3O4@NCNTs-X复合材料的相对复介电常数表现出明显的频率依赖性:随着频率的提高略有波动的下降;在高频区域,异质结构材料的多级界面及极化弛豫,如界面极化、缺陷/偶极极化、空间电荷极化,使ε″出现多个介电共振峰,有助于增强复合材料的介电损耗。同时,Fe3O4@NCNTs-650的ε′和ε″较低,表明在此温度煅烧的材料对电磁波的耗散能力较低;而Fe3O4@NCNTs-750和Fe3O4@NCNTs-850复合材料的ε′和ε″较大,表明其具有优异的电能储存和损耗能力。与介电常数相比,在不同温度煅烧的Fe3O4@NCNTs-X复合材料的磁导率虚部差别不大,在高频区磁导率虚部出现负值,与磁场能和电场能之间的转化有关。根据麦克斯韦方程,交变电场感应出反向感应磁场,如果感应磁场比原始磁场强,则磁能将从样品中辐射出来或转化为电能。因此,在高频处出现的μ″负值表明磁场能从Fe3O4@NCNTs-X复合材料中辐射出来。与ε″类似,μ″亦出现多个共振峰,源于自然共振、交换共振以及涡流损耗等磁损耗机制[19]。

图4

图4

在不同温度煅烧的Fe3O4@NCNTs-X复合材料的介电常数

Fig.4

Relative complex permittivity of Fe3O4@NCNTs-X under different calcination temperatures (a) real part (ε′), (b) imaginary part (ε″), dielectric loss tangent (tanδε); relative complex permeability: (c) real part (μ′), (d) imaginary part (μ″) and (e) magnetic loss tangent (tanδμ)

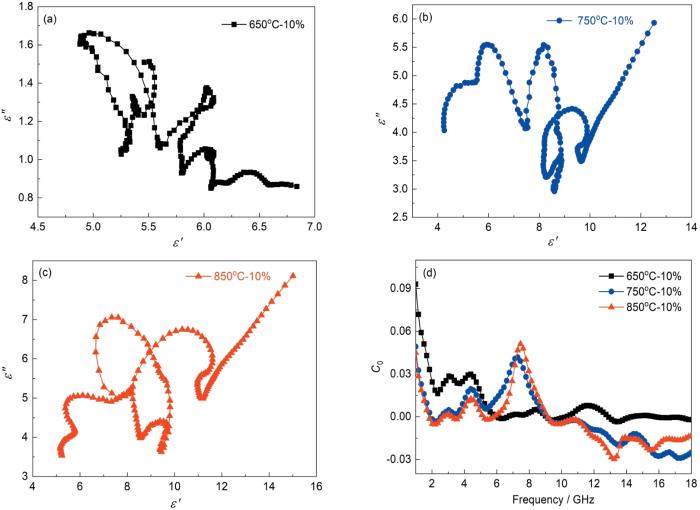

ε′与ε″的关系是一个半圆,称为Cole-Cole半圆。图5给出了在不同温度煅烧的M@NCNTs复合材料的Cole-Cole环,每个Cole-Cole半圆代表一次极化松弛过程。由图5可见,Fe3O4@NCNTs复合材料有多个变形和不规则的Cole-Cole半圆环。这表明,复合材料有多个松弛过程,如Maxwell-Wagner松弛、电子极化、界面极化、偶极极化等。复合材料中碳纳米管与磁性纳米颗粒之间的电导率差异较大,使电荷堆积在界面处并产生大量偶极子,增强了界面附近的电子、偶极子松弛极化的作用,提高了复合材料对电磁波的衰减性能。同时,随着煅烧温度的提高碳层变厚,使复合材料的电导率提高,电导损耗增强。1D NCNTs交错搭接成三维导电网络,载流子在导电网络的定向运动产生电导损耗,Cole-Cole环低频区域拖着一个长尾巴,也表明复合材料存在较强的电导损耗[21]。磁损耗机制主要包括自然共振、交换共振、涡流损耗、多畴壁共振以及滞后损耗等,其中滞后损耗和多畴壁共振在本文的实验条件下可以忽略[22]。依据趋肤效应,涡流损耗可表示为[23,24]

图5

图5

在不同温度煅烧的Fe3O4@NCNTs复合材料的Cole-Cole环和涡流损耗系数

Fig.5

Cole-Cole semicircles and Eddy current loss coefficient of composites under different calcination temperatures (a) Fe3O4@NCNTs-650, (b) Fe3O4@NCNTs-750, (c) Fe3O4@NCNTs-850 and (d) C0

其中μ0、σ、d分别为真空磁导率、电导率和吸波剂厚度。若磁损耗只与涡流损耗有关,则C0不随频率变化。由图5d可知,复合材料的涡流损耗因子C0存在波动,表明涡流损耗对电磁波吸收性能的贡献。

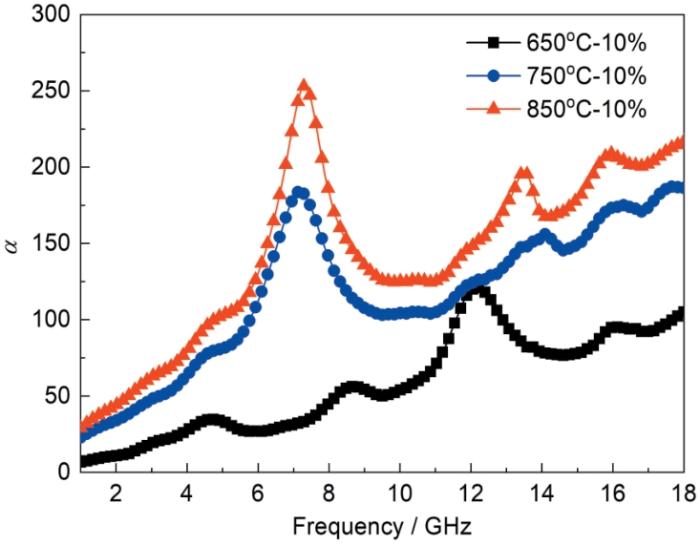

电磁波吸收性能与材料的衰减系数α有密切的关系。为了提高材料的吸波性能,优异的衰减性能尤为重要,使进入材料内的电磁波吸收衰减最大。衰减系数可表示为[25]

由图6可见,Fe3O4@NCNTs-750和Fe3O4@NCNTs-850复合材料的衰减系数优异,表明其具有最佳的衰减特性。因此,与Fe3O4@NCNTs-650相比,Fe3O4@NCNTs-750和Fe3O4@NCNTs-850复合材料的电磁波吸收性能较为优异。

图6

图6

在不同温度煅烧的Fe3O4@NCNTs-X复合材料的衰减系数

Fig.6

Attenuation constant (α) of Fe3O4@NCNTs-X calcinated under different temperatures

3 结论

采用一步原位热解工艺生长过渡金属盐催化碳纳米管并原位封装磁性粒子可构筑Fe3O4@NCNTs-X功能化复合材料。煅烧温度对复合材料的衰减特性和微波吸收性能有重要的影响。导电损耗、介电损耗(界面极化、偶极极化)和磁损耗(自然共振、交换共振)以及不同损耗机制间的协同作用使填充量为10%的Fe3O4@NCNTs-750复合材料具有最优的吸波性能,其RLmin为-57.7 dB,匹配厚度为2.0 mm时最宽EAB达到6.4 GHz。

参考文献

Heterogeneous N-doped carbon composite NiSe2-FeSe double-shell hollow nanorods for tunable and high-efficient microwave attenuation

[J].

Reduced graphene oxide decorated with carbon nanopolyhedrons as an efficient and light weight microwave absorber

[J].

Intelligent off/on switchable microwave absorption performance of reduced graphene oxide/VO2 composite aerogel

[J].

Metal organic frameworks-derived Fe-Co nanoporous carbon/graphene composite as a high-performance electromagnetic wave absorber

[J].

Synthesis of super-hydrophobic and self-cleaning magnetic graphene aerogel with excellent microwave absorption properties

[J].

Electromagnetic property and tunable microwave absorption of 3D nets from nickel chains at elevated temperature

[J].

Co/CoO@C nanocomposites with a hierarchical bowknot-like nanostructure for high performance broadband electromagnetic wave absorption

[J].

Facile design of 3D hierarchical NiFe2O4/N-GN/ZnO composite as a high performance electromagnetic wave absorber

[J].

Graphene aerogel composites derived from recycled cigarette filters for electromagnetic wave absorption

[J].

Synthesis of light weight N-doped graphene foams with open reticular structure for high-efficiency electromagnetic wave absorption

[J].

Multiscale core-shell CoO@Co€PGN/CNTs composites aerogels for ultra-wide microwave absorption

[J].

A review on graphene-based electromagnetic functional materials: electromagnetic wave shielding and absorption

[J].

A review of three-dimensional graphene-based aerogels: Synthesis, structure and application for microwave absorption

[J].

Rational design of core-shell Co@C microspheres for high-performance microwave absorption

[J].

Highly efficient and broad electromagnetic wave absorbers tuned via topology-controllable metal-organic frameworks

[J].

HierarchicalTi3C2T x @ZnO hollow spheres with excellent microwave absorption inspired by the visual phenomenon of eyeless urchins

[J].

Hollow beaded Fe3C/N-doped carbon fibers toward broadband microwave absorption

[J].

Mace‑like carbon fiber/ZnO nanorod composite derived from Typha orientalis for lightweight and high‑efficient electromagnetic wave absorber

[J].

Reduced graphene oxide-wrapped Fe-Fe3O4@mSiO2 hollow core-shell composites with enhanced electromagnetic wave absorption properties

[J].

TiN/Ni/C ternary composites with expanded heterogeneous interfaces for efficient microwave absorption

[J].

Morphology-controlled CoNi/C hybrids with bifunctions of efficient anti-corrosion and microwave absorption

[J].Till now, fewer literatures have investigated the corrosion resistance of microwave absorbers, especially mental@C/carbon matrix derived from MOF composites, although it is known that carbon shells possess a protective effect. Herein, three kinds of morphology-controlled CoNi/C-N doped architectures were successfully fabricated via a sequence of processing, namely coprecipitation for ZIF-67, subsequent Ni2+ exchange and ultimate carbonization. Apart from composition characterization, the effects of microstructure tailoring and temperature controlling on electromagnetic response as well as attenuation performance were revealed, where dodecahedron-shaped composites possessed the highest permittivity. By contrast, rod-shaped composites (CoNi/C-r-550 and CoNi/C-r-700) were endowed with superior comprehensive absorption properties, e.g., RLmin:-49.8 dB and-64.0 dB; EAB: 5.7 GHz and 4.8 GHz, respectively. Besides, samples CoNi/C-d-700 and CoNi/C-r-700 present higher corrosion potential (Ecorr) and lower corrosion current (Icorr). Hence, these corrosion-resistant microwave absorbers with outstanding absorption stability, wetting effect as well as environmental adaptability, can be used as a candidate/raw material for intelligent devices.

Thermal conversion of wheat-like metal organic frameworks to achieve MgO/carbon composites with tunable morphology and microwave response

[J].

A review on metal-organic framework‑derived porous carbon‑based novel microwave absorption materials

[J].

Modified graphitic carbon nitride (MCN)/Fe3O4 composite as a super electromagnetic wave absorber

[J].

In situ formation of CoS2 hollow nanoboxes via ion-exchange for high-performance microwave absorption

[J].