研究发现,添加适量的稀土元素能提高耐热钢的蠕变性能。加入质量分数为0.053%Ce的T/P91耐热钢在600℃、100 MPa条件下的蠕变断裂寿命是未加Ce时的2.3倍,1 × 105 h持久强度提高了7%[5]。场发射扫描透射电子显微镜分析(FEGSTEM)结果表明,Ce在晶界处偏聚能增强晶界结合力,提高蠕变空洞形核的临界应力。Yang等[6]发现,在316LN不锈钢中添加质量分数为0.032%的Ce能促进晶内Laves相的析出和增强基体蠕变抗力,其在700℃、150 MPa条件下的蠕变寿命提高78%。研究表明,在有色金属中添加稀土元素,能显著改善其组织和提高其蠕变性能。在Al-7Si-0.3Mg中添加质量分数为0.5% 稀土Er促进了连续共晶Si以及富Er相的生成并将共晶Si结构从粗大的板状转变为纤维状,能阻碍蠕变过程中的位错滑移,将蠕变激活能从121.6±5.8 kJ/mol提高到142.5±4.7 kJ/mol[7]。在金属Zn中添加Ce能促进CeZn3金属间化合物和蠕变过程中位错的生成,使其蠕变机制由交叉滑移变为锥形滑移,使蠕变速率降低1.68 × 10-7 s-1和提高其高温蠕变性能[8]。文献[9]的结果表明,在X20Co中添加微量的Ce能细化初始奥氏体晶粒、抑制碳化物沿着晶界聚集粗化,使其室温韧性、塑性和高温塑性显著改善。

本文研究在680~720℃、100~200 MPa条件下不同Ce含量的X20Co的高温蠕变行为和微观组织的演化,研究Ce对其高温蠕变性能的影响及其机制。

1 实验方法

用真空感应熔炼炉制备三种稀土Ce含量不同的X20Co铸锭[10],实测化学成分列于表1。三种X20Co铸锭稀土Ce的含量(质量分数)分别为0%,0.005%和0.012%。0Ce,5Ce和12Ce钢,分别对应这三种X20Co。将铸锭在680℃保温8 h (等温退火)后炉冷,再将其在900~1200℃锻造成截面积为40 mm × 40 mm的方坯。随后将方坯先后在1150和800℃进行保温预处理,以消除锻态缺陷和细化组织。从保温预处理后的方坯切取长度为800 mm的试样,将其在箱式电阻炉中进行淬火+两次高温回火热处理。淬火工艺:在1130℃保温1.5 h后空冷;一次回火工艺:在700℃保温3 h后空冷;二次回火工艺:在680℃保温3 h后空冷。

表1 X20Co耐热钢的化学成分

Table 1

| Steel | C | Si | Mn | Cr | Co | Mo | W | V | Nb | Ce | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0Ce | 0.21 | 0.25 | 0.31 | 9.91 | 9.79 | 3.06 | 5.91 | 0.22 | 0.07 | 0 | Bal. |

| 5Ce | 0.26 | 0.21 | 0.22 | 9.88 | 10.06 | 3.06 | 5.93 | 0.22 | 0.07 | 0.005 | Bal. |

| 12Ce | 0.22 | 0.25 | 0.31 | 9.99 | 9.95 | 3.09 | 5.89 | 0.23 | 0.07 | 0.012 | Bal. |

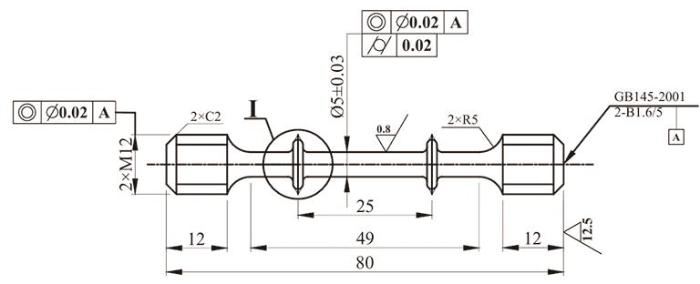

将热处理后的试块加工成标准蠕变试样,如图1所示。用RDJ50型高温蠕变试验机继续两组蠕变实验。第一组:蠕变温度为700℃,应力分别为100、150和200 MPa;第二组:应力为200 MPa,蠕变温度分别为680和720℃。

图1

在蠕变前和蠕变断裂后的试样上切取金相试样,将其研磨、抛光和氯化铁盐酸溶液(5 g FeCl3 + 50 mL HCl + 100 mL H2O)浸蚀,用Inspect F50扫描电子显微镜(SEM)和能谱仪(EDS)观察蠕变前和断裂后的微观组织和蠕变断口形貌。用Talos-F200X型场发射透射电子显微镜(STEM)并结合选区电子衍射(SAED)和STEM能谱仪(STEM-EDS)进一步分析蠕变前和蠕变断裂后的微观组织结构和成分。STEM试样是直径为3 mm的圆片,将其机械减薄至50 mm厚度后再用Tenupol-5型电解双喷仪减薄出足够的薄区。电解双喷液是10%高氯酸酒精溶液(10 mL HClO4 + 90 mL C2H5OH),电压为25 V,温度为-20℃。

2 实验结果

2.1 蠕变曲线

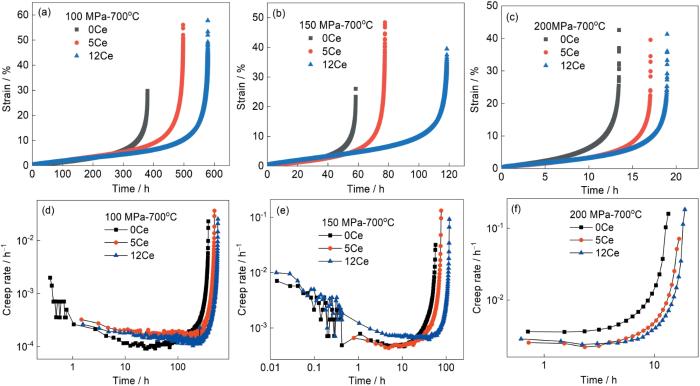

图2a~c给出了在700℃、100~200 MPa条件下三种(稀土Ce含量不同的)X20Co的蠕变应变曲线。与此对应,表2列出了X20Co的最小蠕变速率、断裂时间和加速蠕变开始时间。可以看出,在700℃、不同蠕变应力下稀土Ce的添加都延长了X20Co的蠕变寿命。蠕变应力为100 MPa时0Ce、5Ce和12Ce钢的蠕变断裂时间分别为379、497和578 h,如图2a所示。添加质量分数为0.005%和0.012%的Ce,使X20Co的蠕变寿命分别延长了31%和53%。这表明,Ce的含量越高X20Co蠕变寿命延长的幅度越大。蠕变应力为150 MPa时,添加0.005%和0.012%Ce(质量分数),X20Co的蠕变断裂时间分别为77.6和119 h,比不添加Ce的58.3 h分别提高33%和104%以上。蠕变应力为200 MPa时,随着Ce元素含量的提高X20Co的蠕变断裂时间分别为13、17和19 h,如图2c所示。

图2

图2

在700℃、不同应力条件下三种不同Ce元素含量X20Co的蠕变应变曲线和蠕变速率曲线

Fig.2

Creep strain versus creep time curves (a~c) and the creep rate versus creep time curves (d~f) of three X20Co steels under the stress of 100 MPa (a, d), 150 MPa (b, e) and 200 MPa (c, f) at 700oC

表2 X20Co的蠕变断裂时间、最小蠕变速率和加速蠕变阶段开始时间

Table 2

| Temperature / oC | Stress / MPa | Rupture time / h | Minimum creep rate / h-1 | Start time of the creep acceleration phase / h | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0Ce | 5Ce | 12Ce | 0Ce | 5Ce | 12Ce | 0C | 5Ce | 12Ce | ||||

| 700 | 100 | 379 | 497 | 578 | 9.13 × 10-5 | 1.56 × 10-4 | 1.03 × 10-4 | 355 | 440 | 519 | ||

| 700 | 150 | 58.4 | 77.6 | 119 | 4.63 × 10-3 | 4.32 × 10-3 | 6.81 × 10-3 | 51.4 | 70 | 106 | ||

| 700 | 200 | 13 | 17 | 19 | 3.58 × 10-3 | 2.21 × 10-3 | 2.40 × 10-3 | 12 | 15 | 17 | ||

| 680 | 200 | 93 | 107 | 111 | 3.59 × 10-3 | 2.81 × 10-3 | 1.18 × 10-3 | 85 | 99 | 104 | ||

| 720 | 200 | 3.3 | 4.8 | 7.0 | 1.17 × 10-2 | 3.55 × 10-3 | 5.38 × 10-3 | 2.7 | 3.6 | 6.2 | ||

图2d~f给出了在700℃、100~200 MPa条件下三种Ce含量X20Co的蠕变速率曲线。可以看出,X20Co的蠕变过程都主要由稳态蠕变阶段和加速蠕变阶段组成;并且随着蠕变时间的延长X20Co的蠕变速率先保持稳定而后很快提高。在700℃、不同蠕变应力下,X20Co的最小蠕变速率相近。在100 MPa低应力下0Ce、5Ce和12Ce钢的最小蠕变速率分别为9.13 × 10-5、1.56 × 10-4和1.03 × 10-4 h-1,稀土Ce的添加略微提高了X20Co最小蠕变速率,如图2d所示。当蠕变应力提高到200 MPa时,0Ce、5Ce和12Ce钢的最小速率分别为3.58 × 10-3、2.21 × 10-3和2.40 × 10-3 h-1,如图2f所示。这表明,在蠕变温度相同的条件下添加相同的Ce对X20Co的最小蠕变速率没有显著的影响。但是,Ce的添加推迟了X20Co的加速蠕变阶段开始时间。在700℃、150 MPa条件下0Ce、5Ce和12CeX20Co钢的加速蠕变阶段开始时间从51.4 h分别延长到70和106 h。这表明,Ce元素的添加使X20Co的蠕变损伤延迟发生[11]。

图3

图3

在200 MPa、不同温度条件下三种不同Ce元素含量X20Co的蠕变应变曲线和蠕变速率曲线

Fig.3

Creep strain versus creep time curves (a, b) and the creep rate versus creep time curves (c, d) of three studied X20Co steels crept at 680oC (a, c) and 720oC (b, d) under the stress of 200 MPa

图3c、d给出了在200 MPa、680和720℃条件下三种不同Ce含量X20Co的蠕变速率曲线。可以看出,在蠕变应力为200 MPa的不同温度下5Ce和12Ce钢的最小蠕变速率均比0Ce钢的低,表明Ce的添加显著降低了X20Co的最小蠕变速率。在680℃下0Ce、5Ce和12Ce钢的最小速率分别为3.59 × 10-3、2.81 × 10-3和1.18 × 10-3 h-1,添加质量分数为0.005%和0.012%的Ce使X20Co的最小蠕变速率分别降低了22%和67%;并且Ce元素的含量越高X20Co的最小蠕变速率降低的幅度越大,如图3d所示。在720℃下0Ce、5Ce和12Ce钢的最小蠕变速率分别为1.17 × 10-2、3.55 × 10-3和5.38 × 10-3 h-1,Ce的添加使X20Co的最小蠕变速率分别降低了70%和54%,如图3d所示。

2.2 微观组织

2.2.1 初始微观组织

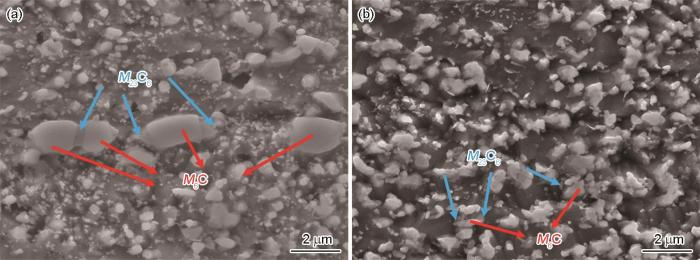

图4

图4

X20Co蠕变前的初始微观组织

Fig.4

SEM micrographs of 0Ce (a) and 12Ce (b) steel before creep

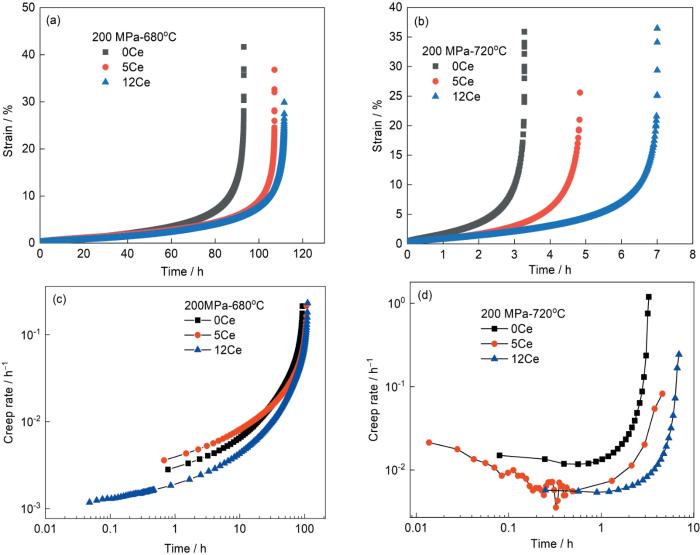

图5给出了蠕变前12Ce钢中析出相的STEM图像及其相应的EDS能谱分析和SAED衍射照片。可以看出,12Ce钢的初始组织中有三种类型的析出相,包括富W的大颗粒析出相、富Cr的近球形析出相和富V的纳米颗粒相,如图5b所示。三种类型析出相的成分,列于表3所示。富W的大颗粒析出相其尺寸为200 nm~1 μm,主要分布在晶界和亚晶界,W含量(原子分数)为19.25%,Mo含量(原子分数)为11.94%;结合衍射斑标定分析结果可知,如图5c所示,这类析出相为fcc结构的M6C相,晶格常数a =1.11094 nm,化学式为Fe3 (W, Mo)3C。紧邻M6C相的是近球形富Cr析出相,尺寸约为200 nm,Cr含量(原子分数)高达63.75%;由图5d可知,这类析出相为fcc结构的M23C6相,晶格常数a = 1.06599 nm。基体中尺寸约为50 nm的细小颗粒析出相,主要富集了V元素(原子分数为65.98%);由图5e可知,这类析出相为fcc结构的MC相,晶格常数

图5

图5

蠕变前12Ce钢初始组织中析出相的STEM图像及其EDS元素面分布和SAED图

Fig.5

STEM images of precipitates in 12Ce steel before creep (a), the corresponding elemental overlaid map of V, Cr, W (b) and SAED diagram (c~e)

表3 12Ce钢蠕变前初始组织中析出相的成分

Table 3

| Phase | V | Cr | Fe | Co | Mo | W | Mn | Nb |

|---|---|---|---|---|---|---|---|---|

| Matrix | 0.9 | 11.7 | 65.5 | 11.6 | 3.7 | 5.9 | 0.7 | - |

| MC | 73.4 | 2.4 | 2.2 | 3.9 | 2.6 | 2.1 | - | 13.4 |

| M6C | 1.3 | 11.4 | 39.4 | 6.1 | 15.9 | 25.7 | - | - |

| M23C6 | 1.8 | 72.4 | 8.2 | 14.3 | 2.5 | 0.7 | 0.1 | - |

图6给出了蠕变前0Ce钢中析出相的STEM图像及其相应的EDS分析。与12Ce钢类似,0Ce钢中也有三类析出相,分别是富W的M6C、富Cr的M23C6和富V的MC。这表明,稀土Ce的添加不影响蠕变前X20Co的初始组织中析出相的类型。但是,与12Ce钢相比,0Ce钢中大颗粒M6C的数量较多,M23C6的数量较少但是尺寸较大。

图6

图6

0Ce钢蠕变前初始组织中析出相的STEM图像及其EDS元素面分布

Fig.6

STEM images of precipitates in 0Ce steel before creep (a) with corresponding elemental mapping of V, Cr, W (b)

2.2.2 蠕变断裂后的微观组织

图7

图7

0Ce和12Ce钢在700℃、100 MPa条件下蠕变断裂后微观组织的SEM图像

Fig.7

SEM micrographs of 0Ce (a) and 12Ce (b) steel after crept under 100 MPa at 700oC

图8给出了在700℃、100 MPa条件下蠕变断裂后0Ce和12Ce钢中析出相的STEM图像及其EDS元素面分布。图8表明,0Ce钢中富W的大颗粒M6C数量较少、尺寸较大,平均等效直径达到500 nm,如图8a所示;12Ce钢中除少量的较大M6C颗粒外,在高温蠕变过程中还在基体马氏体板条块界面处析出了较细的M6C颗粒,其平均等效直径为300~400 nm,如图8b所示。EDS能谱分析结果表明,在大颗粒M6C周围分布着富Cr的M23C6,如图8c和8d所示。同时,Ce元素分布面扫描发现,在蠕变断裂后的12Ce钢中Ce元素在围绕M6C颗粒的M23C6中偏聚,如图8j所示。与蠕变前析出相的形貌和成分对比,在高温蠕变过程中0Ce和12Ce钢中的粗大M6C颗粒不断向较细M23C6颗粒转变,同时在基体中析出了较细的M6C颗粒。Ce的添加,可能促进了X20Co中粗大M6C颗粒的转化和较细M6C、M23C6颗粒的析出。

图8

图8

0Ce和12Ce钢在700℃、100 MPa条件下蠕变断裂后析出相的STEM图像及其EDS元素面分布

Fig.8

STEM micrographs of precipitates in 0Ce (a) and 12Ce steel (b) after crept under 100 MPa at 700oC corresponding with elemental mapping of Cr (c, g), W (d, h), V (e, i), Mo (f) and Ce (j)

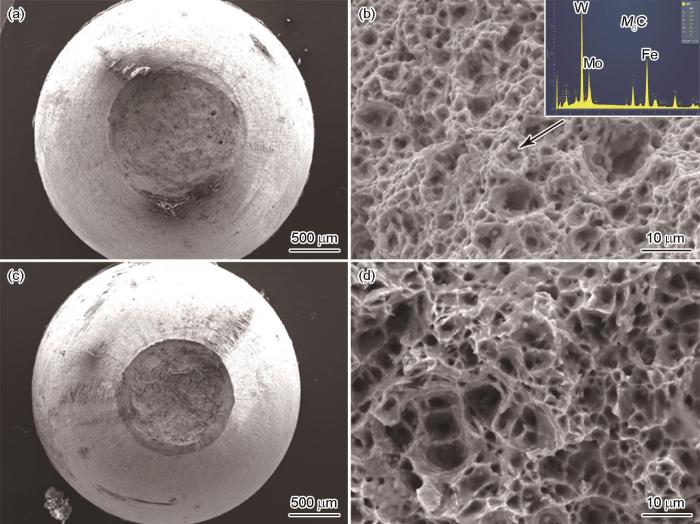

2.3 蠕变断口的形貌

图9给出了在700℃、100 MPa条件下0Ce和12Ce钢蠕变断口的SEM形貌。0Ce和12Ce钢的蠕变断口由边缘剪切唇和内部纤维区组成,在断裂过程中均发生了明显的颈缩,二者的断面收缩率分别为91.38%和92.99%。断口内部纤维区的微观形貌表明,二者的蠕变断口均有大量的韧窝。0Ce钢蠕变断口的韧窝数量较多,尺寸小而浅;12Ce钢蠕变断口的韧窝数量较少,尺寸大而深。这表明,0Ce和12Ce钢的蠕变断裂机制均为穿晶韧性断裂,Ce的添加没有改变X20Co的蠕变断裂机制,只是稍微提高了X20Co的蠕变塑性。EDS分析结果表明,蠕变断口韧窝中的析出相颗粒为M6C,如图9b中插图所示。这表明,在蠕变过程中X20Co中的粗大M6C颗粒易于产生应力集中,诱导了裂纹的萌生和促进了裂纹的扩展[14]。

图9

图9

0Ce和12Ce钢在700℃、100 MPa条件下蠕变断口的SEM形貌

Fig.9

SEM fractography images of 0Ce steel (a, b) and 12Ce steel (c, d) after crept at 700oC under 100 MPa

3 讨论

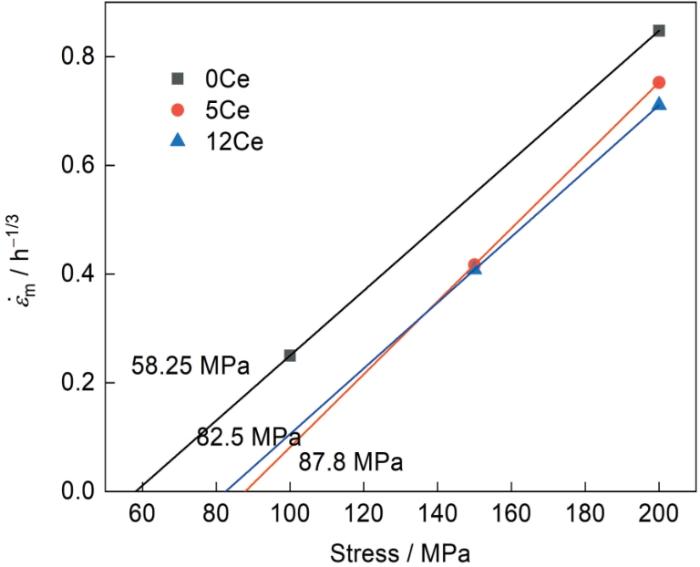

3.1 Ce元素对蠕变行为的影响

蠕变应力指数和蠕变激活能,是分析高温蠕变行为特征的重要参数。最小蠕变速率与蠕变温度、蠕变应力等参数的关系,可用温度补偿幂律蠕变方程

描述[15]。式中

图10

图10

三种不同Ce元素含量X20Co的最小蠕变速率与蠕变应力、温度倒数的对数曲线

Fig.10

Logarithmic curves of the minimum creep rate versus creep stress (δ) at 700oC (a) and the minimum creep rate (

图11

图11

X20Co在700℃蠕变时的最小蠕变速率的1/3次方随应力变化

Fig.11

Variation of minimum creep rate of the one-third power versus creep stress at 700oC of 0Ce, 5Ce and 12Ce steel

3.2 添加稀土Ce对蠕变寿命的影响

蠕变前和断裂后,在添加Ce和未添加Ce的X20Co中均有分布在晶界的富W大尺寸M6C和富Cr的较大尺寸M23C6,以及弥散分布在基体的富V细小MC。虽然Ce的添加不影响析出相的类型,但是明显减少了大尺寸颗粒状M6C的数量,使析出相的分布更均匀,如图4和7所示。同时,分布在M23C6周围的稀土Ce (图8j)可能阻碍Cr或W的扩散[20,21],从而影响高温蠕变过程中M6C和M23C6的析出和长大[22,23]。而且在高温蠕变过程中,Ce的添加促进了大颗粒M6C向较细M23C6颗粒的转变和减少了粗大M6C的数量,减轻了蠕变损伤和提高了蠕变塑性,如图9所示。Ce的添加使X20Co中M23C6的尺寸由100~200 nm细化为50~100 nm,且分布更加均匀(图7),极大地提高了X20Co蠕变抗力[24,25]。由此可见,Ce的添加能显著延长X20Co的蠕变寿命。

4 结论

(1) Ce元素的添加使X20Co在680~720℃、100~200 MPa条件下的蠕变寿命显著提高。在700℃、150 MPa条件下Ce元素含量(质量分数)为0.005%和0.012%的X20Co,其蠕变断裂时间对应为77.6和119 h,比未添加Ce的X20Co的58.3 h分别提高33%和104%以上。

(2) Ce元素的添加并不改变X20Co的蠕变机制,但是使蠕变激活能和门槛应力显著提高。未添加Ce和添加质量分数为0.005%、0.012%Ce的X20Co,其蠕变应力指数分别为5.05、4.76和4.49、蠕变激活能分别为572.3,595.0和642.1 kJ/mol,蠕变门槛应力为58.3,87.8和82.5 MPa。

(3) 在蠕变前和断裂后的X20Co中均存在不同尺寸的三类主要析出相,沿晶界分布的富W大尺寸M6C和富Cr的较大尺寸M23C6、弥散分布在晶内的富V细小MC。Ce元素的添加减少了粗大颗粒状M6C的数量、促进了较细M23C6颗粒的析出和增强了与位错的交互作用,使其蠕变抗力提高和改善其蠕变性能。

参考文献

Effect of microstructural evolution on high-temperature strength of 9Cr-3W-3Co martensitic heat resistant steel under different aging conditions

[J].

Research of high chromium and cobalt refractory steel

[J].

高铬高钴耐热钢的研究

[J].

The wear mechanism of the chamber and plunger materials of hot chamber die casting machine for magnesium alloy

[J].

镁合金热室压铸机压射室材料摩擦磨损机制研究

[J].

Study on a high cobalt and chromium containing die steel for the magnesium alloy die casting

[D].

一种高钴高铬压铸镁合金用模具钢的研究

[D].

Effect of rare earth cerium on the creep properties of modified 9Cr-1Mo heat-resistant steel

[J].

Influence of cerium on the creep properties of 316LN austenitic stainless steel

[J].

Ce元素对316LN奥氏体不锈钢高温蠕变性能的影响

[J].采用蠕变持久试验机、扫描电子显微镜和透射电子显微镜等实验手段,系统研究了Ce元素添加对316LN奥氏体不锈钢(316LN钢)高温蠕变行为和微观组织的影响。结果表明,添加0.032%的Ce元素使316LN钢的蠕变断裂寿命显著提高。在温度为700℃、载荷为150 MPa的条件下,添加0.032%Ce元素的316LN钢蠕变寿命为555.5 h,比不添加Ce元素时的蠕变寿命312.6 h提高了78%。在温度为600~700℃、载荷为150~200 MPa的条件下,未添加Ce元素和添加0.032%Ce元素的316LN钢对应的蠕变应力指数分别为7.64和9.07,蠕变激活能分别为415.3 kJ/mol和454.8 kJ/mol,蠕变门槛应力分别为61.7 MPa和76.6 MPa。蠕变断裂后的微观组织表明,添加0.032%的Ce元素显著促进了蠕变过程中316LN钢晶内Laves相的析出。晶内细小弥散分布的Laves相,在蠕变过程中能够阻碍位错移动,提高基体的蠕变抗力,从而有效改善蠕变性能。

Effects of Y additions on the microstructures and mechanical behaviours of as cast Mg-xY-0.5Zr alloys

[J].

Rare earth improves strength and creep resistance of additively manufactured Zn implants

[J].

Effects of trace Ce on mechanical properties of a ferritic/martensitic heat resistant steel containing high Cr and Co

[J].High Co and Cr containing martensitic heat resisting steels of X20Co without and with trace Ce addition were heat treated under different conditions, then the effect of trace Ce on the microstructure and mechanical properties of the steels were investigated by means of optical microscope, scanning electron microscope, X-ray diffractometer and tensile tester. The results show that in the quenching process, the addition of 50×10-6 Ce can promote the precipitation of M6C type carbides along the grain, therewith hinder the grain boundary migration, and make the refinement of austenite grains; As a consequence, the accumulation and growth of M23C6 type carbides along grain boundaries can be inhibited during tempering process. At the same time, the addition of 50×10-6 Ce has no significant effect on the hardness, strength and high temperature instantaneous tensile strength, but the toughness and plasticity at room temperature as well as the high temperature plasticity are significantly improved for the high Co and Cr containing martensitic steel X20Co.

微量Ce元素对高铬高钴型马氏体耐热钢力学性能的影响

[J].

A high chromium and cobalt containing rare-earth heat resistant steel and its preparation method

[P].

一种高Cr-高Co型稀土耐热钢合金材料及其制备方法

[P].

The effect of microstructure evolution on the mechanical properties of martensite ferritic steel during long-term aging

[J].

Kinetics of transformation of delta ferrite during creep in a type 316(N) stainless steel weld metal

[J].

Overview of σ phase influencing on mechanical properties of stainless steels

[J].

σ相析出对不锈钢力学性能的影响概述

[J].σ相是不锈钢中常见的一种硬而脆的金属间相,它可在铸造、轧制、热处理以及焊接等过程中析出,显著影响不锈钢的力学性能。从冲击韧性、塑性、拉伸强度、高温蠕变以及耐磨性等方面综述了国内外关于σ相对不锈钢力学性能影响研究的状况,分析了σ相的影响机制,并提出了目前研究中存在的一些问题以及将来可能的研究方向。

Effect of stress on microstructural evolution and mechanical properties of 12Cr3W3Co steel during aging and short-term creep

[J].

Application of rare earth element in steel and its influence on steel properties

[J].

稀土元素在钢中的作用及对钢性能的影响

[J].

La interactions with C and N in bcc Fe from first principles

[J].

Combined matrix/boundary precipitation strengthening in creep of Fe-15 Cr-25 Ni alloys

[J].

Flow stress, subgrain size, and subgrain stability at elevated temperature

[J].

Effects of boron addition on the microstructure and creep properties of a Ni-Fe-based superalloy weld metal alloy

[J].

Microstructural changes and improvement of mechanical properties in an Fe-30Cr-5Al alloy with Ce additions

[J].

Fe-30Cr-5Al合金のCe添加に伴う組織変化と機械的性質の改善

[J].

Nucleation of W-rich carbides and Laves phase in a Re-containing 10%Cr steel during creep at 650oC

[J].

Effect of thermal exposure on the stability of carbides in Ni-Cr-W based superalloy

[J].

The discontinuous precipitation of M23C6 in Nimonic 80A

[J].

Microstructural analysis of phase precipitation during high temperature creep in AISI 310 stainless steel

[J].