目前,我国新能源车用铝导线还依赖进口且品类单一。制造铝合金线的材料,主要有纯铝[8,9]、Al-Fe系[3,10]和Al-Mg-Si系[11~14]。纯铝的导电率和塑性都比较高,但是其强度较低;Al-Mg-Si系合金的强度较高,但是导电率较低;Al-Fe合金的强度和导电率都比较高,得到了广泛的应用。Fe在Al-Fe合金中的固溶度极低,温度为655℃时的最大固溶度约为0.025% (原子分数)[15,16],因此Fe元素在Al-Fe合金中只能以第二相的形式存在。新能源汽车中的电子线主要是超细电子线,这些第二相对于保证电子线强度和抗老化性能极为重要。但是,在Al-Fe合金的凝固过程中不可避免的生成一些粗大的脆性富Fe相,并在随后的冷却过程中保留下来。这些粗大的脆性相不仅使合金的导电率降低,还在超细线的拉制过程中产生局部应力集中而提高断丝率。

用快速凝固技术[4, 17]和严重塑性变形技术[18~20]制备铝合金,可降低铝基体中粗大富Fe相的尺寸。在合金的凝固过程中冷速越高富Fe相的尺寸越小、体积分数越低,还能显著提高其抗腐蚀性能[4]。但是,由于冷速过高,目前快速凝固技术还不能大规模在工业生产中应用。因此,工业中只能采用严重塑性变形技术降低粗大富Fe相的尺寸。用严重塑性变形技术可使凝固过程中生成的粗大脆性富Fe相破碎,降低其不利影响。连续挤压技术是一种典型的严重塑形变形技术,具有节能、挤压比高、生产效率高、长度大和金属均匀性高等优点[21~27]。鉴于此,本文在Al-0.5Fe合金导线的制备过程引入连续挤压工艺,分析合金在连续挤压过程中组织的演化和研究连续挤压对合金第二相的影响。

1 实验方法

用RLL-18-9型坩埚炉熔炼实验用Al-0.5Fe合金,原料是高纯工业纯Al和Al-10Fe中间合金。

对Al-0.5Fe合金铸锭进行500℃/24 h的均匀化处理,以消除偏析和提高组织的均匀性。将均匀化处理后的铸锭用1250ST型卧式挤压机挤压成直径为10 mm的圆杆,挤压温度为400℃,冷却方式为空冷。用LLJ300型连续挤压机将热挤压后的圆杆连续挤压,转速为6 r/min,挤出杆的直径为9.5 mm,冷却方式为空冷。

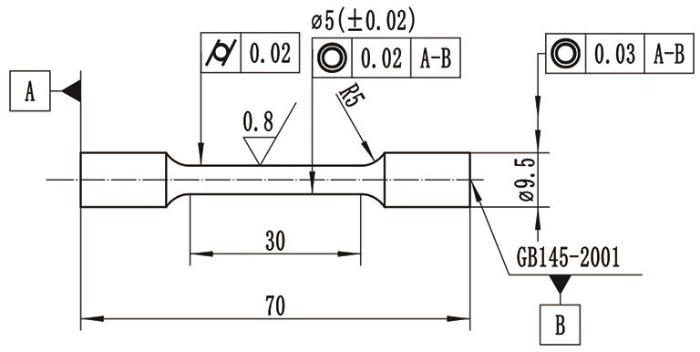

用TESCAN MIRA3型扫描电镜(SEM)表征合金中第二相的形貌和分布。将SEM试样用400#~2500#SiC水磨砂纸研磨后用粒度为50 nm的SiO2抛光液进行机械抛光,然后用0.5%HF水溶液进行化学刻蚀。用配备Symmetry S3电子背散射仪(EBSD)的Thermo Fisher Scios 2型双束显微镜分析挤压样品的晶粒取向和晶界角度。EBSD样品的制备:用电火花线切割将挤压后的圆杆沿挤压方向切割成尺寸为9 mm × 2 mm × 3 mm的小块,将其机械研磨和抛光后进行电解抛光,以去除表面应力层和提高EBSD解析率。用10%高氯酸酒精溶液进行电解抛光,电压为30 V,时间为8~10 s。用Talos F200X型透射电子显微镜(TEM)分析合金的显微组织和第二相。TEM样品的制备:用电火花线切割切取厚度为0.4 mm的薄片,将其研磨至50 μm后冲压出直径为3 mm的圆片,然后用MTP-1A型/电解双喷仪减薄。电解液为30%的硝酸甲醇溶液,电流为50 mA。参照国家标准GB/T 228.1-2010制备室温拉伸试样,试样平行段的长度为30 mm,直径为5 mm (图1)。在RDL50型拉伸试验机上进行拉伸实验,拉伸速率为2 mm/min。

图1

用TX-300智能金属导体电阻率仪测量电导率,样品的长度约为40 mm,直径为9.5 mm。测量样品3个不同区域的电导率取其结果的平均值,以降低样品不均匀性的影响。

2 结果和讨论

2.1 连续挤压道次对初生相的影响

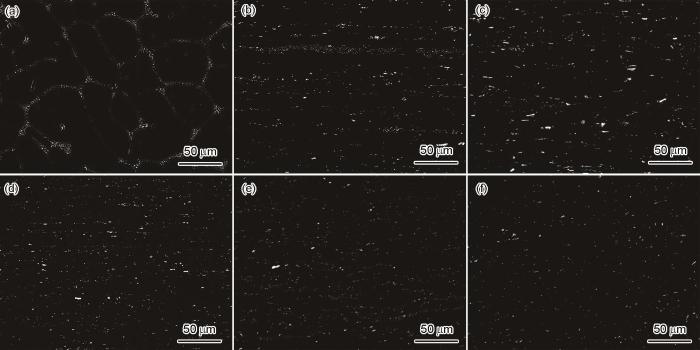

图2给出了经不同道次连续挤压后Al-0.5Fe合金的SEM照片。可以看出,在铸态合金中粗大的网状初生相分布在晶界上,而常规挤压使其破碎沿挤压方向链状分布(图2a和图2b)。合金经1道次连续挤压后初生相依然沿挤压方向分布但是其趋势明显减弱,分布更加均匀(图2c)。随着连续挤压道次的增加初生相链状分布的特征逐渐减弱,但是分布愈加均匀弥散。连续挤压4道次后,合金中初生相链状分布的特征完全消失。为了更直观的观察连续挤压不同道次后初生相的变化,使用Image J软件半定量统计了不同状态合金中等效直径大于400 nm的第二相的SEM照片,结果列于表1。从表1可以看出,常规挤压合金中初生相的等效直径为1.16 μm,随着连续挤压道次的增加等效直径总体上呈下降的趋势;连续挤压4道次后初生相的破碎更加显著且分布更加均匀,其等效直径减小到0.78 μm。

图2

图2

Al-0.5Fe合金的SEM照片

Fig.2

SEM results of Al-0.5Fe alloy (a) cast alloys, (b) conventional extrusion, (c) conform 1st pass, (d) conform 2nd pass, (e) conform 3rd pass, (f) conform 4th pass

表1 Al-0.5Fe合金中初生相的等效直径和面积分数

Table 1

| Conform pass | 0 | 1 | 2 | 3 | 4 |

|---|---|---|---|---|---|

| Equivalent diameter / μm | 1.16 | 1.08 | 0.90 | 0.89 | 0.78 |

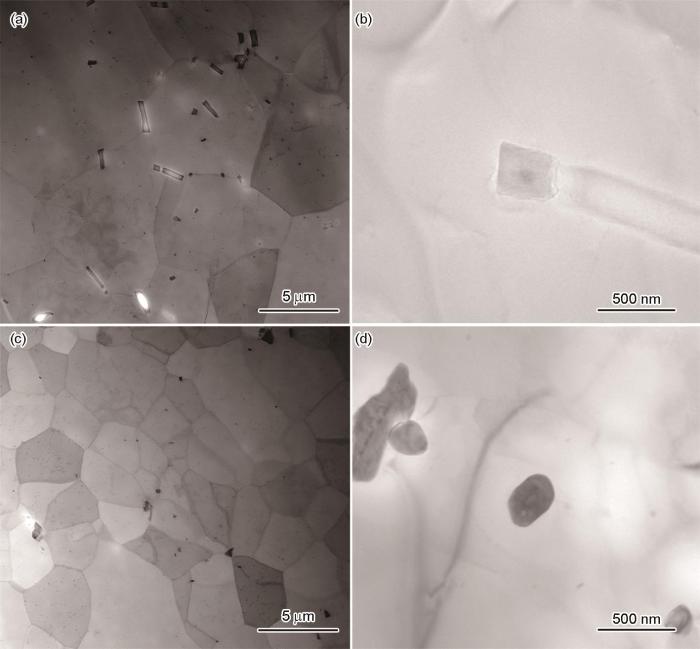

图3

图3

Al-0.5Fe合金的TEM照片

Fig.3

TEM results in different process Al-0.5Fe alloys (a, c) conventional extrusion; (b, d) conform 4th pass

2.2 连续挤压道次对合金组织的影响

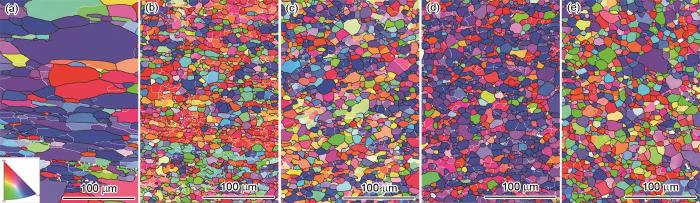

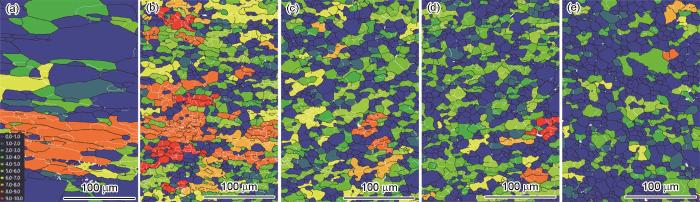

常规挤压和连续挤压合金的EBSD结果在图4中给出,不同状态合金的晶粒尺寸、大角晶界(HAB)和小角晶界(LAB)占比列于表2。晶粒尺寸,用晶粒等效圆直径的面积加权平均值表示。取向差为2°~10°的晶界视为小角晶界,用白线表示;取向差大于10°的晶界视为大角晶界,用黑线表示。常规挤压后合金的组织是一种混晶组织,主要由具有亚结构特征的不完全再结晶晶粒和发生了完全再结晶晶粒构成。与常规挤压相比,在连续挤压1道次的合金中晶粒组织更加均匀,晶粒尺寸显著降低(由23.4 μm降8.6 μm),但是亚结构特征更加丰富且小角晶界比例明显提高,部分晶粒组织仍保留着流线特征。随着连续挤压道次的进一步增加,晶粒尺寸减小、小角晶界占比逐渐降低。连续挤压4道次后晶粒尺寸降低至5.4 μm (表2),比常规挤压降低了76.8%。

图4

图4

Al-0.5Fe合金的EBSD结果

Fig.4

EBSD results in different process Al-0.5Fe alloys (a) conventional extrusion, (b) conform 1st pass, (c) conform 2nd pass, (d) conform 3rd pass, (e) conform 4th pass

表2 Al-0.5Fe合金的晶粒尺寸和大小角晶界占比

Table 2

| Grain size / μm | LAB / % | HAB / % | |

|---|---|---|---|

| Conventional extrusion | 23.4 | 20.1 | 79.9 |

| 1st pass | 8.6 | 27.2 | 72.8 |

| 2nd pass | 6.1 | 19.5 | 80.5 |

| 3rd pass | 5.8 | 18.0 | 82.0 |

| 4th pass | 5.4 | 10.6 | 89.4 |

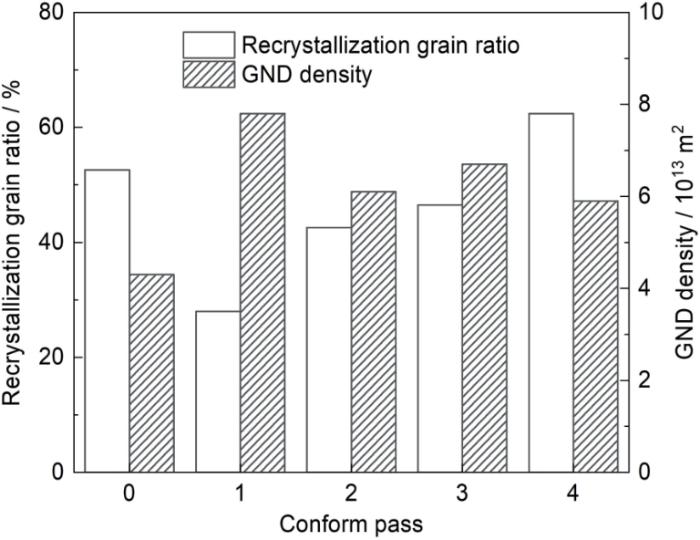

合金发生动态再结晶使晶粒内缺陷的数量急剧减少,晶粒内平均位向差(Grain orientation spread,GOS)保持在较低水平。因此,通常将平均取向差低于1°的晶粒视作再结晶晶粒[28]。图5给出了经不同挤压工艺处理的Al-0.5Fe合金的GOS图,深蓝色表示晶粒内平均位相差< 1°的再结晶晶粒。可以看出,随着颜色逐渐向红色转变,晶粒的平均位向差逐渐增大。图6给出了不同工艺的再结晶晶粒的比例和几何必须位错密度(Geometrically necessary dislocations density,GND density)的统计结果。如图5b所示,经第1道次连续挤压后,再结晶晶粒不均匀地分布在基体中。随着挤压道次的增加再结晶晶粒数量随之增加,均匀地分布在基体中(图5c~f)。连续挤压4道次后,合金中再结晶晶粒的百分比达到62.4%。同时,如图6所示,连续挤压道次的增加使位错密度不断降低。其原因是,在再结晶过程中小角晶界吸收组织中的位错使其取向差不断增大,直到小角晶界转变为大角晶界[28,29]。

图5

图5

Al-Fe合金的GOS图

Fig.5

Different process Al-Fe alloy GOS maps (a) conventional extrusion, (b) conform 1st pass, (c) conform 2nd pass, (d) conform 3rd pass, (e) conform 4th pass

图6

图6

不同道次Al-0.5Fe合金中再结晶晶粒的比例和几何必须位错密度统计结果(常规挤压为0道次)

Fig.6

Statistical results of recrystallized grain ratio and GND of different pass alloys in Al-0.5Fe alloy (0 pass for conventional extrusion)

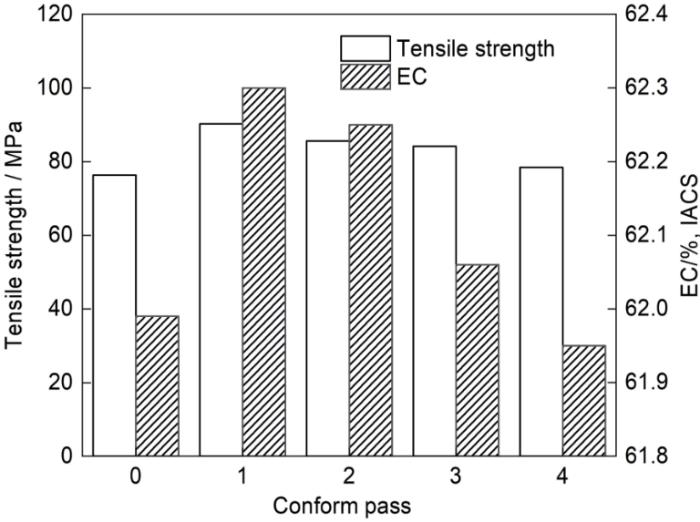

2.3 连续挤压对合金的抗拉强度和导电率的影响

图7

图7

不同道次Al-0.5Fe合金的抗拉强度和导电率

Fig.7

Tensile strength and EC of Al-0.5Fe alloy with different passes

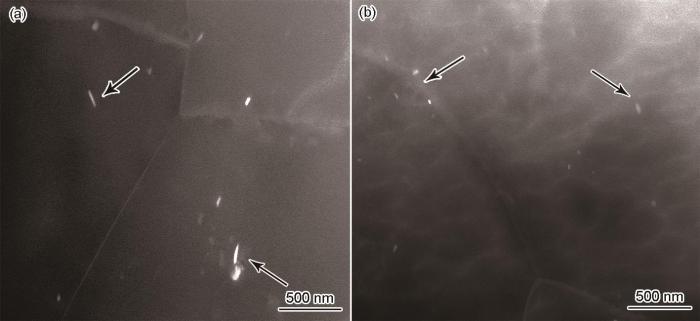

从图7可以看出,随着连续挤压道次的增加Al-0.5Fe合金的导电率呈先提高后降低的趋势,与强度的变化规律一致。根据强度-导电率制约关系[30,31],在强度下降的同时导电率应该呈现上升的趋势,本文关于强度-导电率变化规律的实验结果与此矛盾。为了揭示产生这种反常现象的原因,进一步表征了不同连续挤压道次的Al-0.5Fe合金中的亚微米和纳米尺寸第二相。图8给出了不同道次Al-0.5Fe合金的TEM照片。可以看出,连续挤压1道次合金中的亚微米和纳米尺寸的第二相尺寸较大,且其形貌大多呈现长条状(图8a中的箭头所示);连续挤压4道次后第二相大多为球状,其尺寸较小且棒状的数量大大减少(图8b箭头)。统计合金中第二相的面积分数时,因难以同时统计不同尺寸的第二相,将合金中的第二相划分为等效直径大于400 nm和等效直径小于400 nm两种类型。在较低放大倍数下SEM图片的质量高,所以用SEM方法统计等效直径大于400 nm的第二相,而在较高放大倍数下用结果较好的TEM方法统计等效直径小于400 nm的第二相。使用Image J软件统计了从多张SEM和TEM照片得到的不同道次合金的第二相面积分数,统计结果列于表3。结果表明:连续挤压1道次合金中等效直径大于400 nm和小于400 nm的第二相的面积分数分别为1.1%和0.45%;随着连续挤压道次的增加面积分数逐渐降低,连续挤压4道次时面积分数分别降低至0.44%和0.30%。这表明,随着连续挤压道次的增加第二相发生了溶解,即固溶在合金中的溶质原子浓度提高了。根据金属电子学,电子通过理想的晶格点阵时不发生散射,此时材料的电阻为零[15]。合金固溶度的提高使电子在晶格畸变区域发生散射,是产生电阻的原因。因此,在成分相同的条件下固溶Fe元素的脱溶有利于导电率的提高。连续挤压1道次合金中第二相面积分数较高,基体中的Fe原子的浓度较低,空间点阵的畸变程度低于4道次的合金,使连续挤压1道次合金的导电率高于连续挤压4道次的合金。

图8

图8

Al-0.5Fe合金的TEM照片

Fig.8

TEM results in different process Al-0.5Fe alloys (a) conform 1st pass, (b) conform 4th pass

表3 不同连续挤压道次Al-0.5Fe合金的面积分数

Table 3

| Conform pass | 1 | 2 | 3 | 4 | |

|---|---|---|---|---|---|

| Area fraction / % | > 400 nm | 1.1 | 0.9 | 0.58 | 0.44 |

| < 400 nm | 0.45 | 0.43 | 0.37 | 0.30 | |

3 结论

(1) 连续挤压使Al-0.5Fe合金中的初生相破碎,且随着连续挤压道次的增多初生相的尺寸逐渐减小。

(2) 在连续挤压道次较少的合金中,较高的错密度和较多的亚结构使其抗拉强度远比常规挤压合金的高。随着挤压道次的增加合金的再结晶程度提高,抗拉强度逐渐降低。

(3) 连续挤压道次的增加使合金中第二相的面积分数降低、固溶在合金中溶质原子浓度提高和合金导电率降低。

参考文献

Effect of thermomechanical processing on electrical and mechanical properties of aluminum conductor alloys

[J].

Effect of Zr addition on properties of Al-Mg-Si aluminum alloy used for all aluminum alloy conductor

[J].

Effect of Fe on microstructure and properties of 8xxx aluminum conductor alloys

[J].

Influence of cooling rate on the microstructure and corrosion behavior of Al-Fe alloys

[J].

Nanostructured Al and Cu alloys with superior strength and electrical conductivity

[J].

Investigation on high strength-high electrical conductivity mechanisms of Al and Al alloy wires

[D].

铝及铝合金线高强度高导电率机制研究

[D].

Microstructural evolution and mechanical-and electrical-property of cold-drawn and-rolled electrical aluminum wires

[J].

拉拔和轧制变形铝导线的结构演化及力学与导电性能

[J].对工业用A4纯铝进行拉拔和轧制两种塑性变形,研究了纯铝导线材料的微观结构演化、强度和导电率。结果表明:在变形量较小时拉拔变形和轧制变形后纯铝铝导线主要由拉长晶粒组成,这些拉长晶粒由位错亚结构组成的小角晶界组成;在相近的等效应变变形情况下,轧制样品中高角晶界的比例更高。拉拔变形后样品的强度和塑性均优于轧制变形后的样品。拉拔变形使材料具有更高强度和导电率。探讨了材料的导电性与形变强化间的关系。

Microstructural evolution and service performance of cold-drawn pure aluminum conductor wires

[J].<p>Microstructures and service performance (mechanical and electrical properties) of the commercially pure Al conductor wires subjected to different cold drawing strains were investigated. The results show that the microstructures of the cold-drawn Al wires along the radial direction were inhomogeneous, i.e. the texture in the center region was strong <111> and weak <001> components, while that in the surface region shifted from the initial cubic texture to a <112> component and finally developed into a strong <111> component. The volume fraction of the high angle grain boundaries in the surface region was higher than that in the center region. The cold-drawing process greatly enhanced the yield strength of the pure Al wires while retained the acceptable electrical resistivity. The strengthening mechanism and the variation of electrical conductivity of the cold-drawn Al wires are discussed through correlating with microstructure evolution.</p>

Effect of stress profile on microstructure evolution of cold-drawn commercially pure aluminum wire analyzed by finite element simulation

[J].<p>The evolution of microstructure in the drawing process of commercially pure aluminum wire (CPAW) does not only depend on the nature of materials, but also on the stress profile. In this study, the effect of stress profile on the texture evolution of the CPAW was systematically investigated by combining the numerical simulation and the microstructure observation. The results show that the tensile stress at the wire center promotes the formation of <111> texture, whereas the shear stress nearby the rim makes little contribution to the texture formation. Therefore, the <111> texture at the wire center is stronger than that in the surface layer, which also results in a higher microhardness at the center of the CPAW under axial loading.</p>

High strength and electrical conductivity of Al-Fe alloys produced by synergistic combination of high-pressure torsion and aging

[J].

Optimization of electrical conductivity and strength combination by structure design at the nanoscale in Al-Mg-Si alloys

[J].

Effects of La addition on the mechanical properties and thermal-resistant properties of Al-Mg-Si-Zr alloys based on AA 6201

[J].

Influence of AlB2 compound on elimination of incoherent precipitation in artificial aging of wires drawn from redraw rod extruded from billets cast of alloy AA-6101 by vertical direct chill casting

[J].

Effect of temperature on tensile properties of 6101 Al-alloy wires

[J].Tensile properties of a single-strand conductor of 6101 Al-alloy were investigated in the temperature range from -70℃ to 70℃. It is found that the 6101 Al-alloy wire has high strength and good deformation uniformity at the low temperature (-70℃). However, the yield strength and the ultimate tensile strength of the alloy exhibited a decreasing trend with the increasing testing temperature. The ultimate tensile strength and the yield strength of the alloy at 70℃ decreased by 10.9% and 9.3%, respectively, comparing with those of the counterparts tested at -70℃. From the analysis on the correlation of the work hardening rate and the yield strength with the temperature, it is found that the strain hardening rate of the alloy decreased with the increasing flow stress and the raising temperatures. In addition, the lattice friction stress has a strong correlation with temperature, which is the main factor affecting the yield strength of the alloy. Based on the comparison of the fitting calculated increment of the yield strength of the alloy to the corresponding experimental results, a model about the relation between the yield strength of the alloy and the service temperature was obtained, by which the appropriate yield strength of the alloy at different service temperatures can be predicted.

温度对6101铝合金导线拉伸性能的影响

[J].研究了6101铝合金单股导线在-70℃到70℃温度区间的拉伸性能。结果表明,6101铝合金导线在-70℃低温下具有较高的强度和较好的变形均匀性,但是随着变形温度的提高其屈服强度和强度极限都呈下降趋势。与在-70℃的拉伸性能相比,在70℃合金的强度极限和屈服强度分别降低了10.9%和9.3%。对应变硬化率和屈服强度与温度的相关性分析发现,在拉伸变形过程中合金样品的应变硬化率随着流变应力的增大和温度的升高呈下降趋势。晶格摩擦阻力极大的影响了合金的屈服强度,对比不同温度下6101合金的屈服强度增量的拟合计算结果与实验结果,得到了这种导线屈服强度增量与温度的关系,据此可预测此类导线在不同温度下的服役可靠性。

Corrosion behavior of a bulk nanocrystalline Al-Fe alloy

[J].

Study on microstructures and properties of rapidly solidified Al-Fe-Y/La alloys

[D].

快速凝固Al-Fe-Y/La合金组织和性能的研究

[D].

Microstructure of aluminum-iron alloys subjected to severe plastic deformation

[J].

High strength and electrical conductivity of Al-Fe alloys produced by synergistic combination of high-pressure torsion and aging

[J].

Incremental severe plastic deformation effect on mechanical and microstructural characteristics of AA6063

[J].

Microstructural characteristic of the Al-Fe-Cu alloy during high-speed repetitive continuous extrusion forming

[J].

Production of very fine grained Mg-3%Al-1%Zn alloy by continuous extrusion forming (conform)

[J].

Enhanced mechanical properties of an Al-Mg-Si alloy by repetitive continuous extrusion forming process and subsequent aging treatment

[J].

Microstructures and mechanical properties evolution of an Al-Fe-Cu alloy processed by repetitive continuous extrusion forming

[J].

Mechanisms of primary phase refinement and toughness improvement of Cu-2wt%Ag-0.15wt%La alloy through continuous extrusion forming

[J].

Microstructure and mechanical properties of a CuCrZr welding joint after continuous extrusion

[J].The effect of continuous extrusion forming (CEF) process on the microstructure and mechanical properties of a CuCrZr welding joint was investigated. The experimental results showed that after the CEF process the grains were refined to submicron-scale through dynamic recrystallization, which improved the mechanical properties of the welding joint as well as the base material. Meanwhile, the micron-scale precipitates aggregated at the grain boundaries in the welding process were broken down to smaller ones and recrystallized grains of several micrometers formed around the precipitates after CEF process, which could alleviate the negative effect induced by the micron-scale precipitates during plastic deforming process. Finer grains and smaller micron-scale precipitates made contributions to improve the properties of a CuCrZr alloy with a welding joint.

Evolution of the microstructure of the copper alloy (DIN-ECu-57) in the deformation zone in the process of pressing conform

[J].

Local microstructure and texture development during friction stir spot of 5182 aluminum alloy

[J].

Continuous dynamic recrystallization in an Al-Li-Mg-Sc alloy during equal-channel angular extrusion

[J].

Breaking the trade-off relation of strength and electrical conductivity in pure Al wire by controlling texture and grain boundary

[J].