英国A.Singer教授提出的喷射成形工艺,是将高冷却速率的雾化工艺与冷却缓慢的沉积工艺合为一体,直接由液态金属制取预成型毛坯。喷射成形工艺可同时克服粉末冶金技术工艺复杂以及传统的近成形和半固态加工技术模铸碳化物粗大问题 [7,8]。Mesquita等[9]对比了用粉末冶金、传统铸锻以及喷射成形三种冶炼工艺生产的M3:2型高速钢的强度、韧性等力学性能,发现用粉末冶金制备的高速钢综合力学性能最优,用喷射成形与传统铸锻工艺生产的高速钢强度基本持平,而用喷射成形工艺生产的高速钢的韧性及等向性优异。Ernst等[10]用喷射成形和粉末冶金工艺制备了M4型高速钢,发现这两种高速钢组织中的碳化物均以弥散的粒状形貌分布,粒径分布分别为1~6 μm和1~3 μm,组织中均没出现粗大的网状共晶碳化物。王和斌等[11]用喷射成形工艺制备的含铌M3型高速钢其强硬度与用粉末冶金工艺制备的高速钢ASP23相近;赵顺利[12]用喷射成形工艺制备的与ASP30成分相同的高速钢,其力学性能与用粉末冶金工艺的相当;刘博文[13]调整热处理工艺参数制备的M42型喷射成形高速钢其硬度和强度分别为67HRC和3115 MPa,其性能比传统浇铸高速钢和常压烧结粉末冶金高速钢有较大的优势。

但是,在相同的热处理条件下,与粉末冶金和传统铸锻工艺相比用喷射成形制备的高速钢硬度偏低,二次硬化“消失”。本文对喷射退火态M3高速钢棒材进行不同制度的热处理,研究其在淬、回火过程中组织和硬度的变化以及硬度偏低问题。

1 实验方法

实验用喷射成形M3型高速钢棒材的直径为250 mm,化学成分(质量分数,%)为:C1.11,W6.12,Mo5.29,Cr4.06,V2.82,Fe余量。为了保证样品的均匀性,实验用材料均取自棒材的边部,样品尺寸为15 mm×15 mm×10 mm。

热处理制度为常规高速钢淬火+回火,淬火温度分别为1130、1150、1180、1200、1230和1250℃,在每组淬火温度保温20 min后油冷至室温;将淬火后样品立即在500、520、540、560、580和600 ℃温度区间分别进行3次回火处理,每次1 h。

为了观察碳化物形貌及分布,用4%硝酸酒精溶液对金相样品进行长时间腐蚀(4 min)。用MEF-4M型光学显微镜(OM) 观察淬火温度不同的用品的组织,并用截点法统计晶粒尺寸,统计样本为10张放大倍数为500倍的金相照片。用FEI Quanta 650FEG扫描电镜(SEM)和配备的能谱分析仪(EDS) 观察与统计组织中碳化物形貌、成分以及占比。碳化物颗粒的形貌不规则,因此用等效圆面积法即将碳化物面积看做一个圆的面积进行粒径分布统计;为排除像素点等客观因素的干扰,仅统计尺寸大于0.4 μm的碳化物。用D8 ADVANCE X射线衍射仪(XRD,Co靶,电压35 kV,电流40 mA,扫描角度30°~90°)测试样品的物相,并结合Jade6.5进行物相的定性分析。用透射电镜观察F20回火后的析出相,并结合SEAD谱分析与表征析出相的晶体结构及位相关系。在室温下进行硬度测试,每个样品记录6次实验结果取其平均值。

2 实验结果

2.1 退火组织

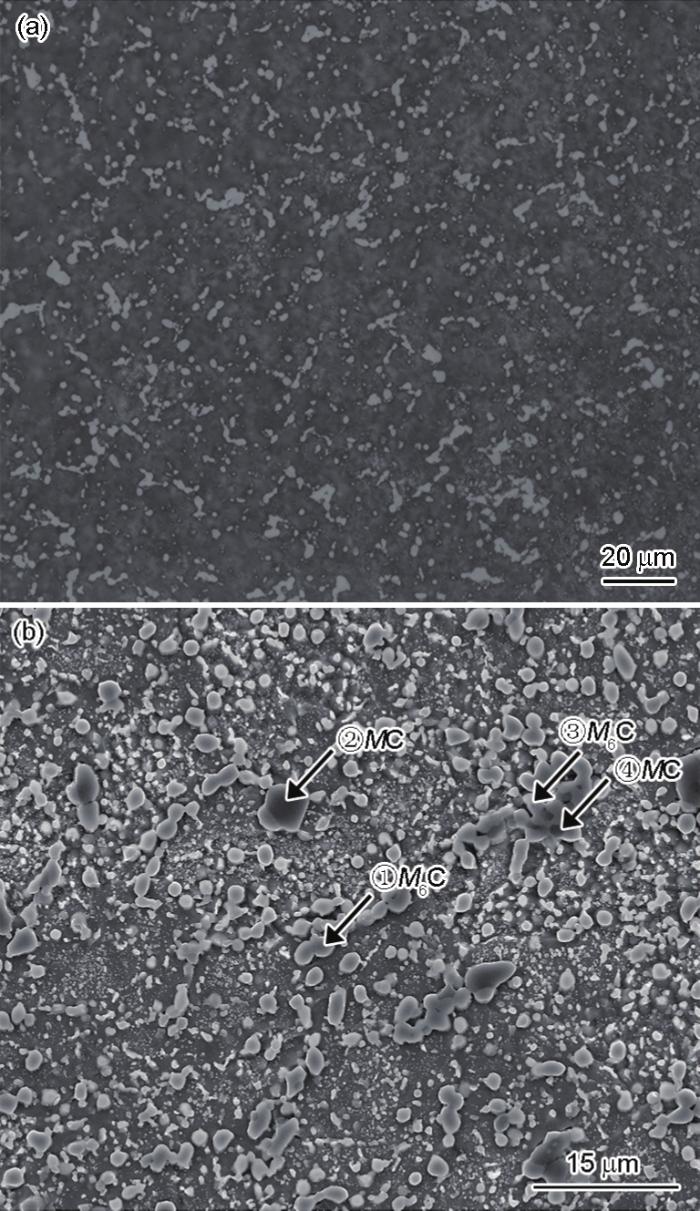

图1给出了喷射M3高速钢退火态的显微组织。在图1a中,由于基体组织碳及合金元素含量较低而不耐蚀呈黑色,白色颗粒即为碳化物。可以看出,碳化物的形貌主要有球状和条链状,分布较为均匀。碳化物的SEM观察结果,如图1b所示。根据衬度和形貌可将碳化物的类型分成三种:弥散分布的灰色颗粒状碳化物,尺寸较大的黑色颗粒状碳化物以及灰色包裹着黑色的条链状碳化物。结合表1EDS分析结果可知,灰色颗粒碳化物主要富集Fe、Mo和W元素;黑色颗粒主要富集V、Mo和W元素;在条链状碳化物中,灰色区域的成分与灰色颗粒碳化物的成分没有明显的差异,而黑色区域的成分比黑色颗粒的V含量略有降低。根据图2中的XRD谱可以判断,退火组织中的碳化物类型可分为灰色M6C型碳化物、黑色MC型碳化物以及条链状复合型的M6C+MC型碳化物[14]。

图1

图1

喷射成形M3高速钢边部的组织

Fig.1

Edge microstructure of SF M3 high speed steel (a) OM image; (b) SEM image

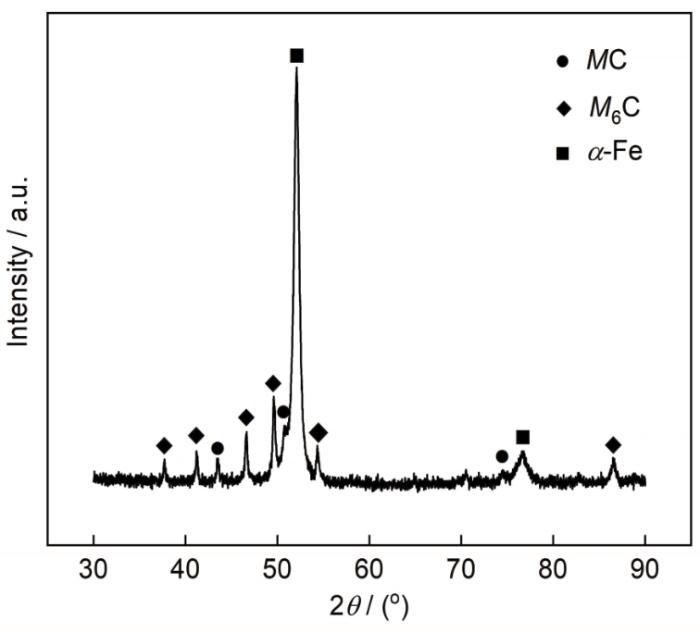

图2

图2

退火态喷射成形M3高速钢的XRD谱

Fig.2

XRD spectrum of SF M3 high-speed steel in annealed state

表2 图1b中1~4处的EDS分析结果

Table 2

| Positions | W | Mo | Cr | Fe | V |

|---|---|---|---|---|---|

| 1 | 34.41 | 26.55 | 3.43 | 33.06 | 2.55 |

| 2 | 12.97 | 15.14 | 5.44 | 3.08 | 63.38 |

| 3 | 39.58 | 26.57 | 4.24 | 26.83 | 4.98 |

| 4 | 19.14 | 20.69 | 4.61 | 4.50 | 51.07 |

2.2 淬火温度对组织的影响

图3

图3

淬火温度不同的喷射成形M3高速钢的XRD谱

Fig.3

XRD spectra of SF M3 high-speed steel at different quenching temperatures

2.3 淬火温度对碳化物的影响

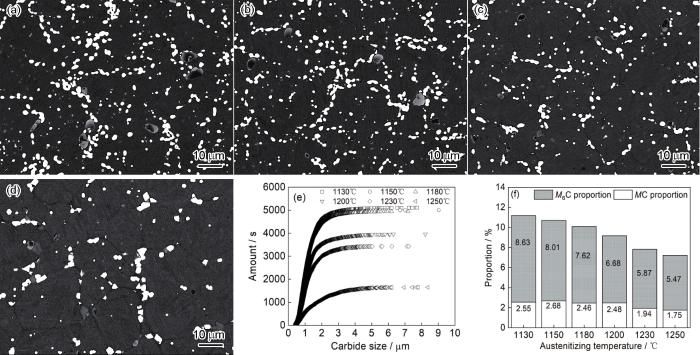

式中Cρ1、Cρ2、C0分别为奥氏体/碳化物界面处曲率为ρ1、ρ2和ρ0的合金元素平衡浓度;Ω为偏摩尔体积,r1和r2为碳化物的曲率半径。根据胶态平衡理论,碳化物曲率半径较小(尖端、凹陷)处的合金元素向曲率半径较大处(碳化物平界面上)扩散,使大曲率半径处的奥氏体变为过饱和,而小曲率半径处的奥氏体变为未饱和。于是,小曲率半径处的碳化物继续向奥氏体溶解使奥氏体中合金元素含量达到饱和,而大曲率半径处的合金元素将从奥氏体中析出而使奥氏体中的合金元素浓度降低。在这种动态脱溶-析出过程中,原先的条链状碳化物基本熔断并以球状形貌分布于基体组织中。由图4e、f中的碳化物统计结果可见,随着淬火温度的提高碳化物的数量及占比均出现明显的下降趋势。其中图4e对应横坐标碳化物粒径区间分布,各淬火温度区间点的密度代表碳化物在该粒径下的数量。这表明,淬火温度为1130~1230℃时碳化物的尺寸大多小于3 μm。而当淬火温度提高到1250℃时碳化物的粒度分布密集区间扩大都5 μm,碳化物的长大出现过热倾向。值得注意到的是,在碳化物百分比的统计结果(图4f)中,MC型碳化物的溶解规律与M6C型碳化物随温度的升高的下降趋势不同,只有当淬火温度提高到1230℃才出现较为明显的下降趋势。

图4

图4

淬火温度不同的钢中碳化物的形貌及统计结果

Fig.4

Morphology and statistical results of carbide at different quenching temperatures (a) 1150℃; (b) 1180℃; (c) 1230℃; (d) 1250℃; (e) carbide size-number distribution; (f) carbide percentage statistics

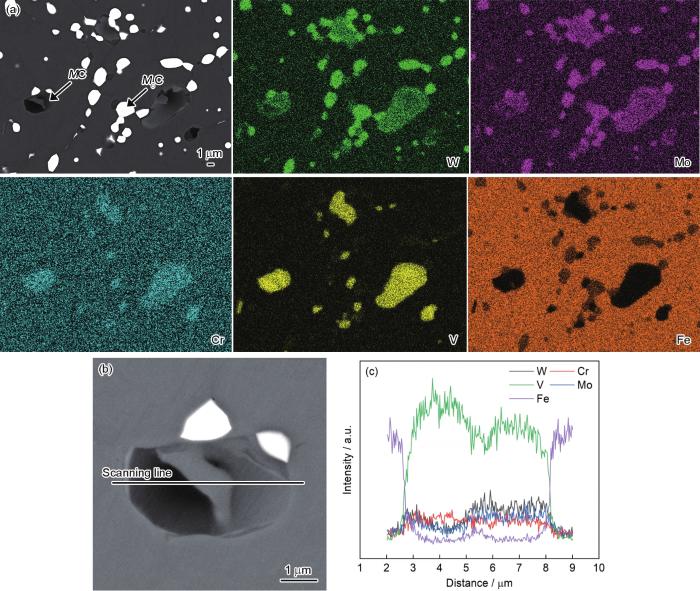

图5

图5

EDS面扫描合金元素分布及MC型碳化物线扫描元素分布

Fig.5

EDS surface scanning alloy element distribution and MC type carbide line scanning element distribution (a) mapping; (b) line scanning; (c) element change corresponding to Fig.5b

2.4 回火硬度及析出行为

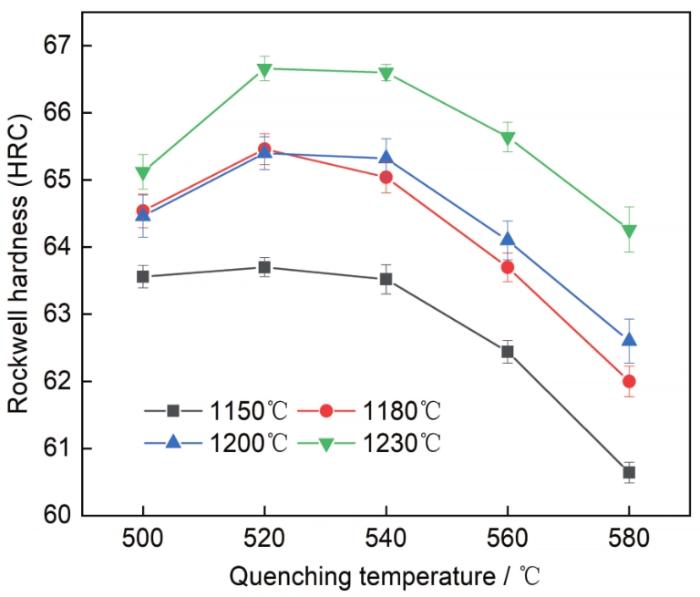

高速钢的淬火温度的选择,以没有出现明显的组织粗化为前提。因此,为了研究热处理对硬度的影响,设计了4组淬火温度(1150、1180、1200、1230℃)和5组回火温度(500、520、540、560、580℃)的正交试验方案。实验结果如图6所示。从图6可以看出,随着淬火温度的提高硬度呈上升趋势。当淬火温度高于1180℃而回火温度由500℃提高到520℃时,出现二次硬化。由此可见,喷射成形高速钢二次硬化消失的原因,可能与淬火温度的选择相关。值得注意的是,随着淬火温度由1200℃提高到1230℃回火后硬度提高的幅度更为明显。结合图4f中碳化物随淬火温度变化的统计结果可以推测,淬火温度为1230℃时回火后硬度的提高可能与组织中MC型碳化物的溶解具有正相关性。

图6

图6

淬回火温度不同的钢的硬度变化

Fig.6

Hardness change curve of steel heat treated at different quenching and tempering temperatures

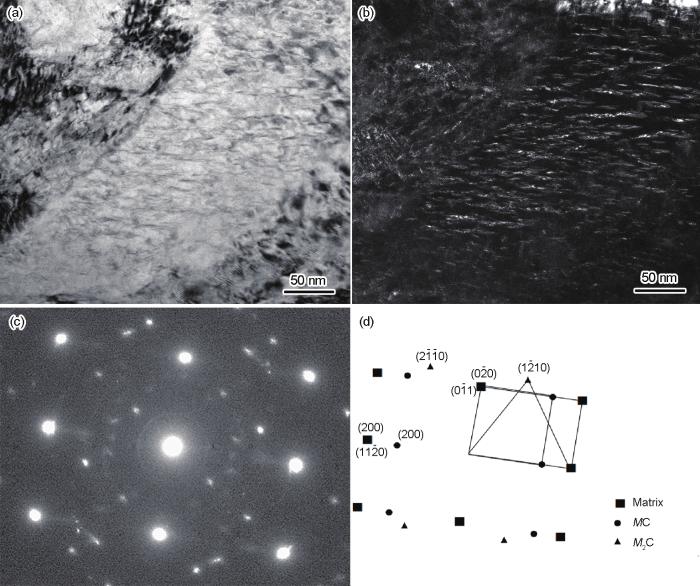

图7

图7

析出相的形貌及位相关系

Fig. 7

Morphology observation and phase relationship of precipitated phase (a) bright field image;(b) dark field image;(c) SAED patterns;(d) diagram corresponding to (c)

3 讨论

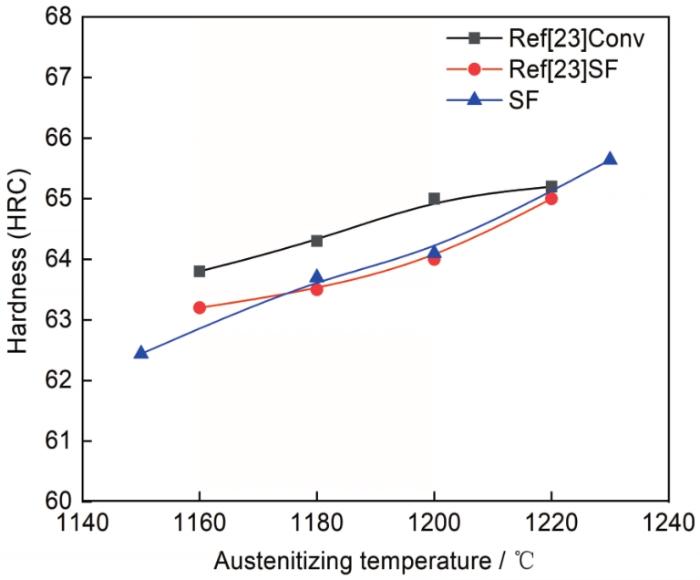

图8给出了文献[23]中喷射成形和传统铸锻的M3高速钢以及本文喷射成形的M3高速钢在不同温度淬火+560℃回火后硬度的变化。可以看出,本文制备的喷射成形M3高速钢硬度值的变化与文献[23]的结果相近。当淬火温度较低时喷射成形M3高速钢回火后的硬度明显低于传统铸锻M3高速钢,只有淬火温度高于1220℃时才能达到与铸锻高速钢相当的水平。如果高速钢的回火制度为在560℃回火3次,每次1 h,则其硬度主要由回火阶段合金碳化物的析出而产生沉淀硬化的效果决定,析出相的体积分数和尺寸决定了回火后硬度的最高值[24]。本文制备的M3型高速钢回火阶段组织中,析出强化相为MC和M2C型碳化物,其中MC主要组成元素为V,M2C主要组成元素为Mo和Cr[25]。基体中的碳及合金元素的含量对析出相起关键作用[26],由此可以推断,喷射成形高速钢较在较低温度淬火后,回火硬度偏低的原因可能是基体组织中析出相所需合金元素含量不足所致。

图8

图8

用喷射成形和铸锻制备的M3高速钢在不同温度淬火后硬度的对比

Fig.8

Hardness comparison between SF and CW M3 high speed steel heat treated at different quenching temperatures

图5表明,喷射成形钢的组织中出现了异常的MC型碳化物。此外,选取不同淬火温度进行正交试验的结果表明,硬度的提高受MC型碳化物溶解的影响更大(在提高淬火温度,MC型碳化物溶解量提升的情况下,回火后硬度提升幅度更大)。由此可以推断,与传统工艺生产的高速钢相比,喷射成形钢的硬度偏低可能与这种碳化物的生成相关。Lee等[24]研究喷射成形过程中生成的过喷粉末时发现,过喷粉中的析出相主要为MC型碳化物,而M2C型碳化物很少。在高冷却速率条件下,MC型碳化物的主要生成V元素可由较弱的碳化物生成元素Mo、W取代[1]。因此,雾化阶段液滴凝固时,尺寸效应导致的冷却速率的上升使MC型碳化物将取代M2C型碳化物[27]。除了数量明显增多外,MC型碳化物的合金成分也因冷却速率而变化[28]。例如图5中MC型碳化物的成分不均匀,或将以包含更多W、Mo、Cr合金元素的形式存在[29]。因此,得益于雾化阶段快速凝固的特点,喷射成形高速钢组织中MC型碳化物的占比将高于传统铸锻工艺[30]。

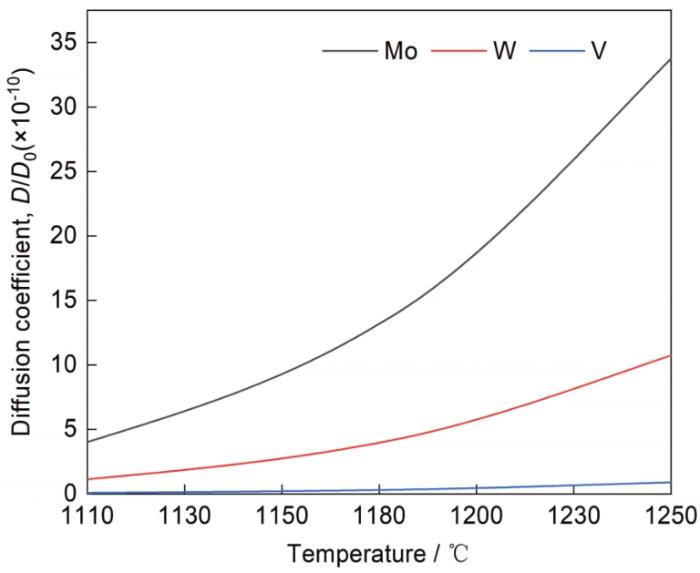

在高温淬火过程中碳化物的溶解,实际上由扩散速率最低的合金元素决定[31]。由于碳元素的扩散系数远高于其它合金元素,钨钼系高速钢中以M6C和MC为主的碳化物则主要受W、Mo、V合金元素的扩散速率制约,这些合金元素在奥氏体中的扩散系数为

式中D0为扩散常数,Q为扩散激活能,R为气体常数,T为温度。奥氏体中Mo、W和V元素的扩散激活能分别为QV=293 kJ/mol,QMo=247 kJ/mol,QW=261.5 kJ/mol[32,33]。由此可作出W、Mo、V元素的扩散系数随温度的变化,如图9所示。其中W、Mo元素的扩散系数随着温度的升高呈抛物线型增长趋势,而V元素只有当温度高于1200℃时才稍有上升。扩散系数的提高会加速碳化物的溶解,这也说明了图5f中M6C碳化物百分比曲线随着温度的升高下降趋势明显,而MC型碳化物的占比只有温度升高至1230℃时才出现较为明显的下降趋势。由于喷射成形工艺中MC型碳化物的占比更高,常规热处理(淬火温度为1180℃)生成的MC型碳化物无法充分溶解,必然使基体中的碳和二次析出所需的合金元素含量降低,结果便出现了二次硬化“消失”,硬度偏低的情况。

图9

图9

在不同温度下W、Mo、V合金元素的扩散曲线

Fig.9

Diffusion curves of W, Mo and V alloy elements at different temperatures

综合上述讨论,喷射成形高速钢硬度偏低的原因有:1) 喷射成形工艺有生成更高占比的MC型碳化物倾向;2) MC型碳化物在较低淬火温度区间基本不会溶解,导致基体中碳及合金元素含量不足而无法充分产生二次硬化效应。

4 结论

(1) 在喷射成形M3高速钢的退火组织中有MC和M6C两种类型碳化物,可判断为颗粒状的MC、M6C型碳化物以及条链状的MC+M6C复合型碳化物。

(2) 在喷射成形M3高速钢的淬火过程中,随着淬火温度的提高晶粒尺寸逐渐长大,碳化物的百占比呈下降趋势,淬火温度低于1230℃时碳化物保持晶粒细小和粒径均匀分布。

(3) 随着淬火温度的提高喷射成形M3高速钢中M6C型碳化物的百分占比降低;只有在淬火温度高于1230℃时MC型碳化物的百分占比才出现明显降低的趋势。

(4) 提高淬火温度可大幅度提高喷射成形M3高速钢的回火硬度。喷射成形M3高速钢雾化阶段的冷却速率较高,生成了量多且合金元素分布不均匀的MC型碳化物。在常规淬火温度MC型碳化物不能充分溶解使基体中的碳和合金元素的含量不高,在回火阶段二次硬化“消失”而使硬度偏低。

参考文献

Solidification of high-speed tool steels

[J].

Review on research progress of steel and iron wear-resistant materials

[J].In this paper, the development history of iron and steel wear-resistant materials is introduced, and the composition, microstructure, wear property, antiwear mechanism and modification technology of three typical wear resistant materials, namely high manganese steel, high chromium cast iron and high vanadium high-speed steel, are mainly reviewed. The wear-resistant steel represented by high manganese steel relies on the matrix with high strength and toughness to resist wear, while the wear-resistant alloy represented by high chromium cast iron and high vanadium high-speed steel mainly relies on the wear-resistant phase with high hardness to resist wear. High vanadium high speed steel has better wear resistance than high chromium cast iron, which is related to VC characteristics with high hardness and good shape. It is proposed that high performance wear-resistant materials should have three elements: high strength and toughness matrix, multi-scale synergistic action of high quality wear-resistant phase with high hardness and good morphology, as well as good bonding interface between wear-resistant phase and matrix.

钢铁耐磨材料研究进展

[J].本文介绍了钢铁耐磨材料的发展历史,重点综述了高锰钢、高铬铸铁、高钒高速钢3类典型耐磨材料的成分、显微组织、磨损性能、抗磨机理和改性技术。以高锰钢为代表的耐磨钢依靠高强韧性的基体抵抗磨损,而以高铬铸铁和高钒高速钢为代表的耐磨合金主要依靠高硬度的耐磨相抵抗磨损,高钒高速钢比高铬铸铁具有更优良的耐磨性,与VC硬度高、形态好的特性有关。提出了高性能耐磨材料应具备3个要素:高强韧基体,高硬度多尺度协同作用的优质耐磨相,耐磨相与基体良好结合。

Effect of aluminum on the solidification microstructure of M2 high speed steel

[J].The effect of aluminum on the solidification microstructure of M2 high speed steel, particularly the morphology and microstructure of eutectic carbides, has been investigated by OM, TEM, SEM, EBSD and XRD. The results show that the as-cast microstructure consists of dislocation martensite and M2C eutectic ledeburite. Excessive amount of aluminum, 1.2%, favors the formation of ferrite and needle-like carbides. After the addition of aluminum, eutectic carbides are distributed more homogeneously. Additionally, the morphology of M2C eutectic carbides transforms from the fibrous to the plate-like, and their microstructure also changes significantly. The plate-like M2C has crystal defects, such as micro-twins and stacking faults, and different growing orientation between adjacent plates whereas the fibrous carbides have few defects and single crystal orientation. Compared to fibrous carbides, the plate-like carbides are much difficult to get spheroidized at high temperature, which is unfavorable for carbide refinement. The ferrite, formed by adding excessive amount of aluminum, cannot be eliminated by ordinary heat treatments, decreasing remarkably the hardness of high speed steel after quenching.

Al对M2高速钢凝固组织的影响

[J].采用OM, TEM, SEM, EBSD, XRD等手段, 分析了不同Al加入量(0%, 0.6%, 1.2%)的M2高速钢的铸态组织, 研究了Al对高速钢凝固组织转变特别是共晶碳化物形貌和微观结构的影响规律. 结果表明, M2高速钢铸态组织主要由位错型马氏体和M<sub>2</sub>C共晶莱氏体组成. 过量Al (1.2%)促进大量铁素体和针状碳化物形成. Al提高了共晶碳化物的分布均匀性, 促进M<sub>2</sub>C形貌由纤维状转变为片状, 并使碳化物微观结构发生明显改变. 片状碳化物表面平行于(0002)晶面, 内部存在微孪晶、层错等缺陷, 片层之间具有不同的晶体取向, 而纤维状碳化物内部缺陷极少, 呈单晶取向. 与纤维状碳化物相比, 加Al后形成的片状碳化物高温加热时不易团球化, 对碳化物尺寸细化不利. 添加过量Al (1.2%)形成的铁素体无法通过常规热处理消除, 使高速钢淬火硬度显著降低.

High speed steel composite roll manufactured by electromagnetism continuous casting

[J].

电磁连续铸造法制备高速钢复合轧辊

[J].

Precipitation behaviors of carbides in M42 high speed steel during ESR and forging

[J].

M42高速钢电渣重熔及锻造退火后碳化物的析出

[J].

PM high speed steel with high performance manufactured by super-fine powder with low oxygen content

[J].

低氧超细粉末制备高性能粉末高速钢

[J].

Research progress of spray forming technology for the manufacture of high performance iron and steel materials (I) principle, characteristics and development status

[J].

喷射成形快速凝固技术制备高性能钢铁材料的研究进展(一)——喷射成形技术的原理、特点及发展现状

[J].

Solidification sequence of spray-formed steels

[J].

Spray forming high speed steel—properties and processing

[J].

ESP4 and TSP4, A comparison of spray formed with powdermetallurgically produced cobalt free high-speed steel of type 6W-5Mo-4V-4Cr

[J].

Microstructures and properties of spray formed Nb-containing M3 high speed steel

[J].The billets of M3 high speed steel (HSS) with or without niobium addition were prepared via spray forming and compared with traditional cast steels with same composition, followed by hot forged and heat treated. The corresponding microstructure evolutions of steels induced by niobium have been investigated using SEM with EDS, XRD, OM, TEM and HRTEM. The results show that finer and uniformly-distributed grains without macrosegregation appear in the as-deposited HSS that are different to the as-cast HSS, 1% (mass fraction) niobium addition can promote the formation of primary MC-type carbides before onset of eutectic reaction, which can make the MC particles refined and evenly distributed. Niobium mainly contribute to the primary MC-type carbides by consuming carbon, the eutectic reaction is suppressed and the quantity of M2C eutectic carbides decrease, leading to more W and Mo atoms dissolve into matrix. Compared to spray formed M3 HSS, the niobium alloying M3 HSS possesses higher stability during austenitization, induced by the high stabilization of Nb-containing MC carbides, which can pin the grain boundaries and keep the grain size of primary austenite below that of spray formed M3 HSS. The quenched hardness of niobium-containing steel is remarkably higher, while the over tempering hardness of it is a little below than that of M3 HSS, it is related to the difference of dissolution rate of carbides during austenitization and the precipitation behavior of the secondary carbides after tempering. The amount of Nb-containing MC carbides are hard to dissolve into matrix, additionally, lower content of M2C carbides are in the as-deposited steel, leading to the larger numbers of nano-scaled M2C secondary carbides precipitate after tempering. Spray formed niobium-containing steel has a more advanced hardness and bending strength compared with ASP23, but possesses a lower impact toughness due to that the stress concentration can easily caused by mass of harder MC carbides distributed in matrix.

喷射成形含铌M3型高速钢组织与性能研究

[J].采用喷射成形快速凝固技术制备了M3型高速钢和以Nb代V的M3型高速钢. 利用SEM(EDS), XRD, OM, TEM, HRTEM研究了Nb对M3型高速钢组织的影响和其组织演变. 结果表明, 喷射成形消除了宏观偏析, 细化了组织, 以Nb代V, 可在共晶反应前析出MC型碳化物, 使其球形化、均匀分布, 由于消耗大量C, 共晶M<sub>2</sub>C碳化物数量减少, 促使更多W和Mo固溶进基体. 均匀分布的高热稳定性含Nb-MC型碳化物能阻碍奥氏体化过程中晶粒长大, 但难以固溶, 使得回火过程中主要析出与基体共格的M<sub>2</sub>C型碳化物. 喷射成形含Nb钢硬度和弯曲强度高于ASP23钢, 大量硬质MC碳化物易于产生应力集中, 使其韧性稍低于ASP23.

Research of microstructure and properties of spray formed high alloyed high speed steel

[D].

喷射成形高合金高速钢的组织与性能研究

[D].

Optimization of alloy composition and properties of high speed steel fabricated by powder metallurgy

[D].

粉末冶金高速钢合金成分及性能优化

[D].

Morphology, microstructure and decomposition behavior of M2C carbides in high speed steel

[J].

As-cast carbides in high-speed steels

[J].

Effect of solidification rate on as-cast microstructure of M2 high speed steel

[J].

凝固速率对M2高速工具钢铸态组织的影响

[J].

Study on decomposition behaviour of M2C eutectic carbide in high speed steel

[J].

Austenite stability and M2C carbide decomposition in experimental secondary hardening ultra-high strength steels during high temperature austenitizing treatments

[J].

Refining carbide dimensions in AISI M2 high speed steel by increasing solidification rates and spheroidising heat treatment

[J].

A dynamic study on the spheroidizing of eutectic carbide in the modified M2 steel

[J].

变质M2高速钢中共晶碳化物加热团球化的动力学研究

[J].采用高温淬火、退火等方法研究了变质M2高速负名共晶碳化物在加热时的团球化过程. 随加热温度的提高和保温时间的延长, 碳化物的团球化是通过碳化物层片的聚集与粗化、共晶碳化物网的熔断和球化、晶内二次碳化物的弥散析出与长大实现的;在此基础上建立了共晶碳化物的粗化、聚集和二次碳化物长大的动力学模型, 推导了碳化物长大的瞬时速度公式.

Direct fabrication of high-performance high speed steel products enhanced by LaB6

[J].

Characterization of the carbides and the martensite phase in powder-metallurgy high-speed steel

[J].

High-speed steels produced by conventional casting, spray forming and powder metallurgy

[J].

Solidification microstructure and M2C carbide decomposition in a spray-formed high-speed steel

[J].

An atom probe study of secondary hardening in high speed steels

[J].

Influences of Co addition and austenitizing temperature on secondary hardening and impact fracture behavior in P/M high speed steels of W-Mo-Cr-V(-Co) system

[J].

Different carbide types and their effect on bend properties of a spray-formed high speed steel

[J].

Powder metallurgy T15 tool steel: Part I. Characterization of powder and hot isostatically pressed material

[J].

Stabilization of non-equilibrium carbides in powder superalloy Rene 95

[J].The high temperature pre-heat treatment was used for Rene95 pow-der-particles before HIP consolidation. It is shown that during pre-heat treatment,the microstrucutre of the powder-particles may be more homogenized and the non-equilibrium carbides can be transformed into stable carbides MC. The appropriatecontrol of this transformation may suppress the formation of detrimental PPB car-bides.

粉末高温合金中亚稳碳化物稳定化处理

[J].在热等静压之前对Rene95合金粉末采用高温预热处理。试验结果表明,预热处理既可使粉末颗粒微观组织更加均匀化,又可使亚稳碳化物MC′发生分解和转变,重新析出二次MC+?和生成M_(23)C_6碳化物。明显改变碳化物的稳定性和分布状态,有效地抑制PPB的形成。

MC complex carbide in AISI M2 high-speed steel

[J].

Quantitative microstructural analysis of M2 grade high speed steel during high temperature treatment

[J].

Physical metallurgical data of vanadium in steel

[J].

钒在钢中的物理冶金学基础数据

[J].

Influence of heat treatment on the microstructural evolution and mechanical properties of W6Mo5-Cr4V2Co5Nb (825 K) high speed steel

[J].