稀土元素(Rare earth elements,简称RE)对钢中夹杂物演化和力学性能的影响,受到了极大的关注[1~5]。大量的研究发现,在钢中添加稀土元素可深度净化钢液,将钢中的氧化铝、硫化锰等夹杂物变质为稀土氧硫化物,从而使材料的宏观力学性能提高。近年来,人们发现稀土使夹杂物减少和变质能影响裂纹的萌生和扩展[1,3,4],以氧化物冶金方式影响材料的显微组织也能使材料的力学性能提高。其主要机制是,添加稀土能生成尺寸合适的稀土氧硫化物,诱导晶内铁素体的非均质形核而在原奥氏体晶粒内生成细小的铁素体组织。同时,细小的稀土氧硫化物还能钉扎晶界和相界,细化材料显微组织从而提高材料的力学性能。Wang等[6]研究发现,在低碳H08A钢中添加稀土能生成LaAlO3,对

1 实验方法

表1 Fe-C-(RE)和Fe-C-Si-Mn-(RE)合金试样的化学成分

Table 1

| Samples | C | Si | Mn | RE (La+Ce) | O | S | P | Fe |

|---|---|---|---|---|---|---|---|---|

| Fe-C | 0.14 | - | - | 0 | 0.0008 | <0.0005 | 0.002 | Bal. |

| Fe-C-RE | 0.14 | - | - | 0.029 | 0.0005 | <0.0005 | 0.003 | Bal. |

| Fe-C-Si-Mn | 0.18 | 0.25 | 1.66 | 0 | 0.0004 | 0.001 | 0.004 | Bal. |

| Fe-C-Si-Mn-RE | 0.19 | 0.25 | 1.64 | 0.036 | 0.0005 | 0.001 | 0.004 | Bal. |

将制备出的稀土含量(质量分数,下同)分别为0和0.029%的Fe-C合金钢锭在1050~900℃锻造成截面尺寸为45 mm×45 mm的棒材,然后空冷至室温。将稀土含量分别为0%和0.036%的Fe-C-Si-Mn合金钢锭在1050~900℃锻造成截面尺寸为60 mm × 60 mm的棒材,然后空冷至室温。再将锻棒在1100℃均匀化处理2 h,然后在1080~950℃进行多道次热轧,从60 mm轧至15 mm,轧后将钢板空冷至室温。

为了避免初始显微组织差异影响后续相变特征,将以上材料在后续实验前进行多次正火以使初始组织尽可能均匀,并将对比材料的初始晶粒度统一成同一等级。

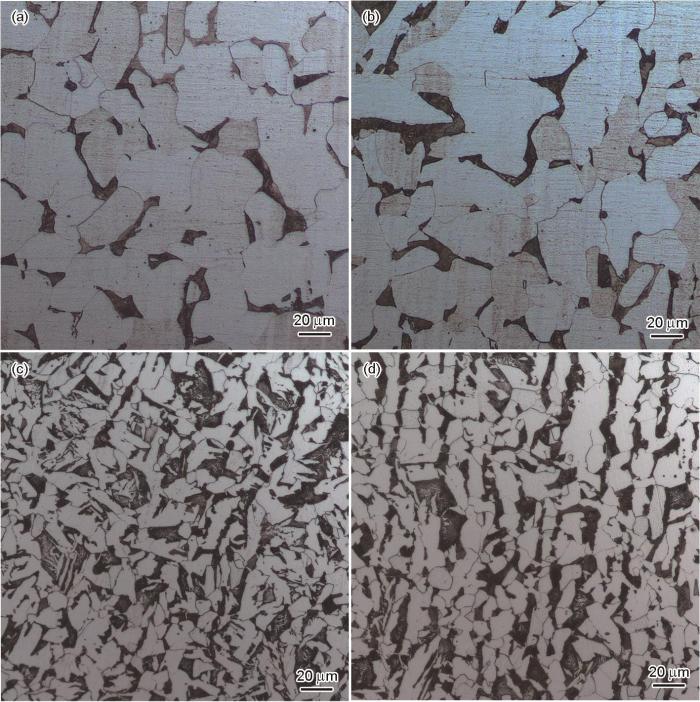

图1给出了Fe-C合金和Fe-C-Si-Mn合金的初始显微组织,可见其初始组织的相组成和晶粒度相差不大。

图1

图1

实验用钢的初始显微组织

Fig.1

Original microstructures of investigated specimens (a) Fe-0.14%C, (b) Fe-0.14%C-RE, (c) Fe-C-Si-Mn, (d) Fe-C-Si-Mn-RE

分别从Fe-C-(RE)棒材和Fe-C-Si-Mn-(RE)热轧板以相同取样方向制取直径为3 mm、长度为10 mm的热膨胀试样。用 Linseis RITA L78膨胀仪记录试样在热循环过程中膨胀量的变化。如图2a所示,在连续冷却相变实验中,先将试样从室温以10℃/s的速率加热至950℃,保温15 min后以1℃/s的速率连续冷却,以考查在连续冷却条件下RE对Fe-C合金和Fe-C-Si-Mn低碳钢中先共析铁素体相变开始点温度的影响。

图2

图2

基于热膨胀实验的热处理工艺示意图

Fig.2

Schematic diagrams of the heat treatment processing profile of continuous cooling (a) and the heat treatment processing profile of isothermal transformation(b)

等温相变动力学实验的热处理方案如图2b所示。将试样以10℃/s的速率加热至1050℃,保温15 min使其充分奥氏体化,再以50℃/s的速率快冷至目标温度(Fe-C-(RE)合金的速率快冷至目标温度为800℃;Fe-C-Si-Mn-(RE)合金为750℃)使其进行等温相变。在γ+α两相温度区间经不同时间的等温处理后快速气淬至室温(冷却速度高于100℃/s)。Fe-C-(RE)合金的等温相变过程的保温时间依次为3 s、10 s、18 s、25 s、45 s、55 s、75 s和100 s。Fe-C-Si-Mn-(RE)低碳钢试样的等温相变的保温时间为5 min、10 min、12.5 min、15 min、20 min、30 min和60 min。将试样沿横截面方向切开后进行机械打磨和抛光,然后用4%(体积分数)的硝酸酒精侵蚀。用蔡司光学显微镜进行组织观察,用点阵计数法在多张显微组织照片上统计不同等温时间先共析铁素体的体积分数。

2 实验结果

2.1 铁素体相变的开始点温度

图3

图3

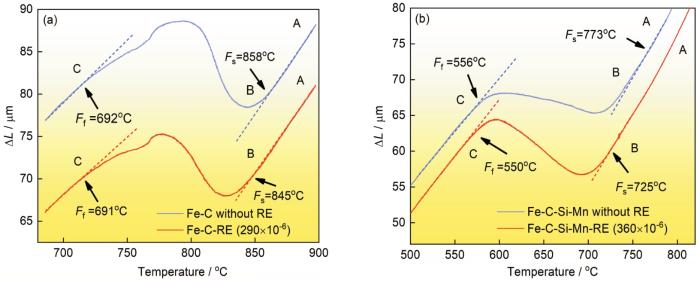

固溶RE对Fe-C合金和Fe-C-Si-Mn低碳钢中先共析铁素体相变开始温度点的影响

Fig.3

Effects of RE solution on phase transition temperature (a) The experimentally measured dilatometric curves of Fe-C-(RE) steels with or without RE addition at a cooling rate of 1℃/s, (b) The experimentally measured dilatometric curves of low-carbon steels with or without RE addition at a cooling rate of 1℃/s

2.2 γ → α 等温相变动力学

图4

图4

Fe-C-(RE)合金铁素体等温相变动力学曲线和铁素体相变速率与时间的关系

Fig.4

Isothermal transformation kinetics curves of Fe-C-(RE) alloy (a) and the relationship between the transformation rate and time (b)

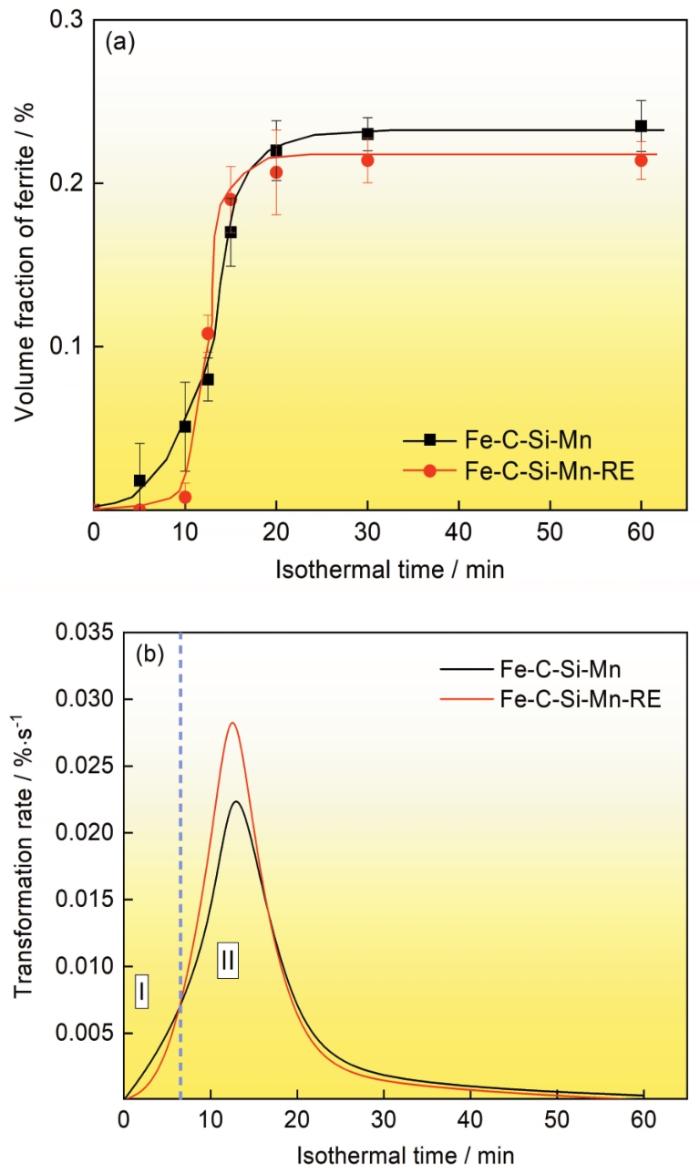

图5a给出了温度为750℃时Fe-C-Si-Mn-(RE)合金中先共析铁素体的相变动力学,可见与Fe-C合金有较大的不同。温度达到750℃时不含RE和含有RE的试样均出现一定的孕育期,而后铁素体的体积分数都在一个平缓的增加后很快增大。根据两个材料铁素体相的分数随时间的变化速率,可将其划分为两个阶段,如图5b所示。(I)阶段,达到目标温度时Fe-C-Si-Mn-RE试样中铁素体相分数的增加速率较低,而Fe-C-Si-Mn试样在开始保温时铁素体相变速率就比较高。随着相变的进行Fe-C-Si-Mn-RE试样进入一个相变速率快速升高的阶段,此时铁素体相变速率不断提高并趋近于未加RE的Fe-C-Si-Mn试样,即图中相变速率曲线相交的时刻。(II)阶段,随着等温相变时间的增加Fe-C-Si-Mn-RE试样中铁素体相变速率进一步提高,进而超过了未加RE的试样。在该阶段,Fe-C-Si-Mn-RE试样中铁素体的体积分数逐渐与Fe-C-Si-Mn试样接近,并在短时间内将其超过,即图5a中两曲线的第一次相交。随着相变的进行,Fe-C-Si-Mn-RE试样中铁素体的相变速率先开始降低随后降低,最终相变趋于停滞。此时两合金试样中的铁素体分数非常接近,对应图5a中曲线的第二次相交。

图5

图5

Fe-C-Si-Mn-(RE)合金铁素体等温相变动力学曲线和铁素体相变速率与时间的关系

Fig.5

Isothermal transformation kinetics curves of Fe-C-Si-Mn-(RE) alloy (a) and the relationship between the transformation rate and time (b)

3 讨论

3.1 在连续冷却条件下RE对先共析铁素体相变温度的影响

以1℃/s的速率连续冷却,RE浓度为290×10-6的Fe-C-(RE)合金,其Fs点的下降幅度为13℃(图3a);RE浓度为360×10-6的Fe-C-Si-Mn-(RE)合金,Fs点的下降幅度接近50℃(图3b)。这种相变开始点温度的变化,主要受固溶稀土在晶界的偏聚降低了晶界作为优先形核位置的优势和碳扩散速率的影响[15~17]。在冷却速率为1℃/s的条件下,Fe-C-(RE)合金和Fe-C-Si-Mn-(RE)合金发生的是先共析铁素体相变,优先在晶界形核且其相变过程被碳元素在奥氏体中的扩散控制。文献[11]的结果表明,RE的存在降低了晶界能量,使晶界形核的优势降低;同时,固溶稀土使C元素在fcc和bcc Fe晶格中的扩散激活能增大,从而显著降低了碳的扩散速率[18]。稀土元素使晶界能量降低和对碳扩散的抑制,滞后了Fe-C-(RE)合金和Fe-C-Si-Mn-(RE)合金在连续冷却过程中的铁素体相变,从而使Fs温度下降。上述实验结果表明,添加少量的稀土即可抑制材料中碳的扩散,从而影响材料的显微组织,改善了钢的组织和力学性能[19~21]。

3.2 RE对Fe-C合金中铁素体相变动力学的影响

3.3 Fe-C-Si-Mn合金中RE对铁素体相变动力学的影响

与Fe-C合金相比,RE对Fe-C-Si-Mn试样中铁素体相变过程的影响较为复杂,如图5b所示。图6给出了Fe-C-Si-Mn-(RE)低碳钢在750℃保温不同时间后用中断淬火方式得到的试样显微组织。图6a,b分别给出了保温10 min后Fe-C-Si-Mn和Fe-C-Si-Mn-RE材料的显微组织。可以看出,保温10 min后Fe-C-Si-Mn材料发生了明显的铁素体相变,而Fe-C-Si-Mn-RE未发生铁素体相变。这表明,添加稀土显著延长了Fe-C-Si-Mn在750℃等温相变的孕育期。RE元素倾向于在显微组织中的晶界和相界处富集[18,19]。基于第一性原理的计算结果也表明,La和Ce元素在晶界偏聚显著降低了晶界能量[11]。因此,在晶界能量的降低和RE抑制碳元素扩散的影响下,添加稀土显著延长了相变孕育期。同时,相变初始阶段RE抑制了C元素在相界面前沿向未相变的奥氏体内部的扩散,使相界面迁移速率下降,减缓了先共析铁素体相变的进行。

图6

图6

等温相变不同时间后试样的显微组织

Fig.6

Microstructure of Fe-C-Si-Mn sample after isothermal transformation for 10 min (a),Fe-C-Si-Mn-RE sample after isothermal transformation for 10 min (b),Fe-C-Si-Mn sample after isothermal transformation for 30 min (c) and Fe-C-Si-Mn-RE sample after isothermal transformation for 30 min (d)

图6c~d给出了等温相变30 min后用中断淬火方法得到的Fe-C-Si-Mn和Fe-C-Si-Mn-RE材料的显微组织。可以看出,虽然此时两个材料中先共析铁素体份数几乎相当,但是Fe-C-Si-Mn-RE材料中铁素体的数量较多。RE元素倾向于在显微组织中的晶界和相界处富集[24~28]。如上所述,稀土在晶界的偏聚影响了晶界能量的分布,与不含稀土的Fe-C-Si-Mn材料中先共析铁素体优先在晶界能量高的地方形核并迅速长大不同;Fe-C-Si-Mn-RE材料的晶界能因RE的影响而更加均匀,随着等温时间的延长可能在晶界同时形核,从而使先共析铁素体的数量更多,使其在随后的生长阶段相变速率提高。在图5b中,处于阶段II的Fe-C-Si-Mn-RE试样其相变速率更高,因此到达相变平缓阶段所需的时间更短。

4 结论

(1) 添加RE元素均可降低低碳Fe-C合金和Fe-C-Si-Mn合金中铁素体相变的开始温度,在冷速为1℃/s的条件下添加360×10-6的稀土可使Fe-C-Si-Mn-(RE)合金先共析铁素体相变的开始温度降低约50℃。

(2) 在Fe-C合金中添加RE能减缓铁素体的相变过程,可归因于RE元素对C元素长程扩散的抑制。Fe-C-Si-Mn合金中的RE通过抑制C元素扩散和改变晶界形核特征,影响其中铁素体的相变动力学。

参考文献

Characteristic and formation mechanism of inclusions in 2205 duplex stainless steel containing rare earth elements

[J].

Effect of inclusions modified by rare earth elements (Ce, La) on localized marine corrosion in Q460NH weathering steel

[J].

Effects of rare earth elements on inclusions and impact toughness of high-carbon chromium bearing steel

[J].High-carbon chromium bearing steels with different rare earth (RE) contents were prepared to investigate the effects of RE on inclusions and impact toughness by different techniques. The results showed that RE addition could modify irregular Al2O3 and MnS into regular RE inclusions. With the increase of RE content, the reaction sequence of RE and potential inclusion forming elements should be O, S, As, P and C successively. RE inclusions containing C might precipitate in molten steel and solid state, but the precipitation temperature was significantly higher than that of carbides in high-carbon chromium bearing steel. For experimental bearing steels, the volume fraction of inclusions increased steadily with the increase of RE content, but smaller and more dispersed inclusions could be obtained by 0.018% RE content compared with bearing steel without RE, whereas the continuous increase of RE content led to an increasing trend for inclusion size and a gradual deterioration for inclusion distribution. RE addition could improve the transverse impact toughness and isotropy of bearing steel, and for modified high-carbon chromium bearing steel by RE alloying, the increase of RE content continuously increased both transverse and longitudinal impact toughness until excessive RE addition.

Effects of rare earth on microstructure and impact toughness of low alloy Cr-Mo-V steels for hydrogenation reactor vessels

[J].The effects of rare earth (RE) on the microstructure and impact toughness of low alloy Cr-Mo-V bainitic steels have been investigated where the steels have RE content of 0 to 0.048 wt.%. The results indicate that the normalized microstructures of the steels are typical granular bainite (GB) composed primarily of bainitic ferrite and martensite and/or austenite (M-A) constituents. The M-A constituents are transformed into ferrite and carbides and/or agglomerated carbides after tempering at 700 °C for 4 h. The addition of RE decreases the onset temperature of bainitic transformation and results in the formation of finer bainitic ferrite, and reduces the amount of carbon-rich M-A constituents. For the normalized and tempered samples, the ductile-to-brittle transition temperature (DBTT) decreases with increasing RE content to a critical value of 0.012 wt.%. Lower DBTT and higher upper shelf energy are attributed to the decreased effective grain size and lower amount of coarse agglomerated carbides from the decomposition of massive M-A constituents. However, the addition of RE in excess of 0.012 wt.% leads to a substantial increase in the volume fraction of large-sized inclusions, which are extremely detrimental to the impact toughness.

Effect of rare earth addition on microstructure, mechanical property and nitriding performance of a medium carbon steel

[J].Effect of rare earth microalloying on the microstructure and mechanical property of a medium carbon steel have been investigated, focusing on the influence of rare earth on the formed surface layer after nitriding heat treatment. The results indicate that by adding rare earth elements into the test steel: the original inclusions of long strips of MnS and the coarse Al2O3 convert into the small spherical inclusions of complex rare earth sulfur oxide; the ferrite volume content is reduced,while more finer lamellar pearlites are formed; the impact energy increases by 126% and the plasticity increases by 10%. After nitriding heat treatment, it is found that the addition of rare earth elements can significantly improve the surface hardness and nitride case depth, as well as improving the vein-like structure of the nitriding layer.

稀土元素对中碳钢组织、力学性能和渗氮的影响

[J].在一种中碳钢中通过添加微量稀土元素,研究稀土微合金化对钢的微观组织、力学性能以及在渗氮热处理条件下对渗层的影响。结果表明,添加稀土后,长条状的MnS夹杂和粗大块状的Al<sub>2</sub>O<sub>3</sub>转变成小球状的稀土硫氧化物夹杂;铁素体的含量降低,并促进细小片层结构的珠光体形成;冲击性能提升126%以及塑性提高10%;渗氮处理后,添加稀土能显著提高表面硬度和加深有效硬化层深,明显改善表面渗层的脉状组织。

Effect of La2O3 on granular bainite microstructure and wear resistance of hardfacing layer metal

[J].

Effects of rare earth metals on steel microstructures

[J].

Effect of adding cerium on microstructure and morphology of Ce-based inclusions formed in low-carbon steel

[J].Intra-granular Acicular Ferrite (IAF), as one of the most well-known desirable microstructure of ferrite with a chaotic crystallographic orientation, can not only refine the microstructure and retard the propagation of cleavage crack but also provide excellent combination of strength and toughness in steel. The effect of adding cerium on microstructure and controlling proper cerium-based inclusions in order to improve properties in low-carbon commercial steel (SS400) were investigated. The type of inclusions can be controlled by changing S/O ratio and Ce content. Without Ce modification, MnS is a dominate inclusion. After adding Ce, the stable inclusion phases change from AlCeO to CeOS. The optimum amount of cerium, 0.0235 wt.%, lead in proper grain refinement and formation of cerium oxide, oxy-sulfide and sulfide inclusions. Having a high amount of cerium results in increasing the number of inclusions significantly as a result it cannot be effective enough and the inclusions will act like barriers for others. It is found that the inclusions with a size of about 4∼7 μm can serve as heterogeneous nucleation sites for AF formation. Thermodynamic calculations have been applied to predict the inclusion formation in this molten steel as well, which show a good agreement with experimental one.

The effect of sulfide type on the fracture behavior of HY180 steel

[J].

Modification of non-metallic inclusions by rare earth elements in micro-alloyed Steels

[J].

Low oxygen rare earth steels

[J].

Effect of rare earth elements on isothermal transformation kinetics in Si-Mn-Mo bainite steels

[J].

Thermodynamics of acicular ferrite nucleation

[J].

Transition from bainite to acicular ferrite in reheated Fe-Cr-C weld deposits

[J].

Direct measurement of carbon enrichment during austenite to ferrite transformation in hypoeutectoid Fe-2Mn-C alloys

[J].

Kinetic transitions during non-partitioned ferrite growth in Fe-C-X alloys

[J].

Self-consistent model for planar ferrite growth in Fe-C-X alloys

[J].

Effect of rare-earth elements in solid solution on phase transformation in low-carbon steels

[J].

Segregation of rare earth during isothermal transformation in low carbon steels

[J].

First-principles calculations of rare earth (Y, La and Ce) diffusivities in bcc Fe

[J].

The influence of rare earth elements on phase transformation in 25Mn steel during continuous heating

[J].

A revised expression for the diffusivity of carbon in binary Fe-C austenite

[J].

Theory of growth of spherical precipitates from solid solution

[J].The radius of a spherical precipitate particle growing in a solid solution of initially uniform composition may be shown to be equal to α(Dt)½, where D is the atomic diffusion coefficient, t the time of growth, and α, the growth coefficient, is a dimensionless function of the pertinent compositions. In this paper the precise dependence is found of this function upon the pertinent concentrations. A similar computation is made for the growth coefficient corresponding to the one-dimensional growth of a plate.

The influence of La and Ce addition on inclusion modification in cast niobium micro-alloyed steels

[J].

Effect of rare earth element yttrium addition on microstructures and properties of a 21Cr-11Ni austenitic heat-resistant stainless steel

[J].

In-situ observation of effect of La on grain refinement in simulated coarse-grain heat-affected zone of high strength low alloy steel

[J].

原位观察稀土镧对低合金高强度钢焊接热影响区晶粒细化的影响

[J].

Research on determination of the rare-earth content in metal phases of steel

[J].