Fe-Mn-Al-C低密度钢(Al含量和Mn含量较高)的强塑性积和抗冲击载荷性能较高,在航空航天、汽车制造、船舶以及国防等领域有广泛的应用前景[1~3]。国内外学者对Fe-Mn-Al-C低密度钢的成分设计、合金元素的作用、组织性能调控以及强韧化机制进行了大量研究[4~9]。但是,这种低密度钢在冶炼、连铸和轧制过程中的收得率较低、连铸时堵水口和轧制开裂 [10]。在优化低密度合金钢成分设计的基础上制定合理的热加工工艺,有助于解决低密度钢的热轧开裂等问题。Li等[11]和Yang等[12]研究了Fe-27Mn-11.5Al-0.95C低密度钢的热变形行为,建立了本构关系并分析了DRX行为。Churyumov等[13]建立了Fe-35Mn-10Al-1C低密度钢的流动应力模型描述其高温流动应力的特性。Kalantari等[14]研究了Fe-11.15Mn-5.6Al-0.07C (质量分数,%)低密度钢的高温变形行为。在所有的本构模型中,双曲正弦Arrhenius唯象本构模型广泛用于描述材料在热变形过程中的流动行为[11~14]。一些学者还基于Arrhenius型本构方程建立了考虑应变对流动应力影响的应变补偿本构模型,可预测合金材料的流动行为[15~18]。

在钢铁材料的热加工过程中,剧烈变形产生了大量的动态再结晶晶粒,消除气孔、孔洞和微裂纹缺陷不仅能细化组织,还能降低其各向异性[19]。动态再结晶(Dynamic recrystallization,DRX,包括动态回复)关系到合金在热加工过程中的软化行为,例如新晶粒的形核、长大和再变形的复杂组织变化。动态再结晶机制有三种[20],分别为非连续动态再结晶(Discontinuous dynamic recrystallization,DDRX)、连续动态再结晶(Continuous dynamic recrystallization,CDRX)[21,22]和几何动态再结晶(Geometric dynamic recrystallization,GDRX)[19,23]。Liu等[24]研究了Fe-11Mn-10Al-0.9C低密度钢在等温压缩过程中的DRX行为。Lu等[25]分析了应变速率和变形温度对Fe-27.34Mn-8.63Al-1.03C奥氏体低密度钢DRX晶粒体积分数的影响,发现变形温度的提高和应变速率的降低都能加速DRX的发生,动态再结晶还受变形温度、应变速率以及变形程度等因素影响。崔志强等[26]研究了9Mn27Al10Ni3Si低密度钢的高温压缩变形过程中的再结晶行为,发现随着应变速率的提高其孪生现象明显,奥氏体的DRX过程显著加快,在高应变速率条件下DRX比低应变速率时更为明显。还有研究表明,材料的动态再结晶与Zener-Hollomon参数(衡量温度和应变速率对热变形行为影响的参数,简称Z参数)有一定的关系,动态再结晶的晶粒尺寸可用Z参数的函数表示[27,28]。因此,进一步分析Fe-Mn-Al-C低密度钢动态再结晶与Z参数的关系有助于深入理解低密度钢等温压缩变形动态再结晶行为。鉴于此,本文进行Fe-29.96Mn-9.56Al-1.01C钢的等温压缩实验,建立基于应变补偿的Arrhenius型本构方程,研究其在不同变形温度和应变速率条件下热变形过程中的组织演化以及Z参数对低密度钢动态再结晶行为影响并揭示其再结晶机制。

1 实验方法

用真空感应电炉在氩气保护下熔炼25 kg低密度钢钢锭,其化学成分为:1.01%C,9.56%Al,29.96% Mn,0.95%Si,0.46%Mo。切去钢锭的冒口后将其在1150℃均匀化处理2 h,然后热锻成截面尺寸为25 mm × 200 mm的坯料,初锻温度为1050℃,终锻温度高于850℃。将坯料线切割成直径为8 mm、长度为12 mm的圆柱形等温压缩试样,在850~1100℃(温度间隔为50℃)用Gleeble-1500D热模拟机进行等温压缩实验,应变速率为0.01~10 s-1。将试样以20℃/s的速度加热至1150℃,保温120 s后以10℃/s的冷却速率冷却至变形温度。每个试样压缩到工程应变为0.6 (真实应变为0.9)后立即水淬到室温以保留热压缩变形组织。在与压缩轴方向平行的纵截面截取金相试样,将其研磨、抛光和侵蚀后观察金相组织。

实验用金相显微镜的型号为UMT203i。热场发射扫描电子显微镜的型号为SIGMA500,工作电压20 kV,步长设置为0.6~1.3 μm。使用AZtecCrystall软件分析所测样品的EBSD数据。用Talos F200S透射显微镜观察薄膜样品的形貌和进行结构分析,工作电压为200 V。

2 结果和讨论

2.1 Fe-29.96Mn-9.56Al-1.01C低密度钢的应力应变特性

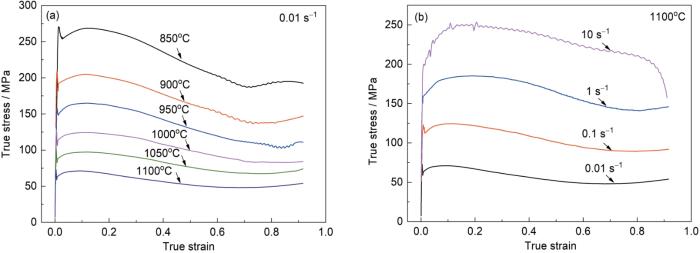

图1

图1

低密度钢在不同变形条件下的真应力-真应变曲线

Fig.1

True stress-true strain curves of low density steels at different deformation condition: (a) 0.01 s-1; (b) 1100oC

2.2 建立基于应变补偿的本构方程

表1 不同应变下的材料参数

Table 1

| Strain | α / mm-2·N-1 | n | Q / J·mol-1 | lnA / s-1 | Strain | α / mm-2·N-1 | n | Q / J·mol-1 | lnA / s-1 | |

|---|---|---|---|---|---|---|---|---|---|---|

| 0.05 | 0.004051 | 6.63 | 415298.82 | 38.60 | 0.45 | 0.004617 | 4.38 | 355015.50 | 32.12 | |

| 0.1 | 0.004133 | 5.67 | 398082.60 | 36.30 | 0.5 | 0.004762 | 4.28 | 350333.66 | 31.68 | |

| 0.15 | 0.004101 | 5.29 | 390787.99 | 35.56 | 0.55 | 0.004888 | 4.20 | 344814.77 | 31.17 | |

| 0.2 | 0.004133 | 5.02 | 384206.66 | 34.90 | 0.6 | 0.005032 | 4.13 | 342338.44 | 30.92 | |

| 0.25 | 0.004195 | 4.86 | 381160.28 | 34.59 | 0.65 | 0.005155 | 4.07 | 336804.98 | 30.38 | |

| 0.3 | 0.004269 | 4.74 | 377405.98 | 34.23 | 0.7 | 0.005266 | 4.01 | 331763.12 | 29.89 | |

| 0.35 | 0.004359 | 4.61 | 368306.20 | 33.37 | 0.75 | 0.005326 | 4.02 | 336002.20 | 30.28 | |

| 0.4 | 0.004491 | 4.48 | 361460.79 | 32.71 | 0.8 | 0.005370 | 4.07 | 339840.92 | 30.65 |

表2 低密度钢的相组成、材料常数(n,α)和热变形激活能

Table 2

| Alloy | T / oC | Phase | n | α / mm-2·N-1 | Q / kJ·mol-1 | References | |

|---|---|---|---|---|---|---|---|

| Fe-27Mn-11.5Al-0.95C | 900~1150 | 0.01~10 | γ + δ | 3.93 | 0.0035 | 294.20 | [11] |

| Fe-27.34Mn-8.63Al-1.03C | 900~1150 | 0.01~5 | γ | 4.24 | 0.0107 | 422.88 | [25] |

| Fe-25.14Mn-10Al-1.46C | 900~1150 | 0.01~10 | γ | 5.14 | 0.0060 | 669.84 | [34] |

| Fe-29.96Mn-9.56Al-1.01C | 850~1100 | 0.01~10 | γ | 4.01~6.63 | 0.0041~0.0054 | 331.76~415.30 | Present work |

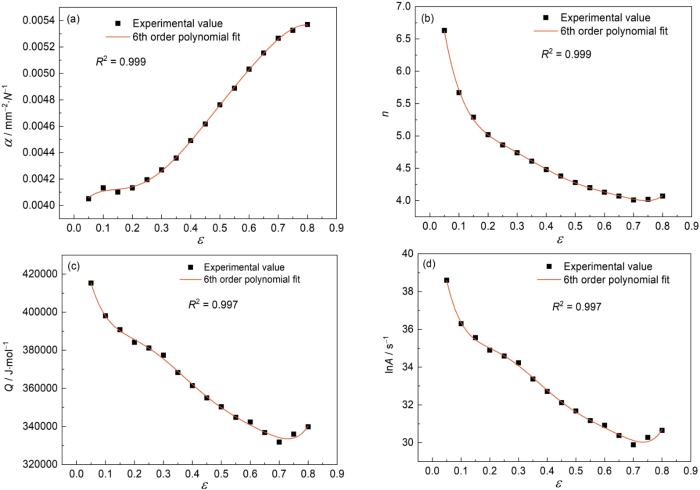

图2

图2

低密度钢的真应变ε分别与α,n,Q,lnA的拟合曲线

Fig.2

Plot of fitting the low density steel true strain ε to α, n, Q and lnA, respectively

表3 材料参数α、n、Q和lnA的第6个多项式系数

Table 3

| α / mm-2·N-1 | n | Q / J·mol-1 | lnA / s-1 |

|---|---|---|---|

| X0 = 0.004 | Y0 = 8.357 | Z0 = 453241.858 | U0 = 43.528 |

| X1 = 0.005 | Y1 = -46.341 | Z1 = -1.064 × 106 | U1 = -139.265 |

| X2 = -0.044 | Y2 = 271.137 | Z2 = 7.351 × 106 | U2 = 966.741 |

| X3 = 0.179 | Y3 = -862.279 | Z3 = -2.706 × 107 | U3 = -3501.208 |

| X4 = -0.335 | Y4 = 1479.257 | Z4 = 5.110 × 107 | U4 = 6550.284 |

| X5 = 0.304 | Y5 = -1295.175 | Z5 = -4.800 × 107 | U5 = -6112.333 |

| X6 = -0.110 | Y6 = 454.902 | Z6 = 1.787 × 107 | U6 = 2259.787 |

根据表3中的数据建立了在不同应变条件下低密度钢的本构方程

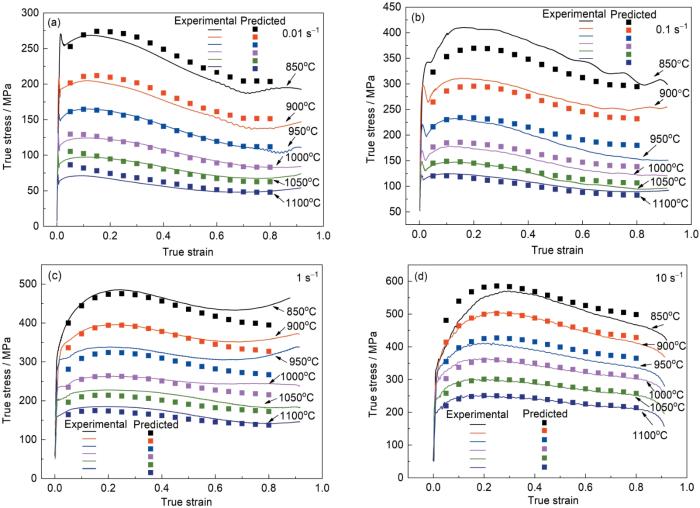

图3给出了根据本构模型得到的低密度钢的流动应力预测值与实测值的比较。

图3

图3

在不同热压缩条件下低密度钢的流动应力预测值与实测值的比较

Fig.3

Comparisons between predicted and measured values of flow stress for low density steel under different hot compression conditions

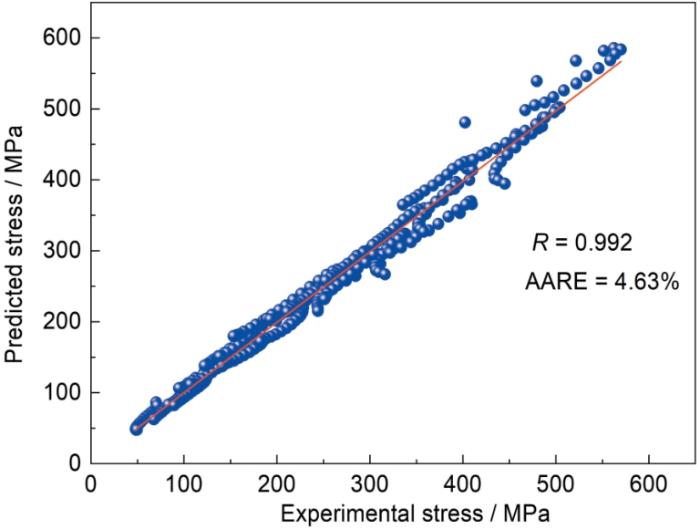

为了验证流动应力模型的准确性,引入平均绝对相对误差(AARE)和R值

式中E为低密度钢实际流动应力(MPa);P为低密度钢预测流动应力(MPa);

图4表明,基于应变补偿构建的本构方程的精度(AARE = 4.63%,R = 0.992)合理,能预测低密度钢的流动应力。

图4

图4

低密度钢在不同变形条件下的流动应力实测值与预测值的对比

Fig.4

Comparison of measured flow stress and predicted flow stress of low density steel under different deformation conditions

2.3 动态再结晶的演化与Z参数的关系

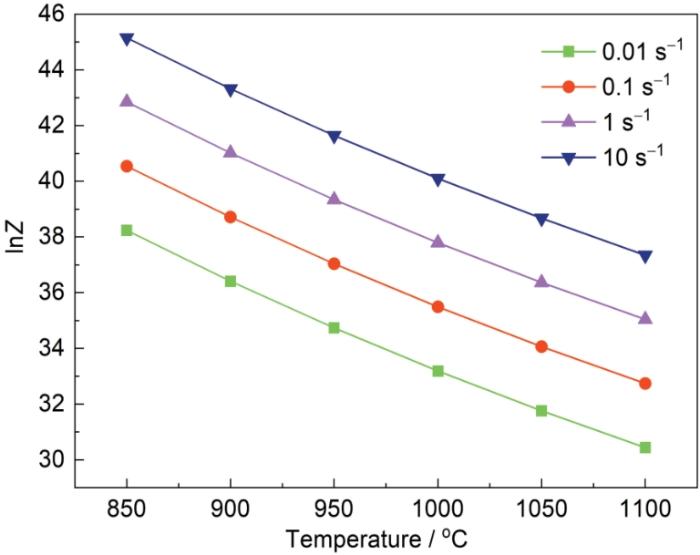

根据上述数据计算出低密度钢在不同应变速率和不同变形温度条件下应变量为0.9的lnZ值,计算结果列于表4。

表4 不同应变速率和变形温度下的lnZ值

Table 4

| lnZ | ||||||

|---|---|---|---|---|---|---|

| 850oC | 900oC | 950oC | 1000oC | 1050oC | 1100oC | |

| 0.01 | 38.2 | 36.4 | 34.7 | 33.2 | 31.8 | 30.4 |

| 0.1 | 40.5 | 38.7 | 37.0 | 35.5 | 34.1 | 32.7 |

| 1 | 42.8 | 41.0 | 39.3 | 37.8 | 36.4 | 35.0 |

| 10 | 45.1 | 43.3 | 41.6 | 40.1 | 38.7 | 37.3 |

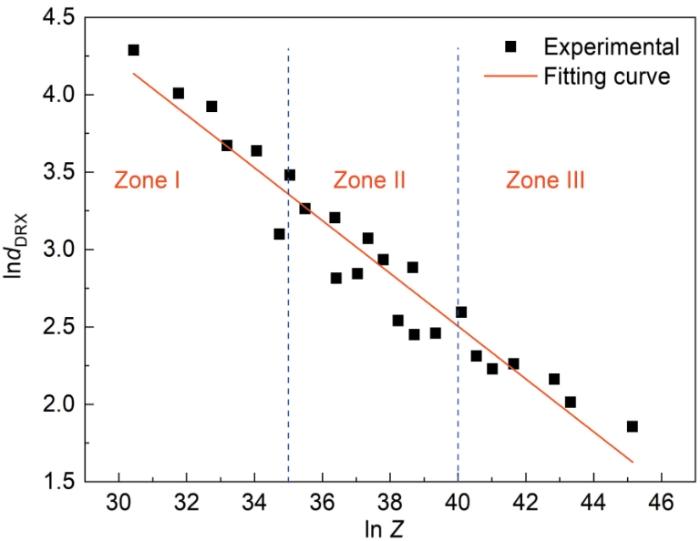

为了分析Z参数对低密度钢再结晶的影响,将其分为Ⅰ、Ⅱ和Ⅲ区。在Ⅰ区Z值的较低,在Ⅱ区Z值中等,在Ⅲ区Z值的较高,如图5所示。

图5

图5

低密度钢Z参数值的区分示意图

Fig.5

Schematic diagram for distinguishing Z-parameter values of low density steel

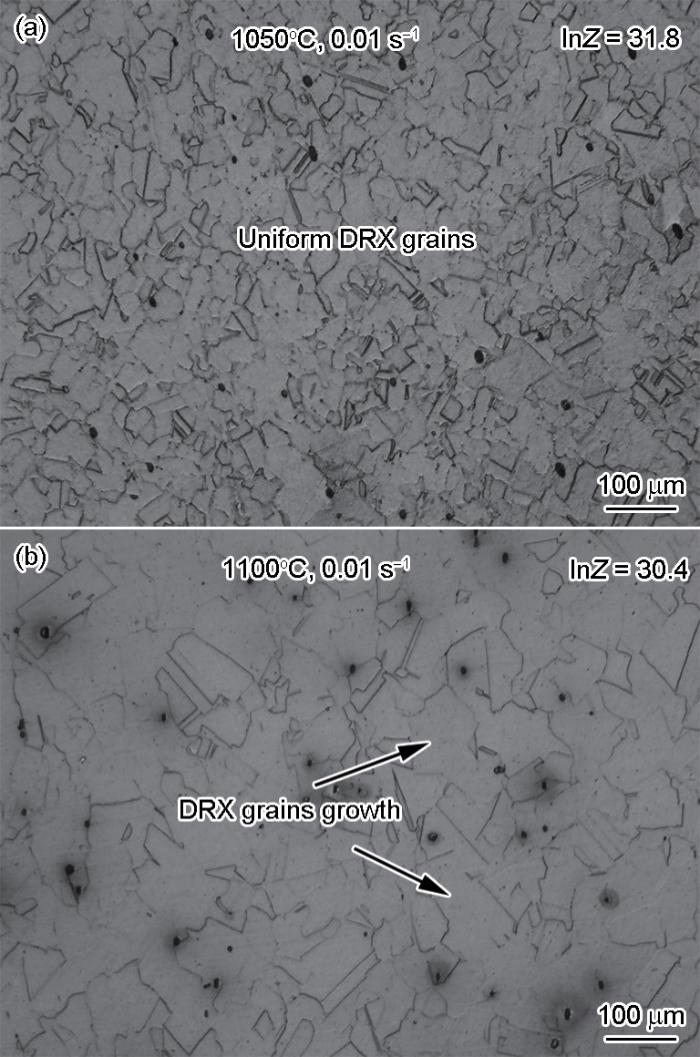

Z值处于Ⅰ区的低密度钢其再结晶组织特征如图6所示,应变速率为0.01 s-1,变形温度为1050℃和1100℃。由图6a可见,在变形速率0.01 s-1、变形温度为1050℃的条件下,动态再结晶较为充分,再结晶晶粒细小均匀呈等轴状,平均晶粒尺寸约为55.1 μm,压缩变形引起的原始带状组织已全部消失。图6b表明,在变形速率为0.01 s-1、变形温度为1100℃的条件下,再结晶晶粒尺寸比1050℃时的大(为72.8 μm)。Z值处在Ⅰ区的低密度钢在高温低应变速率的变形条件下,再结晶晶粒长大的速率高于形核速率。在低应变速率条件下变形合金内的原子有充足的时间扩散,形变储能的减少降低了金属材料的再结晶驱动力;而在较高的温度下热变形使合金内原子的扩散速度提高,为再结晶晶粒长大和晶界迁移提供了足够的能量。因此,Z值处于此范围内的低密度钢热变形时较大的驱动力和足够时间使合金内的再结晶晶粒充分长大[35]。

图6

图6

Z值在Ⅰ区范围内的低密度钢热压缩后的微观组织

Fig.6

Microstructure of low density steel after thermal compression with Z value in the range of zone I (

图7

图7

Z值在Ⅱ区范围内的低密度钢热压缩后的微观组织

Fig.7

Microstructure of low density steel after thermal compression with Z value in the range of zone Ⅱ (

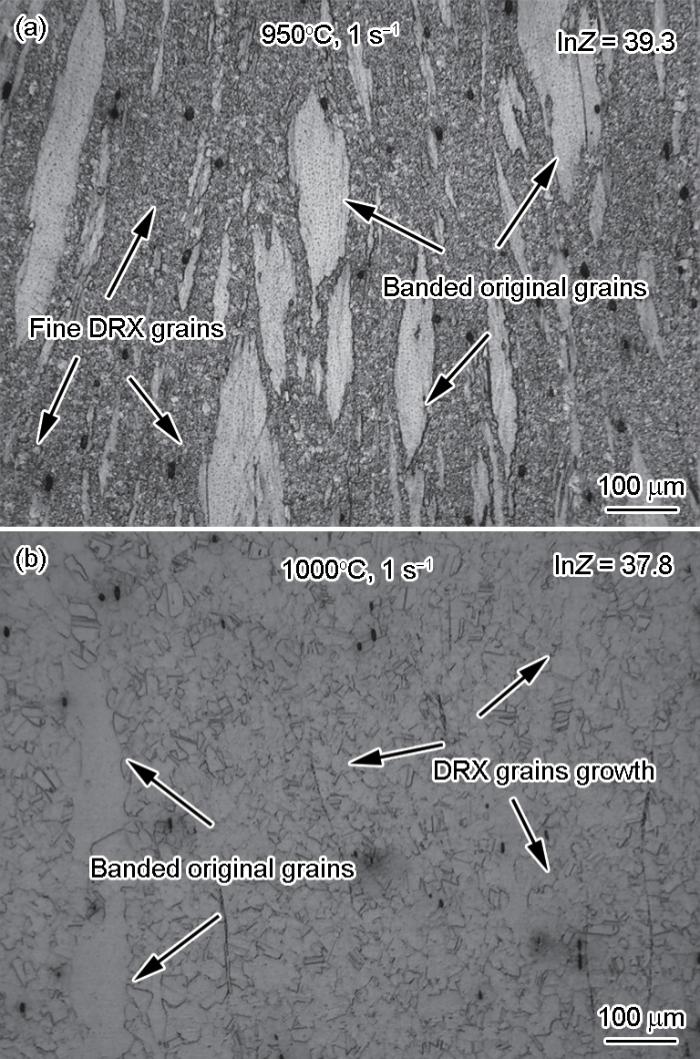

随着Z值的增大,低密度钢的动态再结晶程度有所降低。在应变速率为1 s-1、变形温度为950℃的条件下,原始的带状组织清晰可见,细小的再结晶晶粒在带状组织之间,有的带状组织较为粗大,有的呈细条状,有的“岛状”组织被再结晶晶粒围绕。在应变速率为1 s-1、变形温度为1000℃的条件下,lnZ值为37.8的钢中再结晶晶粒明显长大,(在金相照片视域内)原始的带状组织数量减少,特别是细小的条带状组织消失,只见粗大的原始带状组织,再结晶晶粒中出现细小的孪晶束。合金的动态再结晶程度,随着温度的降低和应变速率的提高而降低。与Ⅰ区的低Z值相比,Ⅱ区的Z值较大,对应的变形条件为中等变形速率和中等温度。动态再结晶包含两个过程,分别为再结晶晶粒的形核和长大。而在合金变形过程中,内部的位错运动也影响再结晶晶粒的形核和长大。在变形温度较低的条件下,原子的热振动减弱,与高温变形条件下相比螺旋位错的交滑移和刃型位错的攀移不容易发生。同时,在低变形温度下金属材料的热激活能也较低,合金内空位浓度的提高使空位对位错迁移的阻力增大[36]。另一方面,应变速率的提高使低密度钢内原子的扩散以及各类位错的滑移和攀移能力降低。这表明,Z值的增大使低密度钢的动态再结晶程度降低。

图8

图8

低密度钢的Z值在Ⅲ区范围内热压缩后的微观组织

Fig.8

Microstructure of low density steel after thermal compression with Z value in the range of zone Ⅲ (ε = 0.9) (a) 1nZ = 45.1; (b) 1nZ = 43.3

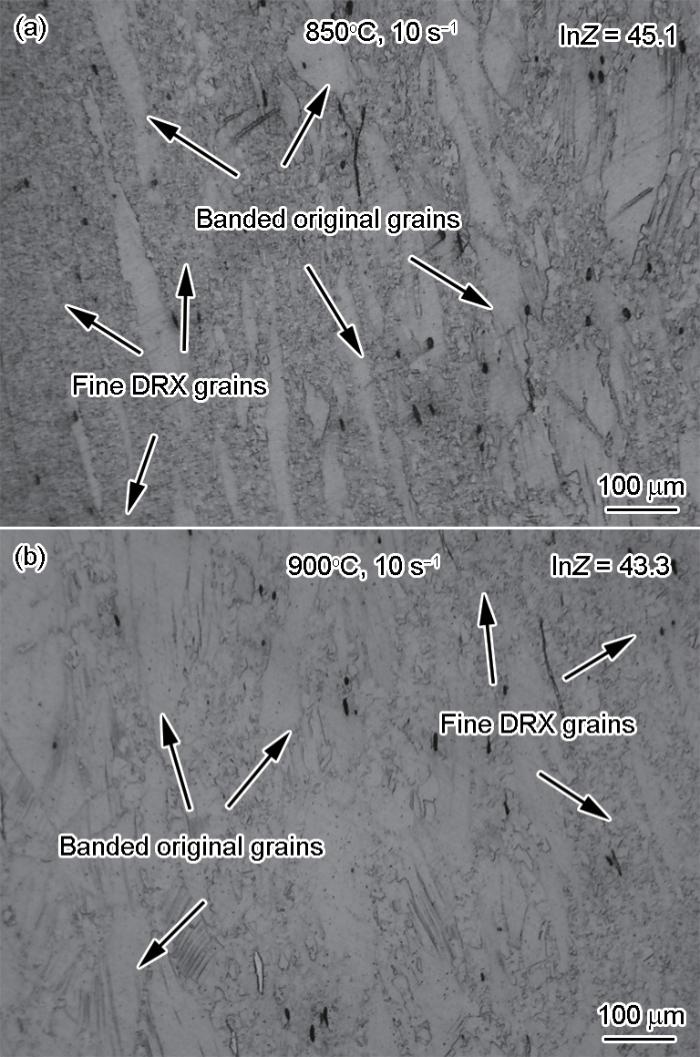

处于Ⅲ区(高值区)的Z值对应低密度钢的低温高应变速率,随着变形温度由850℃提高到900℃其再结晶程度提高。变形温度从两个方面影响合金的动态再结晶:一方面,合金材料变形初期经过动态回复,使位错相互抵消或重排,形成大量的亚晶和位错胞状结构,为后续的合金动态再结晶形核提供条件。而热压缩变形温度的提高促进了合金的动态回复,有利于动态再结晶形核。另一方面,合金热变形时晶界的迁移和运动也影响动态再结晶晶粒的长大。变形温度的提高加剧晶界运动和提高扩散速率,使合金动态再结晶晶粒的生长速率提高。

上述分析表明,合金材料经历热变形时动态再结晶与合金内位错的变化有密切的关系。位错的运动与变形温度和应变速率有关,因此与Z值的大小有密切的关系。对于相同的应变速率,变形温度的提高使Z值和位错密度降低和原子扩散加剧。原子跨越晶粒晶界的运动加快,使大角晶界的运动速度提高,使动态再结晶晶粒得以长大[37]。在变形温度一定的条件下,较高的应变速率使Z值增大,一方面使合金内的位错密度提高而形成大量的亚结构,从而提高动态再结晶的形核率。另一方面,对于一定的变形程度和温度,高应变速率使合金在变形过程中发生动态再结晶的时间减少,再结晶晶粒没有足够的时间长大而生成细小的再结晶晶粒。同时,在高应变速率条件下再结晶晶粒内的位错密度比低应变速率时的高[38]。根据Roberts等[39]提出的材料动态再结晶临界位错密度的计算模型ρc = (20γi

2.4 变形参数对动态再结晶的影响

图9给出了低密度钢在热压缩条件下Z值与变形参数的关系。可以看出,应变速率一定时,随着变形温度的提高Z值减小;变形温度一定时,Z值随着应变速率的提高而增大。结合对低密度钢热变形行为的分析,随着热变形温度的提高和应变速率的降低,Z值随之减小,热变形时低密度钢的流动应力峰值与稳态应力亦随之减小,且其在较低的应变量达到峰值应力和稳态流动,缩短了低密度钢的流变过程。这种现象,与低密度钢的动态再结晶的充分程度有关。

图9

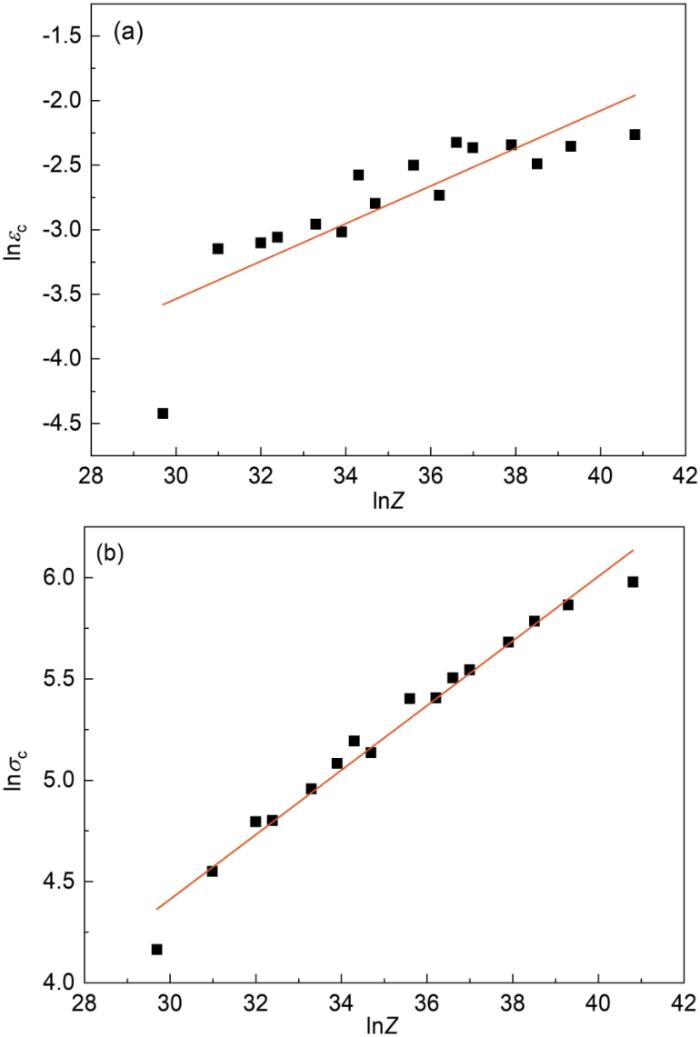

图10

图10

动态再结晶临界应变和应力与lnZ的关系

Fig.10

(a) relationship curve between lnZ and critical strain; (b) relationship curve between lnZ and critical stress

2.5 变形参数不同的钢的动态再结晶微观组织

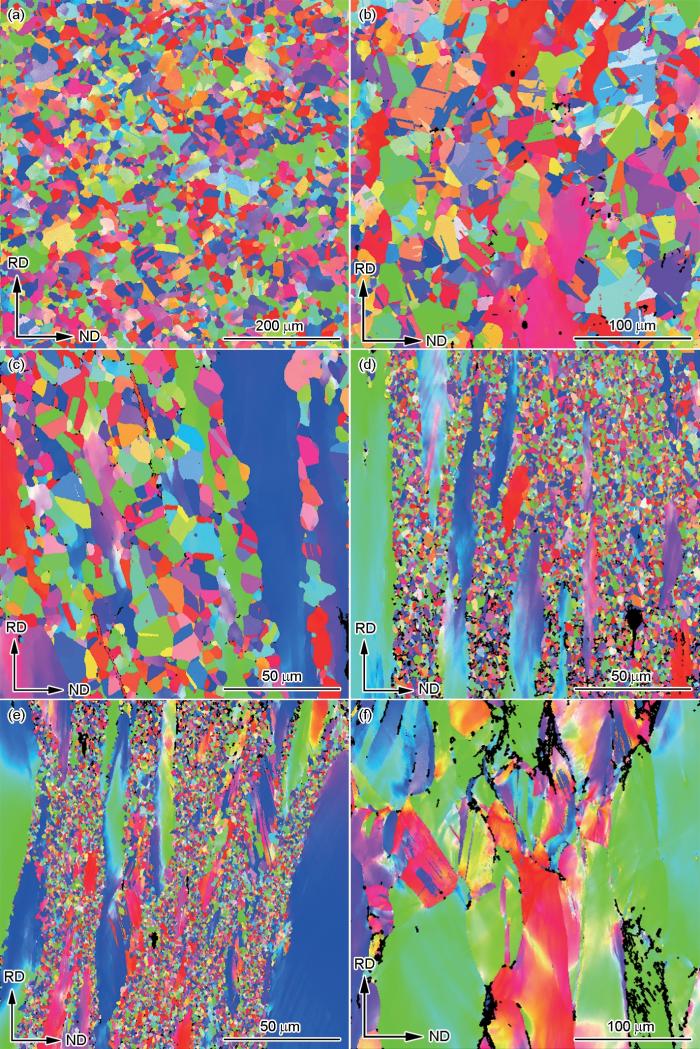

图11给出了lnZ数值分别为31.8、34.1、37.0、39.3、41.0和42.8、热变形条件分别为1050℃-0.01 s-1、1050℃-0.1 s-1、950℃-0.1 s-1、950℃-1 s-1、900℃-1 s-1和850℃-1 s-1时微观组织的EBSD图像(IPF图)。可以看出,不同Z值的低密度钢动态再结晶程度有所不同,随着Z值的增大热压缩时的变形晶粒具有沿轧制方向的带状组织。如图11a所示,在低Z值条件下(lnZ = 31.8)动态再结晶较为充分,未发现原始带状组织,再结晶晶粒较大且大小均匀,平均晶粒尺寸约为55.1 μm,晶界清晰平直。如图11b所示,lnZ值增大到34.1时原始带状组织未全部消失,与lnZ =31.8相比晶界平直清晰但是晶粒分布不均匀,平均尺寸约为38.0 μm。lnZ = 37.0 (中等Z值)时,在图11c中可见明显的原始条带状组织,再结晶晶粒在条带状组织之间,晶粒尺寸较小(17.2 μm);lnZ = 39.3时,在图11d中可见宽度更大的原始带状组织变形晶粒,再结晶晶粒更为细小(11.7 μm),存在于带状组织晶界处。如图11e、f所示,lnZ = 41.0 (高Z值)时原始带状组织变形晶粒增多,尺寸较大,动态再结晶晶粒不仅存在于变形带状组织之间还存在于变形晶粒内部。如图11e所示,此时的动态再结晶平均晶粒尺寸为9.3 μm;当lnZ = 42.8时,由图11f可见,几乎全是压缩变形的带状组织晶粒,再结晶晶粒非常细小(8.7 μm)。

图11

图11

低密度钢热变形组织的反极图(IPF)

Fig.11

Inverse pole figure of thermal deformation structure of low density steel (a) lnZ = 31.8; (b) lnZ = 34.1; (c) lnZ = 37.0;(d) lnZ = 39.3; (e) lnZ = 41.0; (f) lnZ = 42.8

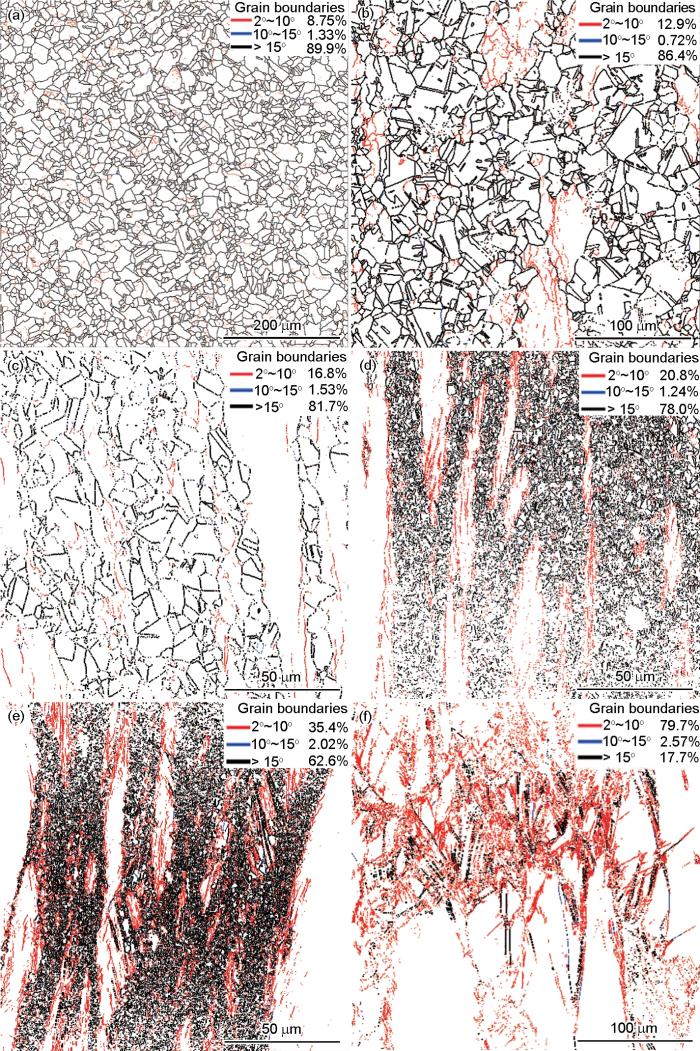

图12给出了低密度钢不同Z值的热变形组织晶界,其中黑色线表示> 15°的大角晶界,蓝色线表示10°~15°的晶界,红色线表示< 10°的晶界。由图12可见,随着Z值的增大大角晶界减少,小角晶界(< 10°的晶界)增多。动态再结晶晶粒中的晶界是大角晶界,因此分析相邻晶界的取向角可研究合金材料的动态再结晶。lnZ = 31.8 (变形温度1050℃,应变速率0.01 s-1)时,Z值处于Ⅰ区,Z值较小,如图12a所示,大角晶界的占比为89.9%,小角晶界的占比为8.75%;当lnZ = 34.1 (变形温度1050℃,应变速率0.1 s-1)时,如图12b所示,大角晶界的占比为86.4%,小角晶界的占比为12.9%。在这两种变形条件下,随着Z值的增大大角晶界的占比降低了3.5%,小角晶界的占比提高了4.15%。大角晶界的占比降低表明低密度钢中再结晶晶粒的含量降低。

图12

图12

低密度钢热变形组织的晶界

Fig.12

Grain boundary diagram of thermal deformation structure of experimental steel (a) lnZ = 31.8; (b) lnZ = 34.1; (c) lnZ = 37.0; (d) lnZ = 39.3; (e) lnZ = 41.0; (f) lnZ = 42.8 (In the figure, the black line indicates the large angle grain boundary > 15°, the blue line indicates the grain boundary 10°~15°, and the red line indicates the grain boundary < 10°)

当Z值处于Ⅲ区,也就是Z值较高,当lnZ = 41.0(变形温度900℃,应变速率1 s-1)时,图12e所示,大角晶界占比为62.6%,小角晶界占比为35.4%;当lnZ = 42.8(变形温度850℃,应变速率1 s-1)时,如图12f所示,大角晶界占比为17.7%,小角晶界占比为79.7%;可以看出,当应变速率1 s-1时,随着变形温度由900℃降到850℃低密度钢中大角晶界的占比迅速降低(降低了44.9%),而小角晶界占比提高(提高44.3%)。这表明,温度的改变对动态再结晶的影响较大,即对温度变化的敏感性较高。同时,小角晶界大都分布在变形晶粒内,且随着Z值的增大占比提高,即再结晶程度降低小角晶界的占比提高。

动态再结晶分为三类:一是非连续动态再结晶,具有典型的形核和长大特征,再结晶理想的形核位置在原始晶界;二是连续动态再结晶,其主要特征是由小角晶界(< 10°的晶界)向大角晶界(> 15°的晶界)转变;三是几何动态再结晶,与变形晶粒破碎有关,锯齿状的弓出晶界接触使原始晶粒破碎产生新晶粒,主要分布在晶界附近[19,41]。图12中蓝色线表示的10°~15°过渡晶界占比较低,lnZ由31.8→34.1→37.0→39.3→41.0再到42.8,对应的过渡晶界占比分别为1.33%,0.72%,1.53%,1.24%,2.02%和2.57%,即向大角晶界过渡的小角晶界占比较低。连续动态再结晶是通过小角晶界不断转变为大角晶界进行的,连续动态再结晶的程度较低,且在高Z值条件下略比低Z值条件下的再结晶程度高。这表明,连续动态再结晶并不是低密度钢的主要动态再结晶机制。

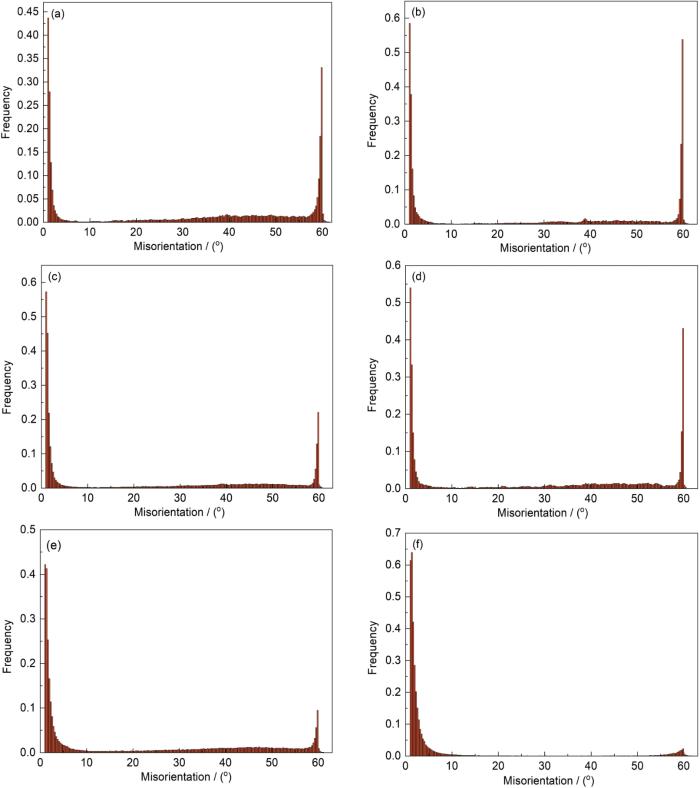

图13

图13

低密度钢热变形组织中晶界取向差的分布

Fig.13

Boundary misorientation angle distribution of thermal deformed microstructure of experimental steel (a) lnZ = 31.8; (b) lnZ = 34.1; (c) lnZ = 37.0; (d) lnZ = 39.3; (e) lnZ = 41.0; (f) lnZ = 42.8

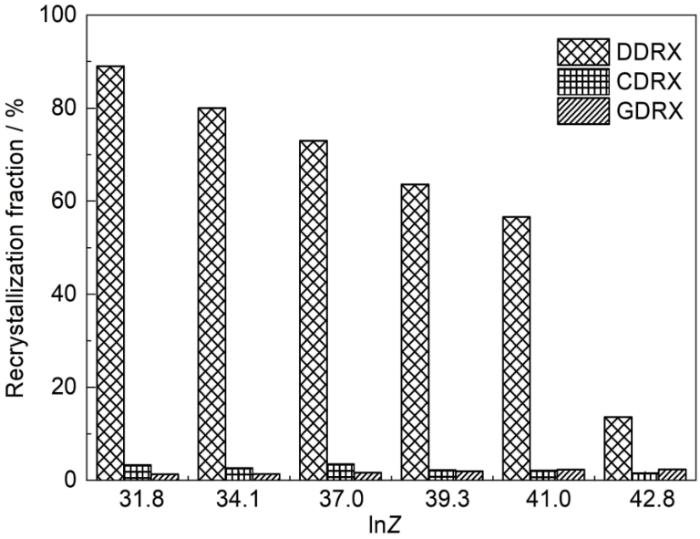

图14

图14

Z值不同条件下的动态再结晶的体积分数

Fig.14

Volume fraction of dynamic recrystallization under different Z-values

综上所述,在低Z值条件下低密度钢热变形时更容易发生动态再结晶,且其平均晶粒尺寸随着Z值的增大而减小,动态再结晶的体积分数降低,再结晶程度随着Z值的增大而降低。高Z值对应的热变形条件,为低变形温度和高应变速率。在应变量相同的条件下材料的变形时间短,没有足够的再结晶时间。同时,在此条件下金属内的位错和晶界的运动以及迁移速率较低,不利于非连续动态再结晶和连续动态再结晶的形核和长大,晶粒的体积分数都较低。Z值的增大使合金材料变形时流变集中加剧,流变集中区域的应变较大,变形晶粒的大角晶界开始接触使其破碎,为几何动态再结晶提供了充分条件。较低的Z值对应的热变形条件为高温低应变速率,使再结晶更加充分。其原因是,应变量确定时合金材料的变形时间较长,再结晶的时间足够,位错运动加剧通过湮灭与多边形化重组,得到更加均匀的亚晶组织,动态回复效果增强。动态回复是连续动态再结晶的一个阶段,因此动态回复的增强可促进连续动态再结晶[42]。同时,在低Z值条件下晶界的移动速率提高,材料内的大角晶界有利于发生弓出和迁移生成非连续动态再结晶晶核。较高的温度使变形速率较低,动态再结晶晶粒形核后可充分长大。连续动态再结晶和几何动态再结晶在低密度钢热变形中不明显。连续动态再结晶是小角晶界向大角晶界转变,需要较大的应变和均匀的转变[43]。这表明,低密度钢热变形以非连续动态再结晶为主。在低密度钢的热变形过程中主要的再结晶机制为非连续动态再结晶。连续动态再结晶和几何动态再结晶在各个热压缩条件下的程度都比较低,低Z值有利于非连续动态再结晶和连续动态再结晶,而几何动态再结晶程度随着Z值的增大呈提高的趋势。

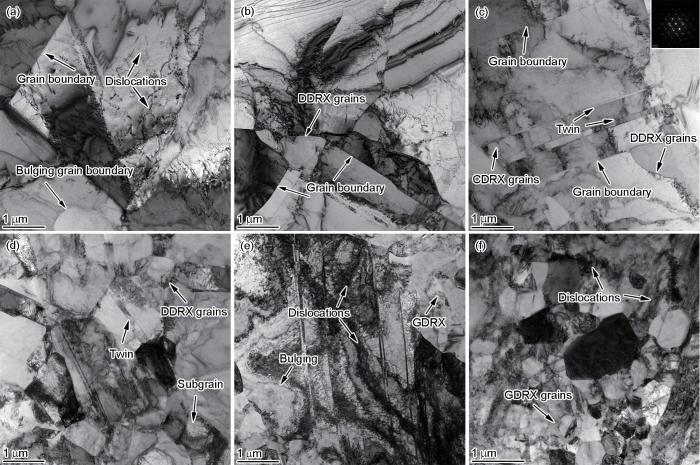

图15给出了低密度钢在不同lnZ条件下的TEM图片。可以看出,lnZ值较低时(lnZ值分别为31.8和34.1)低密度钢组织中的位错密度较低,晶界区域平直清晰,如图15a、b所示。lnZ值为中等值时(lnZ值分别为37.0和39.3)低密度钢组织中的位错密度较低,可清晰观察到变形晶粒内明显的位错缠结,在奥氏体晶界处有较大尺寸的亚晶和链状DDRX晶粒,如图15c、d所示。同时,由小角晶界向大角晶界的转变,还生成一定数量的CDRX晶粒,如图15c所示。lnZ值为高值时低密度钢组织中的位错密度进一步提高,如图15e、f所示,位错的聚集和缠结更明显,且晶界区域变得模糊,在晶界弓出的区域生成了尺寸较小的亚晶。由图15e、f还可见,流变集中加剧引起晶界弓出,变形区域的晶粒受到压应力而发生窄化和伸长,变形晶粒出现破碎形成GDRX的趋势。

图15

图15

低密度钢热变形组织的TEM照片

Fig.15

TEM image of thermal deformation structure of low density steel (a) lnZ = 31.8; (b) lnZ = 34.1; (c) lnZ = 37.0; (d) lnZ = 39.3; (e) lnZ = 41.0; (f) lnZ = 42.8

综上所述,在高Z值条件下组织中的位错密度较高,随着Z值的减小位错密度随之降低,更有利于低密度钢动态再结晶。同时,形变孪晶的存在表明位错滑移是低密度钢热变形主要的但不是唯一的变形机理。

3 结论

(1) 根据Fe-29.96Mn-9.56Al-1.01C低密度钢基于应变补偿的Arrhenius本构方程可预测低密度钢的流动应力变化,其AARE = 4.63%,R = 0.992,预测精度较高。

(2) 低密度钢动态再结晶与Z值有密切的关系,Z值较低的低密度钢其变形条件为高温低应变速率,有利于再结晶的发生及晶粒的长大。高Z值低密度钢其动态再结晶晶粒细小,保留有原始带状组织,再结晶程度较低。

(3) 随着Z值的增大低密度钢热压缩变形组织中大角晶界(> 15°的晶界)的占比大幅度降低,小角晶界(< 10°的晶界)的占比大幅度提高。

(4) 在低密度钢热变形过程中各Z值条件下其晶界取向差均呈双峰结构,主要动态再结晶机制为非连续动态再结晶,在热压缩条件下连续动态再结晶和几何动态再结晶的程度较低。位错滑移,是低密度钢的主要的但不是唯一的热变形机制。

参考文献

Current state of Fe-Mn-Al-C low density steels

[J].

Enhanced mechanical properties of a Fe-Mn-Al-C austenitic low-density steel by increasing hot-rolling reduction

[J].

Low density Fe-Mn-Al-C steels: phase structures, mechanisms and properties

[J].This review introduces the structural phases, microstructural characteristics, and the most relevant room and cryogenic properties of low density Fe-Mn-Al-C steels. The combination of outstanding physical and mechanical properties while offering a weight reduction of up to 18% make low density Fe-Mn-Al-C steels attractive structural materials as lightweight crash-resistant car body structures and structural components in the cryogenic industry. In this review, the latest alloy design strategies are introduced. In particular, the novel aspects of the phase structures and their deformation behavior, in particular, those related to L1(2) (Fe, Mn)(3)AlC carbides (kappa-carbides) and B2-type Ni/Cu-rich precipitates, are critically summarized. Future scientific and technical challenges are provided to establish these steels as structural materials for industrial applications.

Ultrahigh strength and high ductility lightweight steel achieved by dual nanoprecipitate strengthening and dynamic slip refinement

[J].

Strengthening and strain hardening mechanisms in a precipitation-hardened high-Mn lightweight steel

[J].

Microstructure evolution and mechanical behavior of Fe-Mn-Al-C low-density steel upon aging

[J].

Research status and development prospect of Fe-Mn-C-Al system low-density steels

[J].

Effects of pre-strain and two-step aging on microstructure and mechanical properties of Fe-30Mn-11Al-1.2C austenitic low-density steel

[J].Lightweight Fe-Mn-Al-C steels are promising candidates for automobile structural materials and have gained increased scientific and commercial interest owing to their outstanding mechanical properties and low density. To date, several studies have been conducted to illustrate the mechanism of phase transformation, strengthening, and strain hardening under solution and aging state. Moreover, prestrain before aging as a low-cost and simple method to tailor precipitates and control properties has been widely reported; however, it has been barely investigated in the Fe-Mn-Al-C alloy system. Therefore, in this study, the effects of pre-cold rolling and two-step aging on the microstructure and mechanical properties of Fe-30Mn-11Al-1.2C (mass fraction, %) austenitic low-density steel are investigated using EBSD, TEM, and universal testing machine. Results showed that the yield strength (YS) significantly increased via the two-step aging from 580 MPa (at solution state) to 1120 MPa, but the uniform elongation (UE) sharply decreased to approximately 0. However, after the pre-cold rolling and two-step aging, the YS of the material further improved to 1220 MPa, and the UE significantly increased to 18.2%, which implies an improvement in the comprehensive mechanical properties of the material. According to the microstructure analysis, the increase in YS after the two-step aging was caused by the ordering strengthening effect of κ' carbide. Further, the pre-cold rolling could introduce heterogeneous nucleation sites, inducing intragranular precipitation. The combination of the precipitation strengthening of the precipitates and deformation strengthening induced via the pre-cold rolling further increased the YS of the material. Moreover, these intragranular precipitates could improve the work hardening capability, which is the root cause of the high plasticity of materials. This process provides a novel idea for improving the performance of austenitic low-density steels.

预变形和双级时效对Fe-30Mn-11Al-1.2C奥氏体低密度钢显微组织和力学性能的影响

[J].

Research progress in heat treatment of Fe-Mn-Al-C system low-density steel

[J].

Fe-Mn-Al-C系低密度钢热处理研究进展

[J].

Cause analysis and control of edge crack of Iow density steel plate with high aluminum content

[J].

高铝低密度钢板带边裂成因分析及控制

[J].

Hot deformation and dynamic recrystallization behavior of austenite-based low density Fe-Mn-Al-C steel

[J].

Hot deformation behavior of Fe-Mn-Al light-weight steel

[J].

Investigation of hot deformation behavior and microstructure evolution of lightweight Fe-35Mn-10Al-1C steel

[J].

The high temperature deformation behavior of a Triplex (ferrite+austenite+martensite) low density steel

[J].

Constitutive behavior and microstructural evolution of FeMnSiCrNi shape memory alloy subjected to compressive deformation at high temperatures

[J].

A physically-based constitutive modelling of a high strength aluminum alloy at hot working conditions

[J].

Simulation of the flow behavior of AZ91 magnesium alloys at high deformation temperatures using a piecewise function of constitutive equations

[J].

Comparative study of phenomenological constitutive equations for an as-rolled M50NiL steel during hot deformation

[J].

Influence of deformation parameters on dynamic recrystallization of 2195 Al-Li alloy

[J].Al-Li alloys have attracted extensive attentions as promising structural materials in aerospace industries due to their excellent mechanical properties, and are usually formed through a variety of hot workings such as rolling and forging. Dynamic recrystallization (DRX) is considered as one of the key microstructure evolutions of Al alloys during hot working, and many works have been done concerning with DRX. However, the influence of deformation parameters on different types of DRX of 2195 Al-Li alloy is still unclear. In this work, hot plane strain compression tests were conducted at the strain rate range from 0.01 s-1 to 1 s-1 and the temperature range from 350 ℃ to 500 ℃ to investigate the critical condition of dynamic recrystallization of 2195 Al-Li alloy under different hot deformation conditions, DRX mechanisms were discussed, and the influence of deformation parameters on different types of DRX was revealed using EBSD and TEM. The results showed that the critical strain decreased with the decrease of Zener-Hollomon parameter (Z), DRX was more sufficient in lower Z value, and discontinuous dynamic recrystallization (DDRX) was primary type while only a little continuous dynamic recrystallization (CDRX) was found. Both CDRX and DDRX were promoted in lower Z value, geometric dynamic recrystallization (GDRX) only occurred in high Z value and increased with further increase of Z value, and the appearance of GDRX was accompanied by the increase of the number of DRX grains so that the DRX fraction slightly increased.

变形参数对2195 Al-Li合金动态再结晶的影响

[J].

Research progress of dynamic recrystallization in metallic materials

[J].

金属材料的动态再结晶研究进展

[J].

Deformation characteristics of an Al-6Cu-0.4Zr superplastic alloy

[J].

Continuous recrystallization in austenitic stainless steel after large strain deformation

[J].

Geometric dynamic recrystallization in hot torsion of Al-5Mg-0.6Mn (AA5083)

[J].

Dynamic recrystallization and precipitation behaviors during hot deformation of a k-carbide-bearing multiphase Fe-11Mn-10A1-0.9C lightweight steel

[J].

Hot deformation behavior of Fe-27.34Mn-8.63Al-1.03C lightweight steel

[J].

High temperature compression deformation behavior of 9Mn27Al10Ni3Si low density steel

[J].The deformation characteristics of 9Mn27Al10Ni3Si low density steel at 850~1050℃ with strain rate within the range of 0.01~5 s-1 were investigated by using Gleeble thermal simulator, XRD, OM, SEM and TEM. The results show that when the steel is hot compressed at 850~950℃ with low strain rate (0.01~1 s-1), the flow stress of the steel increases obviously as the strain reaches a certain critical value, which may be due to the precipitation and coarsening of κ-carbides, and the increase of friction coefficient of the steel during hot compression. With the increase of strain rate, the number of twins increases significantly, which can speed up the process of dynamic recrystallization of austenite, however, during thermal compression by high strain rate, the dynamic recrystallization process is more significant rather than by low strain rate. Due to the softening effect of recrystallization, the abnormal rise of flow stress gradually weakens or even disappears.

9Mn27Al10Ni3Si低密度钢的高温压缩变形行为及其机制

[J].使用Gleeble热模拟试验机、XRD、OM、SEM和TEM等手段研究了9Mn27Al10Ni3Si低密度钢在850~1050℃和0.01~5 s<sup>-1</sup>条件下的热压缩变形特征及其机制。结果表明,对这种钢在850~950℃进行低应变速率(0.01~1 s<sup>-1</sup>)热压缩时,κ-碳化物的析出和粗化以及在热压缩过程中摩擦系数的增大使其应变达到临界值后流变应力明显增大;随着应变速率的提高,实验钢的孪生显著增强,显著加快了奥氏体的动态再结晶过程,使其在高应变速率热压缩时动态再结晶的程度比低应变速率压缩时更为显著。再结晶的软化作用,使上述流变应力异常增大的现象逐渐减弱甚至消失。

Study on the dynamic recrystallization model and mechanism of nuclear grade 316LN austenitic stainless steel

[J].

The kinetics and cellular automaton modeling of dynamic recrystallization behavior of a medium carbon Cr-Ni-Mo alloyed steel in hot working process

[J].

Hot deformation behavior and microstructural evolution of an Fe-Cr-W-Mo-V-C steel

[J].

On the mechanism of hot deformation

[J].

Strength and structure under hot-working conditions

[J].

Effect of strain-rate upon the plastic flow of steel

[J].

Hot deformation behavior, dynamic recrystallization and processing map of Fe-30Mn-10Al-1C low-density steel

[J].

Dynamic recrystallization behavior and microstructure evolution of low-density high-strength Fe-Mn-Al-C steel

[J].

Study on dynamic recrystallization kinetics of rare earth magnesium alloys

[D].

稀土镁合金动态再结晶动力学研究

[D].

Research on hot deformation behavior of austenite Fe30Mn9Al0.9C low density steel

[J].

奥氏体型Fe30Mn9Al0.9C低密度钢的热变形行为研究

[J].

The thermal deformation behavior and casting simulation of advanced low-density fecrnitiai superalloy

[D].

新型低密度FeCrNiTiAl高温合金的热变形行为与铸造过程模拟

[D].

Study on hot deformation behavior of low density automobile steel containing medium manganese and high aluminum

[D].

中锰高铝低密度汽车用钢热变形行为研究

[D].

A nucleation criterion for dynamic recrystallization during hot working

[J].

A new one-parameter kinetics model of dynamic recrystallization and grain size predication

[J].

新的单参数动态再结晶动力学建模及晶粒尺寸预测

[J].

New developments in geometric dynamic recrystallization

[J].

A model of continuous dynamic recrystallization

[J].

The transition from discontinuous to continuous recrystallization in some aluminium alloys: I-the deformed state

[J].