6XXX系(Al-Mg-Si)铝合金是一种可热处理强化合金,具有中等强度和良好的耐腐蚀性,是制造汽车和轨道交通工具的结构材料[1,2]。热轧或挤压是制备6XXX系铝合金材料的关键工序,决定其最终的组织和性能[3]。在高温变形过程中,这种合金的组织发生复杂的变化[4]。Kumar等[5]发现,6082铝合金的软化机制受热变形温度的影响。变形温度为250℃、应变速率为0.001 s-1时,这种合金的主要软化机制为动态回复(Dynamic recovery,DRV),而当变形温度提高到300、350℃时其主要软化机制从DRV转变为动态再结晶(Dynamic recrystallization,DRX)。Kai等[6]研究6X82铝合金在300~500℃、0.01~10 s-1条件下的热变形行为时发现,流变应力随着变形温度的提高或应变速率的降低而减小,高变形温度和低应变速率都有利于合金发生DRX。变形温度和应变速率对金属变形行为的影响,可以用Zener-Hollomon (Z) 参数表征。Yang等[7]研究6A82铝合金热压缩时流变应力的变化和微观组织演变时发现,随着lnZ的降低再结晶晶粒尺寸逐渐增大,DRX分数呈现先减小后增大的趋势。这表明,合金成分和热变形条件对软化机制和微观组织有重要的影响。深入研究并认识6XXX系铝合金高温变形过程中的动态软化行为和特点,对调控其微观组织和性能有重要的意义[8,9]。

6013铝合金是在6061的基础上研发的,其中Cu和Si元素的含量更高。6013铝合金T6态的抗拉强度比6061高15%~20%,但是挤压成形性能有所降低[10]。Li等[11]研究了6013铝合金在lnZ = 32~49条件下变形时的软化机制,发现随着lnZ的增大主要软化机制由几何动态再结晶变为DRV。肖罡等[12,13]研究6013铝合金在lnZ = 48~75条件下变形的流变行为时发现,在此变形条件下其软化机制以DRV为主,在峰值应力状态下计算出的变形激活能为364.48 kJ/mol。以往的文献中热变形温度大多低于500℃[12,14~20],而实际的热变形温度更高,挤压温度甚至达到580℃[21]。由于lnZ值与变形温度成反比、与应变速率成正比,本文进行6013铝合金的热模拟实验,研究其在更高温度(高于530℃)即更低lnZ (23~31)条件下的热压缩变形行为和微观组织特点,建立稳态条件下的本构方程、总结再结晶面积分数、亚晶粒尺寸与lnZ之间的关系,并探讨其动态软化机制。

1 实验方法

表1 6013铝合金的化学成分(质量分数,%)

Table 1

| Mg | Si | Cu | Mn | Fe | Zn | Cr | Ti | Al |

|---|---|---|---|---|---|---|---|---|

| 0.85 | 0.62 | 0.60 | 0.20 | 0.05 | 0.10 | 0.06 | 0.05 | Bal. |

图1

用线切割切取直径为6 mm、高为9 mm的热压缩试样。热压缩模拟实验在Gleeble-3500模拟机上进行,在试样与夹头接触的两端插入石墨片以减少摩擦和不均匀变形。变形温度分别为530、545、560和575℃,应变速率分别为0.001、0.01和0.1 s-1。压缩前将试样以5℃/s的升温速率加热至设定温度,保温180 s以使试样的温度均匀,然后开始压缩。所有试样压缩至真应变为1.0时立即进行室温水淬,以保留其高温变形组织。

将完成热压缩的样品沿着平行于压缩方向切开,将截面机械抛光后用体积分数为10%HClO4 + 90%C2H5OH溶液对进行电解抛光,然后对中心区域进行电子背散射衍射分析(Electron back scattered diffraction,EBSD)。使用Channel 5软件系统分析EBSD数据得到IPF图、再结晶面积分数和晶界图,使用AZtecCrystal软件分析数据得到几何必须位错 (Geometrically necessary dislocation,GND)密度图。

2 结果和讨论

2.1 真应力-应变曲线

图2给出了不同变形温度和应变速率条件下的真应力-应变曲线。从图2可见,合金的流变应力随着变形温度的降低或应变速率的提高而增大。图2a表明,应变速率为0.001 s-1时,随着变形温度从530℃提高到575℃峰值应力从7.61 MPa降低到5.36 MPa。变形温度为530℃时,随着应变速率从0.001 s-1提高到0.1 s-1峰值应力从7.61 MPa增大到19.70 MPa (图2a~c)。三种应变速率的真应力-应变曲线形状相似,流变应力的变化趋势可大致分为三个阶段。在第Ⅰ阶段,随着应变的增大流变应力很快随之增大,压缩变形使位错极快增殖,基体的位错密度迅速提高[4],流变应力也呈现极快增大的趋势,在此阶段加工硬化占主导地位;随着变形进一步增大流变应力的增大缓慢,进入第Ⅱ阶段。在第Ⅱ阶段,应力缓慢增大到峰值后开始减小,因为变形储能的积累发生动态回复和动态再结晶而使其软化[22];动态软化超过加工硬化时,流变应力减小。在变形的后期进入稳态阶段,即第Ⅲ阶段,流变应力不再随着应变的变化而剧烈变化,曲线趋于稳定。这与动态再结晶或动态回复引起的软化与材料加工硬化之间的动态平衡有关[18]。

图2

图2

不同应变速率下的真应力-应变曲线

Fig.2

True stress-strain curves at different strain rates (a) 0.001 s-1, (b) 0.01 s-1, (c) 0.1 s-1

2.2 本构方程

描述低应力水平的热变形流变应力行为;使用指数公式

描述高应力水平的流变应力行为;使用双曲正弦函数

描述所有应力水平下的流变应力行为。式中

假设热变形激活能Q与变形温度T无关,当变形温度T一定时对式(

在一定的变形温度和应变速率条件下对

图3

图3

不同变形条件下6013铝合金的稳态应力、应变速率与变形温度的关系

Fig.3

Relationship between steady-state stress, strain rate and deformation temperature of 6013 aluminum alloy under different deformation conditions (a) ln

表示变形温度和应变速率的综合影响。

将

表2 真应变为1.0时不同热变形条件下的lnZ

Table 2

| Strain rate / s-1 | lnZ of different temperature | |||

|---|---|---|---|---|

| 530oC | 545oC | 560oC | 575oC | |

| 0.001 | 25.64 | 25.04 | 24.47 | 23.91 |

| 0.01 | 27.94 | 27.34 | 26.77 | 26.21 |

| 0.1 | 30.24 | 29.65 | 29.07 | 28.52 |

将计算出的材料常数α、n、Q、A值代入

2.3 晶粒组织

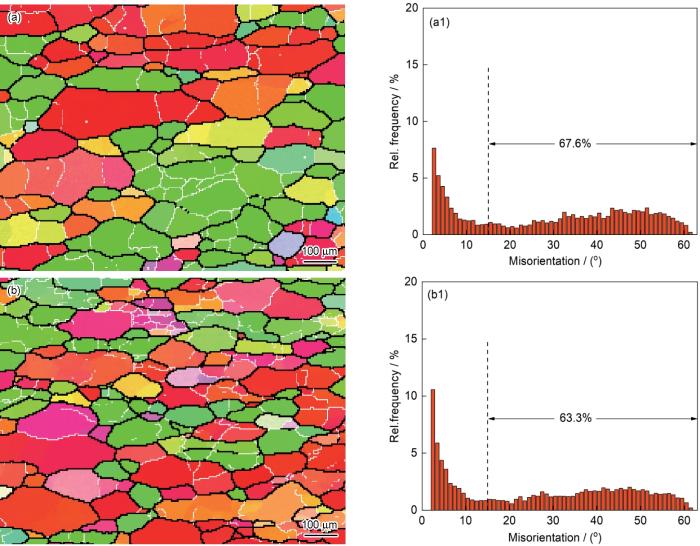

为了研究不同变形温度和应变速率对组织演变的影响,选取应变速率为0.1 s-1在不同变形温度下的IPF图和取向差分布图并对其分析,结果在图4中给出。图中的白线表示2°~15°的小角度晶界,黑线表示大于15°的大角度晶界。

图4

图4

在不同温度、应变速率为0.1 s-1条件下的IPF图和取向差分布

Fig.4

IPF images and misorientation distribution at different temperatures and strain rates of 0.1 s-1 (a, a1) 530oC, (b, b1) 545oC, (c, c1) 560oC, (d, d1) 575oC

表3 在不同热变形条件下晶粒的平均等效圆尺寸

Table 3

| Strain rate / s-1 | Average equivalent circle size of grains at different temperature /μm | |||

|---|---|---|---|---|

| 530oC | 545oC | 560oC | 575oC | |

| 0.001 | 103.7 ± 33.5 | 111.3 ± 39.2 | 114.0 ± 42.6 | 124.5 ± 47.8 |

| 0.01 | 88.7 ± 39.7 | 79.4 ± 28.1 | 99.2 ± 32.4 | 104.9 ± 37.2 |

| 0.1 | 70.0 ± 33.9 | 73.8 ± 26.4 | 80.3 ± 24.5 | 84.0 ± 36.4 |

图5

图5

应变速率不同变形温度为560℃条件下的IPF图和取向差分布

Fig.5

IPF images and misorientation distribution at different strain rates and deformation temperature of 560oC (a, a1) 0.001 s-1, (b, b1) 0.01 s-1

图6

图6

不同lnZ条件下的再结晶面积分数和亚晶粒尺寸

Fig.6

Recrystallization area fraction and sub-grain size under different lnZ (a) recrystallization area fraction, (b) sub-grain size

根据

线性相关系数R为0.94865,表明两者之间有良好的线性关系。

2.4 再结晶机制

根据晶粒组织特征,再结晶机制包括连续动态再结晶(Continuous dynamic recrystallization,CDRX)、不连续动态再结晶(Discontinuous dynamic recrystallization,DDRX)和几何动态再结晶(Geometric dynamic recrystallization,GDRX)。作为例子,选取四个典型lnZ对应的晶界图和GND图分析再结晶机制,如图7所示。

图7

图7

不同lnZ值条件下的晶界图和对应的GND图

Fig.7

Grain boundary diagram and the corresponding GND diagram under different lnZ value (a, e) 24.47, (b, f, i) 26.77, (c, g, j) 28.52, (d, h, k) 30.24

图7a、e给出了lnZ = 24.47条件下的晶界图和GND图。图中有许多“砖块状”的晶粒,如图7a红色虚线框1、2所示,这些晶粒的上、下大角度晶界几乎相互平行,晶粒内的小角度晶界与之垂直。这个结果,与文献[11,25,26]报道的GDRX晶粒形貌特征一致,据此可以确定发生了GDRX。从图7b可见,变形条件lnZ = 26.77时也有GDRX晶粒,如图中的红色虚线框3、4所示。对比可以发现有两种不同的GDRX机制,不同之处在于晶界的取向差分布特征,如图8所示。图8a中GDRX晶粒的晶界取向差均大于35°,由于这两个晶界的取向差很大,不可能是小角度晶界吸收周围位错而形成的,它们是原始晶界;随着变形的继续这两个原始大角度晶界会逐渐靠近,并与其内部的亚晶界相互垂直,当达到亚晶粒直径的1~2倍时原始晶界将接触并发生“掐断”,从而生成新的GRDX晶粒,对应图7a,b中2、4红色虚线框中的晶粒特征。图8b代表另一种GDRX机制,相互平行晶界一侧的取向差大于35°,而另外一侧的取向差小于35°。这表明,这类晶界原本是亚晶界,在热变形过程中吸收周围的位错发生旋转合并从而转变为大角度晶界;随着变形的继续进行,两个大角度晶界之间的间距减小到亚晶粒临界尺寸时就发生碰撞生成新的GDRX晶粒,对应图7a,b中1、3红色虚线框中的晶粒特征。

图8

图8

两种几何动态再结晶机制的示意图

Fig.8

Schematic of two geometric dynamic recrystallization mechanism (a) mechanism 1, (b) mechanism 2

在图7中还能观察到许多连续动态再结晶晶粒,如图7a~d中的黑色箭头所示。分析大角度和小角度晶界的特征可以发现,在两种CDRX机制之间有一个中间阶段,如图7b中的黑色虚线圆框所示,图7i是图7b的放大GND图。图7i中的A区和B区代表两种不同的CDRX机制。在A区中,位错通过DRV形成亚结构而与原始晶界相互连接,如图中白线所示,变形继续时亚晶界消耗周围的位错而使附近的取向差逐渐增大,使小角度晶界转变为大角度晶界,演变过程如图9a所示。在图7i中的B区可见另一种CDRX机制的中间阶段,演变过程如图9b所示。这种亚晶粒的边界由小角度晶界和原始晶界组成,因原始晶界附近的位错密度较低晶界不会向外凸起[11]。试样进一步变形时,小角度晶界经过亚晶粒旋转并消耗周围位错转变为大角度晶界,生成的新CDRX晶粒如图7c中的黑色箭头所指。

图9

图9

两种连续动态再结晶机制的示意图

Fig.9

Schematic of two continuous dynamic recrystallization mechanism (a) mechanism 1, (b) mechanism 2

图7a~d中的红色箭头所指的,是不连续动态再结晶晶粒。观察相应的GND图可以发现,这些晶粒附近的位错密度比其他区域高得多,如图7j中的C区和图7k中的D区所示。在热压缩变形过程中,应变诱导晶界向外“凸起”,形貌呈“项链”状,主要在三叉晶界夹角或原始晶界处形成[25,27],分别如图10a、b所示。如果试样继续热压缩变形,则其附近的位错密度进一步提高,周围的取向差激增使小角度晶界直接转变为大角度晶界,生成一个无应变的DDRX晶核,对应图7d中的红色箭头所指。这与CDRX机制的形核方式不同。CDRX机制经历小角度晶界吸收位错逐渐转变为大角度晶界的过程,即在CDRX机制的中间阶段有10°~15°[11,28]。

图10

图10

两种不连续动态再结晶机制的示意图

Fig.10

Schematic of two discontinuous dynamic recrystallization mechanism (a) mechanism 1, (b) mechanism 2

除了上述的再结晶机制,从图7还可见:lnZ为30.24时可观察到许多亚晶界(2°~15°),表明在此条件下软化机制以DRV为主。综上所述,29.55 <lnZ ≤ 30.24时以DRV为主,还有CDRX和DDRX软化机制;23.91 ≤ lnZ < 29.55时DRX是主要的软化机制,还有CDRX和DDRX机制。

3 结论

(1) 6013铝合金热压缩时的流变应力随着lnZ的增大而增大,稳态条件下的变形激活能为217.3 kJ/mol,Arrhenius本构方程为

(2) 在热变形过程中,在23.91 ≤ lnZ < 29.55条件下DRX是主要的软化机制,其中GDRX占主导,同时存在CDRX和DDRX;在29.55 < lnZ ≤ 30.24条件下DRV是主要的软化机制,同时出现CDRX和DDRX。

(3) 热压缩后再结晶的面积分数和亚晶粒的尺寸均随着lnZ的增大而呈现线性减小的趋势,提高变形温度或降低应变速率都能促进亚晶粒长大。

参考文献

Hot deformation behavior and microstructure evolution of hot-extruded 6A02 aluminum alloy

[J].

Deformation behavior and microscopic mechanism of extruded 6013-T4 aluminum alloy under dynamic impact load

[J].

挤压态6013-T4铝合金在动态冲击载荷下的变形行为及其微观机理

[J].

Hot compression deformation behavior and processing maps of Al-0.5Mg-0.4Si-0.1Cu alloy

[J].

Simulation of dynamic recrystallization in an Al-Mg-Si alloy during inhomogeneous hot deformation

[J].

Hot compression response of solution treated Al-Mg-Si alloy

[J].The main objective of the present study was to investigate the effect of Mg/Si precipitates on the hot-compression response of Al-Mg-Si alloy and further inspect the influence of compression temperatures and Mg/Si precipitates on microstructural changes. The processing maps were drawn using the dynamic materials model approach. To validate the processing maps, metallurgical factors of different regions of processing map were investigated using differential scanning calorimetry (DSC) and electron back-scattered diffraction. The influence of strain rate on the flow stresses of Al-Mg-Si alloy is not consistent with the traditional results after compression from 100 to 250 degrees C, due to the strain ageing produced by the Mg/Si precipitates. The DSC study reveals that no Mg/Si precipitate evolved during the compression test after compressing beyond 250 degrees C. The processing maps (drawn at 0.1 true strain to 0.6 true strain) and metallurgical factors (high-angle grain boundaries or dynamic recrystallized grains) indicated that hot-compression efficiency of Al-Mg-Si alloy is significantly improved after compression beyond 250 degrees C, because no Mg/Si precipitates evolved.

Hot deformation behavior and optimization of processing parameters of a typical high-strength Al-Mg-Si alloy

[J].

Flow behavior and microstructure evolution of AA6A82 aluminium alloy with high copper during hot compression deformation at elevated temperature

[J].

Effects of strain rate and temperature on hot tensile deformation of severe plastic deformed 6061 aluminum alloy

[J].

Dynamic recrystallisation and dynamic precipitation in AA6061 aluminium alloy during hot deformation

[J].

Study on dynamic compression deformation behavior of 6013 aluminum alloy

[D].

6013铝合金动态压缩变形行为研究

[D].

Hot deformation and dynamic recrystallization in Al-Mg-Si alloy

[J].

Flow stress curve correction and constitutive equation of 6013 aluminum alloy plane hot compression

[J].

6013铝合金平面热压缩流变应力曲线修正与本构方程

[J].

Optimization of hot deformation constitutive model of 6013 aluminum alloy based on material parameter correction

[J].

基于材料参数修正的6013铝合金热变形本构模型优化

[J].

Characterization of hot deformation behavior and constitutive modeling of Al-Mg-Si-Mn-Cr alloy

[J].

Flow stress equation for hot compression deformation of Al-Mg-Si alloy

[J].<FONT face=Verdana>In order to provide the theoretical basis for the establishment and optimization of technological parameters for hot working process, the flow stress behavior of the Al-Mg-Si alloy containing Zr element during hot compression deformation was studied with Gleeble1500 thermalmechanical simulator at temperatures from 653K to 803K and deformation rates from 0.01 s<SUP>-1</SUP> to 1 s<SUP>-1</SUP>. In additon, a mathematical model for the flow stress of material deformation was established with regression method. The results show that the alloy is a material sensitive to normal strain rate, and the obvious steadystate rheological feature exists on the true stresstrue strain curves. With increasing the deformation rate and decreasing the deformation temperature, the flow stress increases. The true stresstrue strain curves are dynamic recovery curves at lower deformation tempertures, and are dynamic recrystallization curves at higher deformation temperatures. The flow stress σ of the alloy can be described by the ZenerHollomon parameter including Arrhenius term, where the values of parameters A, α and n are 1.89×10<SUP>10</SUP>s<SUP>-1</SUP>, 0.024MPa<SUP>-1</SUP> and 7.46 respectively. Moreover, the activation energy Q for the hot deformation is 166.85kJ/mol.</FONT>

Hot deformation and mechanical properties of novel Al-Mg-Si-Cu alloy

[J].

Constitutive analysis of 6013 aluminum alloy in hot plane strain compression process considering deformation heating integrated with heat transfer

[J].

The constitutive modeling and processing map of homogenized Al-Mg-Si-Cu-Zn alloy

[J].

Dynamic softening mechanisms and Zener-Hollomon parameter of Al-Mg-Si-Ce-B alloy during hot deformation

[J].

Modeling constitutive relationship of 6013 aluminum alloy during hot plane strain compression based on Kriging method

[J].

Effect of extrusion temperature on microstructure and mechanical properties of welded zone of 6005A aluminum alloy

[J].

挤压温度对6005A铝合金焊合区域显微组织和力学性能的影响

[J].

Hot workability and dynamic recrystallization behavior of a spray formed 7055 aluminum alloy

[J].

On the mechanism of hot deformation

[J].

Analysis of flow stress and microstructure during hot compression of 6099 aluminum alloy (AA6099)

[J].

A review of dynamic recrystallization phenomena in metallic materials

[J].

New developments in geometric dynamic recrystallization

[J].

Dynamic recrystallization and microstructure evolution mechanism of superalloy GH4169

[J].

高温合金GH4169的动态再结晶和组织演化机制

[J].

Dynamic recrystallization mechanisms of 2195 aluminum alloy during medium/high temperature compression deformation

[J].