目前对多孔金属材料的制备开展了大量研究[10~14],相继发展了多种制备方法,包括铸造法、烧结法、沉积法、化学脱合金法以及合金相分离法。化学脱合金法,是多孔金属材料的常规制备方法。化学脱合金技术,是将前驱体浸入酸性/碱性试剂介质中对合金组元进行选择性腐蚀而形成多孔结构。化学脱合金法对多孔结构形成过程的可控性差,易产生裂纹等缺陷[15]。为了促进可溶元素的溶解并制备优质的纳米多孔金属材料,在化学脱合金过程中引入电流作用,通过调节电位增强对元素选择性溶解过程的控制。合金相分离法通常在高温下进行,因此多孔结构的形成很快;合金相分离法拓宽了可制备多孔金属材料的种类,调整前驱体的组成和成分、改变反应温度和时间等因素即可灵活地调控多孔金属形貌特征和微孔尺寸特征。用合金相分离工艺制备的多孔金属材料具有高比表面积、高力学性能等特性,可应用在催化、电池和生物医用等领域。

1 合金相分离制备多孔金属材料的机理

1.1 合金相分离过程

用合金相分离(液态金属脱合金)制备多孔金属材料,是基于相分离合金体系的独特凝固行为。相分离合金,是一类存在稳态或亚稳态组元液态不混溶区域的合金体系[21~23]。图1给出了典型的相分离合金相图。可以看出,在常规凝固条件下在此区域内发生液-液相分离(L→L1+L2),两种液相互不混溶并以平衡状态共存[24],形成类似油-水分离结构。当合金熔体的温度降低到Tm时发生固液转变(L→SA+L2)分解出固相SA和另一成分的液相L2;当温度达到TE时,则形成由密度差造成的偏析分层组织[25]。在相分离合金相图的三大主相区(L1+L2、SA+L2、SA+SB)中,组元A和B的互溶度低,在液态和固态下两组元均不混溶。

图1

图1

A-B二元相分离合金的典型相图

Fig.1

Typical phase diagram of A-B binary phase-separated alloy

因此,在TE-Tm温度段引入适当的液态金属与前驱体构成的相分离合金体系,基于合金元素的“相似相溶,相异排斥”原理,用原子间的相互作用诱导均质前驱体发生选择性溶解和相分离现象,从而形成“互联状”组织结构。这种独特形态的双连续结构相,为制备多孔金属材料提供了新思路。具体过程为:引入液态金属L2使前驱体合金组元与液态金属发生选择性排斥(相分离)或吸引(互溶),其中溶解组分扩散进入液相区(L2),而相斥未溶解的组分始终保持为固态(S1)并在固-液界面通过扩散-生长重组形成互联结构。当体系冷却至室温后,形成由前驱体中未溶解组分S1相和液态金属凝固相S2组成的双连续复合材料。然后用刻蚀剂去除液态金属凝固相S2,即得到由前驱体未溶解组分构成的多孔金属材料。

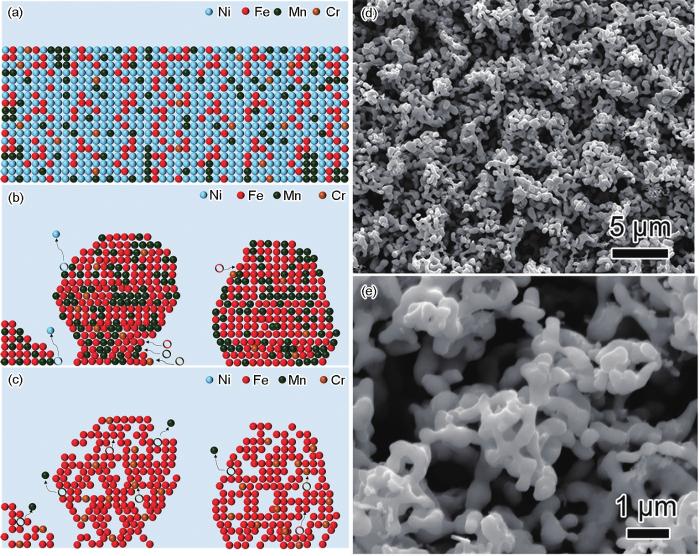

1.2 多孔结构的形成机制

如示意图2所示,多孔结构的形成和生长由两个阶段组成:(1) 初始阶段的界面调幅分解。界面调幅分解过程导致固液前沿界面的不混溶元素重新分布,形成不混溶元素局部富集的成分畴。这些初始间距为几纳米的成分畴破坏了前沿界面的稳定性,使原来的平整界面变为波纹状,如图2b所示;(2) 后续扩散耦合生长阶段。随后多孔结构的生长,是不混溶元素与溶解元素分别选择性富集至固相和液相中,使固相与液相协同生长,在液体通道之间生成纳米级细丝。不混溶元素富集的固相持续生长,增加了初始结构的特征长度、形成了粗化的韧带。Geslin等[26]首次将相场建模与实验结合,阐述了前驱体Ti-Ta合金与液态金属Cu在合金相分离作用下的多孔结构形成过程。在相分离反应过程中,富Ta和富Ti相通过互扩散到相邻的固相与液相中实现两相的耦合(协同)生长。界面调幅分解机制与扩散耦合生长机制,是目前理解多孔结构形成与生长的两个重要方式。

图2

图2

合金相分离形成多孔结构的机理

Fig. 2

Mechanism of alloy phase separation to form porous structure (a) stable state of precursor; (b) interfacial spinodal decomposition leading to interfacial instability; (c) diffusion-coupled mechanisms form porous frameworks; (d) generation of continuous porous structure

图3

2 合金相分离对多孔结构的影响

2.1 合金体系的影响

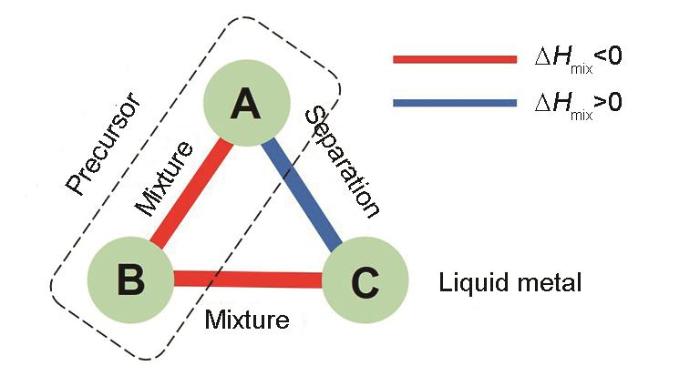

不同金属原子间吸引/排斥作用的程度,与两组元间的混合焓的正负和大小有密切的关系。因此,合金相分离体系(前驱体+液态金属)成分的设计对于金属的分离和多孔结构的形成至关重要。如图4所示,对于二元合金A-B前驱体,在设计或选取液态金属C并构建分离体系时必须同时满足以下两个条件:(1) 前驱体A-B合金组元之间的混合焓为负;(2) 液态金属C应与前驱体固溶体A-B合金中一个组元如A的混合焓为正而与组元B的混合焓为负,它们之间混合焓的相对值较大。由此构建的合金系统中前驱体的B组元能扩散溶解至液态金属C中,而前驱体中剩余的组元A与液态金属C相互排斥且互不混溶,剩余组元A随后自组装形成多孔结构。基于此,多孔金属A的制备可将A-B固态前驱体浸入液态金属C中进行。目前二元体系设计,如TiCu[20]、FeNi[35]、TiTa[31]等,均基于混合焓的大小进行。表1列出了常见的液态金属与前驱体成分的混合焓[36],为其他金属体系的设计提供了依据。

图4

图4

合金相分离体系中A、B、C的混合焓关系

Fig.4

Mixing enthalpy relationship of A, B and C in the alloy phase separation system

| Metal | Mg | Bi | Pb | Cu | Sn | Ag | In |

|---|---|---|---|---|---|---|---|

| Ti | +16 | -14 | +8 | -9 | -21 | -2 | -5 |

| V | +23 | +10 | +15 | +5 | -1 | +17 | +12 |

| Cr | +24 | +24 | +28 | +12 | +10 | +27 | +20 |

| Mn | +10 | +3 | +7 | +4 | -7 | +13 | +3 |

| Fe | +18 | +26 | +29 | +13 | +11 | +28 | +19 |

| Co | +3 | +14 | +17 | +6 | 0 | +19 | +7 |

| Ni | -4 | +10 | +13 | +4 | -4 | +15 | +2 |

| Nb | +32 | +12 | +17 | +9 | -1 | +16 | +15 |

| Cu | -3 | +15 | +15 | +7 | +2 | +10 |

当前驱体为多组元合金时,由于元素之间复杂的相互作用,混合焓并不能作为唯一的设计参考,还要考虑第一可混溶元素溶解至熔体中形成的化合物对未溶解元素溶解度的影响。Joo等[37] 选择(FeCo)100-x Ni x 和Mg分别作为前驱体和液态金属制备FeCo多孔金属。由于Ni-Mg的混合焓为负(-4 kJ/mol),因此Ni作为第一可混溶元素必然溶解在Mg中。Co-Mg的混合焓为正(+3 kJ/mol),理论上不会在Mg中溶解,但是Co-Mg的相图存在共晶点(Co在Mg中溶解度为1.9%,原子分数),使Co作为第二可混溶元素也会在Mg中部分溶解。同时,组元Ni作为优先溶解元素大量溶解在Mg中形成镁镍熔体,Co-Ni的混合焓为0且低于Co-Mg体系,因此在高温下Co易与镁熔体中的Ni形成FCC固溶体,进一步促进反应层Co的溶解,不能得到理想的FeCo多孔结构。

表2 通过合金相分离制备多孔材料的总结

Table 2

| Precursor | Dealloying medium | Etching medium | Porous metal |

|---|---|---|---|

| TiCu | Mg | HNO3 | Ti[20] |

| FeNi | Mg | HNO3 | Fe[35] |

| CrNi | Mg | HNO3 | Cr[35] |

| NiNb | Mg | HNO3 | Nb[33] |

| TiTa | Cu | CuCl2+HCl | Ta[31] |

| TaTiCu | Mg | HF | Mg[38] |

| TiZrCu | Mg | HNO3 | TiZr[39] |

| TiCrZrCu | Mg+MgCa | HNO3 | TiCrZr[40] |

| TiHfCu | Mg | HNO3 | TiHf[41] |

| FeCrNi | Mg | HNO3 | FeCr[35] |

| TiNbCu | Mg | HNO3 | TiNb[42] |

| NiCrCu | Ag | HNO3 | NiCr[43] |

| TiMoCu | Mg | HNO3 | TiMo[44] |

| Incoloy 800/825 | Mg | HNO3 | Fe-based[45, 46] |

| TiVNbMoNi | Mg | HNO3 | TiVNbMo[47, 48] |

| MnC | Bi | HNO3 | C[52] |

| MgSi | Bi | HNO3 | Si[50] |

| CoMoNi | Mg | HCL | Co7Mo6[49] |

| FeMoNi | Mg | HCL | Fe7Mo6[49] |

| FeCrMnNi | Mg+Bi | HNO3 | FeCr-based |

2.2 合金成分的影响

分离极限(通常为溶解组分的百分比)是前驱体完全多孔化所需的临界合金成分,可作为液态金属能否从前驱体表面溶解至整个样品的理论判据。对于二元合金前驱体,溶解组分的含量直接影响孔的形貌。目前,人们对分离极限未进行深入理论分析,主要根据实验结果推测分离极限。如果实际溶解组分占比低于分离极限,则前驱体不能完全多孔化。McCue I等[31]通过前驱体Ti30Ta70、Ti20Ta80和Ti55Ta45、Ti70Ta30合金样品在液态金属Cu中的合金相分离反应研究,未观察到前两组样品的组分Ti和Ta明显溶解,只在前驱体表面观察到不足500 nm厚的溶解反应层,实验推测前驱体Ti-Ta二元合金与液态金属Cu的分离体系中Ti的分离极限约为40%Ti。

对于溶解组分高于分离极限的前驱体,体系的组成对多孔材料的拓扑结构有明显的影响。反应层内不混溶元素的累积可使相分离反应沿界面横向进行,形成不混溶元素富集区和贫乏区。在Cu-TiTa[26]分离体系中,当溶解元素Ti处于高含量范围时(如Ti含量为95%),如图5a所示,先通过调幅分解形成拓扑上断开的富Ta畴,但是Ta的浓度不足以维持2D层状或3D丝状结构的扩散耦合生长,导致富Ta畴停止与液相协同生长;然后通过界面调幅分解再次形成新畴,在Cu基体中形成了随机分散的富Ta 三维斑点。当Ti%=85%时,在Cu基体内则形成由断开的Ta结构组成的丝状结构,如图5b所示。当Ti成分含量适中时(Ti%=75%),初始阶段形成的富Ta结构在很大程度上是断开的,但是Ta的浓度足以维持扩散耦合生长,从而允许合金相分离反应继续进行,而非发生二次调幅分解,从而形成连续的多孔结构,如图5c和5d所示。因此,前驱体中可溶组分的含量对孔的形貌特征有决定性的影响。

图5

在合理的成分范围内,前驱体溶解组分的含量越高则形成的孔隙率越大。Zhao等[52]和Soo-Hyun Joo等[37]通过Mg-FeCrNi分离体系和Mg-FeCoNi分离体系验证了孔隙率与前驱体溶解组分Ni含量之间的关系,如图6所示。另外,对于多组元前驱体合金,选择适合的液态金属并采用多步合金相分离方法可使前驱体中的组分发生分级扩散分离反应,制备出具有双峰孔径分布的多孔金属材料。前驱体发生初级合金相分离反应时界面调幅分解与扩散耦合生长机制协同进行,形成大尺寸的双连续多孔结构,如图示意图7b所示。随后,选择合适的液态金属与上一步得到的多孔金属韧带进行相分离反应,在上一步多孔金属材料的粗韧带中形成纳米多孔结构,如图7c所示。Wada等[53]基于混合焓正负和大小设计了(Fe0.8Cr0.2)0.3Mn0.7)60Ni40前驱体,先用液态金属Mg与(Fe0.8Cr0.2)0.3Mn0.7)60Ni40前驱体进行了初级合金相分离反应生成成分为Fe27.2Cr7.5Mn63.6的多孔金属材料;然后选择液态金属Bi并将其与上一步得到的Fe27.2Cr7.5Mn63.6多孔金属材料进行合金相分离反应,金属韧带中Mn组分和剩余的Mg溶解到液态金属Bi中制备出分级多孔的Fe-Cr不锈钢,如图7d和7e所示。这是迄今为止关于合金相分离制备分级多孔金属材料的唯一研究报告。从前驱体合金设计和液态金属选择的角度分析,通过合金相分离法调控分级多孔金属材料仍需更深入的研究。

图6

图7

2.3 工艺参数的影响

图8

温度对韧带尺寸的影响与不混溶元素在液态金属中的表面扩散率(

其中

由(1)~(3)式建立的多孔结构与工艺参数关系表明,通过优化相分离过程的温度和时间可有效调控多孔结构的韧带尺寸。

3 多孔金属材料的性能和应用前景

多孔金属材料的连通开孔和微米或纳米级长度的互连韧带的特征,使其具有优越的性能,包括较大的表面积比、优异的导电性、高效的质量传输、丰富的表面缺陷、高催化活性和高机械强度。合金相分离法丰富了可制备多孔金属材料的范围,从而拓宽了多孔金属材料的应用领域。同时,用合金相分离技术制备的多孔金属材料的特征长度可以在几纳米到几十微米之间进行调整,孔隙率可以在40%到80%之间进行调整。对于不同的应用场景,“控形”与”控性”调控具有很强的灵活性。

3.1 机械性能

良好的机械性能是多孔材料功能性应用的前提条件。介观尺度的多孔材料力学性能,对组织结构有极大的依赖性。Hakamada等[54]通过后续退火以粗化多孔Au韧带研究屈服强度对韧带尺寸的依赖性。研究发现,韧带尺寸从5 nm增大到126 nm则屈服强度从1.35 GPa降低至0.7 GPa,表明多孔Au的屈服强度随韧带尺寸的减小而增加;并且韧带尺寸为纳米尺度时,材料的总体屈服强度远高于理论计算值。Biener等[55]也以多孔Au为对象研究了屈服强度与韧带尺寸的关系。结果表明,当韧带尺寸在10 nm~1 μm范围内变化时,Au的屈服强度与韧带尺寸也具有负相关的趋势。这种现象可归因于韧带的“尺寸效应”。多孔材料的屈服强度对韧带尺寸的依赖性可表示为

其中

关于用合金相分离法制备的多孔金属材料的力学性能与组织结构关系,系统性的研究较少[56]。目前的研究结果表明,合金相分离可通过改变前驱体的成分、相分离反应温度和时间灵活地调整多孔金属材料的固相分数和韧带尺寸从而改善其强度。首先,多孔金属材料的强度和刚度在很大程度上取决于固体分数。固体分数可由前体中溶解组分的含量控制。溶解组分的含量越低则孔隙度或孔隙体积分数越低,意味着固体分数越高则韧带间的互连性越高从而提高强度。例如,多孔Ti和TiZr[39]的强度和刚度随着前驱体中可溶解元素Cu浓度的降低而增强。但是实际情况是,用合金相分离制备的多孔金属材料的屈服强度因韧带粗化的影响达不到理论强度,从而使机械性能急剧恶化。

Okulov等[57]用合金相分离技术制备了多孔Ti90Nb10,在前驱体成分恒定条件下研究了韧带尺寸与屈服强度的关系。结果表明,随着韧带尺寸从0.81±0.16 μm粗化至1.11±0.34 μm屈服强度从72±6 MPa提高到91±8 MPa,表明屈服强度与韧带尺寸呈现正相关的趋势,且根据

图9

图9

Ti基多孔材料的屈服强度与杨氏模量的关系

Fig.9

Relationship between yield strength and Young's modulus of Ti-based porous materials

3.2 应用前景

制备催化剂非常需要具有耐腐蚀性能的多孔不锈钢。商业Incoloy 825不锈钢的典型成分为Ni41~48Fe25Cr23~28(原子分数,%)。由于镍含量超过分离极限,通过合金相分离反应可制备具有高耐腐蚀能力的Fe-Cr基多孔材料[45]。超级电容器通常使用表面积大的金属材料,用于电子快速传导从而实现电化学能量转换和存储。传统的固体电解质电容器的制造可通过在高温下将亚微米多孔Nb粉末烧结成多孔阳极颗粒。但是由于多孔结构中韧带尺寸的显著增长,在烧结过程中会损失大量颗粒表面积。Kim等[33]通过优化相分离反应温度和时间将多孔金属Nb的韧带尺寸减小到137 nm,比表面积提高到3.92 m2/g,最终将Nb电解电容器的质量比电容从400000 μFv/g提高到650000 μFv/g。同时,研究发现,质量比电容与韧带尺寸存在负相关的关系,即韧带尺寸越小额质量比电容越高。在生物医用领域,具有高孔隙率的多孔金属仿骨植入物比致密金属植入物具有更好的生物相容性。Okulov等[39]通过合金相分离法制备出低杨氏模量的强韧多孔Ti基材料,良好的刚度匹配可减少对种植体附近骨组织的损伤,是优异的生物医学植入物。Jim等[58]基于多孔金属材料的纳米尺寸结构和高比表面积等特性,探讨了将其应用于大应变电化学驱动器的可能性。Chen等[59]探讨了多孔结构固相和孔隙相之间的界面效应在电化学储能装置中的应用,发现韧带尺寸直接影响电解质中的质量传输和离子传导过程。因此,多孔金属材料的应用性能与其微观结构密切相关,且合金相分离为设计具有灵活可调节功能的新型功能材料提供了平台。

4 总结和展望

合金相分离已经成为一种制备多孔金属材料的新方法,基于混合焓的正负和大小可以设计制备多孔金属材料的体系,选择合适的前驱体和液态金属并采用分级合金相分离技术,可制备具有分级多孔结构的金属材料,拓展了多孔金属材料的种类。在合金相分离过程中,界面调幅分解和扩散耦合生长机制共同导致多孔结构的形成。调控前驱体的成分即可控制多孔形貌,优化相分离过程温度和时间可有效调控多孔结构的韧带尺寸,以适应不同的应用场景。

合金相分离方法突破了常规多孔材料制备方法的局限性。用合金相分离不仅能制备多孔金属及合金材料,也为制造具有特殊性能的双连续复合材料提供了思路。与传统合金凝固制备技术相比,用合金相分离法可制备具有高均匀性和致密度的三维双连续的复合材料,最大限度发挥各物相独特的物理、化学和力学性能,显著提高复合材料综合性能。另外,合金相分离方法的回收及功能化应用,是未来发展的另一重要方向。设计适当的合金体系可使用工业金属废料作为前驱体,在回收关键性金属资源的同时制备出高性能多孔金属材料。这一方面有助于降低废弃金属排放给生态环境带来的巨大压力,还可将废弃金属变废为宝和回收再利用关键性战略金属资源,有巨大的经济、环境和社会效益。

参考文献

Development status of metal porous materials

[J].

金属多孔材料发展现状

[J].

Deforming nanoporous metal: Role of lattice coherency

[J].

Nanoporous Au-Pt alloys as large strain electrochemical actuators

[J].

Electrochemical actuation of nanoporous gold deformed by compression

[J].The electrochemical actuation performance of nanoporous gold samples deformed by compression was investigated. Although the porosity and specific surface area decrease with increasing compression strain, the strain amplitude of actuation which were measured along the compression direction, increases and then decreases with increasing compression strain. The compression also greatly increases the strain energy density of nanoporous gold actuator. The improvement of actuation performance is attributed to the morphology change of nanoporous structure during compression. The understanding of the underlying mechanism requires quantitative characterization of morphology and morphological evolution of nanoporous structure during compression.

压缩变形纳米多孔金电化学驱动性能研究

[J].研究了压缩塑性变形对纳米多孔金电化学驱动性能的影响. 结果表明, 虽然压缩变形会导致材料孔隙率和比表面积降低, 但随着变形量的增大, 在压缩方向上其驱动幅度呈先升高再降低的趋势. 单位体积和单位质量材料的驱动能量密度也随着变形量的增大而大幅度提高. 压缩变形样品驱动性能的提高是由于压缩过程中纳米多孔结构的空间形貌和分布发生变化. 对压缩变形过程中纳米多孔结构演变进行定量表征, 是理解驱动性能提高根本原因的关键.

Mechanical response of nanoporous metals: A story of size, surface stress, and severed struts

[J].

Diversity of nanoporous metals

[J].Nanoporous metals have been attracting considerable research and industrial attention because of the structural uniqueness of their bicontinuous metallic structure [...]

Recent advancements in the fabrication of functional nanoporous materials and their biomedical applications

[J].Functional nanoporous materials are categorized as an important class of nanostructured materials because of their tunable porosity and pore geometry (size, shape, and distribution) and their unique chemical and physical properties as compared with other nanostructures and bulk counterparts. Progress in developing a broad spectrum of nanoporous materials has accelerated their use for extensive applications in catalysis, sensing, separation, and environmental, energy, and biomedical areas. The purpose of this review is to provide recent advances in synthesis strategies for designing ordered or hierarchical nanoporous materials of tunable porosity and complex architectures. Furthermore, we briefly highlight working principles, potential pitfalls, experimental challenges, and limitations associated with nanoporous material fabrication strategies. Finally, we give a forward look at how digitally controlled additive manufacturing may overcome existing obstacles to guide the design and development of next-generation nanoporous materials with predefined properties for industrial manufacturing and applications.

Nanoporous metals processed by dealloying and their applications

[J].

Review on preparation and applications of porous metal materials

[J].

多孔金属材料的制备及应用研究进展

[J].

Progresses of research on metallic nanoporous materials

[J].

纳米多孔金属材料的研究进展

[J].

Research progress in preparation and mechanical properties of nanoporous metals

[J].

纳米多孔金属的制备方法及其力学性能的研究进展

[J].

Nanoporous metals with structural hierarchy: a review

[J].

Using corrosion to fabricate various nanoporous metal structures

[J].

FeCr composites: from metal/metal to metal/polymer via micro/nano metallic foam, exploitation of liquid metal dealloying process

[D].

Microstructures of rapidly solidified Cu-Fe immiscible alloy

[J].

快速凝固Cu-Fe难混溶合金的显微组织

[J].

Directional solidification and microstructural refinement of immiscible alloys

[J].

Liquid-liquid phase separation of Fe-Cu-Pb alloy and its application in metal separation and recycling of waste printed circuit boards

[J].The pyrolysis processing was carried out on the waste printed circuit boards (WPCBs) of mobile phones to dissociate metals from non-metals and obtain mixed metals with Fe, Cu and Pb as main components. Based on the main compositions of Fe, Cu and Pb, the liquid-liquid phase separation behavior of (Fe0.4Cu0.6)100-xPbx ternary alloy has been studied experimentally. The results show that the liquid-liquid phase separation of L→L(Fe)+L(Cu, Pb) may occur during the ternary Fe-Cu-Pb alloy melt cooling in the miscibility gap. After the liquid L(Fe) solidified, the secondary liquid-liquid phase separation L(Cu, Pb)→L(Cu)+L(Pb) takes place in the residual L(Cu, Pb) liquid phase, finally resulting in a three-zone separation structure. On the basis of the behavior of the liquid-liquid phase separation, a self-organized hierarchical separation system has been designed to separate and recycle these mixed metals from WPCBs. The enrichment behavior of the minor components like Cr, Au and Cd in the separation system was explored. The effect of super-gravity level on the metal separation and recycling rates has been discussed. As a result, a new harmless route has been established to recycle metal resources in WPCBs.

Fe-Cu-Pb合金液-液相分离及废旧电路板混合金属分级分离与回收

[J].

Progress of research on solidification process and microstructure control of immiscible alloys

[J].

偏晶合金凝固过程及凝固组织控制方法研究进展

[J].

Dealloying by metallic melt

[J].

Kinetics of liquid-liquid phase transformation in Cu-based alloys with a metastable miscibility gap

[J].

Cu基亚稳难混溶合金液-液相变

[J].

An experimental study of the rapid continuous solidification of Al-Bi immiscible alloy

[J].

Al-Bi难混溶合金快速连续凝固的实验研究

[J].

Local microstructure evolution at shear bands in metallic glasses with nanoscale phase separation

[J].At room temperature, plastic flow of metallic glasses (MGs) is sharply localized in shear bands, which are a key feature of the plastic deformation in MGs. Despite their clear importance and decades of study, the conditions for formation of shear bands, their structural evolution and multiplication mechanism are still under debate. In this work, we investigate the local conditions at shear bands in new phase-separated bulk MGs containing glassy nanospheres and exhibiting exceptional plasticity under compression. It is found that the glassy nanospheres within the shear band dissolve through mechanical mixing driven by the sharp strain localization there, while those nearby in the matrix coarsen by Ostwald ripening due to the increased atomic mobility. The experimental evidence demonstrates that there exists an affected zone around the shear band. This zone may arise from low-strain plastic deformation in the matrix between the bands. These results suggest that measured property changes originate not only from the shear bands themselves, but also from the affected zones in the adjacent matrix. This work sheds light on direct visualization of deformation-related effects, in particular increased atomic mobility, in the region around shear bands.

Microstructure evolution of immiscible alloys during cooling through the miscibility gap

[J].

Direct observation of the segregation driven by bubble evolution and liquid phase separation in Al-10 wt.% Bi immiscible alloy

[J].

Topology-generating interfacial pattern formation during liquid metal dealloying

[J].Liquid metal dealloying has emerged as a novel technique to produce topologically complex nanoporous and nanocomposite structures with ultra-high interfacial area and other unique properties relevant for diverse material applications. This process is empirically known to require the selective dissolution of one element of a multicomponent solid alloy into a liquid metal to obtain desirable structures. However, how structures form is not known. Here we demonstrate, using mesoscale phase-field modelling and experiments, that nano/microstructural pattern formation during dealloying results from the interplay of (i) interfacial spinodal decomposition, forming compositional domain structures enriched in the immiscible element, and (ii) diffusion-coupled growth of the enriched solid phase and the liquid phase into the alloy. We highlight how those two basic mechanisms interact to yield a rich variety of topologically disconnected and connected structures. Moreover, we deduce scaling laws governing microstructural length scales and dealloying kinetics.

Pattern formation during electrochemical and liquid metal dealloying

[J].

Microstructural pattern formation during liquid metal dealloying: Phase-field simulations and theoretical analyses

[J].

Topological control of liquid-metal-dealloyed structures

[J].The past few years have witnessed the rapid development of liquid metal dealloying to fabricate nano-/meso-scale porous and composite structures with ultra-high interfacial area for diverse materials applications. However, this method currently has two important limitations. First, it produces bicontinuous structures with high-genus topologies for a limited range of alloy compositions. Second, structures have a large ligament size due to substantial coarsening during dealloying at high temperature. Here we demonstrate computationally and experimentally that those limitations can be overcome by adding to the metallic melt an element that promotes high-genus topologies by limiting the leakage of the immiscible element during dealloying. We further interpret this finding by showing that bulk diffusive transport of the immiscible element in the liquid melt strongly influences the evolution of the solid fraction and topology of the structure during dealloying. The results shed light on fundamental differences in liquid metal and electrochemical dealloying and establish a new approach to produce liquid-metal-dealloyed structures with desired size and topologies.© 2022. The Author(s).

Phase-field investigation of the coarsening of porous structures by surface diffusion

[J].

Kinetics and morphological evolution of liquid metal dealloying

[J].

Kinetics of formation and coarsening of nanoporous α-titanium dealloyed with Mg melt

[J].The transition behavior from a Ti–Cu alloy to nanoporous α-Ti, the kinetics of the dealloying reaction, and the coarsening of nanoporous α-Ti were studied, and the mechanism of dealloying with a metallic melt was investigated. When a Ti50Cu50 alloy disk was immersed in a Mg melt, the Cu content decreased from the surface of the disk, and transition layers of α-Ti and Ti2Cu were formed. The growth of the transition layers followed a parabolic law and the activation energy was close to those reported for the diffusion of solute atoms in liquids, suggesting that diffusion of Cu in the Mg melt mainly contributed to the rate-controlling process for the dealloying reaction. The temperature and time dependences of the ligament size followed a power law with an exponent of 4, suggesting that surface diffusion plays an important role in coarsening. All of these results are consistent with those reported for dealloying in aqueous solution, indicating that the underlying dealloying mechanism in a metallic melt is similar to that in aqueous solution.

Optimizing niobium dealloying with metallic melt to fabricate porous structure for electrolytic capacitors

[J].

Evolution of a bicontinuous nanostructure via a solid-state interfacial dealloying reaction

[J].

Classification of bulk metallic glasses by atomic size difference, heat of mixing and period of constituent elements and its application to characterization of the main alloying element

[J].

Development of porous FeCo by liquid metal dealloying: Evolution of porous morphology and effect of interaction between ligaments and melt

[J].

Three-dimensional open-cell macroporous iron, chromium and ferritic stainless steel

[J].

Nanoporous magnesium

[J].

Open porous dealloying-based biomaterials as a novel biomaterial platform

[J].

Nano- to submicro-porous β-Ti alloy prepared from dealloying in a metallic melt

[J].

Dealloying-based metal-polymer composites for biomedical applications

[J].

Dealloying-based interpenetrating-phase nanocomposites matching the elastic behavior of human bone

[J].The long-term performance of orthopedic implants depends crucially on a close match between the mechanical behavior of bone and of the implant material. Yet, the present man-made materials with the required biocompatibility and strength are substantially stiffer than bone. This mismatch results in stress shielding, which can lead to the loss of bone mass and may even lead to a revision surgery. Here we report a new materials design strategy towards metal-polymer composites that are based on constituents with established biocompatibility and that can be matched to bone. Ti-based nanoporous alloys, prepared by liquid-metal dealloying, are infiltrated with epoxy to form interpenetrating-phase nanocomposites. At up to 260 MPa, their yield strength is technologically interesting for a deformable light-weight material. More importantly, Young's modulus can be adjusted between 4.4 and 24 GPa, which affords matching to bone. As another parallel to bone, the strength of the composite materials is strain-rate dependent. These findings suggest that the novel composite materials may provide the basis for promising future implant materials.

Cold-rolling influence on microstructure and mechanical properties of NiCr-Ag composites and porous NiCr obtained by liquid metal dealloying

[J].

Open porous α+β titanium alloy by liquid metal dealloying for biomedical applications

[J].Open porous dendrite-reinforced TiMo alloy was synthesized by liquid metal dealloying of the precursor Ti47.5Mo2.5Cu50 (at.%) alloy in liquid magnesium (Mg). The porous TiMo alloy consists of α-titanium and β-titanium phases and possesses a complex microstructure. The microstructure consists of micrometer scale β-titanium dendrites surrounded by submicrometer scale α-titanium ligaments. Due to the dendrite-reinforced microstructure, the porous TiMo alloy possesses relatively high yield strength value of up to 180 MPa combined with high deformability probed under compression loading. At the same time, the elastic modulus of the porous TiMo alloy (below 10 GPa) is in the range of that found for human bone. This mechanical behavior along with the open porous structure is attractive for biomedical applications and suggests opportunities for using the porous TiMo alloy in implant applications.

Low cost high specific surface architectured nanoporous metal with corrosion resistance produced by liquid metal dealloying from commercial nickel superalloy

[J].

Corrosion resistance of porous ferritic stainless steel produced by liquid metal dealloying of Incoloy 800

[J].

Beating thermal coarsening in nanoporous materials via high-entropy design

[J].

Nanoporous high-entropy alloy by liquid metal dealloying

[J].High-entropy nanomaterials possessing high accessible surface areas have demonstrated outstanding catalytic performance, beating that found for noble metals. In this communication, we report about the synthesis of a new, nanoporous, high-entropy alloy (HEA) possessing open porosity. The nanoporous, high-entropy Ta19.1Mo20.5Nb22.9V30Ni7.5 alloy (at%) was fabricated from a precursor (TaMoNbV)25Ni75 alloy (at%) by liquid metal dealloying using liquid magnesium (Mg). Directly after dealloying, the bicontinuous nanocomposite consisting of a Mg-rich phase and a phase with a bulk-centered cubic (bcc) structure was formed. The Mg-rich phase was removed with a 3M aqueous solution of nitric acid to obtain the open, porous, high-entropy Ta19.1Mo20.5Nb22.9V30Ni7.5 alloy (at%). The ligament size of this nanoporous HEA is about 69 ± 9 nm, indicating the high surface area in this material.

Ultrafine nanoporous intermetallic catalysts by high-temperature liquid metal dealloying for electrochemical hydrogen production

[J].Intermetallic compounds formed from non-precious transition metals are promising cost-effective and robust catalysts for electrochemical hydrogen production. However, the development of monolithic nanoporous intermetallics, with ample active sites and sufficient electrocatalytic activity, remains a challenge. Here we report the fabrication of nanoporous CoMo and FeMo intermetallic compounds via liquid metal dealloying. Along with the development of three-dimensional bicontinuous open porosity, high-temperature dealloying overcomes the kinetic energy barrier, enabling the direct formation of chemically ordered intermetallic phases. Unprecedented small characteristic lengths are observed for the nanoporous intermetallic compounds, resulting from an intermetallic effect whereby the chemical ordering during nanopore formation lowers surface diffusivity and significantly suppresses the thermal coarsening of dealloyed nanostructure. The resulting ultrafine nanoporous CoMo exhibits high catalytic activity and durability in electrochemical hydrogen evolution reactions. This study sheds light on the previously unexplored intermetallic effect in dealloying and facilitates the development of advanced intermetallic catalysts for energy applications.© 2022. The Author(s).

Bulk-nanoporous-silicon negative electrode with extremely high cyclability for lithium-ion batteries prepared using a top-down process

[J].We synthesized freestanding bulk three-dimensional nanoporous Si using dealloying in a metallic melt, a top-down process. Using this nanoporous Si, we fabricated negative electrodes with high lithium capacity, nearing their theoretical limits, and greatly extended cycle lifetimes, considerably improving the battery performance compared with those using electrodes made from silicon nanoparticles. By operating the electrodes below the accommodation volume limit of their pores, we prolonged their cycle lifetime.

Three-dimensional bicontinuous porous graphite generated in low temperature metallic liquid

[J].

Three-dimensional morphological and chemical evolution of nanoporous stainless steel by liquid metal dealloying

[J].

Preparation of hierarchical porous metals by two-step liquid metal dealloying

[J].

Bulk nanoporous metal for actuation

[J].

Nanoporous metal by dealloying for electrochemical energy conversion and storage

[J].

Mechanical strength of nanoporous gold fabricated by dealloying

[J].

Size effects on the mechanical behavior of nanoporous Au

[J].Recent nanomechanical tests on submicron metal columns and wires have revealed a dramatic increase in yield strength with decreasing sample size. Here, we demonstrate that nanoporous metal foams can be envisioned as a three-dimensional network of ultrahigh-strength nanowires, thus bringing together two seemingly conflicting properties: high strength and high porosity. Specifically, we characterized the size-dependent mechanical properties of nanoporous gold using a combination of nanoindentation, column microcompression, and molecular dynamics simulations. We find that nanoporous gold can be as strong as bulk Au, despite being a highly porous material, and that the ligaments in nanoporous gold approach the theoretical yield strength of Au.

Liquid metals dealloying as a general approach for the selective extraction of metals and the fabrication of nanoporous metals: A review

[J].