材料的热处理,可改变其微观结构和力学性能[9]。进行不同制度的热处理,可制备出不同性能的高强度螺栓用钢[10]。目前,关于高强钢的合金成分、轧制工艺以及热处理工艺对组织和性能的影响的研究,取得了较大进展[11~14]。为了满足服役要求,螺栓用低合金钢需要调质处理,即淬火+高温回火。但是,低合金钢的碳和合金元素的含量较高,硬度和变形抗力大,需要进行球化(软化)退火预处理。特别是,在提高材料强度的同时还需要保持一定的塑韧性[15,16]。目前,用有限元模拟,研究螺栓在拉伸载荷下的力学性能,并探索螺栓连接拉伸断裂失效模式和机理[17~19]。但是,大部分研究侧重螺栓连接的整体结构,缺少对螺栓本体材料的优化和探索。

螺栓的螺纹使其宏观几何产生不连续性,通常看作多缺口零件。构件的几何不连续引起应力集中,在应力集中处发生失效[20~22]。另外,装配螺栓时需要施加较大的预紧力,而检测其引起的螺纹早期故障极为困难。蓄能机组中的水泵水轮机顶盖螺栓其公称直径可达100 mm以上,难以直接进行全尺寸螺栓构件的拉伸试验。因此,了解螺栓在拉伸载荷下的失效行为至关重要[23]。研究蓄能机组顶盖螺栓材料不同热处理状态的缺口拉伸性能,有利于螺栓连接顶盖与座环及其整个机组的安全可靠性设计。另外,根据特定应力集中系数设计不同尺寸的缺口弧度也较为困难,而且特定非标件小尺寸缺口加工精度难以保证。因此,建立一种缺口抗拉强度的预测方法,可为优化小尺寸缺口试样的拉伸性能提供参考。鉴于此,本文研究蓄能机组顶盖螺栓钢35CrMo在不同温度回火后各应力集中系数的缺口拉伸性能,根据拉伸断裂形貌研究回火温度及应力集中系数对拉伸性能和断裂机制的影响,以探讨预测缺口抗拉强度的方法。

1 实验方法

实验用材料为低合金结构钢35CrMo,用电感耦合等离子体发射光谱法(ICP)测定的化学成分,列于表1。服役态螺栓材料为调质态(Quenched and tempered state,QT),热处理制度为淬火 + 高温回火,即在860℃保温60 min后油淬冷却至室温,然后在650℃回火120 min后空冷至室温。

表1 35CrMo钢的化学成分

Table 1

| C | Si | Cr | Mo | Mn | P | S | Fe |

|---|---|---|---|---|---|---|---|

| 0.35 | 0.35 | 1.10 | 0.20 | 0.80 | 0.004 | 0.0022 | Bal. |

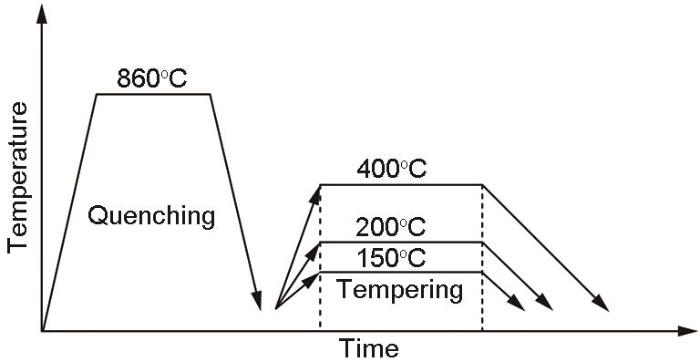

用电火花线切割机在尺寸为M110 mm × 4 mm的服役态高强度螺栓上沿轴向取样,取样棒料的直径为15 mm,长度为70 mm。为获得更宽的强度范围以选取缺口拉伸性能最佳的热处理工艺,对服役态35CrMo钢进行四种制度的热处理,其工艺在图1中给出。为了得到均匀的奥氏体化组织,先将实验用钢棒料加热到860℃保温30 min,随后油淬冷却至室温。然后分别在150、200和400℃回火,保温时间为90 min,随后空冷到室温。将未回火和在不同温度回火的试样,分别标记为Q、QT150、QT200和QT400。

图1

图1

顶盖螺栓用35CrMo钢的热处理工艺示意图

Fig.1

Schematic diagram of heat treatment process for the head cover bolt of 35CrMo steel

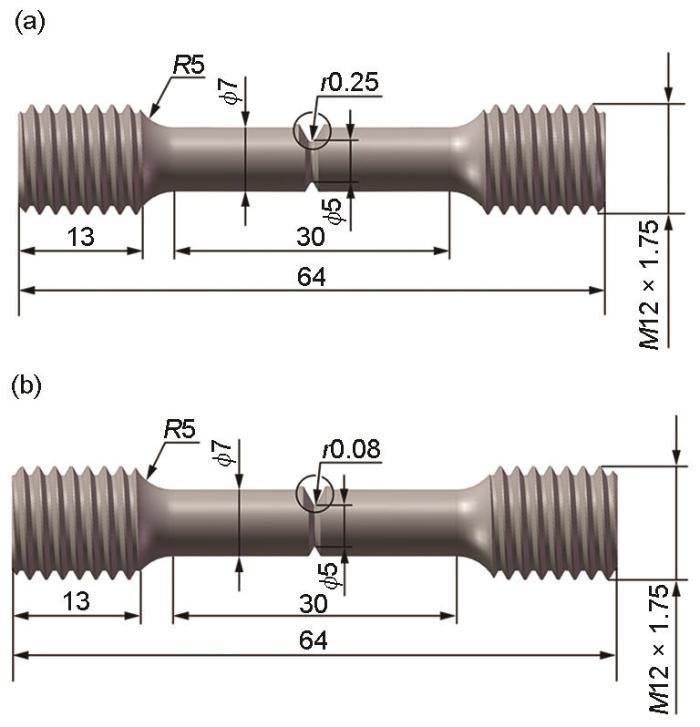

图2

图2

缺口拉伸试样的尺寸

Fig.2

Dimension of notched tensile specimen (a) Kt = 3; (b) Kt = 5 (unit: mm)

根据国家标准GB/T 228-2021在型号为Instron 5982万能实验机上进行常规室温拉伸实验,拉伸速率为1 × 10-3 s-1,拉伸速度为1.8 mm/min。用扫描电子显微镜(SEM)JSM-6510观察断口形貌。每种试样测量三次,取抗拉强度、断面收缩率等数据的平均值。用超景深三维体式显微镜(型号为KEYENCE VHX-1000E)测量断面收缩率。断面收缩率(Z)为

其中F为拉伸后的横截面积;F0为拉伸前的横截面积。

用全自动显微硬度测试系统LECO AMH43测试样品截面的显微硬度,载荷为4.9 N,保载时长15 s。根据国家标准GB/T 4340.1-2009中有关金属材料的维氏硬度实验测试试样的显微硬度。选取每个样品上分散的10个位置进行测量,取其结果的平均值。

用电子背散射衍射显微技术(EBSD)ZEISS SIGMA 500型场发射扫描电子显微镜观察试样截面的微观组织。用EBSD微观组织观察时,截取尺寸为8 mm × 8 mm × 2 mm的方块试样并将其研磨和机械抛光,然后在HClO4∶CH3(CH2)3OH∶CH3OH = 1∶7∶12溶液中进行室温电解腐蚀以去除表面应力。用型号为JSM-6510的扫描电子显微镜(SEM)观察拉伸断口的形貌,加速电压为20 kV,工作距离为18~22 μm。

2 实验结果

2.1 试样的显微组织

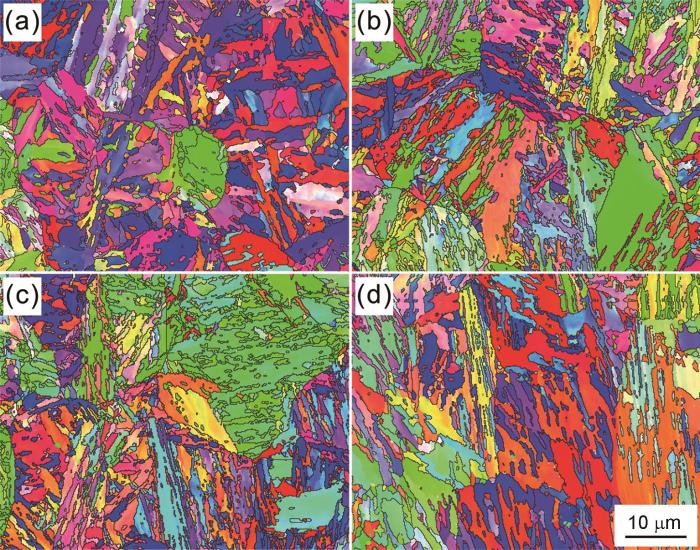

图3

图3

不同回火温度35CrMo钢的EBSD结构特征

Fig.3

EBSD microstructures of 35CrMo steel processed at different tempered temperatures (a) Q; (b) QT150; (c) QT200; (d) QT400

2.2 缺口拉伸性能

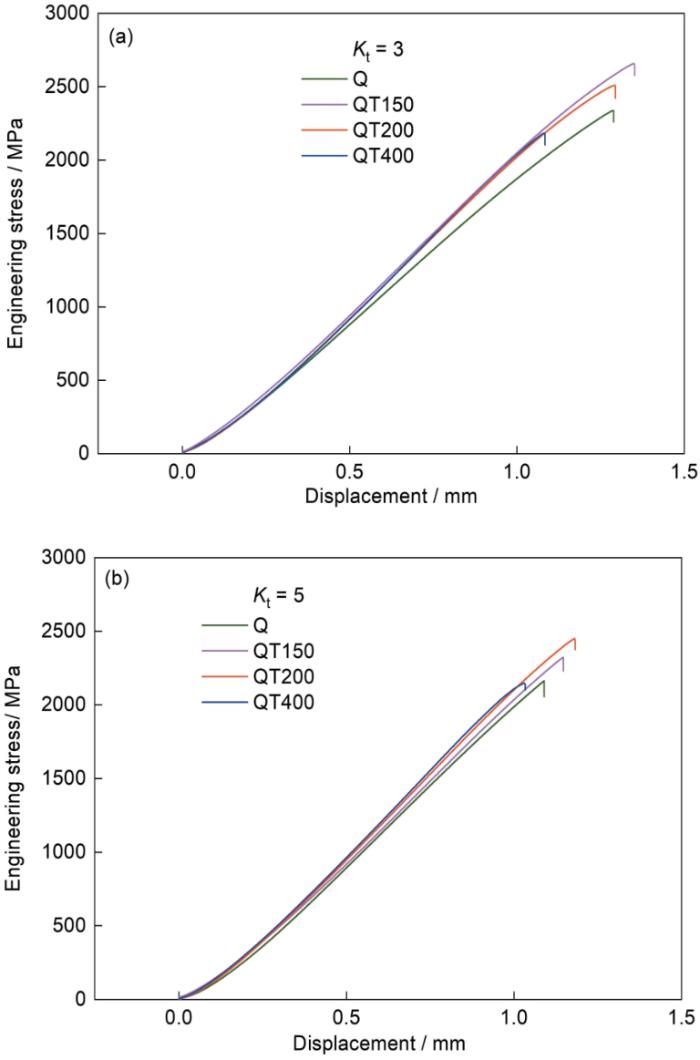

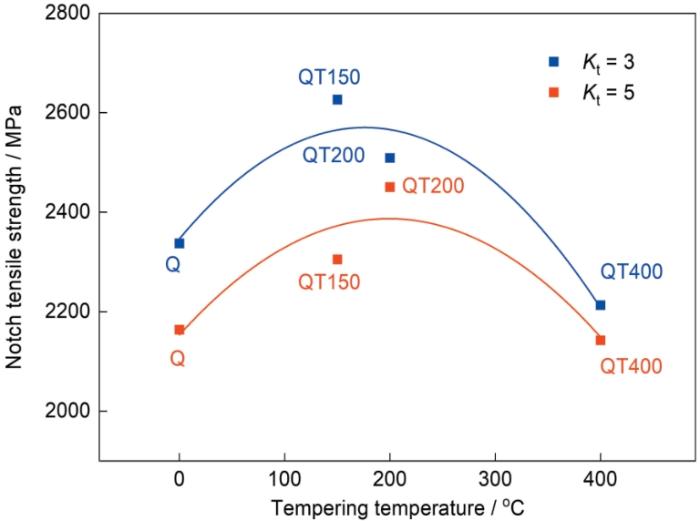

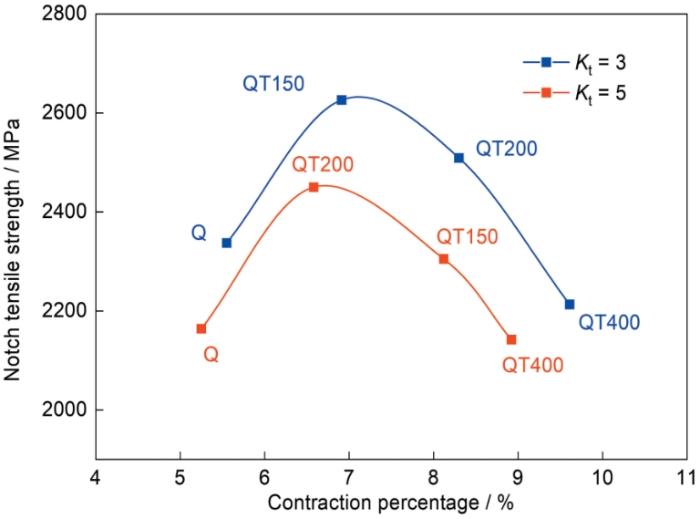

在不同温度回火的35CrMo钢,其应力集中系数不同的缺口试样的抗拉强度,列于如表2。图4给出了在不同温度回火的35CrMo钢缺口试样(Kt = 3和5)的拉伸应力-位移曲线。可以看出,应力集中系数Kt = 3的QT150其抗拉强度最高为2626 MPa,应力集中系数Kt = 5的QT200其抗拉强度最高为2450 MPa。图5给出了回火温度对材料缺口抗拉强度的影响。可以看出,随着回火温度的提高缺口抗拉强度先升高后降低,应力集中系数的增大使抗拉强度有所下降。断面收缩率在表3中给出,可见在不同温度回火的缺口拉伸试样其断面收缩率为5%~10%。在400℃回火的试样其断面收缩率最大,表明在回火400℃的试样塑性最大。图6给出了缺口抗拉强度和断面收缩率的关系,随着缺口抗拉强度的下降,断面收缩率增大。这个结果,与其它金属强度与延性的反比关系相同[25]。

表2 不同回火温度35CrMo钢的缺口抗拉强度

Table 2

| Heat-treatment procedures | Q | QT150 | QT200 | QT400 |

|---|---|---|---|---|

| Kt = 3 | 2337 | 2626 | 2509 | 2213 |

| Kt = 5 | 2164 | 2305 | 2450 | 2142 |

图4

图4

不同回火温度35CrMo钢缺口试样的拉伸应力-位移曲线

Fig.4

Tensile stress-displacement curves for notched specimens of 35CrMo steel under different tempering temperatures (a) Kt = 3; (b) Kt = 5

图5

图5

回火温度对35CrMo钢缺口抗拉强度的影响

Fig.5

Effect of tempering temperature on notch tensile strength of 35CrMo steel

表3 不同回火温度35CrMo钢的缺口拉伸断面收缩率

Table 3

| Heat-treatment procedures | Q | QT150 | QT200 | QT400 |

|---|---|---|---|---|

| Kt = 3 | 5.55 | 6.91 | 8.30 | 9.61 |

| Kt = 5 | 5.25 | 8.12 | 6.58 | 8.92 |

图6

图6

缺口抗拉强度与断面收缩率的关系

Fig.6

Relationship between notch tensile strength and contraction percentage

3 讨论

3.1 缺口拉伸性能

金属材料试样上的缺口,使其塑性降低和脆性增大。金属材料试样上的缺口产生三向应力状态和应力应变集中,从而使材料变脆,称为缺口敏感性。为了量化和比较缺口对各种材料拉伸性能的影响,用缺口试样的抗拉强度σbN与等截面尺寸光滑试样的抗拉强度σb之比表征材料的缺口敏感性[20],记为NSR (Notch sensitivity ratio)

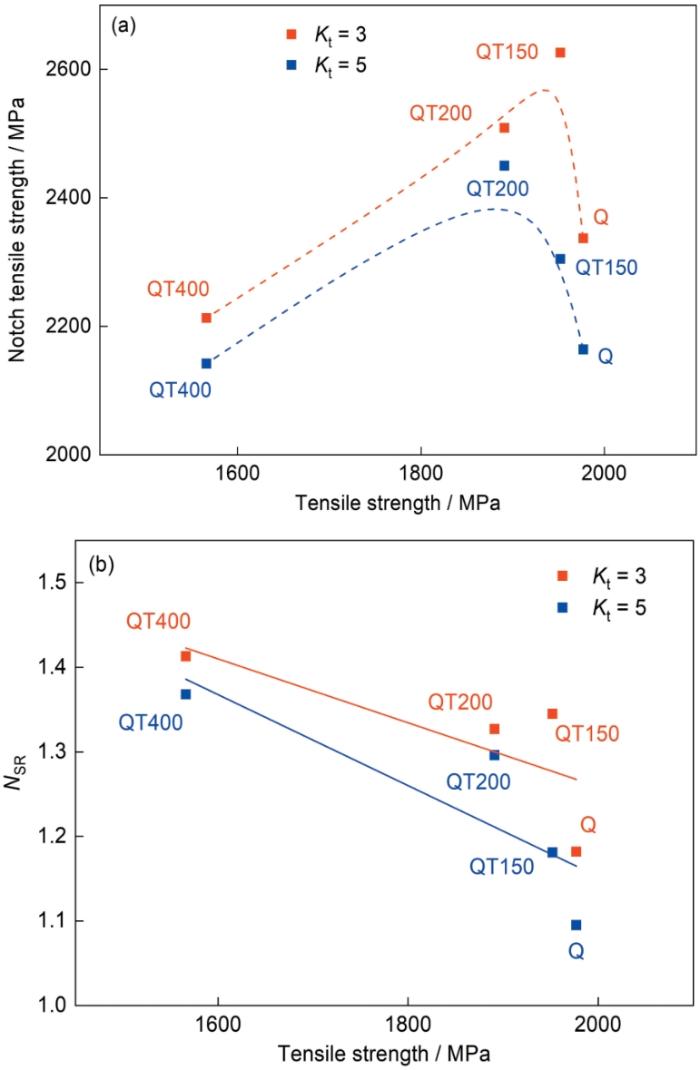

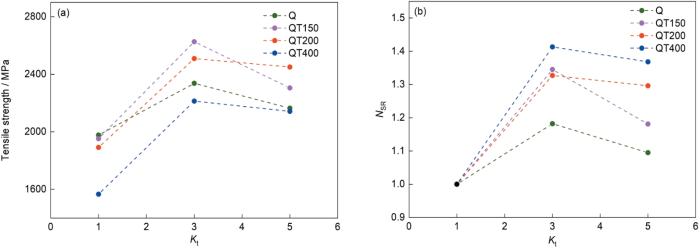

Yang等[28]预测不同热处理35CrMo钢的高周疲劳行为及疲劳强度时,对在不同温度回火(其热处理制度与本文的缺口拉伸试样热处理制度相同)的光滑试样进行拉伸实验。在不同温度回火的35CrMo钢光滑试样的拉伸性能,列于表4。对在不同温度回火的两种应力集中系数缺口试样拉伸性能与光滑试样(Kt = 1)的拉伸性能进行了对比。结果表明,在不同温度回火的缺口试样其抗拉强度比光滑试样显著提高。其原因是,光滑试样的单向应力状态转变为缺口试样的多向应力状态,使抗拉强度提高。对于塑性较好的材料,缺口使其屈服强度或抗拉强度提高但是塑性降低,即所谓“缺口强化”。35CrMo钢出现了明显的“缺口强化效应”,而且缺口的存在约束了塑性变形而使拉伸位移减小。

表4 35CrMo钢在不同温度回火后的拉伸性能[28]

Table 4

| Sample | σb / MPa | σy / MPa | Z / % | A / % |

|---|---|---|---|---|

| Q | 1977 | 1380 | 33.20 | 10.80 |

| QT150 | 1952 | 1364 | 42.78 | 11.00 |

| QT200 | 1891 | 1487 | 47.66 | 12.05 |

| QT400 | 1566 | 1352 | 51.48 | 12.10 |

缺口拉伸实验,主要用于比较淬火低中温回火的各种高强度钢的力学性能。屈服强度< 1200 MPa时,其缺口强度均随着材料屈服强度的提高而提高。但是,屈服强度高于1200 MPa则表现出不同的特性[29]。随着回火温度的提高,35CrMo钢缺口试样的抗拉强度先升高后降低,QT200的光滑试样其最高的屈服强度为1487 MPa,对应的缺口试样(Kt = 5)的最高抗拉强度为2450 MPa;QT150的光滑试样其屈服强度为1364 MPa,对应的缺口试样(Kt = 3)的最高抗拉强度为2626 MPa。

图7

图7

不同回火温度处理35CrMo钢缺口拉伸与光滑拉伸性能对比

Fig.7

Comparisons between notch and smooth tensile properties of 35CrMo steel after tempering at different temperature treatments (a) relationship between notch tensile strength and tensile strength of smooth specimens; (b) relationship between tensile notch sensitivity ratio and tensile strength of smooth specimens

表5 在不同温度回火后35CrMo钢的缺口NSR值

Table 5

| Heat-treatment procedures | Q | QT150 | QT200 | QT400 |

|---|---|---|---|---|

| Kt = 3 | 1.182 | 1.345 | 1.327 | 1.413 |

| Kt = 5 | 1.095 | 1.181 | 1.296 | 1.368 |

表6 不同温度回火的35CrMo钢的缺口抗拉强度增强率

Table 6

| Heat-treatment procedures | Q | QT150 | QT200 | QT400 |

|---|---|---|---|---|

| Kt = 3 | 13.2 | 34.5 | 32.7 | 41.3 |

| Kt = 5 | 9.50 | 18.1 | 29.6 | 36.8 |

图8

图8

应力集中系数对不同回火温度35CrMo钢拉伸性能的影响

Fig.8

Effect of stress concentration factor on tensile properties of 35CrMo Steels under different tempering temperatures treatments (a) relationship between Kt and tensile strength; (b) relationship between Kt and NSR

3.2 缺口试样的拉伸断口

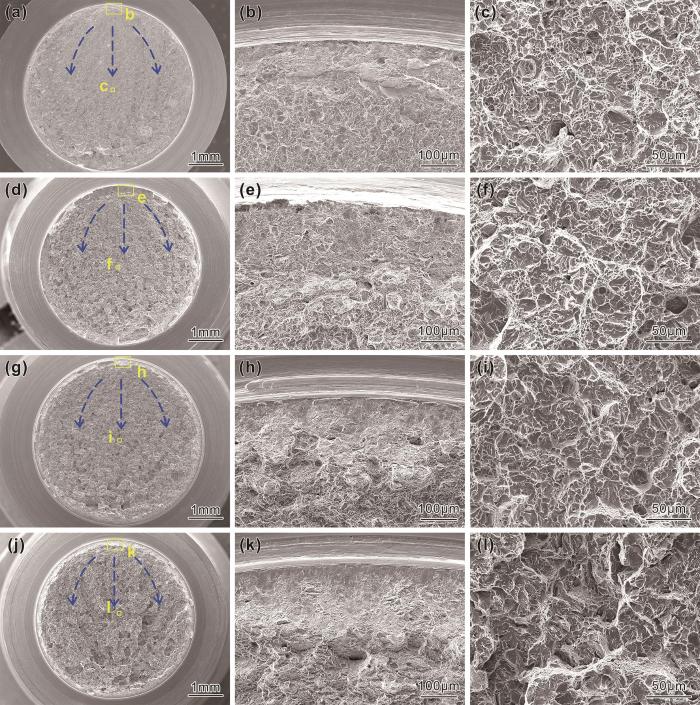

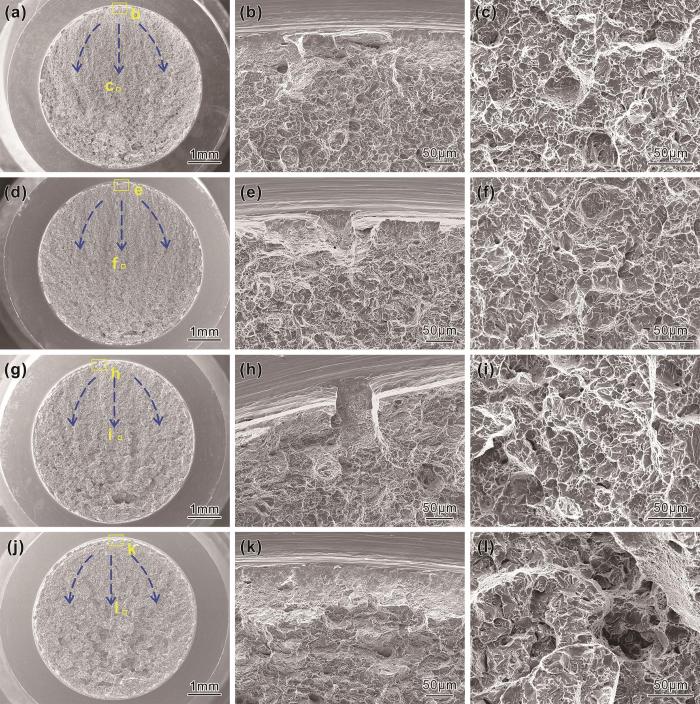

在不同温度回火的35CrMo钢缺口试样的拉伸断口形貌,在图9和图10中给出。可以看出,缺口试样的拉伸宏观断口与光滑试样的拉伸宏观断口形貌明显不同。四种热处理的缺口试样断口形貌没有拉伸断口的三个典型的特征和明显的颈缩现象(图9a、d、g、j;图10a、d、g、j),断面整体较为平坦,也没有出现光滑圆柱体拉伸后的杯壁状剪切唇。从宏观形貌可以看出,裂纹均从边缘起始沿着径向扩展直到断裂。四种试样断口的表面出现明显的凹凸不平的撕裂棱,且沿着裂纹扩展的方向撕裂棱的尺寸越来越大,是在裂纹快速扩展中形成的。另外,从断口宏观形貌还可以看出,随着回火温度的升高断口表面逐渐变的粗糙。

图9

图9

Kt = 3的不同回火温度35CrMo钢的拉伸断口形貌

Fig.9

Notch tensile fracture morphology of 35CrMo Steel after tempering at different temperature at Kt = 3 (a~c) Q; (d~f) QT150; (g~i) QT200; (j~l) QT400

图10

图10

Kt = 5的不同回火温度35CrMo钢的拉伸断口形貌

Fig.10

Notch tensile fracture morphology of 35CrMo Steel after tempering at different temperature at Kt = 5 (a~c) Q; (d~f) QT150; (g~i) QT200; (j~l) QT400

Kt = 3的不同热处理材料35CrMo钢缺口试样的拉伸裂纹起始位置的断口形貌,在图9b、e、h和k中给出。可以看出,四种热处理的缺口拉伸试样的裂纹均在缺口根部表面萌生。Q、QT150、QT200和QT400试样邻近表面的断裂趋于平坦,Q试样临近表面处韧窝较多但比较浅且断裂面比较平整,而QT400试样临近表面的断面较为平坦,韧窝较少,但是断裂面起伏比较大,沿裂纹扩展方向韧窝逐渐增大,数量逐渐增多,断裂面更加粗糙。Q、QT150、QT200和QT400四种热处理工艺的缺口拉伸试样内部区域的断口形貌分别在图9c、f、i和l中给出。可以看出,断口上均有大小不一的韧窝和孔洞,是典型的纤维区特征。Q、QT150和QT200试样的断口内部为韧窝和断裂小平面结合的形貌,表现出韧性和脆性的混合断裂特征。QT400试样的断口内部形貌是较少但是较大的韧窝和解理平面,断裂表面更加起伏不平并出现二次微裂纹,表现为准解理断裂特征。

3.3 抗拉强度的预测

测量硬度较为容易且包含了强度的信息,因此人们用硬度推测材料的抗拉强度。强度与硬度关系的经验公式为

用不同热处理制度处理的35CrMo钢,具有不同的硬度。未回火试样的维氏硬度为5512.71 N/mm2,在150℃回火的试样硬度为5415.92 N/mm2,在200℃回火的试样硬度为5081.1 N/mm2;在400℃回火的试样硬度为4574.28 N/mm2。

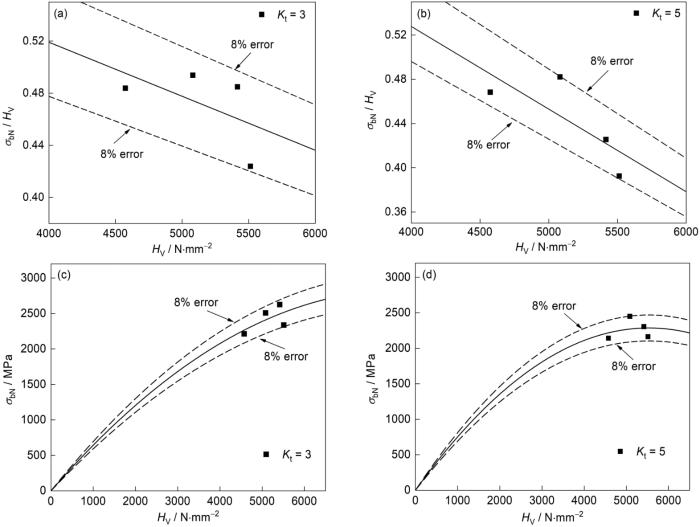

对比在不同温度回火的35CrMo钢试样其硬度和缺口试样的拉伸性能发现,随着硬度的增大其抗拉强度有增大的趋势,于是假设缺口试样的抗拉强度和硬度的关系为

其中σbN为缺口抗拉强度(MPa);a、b为与材料有关的参数;HV为维氏硬度(N/mm2)。拟合应力集中系数分别为Kt = 3和Kt = 5的缺口试样的抗拉强度和维氏硬度的比值(σbN/HV)与维氏硬度的关系,结果在图11a、b中给出。可以看出,拟合结果在8%以内,表明在两种应力集中条件下的缺口抗拉强度和维氏硬度的比值(σbN/HV)与维氏硬度(HV)之间有良好的线性关系:

图11

图11

35CrMo钢的缺口抗拉强度与硬度的关系

Fig.11

Relationship between notch tensile strength and hardness of 35CrMo steel (a) σbN/HV vs. HV (Kt = 3); (b) σbN/HV vs. HV (Kt = 5); (c) σbN vs. HV (Kt = 3); (d) σbN vs. HV (Kt = 5)

由

由

图11c、d给出了根据

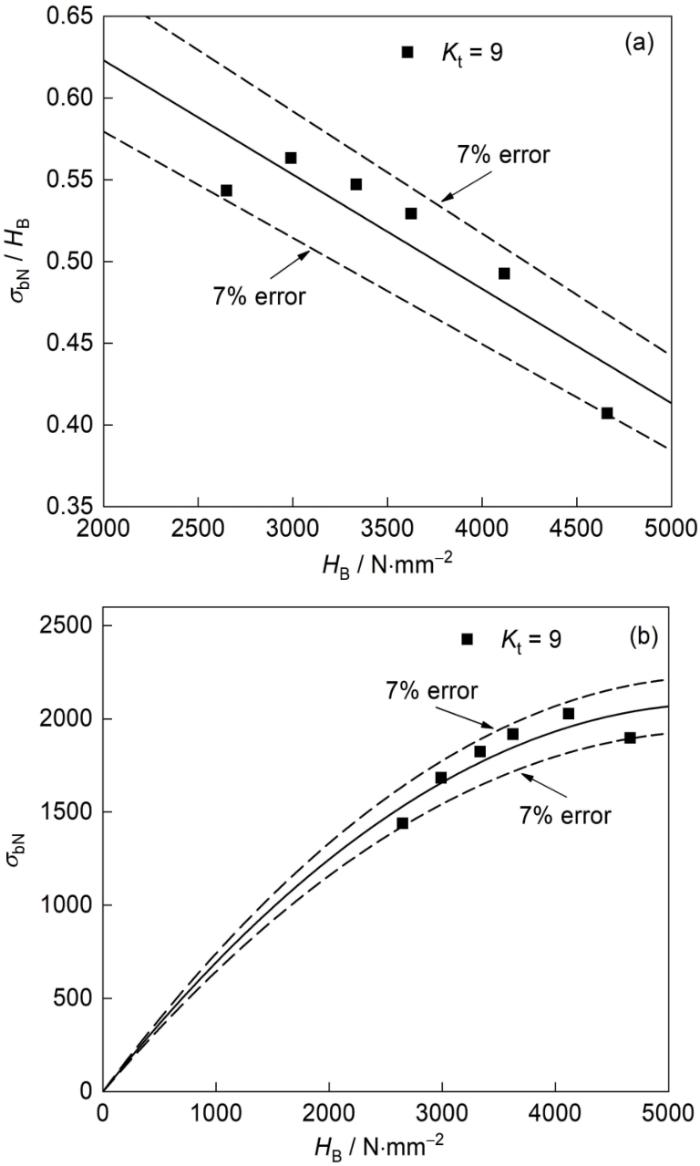

为了验证

其曲线在图12中给出,可见拟合误差均< 7%。

图12

图12

马氏体钢的缺口抗拉强度与硬度的关系

Fig.12

Relationship between notch tensile strength and hardness of martensitic steel (a) σbN/HB vs. HB; (b) σbN vs. HB

4 结论

(1) 油淬后35CrMo钢的组织由大量板条状马氏体和部分残余奥氏体组成,在150℃和200℃低温回火后得到回火马氏体,随着回火温度的提高马氏体逐渐分解,在回火400℃后得到均匀的回火屈氏体组织。

(2) 35CrMo钢的缺口拉伸敏感度均> 1,表明产生了“缺口强化”效应。随着应力集中系数的增大,缺口强化效果呈现出先升后降的趋势。随着回火温度的提高,缺口抗拉强度先上升后下降。在150℃回火Kt = 3的缺口抗拉强度最高为2626 MPa,在200℃回火Kt = 5的缺口抗拉强度最高为2450 MPa。

(3) 缺口拉伸试样均在缺口根部表面开裂,裂纹沿径向扩展,其最终的断裂均为韧性和脆性混合断裂。缺口拉伸断口较为平坦,没有拉伸断口的三个典型特征和明显的颈缩现象。断口表面出现明显凹凸不平的撕裂棱,且沿扩展方向越来越大。

(4) 根据硬度和缺口拉伸数据,提出一种根据硬度预测缺口试样抗拉强度的快速预测方法即抛物线关系,预测结果的误差均< 8%。

参考文献

Research on the flow-induced stress characteristics of head-cover bolts of a pump-turbine during turbine start-up

[J].Nowadays, pump-turbine units have to experience multiple start-stops every day to balance the power production and consumption on the grid. During the transient process of turbine start-up, the hydraulic forces applied to the head-cover would change dramatically and induce high-level stresses on the head-cover bolts. As key components of large hydraulic turbine units, the head-cover bolts are subjected to tens of thousands of tonnes of hydraulic excitation force during operation. Special attention should be paid to the design of the head-cover bolts of large hydraulic pump-turbine units because these units have high water heads and high hydraulic excitation forces. Therefore, the safe design of the head-cover bolts is extremely important to maintain the operational safety of the whole unit. This paper investigates the flow-induced stress characteristics of the head-cover bolts during turbine start-up in a large prototype pump-turbine unit. A complete 3D fluid model and a corresponding 3D structural model, including the head-cover bolts of the pump-turbine unit, were created. The fluid–structure coupling method was used to calculate the structural stresses caused by fluid flow during turbine start-up. The pressure files during turbine start-up calculated by the CFD tool were transferred and mapped to the finite element model of the structural components of the pump-turbine unit. Subsequently, the flow-induced stress characteristics of the head-cover bolts were numerically simulated. The simulation results showed that the hydraulic excitation force on the head-cover bolts increased significantly during turbine start-up, and the displacement and the stress distributions of different head-cover bolts were not uniform. The calculation methods and conclusions in this paper can also be applied to evaluate the flow-induced stress characteristics of head-cover bolts for similar hydraulic pump-turbine units.

Research and development trends of high strength steel for bolts

[J].

高强度螺栓钢的发展动向

[J].

Present situation and development tendency of high strength bolt steel

[J].

高强度螺栓材料的研究现状与趋势

[J].

Study on design, preparation and properties of 2200 MPa grade low alloy steel

[D].

2200 MPa级低合金钢设计制备与性能研究

[D].

A study of crack initiation in a low alloy steel

[J].

Effects of rare earth on microstructure and impact toughness of low alloy Cr-Mo-V steels for hydrogenation reactor vessels

[J].

Characterization of transition behavior in SA508 Gr.4N Ni-Cr-Mo low alloy steels with microstructural alteration by Ni and Cr contents

[J].

Effect of quenching temperature on microstructure and properties of Cu-bearing 5Cr15MoV martensitic stainless steel

[J].The Cu-bearing martensitic stainless steel 5Cr15MoV was heat treated at different temperatures for 30 min and then oil quenched. The effect of quenching temperature on the microstructure, hardness and corrosion resistance of the steel were investigated by means of optical microscopy (OM), scanning electron microscopy (SEM), X-ray diffraction (XRD), transmission electron microscopy (TEM), hardness tester and electrochemical test. The results show that the addition of Cu increases the volume fraction of residual austenite and decreases the hardness of the steel, the undissolved carbides in the quenched steel are Cr rich M23C6 type carbides with FCC structure, and the addition of Cu has no obvious effect on the size and morphology of the carbides in the 5Cr15MoV martensitic stainless steel, but its corrosion resistance is slightly reduced. With increase of the quenching temperature from 1000oC to 1100oC the undissolved carbides decrease, while the corrosion resistance of the steel increases. Meanwhile, the content of residual austenite also increases with the increase of quenching temperature. The combined action of carbide and residual austenite makes the hardness versus temperature curve of the quenched steel a parabolic shape with a maximum value at 1050°C.

淬火温度对含铜5Cr15MoV马氏体不锈钢性能的影响

[J].将含铜5Cr15MoV马氏体不锈钢在不同温度热处理并使用光学显微镜(OM)、扫描电子显微镜(SEM)、X射线衍射(XRD)、透射电子显微镜(TEM)、硬度测试和电化学测试等手段对其表征,研究了淬火温度对其组织、硬度以及耐蚀性能的影响。结果表明,铜元素的添加提高了材料中残余奥氏体的体积分数,而使其硬度降低。淬火后钢中的未溶碳化物为fcc结构的富铬M<sub>23</sub>C<sub>6</sub>型碳化物,铜元素的添加对5Cr15MoV马氏体不锈钢中碳化物的尺寸和形貌没有明显的影响,但是使其耐蚀性能略微降低。随着淬火温度从1000℃提高到1100℃,未溶碳化物逐渐减少,耐蚀性提高。残余奥氏体的含量也随着淬火温度的提高而增多,碳化物与残余奥氏体的共同作用使淬火后钢的硬度曲线呈抛物线状并在1050℃达到最大值。

Heat treatment effects on the mechanical properties and microstructure of 30MnB4 steel bolts

[J].This study targeted the effects of heat treatment on the mechanical properties of high-strength steel bolts. High-strength steel bolt samples were manufactured by sequential cutting, cold forming, heading and heat treatment. All sample bolts were M12, and the material was 30MnB4. During the heat treatment, quenching and tempering were applied to high-strength steel. Stress-strain curves were obtained for the steel bolt samples after different heat treatments. The mechanical properties of the steel bolts, such as yield strength, tensile strength, hardness and elongation, were determined for the various heat treatments. It was concluded that heat treatment is an important process that changes the microstructure of the steel bolts and their mechanical properties. By heat treatment at different temperatures it is possible to obtain high-strength steel bolts with different properties.

Microstructural evolution and mechanical properties of low alloy steel tempered by induction heating

[J].

Effect of heat treatment process on properties of 1000 MPa ultra-high strength steel

[J].

Microstructure and mechanical properties of 780 MPa high strength steels produced by direct-quenching and tempering process

[J].

Effect of long-term aging on microstructure and mechanical properties of 20Cr1Mo1VTiB bolt steel

[J].The 20Cr1Mo1VTiB bolt steel was aged at 500℃ for 0~2000 h and then the effect of long-term aging on microstructure and mechanical properties were investigated by means of TEM, SEM, XRD, tensile- and impact-tester. Results show that the lath bainite in the steel was divided into several packets during the aging process. The size of the bainite package in the steel decreased from 13 μm before aging to 9 μm after aged for 2000 h. The main precipitates VC and TiC in the steel dispersed in the intragranular, lath boundaries and inside lath bainite after the aging process. TiC changed from a long strip to a square shape with an extension of the aging time. The boundary of bainite slabs gradually blurred with the increase of aging time, and the width of lath increased obviously after 2000 h aging. After aging for 2000 h the 20Cr1Mo1VTiB bolt steel still has high strength and toughness, therefore, which is suitable for long term service at high temperature.

长期时效对20Cr1Mo1VTiB螺栓钢的组织和力学性能的影响

[J].对20Cr1Mo1VTiB螺栓钢进行拉伸和冲击实验、TEM和SEM观测并测量其XRD谱,研究了其在500℃进行0~2000 h时效处理后的组织和力学性能。结果表明:随着时效时间的增加原板条状贝氏体分成若干个包体,其平均尺寸由时效前的14 μm减小到时效2000 h后的9 μm。在0~2000 h时效过程中碳化物尺寸没有明显增大,主要析出相VC和TiC弥散分布在晶内、板条界和板条内。VC相呈椭球状,随时效时间的延长TiC相由长条状变为方形。随着时效时间的延长贝氏体板条的边界逐渐模糊,时效2000 h后板条的宽度明显增加。在长时间时效过程中20Cr1Mo1VTiB螺栓钢的力学性能没有大幅度的变化而保持着较高的值,表明其可在高温下长期使用。

Effect of heat treatment process on microstructure and mechanical properties of 20Cr1Mo1VTiB steel

[J].

热处理工艺对20Cr1Mo1VTiB螺栓钢组织及性能的影响

[J].

Effect of heat treatment process on microstructure and mechanical properties of titanium alloy Ti6246

[J].The influence of heat treatment temperature and cooling rate on the microstructure, phase and tensile deformation behavior of Ti-alloy Ti6246 alloy was investigated. The results show that the α′′ martensite was observed in prior β phase after solution heat treatment followed by water quenching. While a fine transformed β microstructure produced as a result of air cooling. For the air cooling alloy, both the size and volume fraction of the secondary α grain increased with the increasing solution heat temperature in air cooling samples. A “double yield” phenomenon appeared in the engineering stress-strain curves of the water quenching alloy samples. After aging treatment, the strength of water- and air-cooled alloys samples increased but the plasticity decreased. An optimal property in strength and ductility was achieved for the alloysamples after soluted solution treated at 900-920°C and then aged at 595°C.

热处理工艺对Ti6246钛合金组织与力学性能的影响

[J].研究了热处理温度和冷却方式对Ti6246合金显微组织、相组成以及室温拉伸性能的影响。结果表明:固溶热处理后合金的相组成主要与冷却方式有关。在β单相区及(α+β)两相区固溶后水冷,β相均转化为α′′马氏体和少量亚稳β相。空冷组织中的β相转变为含有少量次生α相的β转变组织,随着热处理温度的提高次生α相的含量逐渐增加,尺寸也逐渐增大。时效后组织中的亚稳相发生分解,析出细小的次生α相。固溶后水冷试样的拉伸曲线上出现“双屈服”现象,且随着固溶温度的提高合金第一屈服点逐渐升高。水淬和空冷合金试样在595℃/8 h时效后其室温拉伸强度提高,延伸率及断面收缩率降低,水淬试样室温拉伸性能的变化更大。固溶后空冷且在595℃时效处理的合金,其室温拉伸性能可达到较好的强塑性匹配。

Fracture simulation of partially threaded bolts under tensile loading

[J].

FE simulation and experimental tests of high-strength structural bolts under tension

[J].

Failure modes of bolt and nut assemblies under tensile loading

[J].

Notch strengthening or weakening governed by transition of shear failure to normal mode fracture

[J].It is generally observed that the existence of geometrical discontinuity like notches in materials will lead to strength weakening, as a resultant of local stress concentration. By comparing the influence of notches to the strength of three typical materials, aluminum alloys with intermediate tensile ductility, metallic glasses with no tensile ductility, and brittle ceramics, we observed strengthening in aluminum alloys and metallic glasses: Tensile strength of the net section in circumferentially notched cylinders increases with the constraint quantified by the ratio of notch depth over notch root radius; in contrast, the ceramic exhibit notch weakening. The strengthening in the former two is due to resultant deformation transition: Shear failure occurs in intact samples while samples with deep notches break in normal mode fracture. No such deformation transition was observed in the ceramic, and stress concentration leads to its notch weakening. The experimental results are confirmed by theoretical analyses and numerical simulation. The results reported here suggest that the conventional criterion to use brittleness and/or ductility to differentiate notch strengthening or weakening is not physically sound. Notch strengthening or weakening relies on the existence of failure mode transition and materials exhibiting shear failure while subjected to tension will notch strengthen.

Effect of microstructure on mechanical properties of dual phase steels in the presence of stress concentrators

[J].

Evaluation of the current resistance factors for high-strength bolts

[D].

Fatigue life prediction method of 35CrMo alloy steel bolt

[J].

35CrMo 钢螺栓疲劳寿命预测方法研究

[J].

General relation between tensile strength and fatigue strength of metallic materials

[J].

Notch sensitivity of embrittled HR3C steel tube after service

[J].Notches with different types (V, U), different root curvature radii (0.10, 0.13, 0.25, 0.85 mm) and different length (0.25, 0.50, 0.75, 1.00 mm) were pre-made in tensile samples from HR3C steel tube before and after service for 50 000 h, and then the notch sensitivity of the steel tube was studied by tensile tests. The results show that the unserviced HR3C steel tube had no notch sensitivity. After service, the steel tube was embrittled, and therefore became sensitive to notches. The embrittled steel tube had higher sensitivity to the V-notch than to the U-notch, especially being sensitive to the V-notches with a relatively large angle, relatively small root curvature radii (0.10-0.25 mm) and relatively long length (0.50-1.00 mm). When the stress concentration factor was greater than 3.5, the notch sensitivity of embrittled HR3C steel tube was high.

服役脆化态HR3C钢管的缺口敏感性

[J].

Notch effect of metallic material during tensile testing

[J].

金属材料拉伸试验的缺口效应

[J].

High-cycle fatigue behavior and fatigue strength prediction of differently heat-treated 35CrMo steels

[J].In order to obtain the optimum fatigue performance, 35CrMo steel was processed by different heat treatment procedures. The microstructure, tensile properties, fatigue properties, and fatigue cracking mechanisms were compared and analyzed. The results show that fatigue strength and yield strength slowly increase at first and then rapidly decrease with the increase of tempering temperature, and both reach the maximum values at a tempering temperature of 200 °C. The yield strength affects the ratio of crack initiation site, fatigue strength coefficient, and fatigue strength exponent to a certain extent. Based on Basquin equation and fatigue crack initiation mechanism, a fatigue strength prediction method for 35CrMo steel was established.

China Materials Enginering Canon

第26卷: 材料表征与检测技术

[M].

Observation of notch effect in Al6061-T6 specimens under tensile loading using digital image correlation and finite element method

[J].

Relations between fatigue strength and other mechanical properties of metallic materials

[J].

Relationship between 0.2% proof stress and vickers hardness of work-hardened low carbon austenitic stainless steel, 316SS

[J].

Optimum microstructure combination for maximizing tensile strength in a polycrystalline superalloy with a two-phase structure

[J].