温度对钛合金拉伸性能有较大的影响,随着温度的降低其强度提高、塑性和韧性降低。在极端低温条件下,为了保证钛合金结构长期服役安全可靠性,对其低温力学性能提出了更高的要求。钛合金的塑性变形机制,主要是滑移和孪生[7]。服役温度改变钛合金的塑性变形机制而影响其力学性能,例如Ti-Al单晶在不同温度下的滑移类型和孪晶类型有较大的不同[8]。TA2和TA7ELI合金的室温拉伸变形机制都是位错滑移,在液氮温度下TA2产生大量的{10

1 实验方法

表1 Ti-Al-Fe合金的化学成分

Table 1

| Al | Fe | C | N | H | O | Si | Ti |

|---|---|---|---|---|---|---|---|

| 0.991 | 1.13 | 0.01 | 0.006 | 0.001 | 0.085 | 0.01 | Bal. |

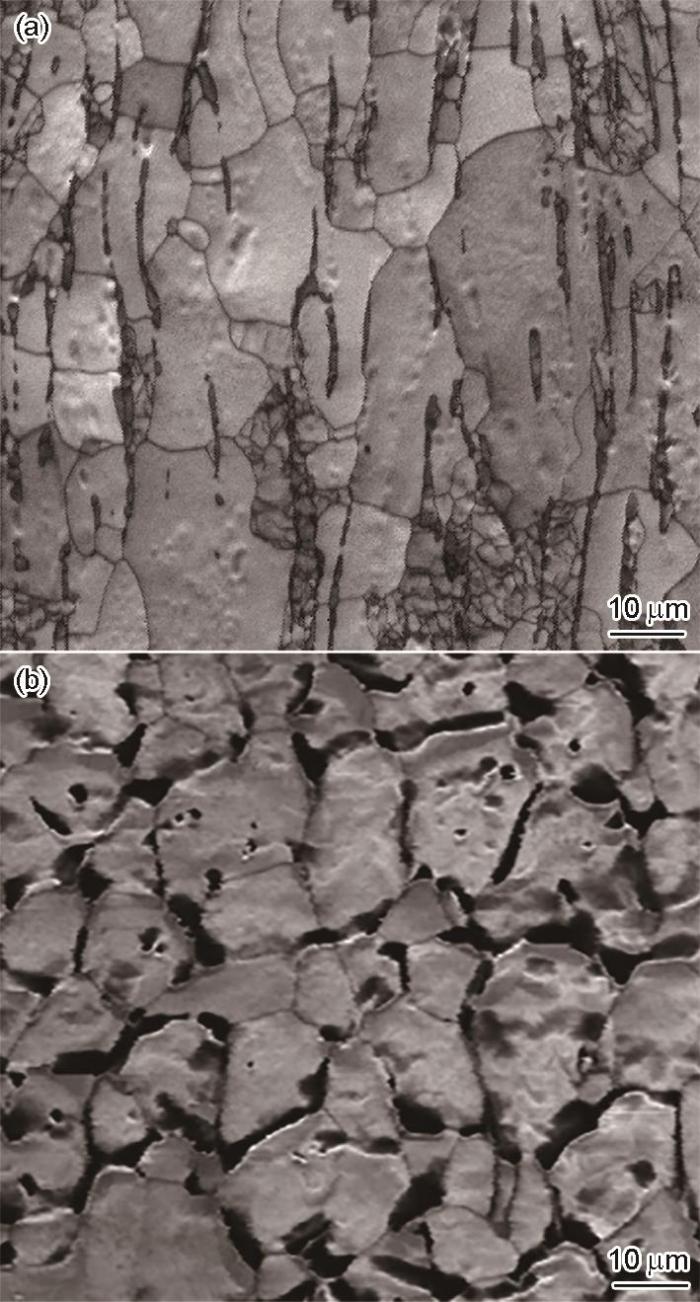

图1

图1

Ti-Al-Fe合金的显微组织

Fig.1

Microstructure of Ti-Al-Fe alloy (a) as-received; (b) as-annealed

用线切割方式截取拉伸试样样坯并加工成标距段直径为10 mm、长度为60 mm的拉伸试样,其轴向与棒材的轴向平行。参照GB/T228.1-2021《金属材料 拉伸试验 第1部分:室温试验方法》和GB/T228.3-2019《金属材料 拉伸试验 第3部分:低温试验方法》,分别在25℃和-196℃下对原始态和退火态Ti-Al-Fe合金进行拉伸实验。用Quanta650扫描电镜(SEM)观察断口的形貌。为了研究退火态Ti-Al-Fe合金在-196℃下不同拉伸变形阶段的变形机制,拉伸到不同塑性应变量时停机。在退火态Ti-Al-Fe合金拉伸试样均匀变形段截取电子背散射衍射(EBSD)和透射电镜(TEM)试样,观测面与试样轴向平行、观测面的法向与径向垂直。用电解双喷方式制成透射电镜样品,用JEM-2100透射电子显微镜观察位错组态和孪晶形态。用装有Pegasus XM2EBSD探头的场发射扫描电子显微镜JSM-7001F进行EBSD分析。

2 结果和讨论

2.1 Ti-Al-Fe合金的拉伸力学性能和断口形貌

Ti-Al-Fe合金在25℃、-196℃的拉伸力学性能,列于表2。可以看出,在-196℃原始态和退火态Ti-Al-Fe合金的屈服强度、抗拉强度均有提高,屈服强度为25℃时的1.97和1.99倍。与常规金属塑性随温度的降低而降低的规律不同,在-196℃原始态和退火态Ti-Al-Fe合金的延伸率不降反升且有较大幅度的提高,是25℃时的1.44和1.63倍。这种现象与高锰钢和不锈钢相变诱发塑性和纯钛孪生诱发塑性相似[10,17,18],均表现出低温塑性增强。退火后Ti-Al-Fe合金的显微组织由大小均匀的等轴α相和少量β相组成,晶粒尺寸约为20 μm。退火态Ti-Al-Fe合金在25℃和-196℃的屈服强度和抗拉强度比原始态均有下降,延伸率稍有提高。原始态和退火态Ti-Al-Fe合金在-196℃的延伸率提高,但是断面收缩率不变或降低。这表明,延伸率提高的主要原因是在低温下拉伸试样标距部分的均匀变形能力提高,而不是拉伸后期试样发生颈缩。

表2 原始态和退火态Ti-Al-Fe合金的拉伸力学性能

Table 2

| State | Temperature / oC | Rp0.2/ MPa | Rm/ MPa | A/ % | Z/ % |

|---|---|---|---|---|---|

| As-received | 25 | 409 | 606 | 23 | 41 |

| -196 | 805 | 1024 | 33 | 41 | |

| As-annealed | 25 | 335 | 530 | 24 | 42 |

| -196 | 669 | 1011 | 39 | 34 |

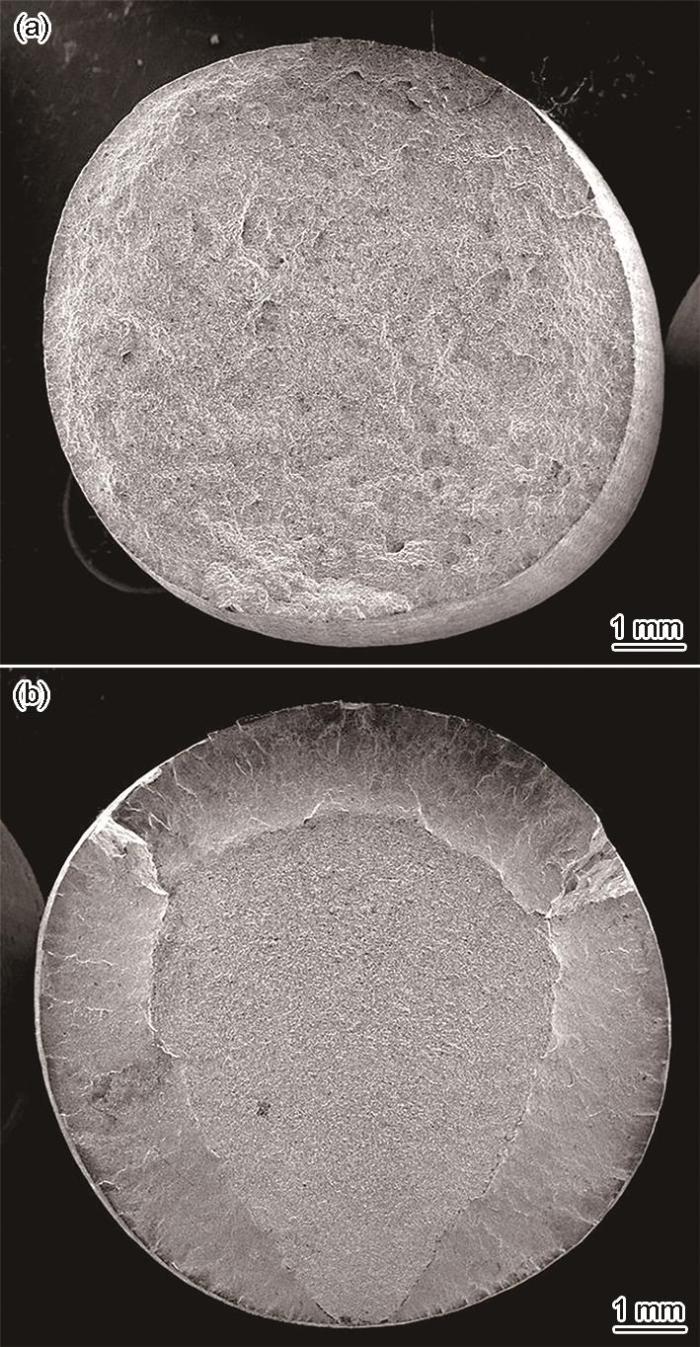

图2

图2

退火态Ti-Al-Fe合金拉伸试样在不同温度下的断口宏观形貌

Fig.2

Macro-morphologies of tensile fracture surfaces of as annealed Ti-Al-Fe alloy (a) 25oC; (b) -196oC

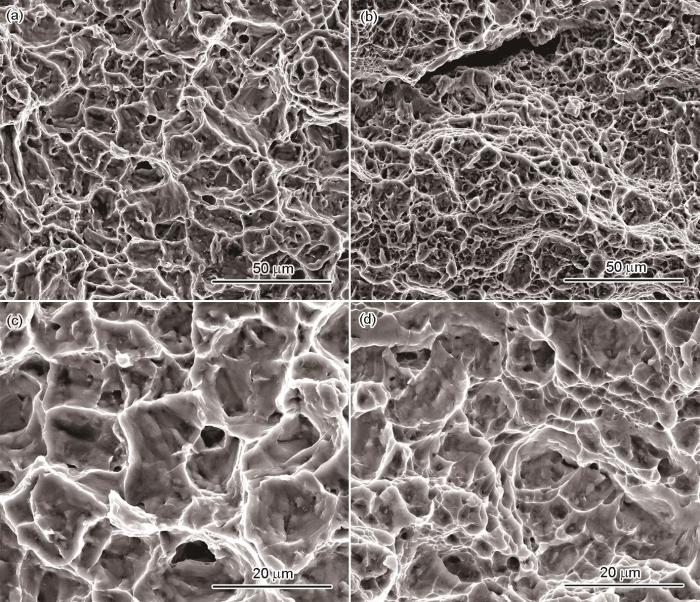

图3

图3

退火态Ti-Al-Fe合金在不同温度下拉伸试样断口的微观形貌

Fig.3

Micro-morphologies of tensile fracture surfaces of as annealed Ti-Al-Fe alloy (a, c) 25oC; (b, d) -196oC

2.2 在低温下不同塑性变形阶段样品显微组织的演化

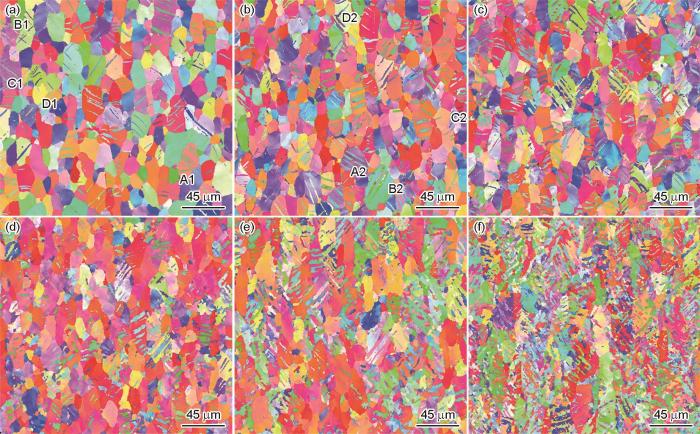

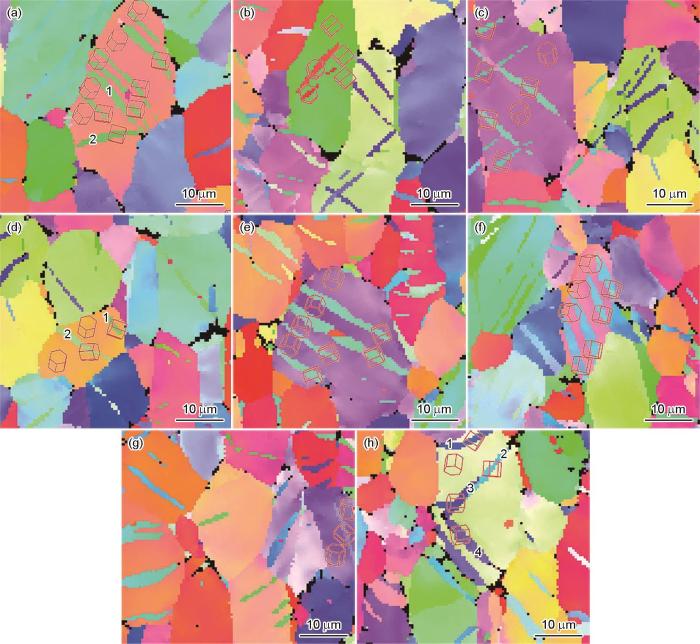

为了研究退火态Ti-Al-Fe合金在-196℃不同拉伸变形阶段显微组织的演化,对不同塑性变形量的均匀变形样品进行了EBSD测试,结果如图4所示。在变形的初始阶段塑性变形量为7.0%,晶粒的变形量小,仍保持原始等轴状,原始晶界比较清晰,在大部分晶粒中生成了孪晶。在单个晶粒中有一个或多个孪晶,相互交叉或相互平行分布。此时孪晶的生长空间较大且没有孪晶交互的破碎作用,其尺寸较大可贯穿整个晶粒,如图 4a所示。塑性变形量增大到14.5%,晶粒因变形而拉长,小区域原始晶界的边界模糊化。因为塑性变形量较大,孪晶的数量明显增加,部分晶粒内的孪晶破碎,如图4b所示。塑性变形量进一步增大到22.5%,塑性变形更加剧烈使大部分原始晶界和孪晶边界无法区分,孪晶的破碎和交互更加剧烈,如图4c所示。塑性变形量为34.0%时,原始晶粒因剧烈变形已无法识别,原始晶界完全破坏,组织完全模糊化,孪晶严重破碎成较小的尺寸,如图4d所示。Ti-Al-Fe合金在-196℃的拉伸变形过程中,在变形初期孪晶的尺寸较大,孪晶交互和破碎较少。随着塑性变形量的增大孪晶数量增多、未发生孪晶的区域减少,孪晶的生长空间受到限制,孪晶的交互和破碎使其尺寸减小。

图4

图4

在-196℃拉伸不同变形量后退火态Ti-Al-Fe合金的显微组织

Fig.4

Micrographs of as annealed Ti-Al-Fe alloy after different plastic deformations at -196oC (a) 7.0%; (b) 11.0%; (c) 14.5%; (d) 19.5%; (e) 22.5%; (f) 34.0%

由图4a、b可见,同一晶粒内孪晶的取向基本上一致,在极少数晶粒内部发生二次孪晶或者孪晶的交互作用,出现2种或2种以上取向的孪晶,如图4a、b中的A、B、C、D位置。同一取向的晶粒因受力状态不同也会生成不同类型的孪晶。对A1区域的基体晶粒和内部孪晶取向进行标定,如图5a所示。可以看出,具有相同取向的平行状孪晶1与基体的取向差为64°。平行状孪晶和基体关于{11

图5

图5

局部区域孪晶的形貌和取向

Fig.5

Morphologies and orientation of twinning (a) A1; (b) B1; (c) C1; (d) D1; (e) A2; (f) B2; (g) C2; (h) D2

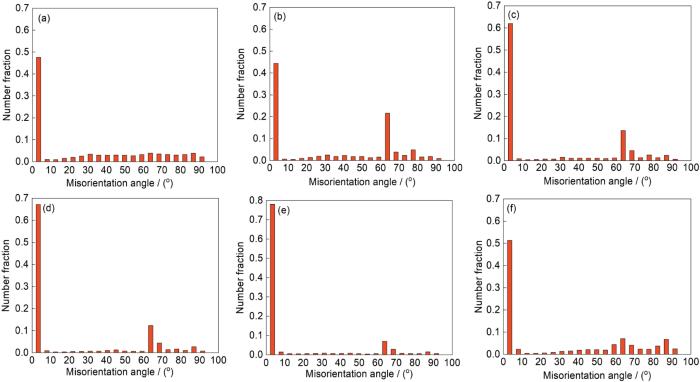

图6

图6

在-196℃拉伸不同变形量后退火态Ti-Al-Fe合金的晶粒取向差百分比

Fig.6

Misorientation angle of as annealed Ti-Al-Fe alloy at -196oC (a) HTA; (b) 7.0%; (c) 11.0%; (d) 14.5%; (e) 19.5%; (f) 34.0%

2.3 破断后均匀变形塑性区的显微组织

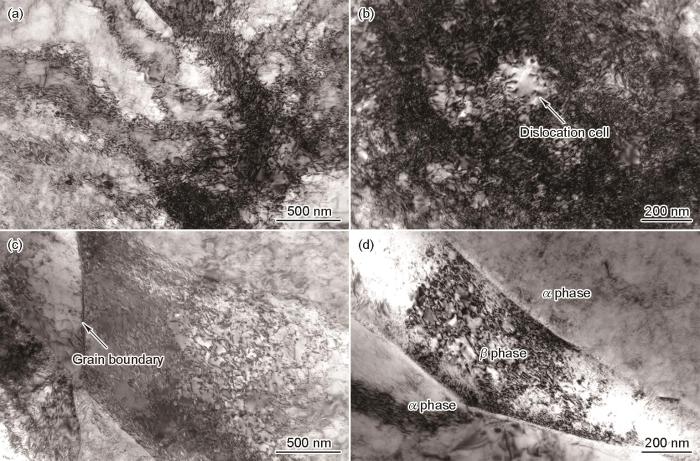

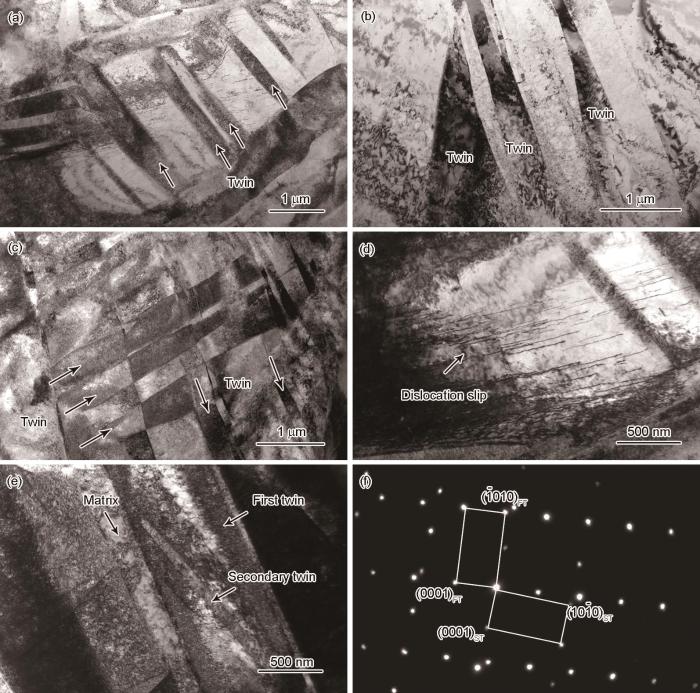

为了进一步研究退火态Ti-Al-Fe合金的塑性变形机制,用TEM细致观察了破断后试样均匀变形塑性区的显微组织。图7给出了在25℃退火态Ti-Al-Fe合金拉伸塑性变形区域的TEM照片。可以看出,在25℃下Ti-Al-Fe合金塑性变形区域的显微组织为高密度位错区和位错胞,极少发现变形组织和孪晶。此时,如图7a所示,大量位错开动并缠结形成高密度位错区。随着位错数量的增加和缠结程度的提高在部分区域形成位错胞,如图7b所示。在晶界、β与α相界面处均出现大量位错聚集和形成塞积,分别如图7c和7d所示。在-196℃下Ti-Al-Fe合金塑性变形区域的显微组织形貌发生了显著的变化,生成了大量的孪晶。孪晶的形态各异,有平行状孪晶、交叉状孪晶以及编织状孪晶,如图8a~c所示。由于塑性变形量较大,晶粒破碎严重,在组织内出现了大量的变形组织。大量位错在相界面、孪晶界面累积造成应力集中,触发孪晶内的位错滑移,如图8d所示。因取向问题,少量一次孪晶的滑移难以开动,在内部产生了二次孪晶。一次孪晶界面使二次孪晶的长大受到抑制,因此其尺寸较小,如图8e所示。如图8f所示,根据衍射斑点标定分析,二次孪晶的类型为{10

图7

图7

在25℃退火态Ti-Al-Fe合金拉伸塑性变形区域的TEM照片

Fig.7

TEM micrographs of tensile specimen of as annealed Ti-Al-Fe alloy deformed at 25oC (a) high density dislocation area; (b) dislocation cell; (c) dislocation block at triple junction of grain boundary; (d) dislocation block at the interface of α phase and β phase

图8

图8

在-196℃退火态Ti-Al-Fe合金拉伸塑性变形区域的TEM照片

Fig.8

TEM micrographs of tensile specimen of as annealed Ti-Al-Fe alloy deformed at -196oC (a) parallel twin; (b) intersected twin; (c) braided twin; (d) dislocation slipping in the twin; (e) secondary twin; (f) TEM diffraction pattern calibration of the first twin and secondary twin

2.4 塑性变形机制

钛合金的主要变形方式,是位错滑移和孪晶切变。在密排六方结构的α相<11

在25℃孪生的临界分切应力远大于滑移的分切应力[8],使滑移容易开动,其主要变形机制为位错滑移。随着温度的降低各滑移系开动的临界分切应力增大,而孪晶开动临界分切应力的变化不明显[26]。滑移系的临界分切应力大于孪晶开动的临界分切应力,便触发某些孪晶系开动,晶体发生孪生切变而生成孪晶。孪晶变形使晶体取向发生变化,有利于滑移继续进行而使材料的塑性提高。Ti-Al-Fe合金在-196℃出现孪生诱发塑性行为,在使其强度提高的同时断后伸长率也有很大的提高。目前在钛合金中已发现的孪晶类型有{10

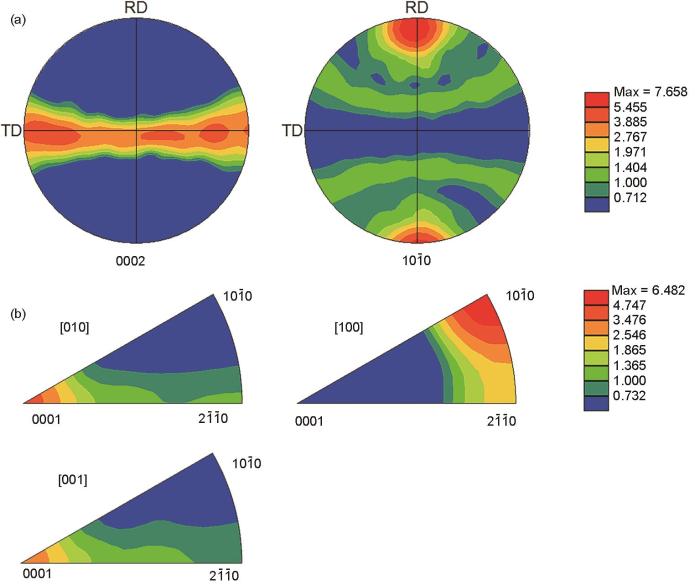

图 9

图 9

退火态Ti-Al-Fe合金棒材的EBSD测试结果

Fig.9

EBSD experimental results of as annealed Ti-Al-Fe alloy bar (a) (0002), (10

3 结论

(1) 原始态和退火态Ti-Al-Fe合金在-196℃表现出明显的孪晶诱发塑性效应,在具有较高强度的同时还具有较好的塑性,其屈服强度和延伸率分别未25℃下的1.97、1.99倍和1.44、1.63倍,断裂模式均为塑性断裂。

(2) Ti-Al-Fe合金在25℃的塑性变形机制为位错滑移;在-196℃的滑移开动受到抑制,孪晶成为主要变形模式,变形机制为孪生、滑移共存,孪晶类型为{11

(3) Ti-Al-Fe合金在-196℃不同变形阶段的孪晶类型和数量不同,在变形初期主要为{11

参考文献

Research progress in titanium alloys at cryogenic temperatures

[J].

低温钛合金的研究进展

[J].

A kind of Ti-Al-Fe system alloys for ship use

[J].

一种Ti-Al-Fe系船用钛合金

[J].

Study on TA36 titanium alloy tube rolling technology

[J].

TA36钛合金管材轧制工艺研究

[J].

Deformation behavior of HCP Ti-Al alloy single crystals

[J].

Tensile behavior of commercial pure titanium at low temperature

[J].

工业纯钛的低温拉伸行为研究

[J].

Tensile and low-cycle fatigue behavior of commercially pure titanium and Ti-5Al-2.5Sn alloy at 293 and 77 K

[J].

Strength and fracture toughness of Ti-5Al2.5Sn ELI alloy at cryogenic temperatures

[J].

Mechanical characterization of Ti-5Al-2.5Sn ELI alloy at cryogenic and room temperatures

[J].

Basal slip and twinning in α-titanium single crystals

[J].

Role of interphases in the deformation mechanisms of an α/β titanium alloy at 20 K

[J].

Twinning-induced high impact toughness of titanium alloy at cryogenic temperature

[J].

Low-temperature impact toughness and deformation mechanism of CT20 titanium alloy

[J].

On deformation twinning in a 17.5% Mn-TWIP steel: a physically based phenomenological model

[J].

Simultaneous enhancement of strength and ductility through coordination deformation and multi-stage transformation induced plasticity (TRIP) effect in heterogeneous metastable austenitic steel

[J].

Oxygen-gradient titanium with high strength, strain hardening and toughness

[J].

Cryoforged nanotwinned titanium with ultrahigh strength and ductility

[J].[Figure: see text].

Elimination of oxygen sensitivity in α-titanium by substitutional alloying with Al

[J].Individually, increasing the concentration of either oxygen or aluminum has a deleterious effect on the ductility of titanium alloys. For example, extremely small amounts of interstitial oxygen can severely deteriorate the tensile ductility of titanium, particularly at cryogenic temperatures. Likewise, substitutional aluminum will decrease the ductility of titanium at low-oxygen concentrations. Here, we demonstrate that, counter-intuitively, significant additions of both Al and O substantially improves both strength and ductility, with a 6-fold increase in ductility for a Ti-6Al-0.3 O alloy as compared to a Ti-0.3 O alloy. The Al and O solutes act together to increase and sustain a high strain-hardening rate by modifying the planar slip that predominates into a delocalized, three-dimensional dislocation pattern. The mechanism can be attributed to decreasing stacking fault energy by Al, modification of the "shuffle" mechanism of oxygen-dislocation interaction by the repulsive Al-O interaction in Ti, and micro-segregation of Al and O by the same cause.© 2021. This is a U.S. Government work and not under copyright protection in the US; foreign copyright protection may apply.

Atomic-scale modeling of twinning in titanium and other HCP alloys

[D].

The effect of aluminium on twinning in binary alpha-titanium

[J].

A low-cost and high-strength Ti-Al-Fe-based cast titanium alloy for structural applications

[J].

The crystallography and deformation modes of hexagonal close-packed metals

[J].

Strain rate sensitivity in commercial pure titanium: the competition between slip and deformation twinning

[J].

Strain rate dependence of deformation-induced transformation and twinning in a metastable titanium alloy

[J].

Anisotropic twinning and slip behaviors and their relative activities in rolled alpha-phase titanium

[J]

Twinning behavior of a basal textured commercially pure titanium alloy TA2 at ambient and cryogenic temperatures

[J].

Evolution of dislocations and deformation twins in Ti6321 titanium alloy under contact explosion

[J].

Mechanism of the anisotropy of yield ratio in TA5 titanium alloy plates

[J].