在含Re/Ru的单晶镍基合金中,虽然大量难熔元素分布于合金的枝晶干区域,但是枝晶间仍有高熔点难熔元素[13],特别是合金的力学性能与枝晶间/枝晶干的成分偏析密切相关[14]。进行高温固溶处理可降低合金的成分偏析,使合金的蠕变抗力提高[15]。特别是制造高推重比先进航空发动机所用的材料需要更高的承温能力,先进发动机在高温下的稳定运行与发动机热端部件的蠕变行为密切相关。虽然Re、Ru可提高合金的高温蠕变强度和抗力以及对组织演化的影响已有文献报道[3,10,16],但是固溶温度对高浓度Re/Ru合金的组织和蠕变性能的影响并不清楚,这种合金蠕变温度的敏感性以及高温蠕变期间的变形与损伤行为也不十分清楚。鉴于此,本文制备一种含4.5%Re/3%Ru单晶合金,在不同温度进行固溶处理后在1100和1140℃测试其蠕变性能,研究固溶和蠕变温度对其组织和蠕变行为的影响。

1 实验方法

合金的名义成分和实际成分列于表1。用真空定向凝固炉将成分为Ni-Al-Ta-Cr-Co-W-Mo-4.5%Re-3%Ru的母合金制备成单晶棒,单晶棒与[001]方向的取向差控制在6°以内。

表1 实验用合金的化学成分

Table 1

| Al | Cr | Co | Ta + W + Mo | Re | Ru | Ni | |

|---|---|---|---|---|---|---|---|

| Nominal | 6.0 | 3.0 | 6.0 | 16.0 | 4.5 | 3.0 | Bal. |

| True | 5.83 | 2.78 | 6.05 | 15.6 | 4.38 | 2.85 |

用差热分析方法测定出铸态合金中γ′相的溶解温度为1242℃,初熔温度为1346℃。采用分级加热进行合金的高温固溶处理,以避免合金的局部区域发生初熔。采用“工艺1和工艺2”在不同温度进行固溶处理和测试蠕变性能,以研究固溶温度对合金的组织和蠕变性能的影响。采用的两种热处理制度分别在图1中给出。在两种热处理制度中,在温度低于1328℃时采用相同的固溶温度和保温时间,工艺2只增加了在1332℃保温5 h的固溶处理环节。固溶处理后,两种热处理制度均采用相同的一次时效和二次时效处理工艺。

图1

为了避免热处理期间发生过分氧化,在氩气气氛保护下将合金加热和保温,热处理加热炉温度的误差为 ±2℃。进行高温固溶热处理以消除合金在凝固期间生成的共晶组织,并最大限度地提高单晶合金化学成分的均匀化程度。在较高温度进行一次时效处理可将合金中立方γ′相的尺寸调整到大约0.4 μm,并保持γ′/γ两相的共格界面。进行二次时效处理,以调整合金中γ′相的立方度。

完全热处理后,沿单晶棒[001]取向的(100)晶面加工横断面积为4.6 mm × 2.4 mm的板状蠕变样品。将不同工艺热处理样品研磨和抛光后置于蠕变试验机上,进行制度为1100℃/140 MPa的蠕变性能测试,以比较固溶温度对合金的组织和蠕变性能的影响。采用工艺2处理的合金,分别在蠕变不同时间终止试验,以了解其组织与蠕变时间的关系。对用工艺2热处理的样品进行1140℃/140 MPa的蠕变性能测试,以揭示合金蠕变温度的敏感性。

对不同工艺处理及蠕变后的样品进行化学腐蚀,用型号为S3400的扫描电子显微镜观察形貌。将部分蠕变样品制备成TEM试样,用型号为JWM-2000FXII的透射电子显微镜(TEM)观察形貌,以研究合金蠕变期间的组织演化特征与损伤机制。

2 实验结果

2.1 固溶温度对蠕变性能的影响

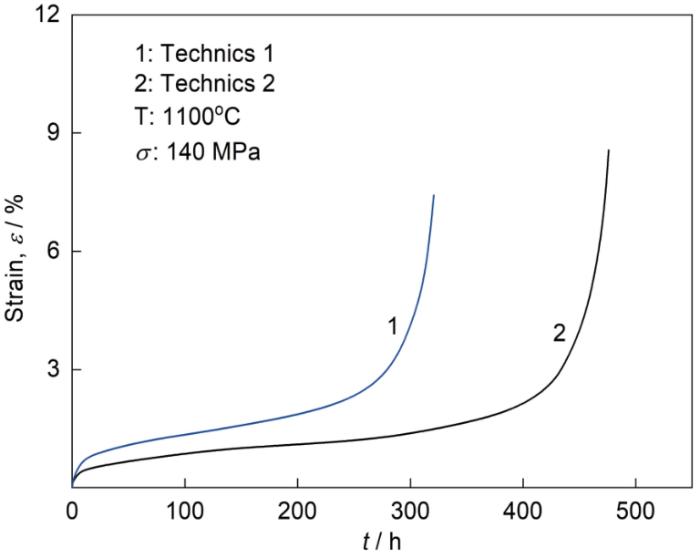

图2给出了分别经工艺1和工艺2处理的合金试样在1100℃/140 MPa条件下的蠕变曲线。其中经工艺1处理的合金试样其蠕变寿命为321 h,而经1332℃固溶处理的试样其蠕变寿命为476 h。与工艺1处理的合金相比,经工艺2处理的合金其蠕变寿命提高约48.3%,这表明,固溶温度对合金的蠕变强度和性能有重要的影响,且经工艺2处理合金其抗蠕变性能更好。

图2

图2

不同工艺处理合金经1100℃/140 MPa测定的蠕变曲线

Fig.2

After treated by different techniques, creep properties of alloy at 1100oC/140 MPa

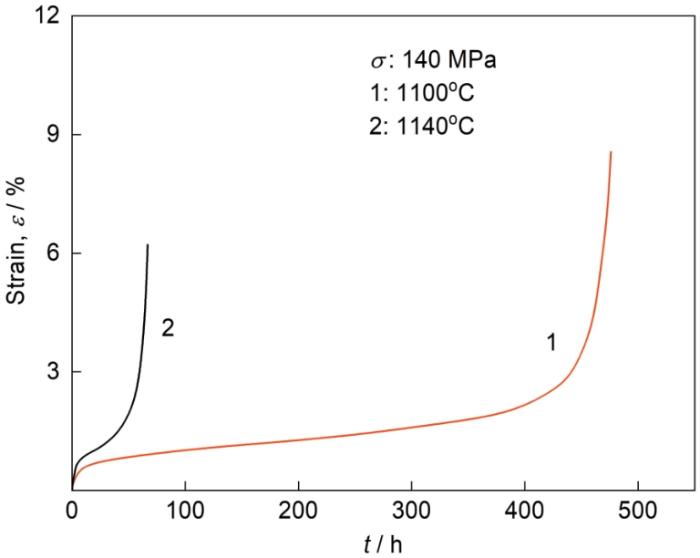

图3

图3

施加140 MPa压力下,在不同温度测定的蠕变曲线

Fig.3

Creep curves of alloy at various temperatures under the applied stress of 140 MPa

合金在加载瞬间产生了较大的瞬间应变,随后应变速率逐渐降低,表明在合金基体中因位错增值而产生了应变硬化。在蠕变稳态阶段,位错攀移是应变速率的限制性环节[17]。根据Dorn定律计算出合金在稳态期间的蠕变激活能为Q = 517.8 kJ/mol,表明用工艺2处理的合金其蠕变强度和抗蠕变性能优异。

2.2 固溶温度对组织结构的影响

图4

图4

经工艺1热处理后合金中残留的粒状共晶组织

Fig.4

After heat treated by technique 1, configuration of the residual eutectic in the alloy

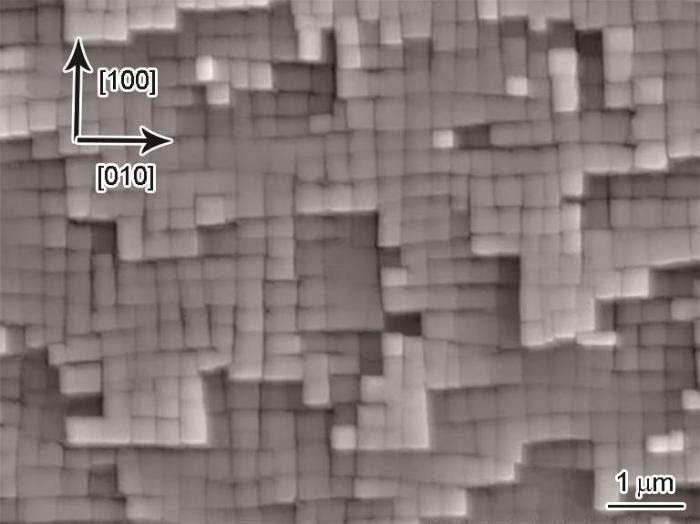

合金中存留的残余共晶组织割裂了组织的连续性,是合金蠕变抗力较低的主要原因。经工艺2(1332℃固溶处理)完全热处理的合金,其枝晶间区域的共晶组织完全溶解,其组织是尺寸约为0.4 μm均匀分布于γ基体中并沿<100>方向规则排列的立方γ′相。如图5所示,γ基体通道的尺寸约为0.08 μm,两相之间没有界面位错。根据残余共晶的形貌(图4),在1328℃固溶处理期间该共晶组织已经溶解,使尺寸较大的块状共晶转变为较小粒状或线状形态。因为共晶组织的尺寸和体积分数明显减少,共晶组织的溶解不完全是合金中存留残余共晶的主要原因。因此,固溶温度由1328℃提高到1332℃使共晶溶解加速,是完全消除合金中残余共晶的主要原因。这表明,高温固溶处理消除残余共晶组织、降低合金的偏析程度并得到规则的组织结构,可使该合金具有优异的高温蠕变性能 。

图5

图5

经工艺2热处理后合金的组织

Fig.5

Microstructure of the alloy after heat treated by the technique 2

2.3 蠕变期间变形的特征

用工艺2处理的合金其高温蠕变性能更好,且在1100℃/140 MPa条件下蠕变时表现出优异的蠕变抗力,因此本文主要研究合金在1100℃/140 MPa条件下蠕变期间的变形和损伤行为。

图6

图6

合金经1100℃/140 MPa蠕变5 h后的组织

Fig.6

Microstructure of alloy crept for 5 h at 1100oC/140 MPa

图7

图7

在1100℃/140 MPa蠕变期间合金的组织随蠕变时间的变化

Fig.7

Changing features of microstructure of alloy with creeping time at 1100oC/140 MPa (a) crept for 10 h, (b) crept for 200 h, (c) crept for 400 h

图8

图8

样品在1100℃/140 MPa和1140℃/140 MPa条件下蠕变断裂后不同位置的γ′相形貌

Fig.8

Microstructure in various zones of sample after crept until fracture at 1100oC/140 MPa and 1140oC/140 MPa (a) region far from fracture at 1100oC, (b) region near fracture at 1100oC, (c) region far from fracture at 1140oC and (d) region near fracture at 1140oC

在1140℃/140 MPa条件下蠕变67 h断裂后,样品中远离断口区域的组织形貌示于图8c,其中筏状γ′相保持平直形态,厚度约为0.4 μm,如图中的水平箭头所示。与图8a相比,筏状γ′/γ两相的形貌相似,但是筏状γ′相的厚度减小,γ相基体的厚度增大。近断口的颈缩区域中的筏状γ′/γ两相已明显扭曲,其扭曲方向与竖直线段的夹角约为35°,如图8d中的线段箭头所示。筏状γ′/γ两相已明显粗化,其γ′、γ两相的厚度分别约为0.4和0.5 μm,γ′/γ两相厚度的比值约为0.8/1,如图8d所示。但是,与图8b相比 (筏状γ′相厚度约为0.8 μm),该区域筏状γ′相的厚度和体积分数明显减少,而γ基体的尺寸和体积分数明显增大,表明在1140℃蠕变期间合金中的γ′相已发生溶解。

γ′-Ni3Al是合金的强化相,但是在1140℃蠕变期间合金中γ′相的溶解使其尺寸和体积分数减小,是其蠕变寿命较短的重要原因。同时,缩颈区域较大的应变使筏状γ′/γ两相碎断转变成“类块状”形态,如图8d中的水平箭头所示。筏状γ′相转变成“类块状”形态的逆向演化,是这种合金高温蠕变后期的新特征。

2.4 蠕变后期的损伤

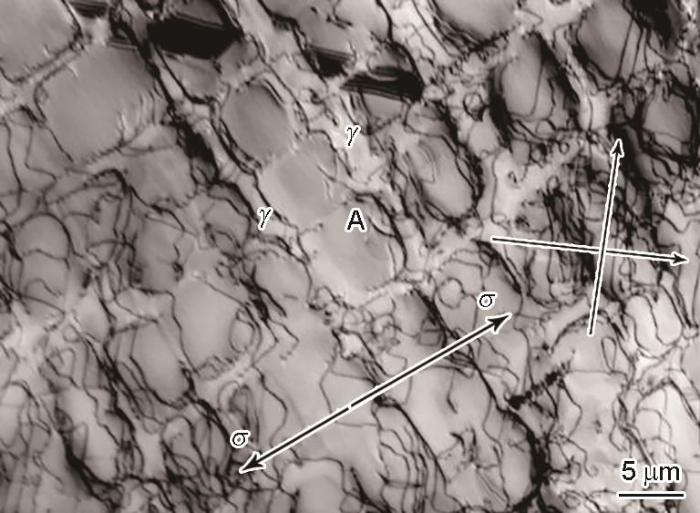

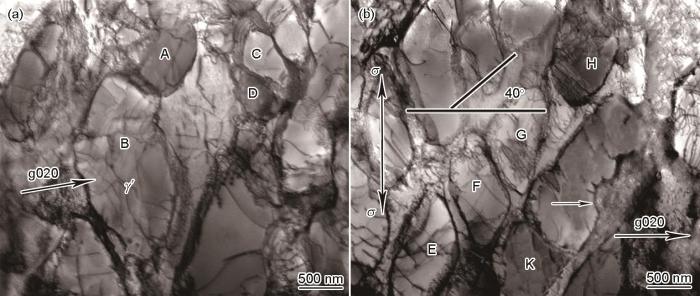

经1100℃/140 MPa蠕变断裂后的合金其组织形貌如图9所示,图中的箭头为施加应力方向。合金此区域中的γ′和γ两相仍保持平直筏状形态,位错网分布在两相的界面,如图中区域D所示。已有位错剪切进入筏状γ′相,γ′相内各位错的迹线特征如字母A、B、C、D所示。在g0

图9

图9

合金在1100℃ /140 MPa条件下蠕变断裂后γ′相内的位错组态

Fig.9

Dislocation configuration in the γ′ rafts after crept up to fracture at 1100oC /140 MPa (a) g020, (b) g0

上述的衬度分析表明,γ′相中的位错既可在{111}面滑移,也可在{100}面滑移,其中γ′相的易滑移面为{111}晶面。在蠕变期间激活的位错先在{111}面滑移,位错在{111}面滑移受阻时可交滑移至{100}晶面,因此图9中位于{100}面的位错起源于{111}面的交滑移。其中在{111}和{100}晶面滑移的位错可分解成不全位错+ APB的位错组态,特别是位错由{111}面交滑移至{100}面,形成的位错锁可抑制位错运动,提高合金的蠕变抗力。

合金试样在1100℃/140 MPa条件下蠕变至断裂,近断口区域的形貌示于图10。可以看出,γ基体的尺寸约为0.2~0.3 μm,筏状γ′相已粗化到0.8 μm,如图10a所示。由于该区域发生颈缩,较大的塑性变形使筏状γ′相发生扭曲和折断,或转变成“类块状”形态,如图10a中的A、B、C和D区域所示。衬度分析表明,具有不同衬度的A、B区域,存在其取向差约为2.8°,相似的取向差也存在于区域C和D。缩颈区域的较大变形使应变速率提高(图2),大量位错的交替滑移使γ′相发生晶体旋转,也使相邻区域出现取向差,并在取向不同的两相邻区域之间存在大量的位错缠结。位错缠结处于高能状态,热激活可使位错缠结发生束集而形成亚晶界并释放能量,是合金中形成亚晶的主要原因[20,21]。一旦形成了具有较小取向差的亚晶结构,其亚晶区域的衬度不同于另一亚晶区域的衬度,如图10a中的A、B、C和D所示。

图10

图10

合金在1100℃/140 MPa条件下蠕变476 h断裂后的组织结构

Fig.10

Microstructure of alloy crept for 476 h until fracture at 1100oC/140 MPa (a) sub-grains in local region, (b) block-like γ′ phase

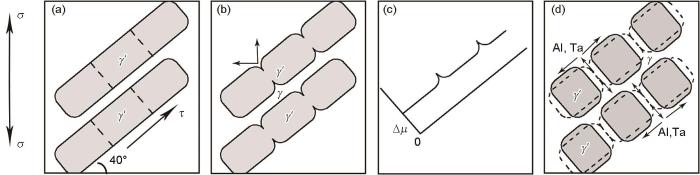

在蠕变后期,样品中颈缩区域位错的交替滑移使筏状γ′和γ两相的扭曲加剧,使原水平方向的筏状γ′相的扭曲角度增加到约为40°,如图8b中的线段所示。该区域的筏结构已转变成“类块状”组织,其放大形貌示于图10b,其“块状”γ′相周围的γ基体相尺寸约为0.1~0.2 mm,但是仍有不规则形态的筏状γ′相存在于图10b的右侧底部区域。同时,已有大量位错切入筏状γ′相,不同区域的衬度差可归因于晶体旋转的筏状γ′相形成了亚晶,如图10b中的区域K所示,其“类块状”γ′相位于筏状γ′相的左上侧,如图10b中的区域E、F、G、H所示,可归因于蠕变后期近断口区域组织结构的逆向转变。合金在1140℃/140 MPa条件下蠕变的后期,γ′相也发生了由“筏状”形态转变为“类块状”形态的逆向组织转变,如图8d所示。该组织结构的逆向转变,对合金的蠕变抗力有重要的影响。

3 讨论

图11

图11

倾斜筏状γ′相熔断过程的示意图

Fig.11

Schematic diagram of inclined γ′ phase dissolved up to fusing (a) inclination of γ′ phase, (b) formation of grooves, (c) chemical potential of grooves and (d) fusing of grooves

合金中的Al和Ta是γ′相形成元素,Re、Ru、Mo是主要的γ基体相形成元素,且各元素根据平衡分配定律分布在γ′/γ两相中。蠕变后期筏状γ′相已变成扭曲形态且与水平方向呈40°角,如图11a所示,该40°角倾斜的筏状γ′相承受施加载荷的最大剪应力(τ),如图中的箭头所示。随着蠕变的进行,在最大剪应力作用下倾斜筏状γ′相发生不均匀粗化和扭曲,使筏状γ/γ′两相界面变成曲面,且呈现出沟槽和凹凸不平的形貌。此时,该区域应力分布的变化可改变γ/γ′两相中溶质元素M(Al, Ta)的平衡浓度。其中在最大剪应力(Fτ

式中

该曲率半径(r)对溶质元素M(Al, Ta)化学位(Δμ)的影响,可表示为:

其中U为比表面能,Va为原子体积,A为常数,W为应变能。γ′相沟槽处的曲率半径(r)较小,使溶质元素M(Al,Ta)的Δμ较高,示于图11c。Δμ作为驱动力使溶质元素M(Al, Ta)扩散迁移到相邻的γ基体中,溶质元素的扩散方向如图11d中的箭头所示。溶质元素的扩散使倾斜筏状γ′相等间距溶解,也使扩散溶质元素M(Al, Ta)外溢。当γ′相中的溶质元素M(Al, Ta)的浓度降低到一定数值后,该区域的γ′相转变为γ基体相,并使沟槽加深直至熔断,从而转变成“类立方体”形态。一旦原倾斜筏状γ′相分解成“类粒状”形态,其界面能提高和该区域γ′相的大量位错使其强度降低和应变速率提高。其中的粒状γ′相在高应变速率下蠕变至断裂并转变成不规则形态,如图10b所示。

4 结论

(1) 含Re/Ru合金的枝晶间区域存在高熔点共晶组织,在1328℃固溶处理后合金中仍存在粒状残余共晶组织。在1332℃进行固溶处理可消除合金中的残余共晶组织,使合金在1100℃/140 MPa条件下的蠕变寿命由321 h提高到476 h。

(2) 合金在1100℃蠕变后期剪切进入γ′相的位错由{111}面交滑移至{100}面,形成的位错锁抑制位错滑移,使合金的高温蠕变强度和抗力提高。随着温度提高到1140℃合金中的γ′相发生溶解,使其尺寸和体积分数减小,是合金在1140℃/140 MPa条件下蠕变寿命较短的主要原因。

(3) 在合金的蠕变后期位错的交替滑移使γ′/γ两相扭曲加剧,从而使样品颈缩区域的γ′相转变成亚晶和“类块状”形态,特别是筏状γ′相转变为“块状”形态的逆向组织演化,使合金的高温蠕变强度和抗力降低以及应变速率提高直至蠕变断裂,是合金在高温蠕变后期损伤和断裂的机制。

参考文献

Research progress of creep behaviors in advanced Ni-based single crystal superalloys

[J].

先进镍基单晶高温合金蠕变行为的研究进展

[J].

Modeling of the deformation behavior of single crystalline Nickel-based superalloys under thermal mechanical loading

[J].

Enhanced creep resistance induced by minor Ti additions to a second generation nickel-based single crystal superalloy

[J].

Effect of ruthenium on the precipitation of topologically close packed phases in Ni-based superalloys of 3rd and 4th generation

[J].

Double minimum creep of single crystal Ni-base superalloys

[J].

Creep microstructure damage and influence on Re-creep behavior for a nickel-based single crystal superalloy

[J].Creep tests of Nickel-based single crystal superalloy DD413 were carried out by constant loads of 980℃/200 MPa and 870℃/430 MPa, while which then were terminated at plastic strain just reaches 0.2%, 0.5% and 1% respectively, so that to acquire the microstructure of the alloy by different creep damage states. Later on, the pre-strained alloys were further subjected to re-creep test again, so as to acquire their residual creep properties and to establish the relationship between different degraded microstructure and creep properties. Meanwhile the microstructure damage characteristics of DD413 alloy under thermal-mechanical coupling were simulated and quantitatively characterized. The results show that the degradated damage of DD413 alloy structure mainly includes the decrease of γ' phase volume fraction and the increase of γ' phase rafting degree. The higher the creep temperature, the more serious the microstructure damage, and the worse the alloy's re-creep performance. Compared with γ' phase rafting, the decrease of γ' phase volume fraction has little effect on the creep properties of the alloy.

一种镍基单晶高温合金的蠕变组织损伤对再蠕变行为的影响

[J].

Unveiling the Re effect on long-term coarsening behaviors of γ′ precipitates in Ni-based single crystal superalloys

[J].

Influence of stress state on the kinetics of γ-channel widening during high temperature and low stress creep of the single crystal superalloy CMSX-4

[J].

Creep deformation related to dislocations cutting the γ′ phase of a Ni-base single crystal superalloy

[J].

Stress dependence of the creep behaviors and mechanisms of a third-generation Ni-based single crystal superalloy

[J].<p>Elevated temperature creep behaviors at 1100 °C over a wide stress regime of 120-174 MPa of a third-generation Ni-based single crystal superalloy were studied. With a reduced stress from 174 to 120 MPa, the creep life increased by a factor of 10.5, from 87 h to 907 h, presenting a strong stress dependence. A splitting phenomenon of the close- (about 100 nm) and sparse- (above 120 nm) spaced dislocation networks became more obvious with increasing stress. Simultaneously, <i>a</i><sub>0</sub><010> superdislocations with low mobilities were frequently observed under a lower stress to pass through γ′ precipitates by a combined slip and climb of two <i>a</i><sub>0</sub><110> superpartials or pure climb. However, <i>a</i><sub>0</sub><110> superdislocations with higher mobility were widely found under a higher stress, which directly sheared into γ′ precipitates. Based on the calculated critical resolved shear stresses for various creep mechanisms, the favorable creep mechanism was systematically analyzed. Furthermore, combined with the microstructural evolutions during different creep stages, the dominant creep mechanism changed from the dislocation climbing to Orowan looping and precipitates shearing under a stress regime of 137-174 MPa, while the dislocation climbing mechanism was operative throughout the whole creep stage under a stress of 120 MPa, resulting a superior creep performance.</p>

Temperature dependence of tensile behavior and deformation microstructure of a Re-containing Ni-base single crystal superalloy

[J].

Creep behavior and a deformation mechanism based creep rate model under high temperature and low stress condition for single crystal superalloy DD5

[J].

New insights into the microstructural stability based on the element segregation behavior at γ/γ′ interface in Ni-based single crystal superalloys with Ru addition

[J].

Effects of Re and Ru on microstructure and segregation of Ni-based single-crystal superalloys

[J].The influence of Re and Ru on segregation and microstructure evolution during heat treatment has been investigated in four Ni-based single-crystal superalloys with varied contents of Re (3%-6%, mass fractions) and Ru (0% and 3%). The additions of Re and Ru lead to the more severe segregation of alloying elements in as-cast structures. However, the effects of Ru on as-cast segregation can be neglected after the stepwise solution heat treatments. The additions of Re and Ru lead to the lower <em>γ'</em>-coarsening rate, more cuboidal <em>γ'</em>-morphology and reduced <em>γ'</em>-size. Electron microprobe analysis (EPMA) indicates that Al, Ta and Ni partition to the <em>γ'</em>-precipitates, whereas Re and Cr strongly partition to the <em>γ</em>-matrix. In comparison to Re and Cr, Ru and W show the less tendency to partition to the <em>γ</em>-matrix. Additionally, Re increases the supersaturation of Re, Cr, Co and W in the <em>γ</em>-matrix, whereas Ru only slightly suppresses the partition of these TCP-forming elements to the <em>γ</em>-matrix.

Re和Ru对镍基单晶高温合金组织偏析的影响

[J].

Influence of various heat treatments on the microstructure of polycrystalline IN738LC

[J].

Effect of Ru on microstructure evolution of the fourth generation nickel-based single crystal superalloy DD22 during long-term aging

[J].The morphological evolution of γ′ phase, the precipitation of TCP phases and the evolution of the interfacial dislocation networks in DD22 nickel-based single crystal superalloys with different Ru contents (3% and 5%, mass fraction) were investigated by transmission electron microscopy and field emission scanning electron microscopy during long-term aging at 1130 ℃. The results show that γ′ phase of 5Ru alloy are smaller in size and more regular in shape than that of 3Ru alloy. The mismatch of γ/γ′ phases is larger in 5Ru alloy, and the high content of Ru causes the reverse distribution of elements such as Re and Mo. During long-term aging at 1130 ℃, the coarsening rate, dissolution rate and rafting rate of γ′ phase in 5Ru alloy are lower than those of 3Ru alloy. There is still no TCP phase precipitation in 5Ru alloy after long-term aging for 1000 h, while a small amount of TCP phase is precipitated in 3Ru alloy after long-term aging for 50 h. With the prolongation of long-term aging time, the number and size of TCP phases both increase. Compared with 3Ru alloy, the interfacial dislocation networks of 5Ru alloy are denser and more regular after long-term aging for 1000 h. Above all, the reverse distribution of elements and low diffusion coefficient of Ru make 5Ru alloy exhibit higher microstructural stability than 3Ru alloy.

Ru对第四代镍基单晶高温合金DD22长期时效组织演化的影响

[J].利用透射电镜和场发射扫描电镜研究了两种不同Ru含量(3%和5%,质量分数)的第四代镍基单晶高温合金DD22在1130 ℃长期时效过程中γ′相形貌演化、TCP相析出和界面位错网的演化情况。研究结果表明:在完全热处理后5Ru合金比3Ru合金的γ′相尺寸更小,形状更规则,γ/γ′相界面的错配度更大,高Ru含量使合金Re,Mo等元素出现反分配现象;5Ru合金在1130 ℃长期时效过程中γ′相粗化速率、溶解速率和形筏速率均低于3Ru合金;5Ru合金在长期时效1000 h后仍没有TCP相析出,而3Ru合金在时效50 h后便析出TCP相,随着长期时效时间延长,TCP相数量增多,尺寸增大;与3Ru合金相比,长期时效1000 h后5Ru合金γ′/γ界面位错网更加致密和规则;综上所述,Ru的元素反分配作用和低的扩散系数使5Ru合金比3Ru合金表现出更高的组织稳定性。

Evolution of phase interface microstructure and its effects on stress rupture property of a 4th generation nickel-based single crystal superalloy after thermal exposure

[J].

Interaction between phase boundary and interfacial dislocations in nickel based single crystalline superalloy

[J].

镍基单晶高温合金相界与界面位错的相互作用

[J].

Influence of element Re on deformation mechanism within γ′ phase of single crystal nickel-based superalloys during creep at elevated temperatures

[J].

Creep behavior and damage feature of Re/Ru-containing single crystal nickel-based superalloy at high temperature

[J].

含Re/Ru镍基单晶合金的高温蠕变行为和损伤特征

[J].

Effects of Ru and Cr on γ/γ' microstructural evolution of Ni-based single crystal superalloys during heat treatment

[J].

Ru和Cr对镍基单晶高温合金γ/γ′热处理组织演变的影响

[J].通过对6种不同Ru (0-5.1%, 质量分数, 下同)和Cr (0-5.7%)含量的镍基单晶高温合金1100 ℃的时效和热处理组织观察与γ/γ'两相的成分分析,研究了Ru和Cr的独立和交互作用对合金元素成分分配比及热处理组织演变的影响.经1100 ℃/8 h时效后, 在枝晶干处, 不含Ru和Cr的基础合金γ'相接近球形,Re在该合金γ/γ'两相中的成分分配比较低, 错配度接近于0.在基础合金中加入高Ru后, γ'相立方度和Re的成分分配比略有增大,错配度变负; 在不含Ru合金与含Ru合金中, 随着Cr含量的增大, γ'相的立方度和Re的成分分配比均显著增大, 错配度明显变负.1100 ℃非加载下的长期热处理研究表明: γ'相接近球形且错配度接近于0的合金γ'相形貌稳定, 在2000 h内只出现了粗化,没有发生筏排化现象; γ'相呈中间态并且错配度较小的合金γ'相粗化趋势较为明显; γ'相接近立方体形且错配度中等的合金在热处理800 h后形成近似筏排组织; 同时加入Ru和Cr, 随着Re的成分分配比和错配度的增大,γ'相为立方体形或长方体形的合金筏排化时间提前; 其中高Ru中Cr合金热处理200 h就出现筏排化趋势, 而错配度最高的高Ru高Cr合金热处理仅50 h就形成筏排组织.

Damage and fracture mechanism of a nickel-based single crystal superalloy during creep at moderate temperature

[J].

Crack propagation and microstructural evolution of Ni-based single crystal alloy under shear loads

[J].

Phase morphology evolution and anisotropic cr- eep behaviour of nickel-base single crystal superalloy CMSX-4

[J].

镍基单晶高温合金CMSX-4相形态演变及蠕变各向异性

[J].研究了1253K,350MPa拉伸蠕变过程中[001],[110]和[111]取向镍基单晶高温合金CMSX-4基体相γ和析出相γ’的演变方式及相尺寸的变化规律比较了不同取向单晶试样中γ和γ’特征尺寸的变化对蠕变应变量和应变速率的影响结果表明,沿γ’定向粗化方向上γ基体通道宽度(即相邻γ’的间距)的变化速率对蠕变应变量和应变速率的影响较为明显.根据不同取向试样中γ基体通道的演变规律和塑性变形机制综合分析了蠕变各向异性行为。