纳米晶(单晶、多晶)高熵合金的独特点阵畸变结构和高熵特性,使其具有高硬度、高强度、抗高温、耐磨损、耐腐蚀以及耐低温等优异性能,在核反应堆燃料棒、太空探测器、深海核潜艇等领域有潜在的应用前景。金属材料的宏观力学性能与其微结构的演化有极大的关联。在原子尺度上捋清纳米晶CoNiCrFeMn高熵合金塑性变形的力学性能,对高熵合金微观结构的调控及其变形机理认知有重要的意义[1]。目前,实验和分子动力学模拟方法已成为研究纳米晶高熵合金材料的塑性变形机制和性能的主要手段[2~5]。但是,仅基于实验法研究纳米晶高熵合金的物性,对仪器的测试精度和内外环境等的要求极为严苛,且所需经费极其高昂。用大规模分子模拟(简称MD)可获与材料的宏观力学性能密切相关的微观结构演化,是探究原子尺度纳米晶高熵合金塑性变形力学行为与变形机制的有力工具[4,5]。

目前对高熵合金力学性能与位错演化特征[6,7]、相变行为[8]、蠕变行为[9]、强韧化机理[10,11]等的研究,已成为热点。Du等[12]的研究结果表明,在循环变形过程中CoCrFeMnNi高熵合金中部分位错相互作用使材料的晶格紊乱,晶格的无序阻碍位错的反向运动而削弱了高熵合金中的包辛格效应。Amar等[13]用激光熔积法制备高强度CrMnFeCoNi高熵合金,发现控制TiC的加入量可调节合金的拉伸性能,拉伸力学性能的提高源于引入的微米级TiC增强相促进了滑移带的传播。Ding等[14]研究了不同服役温度下高熵合金的时效层组织和耐磨性,发现随着温度的升高高熵合金涂层的显微硬度先升高后降低,质量损失则与之相反;在750℃时效后合金镀层的显微硬度和质量损失分别降低了4.3%和11.9%。Huang等[15]指出,C元素的加入提高了CoCrFeNiCx高熵合金的硬度、强度和耐磨性。Xiang等[16]指出,制备工艺参数不同的CrMnFeCoNi高熵合金均为fcc(面心立方)单相固溶体结构;控制激光沉积功率可控制CrMnFeCoNi高熵合金结构中柱状晶和等轴晶的比例,进而控制合金的组织和力学性能。Laplanche等[17]指出,CrMnFeCoNi高熵合金的低温抗拉伸力学性能比室温性能更高;在77 K拉伸应变大于7.4%时孪生主导了材料的塑性变形;293 K时的孪晶仅在接近断裂应变时才能激活,因为此时高熵合金的屈服强度较低,只有较高的应变才能通过加工硬化产生生成孪晶所需的应力。Otto等[18]的研究结果表明,CoCrFeMnNi高熵合金的屈服强度、极限屈服应力和断裂伸长率均随着温度的降低而提高;孪生能提供额外的变形模式适应拉伸的塑性变形,而孪晶不能解释高熵合金屈服强度随着温度的降低而提高。Gludovatz等[19]的结果表明,FeCoCrNiMn合金的室温屈服强度约为400 MPa,屈服应力为760 MPa,断裂延伸率平均值为56%;随着温度的降低该合金的强度、断裂延伸率以及应变硬化率均明显提高。

用分子模拟方法研究纳米晶CoNiCrFeMn高熵合金的拉伸力学性能与空洞裂纹缺陷演化的相关性,比较服役温度和平均晶粒尺寸影响纳米晶Ni、纳米晶CoNiCrFeMn高熵合金的拉伸力学性能、位错分布、微结构演化、位错总长的差异性,有望评估纳米金属材料用于核反应堆燃料棒在极端恶劣服役工况(高温、高压、强辐射)下的力学性能,有重要的理论价值。

1 分子模拟计算

1.1 模拟设置

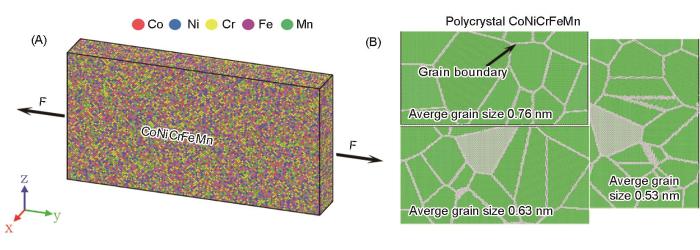

用分子动力学法对CoNiCrFeMn高熵合金、Ni的拉伸塑性变形行为进行原子尺度分析。图1给出了以晶格常数等于0.352 nm的面心立方镍为主元建立的单晶、多晶高熵合金CoNiCrFeMn。高熵合金的Co、Ni、Cr、Fe、Mn五种元素以等比例20%均匀分布。建模时,模型x、y、z轴晶向依次为[100]、[010]、[001],宽长高分别为5 nm (Lx)×35 nm (Ly)×20 nm (Lz)。基于Voronoi算法在Ni和高熵合金中分别建立含8个、16个、24个晶粒的多晶模型(图1b),模型x、y、z轴皆采用周期性边界条件。拉伸前,基于共轭梯度算法优化模型结构并用随机种子数产生该温度的初始速度,然后基于NPT系综对体系控压并弛豫20 ps,弛豫后的系统能量、温度、压强达到稳态。拉伸时的牛顿方程求解基于NPT系综和Verlet算法,积分步长为1 fs,每500步输出体系的应力-应变和热力学信息。模拟时,沿着Y轴方向以应变率为2×109 s-1对模型实施拉伸加载。基于拉伸应变率2×109 s-1,考虑了温度(10、300、1000 K)变化对纳米晶高熵合金和纳米晶镍拉伸力学性能与塑性变形相变转化的影响。所有计算使用LAMMPS软件完成[20]。

图1

图1

多晶CoNiCrFeMn高熵合金拉伸时的原子尺度模型

Fig.1

Atomic physical model of polycrystal CoNiCrFeMn high entropy alloy at stretched process

(A) three-dimensional model of CoNiCrFeMn high entropy alloy; (B) grain boundary model of CoNiCrFeMn high entropy alloy

1.2 势函数作用

MD计算用MEAM势函数[21]描述纳米晶CoNiCrFeMn高熵合金五种元素间的相互作用

1.3 微结构特征识别

1.4 内应力计算

材料承受的内应力超过其临界值时材料内将出现空洞或裂纹,此类损伤与受到的Von Mises应力密不可分,因此用

中的Von Mises应力表征材料受拉伸时塑性变形产生的内应力集中度[26]。

2 结果和分析

2.1 温度对拉伸力学性能的影响

为了评估使役温度和平均晶粒尺寸对CoNiCrFeMn高熵合金力学性能的影响,图2和图3分别给出了平均晶粒尺寸为0.76 nm的多晶CoNiCrFeMn高熵合金和多晶镍的应力-应变曲线。从图3可见,在拉伸前期单晶和多晶镍的应力与应变呈线性关系。这个结果与文献[27]的趋势一致,间接验证了本文参数设置和数值计算结果的可靠性。图2给出了单晶和多晶CoNiCrFeMn高熵合金拉伸前期的应力与应变也呈现出线性关系。图2还表明,单晶CoNiCrFeMn高熵合金温度为10 K时的力学性能最佳,温度为1000 K时的力学性能最差。随着温度的提高单晶CoNiCrFeMn高熵合金的屈服强度从19.21 GPa降低到9.95 GPa,对应弹性模量从213.44 GPa降低到110.55 GPa;多晶CoNiCrFeMn高熵合金的屈服强度从16.34 GPa下降到8.21 GPa,对应弹性模量从187.81 GPa降低到91.26 GPa。同时,单晶和多晶CoNiCrFeMn高熵合金的屈服应力与弹性模量都随着温度的提高呈线性下降的趋势,与用实验法得到的结论一致 [28]。在使役温度相同的条件下,多晶高熵合金的拉伸力学性能比单晶高熵合金的低,且随着温度从10 K提高到1000 K的过程中降幅的变化为14.9%、13.1%、17.4%,展现出先下降后上升的趋势。这可能与高温激活位错滑移、晶界迁移扩张产生大量非晶和空洞裂纹缺陷的尺寸有关。从图3可见,单晶镍的屈服强度从19.04 GPa下降到12.01 GPa,对应弹性模量从317.33 GPa降低到159.21 GPa;多晶镍的屈服强度从11.62 GPa下降到8.12 GPa,对应的弹性模量从190.49 GPa降低到159.21 GPa。与单晶镍相比,在温度从10 K提高到1000 K的过程中,多晶镍的屈服应力降幅的变化为38.9%、30%、32.3%,同时,随着温度的提高单晶和多晶镍的屈服应力也呈线性下降趋势。对比图2和图3可见,单晶高熵合金的屈服应力高于单晶镍,多晶高熵合金和多晶镍的屈服应力显著低于单晶高熵合金和单晶镍,且与多晶高熵合金相比多晶镍的屈服应力降幅更大。其主要原因,一是高熵合金五种组元的差异和极高的原子间能量势垒产生了严重的晶格扭曲和高密度限域位错,阻碍了位错的滑移和传播;二是多晶材料的晶界缺陷诱导塑性变形的抗拉力学性能降低并改变了多晶材料的微结构演化特征和内应力分布。为详细了解纳米晶高熵合金和纳米晶镍屈服应力的显著不同,图5和图6给出了微结构的演化过程。

图2

图2

服役温度对单晶、多晶CoNiCrFeMn(平均晶粒尺寸0.76 nm)高熵合金拉伸力学性能的影响

Fig.2

Temperature influence on mechanical property of single crystal and polycrystal CoNiCrFeMn high entropy alloy (average grain size 0.76 nm) during tensile (A) single crystal and polycrystal CoNiCrFeMn high entropy alloy; (B) polycrystal line high entropy alloy; (C) effect of temperature on yield strength; (D) effect of temperature on elastic modulus

图3

图3

服役温度对单晶、多晶Ni(平均晶粒尺寸0.76 nm)拉伸力学性能的影响

Fig.3

Temperature influence on mechanical property of single crystal and polycrystal (average grain size 0.76 nm) Ni during tensile

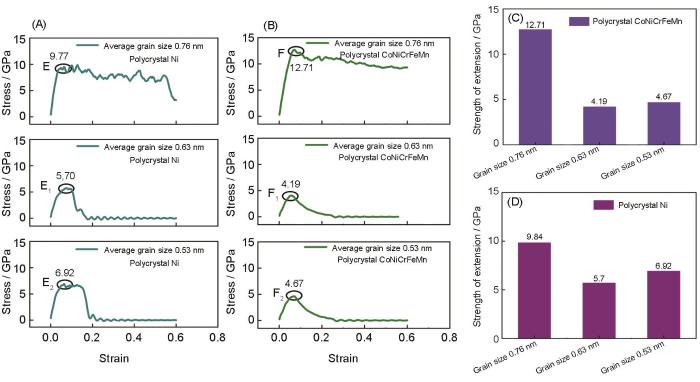

图4

图4

室温平均晶粒尺寸对多晶高熵合金和多晶镍拉伸力学性能的影响

Fig.4

Average grain size influence on mechanical property of polycrystal Ni and polycrystal CoNiCrFeMn high entropy alloy during tensile with ambient temperature 300 K

图5

图5

室温和应变ε=0.16下的平均晶粒尺寸对多晶Ni和多晶CoNiCrFeMn高熵合金中空洞缺陷的影响

Fig.5

Average grain size influence on void defects of polycrystal Ni (A) and polycrystal CoNiCrFeMn (B) with ambient temperature 300 K and strain is equal to 0.16

图6

图6

使役温度下多晶Ni不同拉伸应变时空洞缺陷的演化

Fig.6

Void defects evolution of polycrystal Ni at (A) 10 K, (B) 300 K, (C) 1000 K under different tensile strains

2.2 晶粒尺寸对拉伸力学性能的影响

图4给出了300 K时平均值为0.76、0.63、0.53 nm的晶粒尺寸对多晶镍和多晶CoNiCrFeMn高熵合金拉伸应力-应变的影响。从图4A和图4B可见,随着平均晶粒尺寸的减小多晶Ni和多晶高熵合金的屈服应力尚无统一下降趋势,平均晶粒尺寸为0.76 nm时多晶高熵合金的屈服应力(12.71 GPa)大于多晶镍(9.77 GPa),而平均晶粒尺寸为0.53 nm和0.63 nm时多晶高熵合金的屈服应力却低于多晶镍。这主要与材料中的空洞缺陷外形尺寸有极大的关系。图5给出了应变

图7

图7

1000 K多晶镍晶粒细化演变的进程和裂纹拓展的失效

Fig.7

Graph of grain refinement evolution and crack propagation failure for polycrystal nickel at temperature with 1000 K

2.3 微结构特征

图6给出了多晶镍在不同服役温度下(10~1000 K)的空洞缺陷随着拉伸应变的演化进程。从图6可见,在服役温度相同的条件下,多晶镍的空洞缺陷演化历经空洞缺陷萌生、长大、繁殖和断裂四个演化进程。此外,空洞缺陷的萌生起源于多晶的交叉晶界处,表明多晶的晶界极容易受拉伸载荷的影响产生空洞似的裂纹缺陷,使材料的拉伸力学性能急剧下降。另外,多晶镍也容易受载荷诱导在晶粒内产生变形的孪晶堆垛层错,且随应变的增大逐渐增多。从图6还可见,温度对多晶镍的空洞缺陷形状和大小有很大的影响。温度为300 K时产生的空洞缺陷外形形状最大,其次是10 K时产生的空洞缺陷较大,且繁殖数目较多,高温1000 K时产生的空洞缺陷外形形状最小。其主要原因是多晶材料的晶界在高温逐渐软化,使晶界极易扩张和(见图6C黑色箭头)在晶界富集更多的非晶态颗粒(图6C中的黑色箭头)。为了深入了解多晶镍晶粒内的微结构演化进程,图7绘出了1000 K时多晶晶粒的微结构随着应变的详细演化过程。从图7可见,应变

为了对比多晶镍的微结构演化,图8给出了在不同使役温度下多晶CoNiCrFeMn高熵合金随着应变的增大微结构的演化信息。从图8可见,在多晶CoNiCrFeMn高熵合金的整个应变过程中都没有产生空洞缺陷,表明多晶高熵合金比多晶镍的延展性更好,且屈服应力也比多晶镍的高。这再次说明,空洞缺陷的产生是材料力学性能急剧下降的主要原因。此外,在使役温度相同的条件下,多晶高熵合金内晶粒细化的微结构演化进程呈现出与多晶镍一致的趋势。温度为10 K时多晶高熵合金晶粒内除了产生孪晶片层,更容易在晶界处富集非晶态(图8A中的蓝色箭头)。晶界处产生的非晶原子比300 K和1000 K下更多,也更容易使位错萌生。同时,在室温300 K和1000 K多晶高熵晶界也极容易舒张,非晶原子也极容易在晶界处产生团簇(图8B和图8C中的箭头),从而阻滞位错的运动。

图8

图8

不同使役温度下多晶CoNiCrFeMn高熵合金不同拉伸应变时微结构的演化

Fig.8

Micro-structure evolution of polycrystal CoNiCrFeMn high entropy alloy at (A) 10 K; (B)300 K; (C) 1000 K under different tensile strains

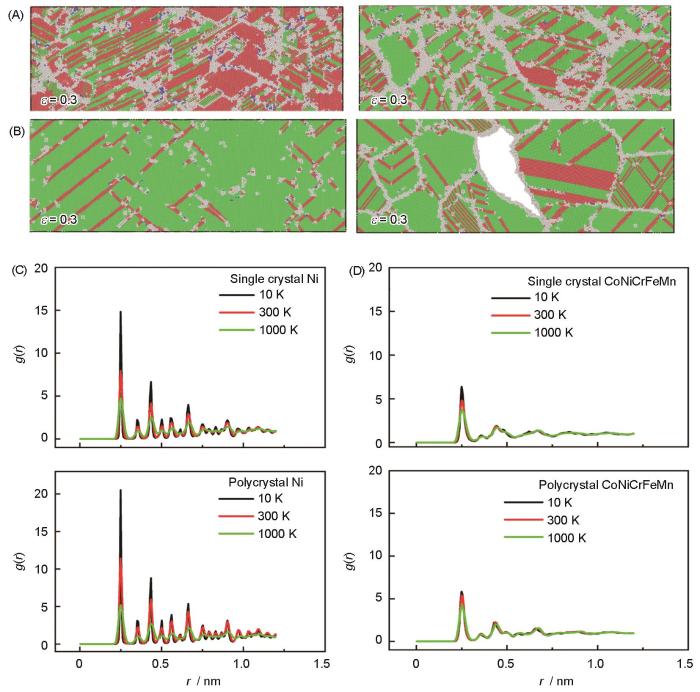

图9绘出了室温300 K时应变

图9

图9

应变

Fig.9

Comparison of micro-structure between nanocrystalline nickel and nanocrystalline high entropy alloy with ε=0.3 at room temperature (A, B), and the curve of the radial distribution function with temperature (C, D)

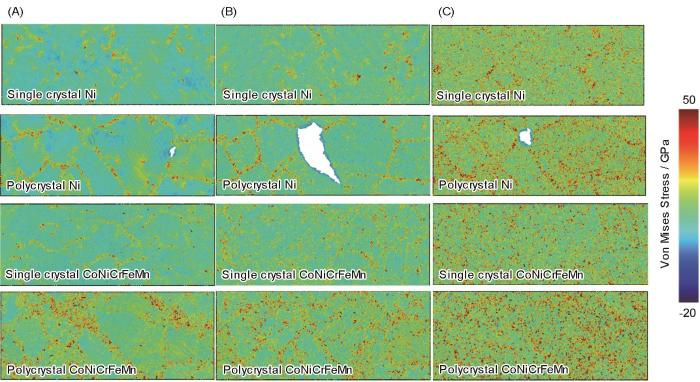

2.4 位错分布和内应力

为了详细了解纳米晶高熵合金和纳米晶镍受拉产生塑性变形的详细位错分布,图10绘制了平均晶粒尺寸为0.76 nm、应变

图10

图10

纳米晶CoNiCrFeMn高熵合金和纳米晶镍中位错的分布类型和位错总长随温度的变化

Fig.10

Dislocation distribution types and the change of the length of dislocation with temperature varies for nanocrystalline CoNiCrFeMn high entropy alloy and nanocrystalline nickel

图11

图11

不同使役温度对应的

Fig.11

The stress distribution of nanocrystalline CoNiCrFeMn high entropy and nanocrystalline nickel under tensile strain with

3 结论

(1) 与单晶高熵合金相比,多晶高熵合金的拉伸力学性能较低,且随着温度从10 K提高到1000 K降幅分别达到14.9%、13.1%和17.4%;与单晶镍相比,随着温度从10 K提高到1000 K,多晶镍的屈服应力降幅分别为38.9%、30%和32.3%,晶界缺陷使多晶镍的屈服应力比单晶高熵合金的整体降幅更大。

(2) 晶粒尺寸为0.76 nm的纳米晶高熵合金和纳米晶镍拉伸时的屈服应力和弹性模量随着温度的提高线性下降。纳米晶高熵合金拉伸时尚无空洞裂纹缺陷产生,表现出良好的延展性;空洞裂纹缺陷是使纳米晶镍的拉伸力学性能随着温度的提高急剧下降的直接原因,且空洞裂纹缺陷的形状和大小直接影响材料的拉伸力学性能;空洞裂纹缺陷的演化历经空洞缺陷的萌生、增大,空洞缺陷繁殖和断裂。

(3) 在纳米晶高熵合金的拉伸过程中尚无空洞裂纹缺陷产生,而纳米晶镍在拉伸中产生空洞裂纹缺陷,表明纳米晶高熵合金比纳米晶镍具有更好的延展性。多晶材料晶粒内充满内秉堆垛层错,且随着温度的提高大晶粒易分化出细小晶粒,出现晶粒细化的纳观现象,在晶界处富集的非晶团簇阻滞位错的运动。

(4) 与单晶高熵合金和单晶镍相比,多晶高熵合金和多晶镍更易在晶界边缘因内应力的诱导而产生位错,是多晶材料内萌生空洞缺陷裂纹使其失效的根本原因。位错的分布与内应力分布有良好的一致性。随着温度的提高多晶材料的晶界范围因热胀冷缩而扩张,以致应力的分布区域比低温时更广。

参考文献

Strengthening CrFeCoNi-Mn0.75Cu0.25 high entropy alloy via laser shock peening

[J].

Stability and thermodynamics properties of CrFeNiCoMn/Pd high entropy alloys from first principles

[J].

The phase composition and mechanical properties of vacuum coatings produced from equiatomic CrFeCoNiMn alloy

[J].

Effects of stacking fault energy on the deformation behavior of CoNiCrFeMn high-entropy alloys: a molecular dynamics study

[J].Tailoring stacking fault energy (SFE) is an effective way for enhancing mechanical properties of certain high entropy alloys (HEAs) such as the prototype Cantor alloy. However, the underlying mechanism, especially the atomistic origins for the enhanced plasticity and strength, is still unclear. In this work, we performed molecular dynamics simulations to investigate the mechanical behavior of CoxNi40−xCr20Fe20Mn20 (x = 10, 20, and 30 at. %) HEAs under tensile loading. The results show that the SFE decreases with the increase in Co concentration and favors the formation of continuous stacking fault networks on which multiple plastic deformation carriers including stacking faults, dislocations, twins, and martensitic transformation were sequentially activated. The activation and complex interaction of these multiple carriers mainly contribute to the improved plasticity, and the increased stair-rod dislocations result in the enhanced strength in Co30Ni10Cr20Fe20Mn20 HEA. The current findings may be important for the understanding of SFE effects at the atomistic scale and also shed light on designing of high-performance HEAs.

Temperature-dependent superplasticity and strengthening in CoNiCrFeMn high entropy alloy nanowires using atomistic simulations

[J].High strength and ductility, often mutually exclusive properties of a structural material, are also responsible for damage tolerance. At low temperatures, due to high surface energy, single element metallic nanowires such as Ag usually transform into a more preferred phase via nucleation and propagation of partial dislocation through the nanowire, enabling superplasticity. In high entropy alloy (HEA) CoNiCrFeMn nanowires, the motion of the partial dislocation is hindered by the friction due to difference in the lattice parameter of the constituent atoms which is responsible for the hardening and lowering the ductility. In this study, we have examined the temperature-dependent superplasticity of single component Ag and multicomponent CoNiCrFeMn HEA nanowires using molecular dynamics simulations. The results demonstrate that Ag nanowires exhibit apparent temperature-dependent superplasticity at cryogenic temperature due to (110) to (100) cross-section reorientation behavior. Interestingly, HEA nanowires can perform exceptional strength-ductility trade-offs at cryogenic temperatures. Even at high temperatures, HEA nanowires can still maintain good flow stress and ductility prior to failure. Mechanical properties of HEA nanowires are better than Ag nanowires due to synergistic interactions of deformation twinning, FCC-HCP phase transformation, and the special reorientation of the cross-section. Further examination reveals that simultaneous activation of twining induced plasticity and transformation induced plasticity are responsible for the plasticity at different stages and temperatures. These findings could be very useful for designing nanowires at different temperatures with high stability and superior mechanical properties in the semiconductor industry.

Microstructure and mechanical properties of Al x Si0.2CrFeCoNiCu1- x high-entropy alloys

[J].

Atomic packing efficiency and phase transition in a high entropy alloy

[J].

Transition of twinning behavior in CoCrFeMnNi high entropy alloy with grain refinement

[J].

Spherical nanoindentation creep behavior of nanocrystalline and coarse-grained CoCrFeMnNi high-entropy alloys

[J].

Simultaneously increasing the strength and ductility of a refractory high-entropy alloy via grain refining

[J].

Boron doped ultrastrong and ductile high-entropy alloys

[J].

Cyclic plasticity of CoCrFeMnNi high-entropy alloy (HEA): a molecular dynamics simulation

[J].The CoCrFeMnNi high-entropy alloy (HEA) is a potential structural material, whose cyclic plasticity is essential for its safety assessment in service. Here, the effects of twin boundaries (TBs) and temperature on the cyclic plasticity of CoCrFeMnNi HEA were studied by the molecular dynamics (MD) simulation. The simulation results showed that a significant amount of lattice disorders were generated due to the interactions between partial dislocations in CoCrFeMnNi HEA during the cyclic deformation. Lattice disorder impeded the reverse movement of dislocations and then weakened Bauschinger’s effect in the HEA. The cyclic plasticity of CoCrFeMnNi HEA, especially Bauschinger’s effect, depends highly on the temperature and pre-existing TBs. Such dependence lies in the effects of temperature and pre-existing TBs on the extent of lattice disorder. This study helps further understand the cyclic plasticity of CoCrFeMnNi HEA from the atomic scale.

Additive manufacturing of high-strength CrMnFeCoNi-based High Entropy Alloys with TiC addition

[J].

Microstructure and abrasion resistance of laser cladding CoCrFeNiTiNbB1.25 high-entropy alloys coatings treated by aging

[J].Laser cladding CoCrFeNiTiNbB1.25 high-entropy alloys coatings on H13 steel was fabricated. The microstructure and abrasion resistance of aged high-entropy alloys coatings at different temperature were researched. Results showed the phase was not changed in the high-entropy\n alloys coatings as the aging temperature elevated, the volume fraction of TiB phase was firstly increased, then reduced. The diffraction peak of fcc phase was firstly shifted to the right, and then shifted to the left. The aged high-entropy alloys coatings consisted of typical dendrite, interdendritic\n eutectic and dispersed intermetallic compound, and the dendrite obviously was coarsened after aging at 850 °C. Compared with non-aged high-entropy alloys coatings, the microhardness of aged high-entropy alloys coatings was firstly elevated as the aging temperature elevated, then decreased,\n and the mass loss was opposite. The microhardness and mass loss was decreased by 4.3% and 11.9%, respectively, for the aging at 750 °C. The abrasion mechanism of non-aged high-entropy alloys coatings was the abrasive wear, and was the abrasive wear and adhesive wear after aging.

Effect of carbon addition on the microstructure and mechanical properties of CoCrFeNi high entropy alloy

[J].

Effect of laser melting deposition process on microstructure and mechanical properties of CrMnFeCoNi high-entropy alloys

[J].

激光熔化沉积工艺对CrMnFeCoNi高熵合金组织和性能的影响

[J].

Microstructure evolution and critical stress for twinning in the CrMnFeCoNi high-entropy alloy

[J].

The influences of temperature and microstructure on the tensile properties of a CoCrFeMnNi high-entropy alloy

[J].

A fracture-resistant high-entropy alloy for cryogenic applications

[J].High-entropy alloys are equiatomic, multi-element systems that can crystallize as a single phase, despite containing multiple elements with different crystal structures. A rationale for this is that the configurational entropy contribution to the total free energy in alloys with five or more major elements may stabilize the solid-solution state relative to multiphase microstructures. We examined a five-element high-entropy alloy, CrMnFeCoNi, which forms a single-phase face-centered cubic solid solution, and found it to have exceptional damage tolerance with tensile strengths above 1 GPa and fracture toughness values exceeding 200 MPa·m(1/2). Furthermore, its mechanical properties actually improve at cryogenic temperatures; we attribute this to a transition from planar-slip dislocation activity at room temperature to deformation by mechanical nanotwinning with decreasing temperature, which results in continuous steady strain hardening. Copyright © 2014, American Association for the Advancement of Science.

Fast parallel algorithms for short-range molecular dynamics

[J].

Semiempirical atomic potentials for the fcc metals Cu, Ag, Au, Ni, Pd, Pt, Al, and Pb based on first and second nearest-neighbor modified embedded atom method

[J].

Study on the mechanical performance and microstructure of FeCoCrCuNi high-entropy alloy with crack and void by molecular dynamics simulations

[J].

FeCoCrCuNi高熵合金裂纹及孔洞结构的力学与微观构象演化的分子动力学模拟研究

[J].

Probing the phase transformation and dislocation evolution in dual-phase high-entropy alloys

[J].

Formation of prismatic loops in AlN and GaN under nanoindentation

[J].

The mechanism of plastic deformation in intact and irradiated GaN during indentation: a molecular dynamics study

[J].

Shear instability of nanocrystalline silicon carbide during nanometric cutting

[J].The shear instability of the nanoscrystalline 3C-SiC during nanometric cutting at a cutting speed of 100 m/s has been investigated using molecular dynamics simulation. The deviatoric stress in the cutting zone was found to cause sp3-sp2 disorder resulting in the local formation of SiC-graphene and Herzfeld-Mott transitions of 3C-SiC at much lower transition pressures than that required under pure compression. Besides explaining the ductility of SiC at 1500 K, this is a promising phenomenon in general nanoscale engineering of SiC. It shows that modifying the tetrahedral bonding of 3C-SiC, which would otherwise require sophisticated pressure cells, can be achieved more easily by introducing non-hydrostatic stress conditions.

Molecular dynamics simulations of the tensile mechanical response of single crystal/polycrystalline nickel

[J].

单晶/多晶镍拉伸力学性能的分子动力学模拟

[J].

Temperature dependence of the Hall-Petch relationship in CoCrFeMnNi high-entropy alloy

[J].