适当的合金化,是提高316LN钢高温蠕变性能的有效途径。M.D.Mathew等[5]研究N元素对316LN钢高温蠕变性能的影响时发现,在650℃、140~225 MPa条件下添加0.22%的N元素产生显著的固溶强化,促进基体中细小碳氮化物的析出,因此大幅度延长了316LN钢高温蠕变断裂的时间(近10倍)。在316LN钢中添加适量的Nb元素能抑制M23C6碳化物的析出和促进晶内生成尺寸稳定性较高的Z相纳米颗粒,显著降低在650℃、100 MPa条件下的最小蠕变速率,延迟蠕变第三阶段的开始时间;但是,添加Nb元素也会加快晶界处粗大Laves相和Sigma相的析出,加速蠕变空洞的形核和长大,大幅度缩短蠕变第三阶段,从而影响316LN钢的高温蠕变寿命[6~8]。在316LN钢中添加2.05%的Cu元素,在650℃低应力条件下的高温蠕变过程中,在基体中析出纳米富Cu相,能显著延长蠕变寿命[9]。

近年的研究[10~12]表明,添加稀土元素影响第二相的析出行为,从而延长奥氏体钢的高温蠕变寿命。一方面,添加稀土元素能细化奥氏体钢中的碳化物,抑制蠕变空洞的连续形核和扩展[13]。Nune[14,15]的研究发现,稀土碳化物(Y2C或Y3C)作为形核质点能促进HP40耐热钢中Cr23C6断续分布,阻碍蠕变裂纹的扩展。Chen等[16]认为,稀土元素的偏聚改变了21Cr11NiN耐热钢的晶界化学特征,导致晶界上的M23C6由连续网状分布变为不连续分布。因此,添加0.0063%的Ce元素,使21Cr11NiN耐热钢在650℃、100 MPa条件下的蠕变寿命延长近2倍。另一方面,添加稀土元素能抑制有害相的析出。Kim等[17]研究发现,在27Cr-7Ni双相钢中添加55~110 × 10-6的Ce元素能推迟高温时效过程Sigma相的析出,使室温冲击韧性显著提高。

由此可见,添加适量的稀土元素调控316LN钢高温蠕变过程中关键相的析出,对提高316LN钢的高温蠕变性能极富潜力。本文在600~700℃、150~200 MPa蠕变实验条件下系统对比分析316LN钢添加0.032%Ce元素前后蠕变微观组织的演化规律,研究添加0.032%的Ce元素对316LN钢高温蠕变行为的影响及其机制。

1 实验方法

采用50 kg真空感应熔炼炉,制备两炉不添加Ce和添加Ce的316LN实验铸锭。使用ICP6300电感耦合等离子体发射光谱仪测量316LN钢的化学成分,结果列于表1。添加Ce的316LN钢中稀土Ce的实际质量分数为0.032%,记为32Ce表示;不添加Ce的316LN钢记为0Ce。

表1 两种316LN奥氏体不锈钢的主要化学成分

Table 1

| Steel | C | Si | Mn | Cr | Mo | Ni | Ce | N | Fe | Grain size / μm |

|---|---|---|---|---|---|---|---|---|---|---|

| 0Ce | 0.010 | 0.31 | 1.63 | 17.73 | 2.77 | 13.76 | 0 | 0.13 | Bal. | 77 ± 37 |

| 32Ce | 0.013 | 0.26 | 1.80 | 17.76 | 2.83 | 13.65 | 0.032 | 0.13 | Bal. | 66 ± 32 |

将铸锭在1200℃保温4 h后,在1200~950℃温度范围内锻造成横截面尺寸为40 × 40 mm的方棒。将方棒在1150℃保温2 h固溶处理后,沿其长度方向切取直径为12 mm的圆棒并加工成直径为5 mm、平行段的长度为25 mm的标准蠕变试样。

用RDL-50电子式蠕变持久试验机进行三组蠕变实验。第一组:进行温度为700℃,应力分别为150 MPa、175 MPa和200 MPa的蠕变实验;第二组:为了得到蠕变本构方程,进行应力为200 MPa,温度分别为600℃、650℃和700℃的蠕变实验。其中,在600℃、200 MPa条件下的蠕变实验在500 h中断,其余实验条件下的试样均一直进行到拉断;第三组:为了研究Ce对316LN钢蠕变过程析出相的影响,在700℃、150 MPa实验条件下的稳态蠕变阶段中断实验,中断蠕变应变为10%和20%。

从固溶处理后的样品上切取标准金相试样,将其机械研磨和抛光后浸入65℃的高锰酸钾硫酸水溶液(1 g KMnO4 + 9 mL H2SO4 + 90 mL H2O)热腐蚀90 min,然后使用Image Pro Plus 6.0软件统计奥氏体的晶粒尺寸。沿着蠕变断裂后试样的横截面切取金相样品,对其机械研磨、抛光和使用40%的王水溶液(30 mL HCl + 10 mL HNO3 + 60 mL H2O)侵蚀后,用Inspect F50扫描电子显微镜(SEM)观察蠕变微观组织。在蠕变断裂试样的断口以下2 mm位置处切取厚度约为500 μm的透射电镜样品,用砂纸磨至50 μm后使用电解双喷仪(TenuPol-5)将其减薄。减薄用电解液为10%高氯酸酒精溶液(10 mL HClO4 + 90 mL C2H5OH),温度为-30℃,电压为27 V。用Talos F200X透射电子显微镜(TEM)观察显微组织和析出相的形貌,结合选区电子衍射(SAED)和扫描TEM能谱仪(STEM-EDS)分析析出相的结构和成分。

2 实验结果

2.1 两种316LN钢的蠕变性能

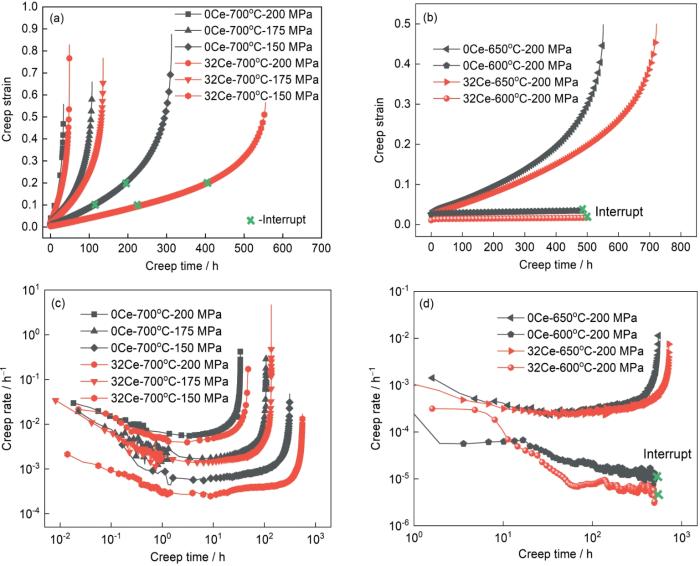

图1a给出了添加0.032%Ce元素前后316LN钢在700℃、150~200 MPa条件下的蠕变应变曲线。可以看出,添加0.032%的Ce元素,显著提高了316LN钢蠕变断裂寿命。在700℃、200 MPa条件下,0Ce和32Ce钢的蠕变断裂时间分别为33.7 h和48.1 h,添加Ce元素使316LN钢的蠕变寿命提升了42.7%。应力为150 MPa时,32Ce钢的蠕变断裂时间为555.5 h,比0Ce钢的312.6 h提升了78%。这表明,在低应力条件下添加Ce元素对蠕变寿命的提升更显著。此外,对比2种316LN钢在650℃、200 MPa条件下的蠕变应变曲线可以发现,32Ce钢的蠕变断裂时间为722 h,明显高于0Ce钢的551 h。在600℃、200 MPa条件下,0Ce和32Ce的蠕变应变曲线均在500 h中断,如图1b所示。可以看出,在600~700℃、150~200 MPa条件下,添加0.032%的Ce元素均显著提升了316LN钢的蠕变寿命。

图1

图1

不同温度和应力条件下0Ce和32Ce钢的蠕变应变曲线和蠕变速率曲线

Fig.1

Creep strain versus creep time curves (a, b) and the creep rate versus creep time curves (c, d) at 700oC under the stress of 150~200 MPa (a, c) and at 600oC, 650oC under 200 MPa (b, d) of 0Ce and 32Ce

图1c和1d分别给出了0Ce和32Ce钢在700℃、150~200 MPa条件下和200 MPa、600~650℃条件下的蠕变速率曲线。可以看出,32Ce钢的蠕变速率均低于0Ce钢,添加0.032%的Ce元素显著降低了316LN钢蠕变速率。在700℃、200 MPa条件下,0Ce和32Ce钢的最小蠕变速率分别为5.77 × 10-3 h-1和4.28 × 10-3 h-1,添加Ce元素使316LN钢的最小蠕变速率降低了25.8%。当应力降低至150 MPa时,32Ce钢的最小蠕变速率为3.166 × 10-4 h-1,比0Ce钢的6.354 × 10-4 h-1降低了50%。这表明,蠕变应力越低,添加0.032%的Ce元素对蠕变速率的影响越显著。这个结果,也与蠕变寿命的变化趋势一致。此外,600℃、200 MPa条件在500 h中断时,0Ce和32Ce钢的蠕变速率均趋于稳定,表明蠕变进入了稳态蠕变阶段,如图1d所示。此时32Ce钢的最小蠕变速率为6.886 × 10-6 h-1,仍远低于0Ce钢的1.597 × 10-5 h-1,表明添加0.032%的Ce元素能显著提升316LN钢的蠕变抗力。

在700℃不同的应力条件下,0Ce和32Ce钢的蠕变断裂应变存在较明显的差异。如图1a所示,应力为200 MPa和175 MPa时,32Ce钢的蠕变断裂应变分别为0.787和0.766,0Ce钢的蠕变断裂应变分别为0.558和0.659,32Ce钢的蠕变断裂应变均高于0Ce钢。应力为150 MPa时0Ce钢和32Ce钢的断裂应变分别为0.875和0.566,32Ce钢的蠕变断裂应变比0Ce钢降低了34%。由此可见,在较高的应力条件下添加0.032%的Ce元素提高了316LN钢蠕变断裂应变;而在较低的应力条件下,添加0.032%的Ce元素则降低了316LN钢蠕变断裂应变。

最小蠕变速率

图2

图2

0Ce和32Ce钢的最小蠕变速率与蠕变应力、温度倒数的对数曲线

Fig.2

Logarithmic curve of the minimum creep rate versus creep stress at 700oC (a) and the minimum creep rate versus the reciprocal of temperature multiplied by 1000 under 200 MPa (b) of 0Ce and 32Ce steel

2.2 蠕变断裂后的微观组织

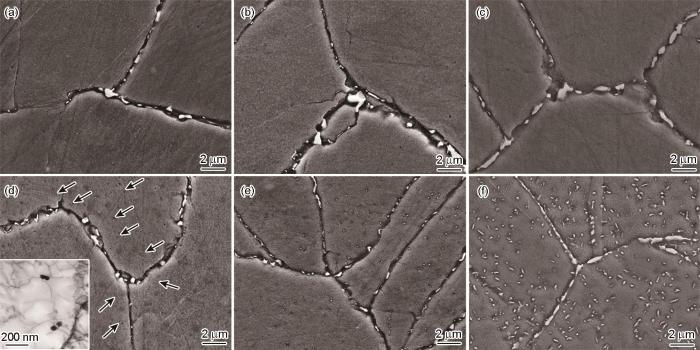

图3给出了在700℃、150~200 MPa条件下0Ce钢和32Ce钢蠕变断裂试样横截面的微观组织。蠕变断裂后,0Ce钢和32Ce钢的晶界处均出现颗粒状析出相。应力为200 MPa时,晶界处颗粒状析出相的数量较少,尺寸约为亚微米级,如图3a和3d所示。应力降低至150 MPa,晶界处的颗粒状析出相明显长大,尺寸为1~2 μm,如图3c和3f所示。但是,0Ce钢和32Ce钢晶界处析出相的形貌、尺寸和数量均没有明显差别。此外,在不同应力下蠕变断裂后,32Ce钢的晶内均出现大量的颗粒状析出相。应力为200 MPa时,32Ce钢晶内析出相的数量较少,尺寸约为100 nm,如图3d中的TEM插图所示。随着蠕变应力的降低,晶内析出相的尺寸明显增大,数量明显增多。应力为150 MPa时蠕变断裂,在32Ce钢中可明显观察到弥散分布在基体中的颗粒状析出相,如图3f所示。相比之下,在不同应力下蠕变断裂后,0Ce钢的晶内均没有析出颗粒状析出相。由此可见,添加0.032%的Ce元素对蠕变过程中晶界处析出相没有明显的影响,但是促进了晶内细小颗粒状析出相的析出。

图3

图3

0Ce和32Ce钢在700℃不同应力蠕变断裂后的SEM微观组织

Fig.3

SEM micrographs of 0Ce (a-c) and 32Ce (d-f) steel after crept under 200 MPa (a, d), 175 MPa (b, e), 150 MPa (c, f) at 700oC (Inset in d is the TEM observation of intragranular precipitates)

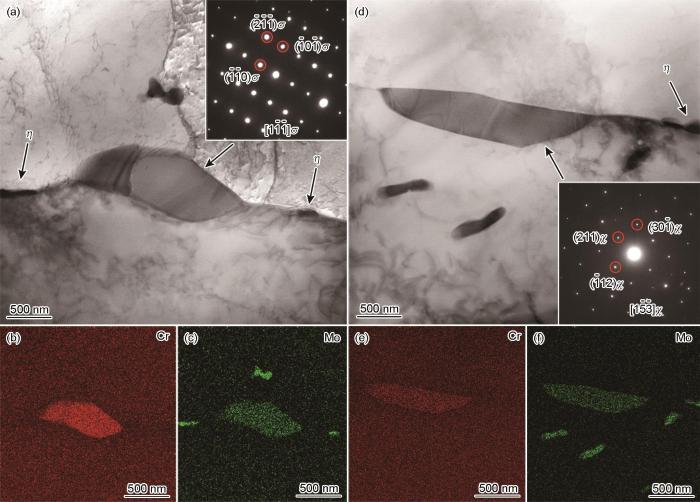

图4给出了在700℃、150 MPa条件下蠕变断裂后,0Ce钢晶界处析出相的TEM图像和Mo、Cr元素的面分布。由图4a可见,0Ce钢的晶界分布着两类析出相。一类为大块状析出相,尺寸约为1 μm。EDS元素面分布图显示,大块状析出相富集Cr和Mo元素,其成分列于表2。从表2可见,大块状析出相中Cr的含量为31.9%,Mo的含量为11.1%,Fe的含量约为48.7%。这表明,这种析出相是一种FeCrMo金属间化合物。根据析出相的SAED谱(图4a插图)可以确定,大块状析出相为四方结构的Sigma相,其化学式为Fe(Cr, Mo)。另一类是小颗粒状析出相,尺寸约为200 nm。小颗粒状析出相也富集Cr和Mo元素,但是与Sigma相不同的是,小颗粒状析出相中Mo的含量高达31.1%,是Fe2Mo型Laves(η)相[22,23]。由此可以确定,在700℃、150 MPa条件下蠕变断裂后,0Ce钢晶界的析出相为大块状Sigma相和小颗粒状Laves相。此外,部分Laves相在晶界处沿着Sigma相边缘分布,如图4a虚线圈中所示。其原因可能是,Sigma相沿着Laves相界面析出,并随着蠕变时间的增加通过消耗Laves相而长大[24]。

图4

图4

700℃、150 MPa条件蠕变断裂后0Ce钢晶界处析出相的TEM图像和Mo、Cr元素的面分布

Fig.4

TEM image of intergranular precipitates in 0Ce steel after crept at 700℃/150 MPa (a) with corresponding elemental mapping of Mo (b) and Cr (c) (Inset SAED pattern in a was obtained from [1-1-1] zone axis of Sigma phase)

表2 316LN奥氏体不锈钢蠕变析出相的化学成分

Table 2

| Phase | C | Si | Mn | Cr | Mo | Ni | Fe |

|---|---|---|---|---|---|---|---|

| Laves | 2.0 ± 0.4 | 1.5 ± 0.1 | 1.5 | 15.3 ± 1.5 | 31.1 ± 2.4 | 6.9 ± 0.5 | 41.7 |

| Chi | 0.9 ± 0.8 | 0.6 ± 0.1 | 1.8 | 24.5 ± 0.2 | 20.4 ± 0.6 | 4.2 ± 0.1 | 47.6 |

| Sigma | 0.3 ± 0.1 | 1.2 ± 0.8 | 1.7 | 31.9 ± 1.5 | 11.1 ± 1.1 | 5.1 ± 0.5 | 48.7 |

图5给出了在700℃、150 MPa条件下蠕变断裂后,32Ce钢晶界处析出相的TEM图像以及Mo、Cr元素的面分布。与0Ce钢晶界处析出相的类型相同的是,32Ce钢的晶界也有大块状Sigma和小颗粒状Laves相,如图5a所示。但是,与0Ce钢相比,32Ce钢晶界处Sigma相的数量较少。同时32Ce钢的晶界出现一种明显富集Cr和Mo的大块状Chi(χ)相,如图5d所示。Chi相的平均尺寸为1~2 μm,与Sigma相尺寸相当,且与Sigma相同为FeCrMo金属间化合物,但是Chi相中Cr和Mo含量分别为24.5%和20.4%,比Sigma相含有更少的Cr(31.9%)和更多的Mo(11.1%),其化学成分列于表2。

图5

图5

700℃、150 MPa条件蠕变断裂后32Ce钢晶界处析出相的TEM图像和Cr、Mo元素面分布

Fig.5

TEM images of intergranular precipitates in 32Ce steel after crept at 700oC/150 MPa (a, d) together with elemental mapping of Cr (b, e) and Mo (c, f) (The SAED pattern inset in a was obtained from [1-1-1] zone axis of Sigma phase while that in d was acquired from [1-5-3] zone axis of Chi phase)

图6给出了在700℃、200 MPa和150 MPa条件下蠕变断裂后,32Ce钢晶内析出相的TEM图像和元素分析。在700℃、200 MPa条件下蠕变断裂后,32Ce钢晶内的析出相数量较少,尺寸约为100 nm,主要呈颗粒状,如图6a所示。由晶内析出相的SAED谱(图6b)和EDS元素线扫描分析(图6c)可知,晶内析出相主要富集Mo元素,为Fe2Mo型的Laves相。在700℃、150 MPa条件下蠕变断裂后,32Ce钢晶内析出相的TEM图像,如图6e所示。可以看出,32Ce钢晶内析出相的尺寸约为200 nm,呈长条状和颗粒状,弥散分布在基体中。EDS元素分析结果表明,晶内析出相主要富集Mo元素和少量Si元素,如图6f和6g所示。由此可以确定,在700℃、150 MPa条件下蠕变断裂后,32Ce钢晶内的析出相仍为Laves相。

图6

图6

700℃、200 MPa和150 MPa条件蠕变断裂后32Ce钢晶内析出相的TEM图像和元素分析

Fig.6

TEM image of the intragranular precipitates in 32Ce steel after crept at 700oC/200 MPa (a) and the enlarged view of an intragranular precipitate (b) corresponding with SAED pattern (c), EDS line scanning analyses (d); TEM micrograph of the intragranular precipitates in 32Ce steel after crept at 700oC/150 MPa (e) and elemental distribution of Mo (f) and Si (g) acquired from the area delimited by the rectangles in (e)

3 讨论

3.1 稀土Ce对蠕变析出相的影响

在700℃、150 MPa条件下,0Ce钢应变为20%时的蠕变时间(180 h)与32Ce钢应变为10%时的蠕变时间(175 h)相近,由此可对比分析在蠕变时间相同的条件下添加Ce对316LN钢析出相特征的影响。图7给出了在700℃、150 MPa条件下经过相同时间(约180 h)蠕变中断后0Ce和32Ce钢的微观组织。可以看出,蠕变180 h后在0Ce钢的晶内并未观察到析出相,如图7a所示。但是,在32Ce钢的晶内弥散分布着大量的Laves相,如图7b所示。这表明,添加0.032%的Ce元素显著促进了晶内Laves相的析出。已有研究[25]表明,Laves相的析出主要受Mo元素扩散的控制。热力学计算结果表明,在316LN钢中添加Ce元素能略微提高Mo元素的活度和扩散系数,降低Laves相的形核激活能,从而促进了晶内Laves相的析出[26]。此外,对比中断后晶界处的析出相可见,0Ce钢的晶界处出现大块状Sigma相和颗粒状Laves相,而在32Ce钢的晶界处只出现了颗粒状Laves相。这表明,添加0.032%的Ce元素可能延缓、甚至抑制晶界处Sigma相的析出。

图7

图7

0Ce和32Ce钢在700℃、150 MPa实验条件中断蠕变后的SEM微观组织

Fig.7

SEM micrographs of 0Ce (a) and 32Ce (b) steel after interrupt crept at 700oC/150 MPa for about 180 h

3.2 稀土Ce对蠕变性能的影响

固溶处理后的0Ce钢和32Ce钢平均晶粒尺寸分别为77 μm和66 μm,添加0.032%的Ce元素使316LN钢的晶粒尺寸略微降低。在高温下,晶界容易萌生空洞和裂纹,因此晶粒尺寸越小其蠕变性能越差。但是,晶粒尺寸较小的32Ce钢蠕变性能显著优于晶粒尺寸较大的0Ce钢,可能与析出相阻碍位错的攀移运动有关。在高温蠕变过程中,316LN钢中存在大量的析出相且与位错发生明显的交互作用,提高了位错攀移运动的临界应力值,即蠕变变形存在一定的门槛应力。由此,可用门槛应力(σth)修正蠕变方程,定量分析析出相对316LN钢蠕变性能的影响。门槛应力修正的蠕变速率方程为[18]

式中A′为材料常数,n′和Q分别为真蠕变应力指数和真蠕变激活能,(σ-σth)表示蠕变变形有效应力。对2种不同Ce含量的316LN钢的蠕变数据拟合,结果表明:n′ = 5时线性相关度最高,

图8

图8

0Ce和32Ce钢在700℃最小蠕变速率的1/5次方随蠕变应力的变化

Fig.8

Variation of minimum creep rate of the one-fifth power versus creep stress at 700oC of 0Ce and 32Ce steel

在蠕变过程中,没有添加Ce元素的316LN钢晶界处析出了Sigma相和Laves相。晶界处大尺寸Sigma相的析出严重损害蠕变性能,因为Sigma相与基体界面的结合强度较低,并且大尺寸Sigma相周围产生的较大应力集中诱导蠕变裂纹的生成和扩展,使蠕变寿命和塑性降低[27]。由此可见,0Ce钢蠕变门槛应力主要源于晶界处Laves相的强化作用。在添加0.032%Ce的316LN钢晶界处存在Sigma相、Laves相、Chi相和晶内析出Laves相。与Sigma相相同,Chi相也是一种脆性的金属间化合物,其析出也严重损伤材料强度和塑性[28]。同时,添加0.032%Ce元素的316LN钢晶界处Chi相与Sigma相的尺寸相当,对蠕变性能的影响与Sigma相类似。由此可见,32Ce钢的蠕变门槛应力源于晶界和晶内Laves相的共同作用[29]。与没有添加Ce元素的316LN钢比较,添加0.032%的Ce元素后316LN钢蠕变门槛应力提高主要是晶内Laves相引起的。添加0.032%的Ce元素促进了316LN钢中晶内Laves相的析出,在基体弥散分布的细小Laves相钉扎位错和阻碍蠕变过程中位错的运动(图6a),提高了316LN钢基体的蠕变抗力[30]。

4 结论

(1) 在600~700℃、150~200 MPa实验条件,添加0.032%的Ce元素能显著延长316LN钢的高温蠕变寿命。在700℃、150 MPa实验条件下,添加0.032% Ce元素的316LN钢蠕变断裂时间为555.5 h,比不添加Ce元素时的312.6 h提升了78%。

(2) 不添加Ce和含0.032%Ce的316LN钢的蠕变应力指数分别为7.64和9.07,蠕变激活能分别为415.3 kJ/mol和454.8 kJ/mol,门槛应力分别为61.7 MPa和76.6 MPa。在蠕变过程中2种316LN钢的蠕变机制均为位错攀移控制机制,添加0.032%的Ce元素不影响316LN钢的蠕变机制,但是使316LN钢的蠕变激活能和蠕变门槛应力值分别提高39.5 kJ/mol和15 MPa。

(3) 添加0.032%的Ce元素显著促进高温蠕变过程中316LN钢晶界处Chi相和晶内Laves相的析出。在700℃、150 MPa的蠕变过程中,不添加Ce元素的316LN钢晶界处析出Laves相和Sigma相,而添加0.032%Ce元素的316LN钢除晶界处析出Laves相、Chi相、Sigma相外,晶内还析出细小、弥散的颗粒状Laves相。

(4) 添加0.032%的Ce元素促进了316LN钢晶内析出细小、弥散的Laves相,能有效阻碍位错运动、提升蠕变激活能和蠕变门槛应力,从而增强基体蠕变抗力,改善316LN钢的高温蠕变性能。

参考文献

Materials challenges in nuclear energy

[J].

Structural materials for fission & fusion energy

[J].

Improving creep strength of 316L stainless steel by alloying with nitrogen

[J].

Creep behaviour and microstructural evolution in AISI 316LN + Nb steels at 650oC

[J].

Stability of Z-phase and M6X in creep-resistant steels

[J].

Aging precipitation behaviors of Nb-contained 316LN SS

[J].

Effects of N and Cu on the precipitation and the creep life of 316L austenitic stainless steel at 650oC

[J].

Effect of rare earth cerium on the creep properties of modified 9Cr-1Mo heat-resistant steel

[J].

An advanced creep cavitation resistance Cu-containing 18Cr-12Ni-Nb austenitic stainless steel

[J].

Influence of yttrium addition on the microstructural evolution and mechanical properties of superalloy 718

[J].

Microstructural changes caused by yttrium addition to NbTi-modified centrifugally cast HP-type stainless steels

[J].

Yttrium addition to heat-resistant cast stainless steel

[J].

Effect of rare earth alloying on creep rupture of economical 21Cr-11Ni-N heat-resistant austenitic steel at 650oC

[J].

Effect of Ce addition on secondary phase transformation and mechanical properties of 27Cr-7Ni hyper duplex stainless steels

[J].

Influence of grain size, solute atoms and second-phase particles on creep behavior of polycrystalline solids

[J].

A comprising steady-state creep model for the austenitic AISI 316 L(N) steel

[J].

High temperature creep characteristics of in-situ micro-/nano-meter TiC dispersion strengthened 304 stainless steel

[J].Micro-/nano-metered TiC particulates dispersion strengthened 304 stainless steel (TiC-304SS strengthened steel) were prepared by in-situ reaction technology with 2% and 5% TiC (in volume fraction) respectively. The high temperature creep properties of the plain 304SS and two TiC-304SS strengthened steels were investigated. The results show that the in situ formed TiC particulates, most of which exhibited polygonal shape, were distributed uniformly in the matrix of 304 SS and are well bonded with the matrix. Moreover, TiC particulates present a significant effect on the grain refinement of the steel matrix. It reveals that being subjected to creep test by100 MPa at 700oC for 200 h, the grains of the plain 304SS grew up evidently with elongated shape along the loading direction, in the contrary, the grain growth tendency of the TiC-304SS strengthened steels seems to be inhibited, thereby, the creep deformation was effectively reduced. The above results imply that dislocation motion in the three steels accords with dislocation climb mechanism. Besides, the values of apparent creep stress exponent and activate energy of the two TiC-304 strengthened steels are higher than that of the plain 304SS. It is proposed that the enhancement of creep performance of TiC-304SS strengthened steel may be ascribed to the enhanced threshold stress and load transfer barrier, as well as the microstructural strengthening effect.

原位微米/纳米TiC颗粒弥散强化304不锈钢的高温蠕变特性

[J].以304SS不锈钢为母合金采用原位合成工艺制备微米/纳米TiC颗粒弥散强化304不锈钢(TiC-304SS强化钢),研究了强化钢和母合金的高温蠕变性能。结果表明:原位生成的TiC颗粒大多呈多边形,在母合金中均匀分布且与其良好结合。TiC颗粒的加入对强化钢的母合金晶粒有明显的细化作用。在700/100 MPa蠕变条件下母合金304SS蠕变后晶粒明显长大,且沿应力方向拉长。而TiC颗粒的加入抑制了母合金晶粒的长大,阻止了蠕变变形。显微组织和蠕变性能的结果表明,在强化钢和母合金的蠕变过程中位错的运动符合位错攀移机制。但是与304SS母合金相比,TiC颗粒的加入提高了TiC-304SS强化钢的蠕变表观应力指数和蠕变激活能。门槛应力、载荷传递和微结构的增强,是TiC-304SS强化钢的蠕变增强特征。

Effects of ageing conditions on the precipitates evolution, chromium depletion and intergranular corrosion susceptibility of AISI 316L: experimental and modeling results

[J].

Phase instabilities during high temperature exposure of 316 austenitic stainless steel

[J].

Characterization of precipitation sequences in superaustenitic stainless steels

[J].

Kinetics of transformation of delta ferrite during creep in a type 316(N) stainless steel weld metal

[J].

Enhancement of mechanism of cerium in 316LN austenitic stainless steel during creep at 700oC

[J].

Overview of σ phase influence on mechanical properties of stainless steel

[J].

σ相析出对不锈钢力学性能的影响概述

[J].

Influence of the χ-phase on the tensile properties of ODS steels

[J].

Combined matrix/boundary precipitation strengthening in creep of Fe-15 Cr-25 Ni alloys

[J].

Laves phases: a review of their functional and structural applications and an improved fundamental understanding of stability and properties

[J].Laves phases with their comparably simple crystal structure are very common intermetallic phases and can be formed from element combinations all over the periodic table resulting in a huge number of known examples. Even though this type of phases is known for almost 100 years, and although a lot of information on stability, structure, and properties has accumulated especially during the last about 20 years, systematic evaluation and rationalization of this information in particular as a function of the involved elements is often lacking. It is one of the two main goals of this review to summarize the knowledge for some selected respective topics with a certain focus on non-stoichiometric, i.e., non-ideal Laves phases. The second, central goal of the review is to give a systematic overview about the role of Laves phases in all kinds of materials for functional and structural applications. There is a surprisingly broad range of successful utilization of Laves phases in functional applications comprising Laves phases as hydrogen storage material (Hydraloy), as magneto-mechanical sensors and actuators (Terfenol), or for wear- and corrosion-resistant coatings in corrosive atmospheres and at high temperatures (Tribaloy), to name but a few. Regarding structural applications, there is a renewed interest in using Laves phases for creep-strengthening of high-temperature steels and new respective alloy design concepts were developed and successfully tested. Apart from steels, Laves phases also occur in various other kinds of structural materials sometimes effectively improving properties, but often also acting in a detrimental way.